Using The Electronic Manual

Requirements

The following is a list of system requirements for the electronic manual:

Pentium Processor

64 MB of RAM

50 MB of Available Hard Drive Space

Windows

CD-ROM Drive

800 x 600 Screen Resolution

AutoCAD® or Volo™ View 2000-129 (Volo™ View is provided on CD)

Adobe

Opening the Manual

To open the electronic manual, insert the manual CD into your CD-ROM drive. The manual startup menu will

appear. If this is the first time the manual has been used, a disclaimer will have to be acknowledged. If your CDROM drive is not configured to Auto Run, open Windows Explorer

Navigation

Navigating the electronic manual can be done by clicking on a topic in the left pane. Several of the topics have

sub-topics which can be accesses by clicking on the [+] symbol to the left of the parent topic. The table of

contents also has links to specific areas of the manual. To search for a specific topic, use the find function by

keying ‘CTRL+F’.

®

98 SE, Millenium, NT, 2000, or XP Operating System

®

Acrobat® or Acrobat® Reader (Acrobat® Reader is provided on CD)

®

and open ‘Startupmenu.exe’.

Viewing Documents

The electronic manual uses external documentation for schematics, custom equipment documentation, etc. To

view these documents, click the link to the specified topic. If the topic is located on an external document, there

will be a button to access these documents. When you click the button, Adobe

®

may display a confirmation

message asking if you want to launch the application used to view the document. Select All, and a list of

available documents on that topic will appear. Click the document you wish to view. To return from an external

document, click on the back arrow for PDF documents. Close the AutoCAD

®

viewer to return from viewing a

schematic. All schematics are in a *.dwg format, and all other external documents are in *.pdf format. A

compatible viewer for each type of document is required to run the electronic manual.

Troubleshooting

If you have a problem with the electronic manual, check the following:

• The electronic manual was started using the ‘Startupmenu.exe’ file.

• The electronic manual disclaimer has been acknowledged.

• There is an AutoCAD

• There is a Portable Document Format compatible viewer installed (PDF Viewer).

• The original directory structure has not changed.

If everything in the above list checks out and you are still having problems with the electronic manual, uninstall

®

Adobe

Acrobat® (or Adobe® Reader), and AutoCAD® (or Volo™ View), then reinstall each.

®

compatible viewer installed.

Disclaimer

CAREFULLY READ ALL OF THE TERMS AND CONDITIONS OF THIS DOCUMENT BEFORE

INSTALLING THIS MEDIA. OPENING OF THIS MEDIA CONSTITUTES ACCEPTANCE OF ALL OF

THE TERMS AND CONDITIONS OF THIS AGREEMENT.

If you do not agree to these terms and conditions, you may return this media and the other components of this

product.

PRECISION VALVE & AUTOMATION, INC. owns the copyright to this media.

Copyright© 1997-2004 Precision Valve & Automation, Inc.

All Rights Reserved.

This document may not, in whole or in part, be copied, photocopied, reproduced, translated, or copied to any

electronic medium or machine-readable form without prior consent in writing to Precision Valve &

Automation, Inc., 15 Solar Drive, Halfmoon, NY 12065.

Limitation of Liability. In no event will Precision Valve & Automation, Inc. be liable for any damages,

including lost profits or any special, indirect, incidental or consequential damages, arising out of this

agreement or the inability to use this media, whether claimed under this agreement or otherwise.

Nondisclosure. The documents in this media, terms, pricing and all information identified as confidential under

this Agreement are considered confidential information (“Confidential Information”). Confidential Information

shall not include information that: a) becomes part of the public domain without breach of this Agreement by

Customer; b) has been published or is generally known to the public at the time of its disclosure to Customer; c)

was at the time of receipt otherwise lawfully known to the Customer; or d) is disclosed with the written approval

of Precision Valve & Automation, Inc. Customer agrees not to make Confidential Information available in any

form to any third party and not to use Confid ential Information for any purpose other than the implementation of

this Agreement. Customer agrees to take all reasonable steps to ensure that Confidential Information is not

disclosed in violation of the terms of this Agreement.

This Agreement shall be governed by the laws of the State of New York and Customer agrees to submit to the

exclusive jurisdiction of New York courts.

Coating and Dispensing

System Manual

- PVA2000

- PVA3000

- PVA2000C

- PVA750

- PVA550

- PVA250

info@pva.net

(518) 371-2684

15 SOLAR DRIVE - HALFMOON, NY 12065

PHONE: (518) 371-2684 - FAX: (518) 371-2684

All Rights Reserved, Copyright (c) 2003 Precision Valve & Automation, Inc.

PVA250

P/N: SNGT1133 S/N: W1948

Singletec, Inc.

TM

Operating Guide

Automated Dispensing System

15 Solar Drive – Halfmoon, NY 12065

Table Of Contents

Configuration

1

Operation and Maintenance Manual

2

PathMaster® Manual

3

4

5

6

Cut Sheets

Schematics

Software

Configuration

Configuration

1

Operation and Maintenance Manual

PathMaster® Manual

Cut Sheets

Schematics

Software

Configuration

W1948

3.04

2.3.49

3/05

120 Vac, 60 Hz, 5 Amps

10 kA

REG-1

Main air pressure

90 P.S.I. +/- 10 P.S.I

REG-2

Pump Air Motor Pressure

60 P.S.I. +/- 10 P.S.I

REG-3

Material Regulator Pressure

Customer Determined

REG-4

Regulator Output Pressure

Customer Determined

REG-5

Pail Pump Elevation Press.

15 P.S.I. +/- 5 P.S.I.

1

FC100

Dispense Valve

No

No

Notice

This document, including the information contained herein, is the property of Precision Valve &

Automation, Inc. and is considered confidential and proprietary information. It is delivered on the

express condition that it not be used, disclosed, or reproduced in whole or in part, for any reason without

prior written consent of Precision Valve & Automation, Inc.

Machine Specifics

Serial Number:

Program Revision:

PathMaster® Version:

Date of Ship:

Power Requirements

Electrical Rating:

Interrupting Capacity:

Pressure Settings

Regulator Description Setting

Valve Nomenclature

Head # Name Description Z-slide Rotary

Table 1 – Pressure Settings

Table 2 – Valve Nomenclature

Workcell Configuration

- 1 -

Optional Equipment

Select Optional Equipment

Documentation on non-Standard equipment installed on the workcell is included with this

manual. To view these documents click the button below.

Notes

Operation and Maintenance

Configuration

Operation and Maintenance Manual

2

PathMaster® Manual

Cut Sheets

Schematics

Software

Operation and Maintenance Manual

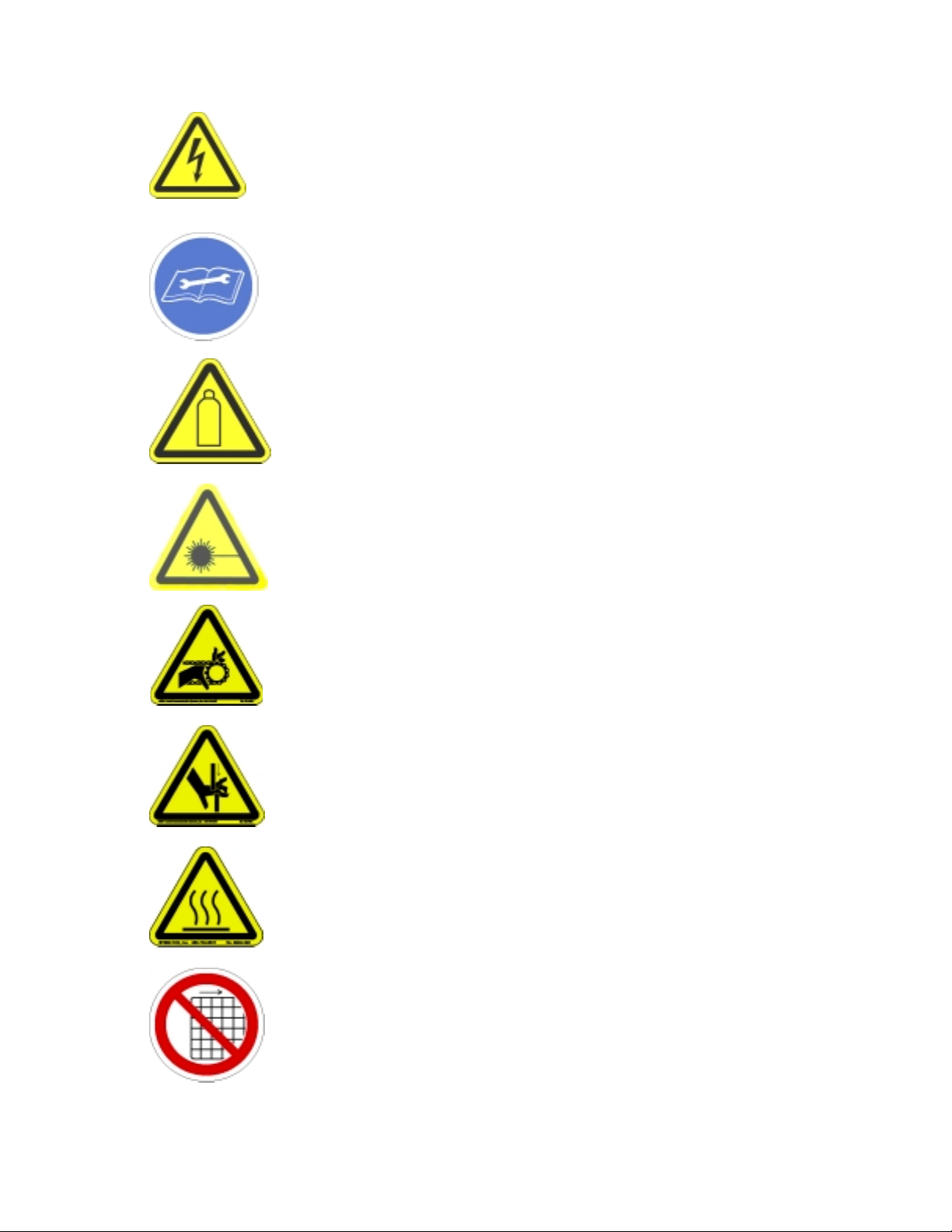

Warnings, Cautions, and Notes

Certain warning symbols are affixed to the machine and correspond to notations in this manual. Before

operating the workcell, identify these warning labels and read the notices described below. Not all labels

may be used on any specific system.

Always wear approved safety glasses when operating or working near the

workcell.

6040

In situations where inattention could cause either personal injury or

damage to equipment a warning notice is used.

6014

Do not smoke near the workcell. Always have a fire extinguisher

available for emergency use.

6019

Before operating the system, read and understand the manuals provided

with the unit.

6017

Before performing any repairs or maintenance to the system, turn off

power and lock out the power disconnect switch.

6011

Never place hands or tools in areas designated by this symbol when the

machine is in operation. A dangerous condition may exist.

6008

Warning notices are used to emphasize that hazardous voltages, current,

temperatures, or other conditions that could case personal injury exist in

this equipment or may be associated with its use. Only qualified

personnel should enter areas designated with this symbol.

6010

Before performing any repairs or maintenance to the system, read and

understand the manuals provided with the unit. Service should only be

performed by a qualified individual.

6018

Exercise caution when pressurized vessels are present. Identify and

repair any leaks immediately. Always wear appropriate safety equipment

when working with pressurized vessels or vessels containing chemicals.

6054

Laser light source present. Do not stare directly into the beam. Do not

use in the presence of highly reflective surfaces.

6003

Pinch hazard from moving parts. Avoid contact.

1012

Shear hazard from moving parts. Avoid contact.

1099

Hot surface. Avoid contact.

6043

Do not remove protective guarding.

6060

This document is based on information available at the time of its publication. While efforts have been

made to be accurate, the information contained herein does not purport to cover all details or variations in

hardware or software, nor to provide for every possible contingency in connection with installation,

operation, or maintenance. Features may be described herein which are not present in all hardware and

software systems. Precision Valve & Automation, Inc. assumes no obligation of notice to holders of this

document with respect to changes subsequently made.

Precision Valve & Automation, Inc. makes no representation or warranty, expressed, implied, or statutory

with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency, or usefulness of

the information contained herein. No warranties of merchantability or fitness for purpose shall apply.

This document, including the inform ation contained herein, is the property of Precision Valve &

Automation, Inc. and is considered co nfidential and proprietary information. It is delivered on the

express condition that it not be used, disclosed , or reproduced in whole or in part, for any reason without

prior written consent of Precision Valve & Automation, Inc.

Copyright © 2003 Precision Valve & Automation, Inc.

All Rights Reserved.

Preface

Notice & Disclaimer

This manual applies to one of the following automated workcells produced by Precision Valve &

Automation, Inc.:

o PVA250™

o PVA550™

o PVA750™

o PVA1000™

o PVA2000™

o PVA200C™

o PVA3000™

All machines are refere nced t hroughout the manual as the workce ll. T his manual pr ovide s informat ion and

functionality descriptions covering all the common options and configurations for a workcell. The

particular machine associated with this manual may not contain all items or may have additions. If the

manual refers to an option that was not purchased, ignore that section. If options exist on the machine not

mentioned in this manual, please consult the Optional Equipment section of the Operating Guide for more

information on these additions.

Revisions to This Manual

The following list describes the major revisions in this manual (Rev M (ii) (4/03)) as compared to the

previous versi on:

o Rewrite for latest program revisions (3.01 & 3.02 & 3.03 & 3.04).

o Altered Power Check procedure and added Door Interlock Check procedure.

o Added compatibility for the PVA250™, PVA2000C™, solvent cups, flow monitor, and teach pendant.

2/10/03 TMB

o Updated Power Check procedure. 2/10/03 TMB

o Added PVA750™ references. 8/1/03 TMB

Operation and Maintenance Manual Rev M(ii) 4/03

- iv -

Content of This Manual

Introduction. Provides an overview of the workcell functionality and physical characteristics.

Installation and Setup. Describes the procedures for installing the workcell and preparing the system for

use. Included in this chapter are instructions for unpacking, inspecting, and installing the workcell.

Operating Safety. Basic safety practices are reviewed. The safety devices and guarding for the workcell

are described.

Operation. Describes system operations of the workcell. It includes a discussion of the system power-up

and power-down sequences and modes of operation.

Troubleshooting. Provides a guide to troubleshooting the workcell. A fault diagnosis table is used to lead

the operator through common problems and sol ut i ons. Several troublesho oting procedures are described.

Maintenance. Provides a preventive maintenance schedule and replacement procedures.

Appendix A – Definitions. Definitions for commonly used terms.

Appendix B – Serial Communication. A brief overview of establishing communication with the workcell.

Appendix C – Error Codes. A list of error codes that may be encountered while using the workcell.

Appendix D – Open Loop Velocity Settings. A list of maximum velocity settings for an open loop drive

system.

Appendix E – Wiring Schema tic Legend. A l egend for t he number ing and c olo r c odi ng used i n the co ntro l

enclosure for the workcell.

Operation and Maintenance Manual Rev M(ii) 4/03

- v -

Contents

Table Of Contents

Preface ......................................................................................................................................... iv

Notice & Disclaimer............................................................................................................................. iv

Revisions to This Manual .....................................................................................................................iv

Content of This Manual......................................................................................................................... v

Contents....................................................................................................................................... vi

Table Of Contents................................................................................................................................. vi

List of Tables........................................................................................................................................ix

Introduction................................................................................................................................10

System Description..............................................................................................................................10

Year 2000 Compliance................................................................................................................. 10

Environmental......................................................................................................................................11

Noise Levels................................................................................................................................. 11

Materials/Chemicals..................................................................................................................... 11

Hazards Due to Contact................................................................................................................11

Handling, Transportation and Storage................................................................................................. 11

Handling and Transportation........................................................................................................ 11

Storage..........................................................................................................................................11

Installation and Setup................................................................................................................ 12

Unpacking and Inspection....................................................................................................................12

Installation...........................................................................................................................................12

Operating Environment........................................................................................................................ 13

Location........................................................................................................................................13

Temperature and Humidity........................................................................................................... 13

Dip Switch Settings..............................................................................................................................13

Operator Interface Dip Switch Settings ............................................................................................... 14

Software............................................................................................................................................... 14

Main program file.........................................................................................................................14

PathMaster®.................................................................................................................................14

Project File ................................................................................................................................... 14

Machine Communications ................................................................................................................... 14

SMEMA ....................................................................................................................................... 14

Operating Safety ........................................................................................................................ 16

Notices and Warnings.......................................................................................................................... 16

Safety Devices and Guarding............................................................................................................... 16

Safety Circuit................................................................................................................................ 16

Lexan Guarding............................................................................................................................ 16

Doors............................................................................................................................................16

Light Curtain.................................................................................................................................17

Exhaust Fan.................................................................................................................... .............. 17

Operation .................................................................................................................................... 18

Startup Procedure.................................................................................................................................18

Operation and Maintenance Manual Rev M(ii) 4/03

- vi -

Light Tower Operation........................................................................................................................ 18

Exhaust Verification............................................................................................................................ 18

Machine Safety Check.........................................................................................................................19

Homing the Axes ................................................................................................................................. 19

Standby Position.................................................................................................................................. 20

Solvent Cups ........................................................................................................................................20

Flow Monitor System...........................................................................................................................20

Priming the Flow Monitor ............................................................................................................ 20

Determining the Correct Material Volume...................................................................................21

Setting the Material Volume Check..............................................................................................21

Auto Cycle Flow Error ................................................................................................................. 21

Flow Monitor Calibration.............................................................................................................22

Flow Control Mode.......................................................................................................................22

Calibration Procedures......................................................................................................................... 23

Standard Needle Calibration......................................................................................................... 23

Operator Defined Needle Calibration...........................................................................................23

Sensor Defined Needle Calibration.............................................................................................. 23

Shutdown Procedure............................................................................................................................23

Cycle Stop............................................................................................................................................ 24

Program Selection................................................................................................................................ 24

Needle Calibration............................................................................................................................... 24

Standard........................................................................................................................................25

Operator Defined.......................................................................................................................... 25

Sensor Defined .............................................................................................................................25

Manual Mode....................................................................................................................................... 26

Valve Selection....................................................................................................................................27

Automatic Mode.................................................................................................................................. 27

Status Mode......................................................................................................................................... 28

Status Sequence................................................................................................................................... 28

Setup Mode.......................................................................................................................................... 29

Conveyor Control................................................................................................................................29

Trackball Control................................................................................................................................. 30

Teach Pendant...................................................................................................................................... 31

OIT Jog Control................................................................................................................ ................... 31

Fault Recovery..................................................................................................................................... 33

Recovering from Emergency Stop and Other Machine Errors......................................................33

Pneumatic Error Recovery Procedure........................................................................................... 34

Run-Time Error Recovery Procedure........................................................................................... 35

Position Error Recovery Procedure.............................................................................................. 35

Limit Error Recovery Procedure................................................................................................... 36

Stop Codes.................................................................................................................................... 36

Startup Errors................................................................................................................................36

Subroutine Error........................................................................................................................... 37

Troubleshooting......................................................................................................................... 38

If Something Goes Wrong . . . .............................................................................................................38

Calling Technical Support............................................................................................................38

Fault Diagnostic...................................................................................................................................38

Closed Loop Servo Systems......................................................................................................... 38

Open Loop Stepper Systems...................................................................................................... ... 41

Controller Master Reset.......................................................................................................................44

Request Controller Version..................................................................................................................44

EEPROM Upgrade Procedure............................................................................................................. 44

Power Check........................................................................................................................................ 45

Operation and Maintenance Manual Rev M(ii) 4/03

- vii -

Door Interlock Check...........................................................................................................................46

Encoder Feedback Test........................................................................................................................ 46

Motor Feedback Test........................................................................................................................... 47

Maintenance ............................................................................................................................... 48

Schedule............................................................................................................................................... 48

Procedures ........................................................................................................................................... 50

Ball Screw Slides.......................................................................................................................... 50

Inspection .....................................................................................................................................50

Conveyor Belt Replacement......................................................................................................... 50

Valves...........................................................................................................................................50

Servicing the Inline Material Filter............................................................................................... 50

Exhaust Fan Setup........................................................................................................................ 51

Pressure Differential Switch Setup ...............................................................................................51

Appendix A – Definitions........................................................................................................... 52

Appendix B – Serial Communication....................................................................................... 54

Serial Communication..........................................................................................................................54

Overview ......................................................................................................................................54

9 Pin Serial Connector..................................................................................................................54

25 Pin Serial Connector................................................................................................................54

Computer 9 Pin to workcell Programming Port............................................................................55

Computer 25 Pin to workcell Programming Port..........................................................................55

Appendix C – Error Codes......................................................................................................... 56

DMC Error Codes................................................................................................................................ 56

Appendix D – Open Loop Velocity Settings............................................................................ 58

Maximum Velocity settings................................................................................................................. 58

Appendix E – Wiring Schematic Legend ................................................................................. 59

Wire Numbering.................................................................................................................................. 59

Wire Color Code.................................................................................................................................. 59

Operation and Maintenance Manual Rev M(ii) 4/03

- viii -

List of Tables

Table 1 – DMC-1500 Dip Switch Settings................................................................................................. 13

Table 2 – DMC-2100 Dip Switch Settings................................................................................................. 13

Table 3 – OIT Jumper Settings................................................................................................................... 14

Table 4 – Light Tower & Buzzer Status..................................................................................................... 18

Table 5 – Stop Code Definitions................................................................................................................. 36

Table 6 – PVA550™, PVA1000™, PVA2000™ and PVA3000™ systems Fault Diagnosis.................... 38

Table 7 – PVA250™, PVA750, and PVA2000C Fault Diagnosis............................................................. 41

Table 8 – Preventive Maintenance Schedule.............................................................................................. 48

Table 9 – DTE 9 Pin Serial Connector .......................................................................................................54

Table 10 – DTE 25 Pin Serial Connector ...................................................................................................54

Table 11 – Cable for Computer DB9 to workcell....................................................................................... 55

Table 12 – Cable for Computer DB25 to workcell..................................................................................... 55

Table 13 – DMC Error Codes..................................................................................................................... 56

Table 14 – PVA250™ Velocity Limits........................................................................................................58

Table 15 – PVA750™, PVA2000C™ Velocity Limits.............................................................................. 58

Table 16 – Wire Numbering....................................................................................................................... 59

Table 17 – Wire Color Code....................................................................................................................... 59

Operation and Maintenance Manual Rev M(ii) 4/03

- ix -

Introduction

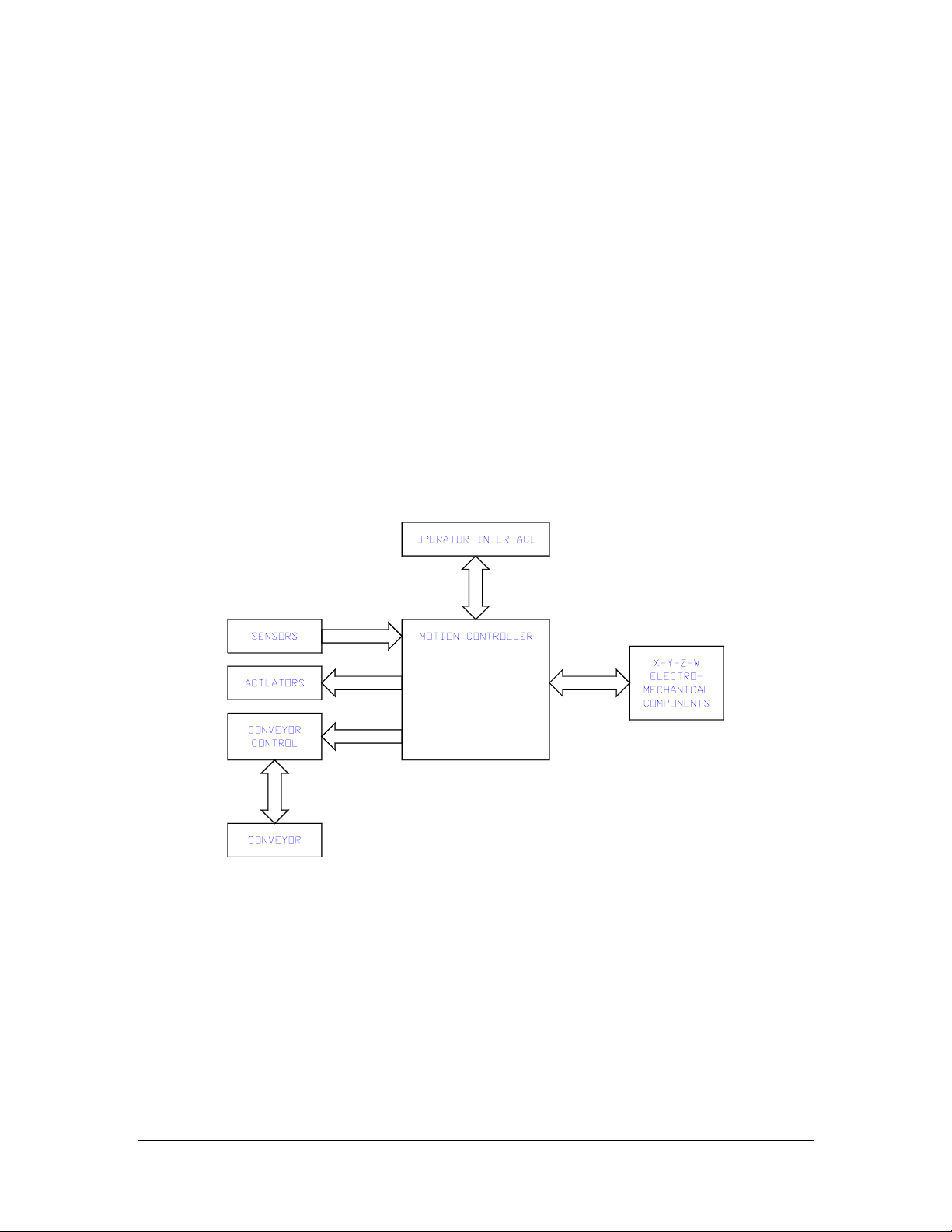

System Description

The workcell has been designed specifically for applications involving industrial dispensing and conformal

coating. The flexibility of the machine allows it to be used effectively for a wide range of applications.

The valves are mounted to the end effector of a two, three or four axis Cartesian robot. All dispensing /

spraying is performed within the lexan enclosed work area. Limits have been imposed on the axes to

prevent damage to the machine. The dispense / spray path and active heads are controlled by a program

stored in the motion controller. The controller can store and retrieve up to 30 programs.

NOTE: Not all models are equipped with lexan guarding.

The operator interface permits the operator complete control of the machine. This includes machine setup,

manual operation, program selection and automatic operation. Machine status and error messages are

displayed on the LCD screen and via the optional light tower. It is necessary that operator(s) have read or

by training understand the operation of this machine.

Any uses other than listed above could result in a dangerous condition and cannot be protected against by

the safety features installed on the system.

Figure 1 – workcell Functional Block Diagram

Year 2000 Compliance

The workcell is compliant with and comprehends the year 2000 century date change. The workcell will not

have any operational impediments, malfunction, cease to perform, generate incorrect or ambiguous data

and/or produce incorrect or ambiguous results with respect to same-century and multi-century formulas,

functions, date values and date-data interfaces.

Operation and Maintenance Manual Rev M(ii) 4/03

- 10 -

Environmental

Noise Levels

The audible noise level of the workcell is below 65 dBA.

Materials/Chemicals

There are no dangerous materials or chemicals used in the operation of the machine except for the required

application material. The application material should include a Material Safety Data Sheet (MSDS) which

specifies known dange rs and toxicity.

Hazards Due to Contact

The workcell is designed in such a way as to minimize injury from contact with any accessible portion of

the machine. However, under certain modes of operation, it is possible to enter the work area while the

motion platform is under power. Only a qualified person should do this. All hot surfaces are indicated with

a warning label.

Handling, Transportation and Storage

Handling and Transportation

Handling and transportation should be done in such a fashion as to minimize the vibration and shock

introduced to the system. An air-ride tr uck is reco mmended for ro adway transpor t. Although the machi ne

is designed and built to perform in an industrial environment, excessive abuse will greatly impact the

performance of the machine.

Storage

Dust and Debris

All enclosures and connector covers should be closed tightly. It is recommended that a cover be place over

the system if dust or other airborne debris is present in the storage area.

Temperature and Humidity

Storage should be done in an area at 40°F - 105°F (4°C – 41°C) and low humidity. Condensation should

not be allowed to collect on the machine.

Dispensing / Spraying Equipment

Whenever the machine is to be stored for extended periods of time, the workcell should be flushed using a

solvent compatible with the application material. This includes the following systems, if applicable:

o Dispensing valves, spray valves and servo valves.

o Material lines and hoses.

o Pressure vessels.

o Pumping systems.

Operation and Maintenance Manual Rev M(ii) 4/03

- 11 -

Installation and Setup

WARNING The following procedures should be performed by qualified persons in

accordance with this manual and applicable safety regulations. A “ qualified person” is defined as “a

person or persons who, by possession of a recognized degree or certificate or professional training, or

who, by extensive knowledge, training, and experience, has successfully demonstrated the ability to

solve problems relating to the subject matter and work.” (ref. ANSI/ASME B30.2-1983.)

Unpacking and Inspection

1) Remove all packing materials and strapping. Thoroughly inspect the exterior of the machine for

damage, loose fasteners, etc. Gently move the X & Y axis slides to the center of the work area.

2) At the rear of the machine, inspect all tubing connections, gauges, and regulators.

3) Open the electrical enclosure and visually inspect connectors and components for vibration during

shipping. Close the door, as the machine should not operate with the doors open (All accept .

4) Reinstall the Light tower.

5) Reinstall flow monitor. The flow monitor is typically mounted on the rear of the workcell.

6) Reinstall the main air regulator assembly.

NOTE: Step 3 does not apply to PVA250™ models.

Installation

1) Plug the machine into an appropriate power source as determined by the Machine Specific Information

section of the Operating Guide or the legend plate on the rear of the machine. The electrical service

should be properly grounded, and the power source “clean”. If there is high power equipment

operating off the same source, a line conditioner may be necessary. Errors in machine operation could

indicate poor quality power.

WARNING Failure to comply with electrical specifications can result in damage to the

machine as well as injury to installa tion personnel. Electrical hookup must be made by a qualified

electrician and must comply with any applicable local standards.

2) A ¼” NPT female fitting is provided at the rear of the machine (PVA250™ models have a ¼” quick

disconnect fitting). Connect to a source of clean, dry air. A hose of ¼” inside diameter is sufficient.

3) Ground any pressure vessel to earth or the machine. NOTE: Precision Valve & Automation

STRONGLY recommends the machine not be powered on or material added to the pressure vessels

until they are properly grounded.

4) Close any access doors and push in the EMERGENCY STOP button. At the rear of the machine, turn

on the red air lockout valve (PVA250™ models are not equipped with an air lockout).

5) T urn on power at the red handled switch on the front or rear of the machine (PVA250™ models have a

black “rocker” switch on the rear next to the power cord).

Operation and Maintenance Manual Rev M(ii) 4/03

- 12 -

Operating Environment

Location

The machine should be installed on a level surface away from standing water, possible overspray and

overhead leaks.

Temperature and Humidity

The machine should be operated in an area at 40°F - 105°F (4°C – 41°C) and low humidity. Condensation

should not be allowed to collect on the machine.

Dip Switch Settings

NOTE: During normal operatio n there is no need to adjust the dip switch setting s. If communicatio ns

between the computer and the controller are not reliable, lower the baud rate on both until

communications are satisfactory.

The main RS-232 port on the motion controller must be configured as follows to communicate with the host

computer:

Table 1 – DMC-1500 Dip Switch Settings

Switch Position Description

MRST OFF Master Reset

1200 OFF Baud rate selection

9600 OFF Baud rate selection

19.2K ON Baud rate selection

HSHK ON Hardware Handshaking

(PVA550™, PVA1000™, PVA2000™, and PVA3000™ models)

Table 2 – DMC-2100 Dip Switch Settings

Switch Position Description

MRST OFF Master Reset

XON OFF Software Handshaking

HSHK ON Hardware Handshaking

9600 OFF Baud rate selection

19.2K ON Baud rate selection

38.4K OFF Baud rate selection

OPT OFF Hardware Option

ENET OFF Use Ethernet port as default for

Unsolicited messages.

(PVA250™, PVA750™, PVA2000C models)

CAUTION If hardware handshaking is enabled, the program uses the message command

and a computer is not attached to the Main RS-232 port, the controller eventually halts.

program included with this machine does not contain any message statements.

The

Operation and Maintenance Manual Rev M(ii) 4/03

- 13 -

Operator Interface Dip Switch Settings

NOTE: During normal operation there is no need to adjust the dip switch settings.

The operator interface must be configured to communicate with the controller. The correct settings are

given in the table below. These setting enables 9600 baud, 7 data bits, 1 stop bit and 1 start bit.

Table 3 – OIT Jumper Settings

Jumper Setting

E1 A

E2 A

E3 B

E4 B

E5 A

E6 B

Software

The complete workcell software package consists of several items. To avoid problems and

miscommunication, it is imperative every operator understand what each piece of software is and its

purpose. For more information about PathMaster® and its features, please consult the separate

PathMaster® Manual in the Operating Guide.

Main program file

A text file containing the code that runs the workcell. Under normal circumstances it is not necessary to

change this file, but if needed it can be opened and edited with any text editor, such as Microsoft® Notepad

or Word. The Main program file is downloaded via a drop-down menu in PathMaster® but it should

NEVER be opened within the PathMaster® software.

PathMaster®

Precision Valve & Automation’s Windows®-based programming software. It is used to create, maintain

and download project files for the workcell. The Operating Guide has a separate section on using

PathMaster® to program the workcell.

Project File

A text file containing the code for one or more programs. In almost all cases this file is created within

PathMaster®. This file is downloaded using PathMaster®.

Machine Communications

For manufacturing lines (multiple machines utilizing conveyor systems) it is necessary for the individual

modules to communicate reliably. Therefore, the SMEMA cables must be connected in the correct manner.

NOTE: On the diagrams the J# refers to the label on the machine, not the label on the cable.

SMEMA

The Surface Mount Equipment Manufacturers Association (SMEMA) Electrical Equipment Interface

Standard is used to insure proper sequencing of boards. If these connections are not in place, boards can

not move from one machine to another.

Operation and Maintenance Manual Rev M(ii) 4/03

- 14 -

SMEMA cables have male 14-pin amp-type CPC connectors. The cables are straight-through, so

orientation does not matter. On each module, the wire to the J1 (Previous) plug must connect to the J2

(Next) plug on the machine upstream. Similarly, the J2 plug on each machine must connect to the J1 plug

on the machine downstream, as shown in the following diagram:

Operation and Maintenance Manual Rev M(ii) 4/03

- 15 -

Operating Safety

Notices and Warnings

o Safety glasses, gloves, and long sleeved clothing are necessary precautions when working with

automated industrial equipment.

o Read and understand all operating manua l s before using this equipment.

o Do not disable the safety features of the machine.

o Lock-out and tag the air and power supplies before servicing or cleaning any part of this equipment.

o Do not remove any hose, either air or fluid, without relieving the pressure.

o Do not replace any hose with a hose of inadequate pressure rating.

o Use only replacement parts recommended or supplied by the manufacturer.

o Always remain clear of all moving parts when the system is in operation.

Safety Devices and Guarding

The workcell has several safety features that protect the operator from hazards during normal operation of

the machine.

NOTE: The safety fe atures should NEVER be byp assed, disable d or tampered with. Precision Valve &

Automation, Inc. is not responsible for any damages incurred, mechanical or human, because of

alteration or destruction of any safety features.

Safety Circuit

The main power to the machine is monitored and controlled by the safety circuit. The safety circuit

contains two relays, under-voltage protection, and one or more safety devices. The relays are wired in a

redundant manner. Redundancy consists of two parallel relay circuits which work together electrically with

the safety devices. The tripping contacts of the relays are connected in series to insure that the safety circuit

will disconnect power even if one of the relays has failed. Self-checking consists of positive guided

contacts which are mechanically forced to operate together. If one of the redundant relays fails, the power

contacts are opened. The safety devices monitor the state of the EMERGENCY STOP push button and other

safety mechanisms. When the safety relay detects that the one or more of the safety devices has opened, the

power to the motors and pneumatics is cut.

Lexan Guarding

The work area is enclosed with Lexan guarding. The front of the machine is either open, to allow for

manual part loading and unloading, or guarded by doors.

Doors

For machines with an automatic load/unload cycle the front of the machine is protected by two doors. Each

door is monitored by a non-defeatable limit switch. When the door is opened power to the motors and

pneumatics is disconnected. The DOOR BYPASS key switch is provided to allow maintenance personnel

access to the work area without disconnecting power. This bypass switch only allows access during Manual

and Calibration modes.

Operation and Maintenance Manual Rev M(ii) 4/03

- 16 -

Light Curtain

Some machines are equipped with an optional light curtain. The light curtain is redundant and self

checking. The control signals from the light curtain are included as safety devices in the safety circuit. On

machine power up, the light curtain must be reset by turning the key switch to ‘Reset’ for at least ½ second.

Exhaust Fan

Some machines are equipped with an exhaust fan. The exhaust fan is provided to exhaust fumes from the

work area. The exhaust flange should be connected to an appropriate ducting system that is capable of

receiving 150 CFM (cubic feet per minute). Insufficient air flow through the exhaust system generates an

error.

NOTE: Installed safety devices vary from model to model.

Operation and Maintenance Manual Rev M(ii) 4/03

- 17 -

Operation

Startup Procedure

1) Check the fluid and air pressures.

2) Close all doors and turn the DOOR BYPASS key switch to the OFF position (If applicable).

3) Engage the EMERGENCY STOP button.

4) Turn on main power using the red rotary switch at the front or rear of the machine (Black “rocker”

switch on PVA250™ models).

Light Tower Operation

Three stacked indicator lights and a buzzer are used to indicate the status of the machine. The lights are

green, amber, and red with green on the bottom, amber in the middle and red on top. The buzzer is located

below the green light. The lights are visible from all sides of the machine. The indicators operate as

follows.

o The green indicator is on when the machine is in cycle and producing parts. It is off at all other times.

o The amber indicator is on when the machine is in Auto Cycle and ready to produce parts, but can not

cycle due to an external material handling problem (no incoming parts or no room to unload parts).

PVA750™ and PVA2000C™ models are equipped with a light tower but not an amber light.

o The red indicator is on stead y when the machine is not in Auto Cycle due to operator intervention. It

will flash when the machine is in cycle, but cycle is halted due to a machine problem. It is off at all

other times.

o The buzzer cycles with the red indicator during machine errors.

Table 4 – Light Tower & Buzzer Status

State Red Amber Green Buzzer

Cycle Stop ON OFF OFF OFF

Auto Cycle OFF ON OFF OFF

In Cycle OFF OFF ON OFF

Machine Error FLASH OFF OFF FLASH

Exhaust Verification

Once the workcell has initialized, most models will perform an exhaust flow verification process. If

initialization fails, consult the section Startup Errors on page 36. During this process, and whenever the

workcell is in operation the exhaust flow rate is monitored via the on board pressure differential switch.

The workcell must exhaust at a rate no less than 150 cubic feet per minute, otherwise a critical fault will

occur shutting the motors down. The verification process will also attempt to evacuate any potential vapors

that may already exist in the work area of the workcell. The time this process takes will vary from model to

model, but the remaining time for the process will be displayed as in the screen below:

Verifying exhaust. Please wait ...

060

F1 F2 F3 F4 F5 F6 F7 F8

Operation and Maintenance Manual Rev M(ii) 4/03

- 18 -

Machine Safety Check

Once initialize and exhaust verification is complete, the operator interface displays the following message:

Machine Safety Check

Press F1 to initiate.

F1 F2 F3 F4 F5 F6 F7 F8

The machine safety check ensures the workcell safety devices (emergency stop, door interlocks, light

curtain, etc.) are operating properly. During startup, the operator must enter the safety check and complete

it successfully. Otherwise, the machine halts all operations. After pressing F1 the operator is prompted by

the operator interface to activate and deactivate the safety devices and the POWER ON button, if present.

Certain events in this procedure are timed and if an action is not performed within a specified time the

machine interprets this as a failure and displays an error screen such as this:

EStop button failed.

Press F1 to repeat test.

F1 F2 F3 F4 F5 F6 F7 F8

By pressing F1 the operator can repeat the test one time. If a second failure occurs, a screen such as this

appears:

EStop button failed.

Repair and restart the machine.

F1 F2 F3 F4 F5 F6 F7 F8

After the second failure the program ceases functioning and the machine must be restarted. The second

failure need not be for the same device. An emergency stop failure followed by a door interlock failure

halts the program.

If the safety check fails, the entire system should be thoroughly examined by qualified maintenance

personnel before the machine is returned to operation.

Homing the Axes

Press F1 to home the system.

F1 F2 F3 F4 F5 F6 F7 F8

After successfully completing the safety check, the operator is shown the above screen. Pressing F1 homes

the system and displays the following screen:

Operation and Maintenance Manual Rev M(ii) 4/03

- 19 -

Homing axes. Please wait...

F1 F2 F3 F4 F5 F6 F7 F8

The axes home in the following order: Z, W, then X & Y simultaneously.

Standby Position

Once the machine has completed the homing sequence or finishes a required calibration procedure (if so

equipped), it moves to the standby position. Standby is a defined location, DISTINCT from the home

position, although in some circ umstances it may be defined as the same position as home. In most cases,

the standby position is placed near the board stop to minimize travel during Auto Cycle. The workcell

always returns to the standby position in Cycle Stop. If the standby position needs to be changed, please

consult the Main Program Modifications section of the PathMaster® Manual.

Solvent Cups

Some workcells have solvent cups installed as an option. The need for solvent cups is dictated by the

process by which the workcell will be used for. When solvent cusp are installed, the Auto Purge feature is

overridden by the solvent cup routines regardless of the Setup mode settings.

The solvent cup location varies from model to model, however, the location will be somewhere in the

workspace of the workcell. Solvent cups are used as a means of maintaining clean dispense / spray heads.

In Cycle Stop the heads are situated in the solvent cups. In Manual mode, the heads are removed from the

cups and remain out until exiting this mode. In Auto Cycle the heads lift and run the auto purge routine.

They return to the solvent cups after a pre-programmed period of inactivity.

To change the time delay before the heads enter the solvent cups in Auto Cycle, change the variable

SLP_TM in the Machine-Specific Information section of the Main program. A value of 1000 equals 1000

milliseconds or 1 second.

Flow Monitor System

Some workcells have a flow monitor installed as an option. The flow monitor on the workcell measures the

amount of material moving thr o ugh the mater ia l sup p ly line before it is split to supply the individual valves.

It is used as a verification of the dispensing process, not a control of that process, and reports excessive

deviations from desired values. Both the desired material volume and allowable deviation are determined

by the operator.

Priming the Flow Monitor

The flow monitor must be primed prior to use to prevent damage to the unit. Priming the flow

monitor minimizes the amount of air that will pass through the unit during initial startup. Follow the

procedure below to prime the flow monitor.

o Fill the pressure vessel with material and seal.

o Set the material pressure regulator to 0 P.S.I.

o Turn the inlet air and outlet material valve to the closed position.

o Disconnect the material line from the inlet port of the flow monitor.

o Turn the air inlet and material outlet valves to the open position.

Operation and Maintenance Manual Rev M(ii) 4/03

- 20 -

o Slowly increase the material pressure regulator until material flows from the disconnected material line.

o Turn the outlet material valve to the closed position.

o Bleed pressure for pressure vessel and adjust the material pressure regulator to 0 P.S.I

o Reconnect the material line to the inlet port of the flow monitor.

o Open the valve (dispense or spray) using the manual purge procedure outlined in the operations and

maintenance manual.

o Turn the material outlet valve to the open position.

o Slowly increase the material pressure to the target operating pressure.

o Continue the manual purge procedure for each valve until the material flows free of air.

Determining the Correct Material Volume

Before attempting to determine the appropriate material volume, the operator should have a completed path

program, since any changes to a program alters the flow data results. With the completed program loaded

into memory, the operator should enter the Manual mode, position the board correctly with respect to the

board stop s and run a singul ar cycle . For more info rmatio n on the Manual mode, p lea se co nsult pa ge 21 of

the Operation and Maintenance Manual.

After the singular cycle finishes, it displays the follo wing scr een:

Flow Data Set Pt.=00.00cc Dv.=00.0%

Mat.=00.00cc. Press F1 to continue.

F1 F2 F3 F4 F5 F6 F7 F8

The ‘Mat’ value is the amount of material dispensed. The operator should go to the Flow Control mode and

change the flow set point to the ‘Mat’ value that appeared on the flow data screen, then return to the

singular cycle op t ion to run more cycles and verify the consistency of the path program.

NOTE: The above screen does not display if the material target level is set to zero in the Flow Control

mode. See the section Flow Control Mode for information on changing the material target level.

Setting the Material Volume Check

There are two methods of setting the material volume check parameters.

1) Go to the Flow Control mode and adjust the material volume and deviation parameters.

2) Program the settings into the path program. Two variables are used: AC_SET and AC_DEV.

AC_SET is the setpoint for the material flow, which can range from 0 to 99. AC_DEV is the percent

deviation allowed, which can be anywhere from 0 to 99. As an example, entering the following line

into a path program: AC_SET=0.500;AC_DEV=5 would put the volume setting at 0.5 cc and the

allowable deviation at 5%.

If the settings are programmed into the path program, they are used instead of the settings from Flow

Control mode. If no settings are programmed in the path, the machine defaults to the Flow Control mode

settings.

Auto Cycle Flow Error

The Auto Cycle checks the material flow after every cycle if the error is turned ON in the Flow Control

mode. If the volume was within parameters, no indication is given to the operator. In cases where the

Operation and Maintenance Manual Rev M(ii) 4/03

- 21 -

volume was outside acceptable parameters, the flow error screen appears. This screen is similar to the flow

data screen shown above. The board should be removed before returning the machine to operation.

NOTE: Any changes made to settings in the material delivery system (material pressure, stroke

adjustment, etc.) may affect the data from the flow monitor. If this happens, the operator may need to

determine the correct material volume again.

Flow Monitor Calibration

Periodically, the flow monitor calibration should be checked. Start by connecting a PC to the Dispensing

System, open a terminal screen and enter DEZ=0. This resets the flow monitor encoder to zero. Then

dispense 10 c ubic centimete rs of material t hrough any valve, b y means of a manual purge. When finished,

enter MG _DEZ on the terminal screen. This returns a value representing the number of encoder counts

read by the flow monitor. Calculate the flow monitor calibration value: (Encoder Counts / 10) = FC_CAL.

Change the value of the FC_CAL variable in the Machine-Specific Information section of the Main

program to the result of the calculation.

NOTE: For a more precise calibration, d etermine volume by weight. The specific g ravity or density of

the material must be known to do this.

Flow Control Mode

Flow control mode is typically accessed through the Cycle Stop menu using the F2 function key. If access

to Flow Control mode i s not achieved through Cycle Sto p, or if more than one flow monitor is installed on

the workcell, documentation in the Optional Equipment section of the Operator’s Guide will provide details

on these options.

Flow 00.00cc DEV=00.0% Error

EXIT UP DOWN UP DOWN *ON OFF

F1 F2 F3 F4 F5 F6 F7 F8

Flow mode allows control over the flow monitor data that is used as a process check only during Auto

Cycle. These settings are used to determine the material volume and whether or not it is excessive unless

superceded by commands in a path program. The error selection turns the process verification check on and

off. The error ON/OFF selection cannot be overridden by commands in a path program.

[F1] EXIT

[F3] cc UP

[F4] cc DOWN

[F5] DEV UP – Increase the allowable deviation. Maximum is 99%.

[F6] DEV DOWN – Decrease the allowable deviation. Minimum is 0%.

[F7] Error ON – Turn the material flow error checking on. (default)

[F8] Error OFF

– Leave Flow mode and return to Cycle Stop.

– Increase the material target level. Maximum is 99 cc.

– Decrease the material target level. Minimum is 0.00 cc.

– Turn the material flow error checking off.

Operation and Maintenance Manual Rev M(ii) 4/03

- 22 -

Calibration Procedures

The workcell has one of three calibration methods: Standard, Operator Defined and Sensor Defined. If a

Sensor Defined or Operator Defined method is installed on the workcell, the machine may or may not

automatically enter its particular calibration mode following the homing sequence depending on the

application the workcell was set up for. See page 24 for particulars on operating the workcell during a

calibration sequence.

Standard Needle Calibration

The simplest calibration procedure requires the operator to visually inspect the position of a needle with

respect to a calibration point (such as cross-hairs). If the needle is not directly above the point, the operator

must physically reposition the needle so it is above the calibration point.

Operator Defined Needle Calibration

This method is dependent upon the operator utilizing the trackball to redefine the coordinate system

according to the positioning of a specific needle or dispense head. This process is optional. If the specific

needle is located in the desired position this process can be skipped.

The calibration routine automatically runs when the machine is powered on or if the controller is reset. The

head moves to a calibration point (specified in the main program). When at the calibration position the

operator has control of the axes. Using the trackball, the position of the needle tip can be redefined in

reference to a calibration poi nt (such as cross-hairs). T his process can also b e run manually through the

CAL function key if a needle needs to be replaced for any reason during operation.

Sensor Defined Needle Calibration

This method focuses around the NCU (Needle Calibration Unit). The calibration sequence redefines the

coordinate system according to the positioning of a specific needle or dispense head. Limitations may arise

with a multiple head workcell utilizing two or more dispense heads in the same path program.

The NCU is referenced from the home position on the gantry. The start positions for each head to enter the

NCU are referenced from the cross-hair mark on the top of the NCU. The coordinates are defined for each

head using reflective sensors in the NCU. Z is always calibrated first in a downward motion into the Z

sensor. The X and Y coordinates are then calibrated from this position in reference to the positioning of the

NCU in the work area. The needle moves into the next sensor (X or Y) finding the first coordinate, then

moves to the opposite side of the sensor and finds a second coordinate. The calibration routine then

calculates the average of the first and second coordinates and redefines the new position accordingly. This

sequence is repeated for the remaining axis.

Shutdown Procedure

If the machine is in cycle, wait for the cycle to finish and then return to the Cycle Stop mode. If the

machine is in any other mode, the operator should return to Cycle Stop.

1) Press the EMERGENCY STOP button.

2) T urn off power to the system. Rotate the main disconnect switch to the “0” position (Rocker switch on

PVA250™ models).

3) Clean any excess material from the tips of the needles.

4) Remove spray cap(s), wipe tip of needle/seat as well, clean cap thoroughly.

5) If the system will be down for an extended period of time, it is recommended to turn off the air to the

machine. The red lockout valve at the rear of the machine can be used for this (not applicable on

PVA250™ model).

Operation and Maintenance Manual Rev M(ii) 4/03

- 23 -

CAUTION If maintenance is to be performed during the shutdown, be sure to lockout and

tag the machine.

Cycle Stop

Cycle Stop

PROG CAL MAN AUTO STAT SETUP

F1 F2 F3 F4 F5 F6 F7 F8

The Cycle Stop state is the default state for the workcell. All other modes and capabilities can be accessed

from this state through the function key buttons listed below.

[F1] PROG

[F3] CAL – Enter Needle Calibration mode (see page 24).

[F4] MAN – Manually operate the machine (see page 26). Also known as Jog or Teach mode.

[F5] AUTO – Run the machine in Auto Cycle (see page 27).

[F6] STAT – Check the status of certain machine items.

[F8] SETUP – View or change the setup functions of the machine (see page 29).

– Change the active program in Program Selection (see page 24).

Program Selection

Select Program: Program 1

EXIT PREV NEXT

F1 F2 F3 F4 F5 F6 F7 F8

The workcell is capable of storing up to 30 different programs. The program selection menu allows the

operator to choose which program is used during the Auto Cycle mode.

[F1] EXIT

[F2] PREV – Decrement to the previous program.

[F3] NEXT – Increment to the next program.

– Leave program selection and return to Cycle Stop.

Needle Calibration

The end effector may contain dispense (as opposed to spray) heads, each of which has a needle. Whenever

a needle is replaced or the machine is started the needles should be calibrated. When the machine enters

this mode it automatically moves to a pre-set calibration point.

Operation and Maintenance Manual Rev M(ii) 4/03

- 24 -

Standard

Calibration

EXIT HOME

F1 F2 F3 F4 F5 F6 F7 F8

Once at the preset point, the operator must physically reposition the dispense needle to ensure proper

calibration.

[F1] EXIT

[F3] HOME – Home the system.

– Leave needle calibration and return to Cycle Stop.

Operator Defined

Calibration AXIS: X&Y

EXIT RECAL HOME X&Y XYZW

F1 F2 F3 F4 F5 F6 F7 F8

The needle(s) must be positioned over a cross-hair. Once the operator is satisfied that the needle is properly

positioned, selecting RECAL calibrates the system. The operator can use the trackball to move the end

effector.

[F1] EXIT

[F2] RECAL – Execute re-calibration.

[F3] HOME – Home the system. The workcell returns to the pre-set point.

– Leave needle calibration and return to Cycle Stop.

[F4] X&Y – Operate the X and Y axes simultaneously.

[F5] X – Operate only the X axis.

[F6] Y – Operate only the Y axis.

– Operate only the Z axis.

[F7] Z

[F8] W – Operate only the W axis.

Sensor Defined

Calibration

EXIT CAL HOME

F1 F2 F3 F4 F5 F6 F7 F8

The sensor defined calibration is entirely machine run. No operator intervention is required to execute the

sequence.

[F1] EXIT – Leave needle calibration and return to Cycle Stop.

[F2] CAL

– Run the calibration routine. This is automatic and no operator intervention is required.

Operation and Maintenance Manual Rev M(ii) 4/03

- 25 -

[F3] HOME – Home the system. This automatically runs the calibration routine afterward.

Manual Mode

PVA550™, PVA1000™, PVA2000™,

PVA3000™ models.

Jog Mode Head: FC100 Axis: X&Y

EXIT TEACH VLV RUN PURG TP CONV AXIS

F1 F2 F3 F4 F5 F6 F7 F8

PVA250™, PVA000C™ models

Manual Mode Head: FC100

EXIT TEACH VLV RUN PURG RP JOG

F1 F2 F3 F4 F5 F6 F7 F8

Manual mode allows manual control of all devices on the workcell. There are sublevels within Manual

mode used to access different workcell functions. The workcell is considered to be in Manual mode even

when in a sublevel of Manual mode. Manual mode also serves as the Teach mode for all workcell models.

Models equipped with a trackball can jog the gantry via the trackball from Manual mode. An axis

combination can be selected from the trackball as well as the Axis sublevel. Models that are not equipped

with a trackball (PVA250™, PVA750™, PVA2000C™) can jog the gantry using the function keys from

the Jog sublevel menu.

Programming the workcell is accomplished in concert with a PC-compatible computer by using Precision

Valve & Automation’s PathMaster® software. The operator must be in Manual mode, or a sub level of

Manual mode, for PathMaster® to function properly. For more information on programming, please

consult the separate PathMaster® Manual in the Operating Guide.

[F1] EXIT

– Leave Manual mode and return to Cycle Stop.

[F2] TEACH – Program the current point.

[F3] VLV – Switch to Valve Selection (see page 27).

[F4] RUN – Run singular cycles of the current program. Pressing F1 exits the mode and returns the

operator to Manual mode. In this mode the following screen appears, allowing the operator to run 1 cycle

either wet or dry:

Press F2 or F3 to run 1 cycle.

Exit WET DRY

[F5] PURG

F1 F2 F3 F4 F5 F6 F7 F8

– Actuate the current valve.

[F6] TP – Momentary switch that displays the current position of the head in the following manner:

RP – (PVA250™, PVA200C™ models only) Momentary switch that displays the current reference

position of the head in the following manner:

Current Position:

X 000000, Y 000000, Z 000000, W 000000

[F7] CONV

[F8] AXIS

JOG

– (PVA250™, PVA750™, PVA2000C™ models only) Switch to Jog Mode (see page 31).

F1 F2 F3 F4 F5 F6 F7 F8

– Switch to Conveyor Control (see page 29).

– Switch to Trackball Control (see page 30).

Operation and Maintenance Manual Rev M(ii) 4/03

- 26 -

Valve Selection

Valve Functions Head: FC100

EXIT PURG SEL UP DOWN ROTA ROTB

F1 F2 F3 F4 F5 F6 F7 F8

Units equipped with multiple valves have this mode. The active head or valve can be selected from the

Valve sublevel menu. The pneumatics Z-slide(s) and rotary(s) (if equipped) can be actuated from the Valve

submenu.

NOTE: When program ming or operating the workc ell, the valves should NEVER be used for moving

components or boards. Precision Valve & Automation is not responsible for damages incurred from

using the valves in an inappropriate manner.

[F1] EXIT

[F2] PURG – Actuate the current valve.

[F3] SEL – Change the active head.

[F4] UP – Raise the active head’s Z-slide.

[F5] DOWN – Lower the active head’s Z-slide.

[F6] ROTA – Put the rotary in the home position. (default)

[F7] ROTB – Put the rotary in the auxiliary position.

– Leave Valve submenu and return to the previous menu.

Automatic Mode

Auto Cycle WET Count:000000

STOP PROGRAM 1

F1 F2 F3 F4 F5 F6 F7 F8

This mode handles the automatic cycling of the machine. There are three machine setups that may be

encountered:

o Conveyor equipped.

o Stand-alone without a light curtain.

o Stand-alone with a light curtain.

For a workcell with a conveyor, the part is placed for process on the conveyor either by an operator or

mechanically via an upstream process. SMEMA signals are provided with the machine to be used in

conjunction with an upstream process. The part is recognized at the entrance to the machine and is shuttled

to the stop for cycling. Once against the stop the part is registered and dispensed / sprayed on. Once the

program finishes, the board is released and shuttled to the downstream end of the conveyor to await any

process that may follow. Once released or removed, the process is set to repeat itself.

For machines without a conveyor, all parts must be placed in the workcell manually. Part-in-place sensors

detect if a board is present or not. If a board is misplaced in the cell, the operator is alerted of the fact.

Once a machine is ready for cycling, the operator must activate the hand switches to process parts. All parts

must be removed after cycling before a new cycle may begin.

Operation and Maintenance Manual Rev M(ii) 4/03

- 27 -

If the workcell possesses a light curtain, it operates in a similar manner as a stand-alone model without a

light curtain. However, the light curtain may be used to initiate cycles (bypassing the hand switches).

Screen during cycle. Screen with valves deactivated.

In Cycle... Count:000000

STOP PROGRAM 1

F1 F2 F3 F4 F5 F6 F7 F8

Auto Cycle DRY Count:000000

STOP PROGRAM 1

F1 F2 F3 F4 F5 F6 F7 F8

Status Mode

Status SMEMA Up Ready DN BA

EXIT STAT INP ON *OFF ON *OFF

F1 F2 F3 F4 F5 F6 F7 F8

The status mode a llows the oper ator to check a number o f machine paramete rs, running an entire seque nce

when STAT is selected from within this mode. When the workcell is placed in-line, SMEMA signals

ensure communication with the upstream and downstream machines. The operator can check the inputs to

the workcell and change the Up Ready and Down Board Available output signals.

[F1] EXIT

[F3] STAT – Switch to the Status Sequence (see page 28).

[F4] SMEMA INP – Check the status of the SMEMA inputs (momentary). Displays the following screen:

– Leave Status mode and return to Cycle Stop.

Up Board Available: OFF

Down Ready: OFF

[F5] Up Ready ON

F1 F2 F3 F4 F5 F6 F7 F8

– Turn the Up Ready signal on.

[F6] Up Ready OFF – Turn the Up Ready signal off. (default)

[F7] DN BA ON – Turn the Down Board Available signal on.

[F8] DN BA OFF

– Turn the Down Board Available signal off. (default)

Status Sequence

The status features are available via the setup mode and whenever the machine encounters a position error,

limit error or command error. It gives information on the status of the axes that may be helpful in

debugging a proble m. Once the operato r enters the status mode, exiting is allowed at any time by pressing

F8, while pressing F1 scrolls the operator through the screens.

Machine Status Report. Press F1 to

scroll through screens, F8 to quit.

F1 F2 F3 F4 F5 F6 F7 F8

Operation and Maintenance Manual Rev M(ii) 4/03

- 28 -

Encoder Status (all except PVA250™) Motor Status

X-axis Enc.Pos. Com.Pos. Pos.Err.

F1 F2 F3 F4 F5 F6 F7 F8

000000 000000 000000

X-axis Motors On/Off Torque Tor.Lim.

F1 F2 F3 F4 F5 F6 F7 F8

ON 0.0000 0.0000

Sensor Status Tuning Status

X-axis Sensors Home For.Lim. Rev.Lim.

F1 F2 F3 F4 F5 F6 F7 F8

OFF OFF OFF

X-axis Tuning KD KP KI

F1 F2 F3 F4 F5 F6 F7 F8

000.00 000.00 000.00

Setup Mode

Setup Counter Auto Purge Run Mode

EXIT CNT RES ON *OFF WET *DRY

F1 F2 F3 F4 F5 F6 F7 F8

Setup mode allows the operator to control basic functions of the machine. The valves can be turned off

during Auto Cycle by setting the run mode to dry. This option does NOT affect the run option in the

Manual mode, which is user selected as a wet or dry run.

The auto purge feature dispenses / sprays material from all valves at specific intervals to prevent valves

from clogging. The auto purge default setting is dependent upon the type of material used in the workcell.

The workcell only auto purges when in Auto Cycle or Cycle Stop. If the workcell is in any other state, it

does not auto purge. However, it immediately auto purges, if necessary, once returning to Cycle Stop or

Auto Cycle.