Puregas P4200W2, P4200W2LP, P4202W2LP, P4202W2, P4202W2H User Manual

P4200W2 Series Air Dryer

P4200W2 P4200W2LP P4202W2 P4202W2LP P4202W2H

User’s Guide

Models covered:

P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

1. Welcome & Congratulations

Congratulations on your purchase of a new PUREGAS P4200W2 Series Air Dryer! We

here at PUREGAS are very proud of our products and we are committed to providing you

with the best value and service possible.

We are sure that you will be satisfied with your new air dryer and would like to thank you

for choosing PUREGAS for your air dryer requirements. We also hope that you will

continue to choose us for your future air pressure and related product purchases.

For information about this and other PUREGAS products, please visit us on the web at:

www.puregas.com

2. Introduction

PLEASE READ THIS USER’S GUIDE THOROUGHLY AND SAVE FOR

FUTURE REFERENCE.

This User’s Guide is provided for the benefit of our customers and contains information

and direction specific to the PUREGAS P4200W2 Series Air Dryer. Models covered

include P4200W2, P4200W2LP, P4202W2, P4202W2H and P4202W2LP. It will cover

topics including: safety, specifications, installation, registration, operation, testing,

maintenance, replacement parts, service, and troubleshooting issues. Observation and

compliance with this User’s Guide will ensure the maximum life and efficiency of your

air dryer.

This User’s Guide should be read thoroughly prior to installing, operating, or servicing

the air dryer in order to become familiar with the recommended procedures. This will

minimize the possibility of personal injury or damage to the unit due to improper

operation or handling.

Page 3 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

3. Table of Contents

8.12 Depressurizing the Dryer ........................ 49

1. Welcome & Congratulations .......................... 3

8.13 Connecting to Common Alarm Socket ... 49

2. Introduction ..................................................... 3

3. Table of Contents ............................................. 4

4. Safety & Warning Information ...................... 6

5. Overview & Specifications .............................. 9

5.1 Product Description .................................... 9

5.2 Key Features ............................................... 9

5.3 P4200W2 Series Air Dryer Models ............ 9

5.4 Technical Specifications ........................... 10

5.5 Dryer Function Overview ......................... 11

6. Installing Your Dryer .................................... 12

6.1 Safety & Warning Information ................. 12

6.2 Before You Begin ..................................... 13

6.3 Included Contents ..................................... 14

6.4 Required Tools and Materials ................... 14

6.5 Installation Steps ....................................... 15

6.6 Installation Checklist ................................ 22

8.14 Setting the System Pressure .................... 50

8.15 Setting the Static Pressure ....................... 51

8.16 Setting the Outlet Pressure ...................... 52

8.17 Connecting via Web Browser ................. 53

8.18 Using the Status Screen .......................... 55

8.19 Using the Setup Screen ........................... 58

8.20 Using the Event Screen ........................... 61

8.21 Using the Alarm Screen .......................... 62

8.22 Using the Firmware Screen ..................... 63

8.23 Connecting via SNMP ............................ 65

9. Testing Your Dryer ....................................... 66

9.1 Safety & Warning Information ................. 66

9.2 Measuring Compressor Amp Draw .......... 67

9.3 Measuring Voltage to Compressor ........... 68

9.4 Measuring Voltage at the Power Line

Filter ............................................................... 69

9.5 Measuring Incoming Voltage ................... 70

9.6 Measuring Voltages at Solid State Relay .. 71

9.7 Testing Consistent Heatless Dryer

7. Registering Your Dryer................................. 23

8. Operating Your Dryer .................................. 24

8.1 Safety & Warning Information ................. 24

8.2 Connecting an Air Line to the Dryer ........ 25

8.3 Powering the Dryer ON & OFF ................ 25

8.4 Using the Front Panel Display .................. 26

8.5 Identifying Dryer Alarms ......................... 29

8.6 Accessing the Setup Menu ........................ 33

8.7 Using the System Setup Menu .................. 34

8.8 Using the Alarm Setup Menu ................... 38

8.9 Using the Network Setup Menu................ 43

8.10 Removing the Front Panel ...................... 48

8.11 Removing the Top Cover ........................ 48

Page 4 of 113 P012308 - Rev. E

Cycling............................................................ 73

9.8 Testing Unloader Valve ............................ 74

9.9 Measuring Heatless Dryer Solenoid

Voltage............................................................ 75

9.10 Testing Precooler Fan ............................. 76

9.11 Testing Safety Relief Valve .................... 76

9.12 Testing Compressor ON/OFF Cycling ... 77

9.13 Testing High Duty Cycle Alarm ............. 78

9.14 Testing Humidity Alarm and System

Shutdown ........................................................ 79

9.15 Testing High Outlet Pressure Alarm ....... 81

9.16 Testing Low Outlet Pressure Alarm........ 82

9.17 Testing Air Fittings & Hoses for Leaks .. 84

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

10. Maintaining Your Dryer ............................. 85

10.1 Safety & Warning Information ............... 85

10.2 Six Month Maintenance .......................... 87

10.3 8,000 Hour Maintenance ........................ 88

11. Replacement Parts & Accessories .............. 89

11.1 Top Section Parts .................................... 89

11.2 Middle & Lower Section Parts 1 ............ 90

11.3 Middle & Lower Section Parts 2 ............ 91

11.4 Heatless Dryer Assembly Parts............... 92

11.5 Frame Section Parts ................................ 93

11.6 Accessories for Your Dryer .................... 94

11.7 Ordering Parts from PUREGAS ............. 95

12. Service & Repair.......................................... 96

12.1 Services Offered ..................................... 96

12.2 Initiating a Service Transaction .............. 96

13.11 Can’t Create a High Humidity Alarm /

Shutdown ...................................................... 103

13.12 High Cabinet Temperature Alarm....... 103

13.13 Inconsistent Heatless Dryer Cycling ... 104

13.14 Compressor Doesn’t Operate .............. 104

13.15 Compressor Won’t Build Pressure ...... 104

13.16 Compressor Excessive AMP Draw ..... 105

13.17 High Duty Cycle Alarm ...................... 105

13.18 Can’t Create a High Duty Cycle Alarm106

13.19 Compressor Rapid ON/OFF Cycling .. 106

13.20 Contacting PUREGAS Technical

Support.......................................................... 107

14. Appendix .................................................... 108

14.1 Wiring Diagram .................................... 108

14.2 Operational Limits and Defaults ........... 109

14.3 SNMP Parameters ................................. 110

13. Troubleshooting Your Dryer ...................... 97

13.1 Before You Call PUREGAS ................... 97

13.2 Safety & Warning Information ............... 97

13.3 Air Dryer Won’t Power ON.................... 99

13.4 Display Screen Not Functioning ............. 99

13.5 High Outlet Pressure Alarm .................... 99

13.6 Can’t Create a High Pressure Alarm ..... 100

13.7 Low Outlet Pressure Alarm .................. 100

13.8 Can’t Create a Low Pressure Alarm ..... 101

13.9 High Flow Rate Alarm.......................... 101

13.10 High Humidity .................................... 102

15. Limited Warranty Agreement .................. 111

Registration Reminder .................................. 111

16. Contacting PUREGAS .............................. 112

16.1 General .................................................. 112

16.2 Sales ...................................................... 112

16.3 Service .................................................. 112

16.4 Technical Support ................................. 112

17. Notes............................................................ 113

Page 5 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

4. Safety & Warning Information

This section contains general information about safety and warning points to consider and

adhere to during installation, operation, and maintenance of your air dryer. PLEASE

READ THIS SECTION BEFORE PERFORMING ANY OPERATION OR

PROCEDURE ON YOUR AIR DRYER.

Additional warnings specific to an operation or procedure will also be presented

throughout the following sections. These will include the symbol as well as a label of

“WARNING!”, “CAUTION!”, or “IMPORTANT!”. Please be sure to pay close

attention for these warnings and read them as you encounter them.

WARNING!

For your safety, all the information in this User’s Guide must be

followed to minimize the risk of electrical shock, and prevent

property damage or personal injury.

WARNING!

Extreme care should be exercised to avoid contact with live

electrical circuits. Many procedures performed during installation,

operation, testing, and maintenance of this air dryer require the

equipment to be running, creating a situation for potential electrical

shock. It is highly recommended that you remove all jewelry before

performing any procedures.

WARNING!

Internal surfaces may be hot. Use care when coming into contact

with internal components as there is a potential for some of these

components to become hot when in operation or standby.

Page 6 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

your air dryer.

WARNING!

High Noise. PUREGAS air dryers are meant to be installed in an

unattended area.

CAUTION!

Proper Installation & Maintenance as outlined in this User’s Guide is

extremely important to ensure the reliability and longevity of the

equipment as well as prevent damage or personal injury.

CAUTION!

Depressurizing the air dryer may be necessary before performing

certain procedures. NEVER remove pressure sensing tubes from the

Control Board without depressurizing the air dryer first, or damage to

the Control Board will occur.

CAUTION!

Incoming power to dryer must be:

• 15 amp service recommended

• 10 amp slow blow fuse

• 110 - 125 VAC, 50/60 Hz for P4200W2 & P4200W2LP

models

• 220 - 230 VAC, 50/60 Hz, 1 Phase for P4202W2,

P4202W2LP & P4202W2H models

IMPORTANT!

Performing routine maintenance as outlined in the Maintaining Your

Dryer section will ensure optimal performance over the lifecycle of

Page 7 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

AND MAY VOID THE WARRANTY.

IMPORTANT!

Performing procedures not described in this User’s Guide or installing

components not supplied by PUREGAS is NOT RECOMMENDED

CAUTION!

This Air Dryer does not contain an internal Surge Protection Device

(SPD). If an SPD is required it must be supplied by the user.

CAUTION!

Observe precautions for handling Electrostatic Sensitive Devices.

IMPORTANT!

Installation of PUREGAS air dryers are intended for network

telecommunication facilities (non-customer premises) only.

Page 8 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

5. Overview & Specifications

5.1 Product Description

The P4200W2 Series Air Dryer from PUREGAS is designed to intake wet ambient

air and remove the moisture for delivery to applications requiring a constant, ondemand source of dry, pressurized air. This process is fully automatic and will

remain consistent with minimal required periodic maintenance. This dryer is

designed specifically for indoor use.

The P4200W2 Series Air Dryer employs a fully digital operating platform offering

the most accurate readings of dryer variables, removable access panels allowing

easier access for adjustment and maintenance, and ultra quiet compressors with an

industry leading maintenance interval of 8,000 hours.

5.2 Key Features

• LCD display of all operating parameters

• Solid state microprocessor-based circuitry eliminates costly maintenance

• Accurate humidity sensing within ±0.1% RH

• Quietest dryer on the market

• Pressure Ranges from 35 – 138 KPa or 2 – 69 KPa (LP Models)

• Remote alarm reset capabilities

• SNMP communication compatible

• Remote access through HTML interface

• Oil-less compressor with 8,000 hour maintenance interval

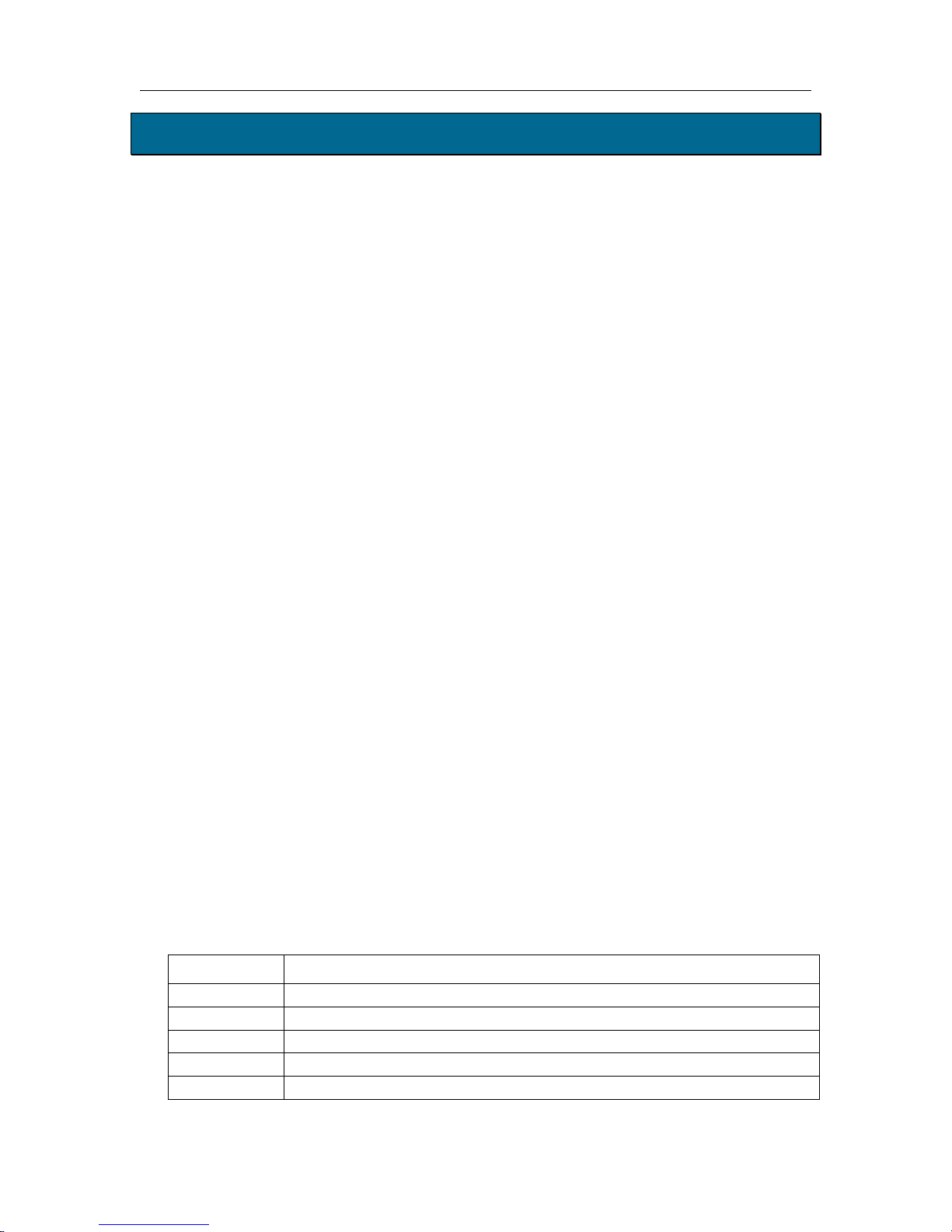

5.3 P4200W2 Series Air Dryer Models

Model Description

P4200W2 110 - 125 VAC, Standard Pressure 35 – 138 KPa

P4200W2LP 110 - 125 VAC , Low Pressure 2 – 69 KPa

P4202W2 220 - 230 VAC , Standard Pressure 35 – 138 KPa

P4202W2LP 220 - 230 VAC , Low Pressure 2 – 69 KPa

P4202W2H 220 - 230 VAC , Standard Pressure 35 – 138 KPa

Page 9 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

5.4 Technical Specifications

Output

Capacity

Power

Requirements

Running Amps

Outlet Pressure

Range

Outlet Air

Humidity

Compressor

Drying Method

P4200W2 P4200W2LP P4202W2

Normal: 74 SCMD Maximum: 119 SCMD

110 - 125 VAC, 1 Phase,

50 / 60 Hz

8.6 Amps

(15 Amp service

recommended)

35 - 138

KPa

2 – 69

KPa

2-cylinder, 3/4 HP, oil-less type compressor

220 - 230 VAC, 1 Phase,

50 / 60 Hz

3.9 Amps

(15 Amp service

recommended)

35 - 138

KPa

Less than 2% RH

Heatless Desiccant

P4202W2

LP

2 – 69

KPa

P4202W2H

Normal: 90 SCMD

Max: 119 SCMD

220-230 VAC, 1 Phase,

50Hz

4.2 Amps

(15 Amp service

recommended)

35 – 138

KPa

Operating

Temperature

Range

Noise Level:

Heat

Dissipation

Alarms

Monitoring

Outlet

Connections

Dimensions

Net / Shipping

Weight

5° to 30° C (optimal)

63 dBA @ 1m

3,521 BTU / hr 2,924 BTU / hr

Standard alarms – complete readings of all critical measurement points, individual

alarm indication display

Web Browser and SNMP compatible communications via Network IP

1/2” NPT Female

53cm D x 64cm W x 124cm H

100 kgs / 126 kgs

Page 10 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

5.5 Dryer Function Overview

# Component Description

1 Compressor Compresses drawn in ambient air.

2 Precooler Cools compressed air prior to drying function.

3 Unloader Valve Relieves excess Compressor head pressure.

4 Heatless Dryer Removes moisture from compressed air.

5 Capacity Control Valve Regulates System Pressure at 345 KPa (50 PSI)

and prevents air from bleeding back through the

Heatless Dryer.

6 Air Tank Stores dry compressed air.

7 Static Pressure Regulator Regulates the Static Pressure at 138 KPa (20 PSI)

and maintains constant pressure on the Combo

Block for accurate Flow measuring.

8 Combo Block Measures the Flow of compressed air and houses

the Humitter.

9 Outlet Pressure Regulator Regulates the Outlet Pressure.

10 Pressure Outlet Outputs the pressure set by the Outlet Pressure

Regulator.

Page 11 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

user.

6. Installing Your Dryer

6.1 Safety & Warning Information

WARNING!

Internal surfaces may be hot. Use care when coming into contact

with internal components as there is a potential for some of these

components to become hot when in operation or standby.

WARNING!

Extreme care should be exercised to avoid contact with live

electrical circuits. Many procedures performed during

installation, operation, testing, and maintenance of this air dryer

require the equipment to be running, creating a situation for

potential electrical shock. It is highly recommended that you

remove all jewelry before performing any procedures.

WARNING!

High Noise. Puregas air dryers are meant to be installed in an

unattended area.

CAUTION!

Proper Installation & Maintenance as outlined in this User’s Guide

is extremely important to ensure the reliability and longevity of the

equipment as well as prevent damage or personal injury.

CAUTION!

This Air Dryer does not contain an internal Surge Protection

Device (SPD). If an SPD is required it must be supplied by the

Page 12 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

RECOMMENDED AND MAY VOID THE WARRANTY.

IMPORTANT!

Performing procedures not described in this User’s Guide or

installing components not supplied by PUREGAS is NOT

IMPORTANT!

Installation of PUREGAS air dryers are intended for network

telecommunication facilities (non-customer premises) only.

6.2 Before You Begin

6.2.1 Carefully inspect the unit, including the shipping box as well as the air

dryer, for ANY DAMAGE CAUSED BY SHIPPING. If any shipping

damage is detected, it is important to file a claim with the shipping

company prior to continuing the installation procedures.

6.2.2 Read the entire Installing Your Dryer section to familiarize yourself with

the components and procedures before performing the air dryer installation.

6.2.3 Verify the installation location of the air dryer:

6.2.3.1 Well ventilated and free from abrasive dust or chemicals.

6.2.3.2 Ambient temperature is between 5° and 30° C (optimal).

NOTE: Higher temperatures will decrease component lifespan.

6.2.3.3 Meets the following power requirements:

• 110 - 125 VAC for P4200W2 and P4200W2LP models

• 220 - 230 VAC, 1 Phase for P4202W2, P4202W2LP & P4202W2H models

• All models require 50/60 Hz and minimum 15 amp service with a 10 amp

slow blow fuse

6.2.4 Notify the alarm center of the installation and potential for alarms during

the process (as necessary).

Page 13 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

6.3 Included Contents

(1) P4200W2 Series Air Dryer

Package located inside the dryer:

(2) Alarm Connector

(1) User’s Guide (not

shown)

(1) Mini CD (not shown) (1) Allen Wrench

(1) Purge Muffler (1) Compressor Connector Tool

(1) Power Cord

6.4 Required Tools and Materials

• Large adjustable wrench

• Medium adjustable wrench

• 7/16” wrench

• Band cutters or snips

• Pipe dope or pipe thread tape

• Cup of soapy water

• 1-inch paint brush

(recommended)

Page 14 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

6.5 Installation Steps

6.5.1 Remove all shipping materials.

NOTE: If ANY SHIPPING

DAMAGE is detected, file a

claim with the shipping

company prior to continuing

the installation procedures.

6.5.2 Place the dryer at the

operating location.

6.5.3 Remove the Front Panel.

6.5.4 Check for loose parts,

hoses, or wiring.

NOTE: If ANY SHIPPING

DAMAGE is detected, file a

claim with the shipping

company prior to continuing

the installation procedures.

Page 15 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

6.5.5 Using a 7/16” wrench,

remove the shipping block

from under the Compressor

Plate.

Discard block and bolt.

6.5.6 Remove the ship-loose

contents package.

On BACK of dryer:

6.5.7 Verify that the Red Orifice

Plug is still installed where

shown.

6.5.8 Install the Purge Muffler

(optional).

6.5.9 Verify that the dryer is

powered OFF.

Page 16 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

6.5.10 Plug the AC Power Cord

into the dryer.

6.5.11 Plug in or wire the Power

Cord to an outlet:

• 110 - 125 VAC power

outlet for P4200W2 and

P4200W2LP model

• 220 – 230 VAC, 1 phase, power outlet for P4202W2, P4202W2LP, and

P4202W2H models.

6.5.12 Power the dryer ON.

NOTE: The Compressor and

Heatless Dryer will start,

creating air flow through the

Red Orifice Plug.

6.5.13 Set the System Pressure:

With Compressor running:

6.5.13.1 Pull the Capacity

Control Valve knob out.

Page 17 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

6.5.13.2 Turn the knob until

the reading on the

Pressure Gauge is 345

KPa (50 PSI).

6.5.13.3 Push the knob in to

lock.

6.5.14 Let the dryer run until the

Humidity drops below 2%

(may take up to 15 minutes).

NOTE: Press RESET if the

dryer goes into

SHUTDOWN.

6.5.15 Power the dryer OFF.

Page 18 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

6.5.16 Remove the Red Orifice

Plug from the Outlet Pressure

Port.

CAUTION: Be careful when

removing plug. System may be

pressurized.

6.5.17 Connect the air supply line to the Outlet Pressure Port.

PUREGAS recommends using Installation Kit P011752 to connect your air dryer

to the air supply line (See section 11.6 for detail).

6.5.18 Power the dryer ON.

6.5.19 Set the Static Pressure:

6.5.19.1 Pull Static Pressure

Regulator knob out.

Page 19 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

6.5.19.2 Turn knob until the

reading on the Pressure

Gauge is 138 KPa (20

PSI).

6.5.19.3 Push knob in to lock.

6.5.20 Set the Outlet Pressure:

6.5.20.1 Pull the Outlet

Pressure Regulator knob

out or loosen the

retaining nut (LP

models).

6.5.20.2 Turn knob until

Outlet Pressure

(OUTLET) reading is

at the desired setting.

6.5.20.3 Push knob in to lock

or tighten retaining nut

(LP models).

Page 20 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

6.5.21 Check for air leaks:

NOTE: This is a general procedure that can be applied to any fitting or hose

that has air pressure in it. DO NOT SOAP TEST THE HUMIDITY

SENSOR FITTING. DAMAGE TO THE SENSOR MAY OCCUR.

With Compressor NOT running:

6.5.21.1 Listen for any ‘hissing’ sounds which may indicate a fitting or hose

air leak.

With Compressor running:

6.5.21.2 Use a 1-inch paint

brush to dab soapy water

on the air fitting or hose

connection to be tested.

If air bubbles appear at the

connection, this indicates that

air is leaking from the

connection.

If any leaks are detected, take steps to seal them off (as necessary):

• Tighten the fitting

• Re-connect the hose end

• Replace the fitting / hose / component

6.5.22 Re-install the Front Panel.

Page 21 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

6.5.23 Connect a Common Alarm (as required):

6.5.23.1 Insert the included

Alarm Connector into

either of the two (2)

Alarm Ports.

6.5.23.2 Wire an external

alarm wire pair to the

Alarm Connector as

required:

• Common and N.C. for

OPEN ON ALARM

operation.

• Common and N.O. for CLOSE ON ALARM operation.

6.5.24 REGISTER YOUR DRYER. See section 7 for details.

6.6 Installation Checklist

No shipping damage was detected.

Dryer location meets the following requirements:

o Well ventilated

o Free from abrasive dust or chemicals

o Ambient temperature is between 5° and 30° C (optimal)

Shipping block removed from Compressor Tray.

System Pressure is set to 345 KPa (50 PSI).

Static Pressure is set to 138 KPa (20 PSI).

No air leaks are present in the system.

No alarms are present on the Display Panel.

Page 22 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

7. Registering Your Dryer

Please take a moment to register your PUREGAS P4200W2 Series Air Dryer.

Registering is necessary to activate the Limited Warranty on your product. Once you

register, you are eligible to receive free technical support, as well as updates

concerning your PUREGAS products.

Register Online at www.puregas.com/registration

Or by Phone 1-800-521-5351 (option 2)

Have the following information available:

Model #: Serial #:

Company Name: Location Name:

Shipping Address:

City: State: Zip Code:

Contact Name: Phone #: ( ) - ext.

Email:

Page 23 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

RECOMMENDED AND MAY VOID THE WARRANTY.

8. Operating Your Dryer

8.1 Safety & Warning Information

WARNING!

Extreme care should be exercised to avoid contact with live

electrical circuits. Many procedures performed during

installation, operation, testing, and maintenance of this air dryer

require the equipment to be running, creating a situation for

potential electrical shock. It is highly recommended that you

remove all jewelry before performing any procedures.

WARNING!

Internal surfaces may be hot. Use care when coming into contact

with internal components as there is a potential for some of these

components to become hot when in operation or standby.

WARNING!

High Noise. Puregas air dryers are meant to be installed in an

unattended area.

CAUTION!

Observe precautions for handling Electrostatic Sensitive Devices.

IMPORTANT!

Performing procedures not described in this User’s Guide or

installing components not supplied by PUREGAS is NOT

Page 24 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

8.2 Connecting an Air Line to the Dryer

8.2.1 Remove the Red Orifice

Plug from the Outlet Pressure

Port.

CAUTION: Be careful when

removing plug. System may be

pressurized.

8.2.2 Connect the air supply line to the Outlet Pressure Port.

PUREGAS recommends using Installation Kit P011752 to connect your air dryer

to the air supply line (See section 11.6 for detail).

8.3 Powering the Dryer ON & OFF

CAUTION!

Incoming power to dryer must be:

• 15 amp service recommended

• 10 amp slow blow fuse

• 110 - 125 VAC, 50/60 Hz for P4200W2 & P4200W2LP

models

• 220 - 230 VAC, 50/60 Hz, 1 Phase for P4202W2,

P4202W2LP & P4202W2H models

8.3.1 Power Circuit Breaker -

Controls the main power to

the dryer.

Page 25 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

8.4 Using the Front Panel Display

CAUTION!

The Display Screen is covered by a clear protective layer that

guards against Electrostatic Discharge (ESD). DO NOT REMOVE

THIS LAYER.

8.4.1 ALARM LED – Indicates an alarm is present.

8.4.2 RESET Button – Clears an alarm and allows the system to continue

operating.

8.4.3 FUNCTION Button –

• Acts as a HOLD button to freeze the current information screen on

the display. When pressed again, it will allow the information

screens to begin cycling again.

• Acts as an ENTER button in the Setup Menu screens.

8.4.4 Arrow Buttons – Used to access, navigate, and change values in the Setup

Menu screens.

Page 26 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

8.4.5 Display Screen - Shows the current dryer readings. Will cycle between

the following three (3) information screens (unless the HOLD button has

been pressed):

8.4.5.1 Sys Status Screen

SYS STATUS - Running Status of the system:

• ONLINE – System is Online.

• SHUTDOWN – System has been shutdown as a result of either a

High Humidity or High Cabinet Temperature alarm.

CAB TEMP – Temperature of the dryer cabinet compartment.

HUMIDITY – Humidity level of the system.

8.4.5.2 Outlet Screen

OUTLET – Outlet Pressure regulated by the Outlet Pressure Regulator.

FLOW – Air Flow Rate.

TANK – Air Tank Pressure - fluctuates between 172 – 345 KPa.

Page 27 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

8.4.5.3 Compressor Run Time Screen

DUTY CYCLE – The percentage of time the Compressor is ON versus

time it is OFF during the last Air Tank pressurization cycle.

TOTAL – How many hours the Compressor has run since the last

Compressor Total Time Reset.

8.4.5.4 Unit in Standby Screen

Occurs when the dryer is connected to a Cycle Kit and has been switched

to Standby Mode.

Page 28 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

8.5 Identifying Dryer Alarms

8.5.1 High Cabinet Temperature Alarm -

Occurs when the temperature in the dryer cabinet (CAB TEMP) rises above

46°C for more than one (1) minute. If the temperature rises above 50°C for

more than one (1) minute, the air dryer will go into SHUTDOWN mode to

protect against damage due to overheating.

This screen will be displayed,

showing the Date and Time that

the alarm occurred.

8.5.1.1 Press the Info () Button

to see the detail of the

alarm.

See section 13.12 for troubleshooting information.

8.5.2 High Humidity Alarm –

Occurs when the Humidity level (HUMIDITY) rises above the alarm

threshold for more than one (1) minute. The air dryer will go into

SHUTDOWN mode to prevent saturated air from being delivered to the

supply line. (Default setting is 10%)

This screen will be displayed,

showing the Date and Time that

the alarm occurred.

8.5.2.1 Press the Info () Button

to see the detail of the

alarm.

See section 13.10 for troubleshooting information.

Page 29 of 113 P012308 - Rev. E

PUREGAS, LLC P4200W2 Series Air Dryer User’s Guide

8.5.3 Low Outlet Pressure Alarm –

Occurs when the Outlet Pressure (OUTLET) drops below the alarm

threshold for more than one (1) minute. (Default setting is 2.0 KPa)

This screen will be displayed,

showing the Date and Time that

the alarm occurred.

8.5.3.1 Press the Info () Button

to see the detail of the

alarm.

See section 13.7 for troubleshooting information.

8.5.4 High Outlet Pressure Alarm -

Occurs when the Outlet Pressure (OUTLET) rises above the alarm threshold

for more than one (1) minute. (Default setting is 138.0 KPa)

This screen will be displayed,

showing the Date and Time that

the alarm occurred.

8.5.4.1 Press the Info () Button

to see the detail of the

alarm.

See section 13.5 for troubleshooting information.

Page 30 of 113 P012308 - Rev. E

Loading...

Loading...