Puregas MHT Series, MHT25, MHT40, MHT60, MHT100 Owner's Manual

...

Owners Manual

Refrigerated Air Dryer

MHT SERIES

TABLE OF CONTENTS

INTRODUCTION, RECEIVING, DATA LABEL 2

HOW THE AIR DRYER WORKS 3

INSTALLATION 4

IMPORTANT: READ THIS MANUAL

CAREFULLY. IT CONTAINS INFORMATION

ABOUT SAFETY AND THE SAFETY OF OTHERS.

ALSO BECOME FAMILAR WITH THE PROPER

INSTALLATION AND CONTROLS OF THE AIR

DRYER BEFORE OPERATING. ONLY QUALIFIED,

TRAINED AND LISCENSED PERSONAL SHOULD

SERVICE OR OPERATE THIS EQUIPMENT.

CAUTION:THIS MACHINE CONTAINS HIGH

PRESSURE GAS AND ELECTRICITY.

DRYER CONTROLS, START UP, INITIAL RUN

PROCEDURE

WEEKLY MAINTENANCE, SETTING DRAIN

TIMER, TECHNICAL DATA

ADJUSTING SUCTION PRESSURE/EVAP

TEMP, ELECT SCHEMATICS

NOTE:

If you need service on your dryer please have

the following information:

1. Model #__________________________

2. Serial #___________________________

3. Voltage___________________________

4. Name of distributor that dryer was purchased from:

_________________________________

_________________________________

5. Description of the problem:

5

6

7

INTRODUCTION

Thank you for selecting an MHT Series refrigerated air dryer from PUREGAS. The refrigerated air dryer is specifically designed

and manufactured for drying and purifying compressed air generated by an air compressor.

PLEASE READ THIS INSTRUCTION MANUAL CAREFULLY BEFORE USING THE DRYER.

Please pay attention to the precautions in transportation, installation and operation that are listed in this manual. Please use the dryer

according to our application guide and be sure to perform the proper preventative maintenance recommended in this manual. Failure

to perform the preventative maintenance will void the air dryer warranty. Refrigeration used in this air dryer is environmentally

friendly R134a and is available at local refrigeration wholesalers. Direct any question not covered in this manual to your distributor

or call PUREGAS at 1-800-521-5351. Before calling with any questions always have the air dryer model #, serial # and

pressure gauge readings. Service and maintenance can be obtained from your distributor. If you do not know your

distributor please contact the factory. Authorization # must be obtained from PUREGAS. before any parts or dryers are returned to

the factory. PUREGAS. will not be responsible for anything returned without authorization.

RECEIVING AND INSPECTION

1. The dryer cannot be tilted on its’ side or upside down during shipping.

2. Use forklift from the bottom of the dryer when installing and moving.

3. Dryers are shipped F.O.B. factory. Immediately upon arrival check the dryer for possible damage. If damage is found, report it to

the carrier and file a damage claim.

4. Check dryer data label to be sure you have the right dryer. Check the data labels voltage and amperage to be sure it is correct and

the one you ordered.

5. Check refrigeration gauges for pressure. If gauges read 0 PSIG STOP! Do not start dryer. Call your distributor for service. This

could mean there is a leak and refrigerant has leaked out.

DATA LABEL

The data label is affixed to the outside of the cabinet. This label identifies the air dryer’s model and serial numbers and important

technical data. Before installing the dryer check all of the information on the data label for the correct model and voltage. If the

model number and voltage are incorrect do not install the dryer. Do not put power to the dryer. Call your local distributor.

2

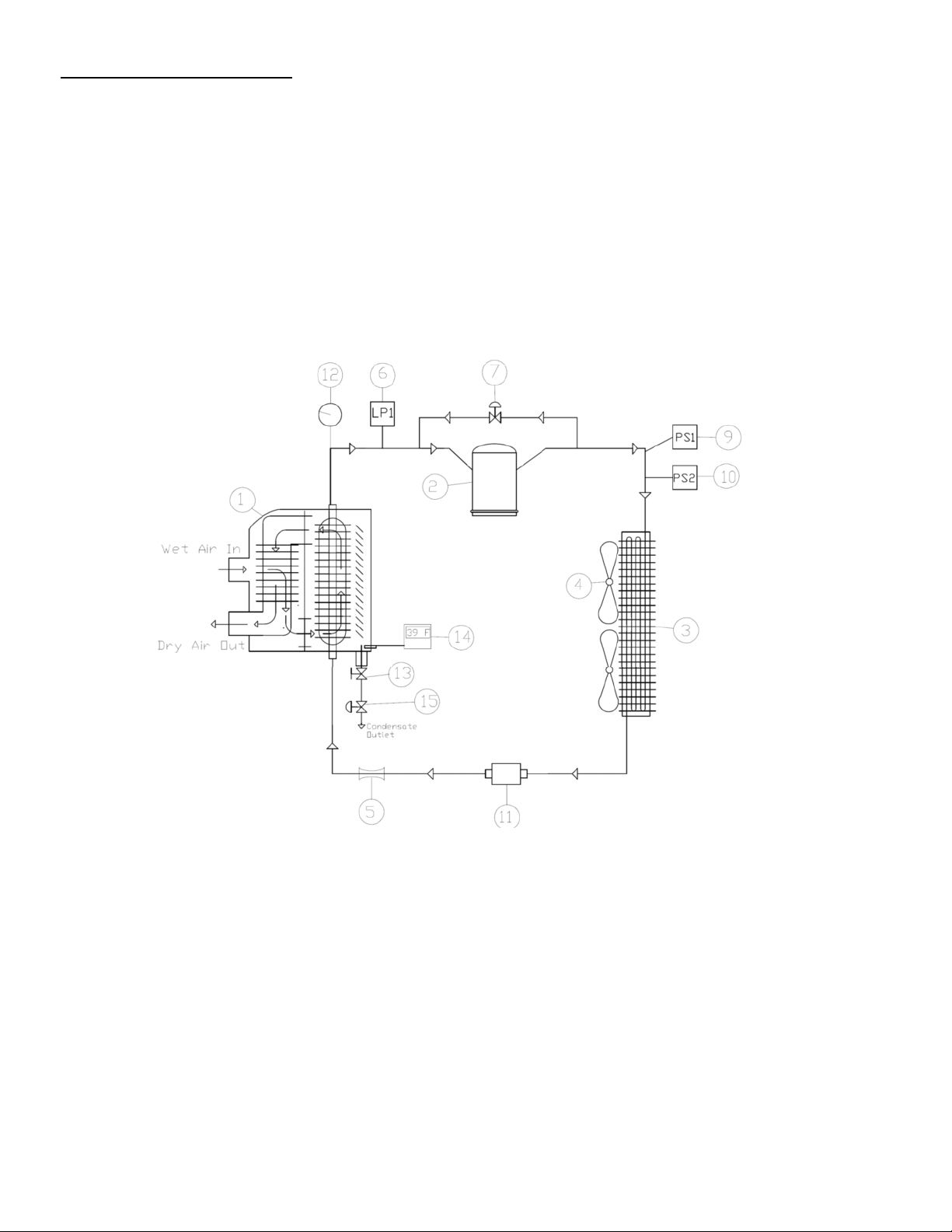

HOW THE AIR DRYER WORKS

MHT Series refrigerated compressed air dryers use refrigeration cooling to condense entrained moisture out of the compressed air

stream. Warm saturated air enters the air-to-air heat exchanger at the dryer inlet. In the air-to-air heat exchanger the inlet air is precooled by the outgoing cold air. The pre-cooled air then enters the air-to-refrigerant heat exchanger where it is cooled to its lowest

point by the refrigeration in the evaporator. As the air is cooled, moisture in the air changes from a vapor to a liquid. The liquid

condensate is removed from the airstream by the separator and discharged from the dryer by the automatic drain valve. The cold air

is reheated by incoming warm air as it passes back through the air-to-air heat exchanger. Pre-cooling the inlet air reduces the heat

load on the refrigerant compressor, permitting the use of a smaller refrigerant compressor. The outgoing cold air is reheated by the

incoming hot air. As a result the outlet air is warmed up as it leaves the dryer. This prevents the outlet pipe from sweating. The air

exits the dryer and is now clean and dry, ready for use.

3

Loading...

Loading...