PurePro PLUG N’ GO PRO-41ZPG, PRO-80ZPG, PIPE N' GO TD-41ZPGLP, TD-80ZPGLP, PLUG N' GO PRO-80ZPG Installation & Operation Manual

...

INSTALLATION, OPERATION

& MAINTENANCE

INSTRUCTIONS

PLUG N’ GO and PIPE N’ GO

INDIRECT-FIRED WATER HEATERS

MODELS COVERED:

PLUG N’ GO PRO-41ZPG, PRO-80ZPG

PIPE N’ GO TD-41ZPGLP, TD-80ZPGLP

INSTALLER: LEAVE THIS MANUAL WITH THE OWNER

IMPORTANT GENERAL SAFETY INFORMATION - ADDITIONAL SPECIFIC SAFETY ALERTS APPEAR IN THE FOLLOWING

INSTRUCTIONS.

READ CAREFULLY THE PRODUCT INSTALLATION, OPERATING AND MAINTENANCE MANUAL.

SERIOUS OR FATAL INJURY AND/OR PROPERTY DAMAGE, AND WILL VOID THE PRODUCT WARRANTY. THIS PRODUCT

MUST BE INSTALLED BY A QUALIFIED PROFESSIONAL. FOLLOW ALL APPLICABLE LOCAL AND STATE CODES AND

REGULATIONS. IN THE ABSENCE OF SUCH CODES, FOLLOW THE CURRENT EDITIONS OF THE NATIONAL PLUMBING

CODE AND NATIONAL ELECTRIC CODE, AS APPLICABLE.

THIS IS THE SAFETY ALERT SYMBOL. IT IS USED TO ALERT YOU TO POTENTIAL PERSONAL INJURY AND

OTHER HAZARDS. OBEY ALL SAFETY MESSAGES THAT FOLLOW THIS SYMBOL TO REDUCE THE RISK OF

PERSONAL INJURY AS WELL AS PROPERTY DAMAGE.

medium must be limited to 30 PSIG by an approved safety or relief valve.

FAILURE TO FOLLOW THE INSTRUCTIONS AND WARNINGS IN THE MANUAL MAY RESULT IN

The heat transfer medium must be water or other nontoxic fluid having a toxicity rating or class of 1, as

listed in Clinical Toxicology of Commercial Products, 5th edition. The pressure of the heat transfer

Part #: 9040-658 (9/06)

1. TABLE OF CONTENTS

2. Pre-Installation Checklist...............................................

3. Required Components and Accessories Checklist.......

4. ZPG - Series Piping Installation ....................................

5. ZPGLP -Series Piping Installation .................................

6. ZPG - Series Wiring.......................................................

7. ZPGLP - Series Wiring ................................................

8. Startup Procedure .......................................................

2

3

4

6

8

10

13

2. PRE-INSTALLATION CHECKLIST

IMPORTANT STEPS AND DECISIONS REQUIRED BEFORE INSTALLATION

M THIS PRODUCT MUST BE INSTALLED AND MAINTAINED

BY A LICENSED PROFESSIONAL. IN ADDITION TO THE

INSTRUCTIONS IN THIS MANUAL, FOLLOW ALL

APPLICABLE LOCAL AND STATE CODES OR IN THE

ABSENCE OF SUCH CODES, THE CURRENT EDITIONS OF

THE NATIONAL PLUMBING CODE AND THE NATIONAL

ELECTRIC CODE.

M DRIP PAN AND DRAIN: This appliance should not be

installed in an area where leakage of the tank or

connections can result in damage to the area adjacent to

the appliance or to lower floors of the structure. When

such locations cannot be avoided, a suitable drain pan,

adequately drained and kept clear, must be installed under

the appliance.

M CAUTION: Determine whether your water is corrosive or

acidic, and that there are no suspended solids, toxic or

other substances or abnormally high chlorine levels in the

water that could damage or affect the water heater or the

rest of your plumbing system.

9. Troubleshooting ...........................................................

10. Replacement Parts ......................................................15

11. General Safety Information..........................................

12. Product Warranty.........................................................

water heater may not be supplied with enough hot boiler water

to "recover" adequately. The delivery of domestic hot water will

be diminished. In many, but not all cases, this is not a problem

because the routine oversizing of boiler output is adequate for

both loads.

2. Priority System - Under this wiring option the water

heater will be supplied before space heating.

In limited circumstances, space

heating can be lost in the home in this

priority mode. Any demand for space heating is postponed

until the water heater has reached its set temperature.

This delay in supplying the space heating zones is usually

not noticed by the inhabitants of the living spaces.

However, in the event of certain malfunctions such as

circulator or thermostat failure, space heating could be

delayed indefinitely. If undetected and uncorrected,

freezing damage to piping could result.

14

16

17

USE GLYCOL ONLY WITH DOUBLE-

MODELS.

seepage or leakage of glycol to surfaces where humans or

animals can ingest it, use glycol only in double-walled

units, so that any leaks will most likely be released to the

atmosphere. However, a leak to a surface area may still

occur, so any use of glycol must be monitored closely and

humans and animals should be protected from contact

with the unit.

other space heating units or elements. Any contaminants

in the baseboard units will contaminate the potable water

in the water heater and also adversely affect its

performance.

M Wiring Options. Select either a Non-Priority or Priority

System:

Two options are available when wiring the controls of the water

heater in the space heating system (boiler and distribution

elements).

1. Non-Priority System - The controls of the water heater

NOTICE: In this non-priority option, the water heater will be

supplied just as another zone. This means that if all space

heating zones call for hot boiler water at the same time, the

Glycol is a poisonous substance. To avoid

must be wired as a separate heating zone with a

standard zone valve or a separate circulator dedicated to

the water heater "zone".

WALLED HEAT EXCHANGER

Do not connect the water heater

domestic supply with baseboard or

M Select Circulator versus Zone Valve

The flow of hot boiler water to the water heater can be

controlled with either a motorized zone valve or a circulator.

1. Separate circulator. The recommended way to provide

adequate flow through the water heater heat exchanger is

to use a separate dedicated circulator with a minimum

flow rate of 5 gpm. This option may be used even though

the heating system utilizes zone valves.

2. Zone valve (system flow of 4-8 gpm). If a zone valve is to

be used, a minimum flow rate of 5 gpm with all zones in

use is required. A full-port zone valve should be used.

M All installations require a low-water cut-off or automatic fill valve

on your boiler system to reduce the risk of boiler water loss.

M Steam boiler installations require a low-water cut-off which is

also required by most codes.

M Installation of a vacuum breaker is required to prevent damage

to the water heater when drained. There must be no valves

installed between the vacuum breaker and water heater.

-2-

3. REQUIRED COMPONENTS AND

ACCESSORIES CHECKLIST

MODEL CIRCULATOR ZONE VALVE* VALVE BREAKER VALVE TANK DRAIN

PRO-41ZPG Included N/A 4 1 Included Required Included

PRO-80ZPG

*If Circulator not used

TD-41ZPGLP 5GPM@ 5ft 3/4" Full Port 4 1 Included Required Included

TD-80ZPGLP or 1" STD

ALL INSTALLATIONS REQUIRE TEFLON SEALING TAPE OR PIPE DOPE FOR THREADED JOINTS.

SEE HEAT EXCHANGER PRESSURE DROP CHART TO DETERMINE PUMP HEAD REQUIREMENTS.

SHUTOFF VACUUM RELIEF THERMAL EXPANSION

If a steel hydropneumatic tank is in place, replace it with a properly sized diaphragm

to be trapped in the heat exchanger. If the boiler system has an existing expansion tank and the boiler

temperatures are being changed, resize the existing diaphragm expansion tank.

expansion tank. Otherwise, significant heat transfer problems can occur by causing air

-3-

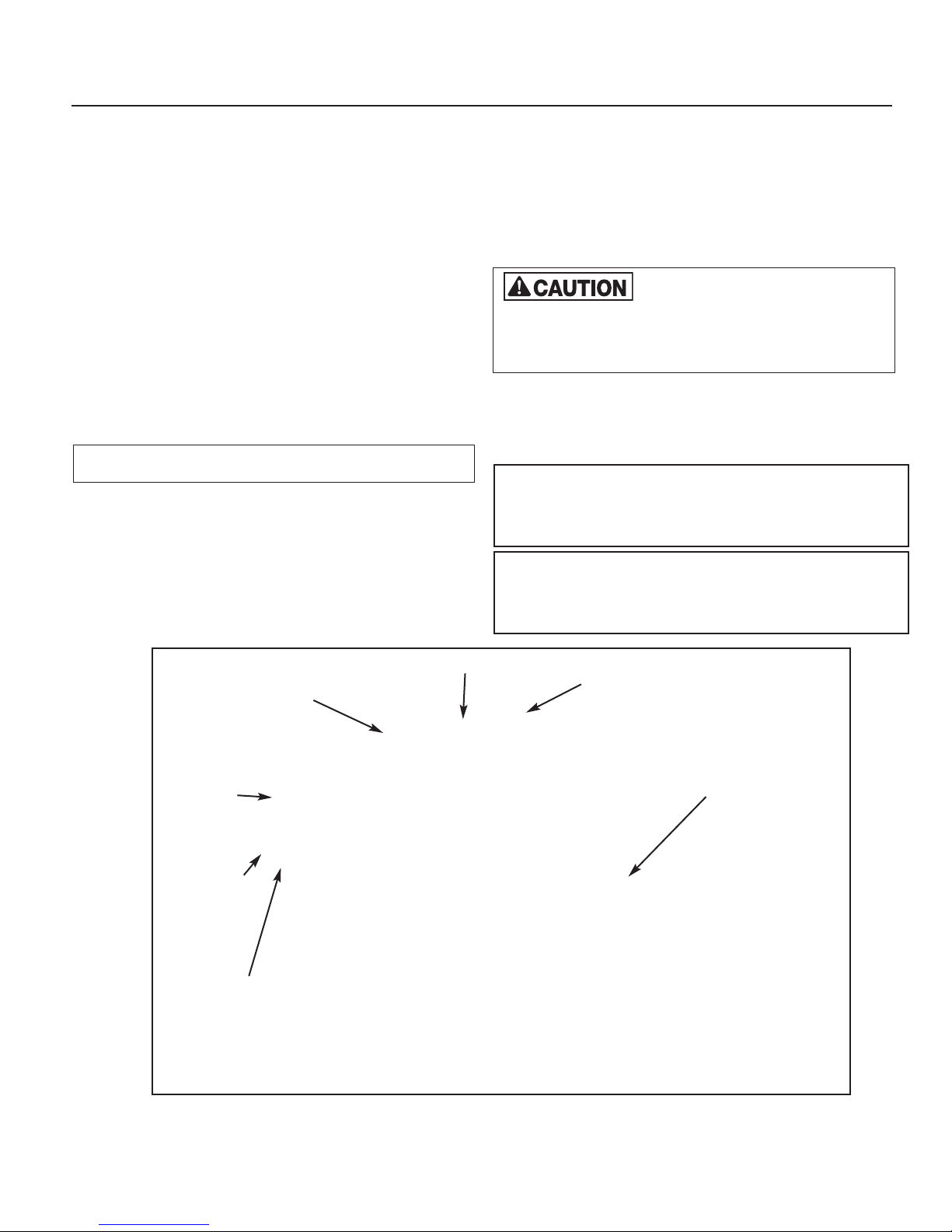

4. ZPG-SERIES WITH CIRCULATOR (PLUG N’ GO)

PIPING INSTALLATION

DOMESTIC WATER PIPING

1. Connect the cold water supply to the pipe labeled COLD

WATER.

2. Connect the HOT WATER piping to the domestic hot water

system.

3. Make an 8-inch “heat trap” on the HOT WATER outlet as shown

in the diagram. This will reduce standby losses from heat

migrating up the piping.

4. When all domestic water piping is complete, open the cold

water supply and allow some water to enter the tank. Look and

listen for signs of leaks and repair as necessary before

continuing.

Note: If installing on a city supply, ensure a dedicated Thermal

Expansion tank is used.

5. Install a blowdown tube on the T&P relief valve outlet. Plumb

to within 6 inches above a floor drain or as directed by

plumbing code.

BOILER PIPING

1. Plumb the BOILER SUPPLY line. The circulator and flow check

are factory installed

2. Pipe the BOILER RETURN connection to the boiler return line.

Be sure the return line is NOT

heating circulators. This may require moving the heating

circulator off the boiler tapping on packaged boilers.

Failure to do so will result in overheating and tank

damage when the heating system is in operation.

3.

After completing the boiler piping, slowly open the boiler fill

valve and pressurize the heat exchanger loop. Check for leaks

and repair as necessary. Proceed to the appropriate wiring

section in this manual.

Clearance From Combustible Surfaces

LEFT SIDE . . . . . . . . . . . . .1”

RIGHT SIDE . . . . . . . . . . .1”

TOP . . . . . . . . . . . . . . . . . .9”

Recommended Clearance for Servicing

LEFT 12”

RIGHT 12”

FRONT 30”

plumbed to the suction side of any

REAR . . . . . . . . . . . . . . . . .1”

FLOOR . . . . . . . . . . . . . . .0”

FRONT . . . . . . . . . . . . . . .1”

HEAD ROOM 36”

REAR 1”

COLD WATER

T&P RELIEF

VALVE

OUTLET

HOT WATER

OUTLET

INLET

CIRCULATOR

PUMP

BOILER SUPPLY

Aquastat

BOILER RETURN

Wiring Conduit

-4-

Thermal

Expansion Tank

PIPING MODELS WITH PRE-INSTALLED CIRCULATOR W/INTEGRAL FLOW CHECK

-5-

5. ZPGLP-SERIES W/O CIRCULATOR (PIPE N’ GO)

PIPING INSTALLATION

DOMESTIC WATER PIPING

1. Connect the cold water supply to the pipe labeled COLD

WATER

2. Connect the HOT WATER piping to the domestic hot water

system.

3. Make an 8-inch “heat trap” on the HOT WATER outlet as

shown in the diagram. This will reduce standby losses from

heat migrating up the piping.

4. When all domestic water piping is complete, open the cold

water supply and allow some water to enter the tank. Look and

listen for signs of leaks and repair as necessary before

continuing.

Note: If installing on a city supply, ensure a dedicated Thermal

Expansion tank is used.

5. Install a blowdown tube on the T&P relief valve outlet. Plumb

to within 6 inches above a floor drain or as directed by

plumbing code.

Clearance From Combustible Surfaces

LEFT SIDE . . . . . . . . . . . . .1”

RIGHT SIDE . . . . . . . . . . .1”

TOP . . . . . . . . . . . . . . . . . .9”

REAR . . . . . . . . . . . . . . . . .1”

FLOOR . . . . . . . . . . . . . . .0”

FRONT . . . . . . . . . . . . . . .1”

BOILER PIPING

1. Plumb the circulator or zone valve on the BOILER SUPPLY line.

If using a separate circulator, the pump flange can be mounted

directly to the threaded pipe marked BOILER SUPPLY.

Alternately, the circulator can be placed anywhere on the boiler

supply line.

2. Pipe the BOILER RETURN connection to the boiler return line.

Be sure the return line is NOT

heating circulators. This may require moving the heating

circulator off the boiler tapping on packaged boilers.

Failure to do so will result in overheating and tank

damage when the heating system is in operation.

3.

Install a weighted flow check on the boiler return line. This is

not necessary on systems utilizing a zone valve to control the

water heater temperature.

4. After completing the boiler piping, slowly open the boiler fill

valve and pressurize the water heater loop. Check for leaks

and repair as necessary. Proceed to the appropriate wiring

section in this manual.

Recommended Clearance for Servicing

LEFT 12”

RIGHT 12”

FRONT 30”

plumbed to the suction side of any

HEAD ROOM 9”

REAR 1”

Cold Water

Inlet

T&P Relief

Valve Outlet

Hot Water

Outlet

Boiler Supply

Boiler Return

Aquastat

-6-

Loading...

Loading...