Page 1

www.purelogic.ru

Moscow +7 (495) 505 63 74

Voronezh +7 (473) 204 51 56

Contacts:

sales@purelogic.ru

149 Office

160, Leninsky avenue

Voronezh, Russia, 394033

Monday - Thursday: 8.00–17:00

Friday: 8.00–16.00

Break: 12.30–13.30

INSTRUCTION MANUAL

SMC4-4-16A16B

Four-axis motion controller

We draw your attention to the fact that there can be some changes in this instruction

due to the product consistent technical improvement.

Page 2

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

2

www.purelogic.ru8 (800) 555 63 74

SAFETY PRECAUTIONS

Before using this control system, please read this manual carefully before do related operations.

Carefully read the operating instructions and user Safety Precautions, the user should do the appropriate protection, take the necessary security

measures before proceeding to operate.

First time operation of the operator, should know the proper use of the corresponding functions, you can perform the appropriate action, For those

unfamiliar the functions or parameters, Prohibited actions or change system parameters.

System maintenance:

When the system is under unusual circumstances, the need to repair the appropriate cable or socket connection, you should turn off power. And then

make the necessary repair.

The operator has not been rigorously trained or authorized by the studio units or individuals, can not open the control system for maintenance

operations, modification, repair, and other acts.

Other matters:

If there is any system functions is different from the manual,please with system software features to prevail.

Control system functions to change or improve (upgrade), without notice. If you have other requirements, please contact us.

OUTLINE

Our latest «motion controller» using high-performance 32-bit CPU,with an LCD display, Humanized Window-type interface, Using external TF card

memory, storage space than 2G, Operating voltage and control voltage using isolation mode, and touch keyboard. The system has high reliability, high

precision, low noise, easy operation characteristics.

The controller can four simultaneous axes,multiple micro segment look ahead control algorithm, The controller can four simultaneous axes,multiple

micro segment look ahead control algorithm, can be achieved with four - axis straight line interpolation and a micro multi-line multi-axis continuous

interpolation,controlled by a breakpoint carving.

Simple, clear parameters for your convenience and fast operation. Input / output can be set up functions to facilitate your use and maintenance.

The main function:

Parameter settings: You can set the processing and operations relating control parameters, Making process to achieve the best condition.

Manual operation: can be achieved manually, jog,back to procedure zero, back to mechanical zero, cleared coordinate operations.

Program Management: Program can create, delete, modify, read, preserve, automatic processing, continuous, and pause.

Page 3

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

3

www.purelogic.ru8 (800) 555 63 74

External Manual: a variety of external functions can be defined Manually,In order to facilitate the use of the freedom to select the input function: the

limited input can achieve a variety of user needs.

System components:

CNC system mainly consists of the following parts:

High-performance, high-speed 32-bit ARM CPU;

Liquid crystal display (resolution: 320 * 240);

Input / Output (16 channels opto-isolated 10MA inputs, 16 channels opto-isolated pull-down tank 500MA output).

Users machining program memory can be arbitrary Storage in TF card.

Technical indicators:

The smallest unit of data 0.0001mm

The maximum data size ± 99999.999mm

Maximum pulse output frequency 50KHZ (three-axis simultaneous 50KHZ)

Control axes 4 axes (X, Y, Z, A)

4-axis intermodal and has a four-axis multi-micro multi-segment prospective interpolation control

Appearance and Panel: Dimensions: length 165, width 101, thickness 50

External view:

Page 4

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

4

www.purelogic.ru8 (800) 555 63 74

OPERATING INSTRUCTIONS

Boot screen:

This boot interface is divided into four zones:

• The top district: the main display file name now opens, real-time the number of processing rows.

• The coordinate display area: The main display real-time three-axis coordinate and real-time processing speed.

• The function key area: the main control keys.

• T file area: file name, or processed documents.

(Note: TF card support hot swap, when the new insert TF card, need to initialization after re-insert, so sometimes prompts OPENER, Just several

times «open file»!)

Because the system requirements for the TF card data is extremely strict, so the general low-end cards (cottage card) will be excluded, and then

replace the other genuine card reading! ! ! For HDSD (TF), because of the card problem, and can not fully understand, replace other cards and then read!

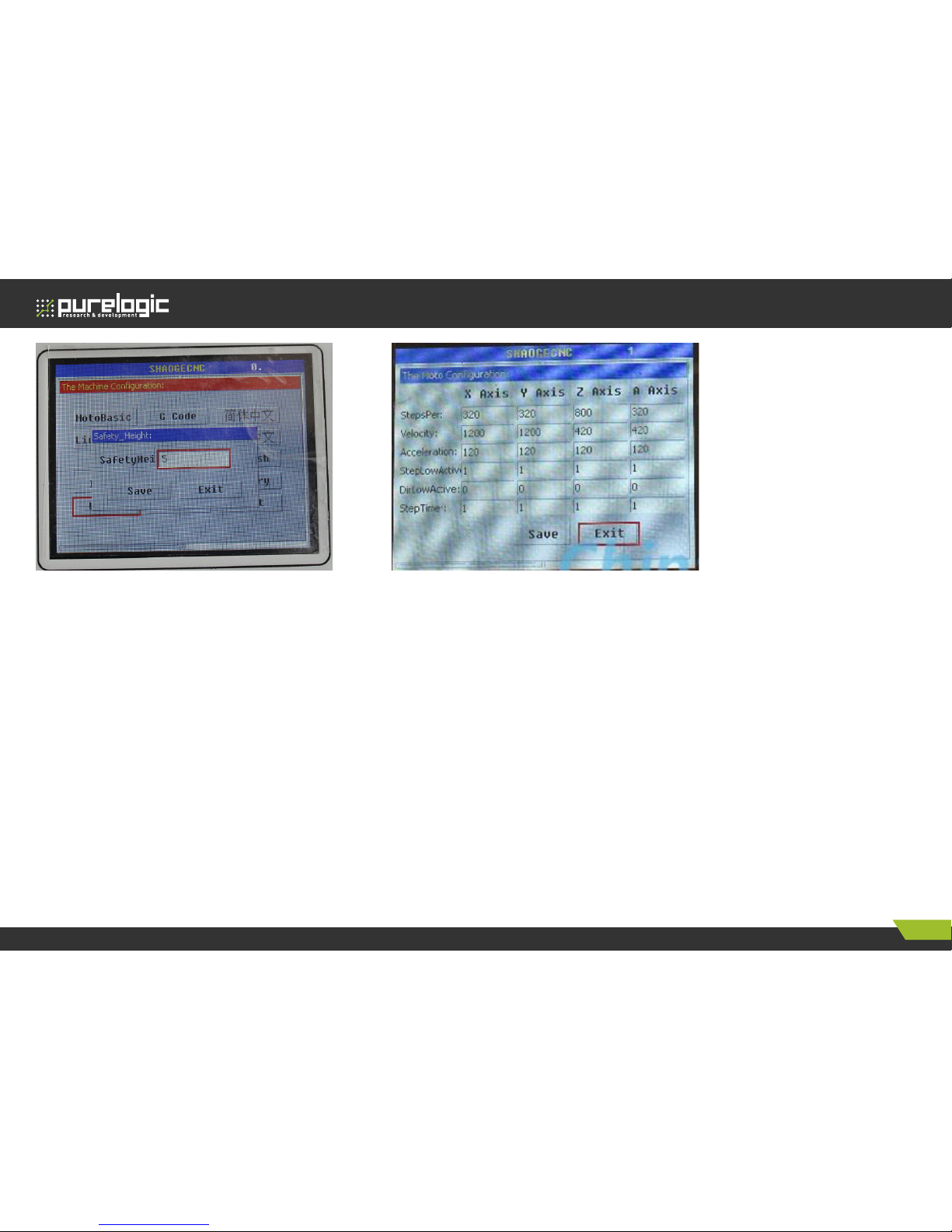

Machine Configuration Click the «Advanced Features» below, then click «motor parameters» to enter the following screen.

Word meaning explanation:

Pulse equivalent: the required number of pulses per unit length, (pulse volume required for each millimeter) support floating-point input.

Maximum speed: maximum speed of this motor can run (mm / min), when the input exceeds the maximum that the system can be achieved, The

maximum is the system can be achieved.

FUNCTION KEY AREA

Open the file

Starts running

Advanced features

Document Management

RESET (RESET)

Jog

The following screen appears after the control system is powered.

Page 5

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

5

www.purelogic.ru8 (800) 555 63 74

Acceleration: Maximum acceleration of the motor can run, this value is too small will be more seriously affected micro segment corner speed.

Pulse level: 1 or 0, active high or active low, determined by the drive.

Direction level: 1 or 0, active high or active low, this change will change running direction.

Pulse Width: Pulse valid output time, only one value,normally can take 0.

Pulse equivalent=Stepper motor driver number of subdivisions * 360 / stepper motor step angle) / screw thread pitch.

Example: Step angle = 1.8 screw pitch = 5mm segments = 8

pulses equivalent = 8 * (360/1.8) / 5 = 320

Maximum speed value: the ability to be finalized in accordance with the motor,based on not fall out step,take 70% of maximum speed values, leaving

30% margin to the motor (characteristics of stepper motor).

T acceleration table is as follows:

Acceleration values: the ability to be finalized in accordance with the motor, based on not fall out step, take 70% of maximum speed values, leaving

30% margin to the motor (characteristics of stepper motor).

Pulse relationship level and pulse width (Note: The actual width is Given width Plus default width).

Page 6

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

6

www.purelogic.ru8 (800) 555 63 74

When the direction level of 1, the shaft is running, the Output is high level, Anti-run is low level.

When the direction level of 0, the shaft is running, the Output is low level, Anti-run is high level.

Open the file

File name appears in the display field, the file name format is the standard format 8_3, 8 character names, 3 suffix.

When displaying the Chinese have four Chinese name, the three suffixes, more than four will not give the full name displayed, with ~ N instead of

advanced rotating function keys, or function keys can flip down display.

Click the function key in the middle of advanced button or «OK» button to select the file, enter the following interface.

Direction level

Page 7

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

7

www.purelogic.ru8 (800) 555 63 74

At this time you can open the file, or return the file selection (re-select), or exit to the main screen.

Click «Open file» access to the contents of the file are shown below.

You can now browse the contents of a file, click the Advanced Function button the middle button, Or OK button brings up a menu interface.

You can select whether to start from the first row, or starting from the N line, or point to the N-line display, you can also choose to re-select the file

directly back to the file.

After selecting input baskets,You can enter the number of lines needed, Enter then select «pointing to select the line» you can jump directly to a

specific number of rows, As for the Extra large, super multi-line, time-consuming will be longer!

If input rows is greater than file rows itself,At this time point to most caudal of the file.

Click on «from the first line to start» and «from the selected line to start»,both will jump to the main interface, Open this file is completed, And hand

the primary key feature to the main precinct.

Starts running

You can start to run directly up! If there is a breakpoint before this, and did not change the file, then a window will pop up as follows:

The first is a safe altitude, the role of safe altitude: In the current head position will be filed with the tool when you want to move to the machining

position, this height is safe altitude, where it can be seen as the height of the Z-axis.

After deduction election baskets selected can change this value, You can also change the default safe altitude of the advanced features.

«Continued Point Run»: When a breakpoint in the point-to-point between N and N +1, Continued Point will start from N points, Which will be repeated

between N to N +1 points have been processed over the tracks, and access to the unfinished track.

Page 8

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

8

www.purelogic.ru8 (800) 555 63 74

« running before Continued points «:When a breakpoint in the point-to-point between N and N +1, running from N +1 to begin direct before Continued

points, Discards N to N +1 line processing track, please pay more attention.

«Exit» to give up this operation.

(Note: When the breakpoint then run large number of rows, Because need to find out Coordinate System and Continued points from the beginning,

There will be some computing time, TF card reader speed will affect the current operation speed, number of runs in the top left corner indicates).

«Limit Input»

Enable: limit function is selected or not.

Pin: For the limit function is selected, the corresponding input pin (selectable 1-16)

Level: Input high level active or low level active (see Figure simulation)

«Mechanical origin»

Enable: limit function is selected or not.

Pin: For the limit function is selected, the corresponding input pin (selectable 1-16)

H/L: Input high level active or low level active (see Figure simulation)

Page 9

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

9

www.purelogic.ru8 (800) 555 63 74

Directions: when Return to machinery XYZ direction, either positive or negative.

Return speed: the speed of returned to the Mechanical point and the knife point.

Above Input pin inputs corresponding to 8 controllers, Can arbitrarily designated as the current limit input pin.

Document Management

Click on «File Manager» icon to the below of the list of files into the interface, you can add new files, delete files, modify the file.

Click on the specified file will enter the following interface:

Page 10

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

10

www.purelogic.ru8 (800) 555 63 74

«Edit this file»: You can edit the selected file

«Return the file selection»: Re-select the file

«New File»: Create a new document

«Delete Files»: delete the selected file

«Return to the main interface»: direct return to the main interface

New file and delete the file interface

Edit this file

Page 11

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

11

www.purelogic.ru8 (800) 555 63 74

«Edit this line» for editing the selected row

Corresponding key on the control panel, enter the desired G code, then press «OK» button to save and return, (the old parameters line in the

front),Repair key panel has «←» can abdication modified for the wrong characters .

«Insert Row», remove this line

Page 12

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

12

www.purelogic.ru8 (800) 555 63 74

insert blank lines in the front selected row as shown: «Delete this line» will delete the specified row.

«Return row selection» to return G command line to re-selected.

«Return the file selection» returns the file list interface.

Note: If the last instruction of the file is not able to run, in the final document to join a blank line! ! !

Panel Shortcuts as «origin Operation»

«Return to origin» Z-axis rise to Safe altitude, XY axis back to the origin, Z axis and then passed back to the origin.

«Return to the mechanical origin»: Z axis retreated mechanical origin, Y-axis retreated mechanical origin, Y-axis retreated mechanical origin, (please

note the configuration foot level and enable)

«Knife» Z-axis decreased (or increased), when it comes to the probe, please stop running then let the Z-axis coordinate is 0,and Z-axis carrying knives

to a safe altitude, the end of this process. (Please note that the configuration of the feet, the level and enable)

Panel shortcut to «coordinate cleanup operation.»

Page 13

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

13

www.purelogic.ru8 (800) 555 63 74

X-axis uniaxial cleared

Y-axis uniaxial cleared

Z-axis uniaxial cleared

A shaft uniaxial cleared

All axes cleared

Exit

Panel shortcuts ¤ «Manual and Jog»

Page 14

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

14

www.purelogic.ru8 (800) 555 63 74

“Manual”Recovery Manual

«1mm»: When selected press the corresponding arrow keys will move the corresponding length (incremental moves)

If the current X-axis coordinate X: 1.235, select 1mm

If you press X +, X-axis immediately moved 2.235 If you press the X-, X-axis is moved immediately 0.235

If you want to move to a specific length, you can enter the specific numbers in the input baskets.

(Only press «OK» button to turn yellowish after baskets can be entered,Returns green effectively), Press the corresponding axis direction key.

Corresponding X + X-Y + Y-Z + Z-A + A-are valid

Panel Shortcuts X Y Z A «direct coordinate operations.»

«Run to» corresponding axis directly run to the specified coordinates.

«Change coordinates»: corresponding axes directly change toto the number set (This operation is not reversible, please carefully Operation)

Spindle control

M03, M04, M05

M03 clockwise run: Now close the M04 corresponding pin, open the M03 corresponding pin.

M04 anti-clockwise run: Now close the M03 corresponding pin, open the M04 corresponding pin.

M05 will also close the M03, M04’s pin

M07, M08, M09

M07 open the corresponding pin will not affect the M08 M08 open the corresponding pin will not affect the M07 M09 will also close the M07, M08’s pin

Delay: Open M03, M04, M07, M08 time spent

PWM pin is fixed at 16 feet, such as opening the pin corresponding to the OUT output should be removed, or due to both control and conflict! ! !

PWM Frequency: refers to the frequency output MAXS: refers to the maximum S corresponding to the maximum frequency was Duty Cycle = S (G

instructions given value) / (MAX S)

Page 15

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

15

www.purelogic.ru8 (800) 555 63 74

When RESET lights flashing, the corresponding pin configuration will output the corresponding level,

This can be used to control the three-axis enable, or machine work tips.

Enter safe altitude baskets

Once entered, saved in the system

G Script Parameters G2/G3 tolerance refers to the input G2/G3 after manual calculations or other calculations. Because of the accuracy problems,

so that circular arc center is inconsistent with the values given moment, there is a tolerance value, the system will be based on the given parameters,

recalculate the best center coordinates, visible G2/G3 detailed instructions.

Chord length: curved Chord length is when generating system to fit an arc segment,See detailed description of G Script

Advanced operating functions:

Page 16

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

16

www.purelogic.ru8 (800) 555 63 74

In standby (no running process) adjust speed:Press and hold the stop

button (black square button), and then rotating the advanced function

keys, you can adjust the speed percentage,On the main screen you can

see the percentage rate (1:100-1) display.

In machining operation, direct rotating advanced function keys, you

can adjust the percentage of the speed, On the main screen you can to

the percentage rate (1:100-1) display.

Overspeed 133.33% run operation:

Run processing: Press the middle button of Advanced function keys,

rotating advanced function keys, you can exceed 33.33% of the system to

the maximum speed.

During standby under: Press and hold the stop button (black square

button),press the middle button of senior function keys, rotating

advanced function keys on it.

(This operation should be noted that the parameters of the system

given the minimum limit, acceleration and top speed parameter

variables will thus make new adjustments, the overall performance of

the machine exceeds the expected value, so be careful to use!!!)

D.Interface mimic diagram

Power supply is SbleDC voltage 12V, Current should be greater than

1A, the controller operates at about 300MA-800MA Power Supply.

Simulation Figure shown in «5V output» refers to the output of the

power supply, Available about 500MA current to external devices to use.

Page 17

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

17

www.purelogic.ru8 (800) 555 63 74

E G command interpretation

G00

Format:. G0X .. Y. Z ... A

Axis rapid traverse, G0 for fast positioning tool, No machining of the workpiece. Can quickly move in several axis simultaneously, thereby producing a

linear trajectory (point to point) as shown.Machine data specified maximum value for each axis rapid traverse rate of an axis running speed on this fastmoving. the moving speed of the synthesized vector speed of the two axes.In the address programmed feed rate F is invalid with G0 move quickly. The

system will be run by the maximum value of each axis vector synthesis rate.

To go four cases:

G0X0Y0Z0

G0X10

G0Y10

G0X0

G0Y0

G01

Format G1X .. Y.. Z.. A.. F..

The tool moves on a straight line from the starting point to the target point, Programming with F feedrate speed. All axes can be run simultaneously.

G1 remain valid until they are replaced by other commands.

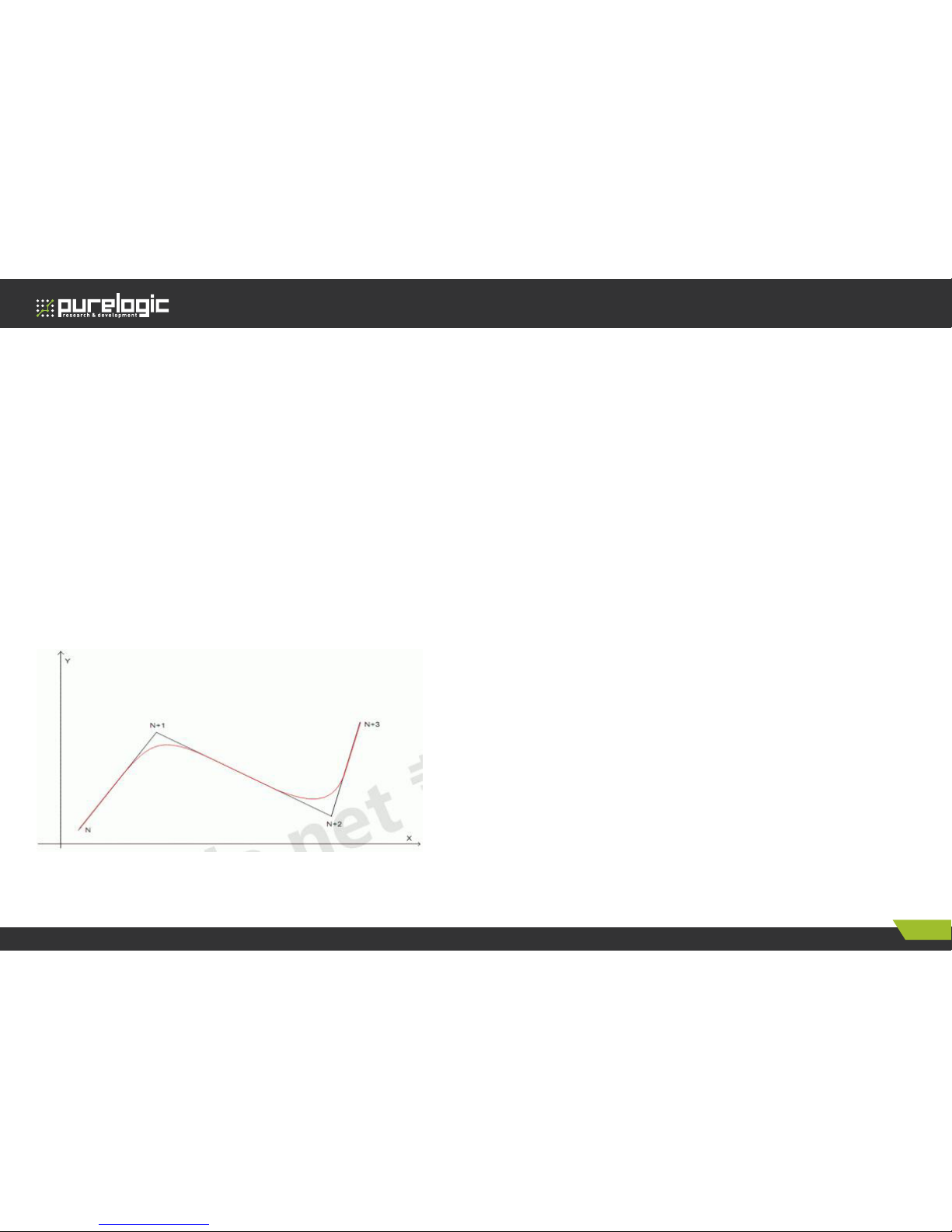

This controller support multi-micro multi-line forward control interpolation algorithm, That is more than one segment will be calculated tracks as

Continuous interpolation algorithm,To achieve a smooth transition,Prospective method and will increase the operating speed as much as possible.

Page 18

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

18

www.purelogic.ru8 (800) 555 63 74

Red trace is the actual running tracks, F is the processing speed

Painting Quartet Case:

G0X0Y0Z0 X10F1200

Y10

X0

Y0

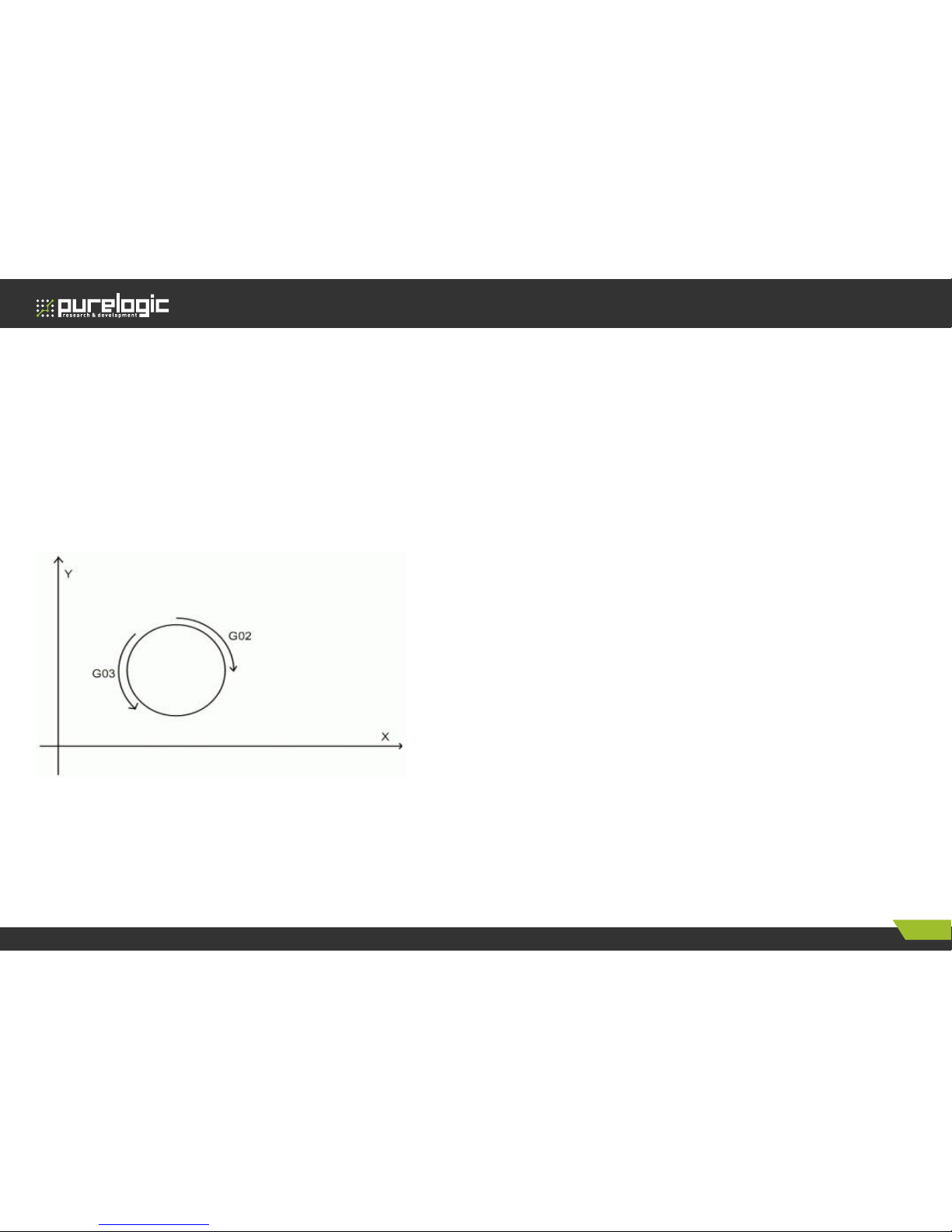

G02 G03

Format (1) G02X .. Y.. Z.. R.. F.. (Radius method)

(2) G02X .. Y.. Z.. I.. J.. K.. F (circle center method)

Format (1) G03X .. Y.. Z.. R.. F.. (Radius method)

(2) G03X .. Y.. Z.. I.. J.. K.. F (circle center method)

G02 clockwise circle G03 counterclockwise circle

Page 19

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

19

www.purelogic.ru8 (800) 555 63 74

G17 (X, Y) coordinate plane (plane default)

G18 (X, Z) coordinate plane

G19 (Y.Z) coordinate plane

circle center method:

G02 (G03) X.. Y.. Z.. I.. J.. K.. F

X. Y. Z represents Terminal point coordinate, F processing speed

I represents projection of the arc starting point to circle center distance in the X-axis

J represents projection of the arc starting point to circle center distance in the Y-axis

K represents projection of the arc starting point to circle center distance in the Z-axis

L, J, K direction is corresponding to the negative direction of the XYZ

Page 20

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

20

www.purelogic.ru8 (800) 555 63 74

Legitimacy of the parameter (in XY plane):

circle center method can be obtained directly radius R = sqrt (i ^ 2 + j ^ 2), If the length of the line start and end points of the arc is greater than 2R is

impossible to go wrong prompt.

When the above conditions are satisfied, the system will recalculate the center coordinates of the most reasonable, When it has some deviation

with given center coordinates actually,Called super difference,If this deviation value is greater than the system given,it will prompt an error,This super

difference can be set in the system,Facilitate more rapid input parameters.

(Note:The difference between the actual center of the arc can constitute

And input circle center called super difference,This difference can be super-max settings, you can tolerate a wider parameter input limit)

Case: G0X0Y0Z0 G1Z-1F1200 Y10 X20 G02X30Y20I10J0 G1X80

Y0

X0

G0X0Y0Z5

Radius method:

G02 (G03) X.. Y.. Z.. R.. F..

Page 21

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

21

www.purelogic.ru8 (800) 555 63 74

X, Y, Z Terminal point coordinates,F processing speed

R represents the radius of the arc

F processing speed

In the case of a known start and end points of the arc with a radius of programming,By geometric mapping will be two arcs, a large arc and a small

arc, in order not to generate ambiguities provisions R> 0 is a small arc, R <0 is great arc.

For full circle, because the starting point coincides with Terminal point, with R programming, there will be countless solution, can not define the

center position, it can only be programmed with the center coordinates method.

case:

G0X0Y0Z0

G1Z-1F1200

Y10

X20

G02X30Y20R10

G1X80

Y0

X0

G0X0Y0Z5

Page 22

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

22

www.purelogic.ru8 (800) 555 63 74

Chord length:

After the system calculates the combined resistance parameter,Given G02, G03 proposed synthesis and decomposition micro segment, This micro

multi-segment shaped scale is Chord length, This length can be set in the system, Reference value (0.1mm-5mm),

Note: Due to system has prospective multi-micro multi-line interpolation calculation, and therefore Chord length is undesirable too short,when it is

necessary to be too short, and processing speed must be somewhat lowered! ! !

G17 (X, Y) coordinate plane (plane default) G18 (X, Z) coordinate plane G19 (Y, Z) coordinate plane G04 (pause, delay)

Format: G04P ..

Between the two blocks by inserting a G4 block, You can make the given time of interrupt the machining P suffix to be milliseconds, a minimum of

500ms + P *

Case: (delay 1 second) G0X0Y0

G1Z-1F1200 G1X20Y20 G04P1000 G1X40Y40 G0Z5 G0X0Y0

G90 (default): Absolute dimensions G91: Incremental dimension

G90 and G91 commands corresponding to the absolute position data input and incremental position data input. G90 represents the coordinate

dimension of coordinates target point, G91 represents the displacement to be run.G90/G91 applies to all axes.These instructions do not decide to end

position trajectory, Trajectory is determined by the other G group G function commands (G0, G1, G2, G3 ...).After the program starts G90 applies to all

axes and remains active until later in the block have appeared G91.

Specific G commands G54 (coordinate system control) Format: G54P .. (coordinates irreversible, please carefully Operation) Coordinate system axes

are cleared the X-axis is cleared: G541 the Y-axis is cleared: G542 the Z-axis is cleared: G543

the A-axis is cleared: G544

Page 23

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

23

www.purelogic.ru8 (800) 555 63 74

On XYZ axes simultaneously cleared: G54P * (except 1,2,3,4,for any value , not fill P also)

G81: (drill instruction)

Format: G81X .. Y.. Z.. R.. F..

X.Y represent end coordinates, Z represents the depth of machining F processing speed

R represent operating plane (safe altitude) at the beginning, represent and Z Terminal point after returned

Case: (coordinates (20.0), (20.20), (0.20), (0,0) four drill holes 5mm in depth, the two safety plane, a speed of 200)

G0X0Y0Z5

G81X20YOR2Z-5F200

G81X20Y20R2Z-5F200

G81X0Y20R2Z-5F200

G81X0Y0R2Z-5F200

G0X0Y0Z5

G82: (drilling instruction)

Format: G83X .. Y.. Z.. R.. P.. F....

X, Y represent Terminal point coordinates,Z represents the depth of machining, S represents dwell time at the hole bottom.

F processing speed

R represent theoperating plane of the beginning,and represent Z terminal point after returned.

Page 24

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

24

www.purelogic.ru8 (800) 555 63 74

Case: (coordinates (20.0), (20.20), (0.20), (0,0) four drill holes 5mm in depth, the two safety plane, and one second stay at the hole bottom, a speed of

200)

G0X0Y0Z5

G82X20YOR2Z-5P1000F200

G82X20Y20R2Z-5P1000F200

G82X0Y20R2Z-5P1000F200

G82X0Y0R2Z-5P1000F200

G0X0Y0Z5

G83: (canned cycle drilling instruction)

Format: G83X .. Y. Z. R. I. F....

X, Y represent end coordinates, Z represents the depth of processing,I represents the displacement of each fall,it will be cut back action When

processed to I depth.

F processing speed

R represents the beginning of the start plane and said Z end after returned

Page 25

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

25

www.purelogic.ru8 (800) 555 63 74

Case: (coordinates (20.0), (20.20), (0.20), (0,0) four drill holes 5mm in depth, the two safety plane, and one second stay at the hole bottom, a speed of

200)

G0X0Y0Z5

G82X20YOR2Z-5P1000F200

G82X20Y20R2Z-5P1000F200

G82X0Y20R2Z-5P1000F200

G82X0Y0R2Z-5P1000F200

G0X0Y0Z5

G83: (canned cycle drilling instruction)

Format: G83X .. Y. Z. R. I. F....

X, Y represent end coordinates, Z represents the depth of processing,I represents the displacement of each fall,it will be cut back action When

processed to I depth.

F processing speed

R represents the beginning of the start plane and said Z end after returned

M107 corresponds OUT_7 Output High Level (artificially high, Facilitate different voltage connect pull-up resistor)

M108 corresponds OUT_8 Output High Level (artificially high, Facilitate different voltage connect pull-up resistor)

M109 corresponds OUT_9 Output High Level (artificially high, Facilitate different voltage connect pull-up resistor)

M110 corresponds OUT_10 Output High Level (artificially high, Facilitate different voltage connect pull-up resistor)

M111 corresponds OUT_11 Output High Level (artificially high, Facilitate different voltage connect pull-up resistor)

M112 corresponds OUT_12 Output High Level (artificially high, Facilitate different voltage connect pull-up resistor)

M113 corresponds OUT_13 Output High Level (artificially high, Facilitate different voltage connect pull-up resistor)

M114 corresponds OUT_14 Output High Level (artificially high, Facilitate different voltage connect pull-up resistor)

M115 corresponds OUT_15 Output High Level (artificially high, Facilitate different voltage connect pull-up resistor)

M116 Because logic easy to confuse, so give up on the OUT_16 Output Control

M210 corresponding OUT_10 output low level (perfusion 500ma to ground)

M211 corresponding OUT_11 output low level (perfusion 500ma to ground)

M212 corresponding OUT_12 output low level (perfusion 500ma to ground)

M213 corresponding OUT_13 output low level (perfusion 500ma to ground)

M214 corresponding OUT_14 output low level (perfusion 500ma to ground)

M215 corresponding OUT_15 output low level (perfusion 500ma to ground)

M216 Because logic easy to confuse, so give up on the OUT_16 Output Control

M201 corresponding OUT_1 output low level (perfusion 500ma to ground)

M202 corresponding OUT_2 output low level (perfusion 500ma to ground)

M203 corresponding OUT_3 output low level (perfusion 500ma to ground)

M204 corresponding OUT_4 output low level (perfusion 500ma to ground)

M205 corresponding OUT_5 output low level (perfusion 500ma to ground)

M206 corresponding OUT_6 output low level (perfusion 500ma to ground)

Page 26

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

26

www.purelogic.ru8 (800) 555 63 74

M207 corresponding OUT_7 output low level (perfusion 500ma to ground)

M208 corresponding OUT_8 output low level (perfusion 500ma to ground)

M209 corresponding OUT_9 output low level (perfusion 500ma to ground)

Enter the judgment M command (M3 **, M4 **) M301 corresponding the input terminal INTPU_1 Judgment if it is low level execute the next line,

otherwise go on waiting

M302 corresponding the input terminal INTPU_2 Judgment if it is low level execute the next line, otherwise go on waiting

M303 corresponding the input terminal INTPU_3 Judgment if it is low level execute the next line, otherwise go on waiting

M304 corresponding the input terminal INTPU_4 Judgment if it is low level execute the next line, otherwise go on waiting

M305 corresponding the input terminal INTPU_5 Judgment if it is low level execute the next line, otherwise go on waiting

M306 corresponding the input terminal INTPU_6 Judgment if it is low level execute the next line, otherwise go on waiting

M307 corresponding the input terminal INTPU_7 Judgment if it is low level execute the next line, otherwise go on waiting

M308 corresponding the input terminal INTPU_8 Judgment if it is low level execute the next line, otherwise go on waiting

M309 corresponding the input terminal INTPU_9 Judgment if it is low level execute the next line, otherwise go on waiting

M310 corresponding the input terminal INTPU_10 Judgment if it is low level execute the next line, otherwise go on waiting

M311 corresponding the input terminal INTPU_11 Judgment if it is low level execute the next line, otherwise go on waiting

M312 corresponding the input terminal INTPU_12 Judgment if it is low level execute the next line, otherwise go on waiting

M313 corresponding the input terminal INTPU_13 Judgment if it is low level execute the next line, otherwise go on waiting

M314 corresponding the input terminal INTPU_14 Judgment if it is low level execute the next line, otherwise go on waiting

M315 corresponding the input terminal INTPU_15 Judgment if it is low level execute the next line, otherwise go on waiting

M316 corresponding the input terminal INTPU_16 Judgment if it is low level execute the next line, otherwise go on waiting

M401 corresponding the input terminal INTPU_1 Judgment if it is low level execute the next line, otherwise go on waiting

M402 corresponding the input terminal INTPU_2 Judgment if it is low level execute the next line, otherwise go on waiting

M403 corresponding the input terminal INTPU_3 Judgment if it is low level execute the next line, otherwise go on waiting

M404 corresponding the input terminal INTPU_4 Judgment if it is low level execute the next line, otherwise go on waiting

M405 corresponding the input terminal INTPU_5 Judgment if it is low level execute the next line, otherwise go on waiting

M406 corresponding the input terminal INTPU_6 Judgment if it is low level execute the next line, otherwise go on waiting

M407 corresponding the input terminal INTPU_7 Judgment if it is low level execute the next line, otherwise go on waiting

M408 corresponding the input terminal INTPU_8 Judgment if it is low level execute the next line, otherwise go on waiting

M409 corresponding the input terminal INTPU_9 Judgment if it is low level execute the next line, otherwise go on waiting

M410 corresponding the input terminal INTPU_10 Judgment if it is low level execute the next line, otherwise go on waiting

M411 corresponding the input terminal INTPU_11 Judgment if it is low level execute the next line, otherwise go on waiting

M412 corresponding the input terminal INTPU_12 Judgment if it is low level execute the next line, otherwise go on waiting

M413 corresponding the input terminal INTPU_13 Judgment if it is low level execute the next line, otherwise go on waiting

M414 corresponding the input terminal INTPU_14 Judgment if it is low level execute the next line, otherwise go on waiting

M415 corresponding the input terminal INTPU_15 Judgment if it is low level execute the next line, otherwise go on waiting

M416 corresponding the input terminal INTPU_16 Judgment if it is low level execute the next line, otherwise go on waiting

Page 27

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

27

www.purelogic.ru8 (800) 555 63 74

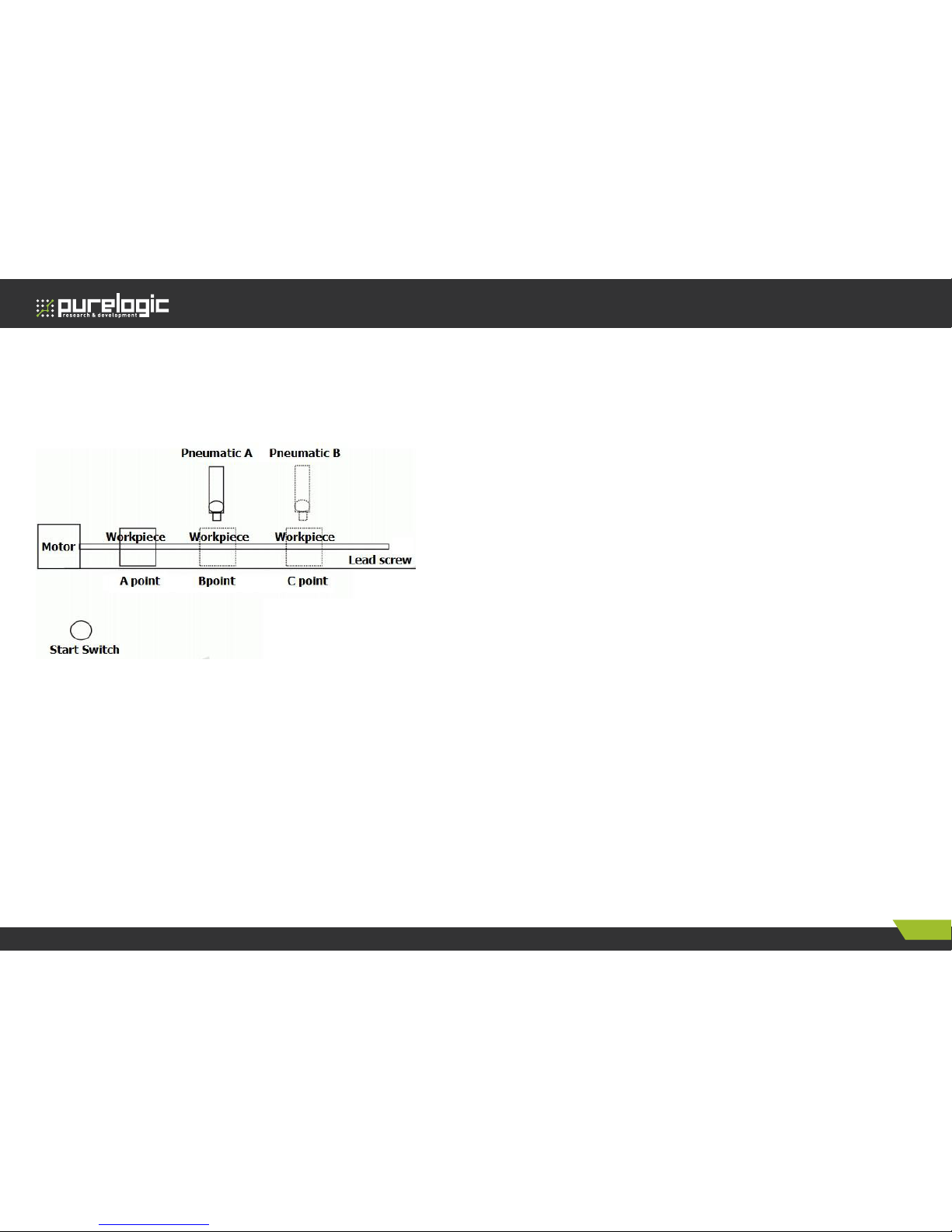

G, M instruction combinations Case

Project goal: to start the switch after triggered,X-axis control operation of the mobile speeds of 600, To specify the location of the first point A,output

an action to pneumatic A,2 seconds,then semi-closed return,1 seconds, then move the operating speed of 600 to point B,Then output a move to the

Pneumatic B,2 seconds,then closing the return, 1 seconds, then move the operating speed of 1200 to return to point A and wait for the start switch

triggered ......

As shown in Figure

A position of the origin point, B point 500MM, C point 1000MM

connect the X-axis control all circuits,An input switch connected to the input port 1 as the start button, and connect the two-way Pneumatic units A, B

to the output port 1,2, A connect 1, B connect 2.

Program instructions are as follows:

G1X500F600 (the workpiece is moved to the 500 position)

M101 (Open Pneumatic A)

G4P2000 (delay 2 seconds)

M201 (Close Pneumatic A return)

G4P1000 (delay 1 second)

G1X1000F600 (the workpiece is moved to the 1000 position)

M102 (Open Pneumatic B)

G4P2000 (delay 2 seconds)

M202 (Close Pneumatic B returns)

G4P1000 (delay 1 second)

G1X0F1200 (the workpiece is moved to the 0 position)

Page 28

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

28

www.purelogic.ru8 (800) 555 63 74

M301 (wait for the start button triggered)

M47 (back to the first line to restart Note: The last line of the last to join the carriage return)

(Carriage return or empty) The controller reliefs carved out of the picture:

Page 29

SMC4-4-16A16B. Four-axis motion controller

Edition of 03.08.2016

29

www.purelogic.ru8 (800) 555 63 74

Loading...

Loading...