PureAire 99088, 99072 Instruction Manual

Air Check Advantage

Methyl Bromide Monitor

Instruction Manual

Part number: 99088 (0-10ppm) 99072 (0-20ppm)

PureAire Monitoring Systems, Inc.

1140 Ensell Road

Lake Zurich, IL. 60047

Phone: 847-726-6000

Fax: 847-726-6051

Toll-Free: 888-788-8050

E-mail: info@pureaire.net

Web: Pureairemonitoring.com

PureAire Monitoring Systems, Inc.

1

Welcome to PureAire Monitoring Systems

I’d like to thank you for investing in our continuous life safety and process control toxic gas

monitoring systems.

PureAire offers an unbeatable combination of experience and innovation in solving the safety

and environmental needs of our customers. We’re capable of providing small systems of a few

points to a total multi-point turnkey computerized package.

PureAire’s proprietary sensor cell technology and state-of-the-art electronics are designed to

interface with the latest distributive or PLC based control systems. We believe that our

experience, innovative products and commitment to service will satisfy your specific monitoring

needs now and in the future.

Our growth is a result of our total commitment to supporting our customers. We’re available 24

hours a day, 7 days a week to help you when you need us. Our 24 hour Emergency phone number is

847-420-3814. We can provide field service, preventative maintenance programs and training

to your technicians in the operation of our equipment. Our goal is to provide the best after sale

service and support in the industry. That’s just one way PureAire takes that extra step to

ensure your complete satisfaction.

Thank you again for investing in PureAire Monitoring Systems for your monitoring needs and

I’m proud to welcome you to our family of valued and satisfied customers.

Sincerely,

Albert A. Carrino

PureAire Monitoring Systems, Inc.

2

President

PureAire Monitoring Systems, Inc.

3

This system has a built-in pyrolizer. The pyrolizer insulation temperature can reach

150 F and can cause burns if touched. Use Caution when working near the pyrolizer.

Read Before Operating

This gas monitoring system has been designed to provide long-term reliable performance. We recommend the

following basic precautions while installing, operating and maintaining this device.

Read this “Guide to Operation and Installation” carefully. Installation, maintenance, calibration and testing

should be performed by qualified personnel only.

Check if the power supply matches the specifications given in this guide and ensure that the system has been

connected properly. This monitor must be powered by a regulated 24VDC power supply.

Please insure the proper polarity. Reversing the polarity will damage the fuse on the drive PCB.

After power up, please let the system equilibrate a few hours before making any adjustments.

The methyl bromide monitor is designed for safety monitoring where normal use is defined as zero gas

concentration with an occasional excursion. If the monitor is continuously exposed to methyl bromide or if the

monitor is exposed to very high short term gas concentrations, it will require more frequent sensor cell

recharges, and complete pyrolizer filament and pump replacement.

Exposing the methyl bromide monitor to continuous levels of sulfur dioxide (SO

storage facilities will shorten the life of the gas sensor. This may require the need for annual gas sensor

replacement.

) from produce in cold

2

The pyrolizer filament is fragile and must never be disturbed once inside the pyro tube. Never twist the

filament inside the pyro tube.

PureAire Monitoring Systems, Inc.

557 Capital Drive

Lake Zurich, Illinois 60047

Ph: 888-788-8050

Ph: 847-726-6000

Fax: 847-726-6051

After Hours Hot Line: 847-420-3814

info@pureaire.net

www.pureairemonitoring.com

PureAire Monitoring Systems, Inc.

4

Rev 4.05 9/18/15

1: Introduction ........................................................................................ 5

1.1 Component Identification……………………………………… 6

2: Specifications .................................................................................... 11

2.1 Performance Specifications........................................................ 11

2.2 Gas Detection System ................................................................ 11

2.3 Signal Outputs ............................................................................ 12

2.4 Electrical Requirements ............................................................. 12

2.5 Physical Characteristics ............................................................. 12

2.6 Air Check Methyl Bromide Default Settings ............................. 13

3: Installation ........................................................................................ 14

3.1 Site Requirements ...................................................................... 14

3.2 Mounting .................................................................................... 14

3.3 Sensor Installation ...................................................................... 14

3.4 Wiring ........................................................................................ 15

3.5 Initial Startup ............................................................................. 16

Table of Contents

4: Air Check Methyl Bromide Programming .................................... 17

4.1 Control Panel Overview ............................................................. 17

4.2 Joystick Operation ..................................................................... 17

4.3 Program Flow Chart ................................................................... 18

4.4 Entering the Password ................................................................ 22

4.5 Changing the User Password ..................................................... 23

4.6 Entering the Menus .................................................................... 26

5: Maintenance & Calibration ............................................................ 37

5.1 Routine Maintenance Schedule .................................................. 37

5.2 Loss of Power Indication ........................................................... 37

5.3 Sensor Cell Removal and Installation ........................................ 38

5.4 Electrolyte Replacement ............................................................ 39

5.5 System Calibration ..................................................................... 43

6: Appendix ........................................................................................... 47

PureAire Monitoring Systems, Inc.

5

5

The Air Check Methyl Bromide Monitor is a compact extractive gas sampling system designed for the

continuous detection and measurement of toxic gas leaks. It is capable of sampling over distances of

up to 100 feet (33 meters).

The Air Check is a single point monitoring system built into an a Nema 4x water resistant housing that

may be wall mounted and is designed to require as little space for installation as possible.

The system has the following features:

24 VDC operation

Built-in pyrolizer

Integral digitally controlled sampling pump and flow system

Local digital display

User selectable dual level alarm and system fault relays

4-20 mA output

Renewable long life electrochemical sensor cell

Supervised electronics monitors sensor, pyrolizer and sample pump

NOTE: The Air Check Methyl Bromide enclosure is NOT rated for Class 1, Division 1

Groups B, C & D

1: Introduction

PureAire Monitoring Systems, Inc.

6

Mounting Tabs

(on each corner)

Cooling Fan

Cable Strain Relief

Front Cover

Cover fastening

screws

(on each corner)

Mounting Tabs

(on each corner)

Sample Exhaust

Sample Inlet

1.1 Component Identification

1.1.1 Overall System Composition

The Air Check Methyl Bromide Monitor may be integrated into the overall hazardous gas monitoring

system. As a result, it may be remotely located for the monitoring of process areas and other

environments where access to the instrument for maintenance or service may be restricted. It may also

be used as a stand-alone detection system.

Front Cover— This permits accessing the inside of the sample and control system.

Mounting Tabs— Adjustable feet designed to connect the methyl bromide enclosure to walls or other

solid surface. There is one on each corner of the enclosure.

Cover Fastening Screws— Captive Philips head plastic screws used to fasten the front cover to the

base of the methyl bromide monitor. There is one on each corner of the front cover.

NOTE: Please do not over tighten the screws as the Phillips head will strip.

Cable Strain Relief — This is the opening in the transmitter housing for connecting the 4-20 mA

output, 24 VDC power cable, and alarm relay wiring.

Sample Inlet — This serves as the connection for the incoming sample line.

Sample exhaust — This serves as the connection for the sample exhaust line.

Cooling Fan — This fan pushes air into the case for cooling. It exhausts on the top righ side of the

case

PureAire Monitoring Systems, Inc.

7

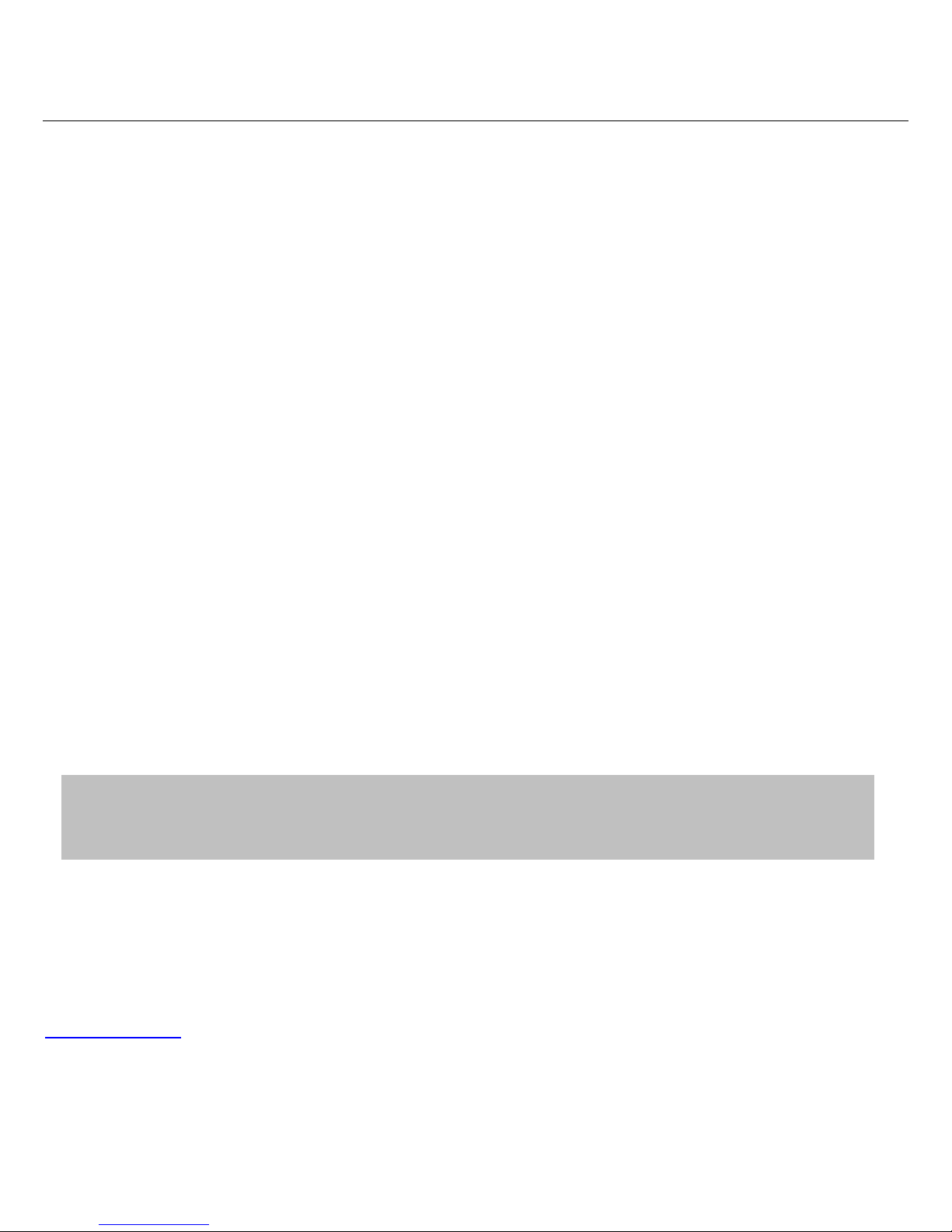

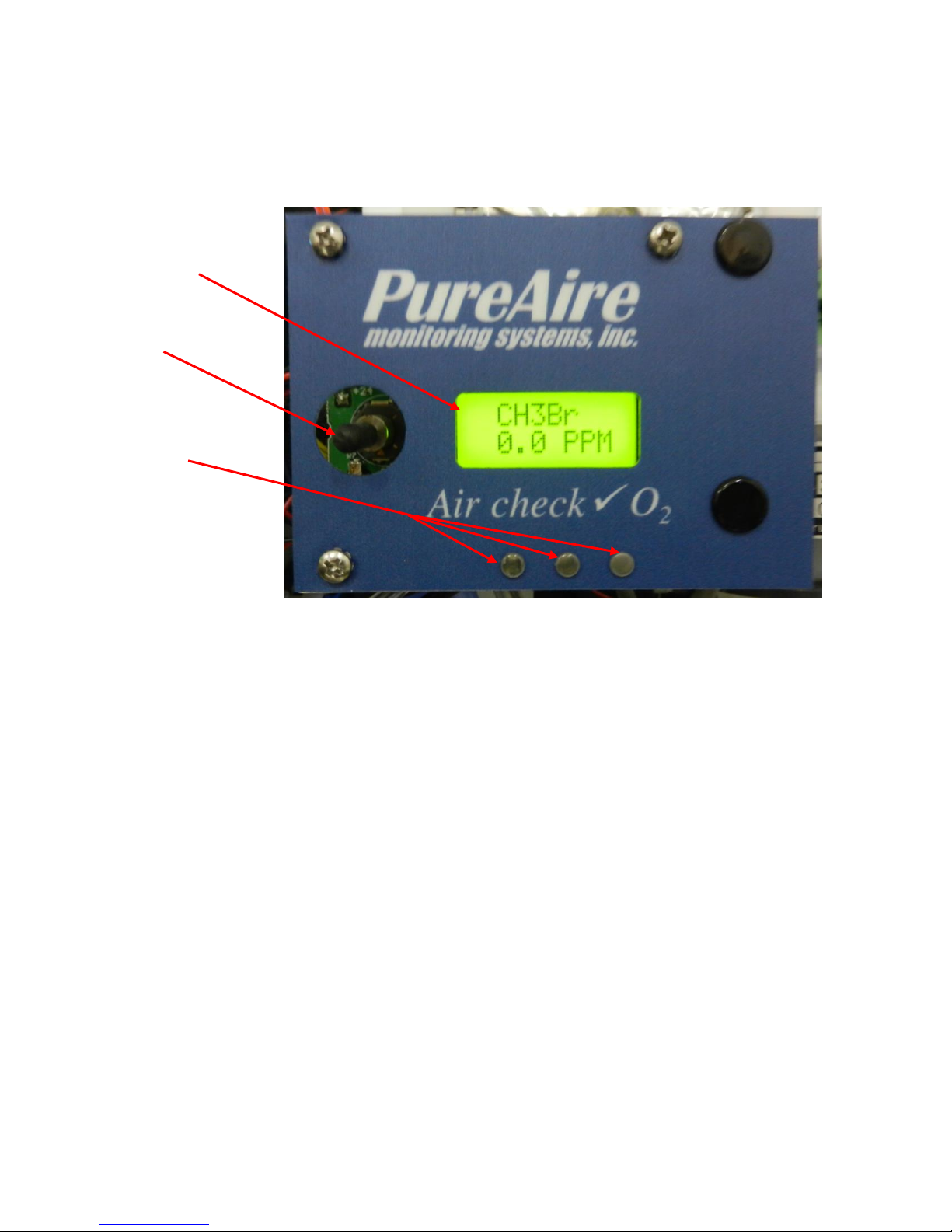

Local Digital

Display

Joystick

Alarm &

Fault

(LED’s)

AL 2 , AL 1

& Fault

7

1.1.2 Front View Control Panel

1. Local Digital Display — During normal operation, displays the name and concentration of the

target gas. Also displays alarm messages and programming/calibration menus and information.

2. Joystick — Used for selecting and adjusting the built-in menus for alarm threshold settings, relay

state, alarm delay etc.

3. Alarm & Fault LED’s — These LED’s illuminate when a gas concentration alarm or instrument

fault is detected.

NOTE – The flow rate is factory set and is continuously regulated via a built-in flow sensor.

Flow rate is factory set for sampling distances up to 100 feet. Field adjustment

cannot be performed.

PureAire Monitoring Systems, Inc.

8

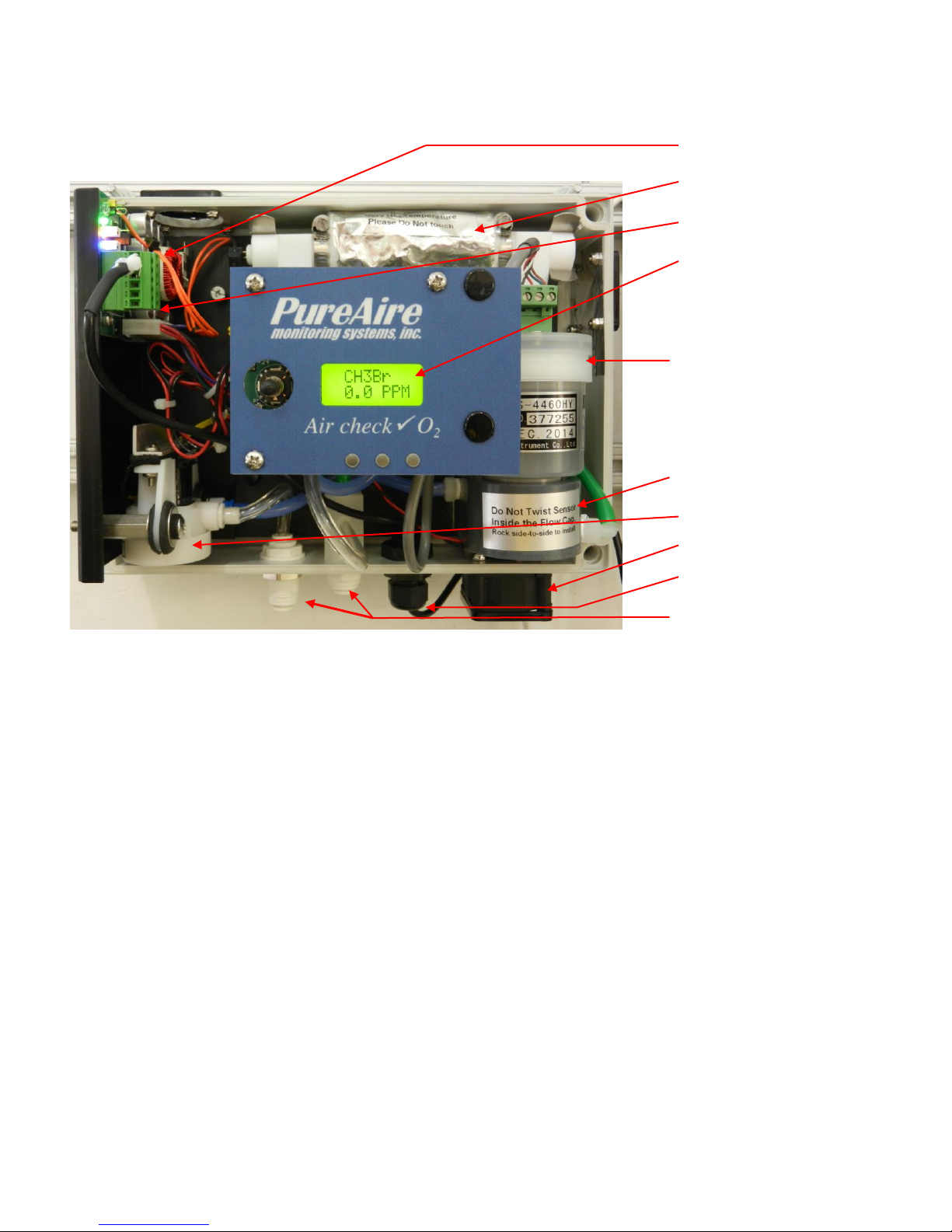

Main Power Connector

Pyrolizer Assembly

Pyro Filament Drive PCB

Control Electronics / Readout

Methyl bromide sensor cell

Flow chamber

Sample Pump

Cooling fan

Strain relief

Exhaust and Inlet

1.1.3 Internal View

1. Main Power Connector — Connector for 24VDC power input. See section 3: Installation for

more information.

2. Pyrolizer Assembly — Converts Methyl bromide gas into Bromine gas prior to presentation to

the gas sensor.

CAUTION - The pyrolizer insulation temperature is above 150 F and can cause burns if touched

3. Pyro Filament Drive PCB — Controls power to the pyrolizer filament and signals the main

control electronics if a fault occurs.

4. Control Electronics and readout — Controls the sample pump, converts the signal from the

sensor cell and sends information to the local digital display and analog /relay terminal block.

NOTE – The flow rate is factory set and is continuously regulated via a built-in flow sensor.

5. Flow Chamber — The converted gas from the pyrolizer is introduced to the gas sensor in this

chamber. Sample flow into the chamber is continually monitored. If the sample pump fails, the

system fault relay is activated.

6. Methyl Bromide Sensor Cell — A renewable electrochemical sensor cell. Typical life is 3 to 6

years under normal operating conditions.

7. Sample Pump — This internal sample pump is used to draw the gas sample from the area into the

pyrolizer and flow chamber.

8. Inlet & Exhaust — These are connections for the incoming gas sample and outgoing exhaust

sample

PureAire Monitoring Systems, Inc.

9

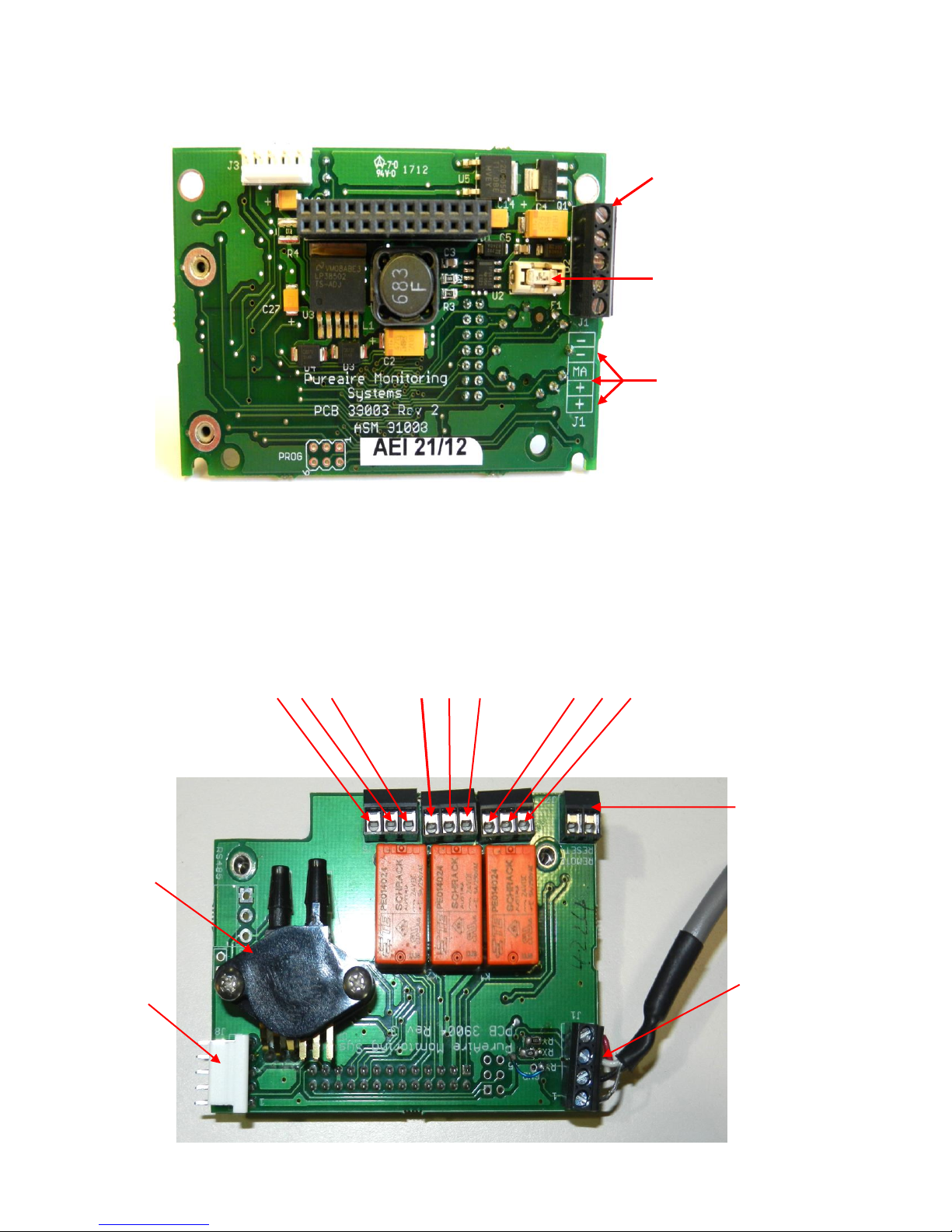

1. Power / Analog

output Terminal Block

Fuse

(Field replaceable)

Common

Common

mA output

+ 24 VDC

+ 24 VDC

9

Flow Sensor

Pump

Connector

Alarm Relay 2 Alarm Relay 1 Fault Relay

NC C NO NC C NO NC C NO

Remote

Reset

Sensor cell

connector

(terminated at the

factory)

1.2.5 Transmitter Interior

1. Power / Analog Terminal Block — This terminal block is where the 24VDC power and

4-20 mA analog output connection is made.

1.2.6 Alarm Relay Board

PureAire Monitoring Systems, Inc.

10

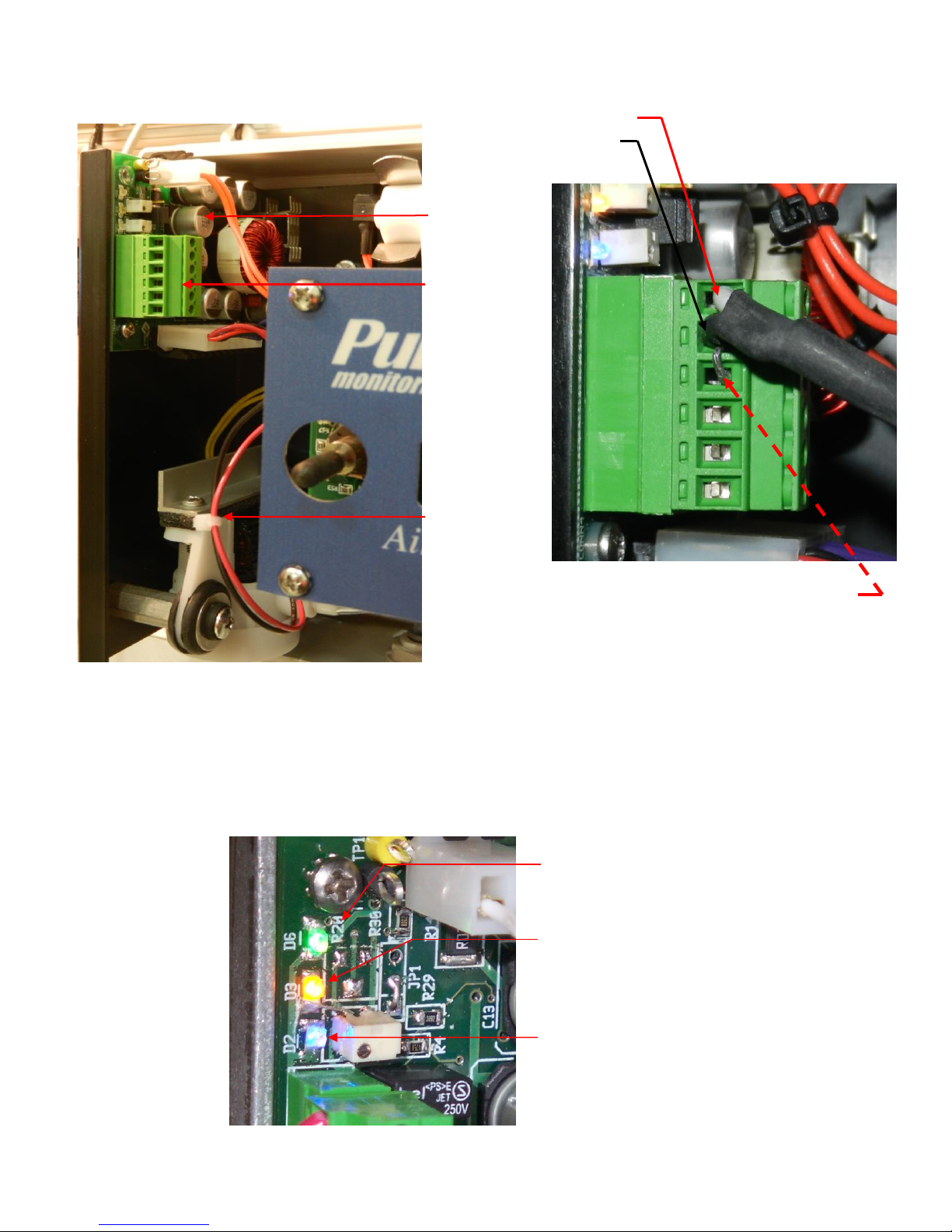

Main power connection

(Terminated by PureAire or

can be terminated by the

customer when using their

own power supply)

Status LED’s

Green Power LED.

Confirms Power is being supplied to

the monitor.

Yellow Status LED.

Confirms the filament drive board is

operational.

Blue Fault Status LED.

Flashes to indicate various system

faults.

When not in fault the Blue LED

remains illuminated continuously

Pump and Pyrolizer Drive Assembly

Pyrolizer

Drive Board

Main 24VDC

Power

Connector

Sample

Pump

+ 24VDC Pin 6

Common Pin 5

NOTE: DO NOT Remove the shorting

pin connected to pins 5 and 4.

PureAire Monitoring Systems, Inc.

11

11

2: Specifications

NOTE: Due to our commitment to continual product improvement, all specifications are subject to

change without notice.

2.1 Performance Specifications

Models: Air Check Methyl Bromide Monitor

Sensor Type: Renewable electrochemical cell. Field rechargeable.

Response Time: Within 60 seconds to T90.

Repeatability: ±10% of full scale.

Fault Indicators: Loss of VDC power (4 mA signal drops to 2, system fault alarm relay de-energizes);

Loss of sensor signal (local visual alarms, system fault alarm de-energizes);

Loss of sample pump (4 mA signal drops to 2, system fault alarm relay de-energizes)

Loss of Pyrolizer filament (4 mA signal drops to 2, system fault alarm relay de-energizes)

Operating Temp: 14° to 86°F (0° to +30°C); consult PureAire for lower or higher operating temperatures.

Humidity: Typically 20 to 95% RH;

Warranty: The warranty is limited to repairing or replacing the instrument or part thereof for a period

of one (1) year after shipment, when in our opinion, the repair or replacement is covered by

this warranty. Any defective equipment must be returned prepaid to the PureAire Monitoring

Systems, Inc. factory or service. Field service is not included. This warranty does not cover

components that are expendable or consumable in normal use and thus have an unpredictable

life such as batteries, fuses, sample pumps, filaments and sensor cell electrolyte & membranes.

2.2 Gas Detection System

Type: Proprietary renewable electrochemical gas sensor.

Sensor Life: 3 to 6 years under normal conditions.

Detectable Gas: Methyl Bromide Standard Range 0-10ppm *

*Consult PureAire for other available gas ranges.

PureAire Monitoring Systems, Inc.

12

2.3 Signal Outputs

Local Display: Digital display calibrated for Methyl Bromide. The range is stated on the serial number and can be

accessed via the joystick on the front panel.

Analog Output: DC 4-20 mA

Relay Output: Dual level user selectable alarm relays and one fault relay

Rated, 2amps @ 30VDC; 2amps @ 250VAC

2.4 Electrical Requirements

Power: 24 VDC external power. NOTE: Must be a regulated 24VDC Power Supply

Consumption: 2.0 amps.

2.5 Physical Characteristics

Dimensions: 10” W x 7.0” H x 7.0” D inches;

254 x 178 x 178 mm

Weight: 10 pounds (4.5 kg)

Enclosure Type: NEMA 4X wall mounted enclosure. Not for use in hazardous environments.

PureAire Monitoring Systems, Inc.

13

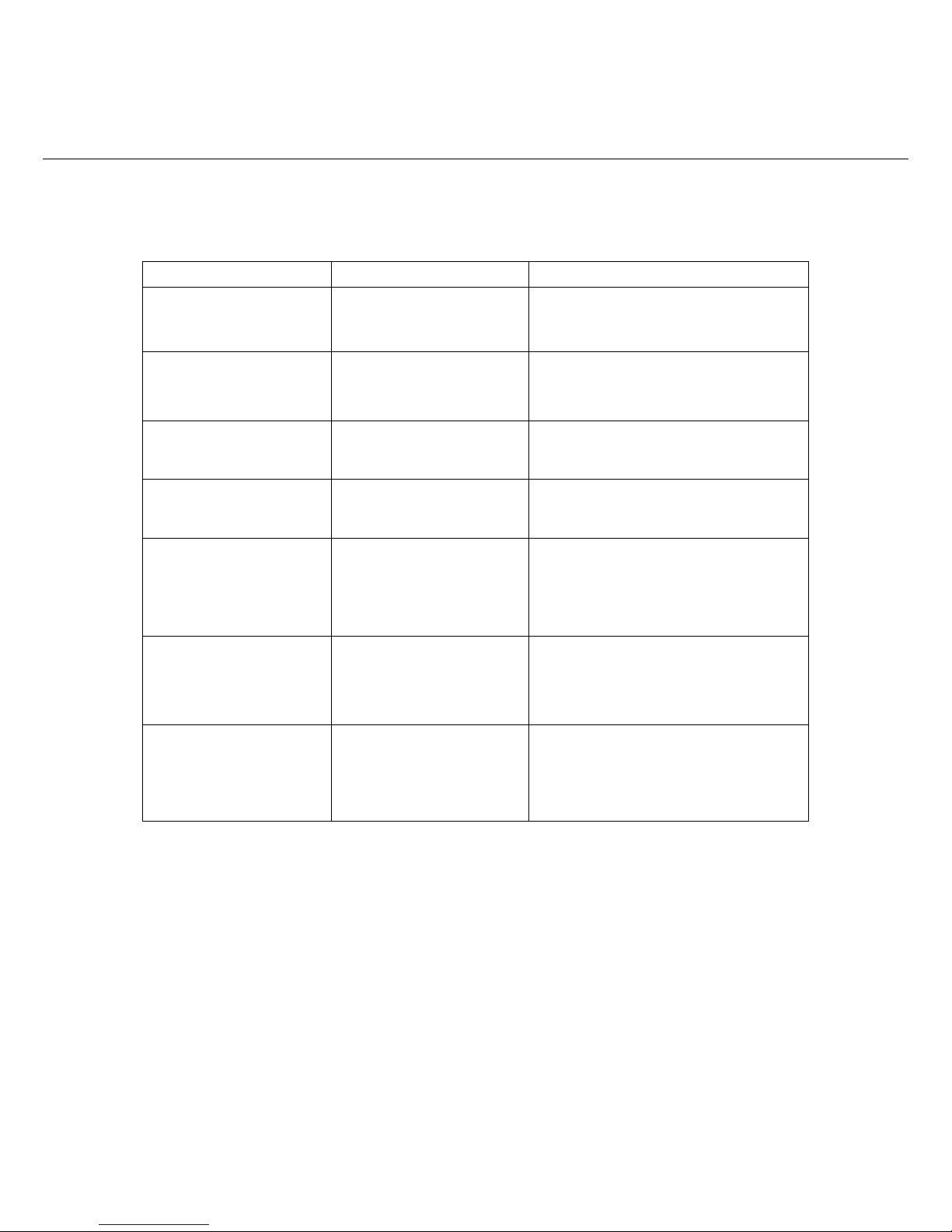

Menu Function

Factory Default

Menu Defined

Alarm Thresholds

Alarm 1 = 1.0ppm

Alarm 2 = 5.0ppm

At what level do you want to alarm?

Set Alarm Threshold

Polarity

Alarm 1 = Normal

Alarm 2 = Normal

Do you want to alarm at a level

higher, (normal) or lower, (inverted)

than the alarm threshold?

Alarm Delay

Alarm = 5 seconds

How long do you want to wait until

the alarms activate?

Zero Suppression

0.3ppm

At what level do you want to see the

initial gas concentration reading?

Set Alarm Hysterisis

Alarm 1 = 0.0 ppm

Alarm 2 = 0.0 ppm

For use when using the monitor for

control. It is recommended to set both

alarm hysterisis at 0.0ppm

Relay Latching

Alarm 1 = Non-latching

Alarm 2 = Non-latching

Do you want the alarm to

automatically reset? (non-latching) or

do you want to manually reset the

alarm? (latching)

Format Relay - LED

State **

Alarm 1 = Normal

Alarm 2 = Normal

Fault = Normal

Do you want the relays to energize,

(normal) or de-energize, (fail safe)

when the alarm activates?

13

2.6 AirCheck Methyl Bromide Default Factory Settings

The Air Check Methyl Bromide Monitor is shipped with factory defaults for the alarm relay settings. The

following are the factory defaults:

NOTE:

The built

in relay

settings

may be

changed

by the user

in the

field.

Refer to

Section

4.5

** NOTE:

The LED

indicators

on the

front panel

are

connected

directly to

the alarm

relays.

PureAire Monitoring Systems, Inc.

14

Insert the sensor cell

into the flow

chamber by pushing

the sensor cell down

until it seats inside

the O-ring.

Never twist the

sensor cell inside

the flow chamber.

3.1 Site Requirements

The Air Check Methyl Bromide monitoring system should be mounted in an area free of vibration and

electrical noise or interference. If possible, avoid areas with continuous high temperatures or relative

humidity.

The unit should be installed in a location where gas leaks are likely to occur or where released gases

may accumulate. Airflow within the monitored area, the characteristics of the target gas (lighter or

heavier than air), and the position of workstations and personnel should all be considered in

determining the most suitable installation location.

Allow sufficient space around the instrument to permit access for maintenance and calibration.

NOTE: The Air Check Methyl Bromide Monitor is NOT designed for installation in hazardous

areas.

3.2 Mounting

The Air Check is designed primarily for wall mounting and should be installed no closer than 36 inches

(915 mm) above floor level. If mounted outdoors, keep direct sunlight off of the enclosure.

3: Installation

3.3 Sensor Installation

IMPORTANT: Be careful not to turn the sensor or touch the membrane on the bottom of the sensor

during installation.

CAUTION: The target gas is factory programmed and cannot be adjusted in the field. Failure to

install the correct sensor in the instrument will adversely affect detection reliability and/or

measurement accuracy.

1. Remove the front cover by turning the cover counter clockwise.

2. Remove the sensor shorting plug.

3. Plug the Methyl Bromide sensor into the flow chamber inside the instrument housing.

NOTE: Do not twist the gas sensor inside the flow chamber. This may loosen the sensor cell box

nut on H type renewable sensor cells.

IMPORTANT: Remove the shorting plug from the sensor cell connector before connecting the

sensor cell to the transmitter.

Loading...

Loading...