Puricom Rider User Manual

MU

User

Manual

Household

Softener

CONTENT

0. MAIN SPECIFICATIONS

1. PRESENTATION

2. INTRODUCTION

3. TECHNICAL SPECIFICATIONS

4. UNPACKAGING AND CONTENTS VERIFICATION

5. WARNINGS

6. SYSTEM INSTALLATION

7. START UP

8. MAINTENANCE/ SANITIZING

9. TROUBLESHOOTING GUIDE

10. MAINTENANCE MANUAL

11. EQUIPMENT INSTALLATION AND INITIAL

OPERATION REGISTRATION SHEET TECHNICIAN

12. GUARANTEE CERTIFICATE

4

5

5

9

10

11

12

15

17

20

22

24

25

0. MAIN SPECIFICATIONS

1. MAIN SPECIFICATIONS

Español

User Manual

ELECTRONIC TIMER

Allows to control all parameters

REGENERATIONS

Delayed or immediate/ programming

MIXING VALVE

Allows to regulate the residual hardnes

INTEGRATED BY-PASS

Allows to isolate the system from installation

TRANSFORMER

Outside

EASY TANK SALT FILLING

Special for Softener

ESP

FRA

ENG

KEEP THIS MANUAL THAT INCLUDES THE SERVICE BOOK AND THE GUARANTEE SECTION.

IT WILL PROVIDE YOU A BETTER POST-SALE SERVICE.

MULTILINGUAL TIMMER

English / French / Spanish

4

1. PRESENTATION

The water treatment equipment that you have bought is

a soener of last generation with one of the most advanced control heads in the market.

This is a system which combines the properties and advantages of the classic Denver with a more eicient water

and salt consumption, thus contributing both to the protection of our environment and the household economy.

Your soener RIDER will provide you and your family the

following advantages.

BENEFITS AND ADVANTAG

• ENERGY SAVINGS: Avoid the future incrustations in

the pipes and connections.

• Great wellness sensation in the shower.

• So and smooth skin.

• Increases the life time of electronic devices and

heating systems.

• ECONOMIC SAVINGS: Reduces the consumption of

soaps, soeners and chemical products.

• Low cost of maintenance.

• Automatic function, your only concern is to add

salt to the tank storage from time to time.

It is important that you keep and read this manual

carefully before the installation and starting up of

this equipment. If you have any doubt about the installation, use or maintenance of this equipment, please

contact with the technical assistance service (T.A.S.) of

your distributor.

1.1. SOFTENER SAFETY

Your safety and other’s safety are very important. We have

included safety messages in this manual and on your

appliance.

This is the safety alert symbol.

This symbol alerts you to the potential hazards that

can be risky for you and for others.

All safety messages will follow the safety alert symbol or either the word “DANGER” or “WARNING”.

• DANGER: Severe or fatal risk if the following instructions are not immediately followed.

• WARNING: All safety messages provide information

about the possible danger, how to reduce the risk of injury and what might happen if the instructions are not

followed.

1.2. BEFORE STARTING

See ‘Section 5’ before installing the water soener. Carefully follow the instructions for the installation (Warranty

may be considered void, if the installation is faulty).

Please read the entire manual before undertaking installation. Then, collect all necessary materials and tools for

the installation.

Check the plumbing installation.

All installations must be done according to the law in

force in each region or country.

Please be careful when handling the water soener. Do

not knock it over, let go of it or place it onto sharp objects.

Under no circumstances should the soener be installed

outdoors, since it must be protected against sunlight and

rough environmental conditions.

2. INTRODUCTION

The RIDER soeners equipments will avoid you all kind

of problems caused by the hardness of the water and will

reduce a lot the maintance requested by your electronical

devices. They will have a longer life.

These systems come with a residual hardness regulator

as standard, which allows selecting the appropriate hardness for your home.

Its user-friendly electronic programmer will allow you to

put the system into operation in an easy and fast manner.

What is hardness?

Hardness is the quantity of scaling salts present in water,

which are mainly composed of low solubility salts of calcium and magnesium. The main salts causing hardness

are listed below:

Calcium bicarbonate:

Calcium chloride:

Calcium sulphate:

Magnesium bicarbonate:

Magnesium chloride:

Magnesium sulphate:

These salts, due to their chemical properties, have a tendency to precipitate, producing scale on pipes and obstructing them as they accumulate.

In the same way, hardness has a high tendency to scale

on the electrical resistors from heaters and to precipitate

in heaters when temperature increases.

The combination of hard minerals and soap produces a

soap curdling, wich reducest he cleansing properties of

soap.

The precipitation of hard minerals build a layer on cook-

Ca(COH)²

CaCl

CaSO

Mg(COH)²

MgCl

MgSO

5

Español

User Manual

ing utensils, connections and plumbing fixtures. It may

even alter the taste of food.

Español

Main problems:

User Manual

· Precipitation on pipes, fixtures and appliances.

· Incrase of the energy consumption due to the generated

isolation.

· Higher soap consumption

· Reduction of the electical appliances’ service life and

increase of the maintenance needed.

All these problems are greatly reduced when using a water soening system.

For the most part of Europe, hardness is indicater in

French hydrometic degrees, but there are also other

measuring units, according to each region.

Below are the most usual equivalences.

UNITS

1 ppm of Calcium

1 ppm ofMagnesium

1 ppm de CaCO3

1º French (ºHF)

1º German (ºd)

1º Englisch (ºe)

1 mmol/L

1 mval/L=eq/L

ppm of CaCO

2,5

4,13

1

10

17,8

14,3

100

50

3

º French

0,25

0,413

0,1

1

1,78

1,43

10

5

How does your system work?

Water soening is carried out by means of an ion exchange process. On this purpose, the system uses resins

with the chemical capacity of capturing Calcium (Ca) and

Magnesium (Mg) ions and removing them from water.

When Calcium and Magnesium ions are captured by the

resin, two Sodium (Na) ions are released which, due to its

chemical properties, produce salts with a higher solubility , thus avoiding all hardness-related problems.

Therefore, when water gets soened, its sodium level

increases.

Further information on this procedure can be found in

‘Section 2.8’.

Ion exchange resins:

They are synthetic compounds, usually with a spherical

shape, able to capture certain chemical substances present in water, which then exchange for other substances.

Water soening uses strong cation resins, which are composed of styrene copolymers and divinylbenzene with a

sulphur base.

The exchange resin charge is located inside the vessel of

the soener, attending an important part of volume of

the same (between 60 and 75% depending on the model).

It is compulsory that one part of the vessel remains free to

allow a correct regeneration of the resin bed.

During the treatment process the water gets through the

multiway valve by the entrance connection, flows to the

upper part of the soener through the distributor producing this way an ionic exchange inside the resin bed.

The treated water is collected by the distributor and driven through the inner tube through the vessel till the multiway valve. It is sent with the out connection till the main

water pipe for consumption. In this point the system has

a counter for treated water to be contabilized.

2.3 Regeneration of the system

The quantity of calcium and magnesium ions that the

resin may retain is limited; therefore, the water volume

a water soener can treat is limited as well. The system

must periodically carry out a process known as regeneration, which allows the resin to recharge with sodium ions,

so it can continue soening water.

In RIDER systems the regeneration process starts automatically when the systems detects that the exchange capacity is going to finish, the timer incorporated in the system allows to configurate in a dierent way the starting

of the regeneration, please see section 6.3 in order to get

more information about how the programme works.

The regeneration of a soener system is made of dierent

parts, each with a concrete finality

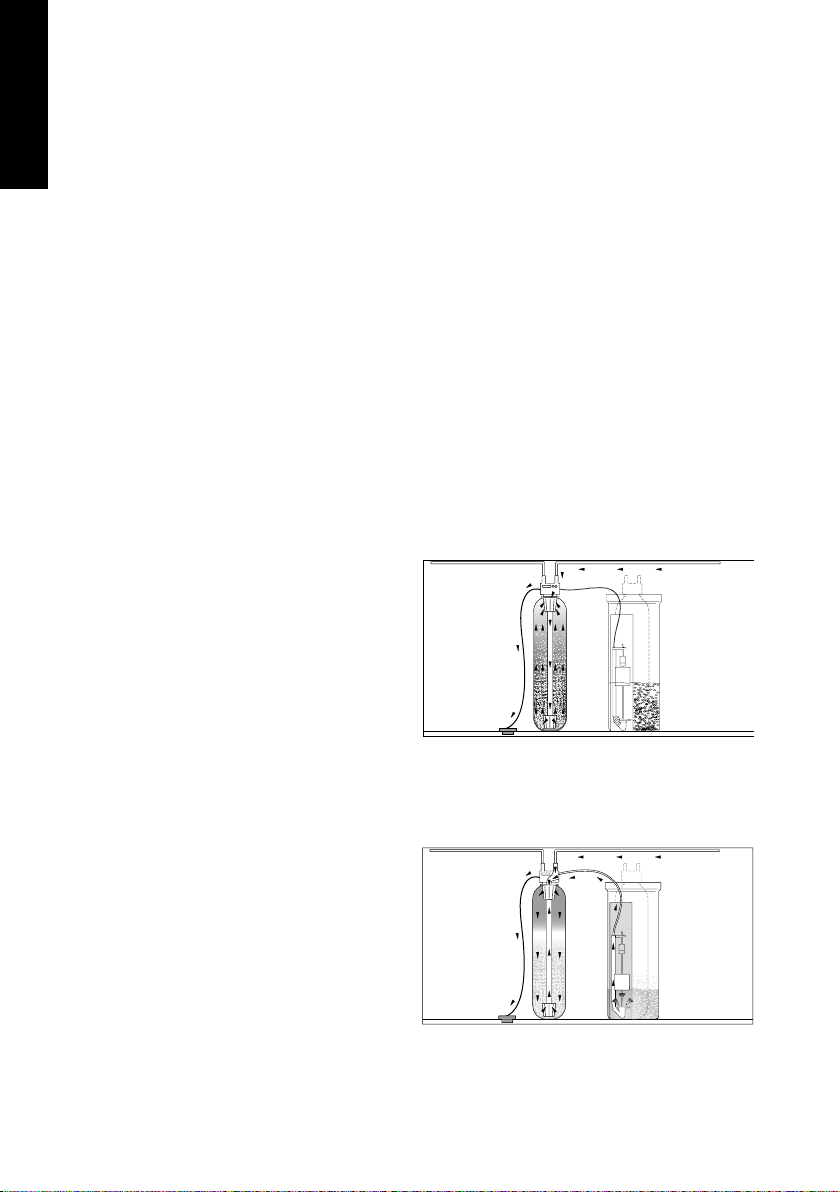

Backwashing:

The water gets into the vessel through an inferior collector, making a washing and a floing of the resin bed and

allowing, this way, the following regeneration process.

Conditioned water Water inlet

To the drain

Brine aspiration:

Through an aspiration process for venturi eect the system suctions the brine liquid solution previously prepared for the regenerating tank. This salt solution is introduced into the soening vessel getting in contact with the

ionic exchange resin and starting the regeneration.

Conditioned water

To the drain

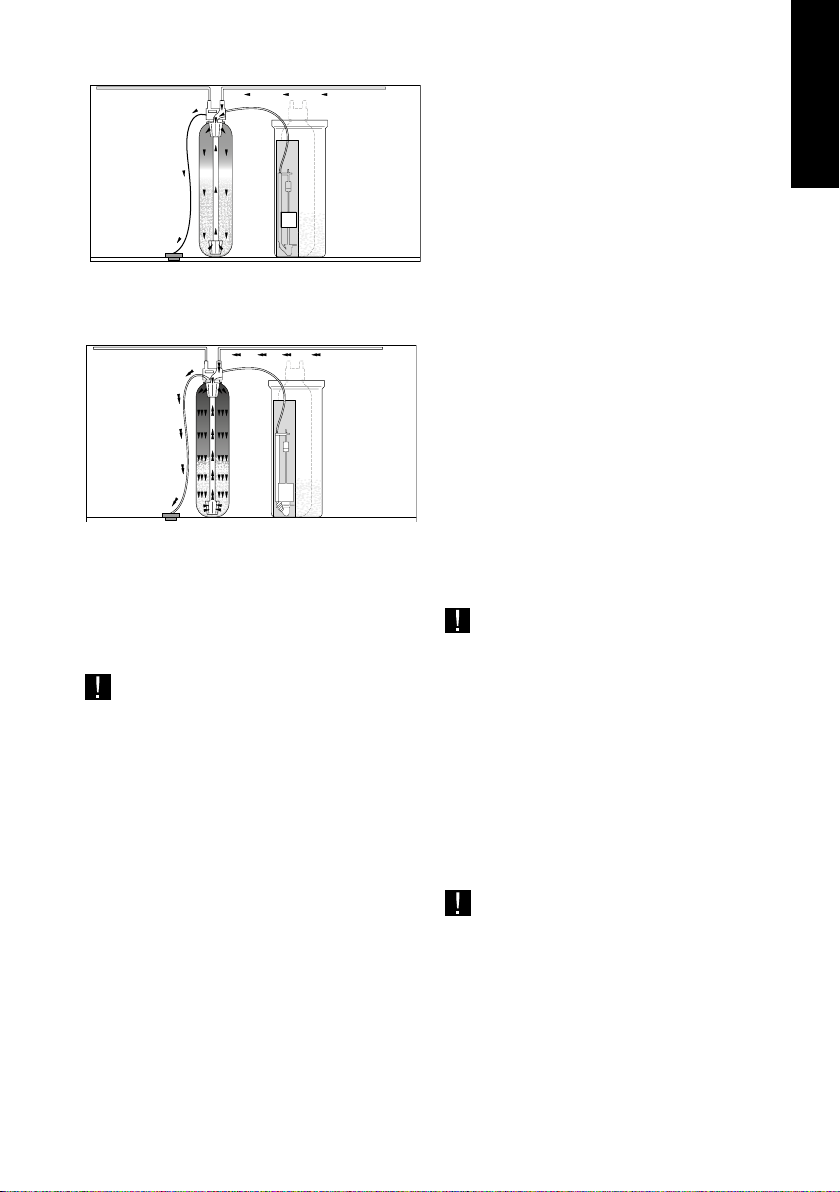

Slow rinse:

It refers to the movement in the resin bed of the salt solution previosly aspirated, this way the contact of the salt

with the resin is higher and the regeneration of the same

is optimized.

Water inlet

Brine aspiration,

Venturi effect

6

Conditioned water

To the drain

FAST RINSE:

The water flows through the resin bed making a final

wash of the same and ensuring the total removing of the

salt that can be inside the vessel.

Conditioned water

To the drain

Water inlet

Brine aspiration,

Venturi effect

Water inlet

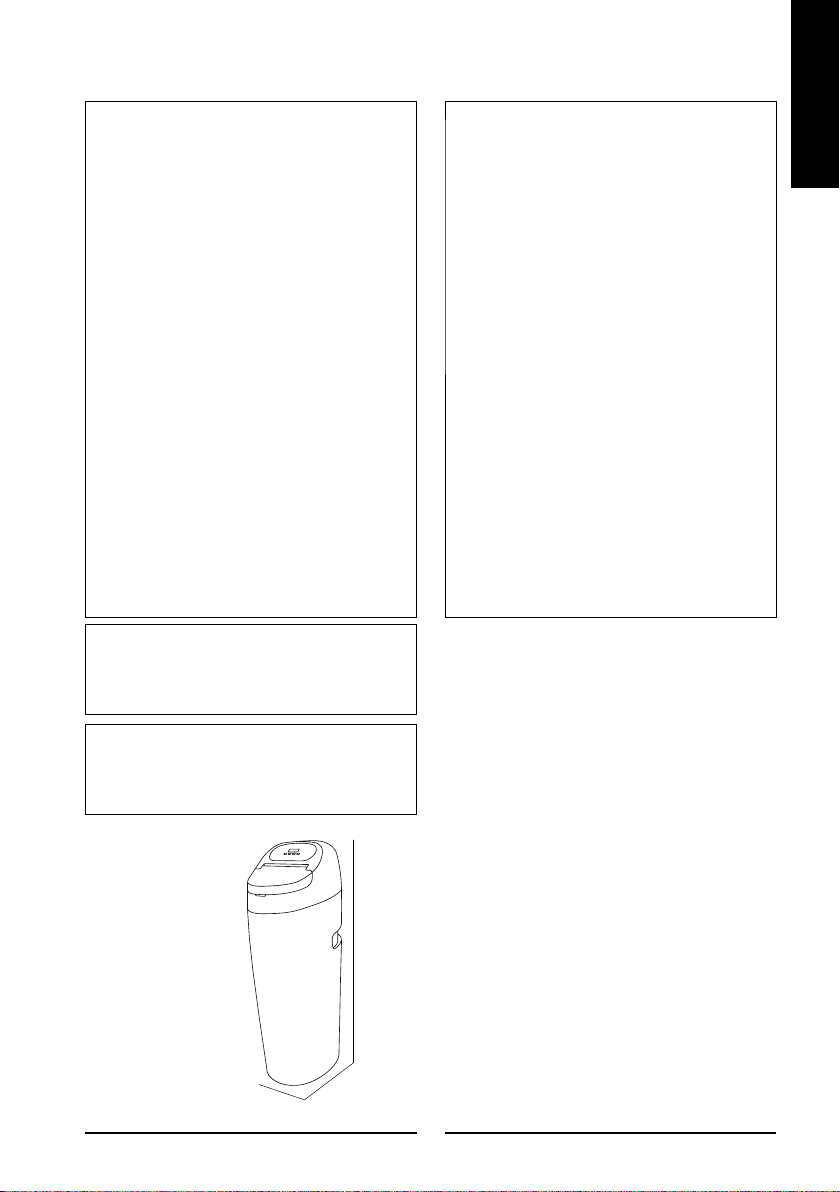

REFILLING THE BRINE TANK:

The volume of water goes automatically to the brine tank

in order to prepare the necessary brine to be consumed

in the next regeneration.This process is automatic, so normally it is not necessary to put more water in the brine

tank (except during the starting up as shown in section 7.

NOTE: During the regeneration process the systems

allows the passage of the non treated water in order

to ensure the disponibilty of the water to be consu-

med.

2.4 Regeneration rate and capacity.

TThe exchange capacity is the quantity of hardness that a

certain resin volume can retain before getting exhausted.

This value is usually expressed as ºHFxm3.

The higher the resin volume of the system is, the higher

will be the quantity of hardness that can be retained before the resin gets exhausted.

Depending on the quantity of sodium chloride used to

regenerate each liter of resin the capacity of exchange

can dier.

2.5 Work Volume

Water soeners using ion exchange must respect certain

contact periods between water to be treated and resin, in

order to ensure that the soening process is carried out

properly.

For the RIDER equipment, please respect the minimum

and maximum flow rates indicated in the Technical Characteristics section.

If the working ranges are outside the recommended ranges, the proper operation of the system will be aected

(excessive loss of charge, hardness leakage, etc.)

2.6 Hardness leak

The ion exchange process on which water soening is

based may be aected by dierent factors, which can reduce its eiciency and cause a certain level of hardness

leakage.

High sodium concentration on water to be treated.

It may interfere in the exchange process.

Excessive flow rates

Since there is not enough contact time, some of the hardness may not be retained by the resin.

2.7 Residual hardness

Depending on the final use of treated water, it may be

necessary to obtain fully soened water or, on the contrary, it may be desirable to leave some residual hardness.

These systems have been designed to supply fully softened water, but the by-pass integrates a residual hardness mixer, which allows the regulation of the desired

hardness degree in treated water (see ‘Section 7’).

NOTE: For human consumption water, it is recom-

mended to have a residual hardness between

5 and 8 ºHF if pipes are made of copper, and be-

tween 8 and 10 ºHF if they are made of iron (for

the latter, it is also recommended to install a silicopolyphosphates filter aerwards).

2.8 Sodium increase

Most of the sodium we consume on a daily basis comes

from food, specially processed food, since salt is an excellent preservative and is used as an additive in prepared

products.

Sodium consumption through the water we drink is rather low when compared with that obtained from food.

WARNING: As mentioned above, water soeners re-

duce the Calcium and Magnesium concentration

in water by replacing it for Sodium. Thus, they

increase the sodium level in water.

The maximum recommended sodium level in water for

human consumption is of 200 ppm. Depending on the

sodium concentration and the hardness of water to be

treated, it is possible that soened water contains a higher concentration of sodium than that recommended.

Should this be the case, or if water is to be consumed by

persons who must follow a low-sodium diet, it is recommended to install a household reverse osmosis system to

drink the water.

Español

User Manual

7

The table below can be used as a guideline to know the

increase on sodium concentration in treated water depending on feed water hardness:

Español

User Manual

Initial hardness

in water (ºHF)

10

15

25

30

35

40

45

50

60

Sodium added

by the water

soener (mgNa/litre)

43

65

108

130

152

173

195

217

260

8

3. TECHNICAL SPECIFICATIONS

Model

Code

Resin volume

Vessel

Working flow

Maximum flow

Maximum hardness

High eiciency configuration

Salt/regeneration

Exchange capacity

Medium capacity configuration

Salt/regeneration

Exchange capacity

High capacity configuration

Salt/regeneration

Exchange capacity

Caudal mínimo

Rango de temperaturas

Rango de presiones

RIDER

795238

25 litres

9x35

3

/h

1,0m

3

1,5m

/h

120ºHF

1,5 Kg Sal

96ºHFxm

3,0 Kg Sal

141ºHFxm

6,25 Kg Sal

175ºHFxm

3

0,1 m

/h

4-35ºC

2,5-8 bar

3.1. Volume of treated water according to inlet hardness

System RIDER

3

HIGH eiciency:

Feed hardness

15 6,40

25 3,84

30 3,20

35 2,74

45 2,13

55 1,75

MEDIUM capacity:

Feed hardness

3

3

3

15 9,40

25 5,64

30 4,70

35 4,03

45 3,13

55 2,56

HIGH capacity:

Feed hardness

15 11,67

25 7,00

30 5,83

35 5,00

45 3,89

55 3,18

141ºHFxm

96ºHFxm

175ºHFxm

3

3

Español

User Manual

Pressure rating

Electrical connection

Rated electrical power

Protection class

Dimensions

Height A

Width B

Depth C

220V/50Hz-24VAC

TIPO III

1100 mm

360 mm

530 mm

C

B

8 bar

4W

DISTRIBUITED BY:

IONFILTER, WATERFILTER, PURICOM

Pol. Ind. L’Ametlla Park - c/Aiguafreda, 8

L’Ametlla del Vallès, Barcelona (España)

T. 902 305 310 - F. +34 936 934 329

A

TECHNICAL SERVICE:

+34 936 934 309

sat@ionfilter.com

9

Loading...

Loading...