Pikes Peak V2

Longs Peak

User Manual R2.2

Table of Contents

1

1. Introduction

1.1. Warranty

1.2. What’s Included

1.3. Technical Specifications

1.4. Disclaimers & Safety Precautions

1.5. Uncrating Your Press

2. Press Setup

2.1. Vertical Orientation Setup

2.2. Horizontal Orientation Setup

2.3. Vertical Dual Pressure Installation

2.4. Horizontal Dual Pressure

Installation

2.5. Automated Pressure Control

Installation

2.6. Using Push Connect Fittings

2.7. Electrical Power

2.8. Compressed Air

4. Pressware Controls

4.1. Home Screen

4.2. Settings

4.3. Workflow Overview

4.4. Quick Press

4.5. Last Run Data

4.6. Edit Recipe

4.6.1. Edit Recipe Cont.

4.7. Preset Recipes

4.8. Recipes (List)

4.9. Run Recipe

4.10. Pre-heat

4.11. Software Updates

5. Press Operation

5.1. Loading the Press

5.2. Automated Pressure Control

5.3. Dual Pressure Control

5.4. Plate Speed Control

3. Rosin Extraction Basics

3.1. Tips & Tricks

3.2. Yield and Material Types

3.3. Choosing Your Material

3.4. Filter Bag Preparation

5.5. Pressing Material

6. Maintenance & Troubleshooting

6.1. Common Issues

6.2. FAQ Part 1

6.3. FAQ Part 2

1. Introduction

From all of us here at PurePressure, thank you for your purchase!

Our rosin presses are engineered to last for many years with proper care.

The following user manual covers virtually every topic, including how to

2

use the press, technical specifications, tips on getting the most out of

your equipment, and much more.

Unless otherwise noted, the instructions contained in this manual apply to

both the Pikes Peak V2 and Longs Peak rosin presses and are

interchangeable.

Sales Inquiries:

sales@gopurepressure.com

General Questions:

info@gopurepressure.com

Technical Support:

support@gopurepressure.com

Contact:

720-446-9565

purepressure.com

@gopurepressure

We’re always here to help. Talk to us!

1.1 Warranty

3

PurePressure's rosin presses are built to last for many years with proper care. We want you to be satisfied with your equipment so if

there are ever any concerns, please do not hesitate to contact us. PurePressure guarantees the following warranty coverage for both the Pikes

Peak and Longs Peak rosin presses:

● 2 year limited warranty against manufacturing defects for structural components (frame, truss and support legs) and pneumatic

cylinder.

● 1 year limited warranty against manufacturing defects for the entire press including electronic and pneumatic components.

Warranty Replacements: In event of an approved warranty replacement or service, PurePressure will supply the necessary part(s) and special

tools, if needed. Shipping costs may be covered by PurePressure at its discretion.

Replacement Parts: Replacement parts for various components are available at reasonable prices for press owners directly from

PurePressure.

Exclusions: Warranty coverage eligibility will be determined by PurePressure and at PurePressure's sole discretion. PurePressure's

warranty obligations do not include (i) reasonable wear and tear; (ii) damage or corrosion caused by outdoor elements or outdoor use; (iii) use

of unapproved parts or unproved alterations to components; (iv) defects or damage caused by misuse, improper electrical power supply, or

compressed air inputs over 150 PSI (v) pneumatic components damaged from internal moisture or having been pressurized with compressed

air which is not clean or dry; (vi) vandalism, negligence, misuse or Force Majeure Events; or (vi) items expected to be consumed or expended

during the normal and routine operation and maintenance. This warranty is eligible for the original purchaser only and is not transferable.

Disclaimer: Except as expressly set forth in this Limited Warranty and to the greatest extent allowed by law, PurePressure makes no other

representations, warranties or conditions, express or implied, including any implied representations, warranties or conditions of

merchantability, fitness for a particular purpose, non-infringement, and non-interference.

Warranty Procedures: If your press is covered under the warranty period, please contact us with detailed information regarding the issue you

are experiencing so that we can get you operational as soon as possible. If you are experiencing a problem and are outside of the warranty

period, we will do everything in our power to get you affordable replacement component(s) in a timely manner. Please send all warranty and

replacement part related inquiries to support@gopurepressure.com. All returned parts must be accompanied by an RMA number, which we

will supply.

1.2 What’s Included

4

Longs Peak

What’s Included With Your Press

(items may differ depending on kit or model)

● LED capacitive touch screen

● Two button safety start

● Emergency-stop

● Plate speed actuation dial

● Compressed air filter / regulator(s)

● Pressure toggle for ramping

control or internal automated

pressure control unit

● Parchment clips

● Vertical orientation legs (qty 2)

● Horizontal orientation legs (qty 2)

● Leveling feet (qty 4)

Pikes Peak V2

● Industrial ¼” male air fitting

● Power cable

5 Tons of Force 8 Tons of Force

1.3 Technical Specifications

5

Specification Pikes Peak V2 Longs Peak

Weight 120 lb 130 lb

Overall Dimensions

Depth x Width x Height

Power Requirement 120/240VAC

Fuses (2x) Type: Fast Acting 250V

Compressed Air Requirements PSI: 5 - 120

Pneumatic Cylinder Maximum Force

Output

Frame & Enclosure Metal A36 Steel A36 Steel

Horizontal: 29.2” x 19.7” x 13.5”

Vertical: 15.5” x 19.7” x 33.3”

8A at startup / 2A continuous

Current: 10A

Dimensions: 5mm x 20mm

CFM: 2.1 or greater

Dry clean air

9,876 lb @ 120 PSI 15,300 lb @ 140 PSI

Horizontal: 32.6” x 19.7” x 13.5”

Vertical: 15.5” x 19.7” x 36.8”

120/240VAC

8A at startup / 2A continuous

Type: Fast Acting 250V

Current: 10A

Dimensions: 5mm x 20mm

PSI: 5 - 140

CFM: 2.7 or greater

Dry clean air

Heat Plates Sizes: 10” x 2.5”

Material: 6061 Aluminum

Maximum Temperature: 300 °F

Sizes: 10” x 3”

Material: 6061 Aluminum

Maximum Temperature: 300 °F

Please review this

1.4 Disclaimers & Safety

Precautions

WARNING: HEAT PLATES CAN CAUSE SERIOUS BURNS. NEVER PLACE FOREIGN OBJECTS, FINGERS, HANDS OR OTHER BODY PARTS

ON OR BETWEEN THE HEAT PLATES.

WARNING: PINCH POINT CAN CAUSE SERIOUS INJURY. NEVER PLACE FOREIGN OBJECTS, FINGERS, HANDS OR OTHER BODY PARTS

ON OR BETWEEN THE HEAT PLATES.

WARNING: ALWAYS WEAR EYE AND EAR PROTECTION AS WELL AS HEAT RESISTANT GLOVES FOR SAFE OPERATION.

WARNING: PUREPRESSURE, LLC IS NOT RESPONSIBLE FOR INJURY OR LOSS DUE TO IMPROPER USE OF EQUIPMENT.

DISCLAIMER: COMPRESSED AIR SOURCE REQUIRED. MAX ALLOWABLE WORKING PRESSURE 140PSI. THIS PRODUCT OPERATES

UTILIZING A PNEUMATIC CYLINDER.

DISCLAIMER: YOUR PRESS SPEED VALVE IS TURNED OFF FOR SHIPPING. THE DIAL MUST BE OPENED TO OPERATE YOUR PRESS

PNEUMATIC.

DISCLAIMER: CONNECTING TO ANY OTHER POWER SOURCE OTHER THAN WHAT YOUR PRESS IS RATED FOR ON ITS SERIAL LABEL

WILL VOID YOUR WARRANTY.

WARNING: EXCEEDING 150PSI ON YOUR PRESS WILL TERMINATE YOUR WARRANTY. A MECHANICAL BLOW OFF VALVE WILL

EXHAUST AND YOUR FIRMWARE WILL DETECT THE OVERPRESSURE FAULT.

WARNING: ONLY USE THE DESIGNATED AC POWER PLUG PROVIDED WITH YOUR PRESS. USING ALTERNATE VOLTAGES OTHER THAN

SPECIFED CAN RESULT IN DAMAGE TO YOUR UNIT.

WARNING: IF THE HEAT PLATE ICON ON YOUR SCREEN IS RED THEN THE PLATES ARE HOT ENOUGH TO CAUSE BURNS.

WARNING: PARCHMENT CLIPS ARE NOT HANDLES. DO NOT USE TO LIFT THE PRESS.

WARNING: EMERGENCY STOP BUTTON - YOU MAY CANCEL THE OPERATION AT ANY POINT BY PRESSING THE EMERGENCY STOP

BUTTON. THIS WILL DISPLAY EMERGENCY STOP ON THE LED TOUCH SCREEN AND WILL CUT POWER TO THE HEATERS WHILE

RETRACTING THE AIR CYLINDER. NOTE: AN INLET AIR SUPPLY OF AT LEAST 10 PSI IS REQUIRED FOR THE CYLINDER TO RETRACT.

DISCONNECTING THE AIR SUPPLY PRIOR TO PRESSING THE EMERGENCY STOP BUTTON WILL NOT RETRACT THE PRESS. TO CLEAR

THE EMERGENCY STOP, TWIST THE BUTTON TO RELEASE. THIS WILL REBOOT THE SYSTEM AND RETURN YOU TO THE MAIN MENU.

THE HEATERS WILL BE OFF AT THIS POINT.

WARNING: DO NOT PRESS ANYTHING OTHER THAN SOFT PLANT MATERIALS IN THE PIKES PEAK, PIKES PEAK V2, OR LONGS PEAK

PRESS. PRESSING OTHER OBJECTS WILL VOID THE WARRANTY.

WARNING: WHEN USING ISOPROPYL ALCOHOL TO CLEAN THE HEAT PLATES THE POWER SHOULD BE DISCONNECTED, AND THE

HEAT PLATES SHOULD BE AT ROOM TEMPERATURE. ALWAYS WEAR GLOVES AND EYE PROTECTION.

6

information

carefully prior to

press operation!

1.5 Uncrating Your Press

7

Steps to Safely Uncrate Your Press

Note: Use two people to lift the press safely.

1. Using a Phillips screwdriver or power tool,

remove wood screws from top lid. (Figure 1A)

2. Lift off crate cover.

3. Remove contents from top section and remove

crate shelf. (Figure 2A)

4. Remove the loose foam packing blocks around

the press (some foam blocks are glued to the

crate itself - do not remove them).

5. Using the two straps around the press pull

straight up to remove the press from the crate

and set on a sturdy table. (Figure 3A)

Figure 1A

Figure 4A

Figure 2A

6. Remove the plastic wrapping and set your Dual

Pressure kit as well as your vertical legs aside.

7. Turn your emergency stop button clockwise to

release.

8. Turn your Speed Controller knob all the way

counter clockwise to open the valve. This will

allow the plates to fully actuate.

Note: Your press comes set up in

2. Press Setup

the horizontal orientation for shipping

purposes.

8

Vertical vs. Horizontal Orientation

Most users will encounter greater utility and productivity using the Pikes Peak V2 or Longs Peak rosin press in the vertical orientation.

This is because loading and unloading bags and parchment tends to be easier. It is our recommendation that you become familiar

with the press in the vertical orientation first, and then move to the horizontal orientation if desired.

For horizontal orientation pressing, virtually any of our silicone products or parchment paper works well as a collection surface.

2.1 Vertical Orientation Setup

Note: Leave leg bolts barely loose

so the press can be leveled before

tightening in place.

9

Vertical Orientation Setup

Warning: HEAVY EQUIPMENT! Two people

recommended for setting up the press vertically or

horizontally.

1. The vertical orientation requires the two triangular

shaped legs. To change to the vertical orientation from

the default horizontal orientation, carefully bring the two

front legs off the edge of a table while ensuring the press

will not fall forward. (Figure 1A)

2. Using a ¼” Allen wrench or bit, remove the (qty4)

screws securing the horizontal legs as well as the (qty2)

adjacent screws just above them. Remove legs on both

sides. (Figure 2A)

3. Line up each vertical triangular leg to the three blank

holes on the side of the frame and then replace the (qty

3) screws on each side. (Figure 3A)

Vertically Oriented Pikes Peak

Figure 2A

Figure 1A

Figure 3A

4. Then, fasten leveling feet into place, and lift the press

into the full upright vertical orientation.

5. Place the touchscreen display enclosure to the recessed

position so it is flush with the front of the press.

2.2 Horizontal Orientation Setup

10

Horizontal Orientation Setup

Warning: HEAVY EQUIPMENT. Two people

recommended for setting up the press vertically or

horizontally.

1. The horizontal orientation requires the two short

rectangular legs. To change to the horizontal orientation

from the vertical orientation, first lean the press slightly

forward and have a friend unscrew the leveling feet.

Then, re-screw two of the leveling feet into the two

holes on back of the press, near the top.

2. Next, carefully lay the press on its back and using a ¼”

Allen wrench or bit, remove the (qty6) screws securing

the vertical legs. (Figure 1A)

3. Line up each horizontal rectangular leg to the two blank

holes on the side of the frame and then replace the (qty

2) screws on each side. (Figure 2A). Put the additional

remaining screw in the empty holes on each side.

Horizontally Oriented Pikes Peak

Figure 2A

Figure 1A

Figure 3A

4. Then, fasten leveling feet (qty2) on the bottom screw

hole ports of the horizontal rectangular legs. (Figure

3A)

5. Slide your press back so it sits securely on your table

for operation.

2.3 Vertical Dual Pressure

Installation

11

Note: Your Dual Pressure system installs

easily in both the horizontal and vertical

orientations with just a Phillips screwdriver.

There is a separate bag included in your

press kit with additional pneumatic tubing for

the horizontal setup..

Hooking Up Your Dual Pressure Regulators

Vertical orientation installation detailed below

1. Unscrew the black collar nuts (qty2) atop each regulator and

remove the aluminum mounting bracket. Using the short screws

(qty2), attach the bracket to your press. (Figure 1A). Tighten

them with your Phillips screwdriver. For horizontal setup, simply

install the bracket perpendicular to this so that the regulators are

always vertically oriented. This allows the condensate trap to

function properly.

2. Take your Dual Pressure regulators and re-insert both through

the mounting bracket. Then, re-screw on your black regulator

collar nuts onto both sides so they are hand tight. (Figure 2A)

3. Next, using the long screws (qty3) provided, attach your Dual

Pressure toggle switch and tighten each screw. (Figure 3A)

4. Attach your short pneumatic hose from the toggle switch to the

push connect fitting on the press, and then attach the pneumatic

hoses from the Dual Pressure regulators to the toggle switch.

(Figure 4A)

Figure 1A

Figure 2A

Figure 3A

Figure 4A

5. In the vertical orientation, your pneumatic tubing from the Dual

Pressure regulators should cross and all push fittings should be

firmly seated.

2.4 Horizontal Dual Pressure Installation

12

Note: Your Dual Pressure system installs

easily in both the horizontal and vertical

orientations with just a Phillips screwdriver.

There is a separate bag included in your press

kit with additional pneumatic tubing for the

horizontal setup.

Hooking Up Your Dual Pressure

Regulators

Horizontal orientation installation detailed below

1. Unscrew the black collar nuts (qty2) atop each regulator and

remove the aluminum mounting bracket. Using the short

screws (qty2), attach the bracket to your press. (Figure 1A).

Tighten them with your Phillips screwdriver. For horizontal

setup, simply install the bracket perpendicular to this so that

the regulators are always vertically oriented. This allows the

condensate trap to function properly.

2. Take your Dual Pressure regulators and re-insert both

through the mounting bracket. Then, re-screw on your black

regulator collar nuts onto both sides so they are hand tight.

(Figure 2A)

3. Next, using the long screws (qty3) provided, attach your

Dual Pressure toggle switch and tighten each screw.

(Figure 3A)

Figure 1A

Figure 2A

Figure 3A

Figure 4A

4. Attach your short pneumatic hose from the toggle switch to

the push connect fitting on the press, and then attach the

pneumatic hoses from the Dual Pressure regulators to the

toggle switch.

5. In the horizontal orientation, your pneumatic tubing from the

Dual Pressure regulators should not cross and all push

fittings should be firmly seated. (Figure 4A)

2.5 Automated Pressure Control

Installation

Note: Your Automated Pressure Control

system also installs easily in both the

horizontal and vertical orientations with just a

Phillips screwdriver.

13

Hooking Up Your Automated Pressure

Control Regulator

Vertical orientation installation detailed below

1. Unscrew the black collar nut (qty1) atop the regulator and

remove the single hoop aluminum mounting bracket. Using the

short screws (qty2), attach the bracket to your press. (Figure

1A). Tighten them with your Phillips screwdriver. For horizontal

setup, simply install the bracket perpendicular to this so that

the regulator is vertically oriented.

2. Take your single regulator and re-insert it through the mounting

bracket. Then, re-screw on your black regulator collar nut onto

both sides so they are hand tight. (Figure 2A)

3. Next, attach your short pneumatic hose from the left side of the

air regulator to the push connect fitting on the press by

carefully pushing it into the black hose port. (Figure 3A)

Figure 1A

Figure 2A

Figure 3A

4. Finally, ensure that your push connect fitting is snug by

gently pulling on it to ensure it’s seated fully.

For horizontal installation, repeat these same steps and make

sure to mount your regulator bracket and regulator so that its

cap is upward.

All other components of your Automated Pressure Control unit are

internally mounted and ready to operate once your air regulator has

been properly installed as shown here.

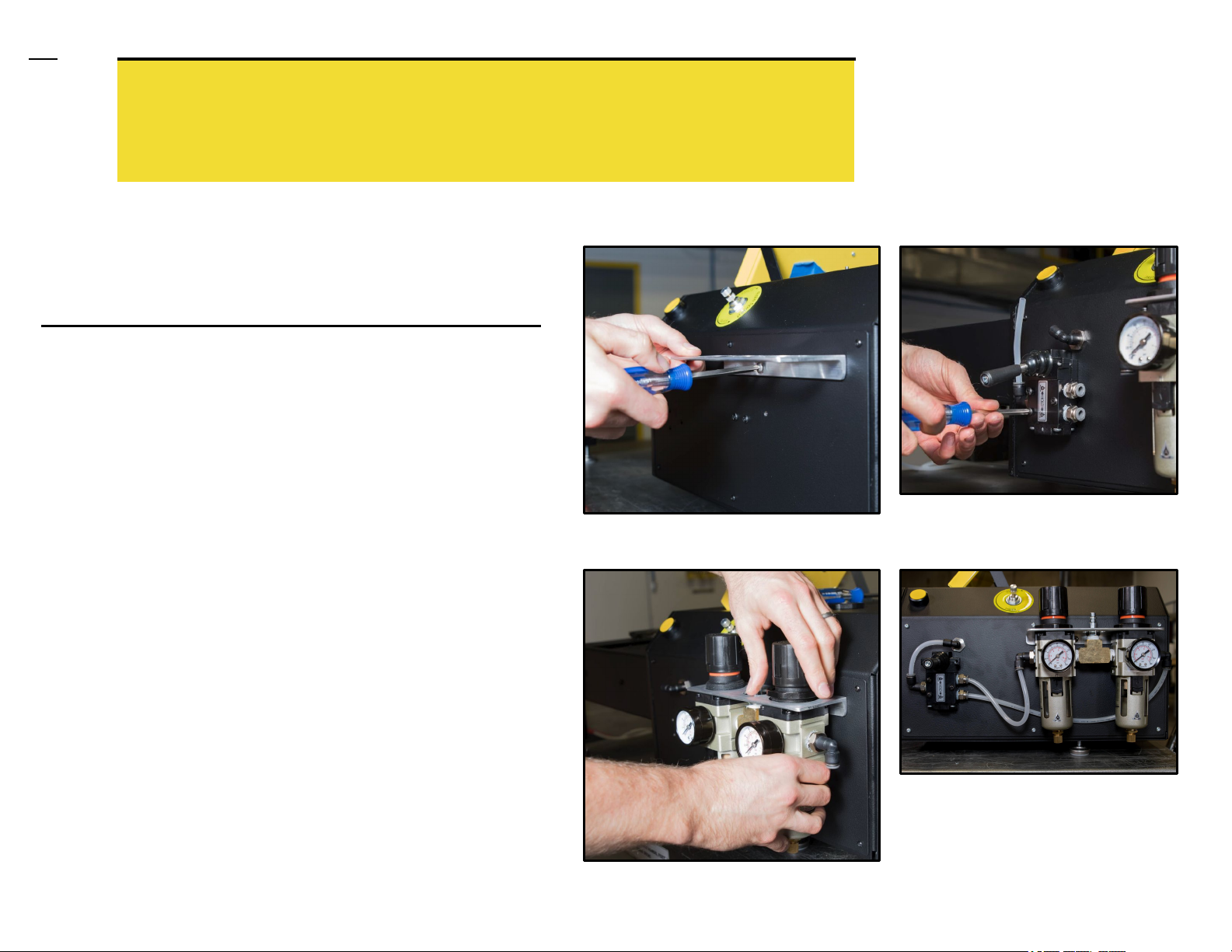

2.6 Using Push Connect Fittings

Attaching & Using Push Connect Fittings

14

Your push connect fittings securely hold your

pneumatic tubing in place.

To Insert:

1. Simply take your pneumatic tubing and insert it as far into the

fitting as it will sit. (Figure 1A)

2. Verify it is fully connected and seated by gently pulling back on

the hose. It should not give and will remain secured.

To Remove:

1. Using your fingers, push down on the grey ring as much as

you are able (it will only move downward a tiny bit).

2. While pushing down on the grey ring, gently push the

pneumatic hose into the fitting, and then pull outward to

remove. If it is not releasing, push down slightly harder onto the

grey ring to release the tubing.

Figure 1A

2.7 Electrical Power

Power Module

Your press kit will come with an appropriate power cable

for your location.

Power Draw: 8 amps while heat ramping, 2 amps

continuous draw.

Emergency Stop: In the event of an emergency, pushing the

E-Stop button disconnects power to the heaters and the

solenoid valve. Disconnecting power to the solenoid valve will

Figure 1A

15

Note: Your product serial label will indicate if

your press is rated for 120/240VAC or just

120VAC. The fuses on this machine should

now under normal operation. Should your

fuses blow, it is likely that there is a problem

with the supplied power.

cause the plates to immediately retract so long as an air

supply (10 PSI minimum for the Pikes Peak and 20 PSI

minimum for the Longs Peak ) is supplied.

Fuse Replacement

1. Ensure the power switch is in the OFF position and remove the

power cable. Wait for at least 60 seconds.

2. Using a small screwdriver, gently pry loose and remove the

fuse holder. (Figures 1A, 2A)

3. Carefully replace the fuses [Fast Acting 250V, 10A, 5mm x

20mm]. (Figure 3A)

Figure 2A

Figure 3A

2.8 Compressed Air

Pneumatic Operation

16

Note: The Pikes Peak V2 (5 PSI

minimum) and Longs Peak (5 PSI

minimum) both require compressed air

supply to actuate the plates down as

well as to retract them.

Both the Pikes Peak V2 and Longs Peak require clean, dry compressed

air for long term reliability. While there are many brands and types of air

compressors, we specifically suggest a California Air Tools

CAT15020C, Quincy QT54 package, or a Chicago Pneumatic QRS air

compressor depending on your total compressed air needs, which can

all be found on our website at at www.purepressure.com.

Please contact us if you are unsure which air compressor to get and we

would gladly help you select the right unit! Make sure to check out our

Universal Air Compressor Connection kit if you aren’t sure which tubing

and fittings you may need.

Pikes Peak V2 Recommended Air Compressor Specifications

Maximum PSI: 140 +

CFM Output: 2.1 +

Storage Tank Size: 30 gallons +

Longs Peak Recommended Air Compressor Specifications

Maximum PSI: 150 +

CFM Output: 2.7 +

Storage Tank Size: 30 gallons +

Figure 1A

¼” Industrial Quick Connect Fitting

If you do not already have the necessary fittings and tubing, check out

our Pneumatics Kit on our website. To hook up your air compressor,

attach your pneumatic hose from your air compressor to your Pikes

Peak V2 or Longs Peak rosin press with a ¼” industrial quick connect

fitting. (Figure 1A)

3. Rosin Extraction Basics

Rosin is created with heat, pressure, and

17

filtration.

● The heat being applied to your material liquefies the

glandular trichome heads present in cannabis, then

the pressure forces the resulting cannabinoid-rich oil

through the filtration media.

● Technically speaking, rosin is a mechanical

separation process, as opposed to a true

“extraction”. However, the term extraction is used

interchangeably with solvent-based and solvent-less

processes.

● Rosin can be produced with a variety of different

textures or consistencies and has a potency level

that is on par with hydrocarbon-based extraction

(60% - 90% +). Rosin can also often be extremely

terpene-rich and aromatic if high quality material is

being pressed.

● Different materials, strains, growing media, and other

factors contribute to the yield and quality of your

rosin. We encourage ample experimentation with

your material to dial in the perfect settings with your

PurePressure rosin press to get the best results

possible!

Consistencies & Textures

Lower temperatures tend to produce

budders and batters, where higher

temperatures can often produce a shatter

or oil-like consistency. Depending on your

material, rosin can be made into sugar,

wax, shatter sauce, budder, and more!

Live Rosin

Live rosin is made by washing fresh frozen

cannabis into bubble hash and then

pressing it into rosin. For optimal results,

use a freeze dryer to dry your hash in order

to get the best color and terpene profile.

3.1 Tips & Tricks

18

Top Rosin Tips

1. For the best, lightest color possible, use

extremely fresh dried material.

2. Always make sure your flower is properly

cured. Flowers should be between 55% - 62%

RH in the jar for optimal yields with flower rosin.

3. Quality in = quality out. Use the best material

available for stellar results.

4. Typically higher temperatures will increase yield

and decrease terpene preservation. Lower

temperatures will ensure the highest level of

terpene preservation but tend to decrease

yields. Press accordingly!

5. For optimal terpene preservation, do not press

rosin above 220 °F unless you know what you

are doing.

6. Making rosin is easy. Stick with it and keep

experimenting with your variables until you get

it just right for your material.

Tricks to Help You Press Amazing

Rosin

1. Making great rosin always starts in the garden.

Certain strains will over perform, and others will

underperform, so always go into the process with

quality in mind.

2. Press within a few weeks after harvesting, if

possible. Older material tends to underperform both

with yield and clarity. As your material ages, it

oxidizes and chemical changes occur within the

cannabinoids themselves, making it both less potent

and less terpene-rich.

3. Store your rosin in an airtight container within a

cooled environment (such as a refrigerator or

freezer) to preserve terpenes and texture.

4. Experiment with different starting materials. If you

normally press flower, try your hand at making

bubble hash or tumbling some kief. The possibilities

with rosin are endless - fresh frozen live rosin, rosin

sauce, solvent-less THCA separation, and more can

be made with a PurePressure rosin press.

3.2 Choosing Your Material

19

Starting Material and Filter Type

1. First and foremost, you will need to choose what kind of starting material you intend to press into rosin. The

most common materials used in this process are freshly dried cannabis flowers, kief (or dry sift), or ice water

bubble hash. We do not recommend pressing trim as-is because of the amount of inert plant material your

oil must travel through to escape the bag. You will achieve greater yields and a better product sifting your

trim first.

2. Next, you’ll need to select the micron filter size you wish to use. A larger micron number corresponds to

larger pore openings in the mesh fabric. We typically recommend 25μm or 36μm for dry sift and hash, and

115μm for flower and shake.

Bubble Hash

Dry Sift / Kief Flower Micron Usages

25μm/36μm/72μm

Ideal for bubble hash, dry sift

90μm/115μm

Ideal for flower, shake

3.3 Yield & Material Types

20

Note: Some strains tend to yield very well,

whereas others may not. Try not to get

discouraged if your yields aren’t what you

expected on your first press. Heavily

resinous, terpene-rich strains will always

yield the highest quality rosin!

PSI: The PSI on the X axis refers to the pressure at your bag, not the compressed air pressure that is available from

your air compressor.

While the Pikes Peak V2 and Longs Peak can automatically calculate bag pressure, the formula is as follows:

(Pressing Force / Bag Area (sq inches) = PSI at the Bag

Example:

(9,000 LBF) / (12 square inch bag) = 750 PSI at the bag

3.4 Filter Bag Preparation

Visit our YouTube channel for helpful

how-to videos!

@GoPurePressure

YouTube.com/c/GoPurePressure

21

Properly Filling Your Rosin Filter

Bag

1. Turn your PurePressure rosin filter bag inside out

using the Quick Flip tool. (Figures 1-3A)

2. Using the provided filling funnel, fill the bag with

your material, making sure it is evenly distributed

in the bag and that there is at least ¾” left at the

end of your bag to fold over. (Figures 1-2B)

3. Fold over the remaining, unfilled portion of your

rosin filter bag and insert the bag, folded-side

down, into chamber of your pre-press mold.

Replace the top of the pre-press mold and push

down with hand pressure, or use an arbor press

(1 ton max). (Figure 1C)

4. Flip your pre-press mold over, remove the top

facing plate, and press down on the middle

chamber to release your prepared rosin filter bag.

Figure 1A

Figure 2A

Figure 3A

Figure 1B

Figure 1C

Figure 2B

See page 32 in this manual for maximum recommended filling capacities

and other helpful tips for your process.

4. Pressware Controls

The Pressware Interface Allows for Total

Control

PurePressure’s Pressware has been

designed and engineered specifically for

solventless cannabinoid oil extraction.

22

Heat, press time, pressure stages for repeatable results,

and more are all custom controlled by the most

consistent results in the market. With individually

customizable pressure stages and ultra accurate

temperature control, you can ensure that your results

are always consistent.

In the settings menu, you can also modify the interface

units individually to be metric or imperial.

Depending on which pressure control unit you’ve

purchased, there will be different options available for

the manual Dual Pressure versus the Automated

Pressure presses. You can upgrade your press to the

Automated version at any time by

www.purepressure.com and purchasing the upgrade

kit.

Save Up to 29 Recipes Touchscreen LCD Tech

In the following sections we will cover exactly how to

use your Pressware controls and how you can get the

most out of your PurePressure rosin press.

4.1 Home Screen

23

The Home Screen appears after startup from this screen you can manage heater settings, view active

pressure values, view a loaded recipe and navigate to a variety of menu options. You cannot press while on

the Home Screen.

1: Heaters 1 and 2

Tap to turn your upper and

lower heaters on and off.

2: Quick Press

Start pressing immediately

with your current settings.

You can also save your Quick

Press settings in order to

build a new recipe from the

Last Run Data tab.

3: Run Recipe

Load and use an existing

pre-made or custom recipe.

4: Last Run Data

View the data from your last

pressing operation. This

includes heat, time, pressure,

and pressure stages.

5: Temperature Settings

Tap to set and change your temperature on

your top and bottom plates; red indicates

the plate surfaces are hot enough to burn

you.

5

1

2

3

4

6: Loaded Recipe

If you’re running a recipe, it will

display which one you are using

here.

6

9

10

11

7: Home Button

Return to the home screen at any

time.

8: Force Toggle Button

7

8

1) Tap to view your total available

force, compressed air PSI, and

pressure at the bag (if set).

2) You may also adjust your

pressure digitally with the

Automated Pressure system here

as well.

9: System Settings

Review and adjust your values for

Imperial or Metric as well as your

desired buzzer sound level and

adjust operating voltages.

10: Recipes

View, save, edit, and load all of your

pre-saved recipes - you may have

up to 30 saved at one time.

11: Contact Info

Return to the home screen at any

time.

Note: Adjusting the

temperature or pressure units

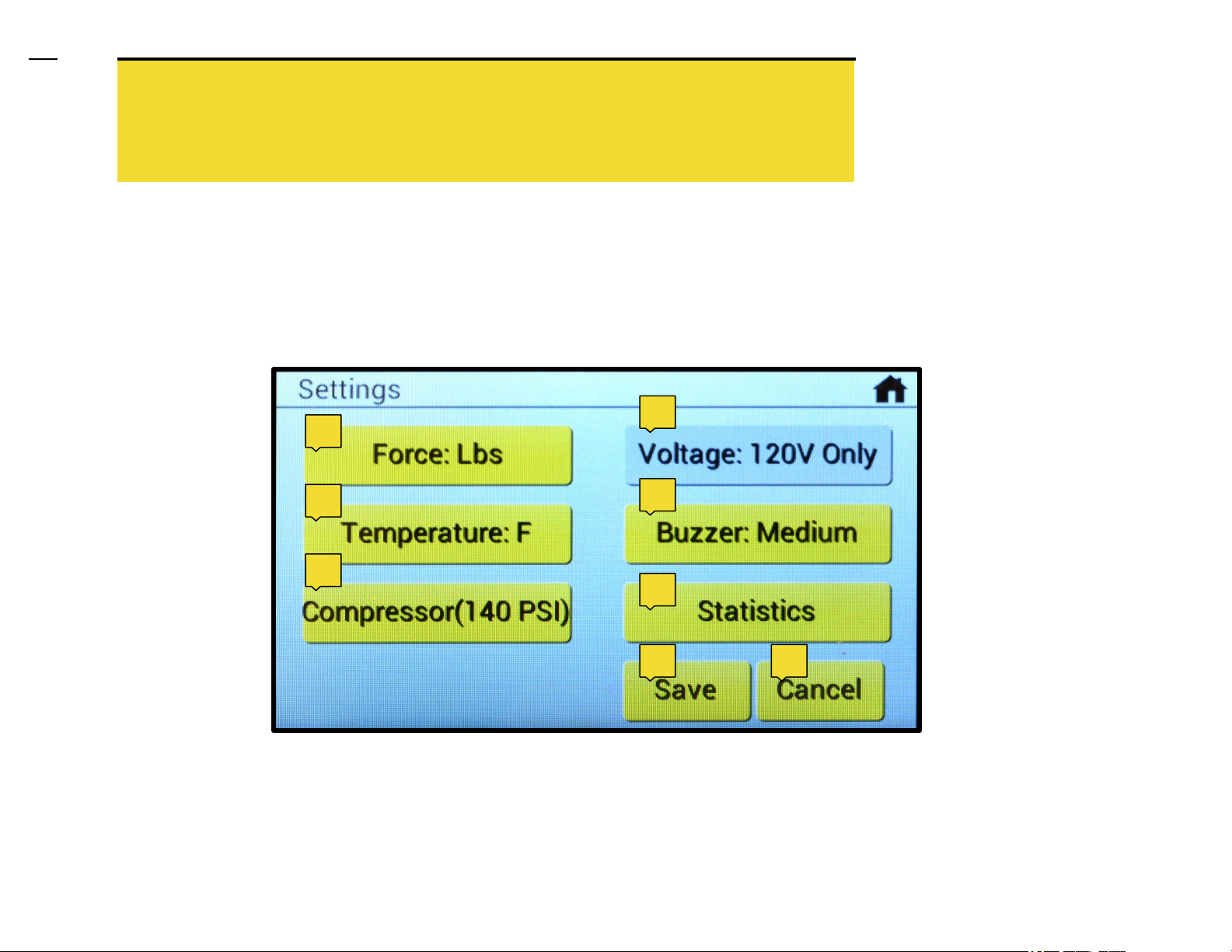

4.2 System Settings

24

will require you to convert

these values manually in any

saved recipes.

You can adjust your System Settings at any time. This will allow you to change a few key things, including

whether your press displays numbers in Imperial or Metric, as well as how loud you want the beeping

indicator to be (you can also silence it) to alert you during cycle pressure changes.

1: Force

Displays in either LB or KG.

2: Temperature

Displays in either Fahrenheit

or Celsius.

3: Compressor

Max air pressure setting. Not

available on Dual Pressure

systems.

4

1

2

5

Displays 120 or 240

depending on your system’s

capabilities. If this option is

not available, your press is

only capable of operating on

120 VAC.

5: Buzzer

4: Input Volts

3

6

7 8

Noise settings available are

high, medium, low, and silent

or off.

6: Statistics

This tab offers detailed

information about your press,

usage stats, and error codes

for debugging if necessary.

7: Save

Saves your settings.

8: Cancel

Exits the menu without saving

any changes.

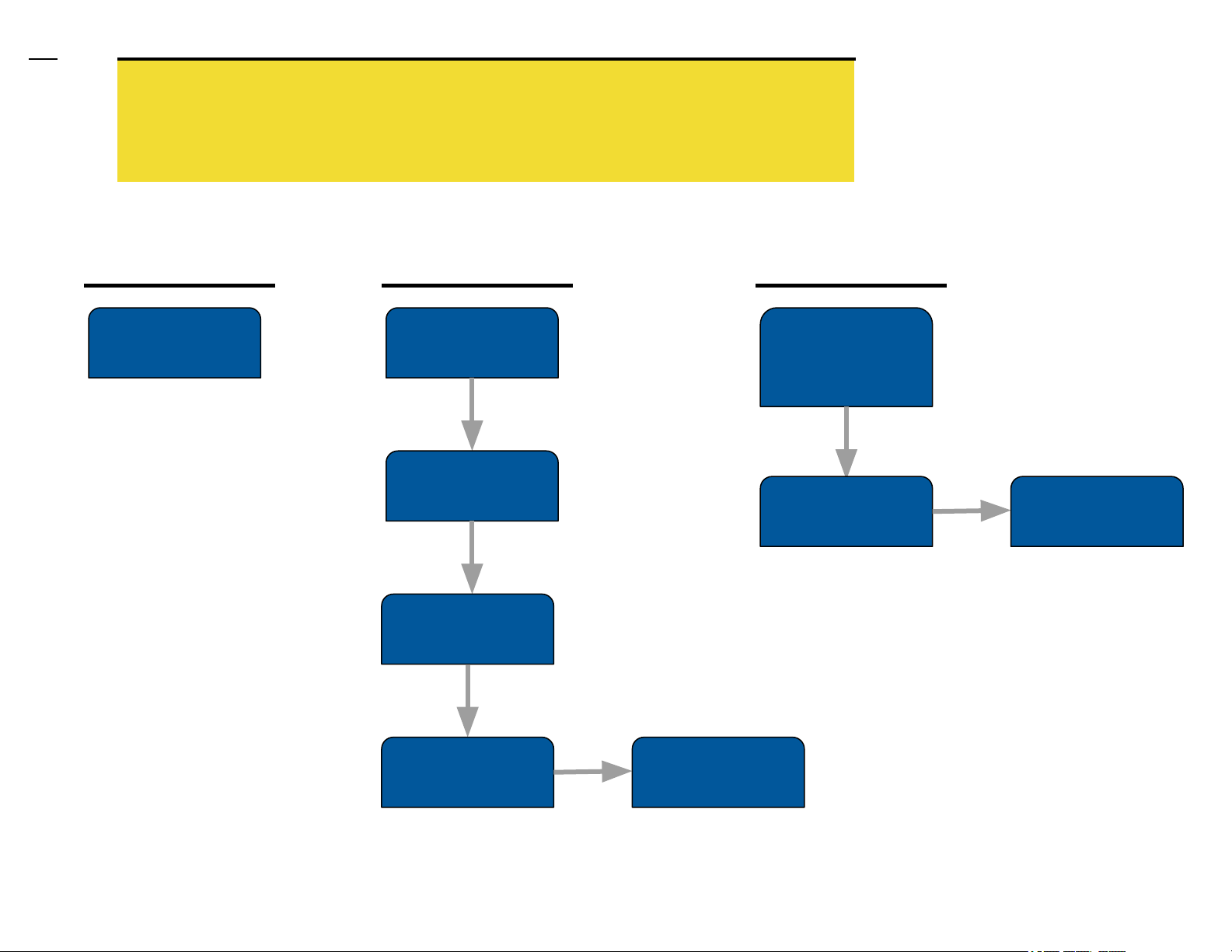

4.3 Workflow Overview

25

One-off Press

Quick Press

Creating a Recipe

Quick Press

Last Run

Data

Edit Recipe

Pressing a Known Material

Recipe / Run

Recipe

Select

Repeat

Run Recipe

Recipe

Run Recipe

Repeat

Recipe

Note: When using the Automated

Pressure system, whenever you use the

4.4 Quick Press

26

force increase or decrease buttons, the

Air Pressure toggle will turn yellow and

wait two seconds to accept the value

before executing the command.

Quick Press is one of Pressware’s most powerful features because it allows you to

save your parameters into a recipe for later use! Set your temperature and starting pressure,

and then begin pressing using two yellow start buttons. Hold for 5 seconds to fully initiate the press.

● Using the Quick Press menu is the

easiest way to start pressing and

figure out how to run a good recipe

for your material. It will enable you to

store up to 6 pressure stages and

the time you spent on each.

● When using the Automated

Pressure system, your pressure

stages will be logged automatically

as you change pressure.

● When using the Dual Pressure

system, simply hit “Next Stage” to

record your maximum force and

initiate the next stage.

Note: Your notification bar will display your current stage, any notifications,

errors, and so on.

● Once you get the perfect press from

your material, you can then view

your Last Run Data and save all of

your settings into a stored recipe!

Note: For each pressure stage, the total time spent and maximum pressure

achieved is what will be recorded. On the Dual Pressure system, you will need

to manually hit “Next Stage” to record the next stage.

4.5 Last Run Data

27

Once you’ve pressed, the Last Run Data menu will tell you exactly what you did

and how you did it. You can save this information directly into a new recipe, or just look to see

what you want to change for your next press.

1. The press records your set

temperature, total press time,

pressure, and pressure stages from

your most recent press cycle.

2. The Last Run Data menu is the most

accurate way to dial in your settings

by learning what you did and then

adjusting from there.

1

3. Easily save your Last Run Data

settings directly into a new Recipe,

where you can make changes or

re-use those settings at will.

2

3

Note: These inputs are dependent on the user and are not automatically

captured by the press when saved into a recipe if you are running a Quick

Press, or will display if you are viewing Last Run Data from running a

pre-existing recipe.

4.6 Edit Recipe

With Recipes, you can save every variable and then your press will run those

settings at the push of a button.

● You can store up to 29 recipes to be

repeated and used later.

● These menu options enable you to run

our pre-loaded recipes, which cover

most materials and bag sizes for instant

results.

● Recipes can be created either manually

with these menu options, or from a Last

Run Data set.

28

● Selecting a bag size will allow the press

to automatically calculate the exact

pressure at your bag.

● Recipes will automatically control your

temperature and press time. The

Automated System also saves and

executes pre-set pressure ramping.

● Material, weight, bag micron type,

actuation speed, and humidity are all for

reference purposes.

4.6.1 Edit Recipe Cont.

29

The Automated Pressure system enables you to set your pressure stages and

their times to execute automatically. The Dual Pressure system allows you to set the same

stages and times, but as a guide to follow.

6: Weight

Set the weight of your

material to have a repeatable

bag fill and make yield

calculations easier.

1: Material

Flower, dry sift, or hash.

2: Stages 1 - 6

Air pressure and pressing

time are set here, with up to

six stages possible. Select the

number of stages with the

Stages box.

3: Name

Enter a reference name for

your recipe. We recommend

entering the strain as the

recipe (and be sure to select

the material type).

4: Save

Save your recipe as-is.

7: Bag Size

Set your bag size in order for

the press to calculate

pressure accurately.

1

2

3 4 5

6 7 8 9 10

8: Micron

Choose the ideal filter micron

for your material.

13

9: Speed

Choose Fast, Medium, or Slow as a

reference for your plate actuation speed,

which is controlled manually with the

speed dial.

10: Humidity

Set the relative humidity value

of your material, if desired.

11: Heater 1 and 2

Set the top and bottom plate

temperatures for your recipe.

12: Cancel

11

Exit the Edit Recipe menu and

discard any changes you

have made.

13: Delete

Erases and deletes your

recipe permanently. Your

settings will not be

recoverable after deletion.

12

5: Save&Run

Saves and brings you to the

Run Recipe screen to be

used immediately.

4.7 Preset Recipes

With the Automated Pressure Control interface, you can select a material type

and a bag size - the system will populate an automatic recipe that will do the rest.

● Tap the “Material” button to

select what you are planning to

press. The available options are

Flower, Kief, and Hash.

● Then, hit the “Bag Size” button

to select which sized bag you

intend to use.

30

● Once these two selections have

been made, your press will

automatically load an

appropriate recipe that you can

simply run.

● Once you run these recipes, you

can then modify time,

temperature, pressure, and so

on to easily make your own

special recipes with your

material, via Last Run Data.

4.8 Recipes (List)

From the Recipes screen, all of your saved recipes are stored and catalogued.

● Each page displays 5 recipes, including

their name, material, weight, bag size,

and micron type (if set).

● To access a specific recipe, simply tap

the name to enter the “Edit Recipes”

screen.

● There are a maximum of 29 total open

recipe slots on both pressure systems.

31

● Any recipe that has been created and

stored is available in this menu subset.

Hit “Page Down” to scroll through all

stored recipes.

● You can also return to the home screen

from the “Recipes” list by hitting

“Home”.

4.9 Run Recipe

From the Run Recipes screen, you can automatically load any saved recipe to be

used immediately. There are two ways to run a recipe. First, you can load a recipe from the “Run

Recipe” off of the home screen, or you can select the recipe you wish to use from the “Saved Recipes” list.

● By hitting the “Load Recipe” button

underneath the “Air Pressure” toggle,

you will be taken to the “Saved Recipes”

list to choose the recipe you wish to run.

● From there, it will take you directly to the

“Recipe” settings menu of your choice.

● Simply hit “Save&Run” at the bottom to

load you recipe and begin using it.

32

● Ensure that your temperatures have

stabilized and your input pressure from

your air regulators is accurate before

initiating your press. This helps ensure

your recipe is executed correctly.

4.10 Pre-heat

The Pre-heat function is available only for Automated Pressure Control systems

and enables you to warm up your bag while applying zero force. This feature is

especially helpful when pressing high quality ice water hash and sift, but is also useful for pressing flower too.

● Once you press the Pre-heat button it

will highlight yellow, indicating it is

enabled.

● Next, press your two start buttons,

which will enable a slow descension of

your plates.

Note: Your press will need at least 5

PSI to descend the plates but when

stopped will not apply any force.

33

● Simply release the two start buttons

once your plates have made contact

with your bag.

● Finally, once you are when you are

ready to apply force, tap the Pre-heat

button once more (it will return to a grey

color) and hold the two start buttons for

5 more seconds as you normally would

to start your press cycle.

4.11 Software Updates

34

With PurePressure’s Pressware Connect

software, you can always stay up to date with

the latest version of our firmware.

1. Using a T15 or T10 (depending on unit) torx screwdriver [star bit],

remove the 11 screws and the top panel from your rosin press.

(Figure 1A)

2. Set your screws and panel aside, and then locate the USB-B port

on top of your electrical panel. (Figure 2A)

3. Using a USB-A to USB-B cable (also known as a standard printer

cable), plug your press into a Windows or Mac computer and run

the Pressware Connect application.

4. Whenever firmware updates are released, we will automatically

email you the file that you need.

Figure 1A

Figure 2A

USB-B Port

5. Next, visit Downloads

(https://gopurepressure.com/pages/downloads) to download the

appropriate files you will need. Make sure to select either the

correct Windows or Mac file version depending on your computer.

6. Once downloaded, unzip and open the files contained within the

firmware update folder. There will be step-by-step instructions

included that are specific for either operating system to update

your firmware to the latest version.

5. Press Operation

35

Loading and operating your PurePressure rosin press is simple and intuitive.

In the following sections, we will cover how to best operate your press.

Basic Steps to Start Pressing

1. Turn your press on.

2. Set your desired temperature(s) and then turn on

your top and bottom heaters.

3. Set your pressure with the air regulators.

4. Load your parchment into the front and rear

parchment clips, and then your bag between the

parchment.

5. Hit the two yellow buttons and start pressing!

5.1 Loading the Press

First, prepare your work area by having your

pre-filled filter bags and parchment paper

ready to go.

WARNING: be mindful of your heated press

plates!

Step 1: Fold a 12” x 20” PurePressure sheet of parchment

paper in half

● For vertical pressing, insert the folded end into the rear parchment clip.

● For horizontal pressing, insert the folded end into the front parchment

clip.

Note: We recommend using high

quality nitrile gloves whenever you

are working with rosin.

36

Figure 1A

Figure 2A

Step 2: Tuck the unfilled end of your rosin bag underneath

itself and then carefully insert and center your rosin filter bag

on top of the lower bottom heat plate. (Figure 1A)

Step 3: Lastly, cover the rosin filter bag with the top

parchment fold, re-center the bag, and while using tension on

the parchment, insert the open parchment end into the

parchment clip. (Figure 2A)

● For horizontal pressing, use tension on the parchment to close it

properly so that your bag does not slip down beyond the edge of the

heat plates.

5.2 Automated Pressure Control

How to Use the Automated Pressure System

Step 1: Ensure Your Air Pressure is Set to Maximum

Your press automatically comes set to the maximum

recommended PSI, but using the Air Regulator cap you can

adjust it up or down if necessary.

Check out this video for simple, visual

instructions.

@GoPurePressure

http://bit.ly/DualPressureVid

37

2

Components:

1. Air Regulator

2. Twist Cap

Recommended Regulator Settings

Pikes Peak: 120 PSI (set to maximum)

Longs Peak: 140 PSI (set to maximum)

Step 2: Adjusting Your Pressure

You can adjust the pressure either in the Quick Press menu

(described on slide 26) while pressing, or with the Air Pressure toggle

screen, which is show here (Figure 4). You can set your force either

in PSI or LBS, depending on your preference. Simply use the three

arrow button next to the Air Pressure menu option to toggle your

force selection.

Simply put in the pressure you wish you achieve and the system will

do the rest. When you are doing a Quick Press, your Automated

Pressure system will automatically record each pressure increase up

to 6 stages so you can save that into a new recipe, which will

increase in pressure just as you did.

Note: We recommend doing a few dry runs using the

Automated Pressure system to get a hang of it before you do

your first press.

1

3

3. Pressure

Gauge

4

5.3 Dual Pressure Control

How to Use the Dual Pressure System

Step 1: Set Regulator Pressures

To adjust pressure, pull up on the air regulator caps so that the

orange band is showing. Turn clockwise [right] to increase

pressure, and counterclockwise [left] to decrease pressure.

Check out this video for simple, visual

instructions.

@GoPurePressure

http://bit.ly/DualPressureVid

38

Components:

1. Regulator A,

Note: When decreasing pressure, it is important to go well below the

set point and then increase pressure to your desired set point. If this

is not performed as described, the pressure will drop as soon as air

begins to flow through the regulator. You may then increase the

pressure to your set point and it will stay steady.

Recommended Regulator Settings

Pikes Peak A: 5 PSI, B: 120 PSI

Longs Peak A: 5 PSI, B: 140 PSI

Note: you must operate your A regulator as the low pressure

regulator, and your B regulator as the high pressure regulator. If

you reverse this, it will cause solenoid/air signal malfunction.

Step 2: Using the Toggle Switch

The press will draw pressure from whichever regulator the toggle is

positioned towards, and will hold pressure (air is trapped in the

cylinder and applies a consistent pressing force) in the HOLD

position (middle).

To increase pressure slowly, move the toggle to the middle position

and then “bump” it to the right for approximately 1-2 seconds, and

then return to the HOLD position. Repeat 2-3 times until you achieve

the desired maximum pressure.

A B

C

used for low

pressure [left]

2. Regulator B,

used for high

pressure

[right]

3. Pressure

Toggle

Switch

Note: We recommend

doing a few dry runs

using the Dual Pressure

system to get a hang of

it before you do your

first press.

Note: Spend some time playing with

5.4 Plate Speed Control

the speed controller to get a hang of

what the press is capable of.

39

Controlling the actuation speed of your plates is helpful depending on what material

you are pressing.

To adjust your plate actuation speed, simply turn the

dial clockwise [right] to decrease speed or

counterclockwise [left] to increase speed.

The plate speed actuation knob acts as a flow

controller which throttles the air that is exhausting

from the opposite side of the piston in the air cylinder.

This opposing air pressure is bled out at a rate

controlled by the speed dial. This also means that the

initial pressing forces is applied at that speed. This is

useful to prevent bag blowouts when pressing kief, dry

sift and bubble hash.

Recommended Usage Speeds

● Flower: fast, fully threaded out

● Kief and Hash: slow, mostly threaded in

Note: If the plate speed controller is set too slow, the plates may not

come into contact and may make a hissing sound.

Note: Check out Section 3 of this

5.5 Pressing Material

manual for top tips, tricks, and

ideas to get the most out of your

PurePressure rosin press.

40

Now it’s time to put it together and press!

Once you’ve filled, packed, and gotten your bag ready to press, set your temperatures on the press. We

highly recommend using the preset recipes to begin pressing.

Step 1: Make sure your temperature and pressure

settings are set.

Step 2: Load your bag between the parchment,

ensuring it is properly centered. Then, secure both

parchment clip ends closed.

Step 3: Enter the “Quick Press” menu or load the recipe

you intend to use. You cannot operate the press from

the “Home” screen.

Step 4: Hold the two yellow buttons for 5 seconds to

initiate your press. If you release either button before

then, the press will automatically retract the heat plates.

There will be a countdown on the top.

Step 5: Once you see the oil flow slowing considerably

or stopping, end your cycle by hitting “Stop Press” or

letting the time expire on your pre-set recipe.

6. Maintenance & Troubleshooting

41

Your PurePressure rosin press is engineered to go the distance. Make sure to do

the following to ensure long term reliability.

★ Use an adequately grounded power outlet or a surge

protector.

★ Use clean, dry compressed air with your press.

★ Use your press indoors in a clean, low-dust room.

★ Use denatured alcohol or rubbing alcohol to quickly

clean your heat plates when they are at room

temperature with power disconnected.

★ If oil overflows onto the heater wires, turn the press off,

remove the power cable, and carefully clean them with

denatured alcohol or rubbing alcohol. Then, use some

extra parchment to prevent it from happening in the

future. Make sure the entire assembly is fully dry before

powering your press back on.

If you encounter an issue with your press that is not described in the following

pages, please contact us at support@gopurepressure.com

6.1 Common Issues

42

Problem: My plates won’t fully make contact.

Solution: Make sure to turn your plate speed

controller counterclockwise a few turns to open it up

as it comes threaded all the way in for shipping.

Problem: My plates aren’t retracting.

Solution: Make sure your pressure toggle switch is in

the A or B position. If it is in the hold position, it will

not be able to draw pressure to retract.

Problem: My pressure isn’t getting high enough.

Solution: Make sure the output pressure of your air

compressor is properly set. If your press is not

receiving full, adequate pressure, your regulators will

not be able to reach full pressure.

Problem: My flower isn’t yielding well.

Solution: Material relative humidity impacts flower

considerably - make sure your flower is properly

humidified to at least 55% - 62%. We recommend

using a humidor or a Boveda pack.

Problem: My bags are blowing out.

Solution: Make sure that you are starting at the

minimum pressure and that your Plate Speed Controller

is dialed nearly all the way in (clockwise) so that your

plates meet very slowly. Ramp up your pressure even

more slowly than you did before and ensure that oil is

flowing before you continue to increase pressure.

Additionally, we recommend double bagging your kief

and bubble hash until you determine safe pressure

stages, and especially if you are pressing very high grade

bubble hash. This is best done by having seams on

opposite sides, and the folded-end of the first bag

inserted downward into the second bag to ensure a fold

on both ends as well. We often double bag a 36 micron

inside of a 115 micron for the durability the 115 offers,

while getting the filtration of the 36 micron.

If you are ever blowing out a bag with flower, it is

probably because the bag is significantly over-packed

causing a blowout.

6.2 Frequently Asked Questions

43

What Micron Filter Bag Should I Use?

We typically recommend 36μm for kief and 115μm for

flower or shake to start, but highly suggest

experimenting with our 4 different micron types to see

where you find your best results.

25μm/36μm/72μm: bubble hash, kief/dry sift

90μm/115μm: flower, shake

Do I Need to Use a Filter Bag?

Unless you are pressing just a few well-humidified buds,

which you can certainly do without a bag, but otherwise,

you will need to.

At What Temperature Should I Press ?

For flower, most users find their best results between

200 °F and 220 °F. With kief or dry sift, most users find

their best results between 190 °F and 220 °F. Finally,

bubble hash, most users find their best results between

160 °F and 210 °F.

A higher temperature typically correlates to a higher

yield, but it can also mean terpene loss. Similarly, at a

lower temperature, quality tends to be higher but yields

often decrease.

What Pressure Should I Use?

For flower, use full pressure at a fast pressing speed. That

means 120 PSI for the Pikes Peak and 140 PSI for the Longs

Peak.

For kief and bubble hash, begin your press at the minimum

pressure (10 PSI) and work up from there.

How Much Should I Put in a Filter Bag?

Maximum Recommended Fill Amounts

● 2” x 3” Flower (6g) Kief/Bubble Hash (8g)

● 2” x 6” Flower (12g) Kief/Bubble Hash (16g)

● 2” x 9” Flower (18g) Kief/Bubble Hash (35g)

● 2.5” x 9” Flower (35g) Kief/Bubble Hash (70g)

How Long Should I Press For?

A good rule of thumb is that the smaller your bag is, the less

time you will need to press. Here are some general time

ranges based on bag size:

● 2” x 3” :45 - 2:00

● 2” x 6” 1:00 - 3:00

● 2” x 9” 1:30 - 4:00

● 2.5” x 9” 2:00 - 5:00

6.2 Frequently Asked Questions

cont.

How Do I Get a Lighter Colored Rosin?

Use the freshest material possible. Freshness of material is

critical to achieving clarity - the older it is, the darker it

tends to be. The sooner after harvesting and drying the

better, ideally within a week or two.

The other key factor involved in clarity is typically

temperature. The hotter the temperature, the darker it may

turn out, but only to a point. Find a balance between yield

and temperature for optimal results.

What Yields Can I Expect?

Material Yield Ranges

Flower: 15% - 30%

-Most commonly 18% - 24% with high quality material

Kief / Dry Sift: 30% - 60%

-Most commonly 40% - 50% with high quality material

44

What Strains Yield the Best?

Highly resinous, trichome-rich, and high potency strains are

always going to be your best yielders. These tend to skew more

towards indicas and hybrids, but sometimes a sativa will

surprise you!

Can I Press Trim?

We do not recommend pressing just straight trim; you will get

much better yields sifting your trim into kief first as opposed to

just pressing it as-is.

What is the Best Starting Material?

It is largely assumed that high quality bubble hash is the best

starting material for making rosin. Ultimately, it really comes

down to the quality of the starting material above all else. Ultra

premium flower will typically create a better rosin than 3 or 4

star bubble hash, however 5 and 6 star bubble hash will make

the highest value rosin.

Bubble Hash: 60% - 80%

-Most commonly 65% - 75% with high quality material

These yield ranges may vary and depend largely on the

quality and age of your material.

Should I Use Dry Ice with My Sifter for Rosin?

Using dry ice can lead to higher concentrations of undesired

plant matter into your dry sift or kief. We recommend only using

a small amount of pelletized dry ice (around the size of a grains

of rice), or even better, not using dry ice at all, if possible.

720-446-9565

purepressure.com

Sales Inquiries:

sales@gopurepressure.com

General Questions:

info@gopurepressure.com

Technical Support:

support@gopurepressure.com

@gopurepressure

User Manual R2.2

We’re always here to help.

Loading...

Loading...