Page 1

TM

Getting Started With

™

Your PWS

BEV-340

Pure Water Appliance

Includes setup and maintenance information for the

™

PWS

BEV-300 Series Pure Water Appliances.

Page 2

Contents

Chapter 1 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Setting Up Your BEV System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unpack the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Planning the Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Attaching the Pre-Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installing the Chrome Faucet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installing the Feed Water Saddle Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installing the Drain Saddle Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Mounting the De-Ionization Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Mounting the Pre-fi lter/RO Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Connecting the System Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Operating Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Chapter 2 Getting to Know Your BEV System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

A Look At The Seven Stages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Stage One . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Stage Two . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Stage Three . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Stage Four. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Stage Five . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Stages Six and Seven . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Component Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Feed Water Saddle Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Drain Saddle Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Sink Mounted Chrome Faucet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Sediment Pre-fi lter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Granular Activated, Unidirectional, Carbon Pre-fi lters . . . . . . . . . . . . . . . . . . 10

RO Pressure Vessel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

RO Membrane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

De-Ionization (DI) Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Built-in Flush Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operating Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

pH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chlorine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Sediment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Iron . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 3 Maintenance and Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Flushing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Filter Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Replacing the Sediment Pre-fi lter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Replacing the Twin GAC Pre-fi lters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Replacing the 4-Stage DI Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Returning the System to Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2

Page 3

Chapter 4 Frequently Asked Questions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 5 Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

What the Warranty Covers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Exceptions to Lifetime Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

What We Will Do To Correct an Inconvenience . . . . . . . . . . . . . . . . . . . . . . . 18

How You Can Get Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

How State Law Relates To the Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Appendix A Specifi cations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Appendix B Replacement Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Replacement Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Maintenance Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Appendix C Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Appendix D Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Pure Water Systems, Inc.

© 2004 Pure Water Systems, Inc. All rights reserved.

Under the copyright laws, this manual may not be copied, in whole or in part, without the written consent of Pure Water Systems, Inc.

Every effort has been made to ensure that the information in this manual is accurate. Pure Water Systems, Inc. is not responsible for

printing or clerical errors.

Pure Water Systems, Inc.

5707 238th Place NE

Redmond, WA 98053

(425) 765-6175

http://www.purewatersystems.com

Pure Water Systems, Inc., the Pure Water Systems logo, PWS, and Bio Compatible Water are trademarks of Pure Water Systems, Inc.

Other product and company names mentioned herein may be trademarks of their respective companies. Product specifi cations are

subject to change without notice.

March 2004

Contents 3

Page 4

CHAPTER

1

Getting Started

Thank you for your purchase of this quality water purifi cation system by Pure Water Systems, Inc. Your

new PWS™ BEV-300 Series system combines several of the most effi cient methods of water treatment

to achieve a very specifi c result—ultra-pure water that meets the rigorous Vincent (BEV) standards for

bio-compatibility.

As the new owner of a PWS™ BEV-300 pure water appliance there is a totally new experience awaiting

you. You and your family will be amazed at the delightful new taste of your tap water—it’s like owning

your own personal mountain spring.

This manual provides information about the application and servicing of your PWS™ BEV-300 Series

pure water appliance. Descriptions of the components and their functions will help to answer frequently

asked questions. By thoroughly reading this manual you will be better able to operate your new system

and perform simple maintenance.

SETTING UP YOUR BEV SYSTEM

Your PWS™ BEV-300 system requires no electricity—the only requirement is adequate water pressure.

This unit is designed to operate within a pressure range of 40–100 PSI (2.75–6.9 bar). The amount of

purifi ed water produced depends primarily on your water pressure, temperature, and the amount of

dissolved solids. The custom reverse osmosis membrane will produce up to 40 gallons (~150 liters) per

day of pure BEV quality water. If you plan to install this unit on a private well system, you should check

your water pressure gauge. If the pressure is less than 40 PSI (2.75 bar), ask a plumber to adjust and raise

the pressure to the minimum level of 40 PSI.

Quick Description of Installation…

1) Unpack the system.

2) Review this manual.

3) Inspect the installation location—verify the system

and storage tank will fi t beneath sink.

4) Attach the pre-fi lters to the frame.

5) Install the faucet.

6) Install the feed water saddle valve.

7) Install the drain saddle valve.

8) Mount the 4-Stage Deionization Module.

9) Mount the pre-fi lter & RO assembly.

10) Turn on the cold water.

11) Produce and then discard the fi rst tank of water.

1) Unpack the System

As you unpack your new PWS™ BEV-300 Series system, inspect all parts to make sure they have not

been damaged in transit. If damage has occurred immediately fi le a claim with the freight company.

Contents include:

• Chrome Faucet Assembly

• Feed Water Saddle Valve Kit

• Drain Water Saddle Valve Kit

• 4-Stage Deionization Module & Clamp

4

Page 5

• RO Pressure Vessel & Frame

• Pre-fi lter canisters and fi lters (3)

• Tubing

• Storage Tank

• Owner’s Manual

• Registration & Warranty Card

2) Planning the Installation

It is advisable to review the following instructions completely before proceeding.

The BEV-340 system is comprised of several large components which, in most cases, fi t easily beneath

most kitchen sinks. It is wise to establish the desired location of each of the components before hand.

The storage tank has built-in feet for upright positioning. However, it may be placed on its side when

space is limited. (A stand is included.)

3) Attaching the Pre-Filters

Open the package containing the frame assembly and RO pressure vessel (ROPV). Mounted to the bottom of the frame are the tops of the three pre-fi lter canisters. Attached to the outlet port of the third

pre-fi lter top is the auto shut-off valve.

Refer to the picture of the BEV-340 unit at the front of this manual: Pre-fi lter position 1 is on the left,

behind the label reading “IN, FEED WATER.” Pre-fi lter position 2 is the center. Pre-fi lter position 3 is

on the right, behind the label reading “OUT, TO TANK.”

The sediment pre-fi lter should be placed into position one (1). Remove the wrapping, place the fi lter

into the canister, then screw the canister to the top until fi rm, taking care to align the fi lter correct ly.

The granular activated carbon pre-fi lters occupy positions 2 and 3.

4) Installing the Chrome Faucet

Open the package containing the chrome faucet and mounting hardware. Study the diagram printed on

the package for additional installation instructions.

a) Select the location of the faucet on the sink top. (NOTE: Make sure there are no reinforcing ribs

under the sink drilling location.)

b) Use factory approved meth-

od or approved plumbing

practice to drill hole in sink.

For porcelain sinks—facto-

Silicon/Carbide Grinding Wheel

Hi Speed Dremmel Tool

ry approved method is: fi rst

grind away porcelain with

Dremmel® tool and silicon

grinding w h e e l (about

¾” circle). Then, using a

standard ½” high-speed

Porcelain

Sink Top

drill bit, drill hole through

metal portion of sink.

(See Figure 1) Alternately,

use a “glass and tile carbide

spade tipped bit.”

Sink

Metal

Figure 1, Using a Dremmel® Tool to Remove Porcelain

For acrylic sinks use a stan-

dard ½” high-speed drill bit.

For stainless steel sinks use a ½” high-speed drill bit or a ½” Greenlee chassis punch.

c) Install faucet according to the diagram on the package, insuring rubber gaskets are place. Tighten

lock nut beneath sink.

Getting Started 5

Page 6

5) Installing the Feed Water Saddle Valve

Open the package marked FEED VALVE. Study the diagram printed on the package for additional installation instructions. Also see Appendix C.

INSTALL ON COLD WATER LINE ONLY!

a) Shut off the cold water supply line.

b) Clamp the feed valve to the cold water line.

c) Turn the handle fully clockwise to pierce the line, then fully counter-clockwise to allow fl ow.

You are now ready to move to the next step – DO NOT TURN ON THE COLD WATER SUPPLY YET!

(In some instances, the feed water saddle valve will not be an appropriate connection to your existing

plumbing. By furnishing a self-piercing feed water saddle valve, we have attempted to provide a connection that will satisfy most installation scenarios. Should the saddle valve be an inappropriate connection

for your installation, you can obtain appropriate parts from most plumbing supply or home improvement stores. Pure Water Systems carries a limited inventory of alternate fi ttings. On rare occasions, it

may be necessary to contact a plumbing contractor to complete your installation.)

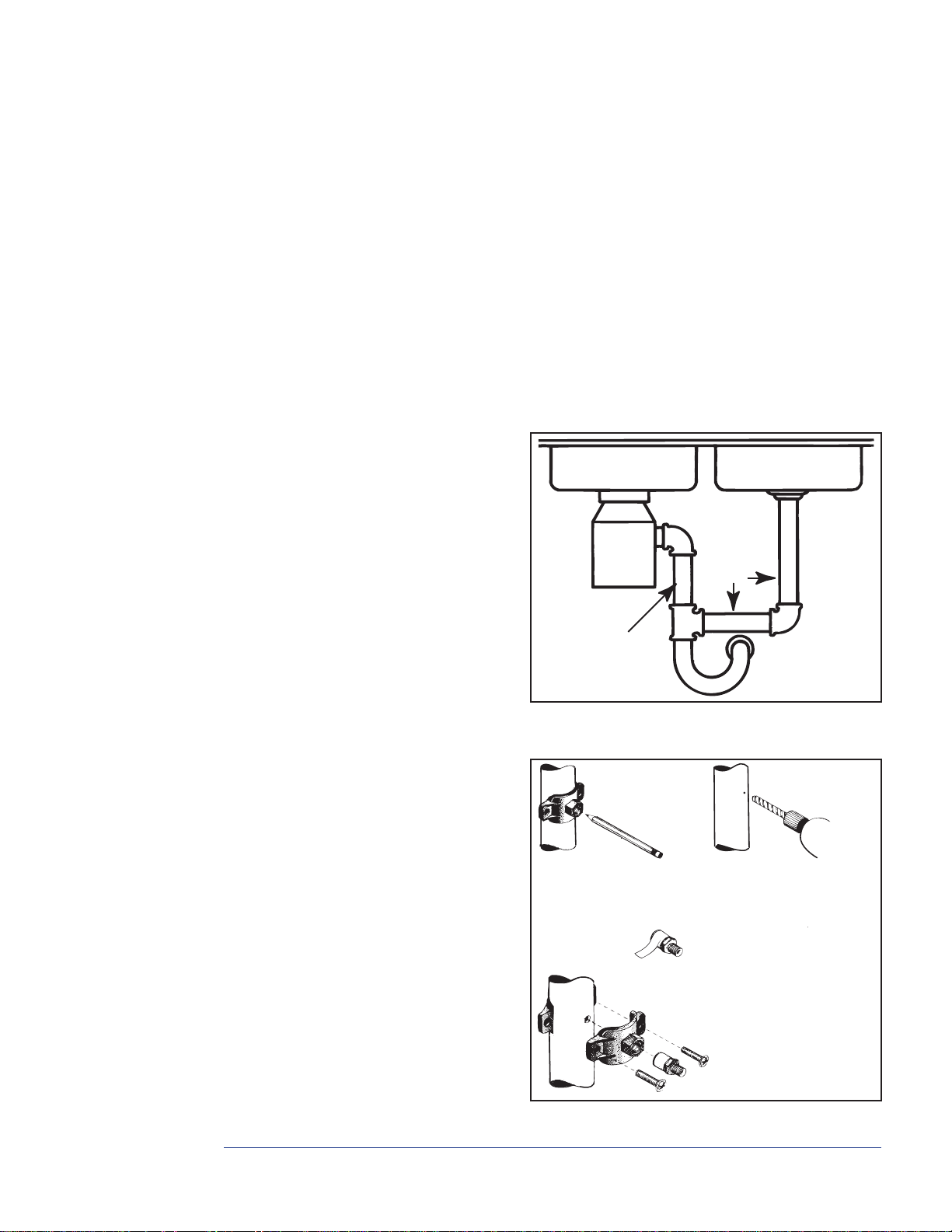

6) Installing the Drain Saddle Valve

Open the package containing the drain

saddle valve and John Guest® fi tting.

a) The drain saddle assembly should

be installed above the trap and on

the vertical or horizontal tailpiece.

(See Figure 2)

Mount

drain saddle

at either

location

NOTE: When installing the pre-

fi lter/RO assembly, it is desirable to

mount the frame above the position

of the drain saddle valve.

Never

mount

here!

b) Refer to Figure 3 and follow steps

one through four to mount the drain

saddle valve.

Figure 2, Drain Saddle Valve mounting locations

7) Mounting the Deionization Module

The 4-stage deionization module can be

placed anywhere convenient, but it is preferable to keep the distance between the

pre-fi lter/RO assembly, the storage tank,

and the DI module as short as possible. The

DI module can be mounted horizontally

(preferred) or vertically. If mounted verti-

cally, the outlet should be at the bottom.

a) Wrap the threads of the supplied John

Guest® “Speedfi t” fi ttings with Tefl on

thread tape and install the fi ttings

into each end of the DI module.

b) Establish the position for the DI module.

c) Secure the module to the wall of the

cabinet using the supplied stainless steel

clamp and screws.

1) Mark hole position,

remove saddle.

2) Drill ¼" hole

through one side.

3) Wrap Teflon tape

on John Guest

“Speedfit” fitting.

Make sure to align

4)

drain saddle to drilled

hole. Attach drain

saddle to the drain

pipe and tighten the

two screws evenly.

Figure 3, Mounting the Drain Saddle Valve

®

Getting Started 6

Page 7

8) Mounting the Pre-fi lter/RO Assembly

Mount the pre-fi lter/RO assembly on the cabinet wall using the screws supplied. It is best to have the

bracket placed above the plane of the drain saddle valve. When this is not possible, it is acceptable to

stand the entire assembly on the cabinet fl oor, but extra care must be taken when routing tubing from

the assembly to the drain saddle valve.

9) Connecting the System Components

A twenty foot length of poly tubing has been supplied with your system. This is more than enough tubing

for most installations. When cutting the poly tubing, DO NOT USE SCISSORS. The approved method

is a razor knife with a fresh blade. When cutting, it is important to not crimp or collapse the tubing. Cut

the tubing with a clean, 90° angle. This will allow the tubing to seat fi rmly into the John Guest® fi ttings,

creating a secure and leak free connection.

a) Measure and cut a length of tubing to connect the sink mounted chrome faucet to the outlet end of

the 4-stage DI module.

To attach the tubing to the chrome faucet extension beneath the sink, use the supplied compres-

sion fi ttings and follow the instructions printed on the plastic bag which contained the chrome

faucet assembly. Connect the other end by pushing the tubing into the John Guest® fi tting at the

outlet of the DI module until you can feel the tubing “bottom out” inside the fi tting. It is normal

to experience some resistance as the tubing is pushed past the O-ring inside the fi tting.

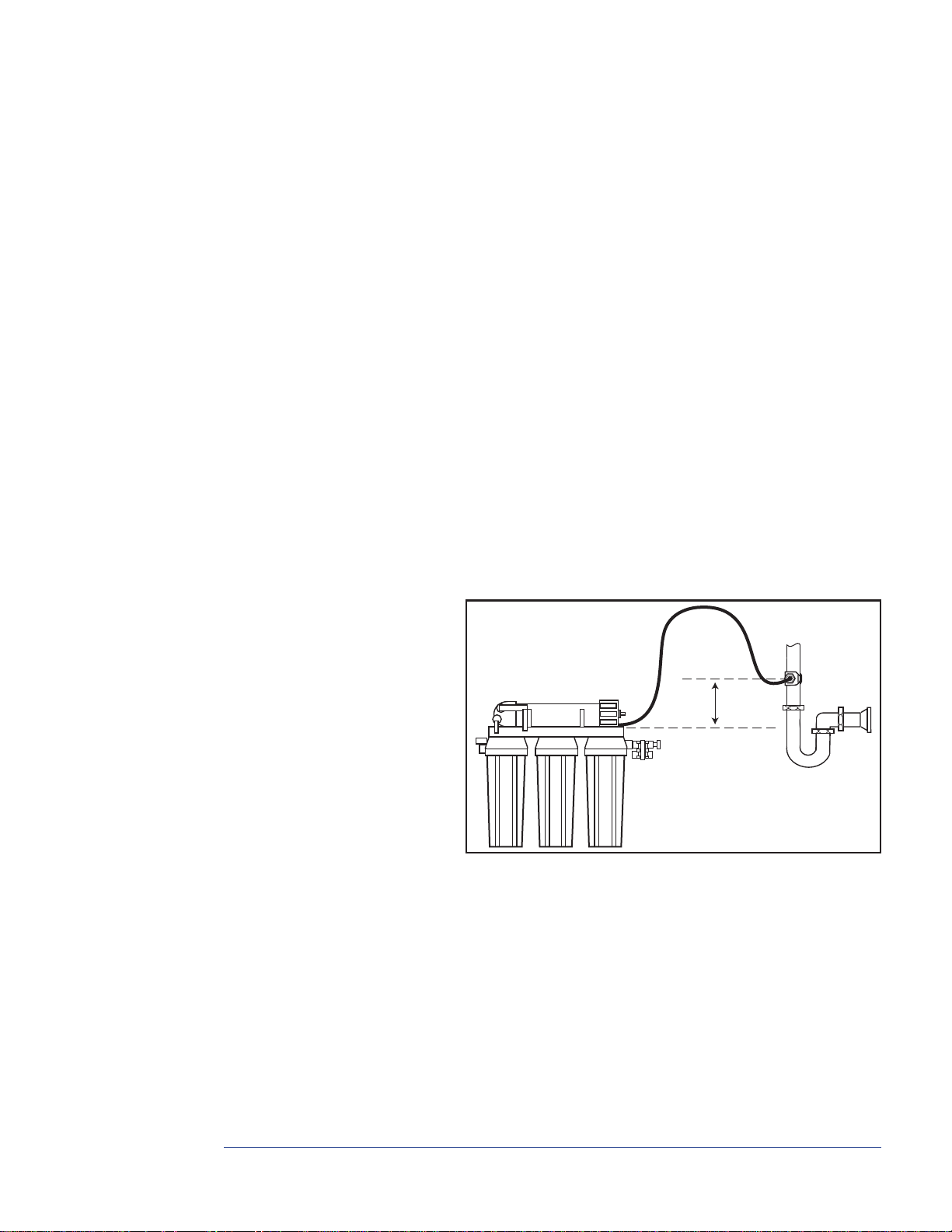

b) Measure and cut a length of tubing to connect the drain water check valve on the pre-fi lter/RO as-

sembly to the drain water saddle valve. See Appendix C.

IMPORTANT: If the frame of the pre-fi lter/RO assembly is not above the drain saddle valve, you

will need to loop the tubing as high as possible beneath the sink. (See fi gure 4) Be sure to allow for

this loop when you measure.

The drain water check valve

is the grey colored fi tting

located just behind the RO

pressure vessel on the top of

the frame. Connect one end

of the tubing to the drain

water check valve and con-

nect the other end to the

drain saddle valve.

c) Measure and cut a length of

tubing to connect the feed

water saddle valve to the

inlet on the left side of the

If frame is below plane of

drain saddle valve, drain tubing

should be looped as high as

possible beneath sink.

pre-fi lter assembly. Connect

the tubing to the saddle

Figure 4, Drain Tubing Connection

valve using the compression

fi ttings provided. See Appendix C.

d) Mounted to the right side of the pre-fi lter/RO assembly, just below the bracket, is the Auto Shut-off

valve. One port from the auto shut-off valve supports a swiveling “T” connector which will con-

nect the pre-fi lter/RO assembly, the storage tank, and the DI module. See Appendix C.

Measure and cut a length of tubing to connect the pre-fi lter/RO assembly to the DI module.

Connect one end to the inlet of the DI module. Connect the other end to one of the ports on the

swivel “T” connector. It does not matter which port you choose.

e) Wrap the threads of the stainless steel fi tting on top of the storage tank with Tefl on thread tape.

Screw the supplied tank shut-off valve onto the storage tank.

f) With all the other components connected, place the storage tank into position. Measure; cut an

appropriate length of tubing; and connect the valve on top of the storage tank to the open port on

Getting Started 7

Page 8

the swivel-T connector. Remember to avoid crimping and excessive tubing length. Open the valve

on top of the storage tank by moving the handle parallel to the tubing.

g) Open the chrome faucet on the sink top.

h) Turn on the cold water supply. In approximately 20 minutes you will see water beginning to drip

from the chrome faucet. Close the faucet and allow the storage tank to fi ll. Check for leaks and

gently tug on all connections to assure a tight fi t.

Operating Notice

The initial fi lling of the storage tank will probably seem slow. The Reverse Osmosis element has been

factory tested for rejection and fl ow, however, the element when new is generally “tight.” The water

cavity of the pressure vessel and deionization module is initially empty and must fi ll before pure water

will appear in the tank. After leaving the unit connected and running for 24–36 hours the storage tank

should be completely full.

Your PWS™ BEV-300 system is easy to operate because the tank auto shut-off does all the work. When

the storage tank is nearly full the auto shut-off will stop the fl ow of feed water to the system. Similarly,

when the water in the tank drops below a certain level, the auto shut-off will re-open the feed water supply allowing the system to refi ll the storage tank.

(The auto shut-off mechanism relies on a pressure differential between the feed water and product water

to operate. For this reason, the system will “turn on” before the tank is completely empty, and will “turn

off” before the tank is completely full.)

Flushing

Flushing is the single most important maintenance function you will need to perform to keep your system

operating at peak effi ciency . This simple operation only takes a few minutes, yet makes a great difference

in the quality of the water your unit produces, and extends the service life of the RO membrane.

a) Flushing the RO membrane can only be accomplished when the system is fi lling (see pressure

gauge). Allow the storage tank to empty until you hear the water fl owing then begin the fl ushing

procedure.

b) Move the black handle on the fl ush valve parallel to the RO pressure vessel. This will open the

fl ush valve and allow water to rapidly fl ow across the surface of the RO membrane, washing away

contaminants which, if allowed to accumulate, might clog the pores of the membrane.

c) Set a kitchen timer so you do not forget to return the fl ush valve to the closed position.

Flushing the unit for 10 minutes every two weeks is ideal.

In the event you forget to fl ush the system for an extended period of time, you can perform an exhaustive fl ush of the membrane by leaving the fl ush valve open for 20 minutes.

If your unit has not been operational for several days (e.g. while you are on vacation), drain the storage

tank (use the water for watering plants, etc.) then fl ush the membrane for 5-10 minutes as described

above.

Getting Started 8

Page 9

CHAPTER

2

Getting to Know Your BEV System

Yo ur PWS™ BEV-300 Series system includes seven unique stages in fi ve different modules. Every system

combines the proven water fi ltration methods of carbon adsorption, reverse osmosis, and deionization. By

carefully matching the components utilizing these methodologies, Pure Water Systems is able to assure

your system produces water which meets or exceeds the Vincent standards for bio-compatibility.

A LOOK AT THE SEVEN STAGES

Stage One

Water entering the system is fi rst subjected to our spun-polyester dual gradient (10-20 micron) sediment

pre-fi lter. Any suspended particles such as sand, rust, or other deposits commonly found in the feed

water supply are removed. This protects the reverse osmosis membrane downstream from particles which

might clog the pores of the membrane. This pre-fi lter has been carefully selected for its extremely high

dirt holding capacity.

Stage Two

Before the feed water reaches the reverse osmosis membrane, it is subjected to twin, unidirectional

granular activated carbon pre-fi lters. Flow is lengthwise, not radial, for maximum contact time and

organic adsorption. Pure Water Systems has chosen to use twin carbon fi lters in this stage where every

other manufacturer uses only a single cartridge. By using twin cartridges we insure complete removal of

organic contaminates including pesticides, herbicides, and other hydrocarbon based compounds.

A single gram of steam washed, bituminous grade, granular activated carbon typically has ~1 500 square

meters of surface area—meaning our twin GAC pre-fi lters provide over 400 acres ( 1.62 square kilometers) of surface area where organic contaminants dissolved in the water have an opportunity to be

adsorbed and eliminated. This immense GAC surface area also insures complete and total conversion of

chlorine—protecting the polyamide thin-fi lm-composite (TFC) reverse osmosis membrane downstream.

Stage Three

A custom designed and extremely effi cient spiral wound reverse osmosis membrane produces up to 40

gallons (~150 liters) of purifi ed water per day. This membrane utilizes the unique properties of a semipermeable material which allows passage of pure water molecules while not allowing dissolved salts,

heavy metals, and organics to pass through. Our extraordinary membrane is designed to consistently and

signifi cantly reduce the total dissolved solids in the source water supply by greater than 97%. It also has

a tremendous capacity to completely reject organic and biological contaminates, including water-borne

microorganisms. (EP A EST. No. 5 253 1 -FL-01)

The operating parameters for this custom designed reverse osmosis membrane are found in the

Specifi cations section of this manual.

Stages four through seven are contained in our unique four-stage, RO matched deionization module.

Stage Four

This stage includes a unique blend of deionization resins carefully matched to our exceptional reverse

osmosis membrane and provides superior rejection of monovalent ions and the ionic residues of pesticides and other hydrocarbon contaminates. It is the inclusion of deionization resins which sets the BEV

9

Page 10

systems apart from other reverse osmosis systems. It is not enough to include any commercial grade

resins; the blend of cationic and anionic resins must be nuclear grade and carefully engineered to match

the reverse osmosis membrane.

Stage Five

Following the DI resins are four inches of granular activated carbon to polish the product water for a

clean, fresh taste. The fl ow rate at this stage provides tremendous contact time to assure complete removal of any remaining organic contaminates.

Stages Six and Seven

The fi nal two stages of our proprietary DI module are included to prevent the reverse migration of contaminates into the system. The incorporation of these stages further separates the BEV systems from other

manufacturer’s designs. After carefully combining the elements of the previous fi ve stages it is essential to

integrate these stages to assure contaminates cannot enter the system from the product water end.

COMPONENT DESCRIPTION

Following is a brief description of the main components of your PWS™ BEV-300 Series system.

Feed W ater Saddle Valve

The feed water saddle valve provides a simple and effective method of connecting your new PWS™ BEV-

300 Series system to most existing home plumbing. Easily attached, the clamp-on valve includes a pierc-

ing mechanism which allows you to tap into the cold water supply line without having to drill holes or

unscrew existing fi ttings.

Drain Saddle Valve

The drain saddle valve included in the installation kit provides a simple and secure method of attaching the brine water discharge from your BEV-300 system to the existing drain line. Like the feed water

saddle valve, this valve is easily attached and does not require disassembly of existing plumbing fi xtures.

Sink Mounted Chrome Faucet

The long reach chrome faucet included in your installation kit is made from the highest quality lead-free

materials and is designed to provide years of trouble free service.

Sediment Pre-fi lter

Our spun-polyester dual gradient (10-20 micron) industrial grade pre-fi lter is designed to remove silt,

sand, rust, scale and other suspended particulates. It has a much higher dirt holding capacity when

compared to sediment pre-fi lters included in most other RO systems. This allows the fi lter to contain

considerably more suspended contaminants before fouling or reducing throughput to the downstream

components.

Granular Activated, Unidirectional, Carbon Pre-fi lters

Only Pure Water Systems offers dual, unidirectional, GAC pre-fi lters where fl ow is engineered to be

lengthwise—not radial like most other designs. Lengthwise fl ow insures maximum contact time providing for total removal of any dissolved organic compounds present in the feed water. By placing two

pre-fi lters in series, we also insure complete chlorine conversion protecting the reverse osmosis membrane which follows.

RO Pressure Vessel

The pressure vessel houses the polyamide thin-fi lm-composite reverse osmosis membrane. The design

provides a means to collect the purifi ed product water and an exhaust opening to drain off the concentrated brine water.

Getting to Know Your BEV System 10

Page 11

RO Membrane

Reverse osmosis is a scientifi c method of reversing nature’s biological process where a dilute or lighter

solution passes through a semi-permeable membrane into a more concentrated solution. In the human

body fl uids pass in and out of such membranes (cell tissues) by the phenomenon known as osmosis

while plants absorb food and moisture from the soil in the same way. Scientists have long realized if

the natural process of osmosis could be reversed—if water from concentrated sources could be made

to pass through a selective membrane and emerge as pure water, many practical applications could be

developed. For instance, unwanted salts and other dissolved inorganic minerals could be removed from

all kinds of water sources. The process was originally perfected by NASA and DOW Chemical to purify

and re-use all liquids aboard spacecraft. Reverse osmosis fi lters out all particles greater than .0001 microns in diameter.

The membrane used in your PWS™ BEV-300 system is a privately manufactured, custom rolled, spiral

wound polyamide thin-fi lm-composite membrane. This membrane has the ability to remove in excess

of 97% of the dissolved inorganics. Rejection is based on degree of removal of sodium and chloride ions.

Although RO has a higher percentage of removal of all di, tri, and quadri-valenced elements (e.g. >99%

of aluminum) any mono-valenced elements are rejected at ~97% level. The nominal remaining 3% of

dissolved solids, mostly monovalent, enter the next stage of the process—the deionization module.

Deionization (DI) Module

Deionization resins are a man-made plastic bead chemically made anionic (OH-) and cationic (H+). The

resins in your PWS™ BEV-300 system are of nuclear grade and carefully matched to the reverse osmosis

membrane. (As opposed to commercial grade resins typically found in water softeners.) In the DI module, H+ and OH- are exchanged for the mono-valenced elements in the product water coming from the

RO membrane. The only thing added to the product water from your BEV-300 system is hydrogen ions

(H+) and hydroxyl (OH-) ions, which combine to form H2O, or pure water.

Following the DI resins are several additional inches of granular activated carbon. This is included to

insure the complete removal of any organic contaminant that might appear in trace form from a partial

degree of removal via RO and DI. Since we’ve never found any organics which are not removed either by

the upstream RO membrane or the DI resins, the GAC at this stage acts primarily to polish the product

water for a clean, fresh taste. GAC is the most common product used to fi lter bottled or “spring” waters.

Finally, the end of the DI module contains two additional stages which are in place as safeguards against

any reverse migration of contaminants.

Built-in Flush Valve

The built-in fl ush valve mounted to the RO pressure vessel provides a quick and simple method to periodically fl ush the surface of the RO membrane. Simply opening the fl ush valve once every two weeks for

ten minutes will wash away impurities that may be concentrating near the surface of the RO membrane.

If not occasionally fl ushed from the membrane surface, impurities can concentrate and clog the pores of

the membrane. Flushing the membrane ensures longer service life and greater rejection of contaminates.

OPERATING PARAMETERS

To insure proper operation of your BEV system, it is advisable to collect the following information about

your water supply. This information is generally available from your municipal water department, and

in many cases is available online.

Pressure

In order to overcome the natural osmotic force, adequate water pressure must be available from your

water supply. The osmotic force is directly proportional to the concentration of dissolved solids in the

water. When the water pressure is equal to the osmotic force, there will be no movement of pure water

molecules across the semi-permeable membrane. A minimum of 40 PSI is recommended. (If your water

pressure is below 40 PSI, a booster pump is available. If you are on a private well, have your plumber

raise the minimum pressure above 40 PSI.)

Getting to Know Your BEV System 11

Page 12

In general, the higher the pressure (up to 100 PSI), the better the performance of the membrane at

rejecting contaminants. Pressures below 40 PSI will result in poor rejection rates and may reduce the

service life of the membrane.

pH

The TFC membrane will hold up very well when the pH of the feed water is between 3 and 11 . Water

supplies with pH over 11 are very rarely, if ever, fo und. (Chlorine bleach has a pH of ~11.5.)

Chlorine

Chlorine is the most common substance added to municipal water supplies. Its purpose is to eliminate

biological growth (i.e. chlorine is toxic). Regulations usually require there to be residual chlorine when

it reaches your tap. Typically, the residual concentrations of chlorine in household water range from 0.5

to 1.0 parts-per-million (ppm).

Besides being toxic, chlorine will degrade the TFC reverse osmosis membrane. Therefore, it is essential

to remove chlorine from your feed water before it reaches the RO membrane. Your BEV system includes

a pre-fi lter containing a special grade of granular activated carbon (GAC) which will very effectively

remove the chlorine from your tap water. It is important to replace the pre-fi lter annually to insure no

chlorine is reaching the membrane.

Sediment

In areas with very high sediment concentrations the pre-fi lter may clog prematurely. If the pre-fi lter becomes clogged, you will likely notice a decrease in the production rate from your system. In areas with

very high sediment concentrations, it may be necessary to replace the pre-fi lter on a semi-annual basis.

Iron

Iron concentrations greater than 0.1 mg/l can degrade overall system performance. If your water supply

has iron concentrations above 0.1 mg/l, iron pretreatment is recommended.

Getting to Know Your BEV System 12

Page 13

CHAPTER

3

Maintenance and Servicing

Minimal work is required to keep your BEV system in peak operating condition. All that is required is

following a regular schedule of fl ushing and replacing the fi lter modules as recommended. Following

these simple steps will insure your unit consistently produces ultra-pure water meeting the Vincent

(BEV) standards for bio-compatibility.

Take care of your BEV system and it will provide many years of healthful drinking and cooking water for

your entire family.

Flushing

Flushing is the single most important maintenance function you will need to perform to keep your

system operating at peak effi ciency. This simple operation only takes a few minutes, yet makes a great

difference in the quality of the water your unit produces, and extends the service life of the RO membrane.

a) Flushing the RO membrane can only be accomplished when the system is fi lling (see pressure

gauge). Allow the storage tank to empty until you hear the water fl owing then begin the fl ushing

procedure.

b) Move the black handle on the fl ush valve parallel to the RO pressure vessel. This will open the

fl ush valve and allow water to rapidly fl ow across the surface of the RO membrane, washing away

contaminants which, if allowed to accumulate, might clog the pores of the membrane.

c) Set a kitchen timer so you do not forget to return the fl ush valve to the closed position.

Flushing the unit for 10 minutes every two weeks is ideal.

In the event you forget to fl ush the system for an extended period of time, you can perform an exhaustive fl ush of the membrane by leaving the fl ush valve open for 20 minutes.

If your unit has not been operational for several days (e.g. while you are on vacation), drain the storage

tank (use the water for watering plants, etc.) then fl ush the membrane for 5-10 minutes as described

above.

FILTER REPLACEMENT

After 12 months of use, it is time to replace the sediment pre-fi lter, the twin GAC carbon fi lters, and the

4-stage Deionization module to insure your system continues to produce water within BEV parameters.

Replacement modules can be ordered directly from Pure Water Systems via our web site at

http: //www.purewatersystems.com.

1) Remove the contents from beneath the kitchen sink where the fi lter assembly is located.

2) Turn off the cold water supply line.

3) Drain ALL the water from the storage tank.

4) Close the valve on the top of the storage tank.

5) Open the Flush Valve

6) Place a towel beneath the pre-fi lter/RO assembly—it will absorb the small amount of water that

will spill from the modules as they are changed out.

It is often helpful to have an empty 3-5 gallon bucket nearby.

13

Page 14

Replacing the Sediment Pre-fi lter

The sediment pre-fi lter is in the fi lter canister on the left side of the assembly (position 1), beneath the

“IN (FEED WATER)” marking on the aluminum frame. The sediment pre-fi lter will likely be rather

distasteful looking—as it is common for sludge to form on the fi lter surface. After one year, this sludge

layer can be fairly thick.

a) Push the red button (on the top of the aluminum frame, above the pre-fi lter canister) to reduce

any back pressure remaining in the canister.

b) Firmly grasp the canister with both hands and unscrew it from the pre-fi lter assembly. Carefu lly

move the canister over the bucket, dump the water, and remove the old pre-fi lte r.

c) Using a long handled, soft bristle brush, scrub the inside of the canister with a mild dish washing

detergent and rinse.

d) Place the new pre-fi lter into the canister, and then carefully re-attach the canister to the assembly.

Tighten until fi rm.

Replacing the Twin GAC Pre-fi lters

The twin unidirectional, GAC pre-fi lters are in the middle canister (position 2) and the canister on the

right (position 3). Follow the same procedure as described for replacing the sediment pre-fi lter (above).

Replacing the 4-Stage DI Module

(Before proceeding, study Figure 5 below)

The tubing is attached to the module using a unique push-in fi tting system manufactured by John

Guest® Company. This system is designed to make connecting and disconnecting fi lter modules very

easy while insuring a water tight connection.

The “collet” assembly will securely

Collet

hold the tubing

in place under

normal operating

conditions. Pulling

on the tubing will

not cause it to release, instead the

“grip” of the collet

will become more

secure. An O-ring

behind the collet

Insert tubing

Figure 5, John Guest® “Speedfi t” fi ttings

5

/

8"

into "collet"

Depress "collet" to release

assures a leak free seal.

a) Disconnect the tubing from both ends of the DI module. (If the DI module was mounted vertically,

you might fi nd less water will be spilled if you remove the tubing from the outlet end afte r remov-

ing the module from the retaining clamp.)

b) Remove one screw from the clamp and remove the old DI module. (The clamp is fairly fl exible and

can be bent out to allow the module to be removed.) Note the direction of the “FLOW” arrow. You

will need to install the new DI module in the same orientation.

c) Place the new DI module into position, taking care to note the direction of fl ow. Secure the clamp

and re-connect the tubing. Gently tug on the tubing to insure a secure, leak free connection.

Returning the System to Service

To return your system to service:

1) Open the sink mounted chrome faucet.

2) Return the membrane fl ush valve to the “production” position.

Maintenance and Servicing 14

Page 15

3) Slowly re-open the cold water supply line.

4) Open the valve on top of the storage tank.

5) After about 20 minutes you should see water coming from the faucet. (It will take some time for

the DI module to fi ll with product water.)

6) Check for leaks around the tops of the pre-fi lter canisters. If water is seeping from any of the canisters turn the cold water supply off, relieve line pressure by pressing the red button on top of the

canister, and then unscrew the leaking canister from the assembly. Check to be sure the O-ring is

properly seated and then carefully re-attach the canister to the assembly, taking care to align the

fi lter module inside. Tighten until fi rm.

7) Check for leaks at either end of the DI module.

8) Close the faucet and allow the system to produce a full storage tank of water.

9) Drain off and discard this initial tank of water. Do not use for cooking or drinking.

10) You are now ready to enjoy great tasting, pure BEV water for another 12 months!

Maintenance and Servicing 15

Page 16

CHAPTER

4

Frequently Asked Questions

Q: How long will my sediment pre-fi lter last before it needs to be replaced?

A: Under typical city water conditions, the pre-fi lter is designed to function properly for 12 months, and

should be replaced annually. Sediment concentrations vary greatly between municipal systems so there

is no way of determining the lifetime of a fi lter without knowing more about the feed water. In some

cases, it may be necessary to replace the pre-fi lter more frequently.

Q: How long will my GAC pre-fi lters last before they need to be replaced?

A: Your PWS™ BEV-300 system has been designed to operate within a wide range of feed water condi-

tions. These conditions vary greatly across municipalities, so it is diffi cult to state precisely how long

your pre-fi lters will last. We have designed the systems so that under the most extreme conditions your

pre-fi lters will still be performing correctly after 12 months of use. Following an annual replacement

schedule will insure your system is consistently performing as designed and producing ultra-pure water

which meets the rigorous Vincent standards for bio-compatibility.

Q: How long will my reverse osmosis membrane last?

A: The membrane’s life depends on the water conditions as listed in the specifi cation section of this

manual. If all these conditions are met, the life of the membrane is generally 2–3 years. If a membrane

fails or its performance becomes reduced before this time, the cause can usually be traced to feed water

conditions outside the specifi cations.

Q: How do I know if there is a problem with the membrane?

A: The best method is to measure the resistivity (conductivity) of the product water and compare it to

the feed water. You can obtain a resistivity meter from Pure Water Systems or you can send samples to

Pure Water Systems for analysis. (Poor rejection rates may also be an indication of a clogged pre-fi lter,

so check that fi lter fi rst.) A large increase in the production rate is also an indication of membrane failure, and can often be traced to the membrane having been subjected to either freezing or hot water.

Q: How can I monitor the performance of the unit?

A: With identical feed water pressure, the production rate should remain fairly constant. If your system

begins to produce water at a much faster rate, the RO membrane may have failed. If your system is producing water at a much lower rate, replacing the pre-fi lter is often indicated.

To monitor the overall system rejection rate, the best method is to obtain either a resistivity meter or

TDS meter from Pure Water Systems.

Q: Will I lose valuable minerals when I drink reverse osmosis water?

A: No, the body does not readily assimilate the minerals found in drinking water. We obtain the major-

ity of our minerals from the foods we eat. There are many, many more chelated minerals in a piece of

organic fruit or a serving of organic vegetables than in several gallons of water.

Q: Will hot water ruin my RO membrane?

16

Page 17

A: YES! Hot water over 100° F will damage the membrane and cause poor rejection of the contaminants

in your water. Make sure you use only COLD water in your BEV system.

Q: How should I store my purifi ed water?

A: We recommend using a sealable glass container. Used one gallon fruit juice bottles are an excellent

choice. We also recommend containers made of 100% LEXAN®, like those available under the Nalgene®

brand. High quality polycarbonate containers are also acceptable for short term storage. If you store or

transport your BEV water in polycarbonate containers, be sure to keep the containers out of direct sunlight.

Q: How should I store my unit when not in use?

A: If you unit is out of service for several days (while you are vacationing, for example) no special pre-

cautions are required. However, we do recommend you fl ush the unit for 10-15 minutes and discard the

fi rst tank of water when you return the system to production.

Frequently Asked Questions 17

Page 18

CHAPTER

5

Limited Warranty

Pure Water Systems, Inc. warrants to the original owner each PWS™ BEV-300 Series pure water appliance to be free from defects in materials and workmanship for as long as you own the product.

What the Warranty Covers

Full Lifetime Warranty on all parts (excluding normal module changes or abuse).

Exceptions to Lifetime Warranty

The Lifetime Warranty does not include damage caused by or resulting from unreasonable use, including failure to provide reasonable maintenance, or incidental or consequential damages, such as water

damage or damage to appliances, fi xtures or other equipment.

Warranty will be void if product failure or damage is due to any of the following:

1) Misuse, misapplication (e.g. unacceptable water conditions), neglect (e.g. inadequate fi lter changes),

alteration, hot feed water, freezing, or accident.

2) Improper installation, operation, or servicing.

No one is authorized to change or add to this warranty.

What We Will Do T o Correct an Inconvenience

Upon notice, we will repair or replace covered defective parts, free of charge.

If it is necessary to ship the product to Pure Water Systems, Inc. or bring it to a dealer for service, the

buyer must pay for any shipping or travel costs.

Pure Water Systems, Inc. will pay for any return shipping charges in the U.S. for parts or products cov-

ered under the warranty.

Pure Water Systems, Inc. will furnish any factory labor to make repairs on parts or products returned to

the factory that are covered under the warranty.

How You Can Get Service

Contact the Pure Water Systems, Inc. customer service department for instructions and authorization

number for returning the defective part or product.

Pure Water Systems, Inc.

Customer Service Dept.

5707 238th Place N.E.

Redmond, WA 98053

Phone: (425) 765-6175

Your Pure Water Systems, Inc. BEV-300 Series pure water appliance is a sophisticated water treatment

system. Failure to use genuine Pure Water Systems, Inc. components shall void the exclusive lifetime

warrant y.

How State Law Relates To the Warranty

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the

above limitation or exclusion may not apply to you. This warranty applies to the original purchaser and

gives you specifi c legal rights. You may also have other rights which vary from state to state.

18

Page 19

APPENDIX

A

Specifi cations

Following are the recommended operating parameters for our custom rolled reverse osmosis membrane:

Membrane type Spiral Wound Polyamide Thin Film Composite (TFC)

Production Up to 40 Gallons-Per-Day (GPD)

Maximum Operating Temperature 40–100° F (4–38° C)

Operating Pressure 40–100 psi (2.75–6.9 bar)

pH Range 3.0–11.0

TDS Level, Maximum 2000 ppm

Turbidity < 1.0 Net Turbidity (NTU)

Chlorine (Cl2) 0.00 mg/l *

Hardness (CaCO3) < 350 mg/l

Iron (Fe) < 0.1 mg/l

Manganese (Mn) < 0.05 mg/l

Hydrogen Sulfi de (H2S) 0.00 mg/l

* Every system is equipped with our unique twin unidirectional granular activated carbon pre-fi lters to

remove organic contaminants and chlorine.

You can obtain specifi cs about your water supply from either your local water department or a water

testing service. If the parameters of your water do not fall within the specifi ed ranges as noted above,

please contact Pure Water Systems or your local dealer for further options.

Production is rated at optimum temperature of 70° F, 60 PSI, and 500 ppm TDS. Actual production will

vary depending on local temperature, pressure, and TDS level.

Low tap water pressure will reduce the volume and quality of the water produced by your system. In low

pressure situations (<40 PSI, 2.75 bar) BEV values cannot be assured. The addition of a booster pump

(PWS-BP-300) is strongly recommended.

ALWAYS USE COLD WATER—hot water will damage the TFC membrane.

The unit must not be allowed to freeze. Freezing water will expand inside the modules—damaging the

membrane and potentially rupturing the fi lter housings. Damage of this type will void the warranty.

19

Page 20

APPENDIX

B

Replacement Schedule

Below you can fi nd the recommended replacement schedule and part numbers for the components of

your BEV-340 pure water appliance. You can order replacement modules online from the Pure Water

Systems, Inc. website at http://www.purewatersystems.com.

Replacement Components

Module Replacement Schedule Order No.

Sediment Pre-fi lter Annually (or as needed) PWS-BEV300-SED

Unidirectional GAC Pre-fi lter Annu al ly PWS-BEV300 -G AC

4-Stage Deionization Module Annually PWS-BEV-DI

BEV 300 Series RO Membrane 2-3 years (as needed) PWS-BEV-RO40

Purchase Date:

Purchased From:

Serial Number:

Maintenance Log

Module Date Replaced

20

Page 21

APPENDIX

C

Connections

Connect tubing from the feed water saddle valve to

the John Guest® “Speedfi t” fi tting on the sediment

pre-fi lter.

Tubing from the tank shut-off valve

connects to one port on the T fi tting.

Tubing from the inlet port of the DI module

connects to the second port on the T fi tting.

It does not matter which port on the T

fi tting is chosen for each connection.

The drain check valve, located on the right side of the frame behind the reverse osmosis pressure vessel, connects to the drain

saddle valve (which is mounted to the existing plumbing).

Drain Check Valve

Flush Valve ,

Open Position

Flush Valve ,

Closed Position

21

Page 22

APPENDIX

D

Schematic

22

Loading...

Loading...