Pure Blue H20 PB-TLRO4H50T Instruction Manual

REVERSE OSMOSIS

WATER FILTRATION SYSTEM

MODEL PB-TLRO4H50T

INSTRUCTION MANUAL

Pure Blue H20, LLC

13813 Monroes Business Park

Tampa, FL 33635 USA

www.pureblueh2o.com

(844) 787-3148 • (844) PURE-1-4-U

2015.06.30 #8739 PAW

Read this Manual BEFORE using this equipment.

This will not only familiarize you with the system, but it will help you determine the best location for

installation whether under a sink or in a remote location. Helpful diagrams follow. Keep this Manual for

future reference.

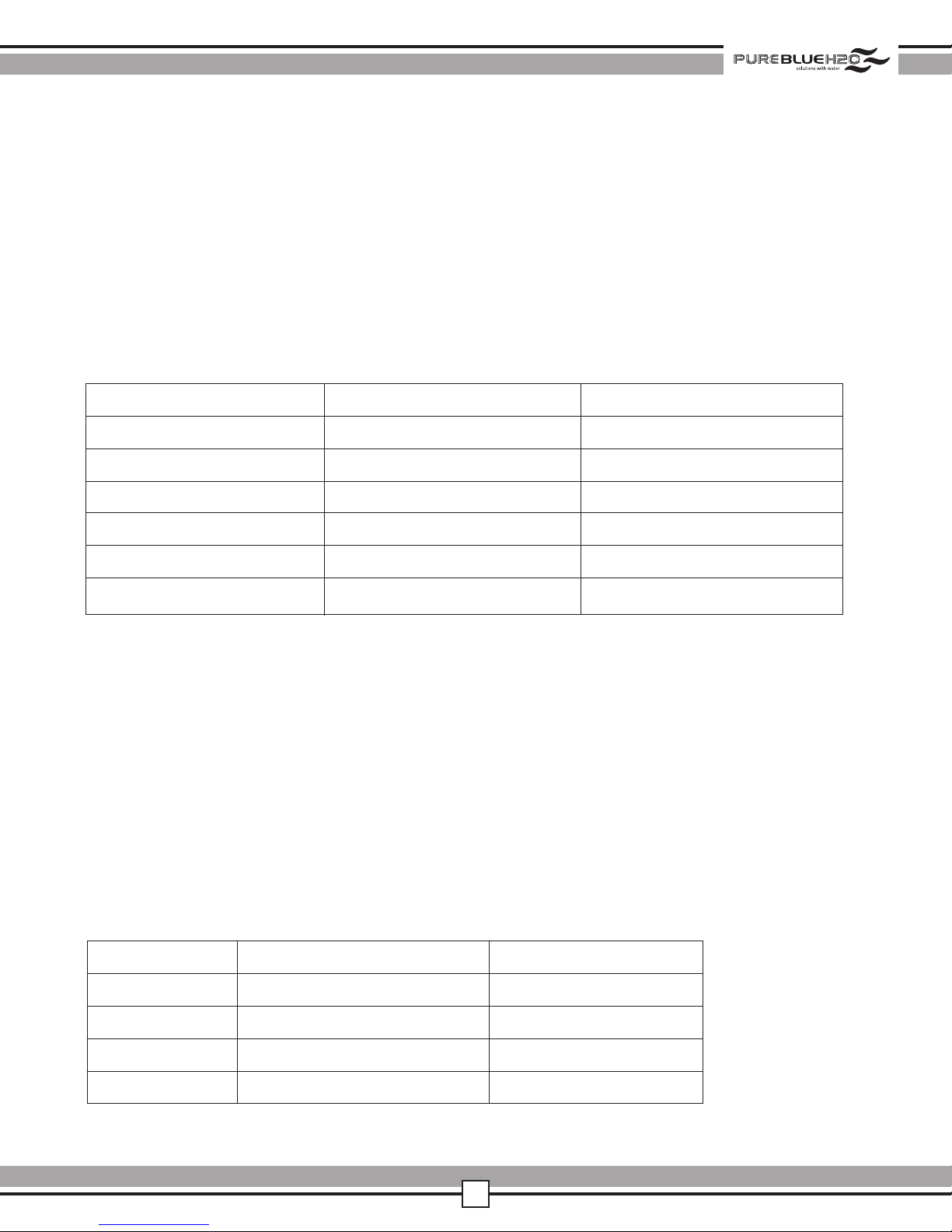

Operational Parameters

Installation must be in compliance with State and local plumbing regulations. Do not use with

microbiologically unsafe water or of unknown quality without adequate disinfection before or after

the system. System is intended to be installed using the cold water supply only.

Operating Temperatures: Maximum 100°F (37.8°C) Minimum 40°F (4.4°C)

Operating Pressure: Maximum 100 psi (7.0 kg/cm2) Minimum 40 psi (2.80 kg/cm2)

pH Parameters: Maximum 11 Minimum 2

Iron: Maximum 0.2 ppm

TDS (Total Dissolved Solids) < 1800 ppm

Turbidity < 5 NTU

Hardness

Hardness: Recommended hardness not to exceed 10 grains per gallon, or 170 parts per million.

Note: System will operate with hardness over 10 grains but the membrane life may be shortened. The

addition of a water softener may lengthen the membrane life.

Water Pressure: The operating water pressure in your home should be tested over, a 24 hour period to

attain the maximum pressure. If the incoming water pressure is above 80 psi then a water pressure

regulator is required. A booster pump is needed for incoming water pressure under 40psi.

Copper Tube: Reverse Osmosis water should not be run through copper tube as the purity of the water

will leach copper, which will cause an undesired taste in water and pin holes may form in the tube.

Note: Polytubing is recommended.

Maximum 10 Grains Per Gallon*

Maintenance of Filters for Model PB-TLRO4H50T:

Part Number Description Replacement

PB-TLRO4SEDT Stage 1 - Sediment Every 6 months

PB-TLRO4CB2T Stage 2 - Pre-Carbon Every 6 months

PB-TLRO4MC50T Stage 3 - RO Membrane Every 2-5 years

PB-TLRO4CB4T Stage 4 - Post-Carbon Every 1 year - Annually

21

Flow

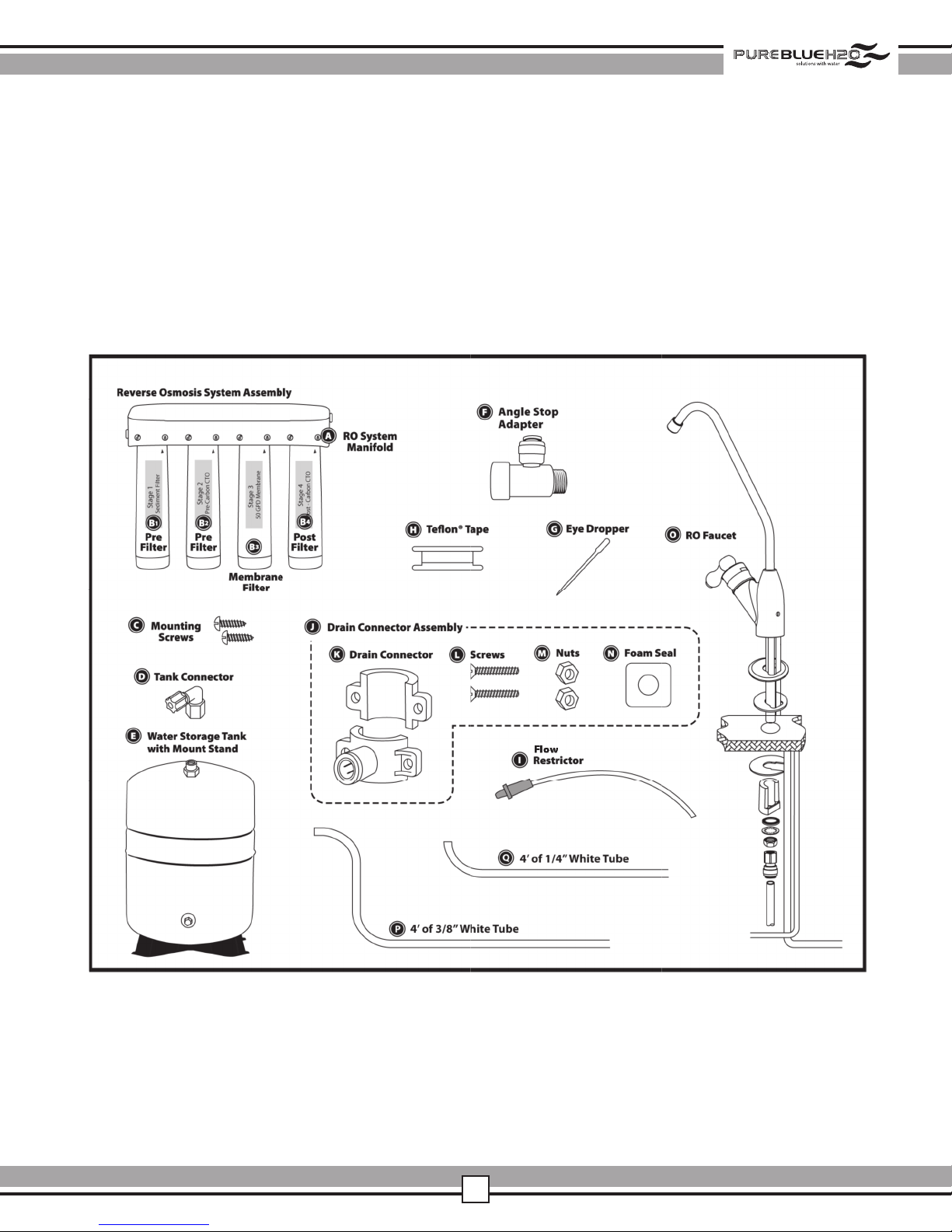

REQUIRED TOOLS & MATERIALS

• Tape Measure • 1/8” & 1/4” Drill Bits • Phillips Head Screwdriver

• Pencil • Adjustable Wrench • Safety Glasses

• Utility Knife • Drill • Pan or Bucket

PACKAGE CONTENTS

22

PREPARE SITE FOR INSTALLATION

1 Prior to starting, close the cold water shut-off valve.

2

Temporarily place tank and filter assembly into cabinet to ensure adequate space and proper positioning.

Note: For filter installation, see page 5, STEP THREE, Filter Installation.

3 Remove tank and filter assembly from cabinet and set aside.

Note: The Filter System should not be installed in a location susceptible to freezing.

INSTALLATION OVERVIEW

There are seven easy steps to installing your RO unit. They are as follows:

Step 1 - Install Angle Stop Adapter (water source for filter system)

Step 2 - Install RO Drain Connector

Step 3 - Install RO Filter Assembly

Step 4 - Install Water Storage Tank

Step 5 - Install RO Faucet

Step 6 - Connect Tubing

Step 7 - System Start Up and Purge System

Notice: You must check and comply with all local plumbing codes.

If installing in a remote location, please refer to OPTIONAL REMOTE INSTALLATION PROCEDURE on page 9.

STANDARD INSTALLATION

2

3

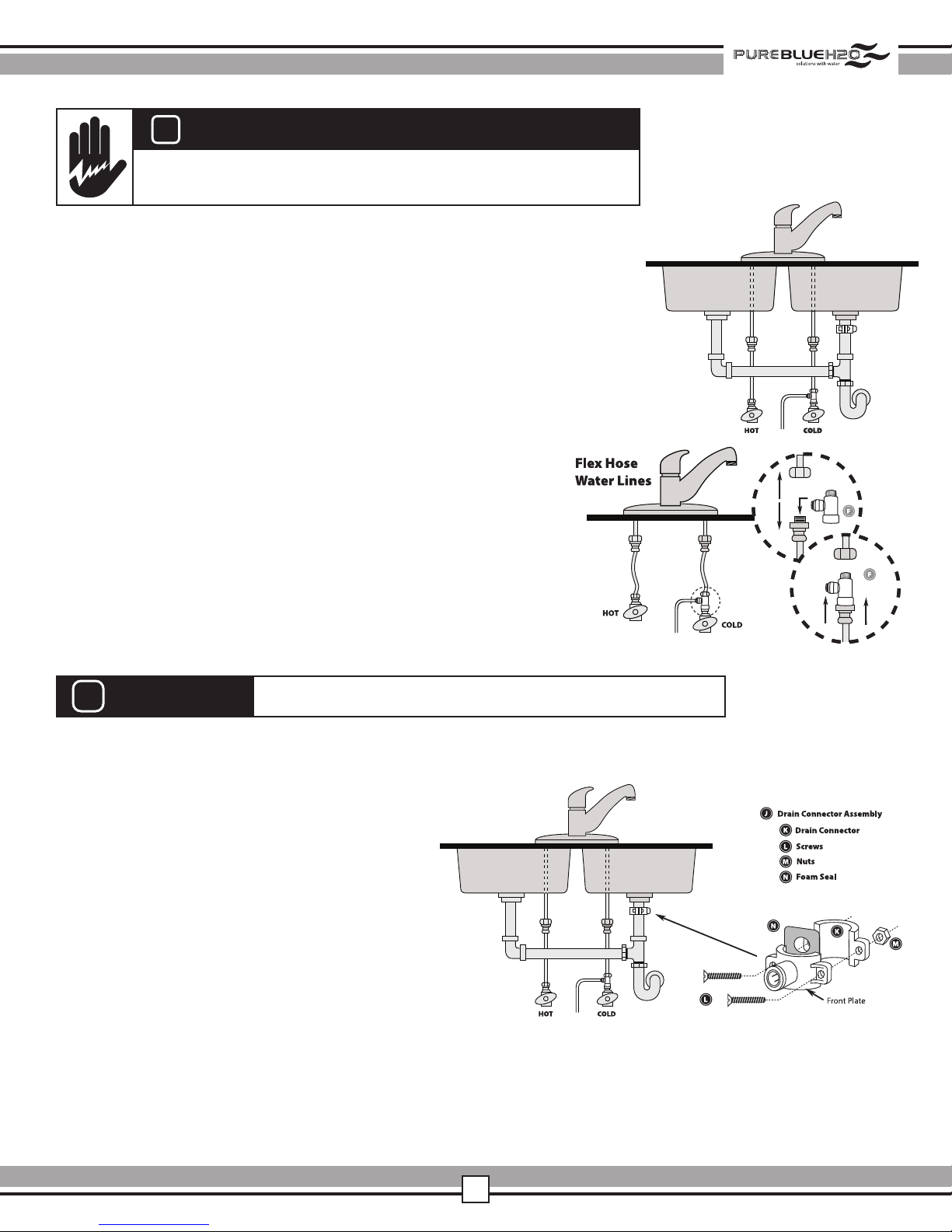

!

WARNING

Be sure that all electrical appliances and outlets are turned off

at the circuit breaker before working in the cabinet area.

STEP ONE – INSTALL ANGLE STOP ADAPTER

1 Identify the cold water line in the sink cabinet.

Turn off the cold water supply to the sink.

2 Turn on the kitchen faucet to release pressure and

allow water to completely drain from the line.

3 Disconnect the cold water line from the cold water angle stop valve.

Note: You may need a plumber to shorten the supply line pipe

using a hacksaw or pipe cutter to accommodate the Kitchen

Faucet Adapter if pipe is rigid.

4 Screw on Angle Stop Adapter to cold water

angle stop valve. Do not over tighten Angle

Stop Adapter. (See diagram to the right)

5 Screw the cold water supply line to the male

thread side of the Angle Stop Adapter.

Caution: Do not over tighten.

STEP TWO – INSTALL RO DRAIN CONNECTOR

!

CAUTION

1 Identify drain outlet location.

2 Knock out center hole on foam seal (N).

3

Use hole in foam seal (N) as a template to

locate your drilling position above drain tap,

mark location with pencil.

4 At marked location, drill 1/4” hole through

wall of drain pipe. Be sure not to penetrate

opposite side of pipe.

5 Remove protective cover from back of foam

seal (N) and attach to front plate of drain

connector (K) in alignment with holes.

6 Begin to position the drain connector (K)

on sink drain pipe with Screws (L) and

Nuts (M), using your pencil (or a thin pen) in the drain connector (K) tube hole, to guide your location

over your drilled hole as you securely tighten Nuts (M) and Screws (L). Note: Remove pencil once

location is established.

Please wear safety glasses to protect eyes when drilling.

24

Loading...

Loading...