Page 1

INSTALLATION & MAINTENANCE MANUAL FOR

PVI FIREPOWER

B40 OIL BURNER

1.0 thru 10.0 gph

CARBON MONOXIDE WARNING:

CAUTION: IMPROPER COMBUSTION MAY CAUSE SERIOUS INJURY.

PVI recommends a seasonal or annual combustion check-out be performed by a

qualified service agency to ensure safe and efficient operation.

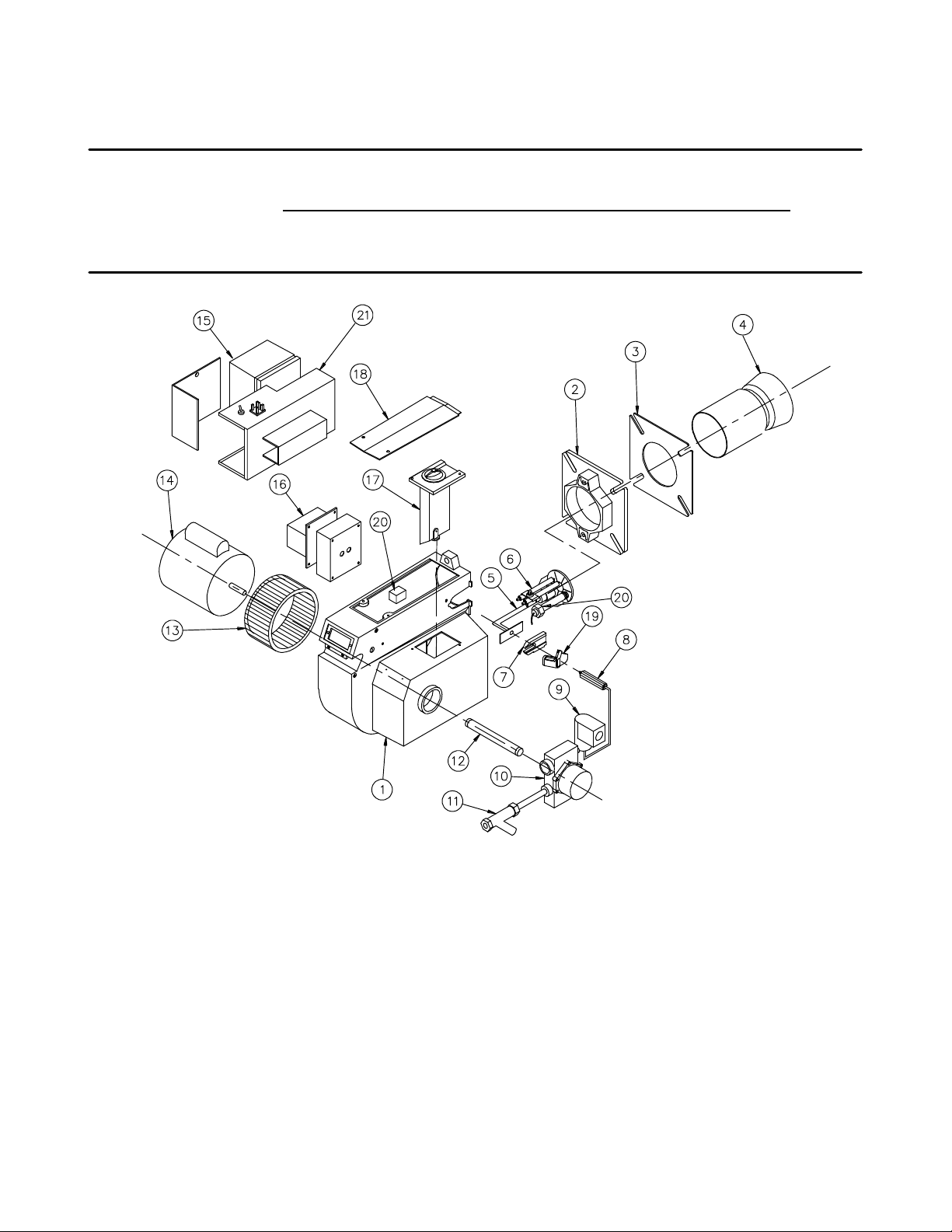

Typical Construction

Figure 22A-1

1. Burner housing 12. Pump coupling

2. Mounting flange 13. Fan wheel

3. Flange gasket 14. Fan motor

4. Blast tube 15. Flame safeguard

5. Oil nozzle assembly 16. Ignition transformer

6. Ignition electrodes 17. Damper assembly

7. Housing plug 18. Housing cover

8. Connecting pipe 19. Locating block

9. Electric oil valve 20. Scanner or photocell

10. Oil pump 21. Control enclosure

11. Oil strainer

PV500-22A 08-98 1 Section 22A

Page 2

PVI FIREPOWER

B40 OIL BURNER

1. Wiring to the unit should conform to the

National Electrical Code or the code legally

authorized to your locality. A fused disconnect

switch should be used for water heater

control. Service wiring connections of 115V, 1

phase, 60 Hz. are located in the enclosure on

the water heater. (See Figure 22-10, pg. 14.)

FOR YOUR SAFETY

DO NOT store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

FOR YOUR SAFETY

WARNING: Improper installation,

adjustment, alteration, service or

maintenance can cause injury or

property damage. Refer to this manual

for assistance, or consult a qualified

service agency.

ELECTRICAL

NOTE: Use only copper wire of proper sizing

for incoming service. Damage resulting from

use of aluminum wiring will be excluded from

coverage under the warranty of this unit.

PV500-22A 08-98 2 Section 22A

Page 3

PVI FIREPOWER

B40 OIL BURNER START-UP

(Refer to Figure 22-1 to identify burner parts)

1. Remove the enclosure panel cover on the water

heater or boiler to expose the control circuit. The

wiring diagram, located on the backside of the

cover, will show the controls used in our circuitry.

2. Visually check that all components are intact and

no damage has occurred during transit.

3. Check all connections in control cabinet. A loose

connection could cause intermittent shutdowns.

4. Check oil supply lines to insure proper practices

have been followed and installation complies with

local codes. Use only a two-pipe system. Check

for adequate burner intake air supply.

NOTE: Do not tamper with or readjust program

dipswitch settings. This will cause the control

to become inoperable. Damage resulting from

tampering will be excluded from coverage

under the warranty of this unit.

5. Remove the flame safeguard control from its

base. Check the connections in control mounting

base; loose connections can cause nuisance

shutdowns. When applicable, check the time card

or programmer, for good connection.

6. With electrodes exposed, check them for the

proper settings as in Figure 22-4 & 7, pages 7 & 8.

Check for any hairline cracks in the insulators.

Should replacement of burner electrodes be

required, certain procedures must be followed. In

all cases, removal of electrodes is accomplished

by loosening the electrode mounting clamps.

Draw electrodes out of the nozzle assembly

through the holes in the pressure plate.

7. Open manual oil valve(s). Make certain check

valves are positioned for the correct oil flow. There

should not be a manual shut-off valve in the return

line from the pump to the tank.

8. Pull the nozzle assembly to check the ignition

electrodes. See Figure 22-3 & 6, pages 7 & 8.

9. Inspect the electrodes for cracked ceramic or

loose retaining studs that hold the wire within the

ceramic. Select the proper pressure plate hole to

place each electrode and insert the electrode

through the hole, retaining stud end first.

10. Tighten the electrode mounting clamp slightly until

electrode ceramics are seated firmly and

completely in the mounting bracket without gaps

between ceramics and mounting bracket at the

bearing faces.

11. Measure and set electrodes according to Figure

22-4 & 7, pages 7 & 8. After gaps and setting are

complete, fully tighten electrode mounting clamp.

Do not overtighten or insulation may crack.

12. Replace nozzle assembly; be sure to connect the

spark rod wires before installing nozzle assembly

fully into blast tube. Check connections on the

ends of the flame and spark rod wires for good

contact. Look for properly stripped wire ends. Be

sure connectors are firmly attached to the ignition

rod ends. Insulating boots can give a false feeling

of proper seating. DO NOT MOVE

ELECTRODES. Be careful not to bump

electrodes. Check fan wheel for free rotation.

13. Connect a test meter to the control for reading the

flame response signal.

NOTE: Some controls read the flame signal in

micro amps and some in volts DC. The MC120

series control has two terminals marked for

reading volts DC.

14. Be sure tank is filled with water. Once the burner

is reassembled, a gauge to read pressure,

preferably a 300 psi gauge, will be needed to read

oil pressures. Connect gauge to the pressure side

of the oil pump. Connect vacuum gauge to supply

side of oil pump (15”HG maximum allowed).

15. Single stage oil burners. Before turning the unit

on, make sure all valves in the oil supply and

return lines are on. Check the air damper setting

against the setup tag attached to the burner.

Turn the unit on using the rocker switch on the

side of the control cabinet. If the operating

control switches are closed, the burner blower

should come on and prepurge begins.

If nothing happens, check the control to be sure it

is not in the tripped position and reset it by

pushing the flame safeguard reset button. Burner

should prepurge for no more than thirty seconds.

PV500-22A 08-98 3 Section 22A

Page 4

PVI FIREPOWER

B40 OIL BURNER START-UP (con't)

After purging is complete, terminal 3 energizes

the oil valve and terminal 4 energizes the ignition

transformer. The flame is then established and

the VDC reading on the meter should read a

steady 14-18 VDC for photocell or 4-6 VDC for

UV amplifiers. Each different control will have the

required flame response signal stamped on it.

This is the minimum for it to properly operate. If

the burner fails to light during the initial period, it

is probably due to air in the line. The control will

lock out. Push the flame safeguard reset button

to restart burner and begin the purge cycle again.

Once the flame is established, set the oil

pressure (measured at the oil pump) at the

pressure shown on the tag attached to the

burner. Oil pressure should be adjusted while

firing on the second stage. Do not exceed the oil

supply pressure specified on the setup tag.

16. Two stage oil burners. Before turning the unit

on, make sure all valves in the oil supply and

return lines are on. Check the first stage air

damper setting against the setup tag attached to

the burner. The second stage air setting must be

adjusted while the burner is operating. Turn the

unit on using the rocker switch on the side of the

control cabinet. If the operating control switches

are closed, the burner blower should come on

and prepurge begin.

If nothing happens, check the control to be sure it

is not in the tripped position and reset it by

pushing the flame safeguard reset button. The

burner should prepurge for no longer than thirty

seconds.

After purging is complete, terminal 3 energizes

the oil valve and terminal 4 energizes the ignition

transformer. The flame is then established and

terminal 5 energizes the main oil valve after a

short delay. This will simultaneously supply oil to

the second stage oil nozzle and the damper

actuator, driving the damper open. The burner

can be temporarily locked in the first or second

stage by adjusting the low-fire hold switch. The

VDC reading on the meter should read a steady

14-18 VDC for photocell or 4-6 VDC for UV

amplifiers. Each different control will have the

required (minimum) flame response signal

stamped on it. If the burner fails to light during the

initial period, check for air in the line. The control

will lock out. Push flame safeguard reset button

to restart burner and begin purge cycle again.

Once the flame is established, set the oil pressure

(measured at the oil pump) at pressure shown on

the tag attached to the burner. Oil pressure should

be adjusted while firing on the second stage. Do

not exceed the oil supply pressure specified on

the setup tag.

17. Check flue gases with a flue analyzer and smoke

spot pump to make final settings of the air

damper.

a. Readings need to be taken from a hole in the

vent several inches from flue outlet

connection.

b. Insert draft gauge into the test opening in the

stack. Draft in stack should read -.02" to -.06"

W.C. Adjust draft regulator, if installed.

c. Insert analyzer in test opening and determine

O2 content in percentage.

d. Gradually close air damper to decrease O2

reading or open air damper to increase O2

reading until optimum O2 % (4-5%) is reached.

Refer to Figure 22-2 & 5, pages 7 & 8 for

damper adjustment details.

e. Once the O2 reading is in the specified range,

check smoke content in the flue gas by

pumping ten times through a new smoke spot

sample paper. Smoke spot should not exceed

a #2. If the smoke spot exceeds a #2, it may

be necessary to increase the O2 %.

f. Once combustion is set, take note of the gross

stack temperature; maximum gross stack is to

be 400°F, minimum net stack is to be 300°F.

(NOTE: net temperature is the total stack

temperature, less room temperature.) If an

excessively high gross stack temperature is

recorded, consult the factory.

g. Make sure air shutter is locked securely in

place.

18. On two-stage oil burners, the preceding analysis

must be done for the first and second stage.

19. Check each operating and limit control to be sure

they function properly by lowering and raising the

temperature setting on each of the controls,

causing the burner to cycle on and off.

PV500-22A 08-98 4 Section 22A

Page 5

PVI FIREPOWER

B SERIES OIL BURNER START-UP (con't)

20. Record the following information for future use:

a) Air shutter position ________________

b) Oil supply pressure ____________PSIG

c) Stack draft _________________" W.C.

d) O2 reading _______________% (4-6%)

e) CO2 reading ____________% (10-12%)

f) CO reading ______ ppm (less than 300)

g) Smoke ________________(less than #2)

h) Stack temperature:

Gross ________________________°F.

Less ambient ___________________°F.

Net __________________________°F.

i) Combustion efficiency ____________%

NOZZLE RATING

gph

GPH 100 PSI 85 100 125 150 175 200 GPH 100 PSI 85 100 125 150 175 200

.40 .36 .40 .45 .49 .53 .56 3.00 2.76 3.00 3.35 3.68 3.97 4.25

.50 .46 .50 .56 .61 .66 .71 3.75 3.45 3.75 4.19 4.59 4.96 5.30

.55 .50 .55 .61 .67 .72 .77 4.50 4.14 4.50 5.04 5.51 5.95 6.36

.60 .55 .60 .67 .74 .79 .85 5.00 4.60 5.00 5.59 6.13 6.61 7.07

.65 .59 .65 .73 .80 .86 .92 5.50 5.07 5.50 6.15 6.74 7.27 7.78

.75 .69 .75 .84 .92 .99 1.06 6.00 5.53 6.00 6.71 7.33 7.94 8.48

.85 .78 .85 .95 1.04 1.13 1.20 6.50 5.99 6.50 7.26 7.96 8.60 9.20

1.00 .92 1.00 1.12 1.23 1.32 1.41 7.50 6.91 7.50 8.38 9.19 9.91 10.60

1.10 1.01 1.10 1.23 1.34 1.45 1.55 8.50 7.83 8.50 9.50 10.41 11.24 12.02

1.25 1.15 1.25 1.39 1.53 1.65 1.76 10.00 9.21 10.00 11.18 12.24 13.22 14.14

1.35 1.24 1.35 1.51 1.65 1.78 1.91 11.00 10.14 11.00 12.29 13.47 14.55 15.55

1.50 1.38 1.50 1.68 1.84 1.98 2.12 12.00 11.06 12.00 13.40 14.70 15.90 17.00

1.75 1.61 1.75 1.96 2.14 2.32 2.48 13.50 12.44 13.50 15.09 16.53 17.85 19.09

2.00 1.84 2.00 2.24 2.45 2.65 2.83 15.00 13.82 15.00 16.77 18.37 19.84 21.21

2.25 2.07 2.25 2.52 2.74 2.98 3.18 17.00 15.67 17.00 19.00 20.82 22.48 24.04

2.50 2.30 2.50 2.80 3.06 3.30 3.54 19.50 17.97 19.50 21.80 23.90 25.80 27.60

2.80 2.58 2.80 3.13 3.42 3.70 3.95 22.00 20.28 22.00 24.59 26.94 29.10 31.11

OPERATING PRESSURE:

IN POUNDS PER SQUARE INCH

NOZZLE RATING

TABLE 22-1

gph

OPERATING PRESSURE:

IN POUNDS PER SQUARE INCH

PV500-22A 08-98 5 Section 22A

Page 6

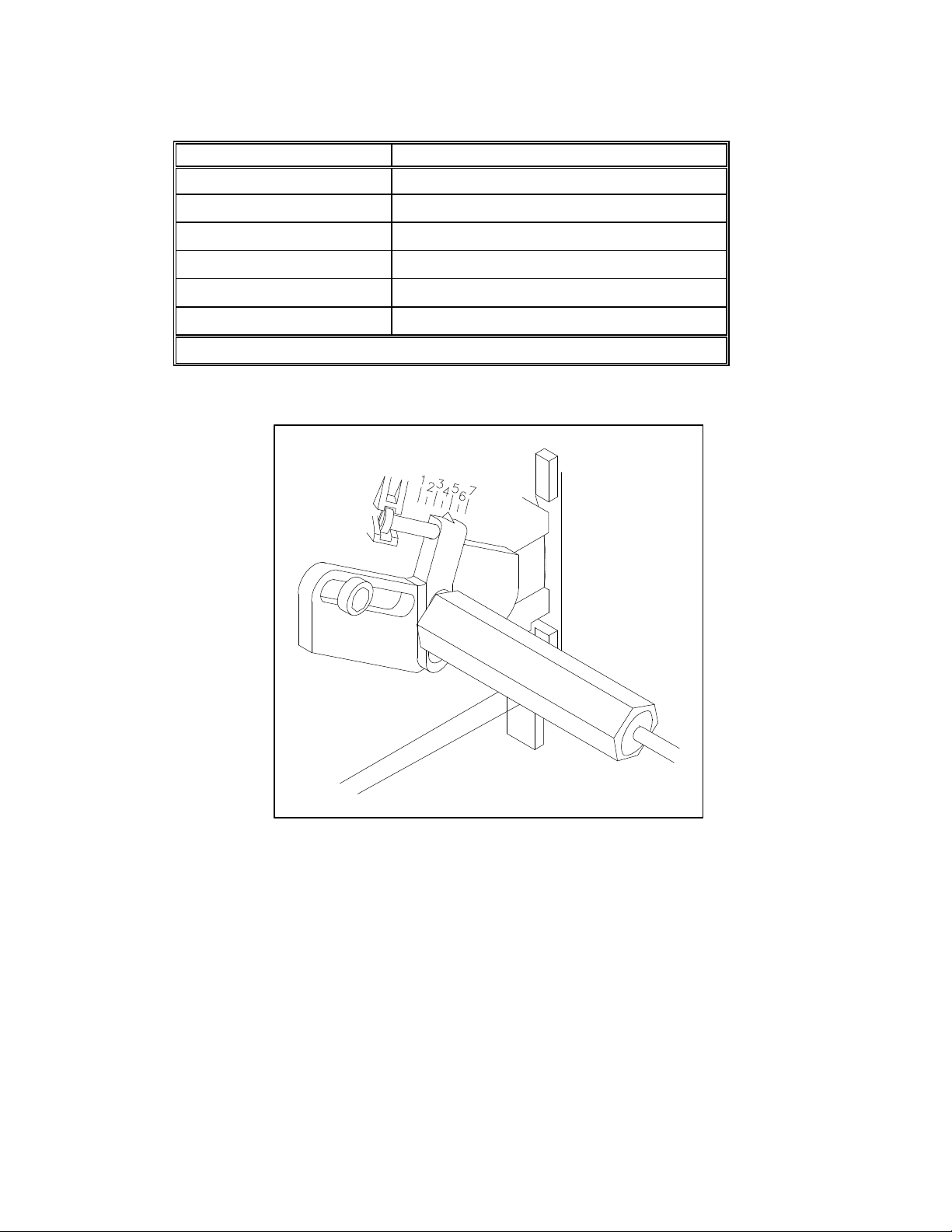

Figure 22A-2

Figure 22A-3

PVI FIREPOWER

SINGLE STAGE B SERIES OIL BURNER ADJUSTMENTS

AIR ADJUSTMENT

Loosen the locking screw and move the knob (A) along the scale (B) to the

position wanted and tighten the screw. Check the air adjustment by making a flue

gas analysis.

ADJUSTMENT & REMOVAL OF NOZZLE ASSEMBLY

To adjust nozzle assembly (C), loosen screw (D) and move

the nozzle forward or retract by turning the adjustment

screw (E). Line up the pointer on the locating block to the

index position specified in Table 22-2 (pg. 9) for best

results.

To remove the nozzle, remove the burner cover and

disconnect the electrode cables. Separate the nozzle

assembly from the fan housing by loosening the

connecting pipe (F) and extracting the connecting pipe

from the nozzle port.

IGNITION ELECTRODE ADJUSTMENT

Check that the measurements between the

nozzle, the ignition electrodes and the pressure

plate correspond to Figure 22-4.

Figure 22A-4

PV500-22A 08-98 6 Section 22A

Page 7

Figure 22A-5

PVI FIREPOWER

TWO STAGE B SERIES OIL BURNER ADJUSTMENTS

AIR ADJUSTMENT

First stage: Set the operating switch on low capacity. Loosen the screw (A) and

move the damper arm (C) along the scale (E) to a position where the flame does

not soot nor blow out. Tighten the screw.

Second stage: The operating switch remains on low capacity. Screw the knurled

ring (B) by means of an adjustment pin in (reduce) or out (increase). The position

of the damper can be read on the damper scale (E).

Check the air adjustments of the second stage by making a flue gas analysis.

ADJUSTMENT & REMOVAL OF NOZZLE ASSEMBLY

To adjust nozzle assembly (C), loosen screw

(D) and move the nozzle forward or retract by

turning the adjustment screw (E). Line up the

pointer on the locating block to the index

position specified in Table 22-2 (pg. 9) for best

results.

To remove the nozzle, remove the burner

cover and disconnect the electrode cables.

Separate the nozzle assembly from the fan

housing by loosening the connecting pipe (F)

and extracting the connecting pipe from the

nozzle port. Then disconnect the 2nd stage oil

line from the fitting located on the inside of the

fan housing.

Figure 22A-6

IGNITION ELECTRODE ADJUSTMENT

Check that the measurements between the

nozzle, the ignition electrodes and the

pressure plate correspond to Figure 22-7.

Figure 22A-7

PV500-22A 08-98 7 Section 22A

Page 8

PVI FIREPOWER

NOZZLE POSITION

INPUT - GPH NOZZLE POSITION

1.4 1

2.8 3

4.3 4

5.7 2

7.2 2

8.6 4

TABLE 22-2

Figure 22A-8

PV500-22A 08-98 8 Section 22A

Page 9

PVI FIREPOWER

TROUBLESHOOTING SUGGESTIONS

OIL BURNER

1. BURNER FAILS TO START:

A. Defective on/off or fuel transfer switch.

Replace switch.

B. Control circuit has an open control contact.

Check limits, low water cutoff, proof of closure

switch and others as applicable.

C. Bad fuse or switch open on incoming power

source. Correct as required.

D. Motor overloads tripped. Reset and correct

cause for trip out.

E. Flame safeguard control safety switch

tripped out. Reset and determine cause of

apparent flame failure.

F. Loose connections or faulty wiring. Tighten

all terminal screws and consult wiring diagram

furnished with the burner.

G. Frozen oil pump shaft preventing blower

motor operation. Replace oil pump.

H. Flame safeguard control starting circuit

blocked due to flame relay being energized.

Possible defective scanner or photocell replace. Possible defective amplifier - replace.

Scanner actually sighting flame due to leaking

fuel valve - correct unwanted flame cause.

Defective flame safeguard control - replace.

I. Defective blower motor. Repair or replace.

2. OCCASIONAL LOCKOUTS FOR NO

APPARENT REASON:

A. Check for proper settings on direct spark oil

ignition electrodes. Make certain that gap is

not too wide and the “light-off” oil pressure is as

recommended.

B. Direct spark ignition. Verify that there are no

cracks in the porcelain and that transformer end

and electrode end plug-in connections are tight.

C. Loose or broken wires. Check all wire nut

connections and tighten all terminal screw

connections in panel and elsewhere as

appropriate.

D. Occasional low supply voltage. Contact local

utility to correct. Make certain the burner control

circuit transformer (if supplied) is correct for the

voltage and power (VAC) being supplied.

3. BURNER MOTOR RUNS, BUT DIRECT SPARK

IGNITED OIL FLAME IS NOT ESTABLISHED:

A. Defective or incorrect size oil nozzle.

Remove and clean or replace.

B. Low oil pressure. Check with gauge for correct

“light-off” pressure.

C. Defective oil pump. Replace.

D. Defective oil solenoid valve. Replace.

E. Oil pump coupling loose and defective.

Replace or tighten as required.

F. Low oil pressure switch (if supplied)

defective or incorrectly set. Adjust or replace

switch.

G. Ignition transformer defective. Replace.

H. Ignition electrode set incorrectly. Remove

electrodes and reset.

I. Ignition electrodes cracked and grounding

out spark. Replace electrodes.

J. Ignition leadwire defective and grounding

out spark. Replace.

K. Ignition plug in connections at transformer

or electrode loose. Tighten.

L. Air flow switch not making circuit. Adjust set

point or replace.

M. Defective flame safeguard control or plug in

purge timer card. Replace.

N. Air dampers held in high fire position due to

mechanical binding of linkage. Readjust

linkage.

O. Loose wiring connections. Check and tighten

all connections.

PV500-22A 08-98 9 Section 22A

Page 10

PVI FIREPOWER

TROUBLESHOOTING SUGGESTIONS

OIL BURNER (con't)

4. OIL FLAME IGNITES, BUT THEN FLAME

SAFEGUARD CONTROL LOCKS OUT ON

SAFETY:

A. Flame scanner lens dirty. Remove and clean.

B. Scanner sight tube blocked or dirty. Check

and clean.

C. Flame scanner defective. Replace.

D. Fuel/air ratios incorrect, resulting in

unstable or smoky flame causing scanner

flame sighting problem. Readjust ratios for

clean stable flame.

E. Defective flame safeguard amplifier or

control. Replace as appropriate.

5. OIL FLAME EXTREMELY SMOKY AT LIGHTOFF OR IN LOW FIRE POSITION:

A. Defective or incorrect size oil nozzle.

Replace.

B. Fuel/air ratio incorrect. Readjust.

6. LIGHT-OFF OIL FLAME IS ESTABLISHED AND

PROVEN, BUT BURNER WILL NOT ATTEMPT

TO GO TO THE HIGH FIRE POSITION:

A. Low/High/Low or modulating burner high

fire temperature or pressure control could

be defective or not set to call for high fire.

Readjust or replace control.

B. Loose wires or incorrectly wired. Verify wiring

and tighten all connections.

C. Flame safeguard control or high fire switch

(if supplied) defective. Verify and correct as

required.

D. Hydraulic oil cylinder defective. Replace.

E. Linkage mechanically binding. Readjust

linkage.

7. LOW OIL FLAME IS ESTABLISHED AND

PROVEN, BUT FLAME OUT OCCURS IN

TRANSITION FROM LOW FIRE TO HIGH FIRE:

A. Defective or incorrect size oil nozzle.

Replace.

B. High fire oil pressure too low. Readjust.

C. Air dampers set too far open at low fire,

which causes flame to blow out during

transition to high fire. Readjust dampers.

D. Oil pump coupling loose or defective.

Tighten or replace.

E. Defective oil pump. Replace.

F. Linkage mechanically binding. Readjust.

G. On modulating systems-fuel/air rations set

incorrectly, causing flame to blow out when

going to high fire. Readjust linkage.

8. WHITE SMOKE FORMATION ON OIL FIRING:

A. Oil/air ratios incorrect due to excess air, or

oil flow is too low. Readjust for proper fuel

input, CO2 and smoke reading.

9. GRAY OR BLACK SMOKE FORMATION ON

OIL FIRING:

A. Impingement on cold combustion chamber

surfaces due to incorrect oil nozzle spray

angle for application. This could also result in

carbon formation on chamber surfaces.

B. Defective or dirty oil nozzle. Replace or clean

nozzle.

C. Incorrect oil/air ratios. Readjust burner to

correct CO2 and smoke levels.

D. Oil pressure too low resulting in poor

atomization. Readjust.

PV500-22A 08-98 10 Section 22A

Page 11

PVI FIREPOWER

TROUBLESHOOTING SUGGESTIONS

OIL BURNER (con't)

6. OIL HIGH FIRE INPUT RATE CANNOT BE

ACHIEVED:

A. Oil nozzle size too small. Remove nozzle

and check marking. Replace with correct size

nozzle.

B. Nozzle defective. Replace. Nozzle mesh filter

(if supplied) dirty. Clean or replace.

C. Oil supply pressure to nozzle too low.

Readjust.

D. Oil pump defective. Replace.

E. Oil pump coupling loose (slipping) or

defective. Replace.

F. Linkage mechanically binding. Readjust.

G. On modulating burner, oil nozzle return line

metering valve set incorrectly. Readjust to

attain required nozzle bypass pressure.

Additional troubleshooting information can be found in the Flame Safeguard bulletin supplied with the burner.

H. Oil suction line too small or partially

blocked. Make vacuum test while at high fire.

The vacuum should not exceed 10-15 inches

Mercury (HG). Make line size changes, if

required.

I. Blocked or dirty suction line oil filter.

Replace or clean.

J. Manual valves in suction line not fully open.

Check and correct.

K. Suction line check valve or foot valve

operating incorrectly. Check and correct.

L. Vent system on oil tank blocked, creating

vacuum on tank with high vacuum and

lowered oil flow to burner. Check and correct.

PV500-22A 08-98 11 Section 22A

Loading...

Loading...