AFD310

PUSHCORP, INC.

Adjustable Force

Device

Manual

January, 2018 U.S. Patent No. 5,448,146PAR04493-1

Dallas, Texas

CAUTION

Active Force Devices contain

calibrated electronics.

HANDLE WITH CARE DO NOT DROP

DO NOT USE LUBRICATED AIR.

This device requires a dry, non-

lubricated 80 to 90 psi (5.5 – 6.2 bar)

air supply filtered to 5 µm and a 0.3

micron oil mist separator.

Non-compliance with these

requirements will void the

manufacturer’s warranty.

(See Section 4.3)

All fasteners, mounting holes and

pipe threads on this tool are

METRIC.

All PushCorp, Inc. electrical cables are rated for

high twist and flex robotic applications with a

minimum cable bending radius specification of

125mm (5 in). Cable damage resulting from

failure to abide by this specification will not be

covered under warranty.

PUSHCORP, INC.

AFD310 Manual

Table of Contents

1.0 LIMITED WARRANTY...........................................................................................2

2.0 GENERAL OVERVIEW.........................................................................................4

3.0 QUICK START.......................................................................................................5

4.0 INSTALLATION.....................................................................................................6

4.1 Mounting Process Equipment.......................................................................................................... 6

4.2 Mounting the 310 Series.................................................................................................................. 7

4.2.1 Mounting the AFD310-1 Vertical and AFD310-2 Horizontal.........................................................7

4.2.2 Mounting the AFD310-3 Table Top.............................................................................................. 8

4.3 Maximum Carriage Load Calculations............................................................................................. 9

4.4 Pneumatic Connection.................................................................................................................. 11

4.5 Internal Air Cartridge Filter............................................................................................................ 13

5.0 ADJUSTING CARRIAGE PRELOAD..................................................................13

6.0 TECHNICAL SPECIFICATIONS.........................................................................16

7.0 PREVENTATIVE MAINTENANCE SCHEDULE.................................................17

PUSHCORP, INC.

AFD310 Manual

1.0 Limited Warranty

Duration:

One year from date of delivery to the original purchaser.

Who gives this warranty (warrantor):

PushCorp, Inc.

Telephone: (972) 840-0208

Corporate Address:

P. O. Box 181915

Dallas, Texas 75218

Shipping Address:

3001 W. Kingsley Rd.

Garland, Texas 75041

Who receives this warranty (purchaser):

The original purchaser (other than for purposes of resale) of the PushCorp,

Inc. product

What products are covered by this warranty:

Any PushCorp, Inc. Adjustable Force Device or Adjustable Force Device

accessory supplied or manufactured by the Warrantor.

What is covered under this warranty:

Defects in material and/or workmanship which occur within the duration of the

warranty period.

What is NOT covered in this warranty:

A. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANT-ABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ARE LIMITED TO ONE

YEAR FROM THE DATE OF ORIGINAL PURCHASE. Some states do

not allow limitations on how long an implied warranty lasts, so the above

limitations may not apply to you.

B. ANY INCIDENTAL, INDIRECT, OR CONSEQUENTIAL LOSS, DAMAGE

or EXPENSE THAT MAY RESULT FROM ANY DEFECT, FAILURE,

MALFUNCTION OF THE PUSHCORP, INC. PRODUCT. Some states

do not allow the exclusion or limitation of incidental or consequential

damages so the above limitation or exclusion may not apply to you.

C. Any failure that results from an accident, purchaser's abuse, neglect,

unauthorized repair or failure to operate the products in accordance with

the instructions provided in the owner's manual(s) supplied with the

product.

Responsibilities of the Warrantor under this warranty:

Repair or replace, at Warrantor's option, products or components which have

failed within the duration of the warranty period.

PUSHCORP, INC.

Responsibilities of the purchaser under this warranty:

A. Deliver or ship the PushCorp, Inc. product or component to PushCorp,

Inc. Service Center, Dallas, TX. Freight and insurance costs, if any, must

be borne by the purchaser.

B. Use reasonable care in the operation and maintenance of the product as

described in the owner's manual(s).

When warrantor will perform repair or replacement under this warranty:

Repair or replacement will be scheduled and serviced according to the

normal work flow at the service center, and depending on the availability of

replacement parts. Purchasers requiring quicker repair may receive such

with payment of a PushCorp, Inc. predetermined expediting fee.

This Limited Warranty gives you specific legal rights and you may also have other

rights which vary from state to state.

AFD310 Manual

PUSHCORP, INC.

AFD310 Manual

2.0 General Overview

The PushCorp, Inc. 310 Series Adjustable Force Device (US Patent No. 5,448,146)

provides a superior force application system for robots and other automated

equipment. The device can be placed in any position to enable a variety of

manufacturing operations requiring a consistent applied force with 0.8 in. (20 mm) of

compliant stroke. The AFD is designed to withstand continuous use in harsh

industrial grinding, polishing, and drilling operations.

The 310 Series compliant tools utilize a pneumatic actuator to provide the force and

provide closed-loop feedback. The 310 Series can apply up to a maximum 70 lbs.

(310 N) of force. The AFD contains an accelerometer that monitors orientation and

allows the unit to automatically compensate for gravitational and inertial effects. A

linear potentiometer is also present within the AFD to sense the position of the

Carriage.

The only external connection that is required to operate the 310 Series is filtered,

non-lubricated, 80 - 90 psi (5.5 – 6.2 bar) supply air provided through flexible tubing.

An optional Purge Port is also provided for applications where great amounts of fine

dust particles are created. The Purge Port connection provides additional airflow

and internal positive pressure to help minimize the amount of contamination

infiltrating the interior of the AFD. The AFD’s sliding Carriage has threaded

mounting holes to provide easy process equipment attachment.

All these features combine to make the PushCorp 310 Series Adjustable Force

Device a rugged, state-of-the-art technology capable of providing reliable, precise,

and consistent results in a variety of industrial applications.

PUSHCORP, INC.

AFD310 Manual

3.0 Quick Start

This section contains step-by-step instructions on how to quickly get the 310 Series

Adjustable Force Device up and running for a quick test of its capabilities. Complete

details on all the features are described in the sections that follow. It is

recommended that the user read the entire manual before beginning any operations

to fully understand all the aspects and features of the 310 Series.

Step 1: Carefully unpack the 310 Series Force Device and verify that all parts

indicated on the packing list are present and in good condition. If

there is a problem, please notify the factory immediately so that

corrective action may be promptly initiated.

Step 2: Securely attach the 310 Series Mounting Bracket to the manipulator

mounting flange or support table per Section 4.2.

Step 3: Connect a dry, non-lubricated, 5 m filtered 80 to 90 psi (5.5 to 6.9

bar) air supply to the 310 Series per Section 4.3.

Step 4: Consult the FCU-FLEX Manual for electrical connections and software

setup information.

Please read the following sections to learn the full potential and features of the

PushCorp 310 Series Adjustable Force Device.

PUSHCORP, INC.

AFD310 Manual

4.0 Installation

4.1 Mounting Process Equipment

The 310 Series Adjustable Force Device can accommodate many different types of

process equipment. PushCorp provides a variety of standard process equipment

such as weld shavers, high speed motors, plus other specialized tooling. Many end

users also develop process equipment for their own applications. The AFD can be

oriented parallel or perpendicular to the robotic manipulator mounting flange,

although it is important to note that the AFD can apply force only in the direction of

Carriage translation.

When mounting process equipment to the Carriage extreme care should be taken

while designing and installing the brackets. Correctly designed brackets will

increase the stiffness of the Carriage by becoming an external superstructure for the

Carriage. The Carriage can gain a tremendous amount of rigidity if this approach is

executed correctly. Incorrectly designed brackets will deform the Carriage surface

causing internal Linear Rail misalignment. A symptom of Carriage deformation is

“slop” or “binding” of the Carriage. A deformed or loose Carriage will damage the

Linear Rails and effect the consistency of your process. The Carriage preload is

correctly set at the factory and should not require adjustment. If the Carriage

becomes loose or binds after installing the process equipment, then the brackets

must be removed and the problem corrected. PushCorp, Inc. can design and

fabricate brackets to user supplied specifications as an option.

Figure 1. Carriage bolt hole pattern

PUSHCORP, INC.

The bolt pattern on the Carriage has been designed to facilitate process equipment

installation. The Carriage has (16) sixteen M6x1 mounting holes with a depth of

0.40 inch (10 mm) to provide secure attachment points. The mounting holes are

spaced 5 inches (127 mm) across and on 1 inch (25.4 mm) centers along the length

of the Carriage. (See Figure 1) The Carriage also has (4) four 5mm dowel pin holes

to facilitate alignment. (See Figure 1 for location) These dowel pin holes are

oversized to allow the pins to be glued into place using Loctite 609, or equivalent.

WARNING: DO NOT press pins into the AFD Carriage as this will likely

damage the bearing Linear Rails.

CAUTION: The Fastener Tightening Torque Specs chart in Section 6.0 should

be used to determine proper fastener length and torque for fasteners into the

Carriage. This is to prevent pull-out of the Carriage helicoil inserts.

Fasteners must not exceed a depth of 0.40 inches (10 mm) into the Carriage

as this could damage the Linear Rails.

4.2 Mounting the 310 Series

The basic configuration of the 310 Series force device allows attachment to a

stationary fixture or a robotic manipulator mounting flange. Specifying an AFD310 1, -2, or -3 determines which Mounting Bracket is supplied. Adapter plates or

"quick-change" attachments can be used as well for mounting. The 310 Series has

(2) two 4mm dowel pins pressed into the base for location and alignment of the

cover and Mounting Brackets.

AFD310 Manual

4.2.1 Mounting the AFD310-1 Vertical and AFD310-2 Horizontal

The AFD310-1 and AFD310-2 are supplied with a standard Mounting Bracket with a

90 mm three hole mounting pattern, See Figure 2. All three holes should be utilized

to secure the Mounting Bracket to the robot mounting flange. If the Mounting

Bracket is supplied blank or additional holes are required, it must first be removed

from the device before drilling. Four cap screws are used to attach the Mounting

Bracket to the 310 Series. Once the Mounting Bracket is removed, mounting holes

may be placed anywhere within the crosshatched area shown in Figure 2.

PushCorp, Inc. will supply engineering support to determine the mounting hole

locations at no cost.

After drilling the required hole pattern, remove any burrs and clean any machining

residue from the Mounting Bracket. The Mounting Bracket can then be reattached.

PUSHCORP, INC.

AFD310 Manual

Figure 2. AFD310-1 and AFD310-2 Mounting Brackets

4.2.2 Mounting the AFD310-3 Table Top

The AFD310-3 is designed for mounting on a stationary fixture. It has (3) three

Ø0.28” (Ø7.0 mm) mounting holes spaced as shown in Figure 3. The AFD310-3

Table Top Mounting Bracket should not be modified without first consulting

PushCorp, Inc.

PUSHCORP, INC.

4.3 Maximum Carriage Load Calculations

AFD310 Manual

Figure 3. AFD310-3 Table Top Mounting Plate

The Linear Rail bearings that support the 310 Series sliding Carriage have been

selected to provide optimal performance with respect to capacity, size, and low

friction. To ensure continued optimal performance it is very important not to

overload these bearings. The following diagrams and associated equations are

provided to check your application for excessive loading.

It is important to note that these equations require the use of Metric units. The

necessary conversions are provided for your convenience. Insert your maximum

applied force and process equipment weight (W) and overhang distances (D) to

calculate an actual bearing load (L) that must be less than the maximum bearing

load shown on the right side of the equation. The life of the bearings is 100,000

meters of linear motion, at the maximum allowable bearing load value. Exceeding

this value (L) will reduce the life and operating at less than this value (L) will

increase the life. It is common to have combined weight and force loads on the

Carriage. These situations may require adding two or more of the scenarios shown

below. If your tooling is not similar to any of the designs listed here, or if the

information is not clear, please contact PushCorp Technical Support for assistance.

Ball-bearing equations apply to the standard 310 Series. Roller-bearing equations

apply to 310 Series ordered with the –HD, Heavy-Duty option.

PUSHCORP, INC.

AFD310 Manual

PUSHCORP, INC.

4.4 Pneumatic Connection

The 310 Series Adjustable Force Devices require a dry, non-lubricated, 5 µm

filtered, 80 to 90 psi (5.5 – 6.2 bar) air supply. Failure to provide supply air to these

specifications can degrade performance and will void any warranty repairs

concerning pneumatic components. Filtered air is required since the high speed

servo spool valve used in the AFD cannot tolerate ANY foreign material in the

supply air. Additionally, a minimum 80 psi (5.5 bar) air pressure must be maintained

at the supply air port for the device to operate within published specifications.

Operating at lower air pressure can cause inferior force control performance and

possibly instability. Operating the AFD at pressures over 90 psi (6.2 bar) will

activate a pressure relief valve inside the tool. This valve prevents damage to the

internal load cell due to operating the tool with excessive pressure. This relief valve

is strictly a protective mechanism and should not be used as a pressure regulator

device.

The pneumatic supply system should be configured as shown in the Figure 4.

AFD310 Manual

Figure 4. Pneumatic configuration

If water condensation is a problem in your air supply system, an air dryer device is

highly recommended. The ideal solution is an industrial chiller dryer capable of

reducing the dew point to less than 32 F (0C). Moisture inside the force device will

cause premature failure that will not be covered under warranty.

Under most circumstances the standard internal purge will provide sufficient air to

keep the 310 Series free of contaminates. In applications where the environment

contains very small suspended particulate matter, additional purge air flow must be

used to ensure that the AFD remains clear of foreign matter. An auxiliary Purge

Port on the 310 Series (See Figure 5.) provides a pneumatic connection to supply

this additional air flow. The port accepts a metric R 1/8 tapered pneumatic fitting.

PushCorp can provide fittings for english or metric tubing. The input pressure to the

purge port can range from 10 PSI to 60 PSI (0.7 – 4.1 bar) with a flow rate of 0.5 to

2.0 SCFM (14 – 56 l/min) depending on the application. The purge air must be dry

and non-lubricated, however it need only be filtered to 20 microns.

PUSHCORP, INC.

AFD310 Manual

Figure 5. 310 Series air connections

The Supply Line and Purge Line to the device should be 1/4 inch or 6mm diameter

flexible polyurethane tubing. The tubing should be routed to the AFD such that there

are no kinks and that there is plenty of slack to allow for manipulator motion. Before

inserting the Supply Line into the force device air fitting, open the Shut-Off valve to

blow out any contaminates which may be in the line. The tubing can now be pushed

into the self-locking fitting located on the side of the AFD. Charge the Supply Line

with compressed air and verify that there are no air leaks and that there is a

minimum of 80 PSI (5.5 bar) at the AFD. If a minimum air pressure cannot be

achieved, then an auxiliary air compressor or booster pump with at least 2 SCFM

(56 l/min) must be installed.

NOTE: PushCorp highly recommends the use of flexible polyurethane tubing

as opposed to nylon tubing. This is because nylon tubing tends to crimp

shut when it is bent. This severely limits air flow to the AFD and causes

instability.

To remove the Supply Line, first discharge all air pressure in the system, then while

pushing inward on the fitting's plastic ring, simultaneously pull the tubing out. Cover

or plug the self-locking fitting any time the Supply Line is not connected. This will

keep any contaminants from entering the AFD.

PUSHCORP, INC.

4.5 Internal Air Cartridge Filter

The 310 Series contains a Cartridge Filter in the base housing. The Cartridge Filter

is designed to be the last line of defense to protect the AFD from contamination.

The Cartridge Filter is not designed to be the sole means of AFD supply air filtration.

The pneumatic supply system must be configured as described in Section 4.4. If

the filter becomes clogged the 310 Series will not function properly. Replacement

Cartridge Filters may be purchased from PushCorp (Part No. PAR01943-1), or from

the manufacturer directly (Parker, Part No. 050-05-DQ). To remove the Cartridge

Filter loosen the Cartridge Filter Holder located on the side of the AFD base

housing, See Figure 5. Remove the Cartridge Filter and perform a visual

inspection. The condition of the Cartridge Filter will give an indication of the quality

of your supply air system. Place a new Cartridge Filter on the Cartridge Filter

Holder and insert them into the AFD base housing. Tighten the Cartridge Filter

Holder to a torque of 11.6 lb-ft. (15.8 N-m).

AFD310 Manual

5.0 Adjusting Carriage Preload

The required preload on the 310 Series Linear Rails has been set at the factory for

optimal performance and, in general, should not require field adjustment. However,

there are situations that could arise that cause the Linear Rails to need adjustment.

Often a loose, or tight, Carriage on a new AFD is indicative of an improperly

designed process equipment bracket. If the problem disappears when the brackets

are removed then this is the case. Normally the Carriage will only require

adjustment after removal for field service.

To check for a loose Carriage, attempt to move the Carriage in a lateral direction as

shown in Figure 6. If the Carriage moves or seems to exhibit any "slop", then the

Linear Rail preload must be readjusted. A dial indicator is helpful, but not necessary

to diagnose and correct a loose Carriage.

A Carriage that is too tight will require additional force to move. This is often

detected during the weighting of the process equipment mounted on the Carriage.

The weight will be inconsistent, varying higher or lower each time the process

equipment is weighed.

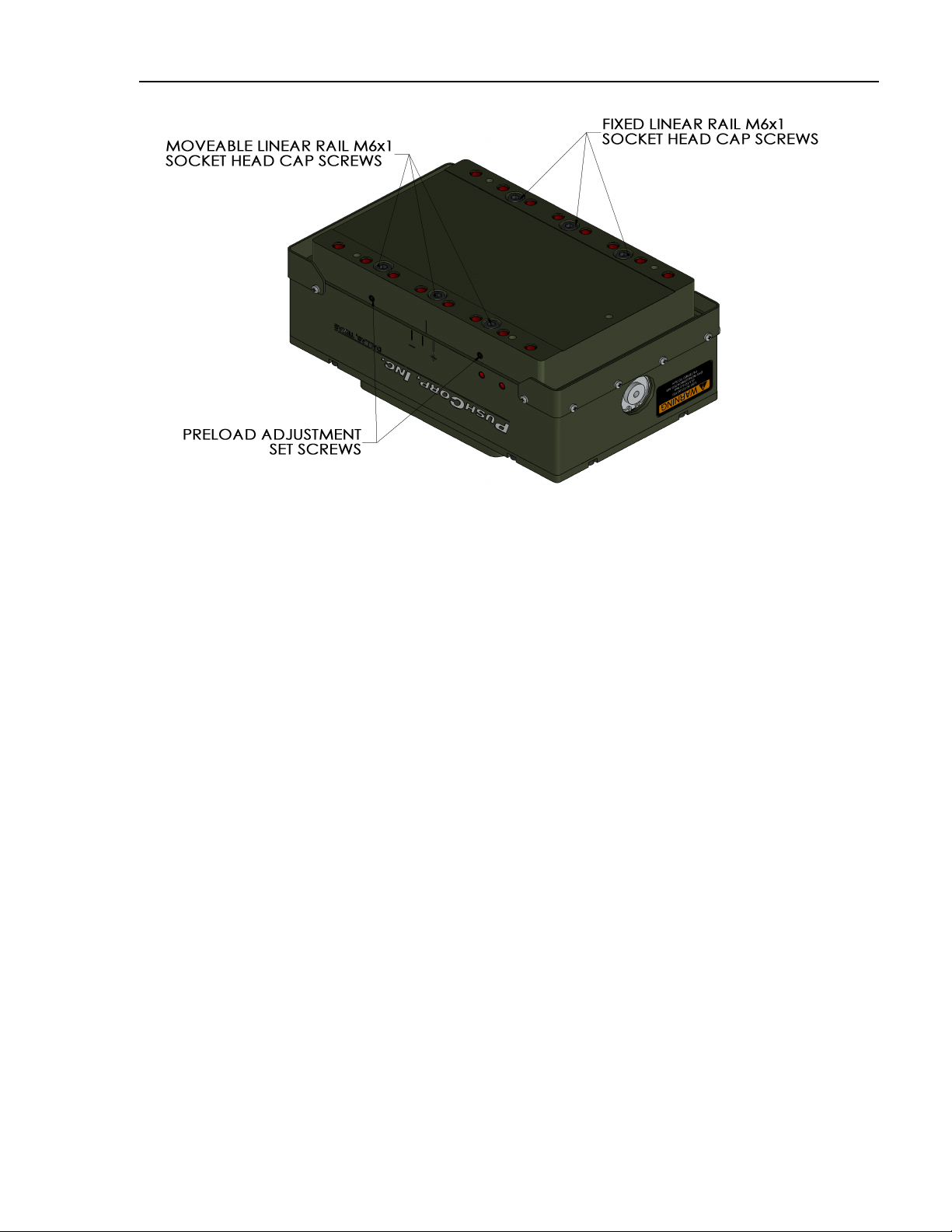

The Linear Rails are attached to the underside of the Carriage with (6) six metric

M6x1 Socket Head Cap Screws. Located on the side of the Carriage are the two

Preload Adjustment Set Screws used to translate the Movable Linear Rail. Moving

the Linear Rail associated with the Preload Adjustment Set Screws is all that is

necessary to adjust the Carriage preload.

PUSHCORP, INC.

AFD310 Manual

Figure 6. Carriage preload adjustment

To perform the preload adjustment, follow the procedure below:

1. Check the tightness of the (3) three Fixed Linear Rail M6x1 Socket Head

Cap Screws holding the Fixed Linear Rail opposite the Movable Linear

Rail. If these fasteners are loose then the Fixed Linear Rail must be

seated against the positioning flange inside the Carriage. To do this,

loosen all (6) six fasteners located on the face of the Carriage just enough

to allow the Linear Rails to move. Next tighten the Preload Adjustment

Set Screws to force the Fixed Linear Rail to seat against the positioning

flange. Tighten the (3) three Fixed Linear Rail M6x1 Socket Head Cap

Screws, which hold the Fixed Linear Rail, to the torque specified in

Section 6.0. The Fixed Linear Rail is now correctly seated and the

Preload Adjustment Set Screws can be loosened. You are now ready to

continue on to preload the Carriage Linear Rails.

2. To preload the Carriage Linear Rails, loosen the Movable Linear Rail M6x1

Socket Head Cap Screws holding the Movable Linear Rail only enough to

allow the rail to move relative to the inside Carriage surface. The Carriage

has slotted holes on the Movable Linear Rail side which allow the rail to

move in the same direction as the Preload Adjustment Set Screws. Make

sure that the Movable Linear Rail M6x1 Socket Head Cap Screws are

loose before attempting to set the preload.

3. If a dial indicator is available, place it against the Carriage surface that

contains the Preload Adjustment Set Screws. Attempt to move the

Carriage laterally while monitoring the dial indicator. If the reading on the

dial indicator varies, then gradually tighten each of the Preload Adjustment

Set Screws. Note that one of the Preload Adjustment Set Screws could

require more adjustment than the other. When the dial indicator ceases to

PUSHCORP, INC.

vary, the preload is set correctly. Do not continue to tighten the Preload

Adjustment Set Screws. Too much preload on the linear rails will cause

excessive friction resulting in force errors.

4. If a dial indicator is not available, the preload can be adjusted by feel.

Attempt to move the Carriage laterally and feel for movement. If the

Carriage moves rotate each of the Preload Adjustment Set Screws no

more than 5 degrees. As soon as no lateral movement can be felt, stop

rotating the Preload Adjustment Set Screws. Note that one of the Preload

Adjustment Set Screws could require more adjustment than the other. Do

not over tighten the Preload Adjustment Set Screws. Over tightening the

Preload Adjustment Set Screws will result in excessive friction and

possible deformation of the Carriage. (If the adjustment cannot be

performed, contact the factory service center.)

The Carriage preload should now be correct.

5. After verifying that the Carriage no longer moves laterally, tighten the (3)

three Movable Linear Rail M6x1 Socket Head Cap Screws on the Movable

Rail side to the torque specified in Section 6.0.

AFD310 Manual

PUSHCORP, INC.

AFD310 Manual

6.0 Technical Specifications

Maximum Applied Force: 70 lbs. (310N)

Maximum Payload: 70 lbs. (31 kg)

Weight: AFD310-1: 17 lbs. (7.7 kg)

AFD310-2: 12 lbs. (5.4 kg)

AFD310-3: 12 lbs. (5.4 kg)

Compliant Stroke: 0.8 in. (20 mm)

Force Accuracy: +/-0.2 lb (+/-1.0 N)

Response Time: 300ms

Temperature: 0 to 122 F (10 to 50 C)

Humidity: 5% to 95%, Non-Condensing

Supply air: Non-lubricated, Dry, 5µm Filtered, 80-90 psi (5.5-6.2 bar)

2 SCFM (56 l/min)

Specifications subject to change without notice. These values are based on measurements taken in a

laboratory environment. Real-world results may be degraded due to external factors beyond

PushCorp’s control.

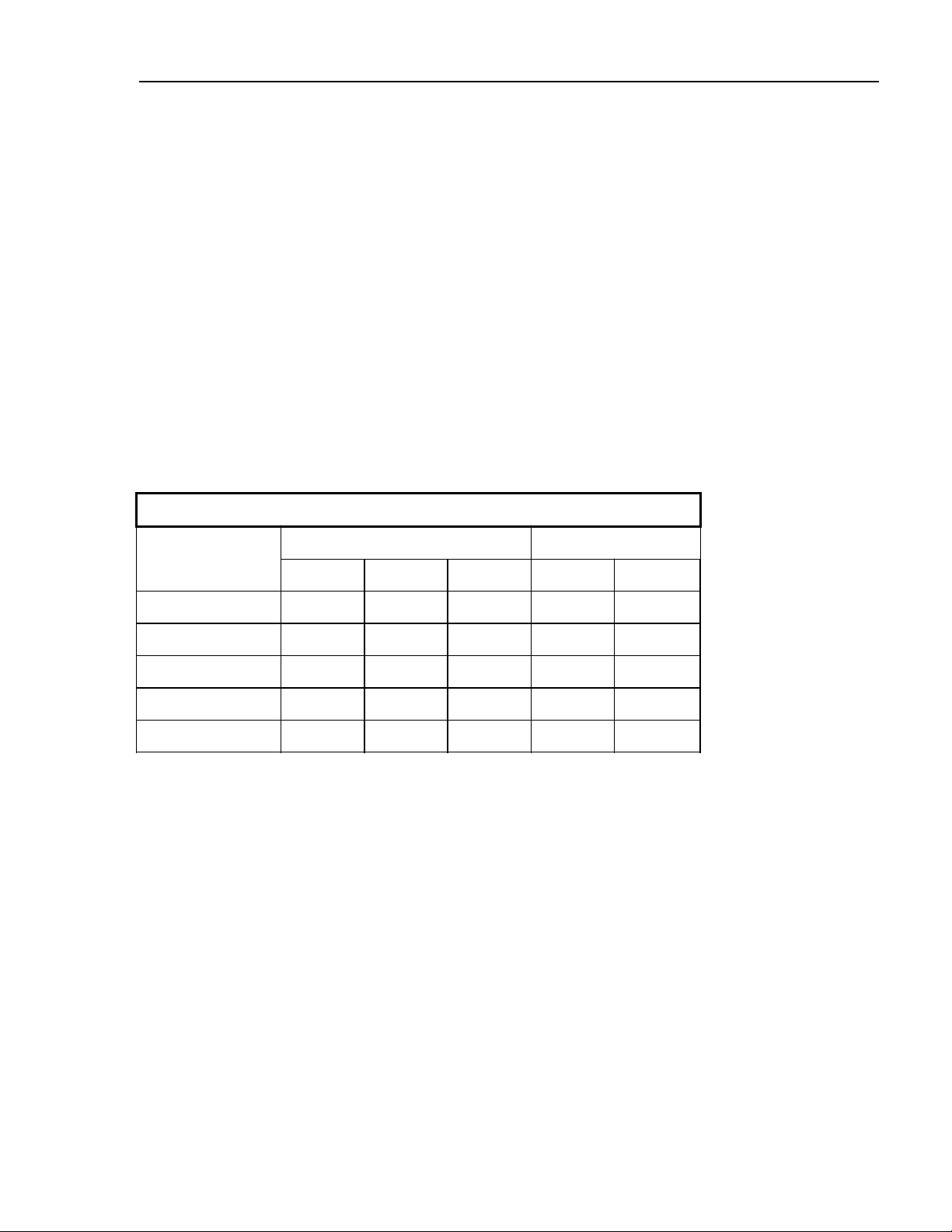

Fastener Tightening Torque Specs

Torque Minimum Depth

Fastener Size in.-lbs. ft.-lbs. N·m in. mm

M4 x .7 50 4.2 5.6 0.17 4.3

M5 x .8 85 7.1 9.6 0.21 5.3

M6 x 1 140 11.7 15.8 0.25 6.3

M8 x 1.25 348 29.0 39.3 0.33 8.4

M10 x 1.5 600 50.0 67.8 0.41 10.5

PUSHCORP, INC.

AFD310 Manual

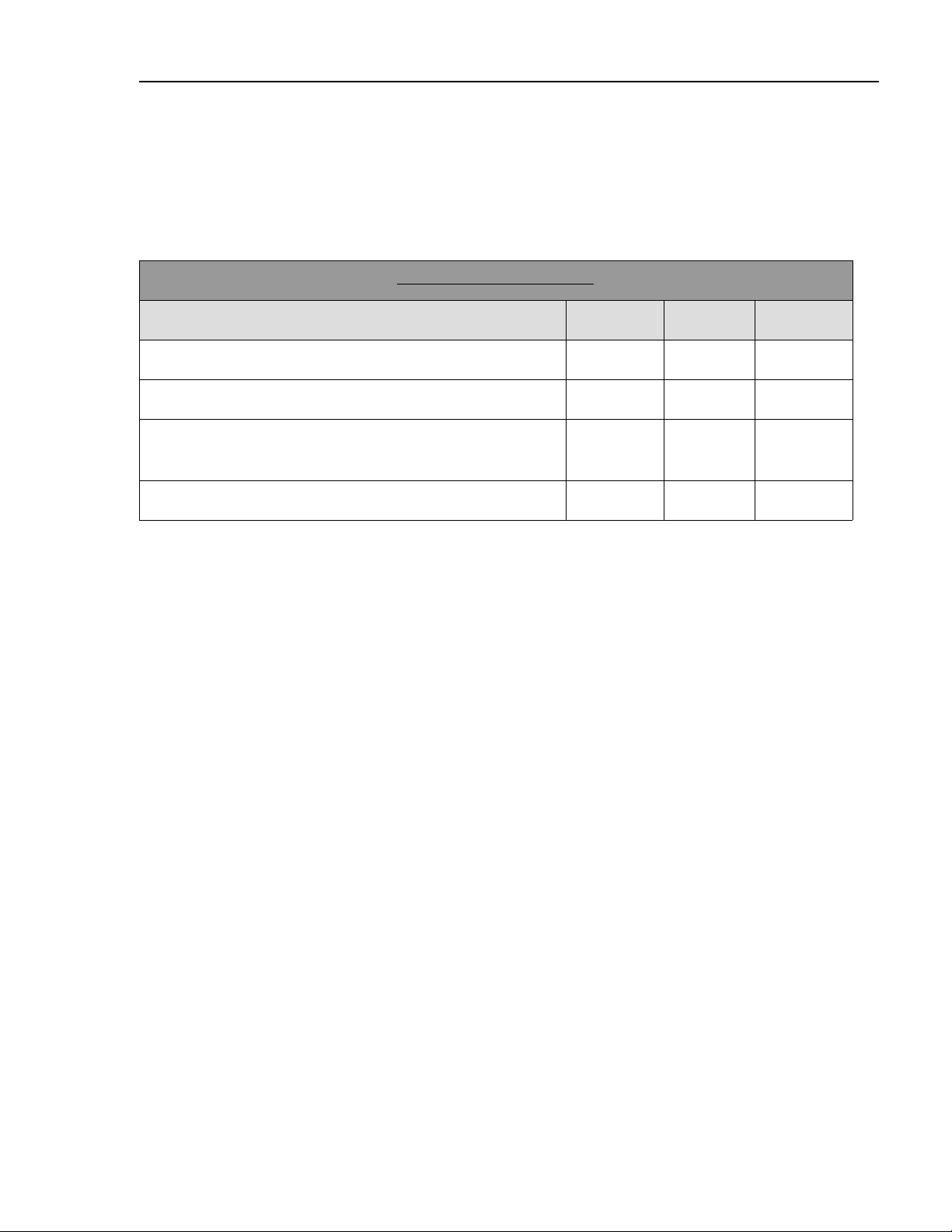

7.0 Preventative Maintenance Schedule

It is highly recommended to adhere to the preventative maintenance schedule in order help

extend the longevity of the specified PushCorp, Inc. equipment. Failing to do so could

cause a loss in functionality as well as a decrease in product life.

PUSHCORP, INC. AFD

Maintenance Weekly Monthly 3 Months

Remove debris from AFD X

Check that the connectors are not bent/damaged X

Check to see if the carriage moves back and forth

X

easily and smoothly

Check for flow in the purge and supply ports X

Agency/Organization:_________________________________________________

Date Completed:_____________________________________________________

Loading...

Loading...