Page 1

01. General Provisions

02. Scope of delivery

03. Specifications

04. Driver installation and ventilation

05. Driver features

06. Driver control signal connection

07. Current and voltage selection

08. Driver SSM connection

09. DIP-switch driver tuning

10. PC driver connection via USB interface

11. Driver parameter adjustment by configuration program

12. Driver error and indication

13. Warranty

OPERATIONAL MANUAL

2

3

3

5

6

7

8

9

12

14

16

21

22

PLDS880

Servo-step motor DSP driver

Page 2

www.purelogic.ru8 (800) 555 63 74

01

General Provisions

PLDS880 is a DSP processor based digital driver of Servo-Step

Motor (SSM) with possibility of driver parameter PC adjustment via

USB interface. Driver may work both in servo mode and SM common

driver mode without encoder. In servo mode SSM is controlled as fully

functional servo motor with position and speed control. This allows

obtaining motor maximum moment output and excluding step skip at

overload. Driver is highly efficient, SSM rotation noise and vibration is

significantly reduced.

Device features integral SSM winding SC, encoder power supply SC,

SSM back EMF effect protection circuits; SSM mid-frequency resonance

compensator; power supply voltage polarity reversal protection and

SSM soft start; damper; STEP frequency generator and STEP inlet

frequency excess protection. Driver operates with STEP/DIR/ENABLE

standard protocol. All driver control inlets are optically isolated and

compatible with 2.5V, 3.3V, 5V logic levels. Also module has AUTOSLEEP mode that is started at STEP signal unavailability.

Driver is optimal choice for Purelogic R&D PL57/PL86 Series 2

phase bipolar servo-step motors. Operation with other 2 phase SSM for

instance Leadshine is also possible.

01. General Provisions

!

For more information on using and configuring our products

please visit our site www.purelogic.ru

Page 3

Edition of 09.11.2016

3

PLDS880. Servo-step motor DSP driver

Specifications

Scope of Delivery

• PLDS880 step motor DSP driver - 1 piece

• Operational Manual - 1 piece

03

02

SSM step division (micro step)

Integral generator SSM speed

ERROR output parameters

Module net weight

STEP signal max. frequency

Module power supply voltage

SSM operating current

SSM max. speed

SB encoder support

Insulation resistance

Operating temperature

Diff.inlet, 500-1024 pulse/rev

500 MOhm

0...50 °С

1...512

0…500 rev/min

50V/50mA MAX

0.45 kg

200 kHz

18…80V (typical value 70V)

2А…10А

3000 rev/min

• All driver connections and operation mode changes shall be made

only with disabled power supply source

• Do not install power supply disconnector (circuit breaker) after

power supply source (at driver power supply line). Disconnector may be

installed only at ~220V side power supply unit inlet.

• Do not connect driver power supply in series. Only “star” type

connection is allowed (each driver separate power supply line is

connected to PSU).

Page 4

www.purelogic.ru8 (800) 555 63 74

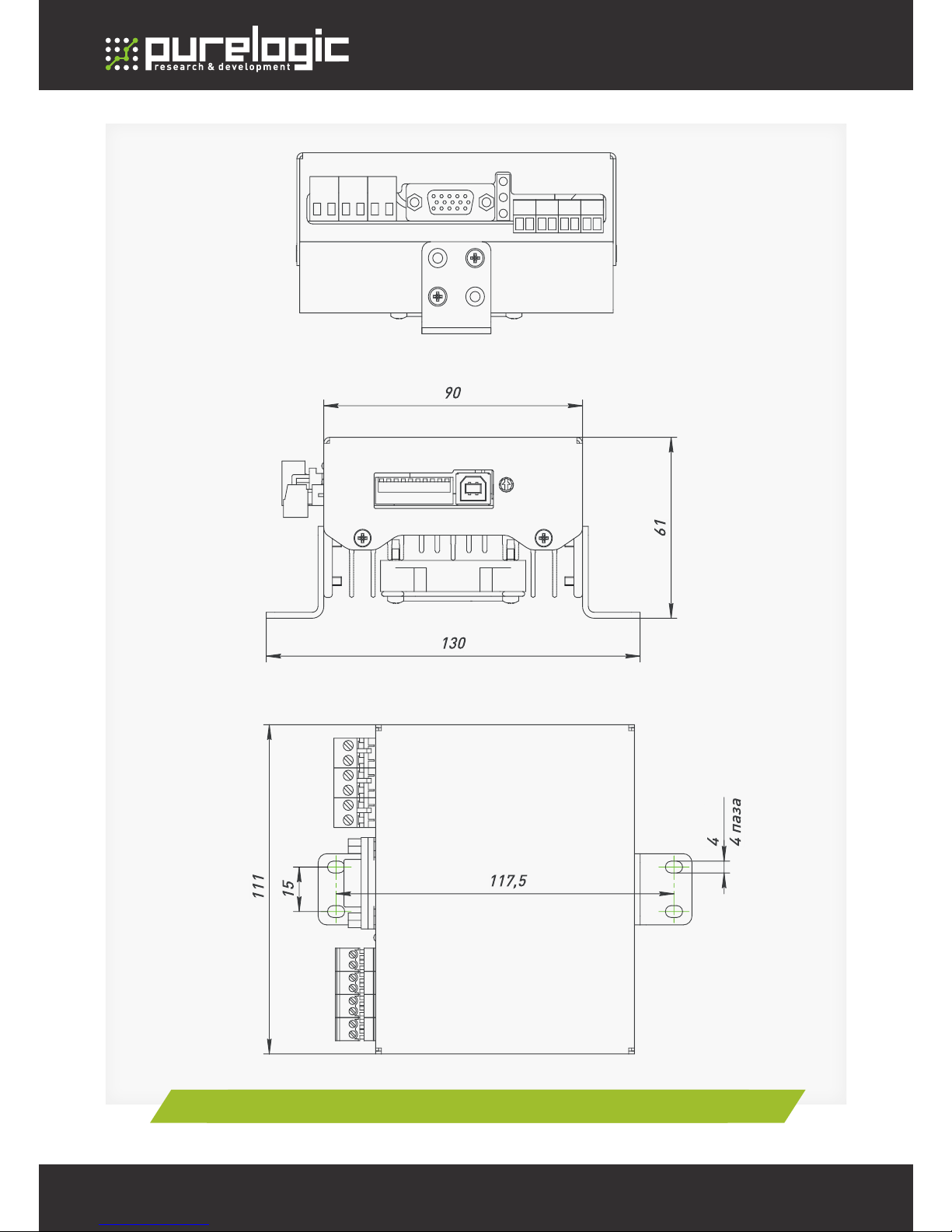

03. Specifications

Figure 1. PLDS880 SSM driver dimensions

Page 5

Edition of 09.11.2016

5

PLDS880. Servo-step motor DSP driver

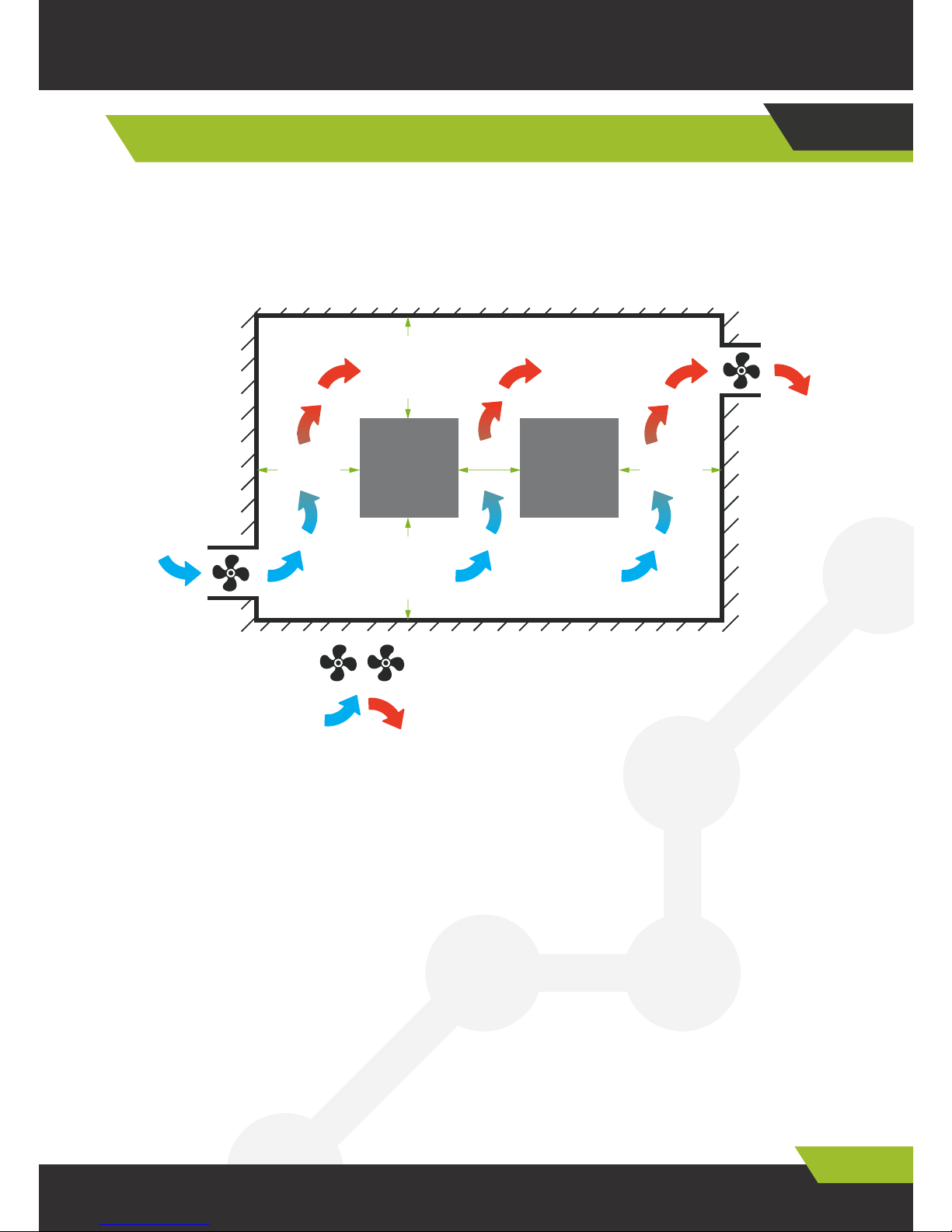

To ensure optimal thermal conditions equipment inside NC control rack

shall be mounted according to diagram below:

Драйвер –Driver

Вентиляторы - Fans

Направление воздушного потока - Air stream direction

Ambient conditions

1) Operating temperature: 0-450C.

2) Ambient operating humidity: below 40-80% (w/o condensation).

3) Storage temperature: -40 ~ 550C.

4) Storage ambient humidity: below 80% (w/o condensation)

5) vibration below 0.5G.

6) avoid moisture entry

7) avoid direct sunlight

Driver Installation and Ventilation

04

>100mm >100mm

>100mm

>25mm

— Направление воздушного потока

Драйвер Драйвер

>100mm

— Вентиляторы

Page 6

www.purelogic.ru8 (800) 555 63 74

04. Driver Features

05

Driver Features

• Driver PC adjustment via USB interface. USB interface is galvanic

isolated from driver.

• Driver may work in both servo mode and SM conventional driver mode

without encoder

• Any SSM step division within 1…512.

• Pulse number per (PPR, CPR) encoder revolution is 500…1024.

• PI-regulator in SSM phase control current loop.

• STEP/DIR/EANBLE/ERROR module control signal optic isolation.

• Integral STEP signal test generator (0…500 rev/min).

• SSM soft start. After energizing or ENABLE signal SSM winding

current is increased gradually. This excludes typical “impact” at SSM

start.

• AUTO-SLEEP mode, driver after 1 sec. of downtime (STEP signal

unavailability) automatically switches to SSM rotor complete/partial

current hold mode to reduce SSM heating.

• SSM winding SC, SSM misconnection module protection

• Encoder power supply circuit SC module protection

• Power supply voltage polarity reversal protection (Driver start is

failed)

• SSM reverse EMF effect protection

• Heating protection (temperature sensor)

• Integral SSM mid-frequency resonance compensator.

• Integral damper

• ERROR driver trouble signal opto-isolated output

• SSM connection easy-to-use dismountable terminals/

• STEP frequency, emergency, driver power supply indication.

8) avoid oil mist and salt entry

9) avoid corrosive liquefied gas entry

Page 7

Edition of 09.11.2016

7

PLDS880. Servo-step motor DSP driver

Module is controlled by standard STEP/DIR and ENABLE signals.

Signals are transmitted at differential opto-isolated inlets.

Yellow LED is illuminated and driver is ON at generated ENABLE

signal. Yellow LED is flashing and SSM is rotating at produced STEP

frequency.

Configuration of control differential inlets and connection to control

system (controller) with “open collector” type outlets are shown at

Figure 2. Module control signals are connected in accordance with (Fig.

5).

STEP signal parameters: Operating voltage 2.5V, 3.3V. 5V (connection

of additional current limiting resistor may be required).

Control Signal Connection

06

Figure 2. Configuration of differential inlets

Page 8

www.purelogic.ru8 (800) 555 63 74

07. Curret and voltage selection

07

Current and voltage selection

Driver power supply max. voltage selection depend upon used SSM

and its required speed. This SSM optimal power supply voltage is

calculated by formula U= √ 32* (SSM phase inductance in mH) but

max. 80V. PL57 type SSM recommended voltage is 45V. PL86 type SSM

recommended voltage is 70V.

Power supply current shall be selected considering 50…70%

of SSM winding specified operating current. SSM operating current is

set by corresponding value in configuration program (Work_Current_

Min and Work_Current_Max). If no STEP signal is available more than

1 second driver is switched to sleep mode (AUTO-SLEEP mode) and

reduces winding current.

max. 20 mA current consumption, signal 2 ms min. time. SSM step is

performed at signal rising edge.

DIR signal parameters: Operating voltage 2.5V, 3.3V. 5V (connection

of additional current limiting resistor may be required), max. 20 mA

current consumption, 200 ns actuation time before/after STEP rising

edge.

ENABLE signal parameters: Operating voltage 2.5V, 3.3V. 5V

(connection of additional current limiting resistor may be required),

max. 20 mA current consumption, 100 ms actuation time. Logical unit

(inlet is energized) is SSM driver is ON and SSM windings are deenergized, zero (nothing is generated or 0V at inlet) is SSM driver is ON

and SSM windings are energized.

Page 9

Edition of 09.11.2016

9

PLDS880. Servo-step motor DSP driver

PLDS880 perfectly fits for controlling of Purelogic R&D PL57/PL86

Series bi-polar and unipolar step motors.

Purelogic R&D SSM is connected to driver according to Fig. 3

(terminals PH1.1(+A), PH1.2(-A) and PH2.1(+B), PH2.2(-B) and encoder

connector). Encoder connector contact designation is also shown at Fig.

3. PLDS880 driver is connected acc. Fig. 4.

Driver is protected against SSM winding misconnection

between each other/to “+” of power supply and Short Circuit in encoder

power supply circuit. Note that motor reverse rotation is started at

reversal of SSM PH1.x<>PH2.x phase connection and encoder A<>B

signals (analog of DIR signal inversion).

Connection of SSM phases and encoder signals is

interrelated. If driver generates error 50 (OverPosition) at initial startup exchange SSM PH1.x<>PH2 phases without changing of encoder

signal connection.

Driver SSM conductor length shall be max. 10 meters.

Longer conductors may result in driver operation failures.

It is highly recommended to arrange SSM wires in phase

bundles: power +A and –A, +B and –B, encoder outlet A and A, B and

B, put bundles in screened metal braids (power wires in one braid,

encoder signal wires to other braid). SSM casing and braids shall be

earthed. Do not arrange and lay encoder signal wires and SSM power

conductor in one braid

Driver MMC connection

08

Page 10

www.purelogic.ru8 (800) 555 63 74

08. Driver SSM connection

Блок питания – Power Supply Unit

Шаговый двигатель – Step motor

Устройство коммутации – Switching device

Page 11

Edition of 09.11.2016

11

PLDS880. Servo-step motor DSP driver

Fig. 3 Driver connection general arrangement drawing

Page 12

www.purelogic.ru8 (800) 555 63 74

08. Driver SSM connection

Fig. 4 Driver motor connection

разъем DHS15F

на кабеле DHS15F-3м

и на драйвере PLDS880

разъем DHS15M

на шаговом двигателе

Разъем

Энкодер Контакт Название

Выход энкодера

И на драйвере

Красный Зеленый Желтый

Синий Черный Белый

Разъем на шаговом двигателе

На кабеле

Цвет Назначение

At cable

Colour Designation

Connector

Encoder Contact Description

Encoder outlet

And at driver

Red Green Yellow

Blue Black White

Connector at step motor

Page 13

Edition of 09.11.2016

13

PLDS880. Servo-step motor DSP driver

Driver operating parameters (step division, Autosleep mode ON/OFF,

integral STEP generator ON/OFF, SSM downloaded profile selection)

may be set by SW1…SW10 switches. All switchings shall be performed

when driver power supply is ON.

Standard profile (certain type SSM parameter set) is selected with

SW1, SW2, SW3 switches according to Figure 5.

At power supply driver automatically downloads profile set by

SW1, SW2, SW3 switches from non-volatile memory “Bank 0” value

downloads profile saved in “0” memory. SSM step division is specified

with SW4, SW5, SW6, SW7 switches according to Figure 6. Autosleep

mode is controlled with SW8 switch. If it is in lower position (ON

position) mode Autosleep is enabled. If it is in upper position Autosleep

is disabled. PLDS880 driver operation mode is selected with SW9 and

SW10 switches.

At started STEP signal internal generator SSM speed and

direction may be controlled by potentiometer STEP GENERATOR. At

potentiometer handle left or right movement from center position SSM

rotor shall rotate clockwise or counter clockwise correspondingly.

SSM rotor speed depends upon inclination of potentiometer handle

from center position.

Fig. 5 Driver standard profile selection diagram

Земля не используется

Напряжение питания

Power supply voltage

Ground Spare

DIP-switch driver adjustment

09

Page 14

www.purelogic.ru8 (800) 555 63 74

10. PC driver connection via USB interface

10

Driver PC connection via USB

PLDS880 driver may be connected to PC via galvanic isolated USB port

for parameter adjustment.

For PLDS880 module PC correct operation configuration

program shall be downloaded and virtual COM-port driver shall be

installed using link: http://www.purelogic.ru/files/downloads/SOFT/

PLDxxx_SW.zip

Module PC connection procedure

• Connect PLDS880 to PC using A/B type USB cable;

• Switch on PLDS880 driver;

• Start configuration program;

• In configuration program pop-up window specify COM-port

assigned to PLDS880 driver. Port number may be found by pressing

WIN+PAUSE in Device Manager, in Port (COM and LPT) group (Fig. 8).

Then press Connect button (Fig. 9)

Fig. 7 Driver operation mode selection diagram

Fig. 6. SM and SSM step division selection diagram

Page 15

Edition of 09.11.2016

15

PLDS880. Servo-step motor DSP driver

Fig.8 Virtual COM-port in Device Manager

Панель управления – Домашняя страница

Панель управления – Домашняя страница

Диспетчер устройств

Файл Действие Вид Справка

Настройка удаленного доступа

IDE ATA/ATAPI контроллеры

Защита системы

Видеоадаптеры

Звуковые, видео и игровые устройства

Диспетчер устройств

Дисковые устройства

Клавиатуры

Control panel –Homepage

Control panel –Homepage

Device manager

File Action View Help

Remote access adjustment

Controllers IDE ATA/ATAPI

System additional parameters

Video adapters

Audio, video and game devices

Device manager

Disk devices

Keyboards

Page 16

www.purelogic.ru8 (800) 555 63 74

10. PC driver connection via USB interface

Fig. 9 Device connection via virtual COM-port

Компьютер

Последовательный порт (СОМ1)

Контроллеры USB

Процессоры

Мониторы

Сетевые адаптеры

Мыши и иные указывающие устройства

Системные устройства

Центр поддержки

Порты (COM и LPT)

Устройства HID (Human Interface Devices)

Центр обновления Windows

Computer

Serial port (СОМ1)

USB controllers

Processors

Monitors

Network adapters

Mouse and other indicating devices

System devices

Support Center

Ports (COM and LPT)

HID (Human Interface Devices) devices

Window Update

Счетчики и средства производительности Performance Information and Tools

Page 17

Edition of 09.11.2016

17

PLDS880. Servo-step motor DSP driver

If COM-port is selected correctly and PLDS880 is ON driver

parameters are displayed in program main window (Fig.10). “Status:

OK” will be in status line.

Fig. 10 Program main window

11

Driver parameter adjustment in configuration program

SSM standard profiles prepared by Purelogic R&D are recommended

and driver parameters shall be adjusted only in exceptional cases.

Each profile comprises set of parameters displayed in configuration

program window. All parameters are divided to adjustable (changeable)

and displayed (not changeable) ones.

Using configuration program Customer is able to:

• Change profile parameters. After any parameter change press

“Apply” button

Page 18

www.purelogic.ru8 (800) 555 63 74

11. Driver parameter adjustment by configuration program

• Save/Download profile (current parameters) to/from driver non-

volatile memory. 7 memory banks “0”….”6” are available.

• Save/Download profile (current parameters) to/from file.

• Download standard profiles from non-volatile memory.

Standard profiles are developed by Purelogic R&D specialists for

certain type SSM.

If Customer changes profile and wishes driver to operate with it

at every start then it is required to save profile in driver non-volatile

memory bank “0” and set profile downloading from “Bank 0” by SW1,

SW2, SW3 switches. Otherwise profile may be saved in “1”…”6” or to file

for following future use.

If Customer changes profile without it saving then modified profile

will be deleted from memory after de-energizing and driver will

download profile set by SW1, SW2, SW3 (Fig.5) after energizing.

Description of driver control program menu items:

• “Connect/Disconnect” is driver connection setup.

• “Apply” is button that shall be pressed after any profile parameter

change. Parameter is modified physically in driver RAM according

values set in program corresponding fields.

Hot key is ENTER.

• “Save →write profile in memory” is saving of current profile

(parameters) in any of 7 available banks of non-volatile memory. “0”

bank is working “Bank 0” and “1”…”6” banks are additional.

• “Save → write profile in file” is saving of current profile

(parameters) to file. This is very useful for quick adjustment of other

drivers with the same parameters.

• “Download→ Download standard profile is downloading of standard

profiles (according to step motor name)

to driver RAM. Enables driver quick adjustment for SSM certain

model.

• “Download → Download profile from memory” is profile

downloading from 7 available banks of non-volatile memory to driver

RAM. Enables quick downloading previously saved profiles.

• “Download → Download profile from file” is profile downloading

from file to driver RAM. Enables downloading of previously saved profile

from file.

Page 19

Edition of 09.11.2016

19

PLDS880. Servo-step motor DSP driver

• “Settings → Information” is description of configuration program

operation, driver parameters.

• “Settings → Language” is selection of configuration program

interface language.

Description of adjustable parameters:

• “Work_Current_Max” is maximum operating current of step motor

phases, peak current. Current is increased to this value automatically

at overloading. Range is 0.2 – 1.0 (corresponds to 2A-10A).

• “Work_Current_Min” is nominal operating current of step

motor phases specified in SM technical certificate. Range is 0.2-0.8

(corresponds to 2A-8A).

• “PI_I_Kp” is PI regulator proportional gain in step motor phase

current regulating loop. Range is 1.0-4.0. Impacts SM acceleration, LF

resonance.

• “PI_I_Ki” is PI regulator integral gain in step motor phase current

regulating loop. Range is 0.0-1.0. Impacts SM acceleration, LF

resonance.

• “PI_M_Kp” is PI regulator proportional gain in frequency multiplier

loop. Range is 0.1-4.0. Value PI_M_Kp <1 permits to smooth STEP

command impulse irregularities. Value PI_M_Kp>1 permits to react

more strongly on STEP command input impulse change.

• “PI_M_Ki” is PI regulator integral gain in frequency multiplier loop.

Range is 0.0-1.0.

• “PI_POS_Kp” is PI regulator proportional gain in position

regulating loop. Range is 0.1-4.0. The higher is PI_POS_Kp the faster

SM rotor is placed in set position.

• “PI_POS_Ki” is PI regulator integral gain in position regulating

loop. Range is 0.0-1.0. Value PI_POS_Ki >0 makes lag effect at SM rotor

placement in set position.

• “PI_SPEED_Kp” is PI regulator proportional gain in speed

regulating loop. Range is 0.1-4.0. The higher PI_SPEED_Kp value is the

higher is SM winding current reaction to STEP command speed change.

• “PI_SPEED_Ki” is PI regulator integral gain in speed regulating

loop. Range is 0.0-1.0. PI_SPEED_Ki > 0 value makes lag effect at SM

winding current reaction at STEP command speed change.

• “Elec_Damp_K” is step motor damping rate (resonance

Page 20

www.purelogic.ru8 (800) 555 63 74

12 Driver error and indication

suppression). Range is 0.0-4.0 (0.0 is damping OFF, 4.0 is maximum

damping).

• “Elec_Damp_Lim” is step motor damping limit. Range is 0.0-1.0.

• “Driver_En” is parameter controlling driver ON/OFF. “1” is driver

ON. “0” is driver OFF.

• “Driver_ID” is driver identification which is assigned by User. Range

is 0 – 10000.

• “El_Damp_En” is parameter controlling resonance suppression

circuit ON/OFF. “1” is ON, “0” is OFF.

• “Auto_Sleep_En” is parameter controlling step motor current

reduction circuit ON/OFF at down time. “1” is ON. “0” is OFF.

• “Control_Type” is parameter selecting step motor control mode:

0 is SERVO mode STEP/DIR/ENABLE;

1 is SERVO with potentiometer R and DIR/ENABLE signals;

2 is STEP/DIR/ENABLE normal mode w/o feedback;

3 is normal mode with potentiometer R & DIR/ENABLE signals and

w/o feedback.

• “Microstep_Sel” is step motor step division ratio. Range is 1-512.

• “QEP_PPR” is Encoder resolution in pulse per CPR, PPR revolution.

Range is 500-1024.

PI_Pos_Kp, PI_Pos_Ki, PI_SPEED_Kp, PI_SPEED_Ki, QEP_PPR

parameters are not used in operational modes w/o encoder.

Description of displayed parameters

Actual parameters are parameters that User is not able to change

from configuration program but they may be changed in process of

device operation.

Actual parameters include:

• “Motor_Speed” is actual step motor rotor speed. Range is 0.0-1.0

(corresponds to 0-3000 rev/min).

• “Error_Code” is driver disabling error code. See below.

• “Bus_Volt” is actual power supply voltage in volts (V).

• “Temp_Core” is DSP processor actual temperature. It is measured

in Celsius degrees (0C). Temperature sensor is installed in DSP

processor.

• “Temp_Heatsink” is radiator actual temperature. It is measured in

Celsius degrees (0C). Temperature sensor is installed at radiator.

• “FLAG_STEP” is STEP optical inlet actual status. “1” is STEP

Page 21

Edition of 09.11.2016

21

PLDS880. Servo-step motor DSP driver

command signal frequency ON. “0” is STEP command signal frequency

OFF.

• “FLAG_DIR” is DIR optical inlet status. “1” is step motor shaft

clockwise rotation. “0” is counter clockwise rotation.

• “FLAG_ENB” is driver actual status ON/OFF. “1” is ON, “0” is OFF.

It depends upon Driver_En parameter and ENABLE optical input status.

In process of operation device tracks several internal parameters.

If value of any parameter exceeds threshold value the driver shall be

disabled. Red LED is lighted, yellow LED is gone out and “Error_Code”

parameter in configuration program will have error code.

Driver errors, “Error_Code” parameter:

0 is OK, normal operation

10 is UnderVoltage, power supply voltage < 15V. 11 is OverVoltage

SW, step motor phase voltage > 85V (including due to reverse EMF that

damper is not able to suppress).

12 is OverVoltage HW, step motor phase voltage > 85V (including due

to reverse EMF that damper is not able to suppress).

20 is OverCurrent SW, current overload.

21 is OverCurrent HW, current overload.

30 is OverTemp1, DSP controller overheating.

31 is OverTemp2, power key, radiator overheating.

40 is OverRPM, step motor shaft speed > 3000 rev/min.

41 is OverFreq, STEP command signal input frequency > 200 kHz.

42 is OverSpeed, speed regulating loop overload.

50 is OverPosition, position regulating loop overload.

Indication:

Green LED is ON, power supply voltage is applied. If it is OFF, power

supply voltage is not applied.

Red LED is ON, driver is OFF, emergency. If this LED is OFF then

driver is ON, no emergency.

Yellow LED is ON, ENABLE signal is generated and driver is ON. If

this LED is OFF, then there is no ENABLE signal and driver is OFF.

Driver errors and indication

12

Page 22

www.purelogic.ru8 (800) 555 63 74

13. Warranty

Guaranteed service life is 12 months from purchase date. Guarantee

is valid only in case of observance of operational and preventive

maintenance conditions.

1. General provisions

1.1. If Goods are purchased as components Seller guarantees

operability of each component but is not responsible for quality of their

joint operation (improper selection of components).

If you have any questions, contact our technical specialists for

technical assistance.

1.2. Seller is not guarantee compatibility of purchased Goods with

Buyer components or Goods purchased from the third parties.

1.3. Article parameters and scope of delivery are subject to change

by Manufacturer without notice due to constant technical improvement

of products.

2. Guarantee service acceptance criteria

2.1. Goods are accepted for guarantee service in the same

configuration as they have been purchased.

3. Guarantee service procedure

3.1. Guarantee service is provided by testing (checking) of Goods

declared defects.

3.2. Guarantee repair is performed after defect confirmation.

4. Guarantee does not cover glass, electric lamps, starters and

consumables and also:

Or driver failure. If this LED is flashing then STEP frequency is

generated and SSM is rotating.

At power supply green and red LEDs are ON. In 1 sec in case

failure unavailability red LED is OFF and yellow LED is set lighting

according to STEP/ENABLE signals.

13

Warranty

Page 23

Edition of 09.11.2016

23

PLDS880. Servo-step motor DSP driver

This article is made and accepted in accordance with mandatory

requirements of effective technical documentation and considered as

suitable for operation

Batch No: QCD:

4.1. Goods with damages due to improper transportation and storage

conditions, misconnection, off-design operation or conditions that

are not specified by Manufacturer (including excess temperature and

humidity), damages due other conditions (power supply voltage surges,

natural disasters etc) and having mechanical and thermal damages.

4.2. Goods with effects of impact and/or entry of foreign matters,

objects (including dust), liquids, insects and having foreign signs.

4.3. Goods with signs of unauthorized access and/or repair (signs of

opening, crude soldering, element replacement etc.)

4.4. Goods with self-diagnostics indicating improper operation

conditions.

4.5. Technically complex Goods which erection, assembling and

commissioning works are performed by other specialists but not

specialists of Seller or companies recommended by Seller except cases

directly specified by Goods documentation.

4.6. Goods that operation is performed under conditions when

electric power supply does not correspond to Manufacturer

requirements and in absence of equipment and network electric

protection devices.

4.7. Goods that have been resold by initial Purchaser to the third

persons.

4.8. Goods with defects occurred as result of use of poor quality or

exhausted spare parts, consumables, accessories and in case of use of

spare parts, consumables, accessories that are not recommended by

Manufacturer.

Page 24

Please note that this documentation is subject to change

due to the continuous technical

improvement of our products. You can always download

the latest version on our website www.purelogic.ru

www.purelogic.ru

Contact information

+7 (495) 505-63-74 - Moscow

+7 (473) 204-51-56 - Voronezh

394033, Russia, city of Voronezh.

Lenin Av., 160

Office 149

Mon-Thu: 8.00–17:00

Fridey: 8.00–16.00

Time-out: 12.30–13.30

sales@purelogic.ru

Loading...

Loading...