1

Thank you, and Congratulations on your purchase of The PureEffectTM ULTRA-UC Water Filtration

System Featuring: Our All-Natural FluorSorbTM Anti-Fluoride, Wide-Spectrum Anti-Radiation,

SuperBlockTM Anti-Chemical, KDF55® Heavy Metal Filtration and Natural Alkalization Technologies.

INSTALLATION INSTRUCTIONS

IMPORTANT! - BEFORE YOU START:

-Ensure there is a pressure regulator installed and is in proper working order before

proceeding. At no time should the filter housings be subject to more than 75PSI (most

common PSI range is between 40-75). You should contact a licensed plumber if you are not

able to check this on your own. Excessive water pressure could cause damage to the system

and water to leak out. Failure to follow proper installation instructions voids all

warranties and liabilities.

- The system should be installed where it is protected from freezing temperatures and

direct sunlight. Do not install the system where if would cause damage if leakage occurred.

1. ❏ Unpack your system, remove and set aside cartridges (by unscrewing chambers) and

inspect system for any transportation damage. If damage is found, please contact us right

away.

2. ❏ Find the individually wrapped White Elbow, also find the RED tubing with the

second white elbow attached. Locate the words “IN” and “OUT” on the unit’s water

connection ports. Screw the elbow with RED tube into the “IN” port and the additional

elbow, into the “OUT”. Note: The white elbow attached to the red tubing is outfitted with

a built-in flow restrictor to ensure optimal 0.5gpm water flow, which helps for greater

contaminant absorption. Please ensure this elbow is always connected on the input side

of the unit, even if you ever change tubing.

Customer Support:

Tel: 1-347-492-4014

Email: info@pureeffectfilters.com

www.PureEffectFilters.com

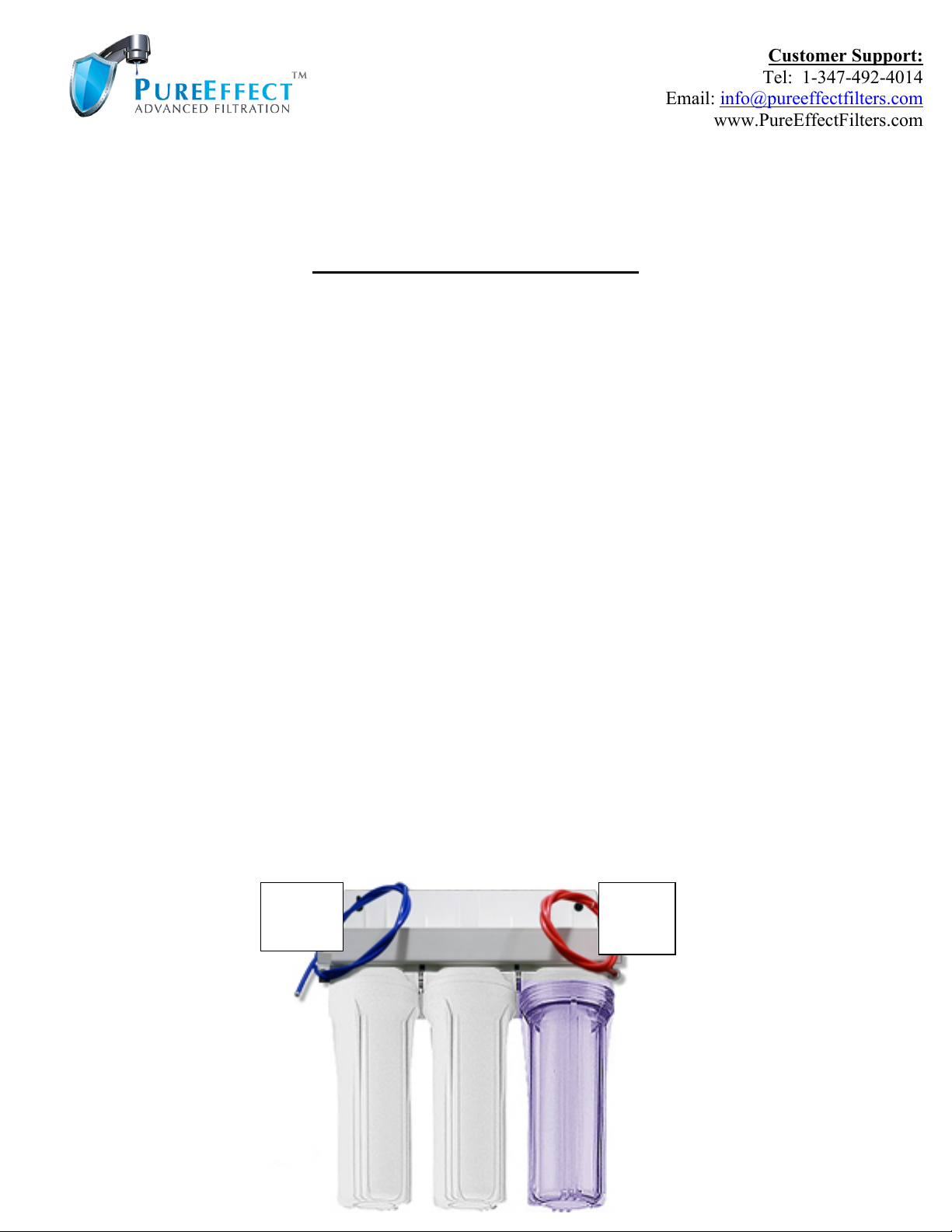

Red

Input

Blue

Output

2

3. ❏ Turn-Off Cold water supply via your Shut-Off Valve (Angle Stop) or water supply to

whole house. Note: It may be necessary to turn off the hot water supply as well.

4. ❏ Disconnect your existing connection(e.g. Riser Tube) from the cold water Angle Stop.

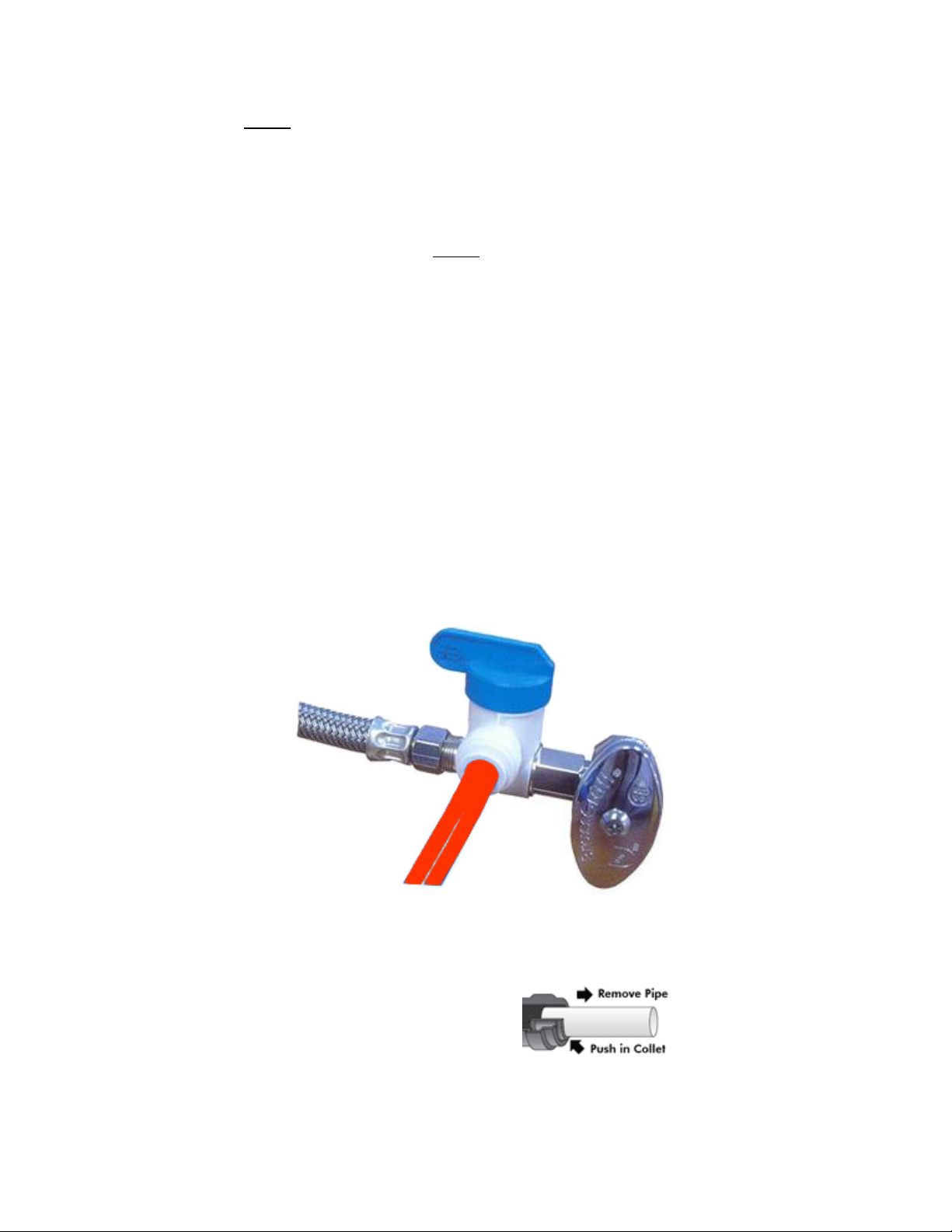

5. ❏ Connect the provided John Guest® Angle Stop Adapter Valve to the cold water Angle

Stop, see example pictured below. Note: Applying Plumbers Tape on the threading can

help with any leaks.

a. Reconnect your Existing Riser Tube to the Angle Stop Adapter Valve.

b. Position unit where you’d like, and ensure that the blue filter faucet and red water

input tubing will adequately reach the unit. Hang the filter system under the sink at

least 4” above floor (to allow for removal of chambers for cartridge changes).

c. Push-in the available end of the ¼” Red “IN” tube into the ¼” output port of the

Angle Stop Adapter Valve until it “pops-in” as far as it can go.

(If additional filtered water output connections are desired, e.g. fridge-water

Supply/Ice-maker connections, etc… please ask us about adding a ¼” 2-way

splitter to your unit’s output port).

6. ❏ Install the provided dedicated faucet into the sink. (See instructions on next page).

** To Disconnect

the tube from

connection:

! Angle Stop

(cold water)

! Angle Stop Adapter Valve

Riser Tube "

Red “IN” Tube "

3

FAUCET INSTALLATION INSTRUCTIONS

1. ❏ Use existing spray hose / soap dispenser hole, or Drill a 7/16” or 1/2” hole in sink top.

(We recommend using a carbide drill, use tape to protect sink top. If your sink is ceramic,

granite or some other fragile material, please consult with an expert to avoid cracking the

material during drilling).

2. ❏ Slide Metal Base Plate onto the threaded faucet shank, followed by Rubber Washer.

3. ❏ Insert Shank through the newly drilled or existing sink hole.

4. ❏ Under sink, Slide Locating

Washer, followed by Locking

Washer onto shank.

5. ❏ Thread the Brass Nut onto shank,

position faucet and tighten nut.

6. ❏ Insert the BLUE ¼” tube into the

“OUT” elbow of the filter unit.

(Ensure it pops in as far as it can go).

7. ❏ Ensure all connections are tight.

8. ❏ Proceed to Page 5 for cartridge

flush and leak test instructions.

Blue 1/4” Tubing (already connected

to faucet).

Existing / New Hole (drill

7/16” or 1/2” Diameter.)

Locating Washer

Brass Nut

Threaded Shank

Brass Nut

Locking Washer

Faucet

Metal Base Plate

4

GENERAL DIAGRAM

FLUORSORB

TM

CARTRIDGE

DUALCARB-SUPERBLOCK

TM

ANTIRAD-PLUS

TM

CARTRIDGE

5

INITIAL CARTRIDGE FLUSH AND SYSTEM LEAK TEST

IMPORTANT! – ENSURE CARTRIDGES ARE INSERTED IN CORRECT ORDER!

Note: You may want to place something under the unit to catch the

water which is released when you unscrew the last chamber for

Step D.

1. Remove shrink wrapping and insert the first two cartridges

only: SuperBlockTM cartridge into Chamber #1 and

FluorSorbTM cartridge into Chamber #2, screw the chambers

closed. Screw the last chamber closed also, it should be empty for

now.

A. Slowly turn on cold water, check newly installed faucet

and all connections for a watertight seal. *Note: you may hear a

slight “hissing” sound when the filter is working, this is normal

and is due to the built-in flow-regulator.

B. With your cold water on, gently turn the Handle on the

newly installed faucet to the side to allow water flow.

C. Check again for any leaks on all tubing and filter

connections to ensure watertight connection. If there are leaks at

input or output ports: ensure that the red and blue tubing is

pushed as far as it can go into the connecting elbows on the unit.

D. As the first water begins to flow, you may notice a small amount of grey carbon

dust pass through as the cartridges get flushed. Allow the cold water to run on full for 10

minutes then turn off faucet & shut off water supply to filter via the Angle Stop Adapter

Valve. Remove Shrink Wrapping and Insert the last cartridge (AntiRad-PlusTM) in

Chamber #3 and flush the entire system again for 15 minutes.

Note: First Water may be cloudy during few seconds of every use for about a week

as the Zeolite in this cartridge adapts and releases harmless mineral dust, this will subside

in about 1 week.

E. To Shut off the filter, turn off the faucet.

Congratulations! Your System is now ready for use.

THE FILTER SYSTEM IS DESIGNED FOR COOL - COLD WATER USE ONLY.

Do not allow hot water to run through the filter system.

Close

empty

until

Step D.

#2

#1

#3

Red

Input

Blue

Output

SuperBlockTM

FluorSorbTM

6

FOR CARE & OPTIMAL PERFORMANCE:

1. You may let the kitchen faucet run for a few seconds before using the filter, as this will

extend the filter life by flushing out any large sediment in the pipes.

2. Flush the system for 2 minutes when it hasn’t been used for 2 or more days.

3. Never run hot water through the filter, as the filtration process will not be effective. Use

only cold/cool water. Throughout usage you may notice the water level fluctuate in the

clear chamber, this is normal effect and does not interfere with proper filter function.

4. IMPORTANT! Whenever opening chambers to replace/remove cartridges, make sure to

first shut off the unit’s main water supply line.

5. Replace filter cartridges every 8 months* for consistently superior water quality. It is

highly recommended you lubricate the black rubber o-rings inside the housing with a

Food-Grade Silicone lubricant (we recommend “Novagard G662” from Amazon.com)

once a year to ensure leak-free performance.

*If there is high sediment amount in your water, your carbon block may clog sooner,

resulting in a reduction in water flow. In this case, only the first cartridge DualCarbSuperblockTM (carbon block) would need to be replaced sooner.

6. Every 6 months (recommended) or during cartridge changes: remove cartridges and

wipe the unit clean inside using Hydrogen Peroxide (do not get hydrogen peroxide inside

the filter cartridges), rinse with warm water, reinsert cartridges and flush with cold water

for 5 minutes.

7. Do not use system if your water pressure above 75PSI. In such a case, contact a plumber

to install a pressure regulator valve.

7

RETURN / EXCHANGE POLICY

1. If the filter arrived damaged, please call us immediately to get an exchange: 1-347-492-4014

2. If you choose to return the filter for any reason other than damage upon arrival, we will be happy to issue

a full purchase price refund or exchange within: 14 days of delivery date, minus shipping cost. The

return policy applies to water filter systems and any unused (sealed) filter media cartridges. If

cartridges have been opened and used, we will deduct the price of the cartridges from the refund, as they will

no longer be re-sellable.

3. If you decide to return past the 14-day return period, we will still accept the item for up to 30 days

from delivery date, however, there will be a reasonable 10% restocking fee applied. Please call us or send

an email to initiate the return process or if you have any further questions.

Once you’ve experienced your new system, feel free to share your positive experience by going to

our website product page and writing a review. ☺ Thank You! - The PureEffect Team

NO-HASSLE, 2-YEAR WARRANTY

SURVIVE & PROSPER, INC. dba PureEffectFilters.com, warrants it's water filter systems to be free of

defects in parts and workmanship for a period of: two (2) years from the date of purchase.

All our systems are made of high-quality components (not made in china) and are designed to last for many

years beyond the warranty period, but if any manufacturing defect is present, it will make itself know well

within the warranty period.

In the rare case that it should become necessary to repair or replace the filtration system or one of it's

components, please take a photo of the damaged part and email it along with your order # and a detailed

description of the defect to: info@pureeffectfilters.com or contact our Customer Service Department at: 1-

888-891-4821. We will handle your claim promptly, and as hassle-free as possible.

This warranty does not apply to defects resulting from action/s of the user such as: misuse, accidents,

improper installation, operation outside of specification (e.g. over the indicated PSI limit, exposure to direct

sunlight, freezing temps, UV light), improper maintenance or repair and unauthorized modification.

Survive & Prosper, Inc.’s total liability is limited solely to repair or replacement of the product. The

warranty set forth above is inclusive and no other warranty, whether written or oral, is expressed or implied.

Loading...

Loading...