Purifiner Aerobica PDAF-1 054 Owner's Operation And Maintenance Manual

Aerobica

PDAF-1 054

Chemical Free Iron Sulphur Filtration System

Owner's Operation and Maintenance Manual

Water Quality Control Systems Limited, 605 Denison Street, Markham, Ontario

Tel: 905-944-9465, 888-830-5776, Web: purifiner.com, Email: service@purifiner.com

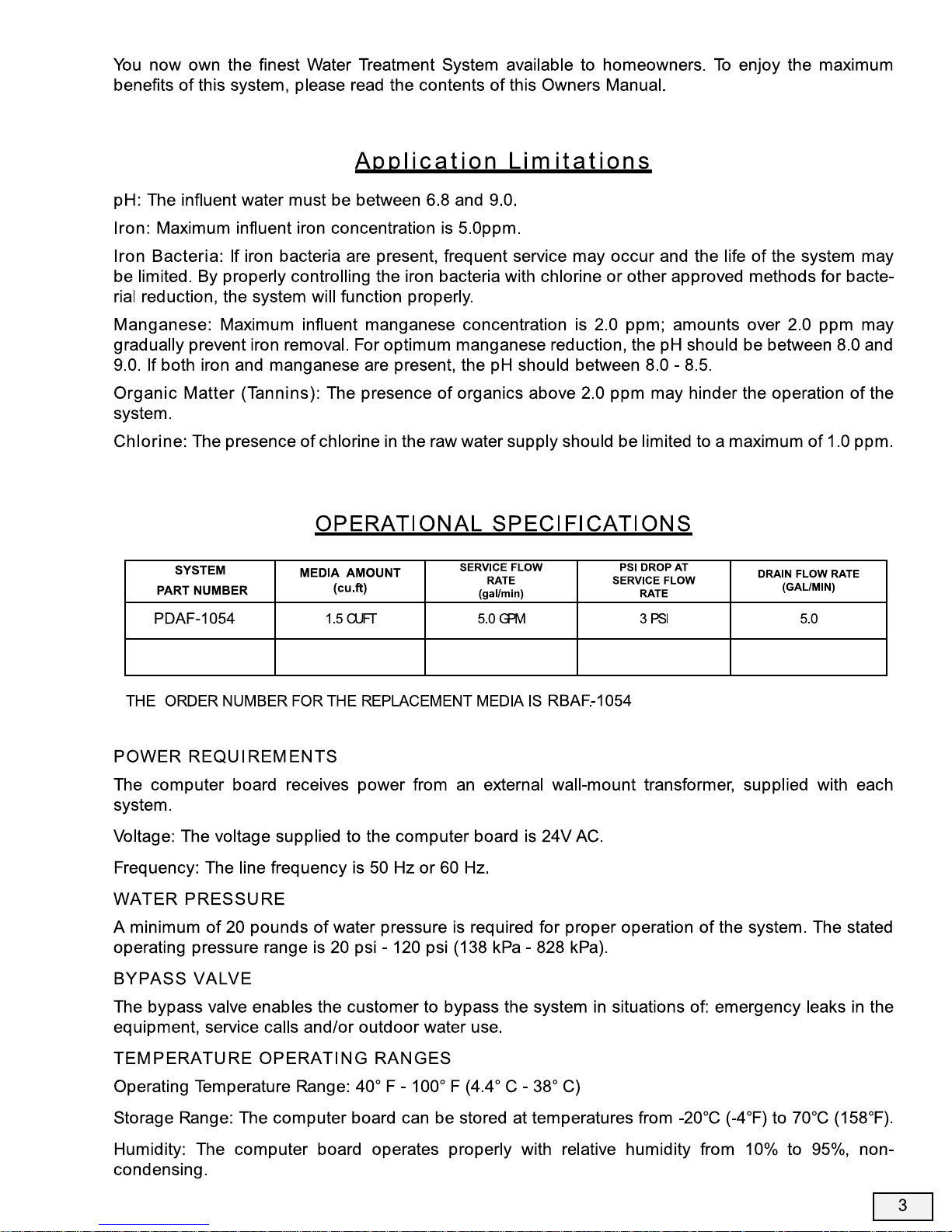

System Information continued from page 3.

ENVIRONMENTAL REQUIREMENTS

Location: The water filter and control cannot be exposed to outdoor elements, such as direct sunlight

or atmospheric precipitation. The system may be installed in a covered, open-air structure such as a

carport, residential or commercial building. Weather covers are also available through the Order

Department ( part number 72370 or 71345).

PRE-INSTALLATION INSTRUCTIONS

• Do not install this system where water is microbiologically unsafe or of unknown quality without

adequate disinfection before or after the system.

• This system must be installed in an area that is not affected by extreme heat, cold or the elements.

The selected installation area must be adequate for easy service of all parts.

• This system must be installed in accordance with all applicable state and local laws and regulations.

• This system is designed to treat cold water only and can be installed on any cold water supply.

MAINTENANCE REQUIREMENTS

• Clean the backwash flow control.

• Verify that the flow meter is functioning correctly. Clean the impeller, if necessary.

• Verify the programming of the control. Reprogram, if necessary.

• Verify the minimum and maximum water pressure. Install a pressure reducer, if necessary.

• Replace the filter media every three to five years. Systems used for treatment of high iron will require

replacement of the filter media more often. Call your local dealer to replace the filter media ( part #

14816)

INSTALLATION INSTRUCTIONS

1. SAFETY PRECAUTIONS

• To prevent accident or injury, do not hoist the unit over your shoulder. Use a hand truck to transport

the unit. Note: Do not lay the unit on its side during transportation and/or installation.

• Wear safety glasses and work gloves during installation and service.

2. TEST THE RAW WATER

• Test the raw water supply to ensure it meets the “Application Limitation” on page 3.

3. CHECK WATER PRESSURE

• Use a pressure gauge to confirm that the water pressure does not exceed 120 psi. If the water

pressure does exceed this limit, install a pressure regulator on the inlet pipe of the unit. The minimum

pressure for a filter is 20 psi. 60 psi is the optimum operating pressure.

4. CHECK THE WELL PUMP FLOW RATE

• Proper backwash is required to maintain the life of the filter media. If installed on a well, check to

make sure the well pump can provide a drain flow rate of 5 gallons per minute.

4

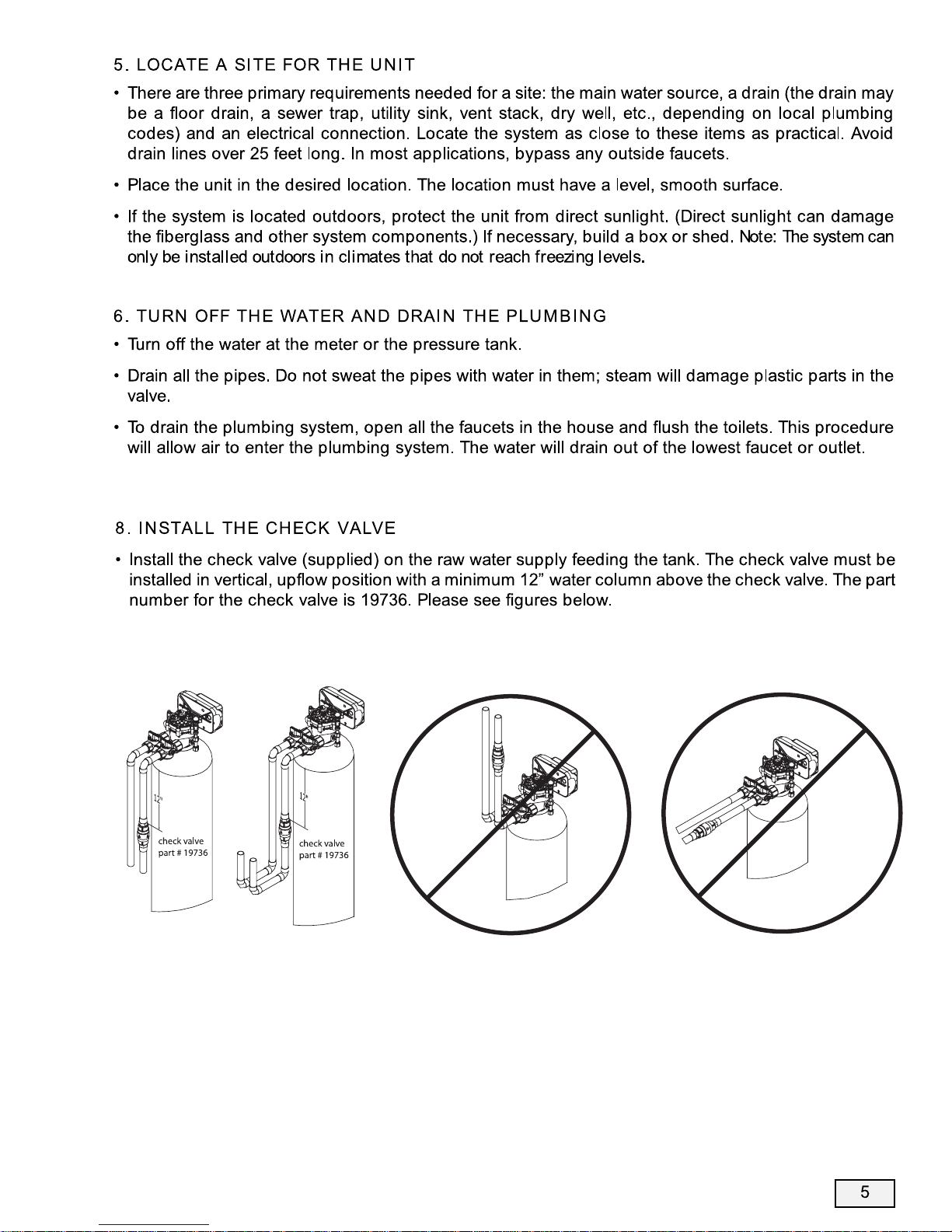

9. CONNECT THE PLUMBING TO THE BYPASS VALVE

• Do not point the soldering torch directly at the system. The thermoplastic material will last a lifetime,

within normal operating temperatures, but will melt in a torch flame.

• To prevent hot water from backing up into the condi

INLET

tioner, avoid short connections of pipe between the

conditioner and the hot water heater. If you can’t avoid

a short connection, move the equipment to another

OUTLET

location. As a last resort, install a check valve. If the

check valve causes “water hammer”, install a water

hammer suppressor.

• Connect the raw water pipe to the INLET pipe connection of the bypass valve. When looking at the

front of the unit, the inlet is the pipe connection on the LEFT side of the valve.

• Connect the treated water pipe to the OUTLET pipe connection of the bypass valve. When looking at

the front of the unit, the outlet is the pipe connection on the RIGHT side of the valve.

10. TURN ON THE WATER AND TEST FOR LEAKS AND FLUSH THE PLUMBING

• Before turning the water back on, place the system in the bypass position, then close all of the faucets

except one cold water tap from a bath tub.

• Turn the water on slowly and allow the water to flow out the bath tub for several minutes to remove

any dirt, solder, glue, etc. from the plumbing system.

• Once the water runs clear, turn the bypass valve handles to the service position and allow the water

to fill the system. It is common for the first few gallons of water to show some color ( orange to brown)

for a few minutes. Once the water runs clear shut off the bath tub.

• The system will now pressurize, allowing you to check for any leaks.

11. FLUSH THE REMAINING DEBRIS FROM THE SYSTEM

• To flush the remaining untreated water from the plumbing, turn on all the faucets in the house and

flush the toilets (approximately two to three minutes per faucet.)

• Run hot water in the bathtub to remove any remaining untreated water.

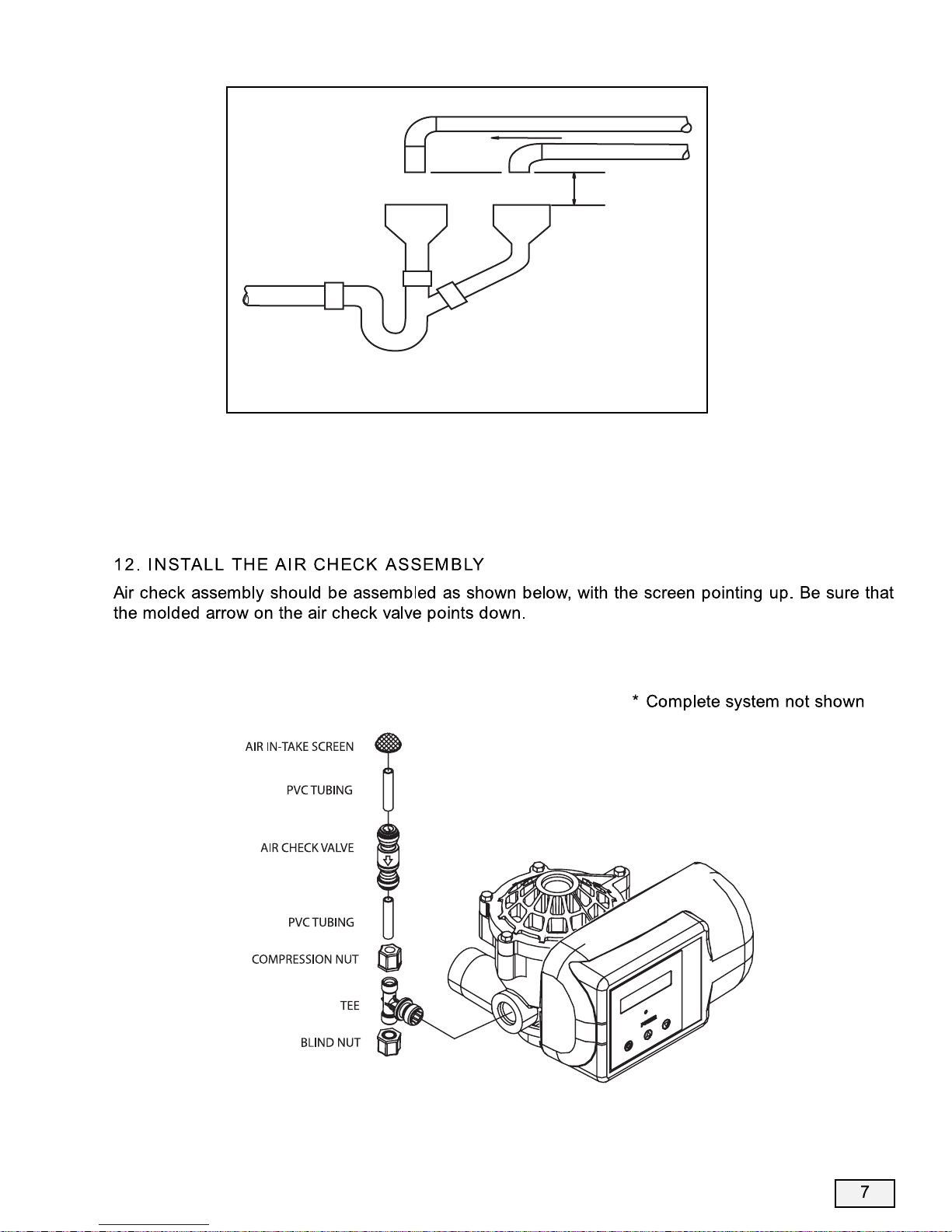

11. INSTALL THE DRAIN LINE AND AIR GAP

• Using the supplied drain line fitting use Teflon tape on the threads and attach to the top of the valve.

Run 1/2 inch ID flexible drain line tubing (not supplied) to an appropriate drain. Most local codes

require an air gap. See pictures on the next page. The Air-Gap is not provided with the product.

Note: Drain line may be plumbed with rigid pipe or PEX, if required by local code. The drain

connection on the valve will accommodate any standard 3/4 inch NPT fitting.

Note: The regeneration cycle is a simple backwash to refresh the filter bed, followed by an intake

of air to establish an air head in the tank. Since no regeneration chemicals are added, the

discharge water may be drained to the outside and used for irrigation in climates where freezing

is not a concern. Please note that iron in the drain water may cause staining, so avoid situations

where the water may splash onto walls, vehicles, patios, etc.

6

Loading...

Loading...