Puregas PHF, PCR, PCDA, PHCA, PCME Instruction Manual

...

Instruction Manual

for PUREGAS

Compressed Air Dryers

and Adsorbers

Models: PHF

PCR

PCDA

PHCA

PCME

PMD

TOC

PUREGAS LLC

226A Commerce Street

Broomfield, CO 80020

Tel: 800-521-5351

Fax: 303-657-2205

Info@puregas.com

www.puregas.com

Made in USA P010535 Rev. E 09/11

Instruction Manual for PUREGAS

Compressed Air Dryers and Adsorbers

IMPORTANT NOTE!

This instruction manual is designed for the benefit of our customers and is intended

to assist them with the installation, operation, and maintenance of their PUREGAS

compressed air dryer or adsorber. The entire manual should be read thoroughly prior

to the installation of the unit and should be retained for future reference. Failure to do

so could result in safety issues and poor performance, and could void the warranty.

LIMITED WARRANTY AGREEMENT

All PUREGAS products carry a one-year warranty against defective workmanship

and material. This period starts with the date of shipment. PUREGAS retains the

right to address warranty claims by shipping replacement parts or by having the unit

returned to our factory for repair.

No claims for labor in replacing defective parts or for consequential damages will be

allowed. Replacement parts will be invoiced in the regular way, with invoices subject

to adjustment after the parts claimed defective are examined at our factory. No units

or parts will be accepted at our factory for warranty repairs or credit without previous

authorization from PUREGAS.

Damage incurred to the product in transit will be the responsibility of the customer,

who in turn should file a damage claim against the responsible carrier.

This warranty shall not apply to any product which has been repaired or altered in

any way by anyone other than PUREGAS, so as to affect its proper function. Neither

will this warranty apply to a product subjected to misuse, negligence, or accidental

damage.

Pressure: Do not exceed maximum operating pressure as listed on the serial label

and be sure that the system is depressurized before servicing.

Electrical: Install this product in compliance with national and local electrical codes.

Breathing Air: This product is not intended for breathing air applications, and air

treated by this equipment may not be suitable for breathing without further purification.

CAUTION!

Instruction Manual for PUREGAS

Compressed Air Dryers and Adsorbers

Table of Contents

SECTION 1 – GENERAL...........................................................................................................................................1

S

COPE OF MANUAL ....................................................................................................................................................1

NITIAL INSPECTION ...................................................................................................................................................1

I

W

ARRANTY................................................................................................................................................................1

SECTION 2 – DESCRIPTION OF OPERATION...................................................................................................1

G

ENERAL DESCRIPTION..............................................................................................................................................1

A

PPLICATIONS............................................................................................................................................................1

OPERATION OF PHF, PCDA, PHCA AND PCME MODELS.........................................................................................2

O

PERATION OF PCR MODEL ......................................................................................................................................3

OPERATION OF PMD AND TOC MODELS ...................................................................................................................4

SECTION 3 – INSTALLATION AND OPERATION.............................................................................................5

I

NSPECTION ................................................................................................................................................................5

OCATION ..................................................................................................................................................................5

L

M

OUNTING.................................................................................................................................................................5

R

ECOMMENDED INSTALLATION DIAGRAM .................................................................................................................8

IPING AND AIR CONNECTIONS ..................................................................................................................................8

P

I

NLET AND OUTLET FILTRATION ................................................................................................................................9

P

RESSURE AND FLOW CONTROL.................................................................................................................................9

INSTRUMENTATION ..................................................................................................................................................10

ELECTRICAL CONNECTIONS AND TIMER...................................................................................................................10

O

PERATING PRESSURE AND SIZING ..........................................................................................................................11

OTHER OPERATING ISSUES.......................................................................................................................................12

SECTION 4 - MAINTENANCE..............................................................................................................................13

G

ENERAL INFORMATION ..........................................................................................................................................13

ANNUAL INSPECTION ...............................................................................................................................................13

MAINTENANCE SCHEDULE .......................................................................................................................................14

SECTION 5 – REPLACEMENT PARTS...............................................................................................................15

G

ENERAL INFORMATION ..........................................................................................................................................15

SECTION 6 – TROUBLESHOOTING INFORMATION.....................................................................................21

G

ENERAL INFORMATION ..........................................................................................................................................21

TROUBLESHOOTING MATRIX....................................................................................................................................21

Figures

F

IGURE 1: OPERATION OF PHF, PCDA, PHCA AND PCME MODELS ......................................................................2

F

IGURE 2: OPERATION OF PCR MODEL......................................................................................................................3

IGURE 3: OPERATION OF PMD AND TOC MODELS..................................................................................................4

F

F

IGURE 4: DIMENSIONS OF PHF, PCDA, PHCA, AND PCME MODELS .................................................................5

F

IGURE 5: DIMENSIONS OF PCR MODEL ....................................................................................................................6

FIGURE 6: DIMENSIONS OF PMD AND TOC MODELS.................................................................................................7

F

IGURE 7: RECOMMENDED INSTALLATION DIAGRAM................................................................................................8

F

IGURE 8: WIRING DIAGRAMS...................................................................................................................................11

IGURE 9: EXPLODED VIEW OF PHF, PCDA, PHCA AND PCME MODELS............................................................15

F

F

IGURE 10: REPLACEMENT PARTS FOR PHF, PCDA, PHCA AND PCME MODELS............................................16

FIGURE 11: EXPLODED VIEW OF PCR MODEL........................................................................................................17

IGURE 12: REPLACEMENT PARTS FOR PCR MODEL..............................................................................................18

F

F

IGURE 13: EXPLODED VIEW OF PMD AND TOC MODELS .....................................................................................19

FIGURE 14: REPLACEMENT PARTS FOR PMD AND TOC MODELS..........................................................................20

SECTION 1 – GENERAL

Scope of Manual

This instruction manual is intended to assist our customers with the installation,

operation, and maintenance of their PUREGAS compressed air dryer or adsorber. The

information contained in this manual is designed to ensure a productive, trouble-free

ownership experience and should be retained for future reference.

Initial Inspection

PUREGAS products are produced in a lean manufacturing environment, where quality

assurance practices are built into all processes. Moreover, all products are thoroughly

inspected and tested prior to shipment. If shipping damage is noted, immediately

contact the responsible carrier to file a freight claim to cover the repair.

Warranty

Please read this instruction manual carefully prior to installing and operating your

PUREGAS product. Failure to follow these instructions could lead to potential safety

concerns and may void the warranty. The warranty agreement can be found on the

inside cover of this instruction manual.

SECTION 2 – DESCRIPTION OF OPERATION

General Description

PUREGAS compressed air dryers and adsorber are used to separate various elements

in compressed air using Pressure Swing Adsorption (PSA) technology. This method

employs two identical desiccant chambers, precision orifices, and solenoid valves

controlled by a solid state electronic timer.

The process is simple. The compressed air is directed through a desiccant chamber,

which contains an adsorbent material with strong affinity for moisture, CO

, and/or other

2

elements within the air stream. Once purified, the majority of the compressed air goes

directly to the application, while a portion is diverted through an orifice to regenerate the

off-line chamber. The solid state timer reverses the flow through the chambers on a

timed cycle by opening and closing the solenoid valves.

Applications

As described above, PUREGAS compressed air dryers and adsorbers are typically

used to purify a compressed air source. They may, however, be used with inert gases

(nitrogen, argon, neon, helium, and carbon dioxide), as well as other common gases

with certain restrictions. For example, oxygen requires a completely oil-free system and

hydrogen (being explosive) should be handled with explosion-proof equipment.

Page 1 of 24

A

A

Please consult the factory PRIOR to installing a unit for any application other than air

or inert gases. Use with certain liquids or gases could be harmful to the unit, result in a

combustible condition, or cause hazardous leakage. In the event of a misapplication,

the product warranty is voided and PUREGAS will assume no responsibility or liability

for any resulting loss.

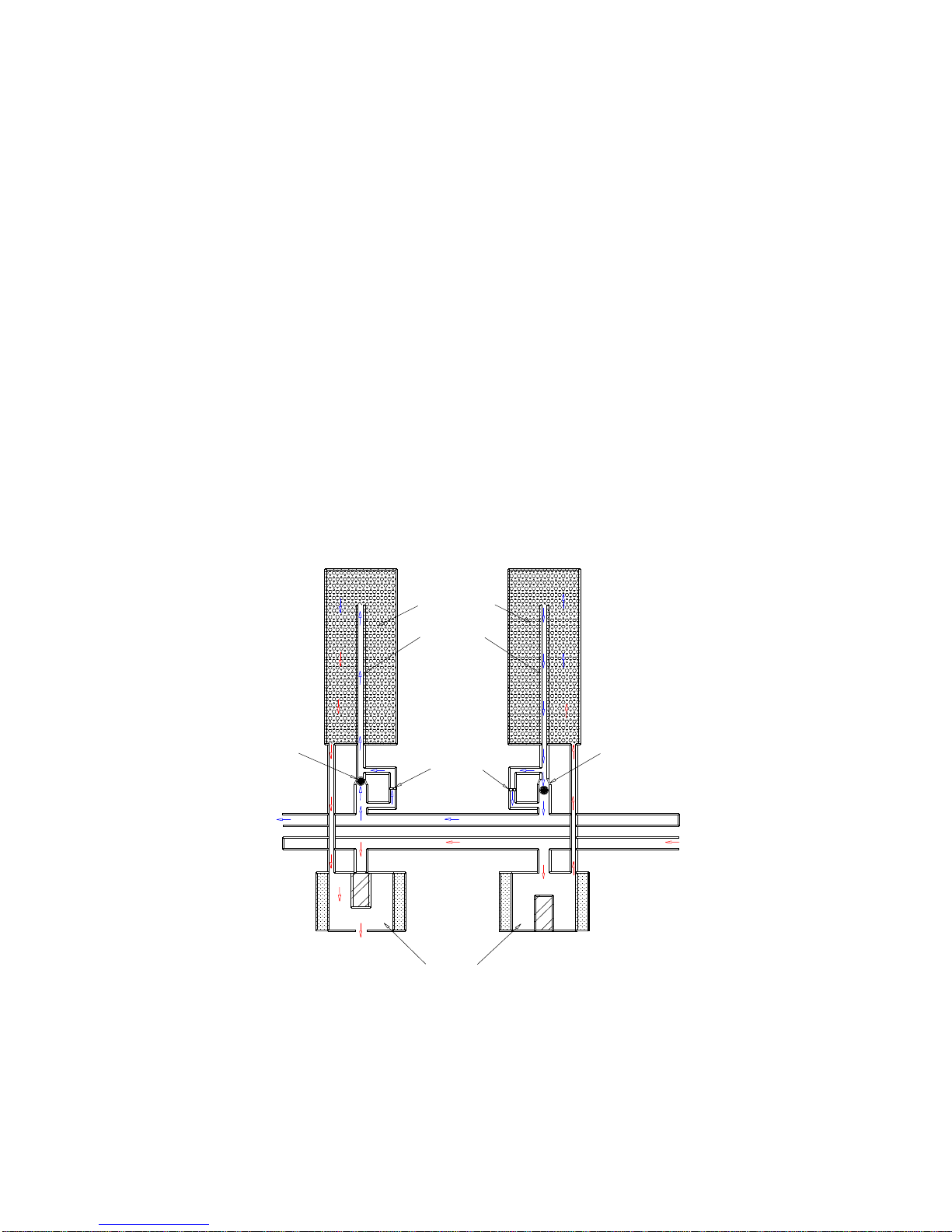

Operation of PHF, PCDA, PHCA and PCME Models

The PHF, PCDA, PHCA and PCME models utilize a common die-cast aluminum

manifold, to which the desiccant towers (chambers), 3-way solenoid valves, timer, and

other components are attached. The inlet air passes upward through the desiccant

tower immediately above the energized DC solenoid valve. When the air reaches the

top of the tower, it is redirected back down the return air tube in the center of the tower,

through the open check valve, and into the outlet passageway. Most of the air is

delivered to the application, while a portion is diverted for purging the off-line desiccant

tower. This air passes through the fixed orifice beneath the off-line tower, upward

through the air tube, and then downward through the desiccant, removing the

accumulated moisture and/or other contaminants. These unwanted elements of the gas

stream exit the unit through the purge port of the de-energized solenoid. This process is

reversed every 30 seconds to provide a continuous source of pure, ultra-dry air.

Desiccant

Tower 2

Check

Valve

(Closed)

Dry gas

Outlet

To

tmosphere

ir Tube

Orifice

3-way

Solenoid

Valve

Tower 1

Check

Valve

(Open)

Wet Gas

Inlet

FIGURE 1: OPERATION OF PHF, PCDA, PHCA AND PCME MODELS

Page 2 of 24

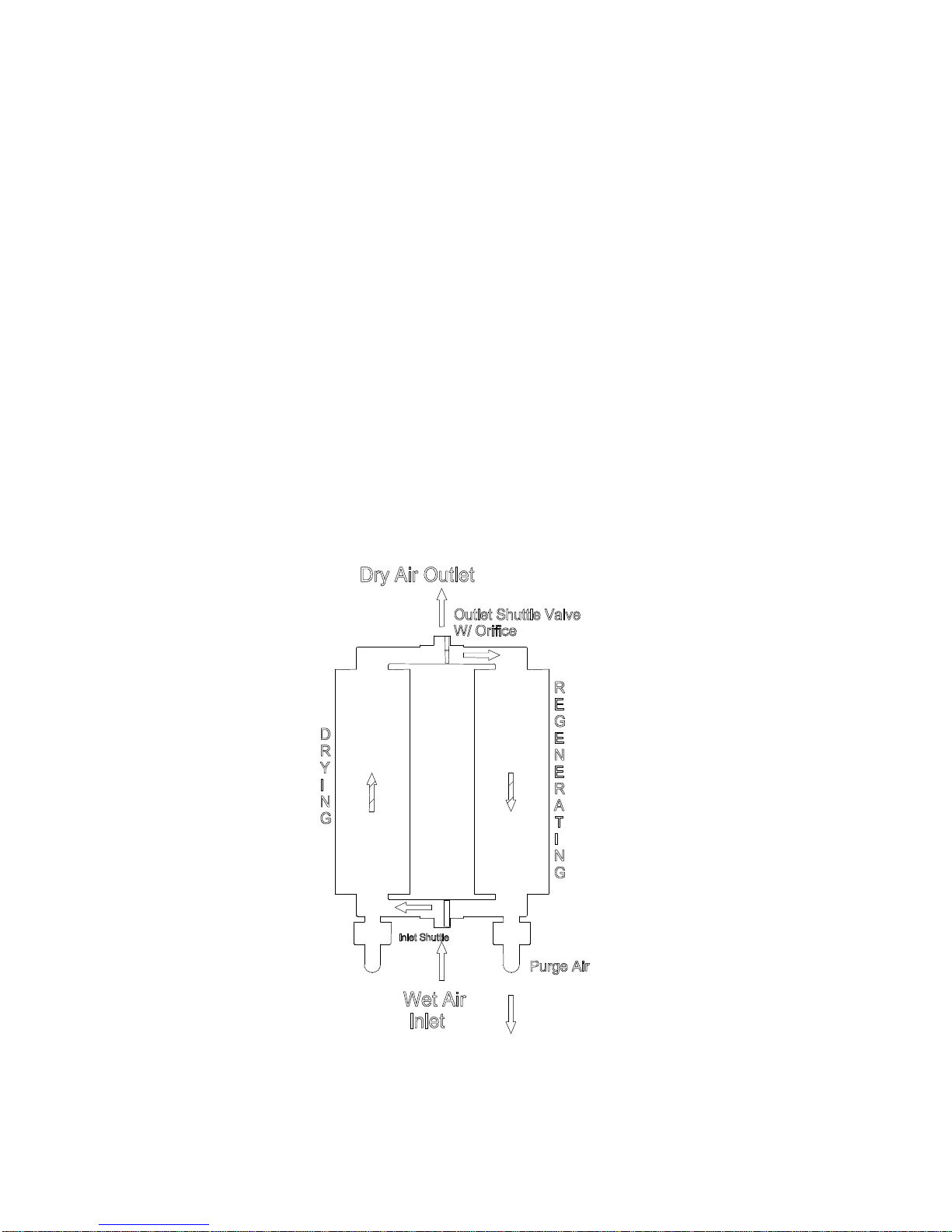

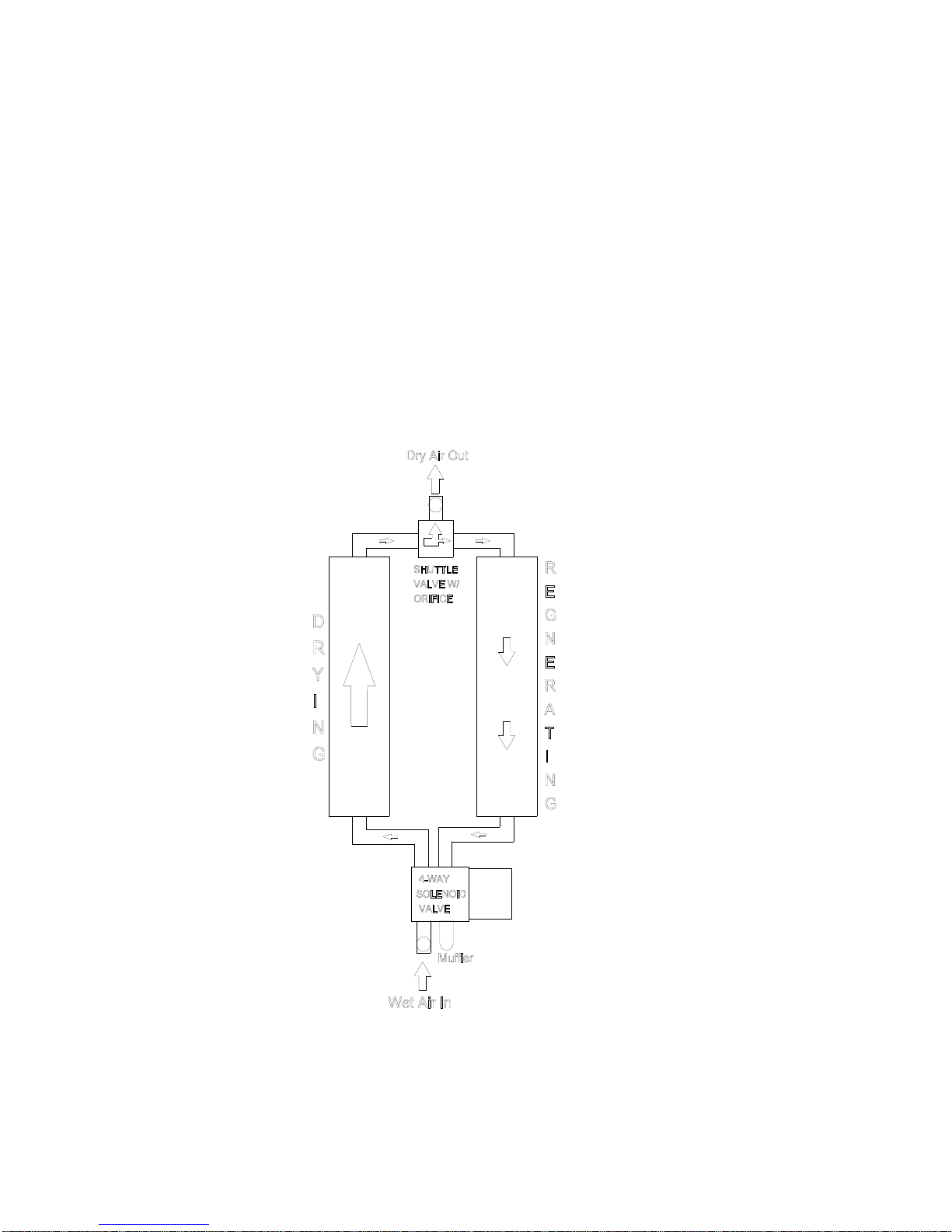

Operation of PCR Model

As previously described, the PCR model employs PSA technology to effectively remove

moisture (or other unwanted components) from a compressed air stream. It is, however,

configured differently than other PUREGAS models based on a common air manifold.

Instead of a manifold and 3-way valves to direct the airflow through the unit, the PCR

model uses shuttle valves and 2-way solenoid valves.

The inlet (lower) shuttle valve directs the compressed air flow into one of the two

desiccant chambers where nearly all of the water vapor is removed. The shuttle valve

contains an internal disk, which “shuttles” back and forth in the valve body based on the

pressure differential created by the 2-way valves (one of which is open and the other

closed).

The ultra-dry air leaving the desiccant chamber passes through the outlet shuttle valve

to the application. A precision orifice in the outlet shuttle disk, however, allows a portion

of the dry outlet flow to be redirected back through the off-line tower to purge it of the

accumulated moisture. The purge stream exits the unit through the open solenoid valve

directly below the chamber. The solid state timer controls the process by opening and

closing the solenoid valves every 60 seconds, which switches the inlet flow to the

regenerated tower.

FIGURE 2: OPERATION OF PCR MODEL

Page 3 of 24

Operation of PMD and TOC Models

The PMD and TOC models also employ Pressure Swing Adsorption (PSA)

technology to remove water vapor and/or CO2 from ordinary compressed air.

These models are configured differently than the PHF or PCR models, in that

they employ a shuttle valve and 4-way valve to direct the airflow through the unit.

The 4-way valve directs the incoming air into one of the two desiccant chambers,

where the water vapor and/or CO2 are removed. Most of the purified air leaving

the desiccant chamber passes through the outlet shuttle valve to the application.

A precision orifice in the outlet shuttle disk, however, allows a portion of the

purified air to be redirected back through the off-line tower, purging it of the

accumulated moisture and CO2. The purge air exits the unit through the 4-way

valve and muffler. A solid state timer governs the process by controlling the 4way valve.

FIGURE 3: OPERATION OF PMD AND TOC MODELS

Page 4 of 24

SECTION 3 – INSTALLATION AND OPERATION

Inspection

Remove the compressed air dryer or adsorber from the shipping carton. Inspect the unit

for any visible shipping damage. If shipping damage is noted, immediately contact the

responsible carrier to file a freight claim to be reimbursed for the repair.

Location

Desiccant-type compressed air dryers and adsorbers should be installed in the coolest

practical location that is not subject to freezing temperatures. An acceptable

temperature range is between 40oF (4oC) and 125oF (52oC). Although the unit will

operate at higher temperatures, the operating life of the components will decrease at

temperatures much above 85oF (29oC). Bear in mind that abrasive dust and chemicals

will also reduce the life of any electromechanical device.

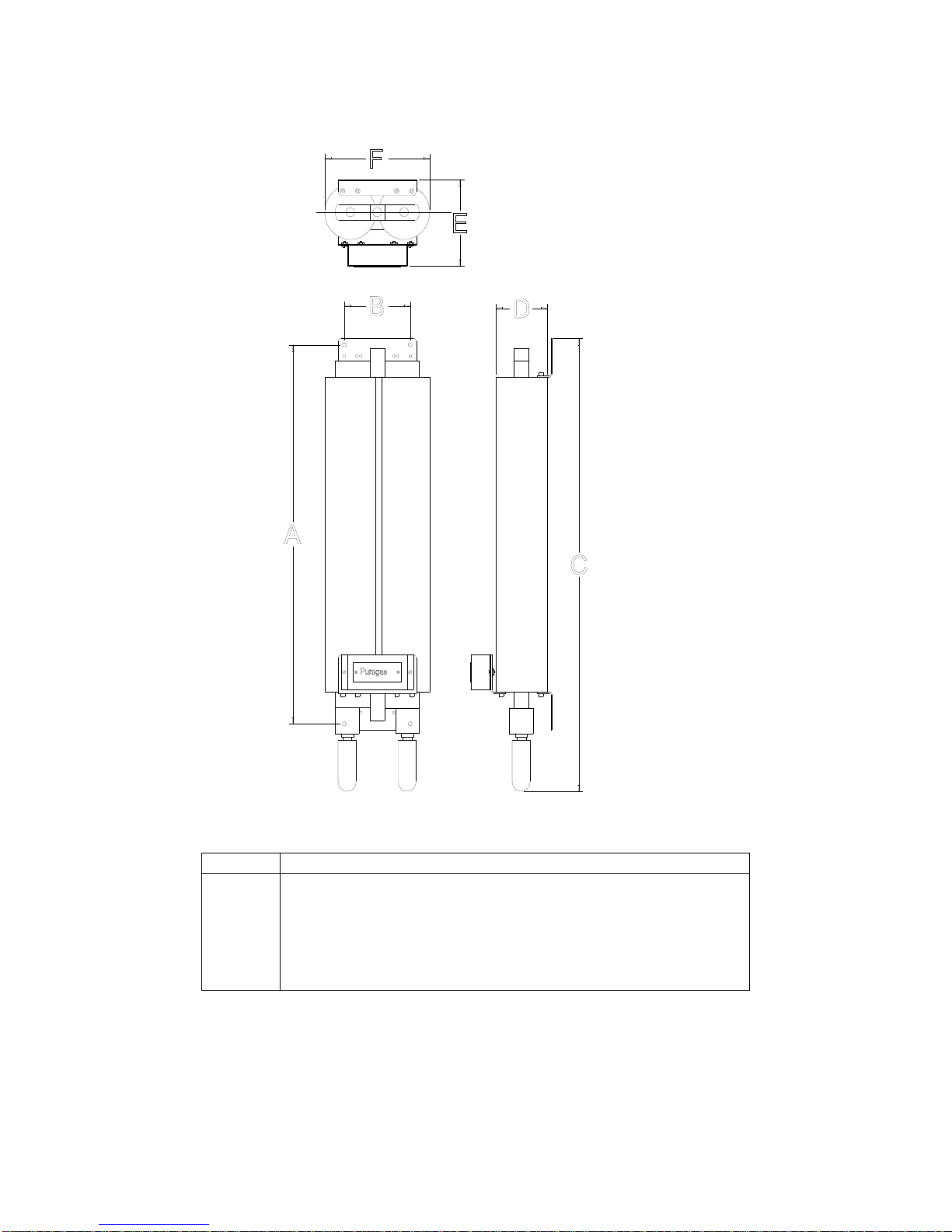

Mounting

All of the models covered by this instruction manual can be wall-mounted using the

brackets provided. Products should be mounted with the desiccant towers in a vertical

orientation for best results. Be careful to not overtighten purge mufflers.

NOTE: Dimension “A” can be 6, 9, 12, or 20,

FIGURE 4: DIMENSIONS OF PHF, PCDA, PHCA, AND PCME MODELS

depending on model. Dimensions in inches.

Page 5 of 24

MODEL A B C D E F

PCR 15

PCR 25

PCR 50

18.625 6 25.5 3.25 5.5 8.25

22.935 6 30 4.25 6.4 9.25

28.125 6 35.25 4.25 6.4 9.25

FIGURE 5: DIMENSIONS OF PCR MODEL

Note: All dimensions are in inches.

Page 6 of 24

Loading...

Loading...