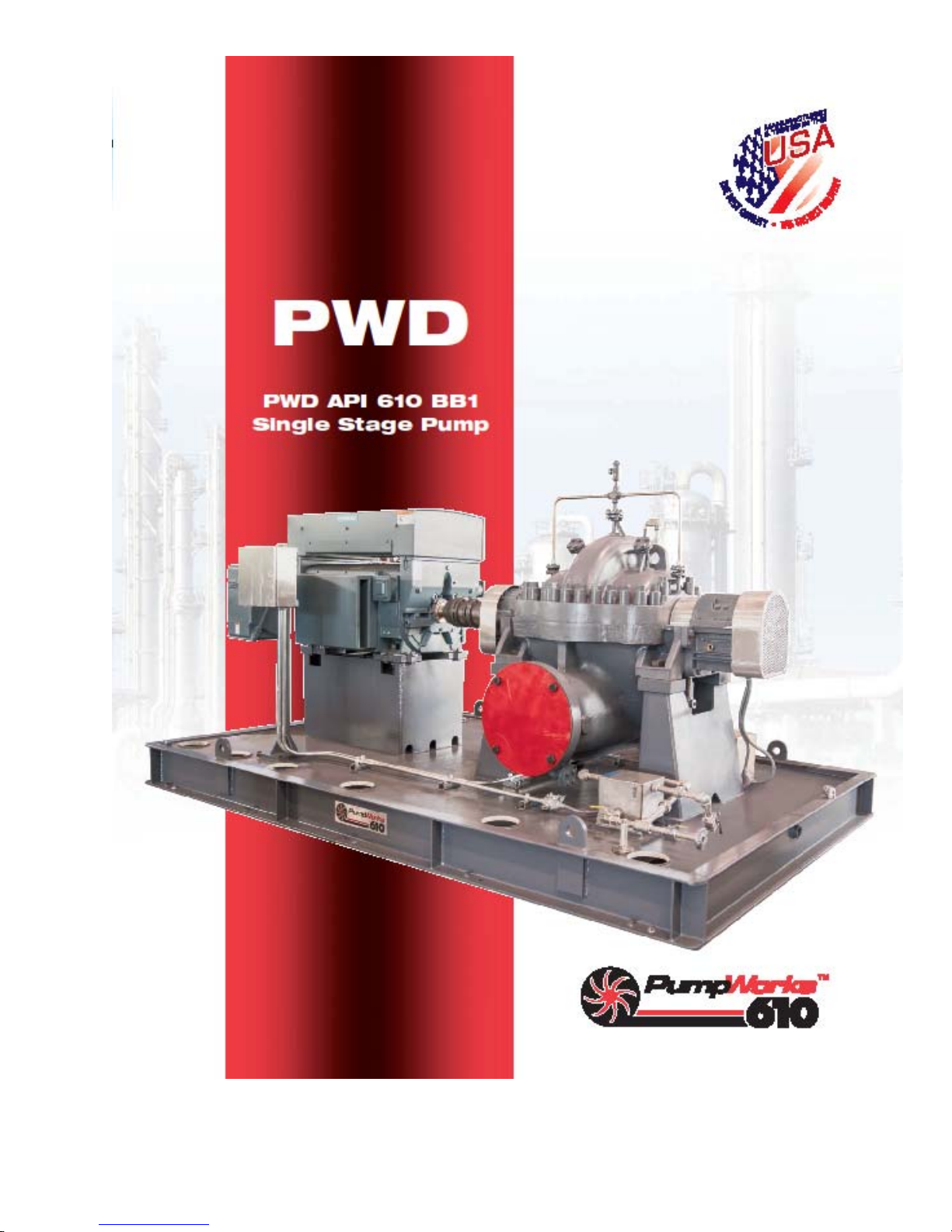

PumpWorks 610 PWD Installation, Operation And Maintenance Instructions

INSTALLATION

OPERATION &

MAINTANENCE

Model: PWD

Page 2 of 28

Model: PWD Rev. B_12/2/2015

TABLE OF CONTENTS

INTRODUCTION

Company Details ........................................................................................................................................ 4

Declaration of Conformity ........................................................................................................................... 5

Scope ................. .......................................................................................................................................6

Description ................................................................................................................................................. 6

General ....................................................................................................................................................... 6

Safety ...................................................................................................................................................... 6-9

CE and ATEX marking and approvals ..................................................................................................... 10

Disclaimer................................................................................................................................................. 10

Copyright .................................................................................................................................................. 10

Design Performance ................................................................................................................................ 10

Duty Conditions ................................................................................................................................... 10-11

Specific Gravity ........................................................................................................................................ 11

Speed ....................................................................................................................................................... 11

NPSH ....................................................................................................................................................... 11

INSTALLATION

Receiving Inspection ................................................................................................................................ 11

Short Term Storage ............................................................................................................................. 11-12

Long Term Storage .................................................................................................................................. 12

Foundation ......................................................................................................................................... 12-1

Leveling .................................................................................................................................................... 13

Grouting .................................................................................................................................................... 13

Piping Recommendations ................................................................................................................... 13-14

Lifting ........................................................................................................................................................ 14

Pump Installation ................................................................................................................................. 14-15

Driver Installation ..................................................................................................................................... 15

Alignment ............................................................................................................................................ 15-16

Couplings ................................................................................................................................................. 16

Lubrication .......................................................................................................................................... 16-

Recommended Control Settings .............................................................................................................

Pre-Startup Procedures ..................................................................................................................... 19-2

Startup Procedures .................................................................................................................................. 20

Startup Inspection .................................................................................................................................... 20

Shutdown ................................................................................................................................................. 21

Extended Shutdown ................................................................................................................................. 21

MAINTENANCE

Preventative Maintenance ................................................................................................................... 21-22

Mechanical Seal / Bearing Housing Removal ..................................................................................... 22-26

Rotating Element Removal ................................................................................................................. 26-27

TROUBLESHOOTING

Troubleshooting .................................................................................................................................. 28-29

REVISIONS

Revisions .................................................................................................................................................. 29

3

18

19

0

Page 3 of 28

Model: PWD Rev. B_12/2/2015

INTRODUCTION

COMPANY DETAILS

MANUFACTURER:

PUMPWORKS 610

P.O. Box 19606

Shreveport, LA 71149

DESCRIPTION OF EQUIPMENT:

Centrifugal API 610 / ISO 13709 pumps for petroleum refinery, gas processing, oil processing,

petrochemical, hydrocarbon and crude oil pipeline, offshore installations (platform) and aviation jet

fueling.

MARKING OF MACHINERY

All machinery is marked visibly with:

— the business name and full address of the manufacturer

— Model

— Size

— ATEX Marking

— Serial number

— The year construction was completed

Page 4 of 28

Model: PWD Rev. B_12/2/2015

o

W

C

T

M

N

B

T

M

B

M

T

a

m

u

s

t

n

o

A

’

n A

m

u

h

2

De

E

m

O

D

A

T

C

E

E

T

1

T

2

A

t

e

e

e

h

e

y

s

a

o

a

E

D

T

e

t

u

n

s

r

c

-

A

,

V

C

s

C

e

a

c

a

t

g

t

t

f

2

2

E

E

e

o

a

u

o

e

,

e

o

a

2

P

F

t

m

t

o

d

a

y

)

S

C

e

n

o

X

u

d

v

b

e

y

clarati

n of In

orpora

ion (M

chiner

)

MANUFA

PRODUC

PART NU

DATE MA

APPLICA

APPLICA

ATEX m

TURER: Pu

DESCRIPTI

BER: 00.00

UFACTURE

LE EUROPE

EX: 94/9/E

A

D: 06/42/

P

ED : 97/23/

LE INTERNA

D: EN 12

A

EX: EN 11

P

ED: ASME

SECTI

rking:

C Decl

pWorks 610

N: PWM 8 x

0126

: 01/14/15

N DIRECTIV

C

C

IONAL STAN

00:2010, ISO

7-1:2011, EN

BOILER AND

ON 5;SECTIO

II 2 G c

ration

10 x 13HE 8

S:

ARDS:

13709: 2009,

13463-1:2009

PRESSURE

N 8; AND SE

3

of Con

STAGE

PI 610: Sept

EN 13463-5:

ESSEL COD

TION 9, NAC

ormity

010, ANSI-HI

011

SECTION 2

RP 176

7

060-2015-CE-

(ATEX

:1.6-2000, AN

ARTS A, B,

USA

I S75-19: No

, AND D;

1995

DNV Ne

The prod

Directive

provided

equipme

applied t

ll EHSR

inspectio

uthorize

ko Presafe

ct described

and relevan

hat contain r

t into servic

this equipm

s related to t

by designat

d Signature:

I

portant safet

nderstand thi

is Document

T

S, ATEX NB

in this EC D

sections of

quirements

. The signat

nt.

is equipme

d bodies.

information i

information p

pplies only to

2460 retain

claration of

he Applicabl

and specific

re on this do

t have been

contained in

ior to installin

the equipmen

a copy of th

onformity c

Internation

tions that m

ument auth

ddressed; a

Dat

he installation

or using this

described ab

Technical

mplies with

l Standards.

st be imple

rizes the dis

Technical C

:

, operation an

quipment

ve and is inv

ile

he applicabl

Integration i

ented prior t

inctive ATE

nstruction F

service man

lid if not repro

European

structions ar

putting this

marking to

ile is availabl

als; read and

duced in its en

e

e

for

tiret

.

Page 5

Model: P

f 28

D Rev. B_1

/2/2015

o

W

SCOP

E

e

u

m

s

n

m

h

n

R

P

p

h

s

d

R

e

a

e

s

n

T

Y

r

s

n

k

h

n

o

2

v

0

a

u

A

n

g

o

s

e

L

o

e

ju

d

e

n

r

e

d

s

r

t

o

r

n

o

o

o

e

m

a

S

u

r

n

g

m

m

r

h

e

e

s

s

d

d

-

e

e

n

e

d

h

e

e

y

n

s

e

s

f

d

e

c

m

P

s

p

e

P

y

m

T

s

u

e

d

r

u

s

r

c

l

o

a

h

o

o

a

e

y

a

M

e

t

R

v

v

s

n

p

b

s

s

e

t

r

t

t

a

M

t

y

c

T

h

r

l

a

a

p

a

o

a

o

t

b

n

a

l

t

b

f

e

t

r

y

s

h

w

a

s

n

w

Thes

the prod

the produ

This

installatio

of the Pu

manual i

sections,

instructio

This

prior to t

maintena

instructions

ct's operatin

ct.

manual pro

, alignment,

pWorks 61

to be used

general arr

s specific to

anual sho

e installation

ce of the un

must alway

g location o

ides instruc

startup, and

PWD mode

in combinati

ngement d

each pump.

ld be read i

, alignment,

it in any regi

be kept nea

directly wit

ions for th

maintenanc

l pumps. Thi

n with cros

awings, an

its entirety

peration an

n worldwide

.

unit must n

The

onditions rel

the

this

manual, hav

umpWorks

phy

ical injury,

pro

erty, or dela

obs

rve all w

Ope

ration, and

umpWorks

injur

y or damag

Pu

pWorks 610

t be put into

ating to safet

been met.

610 shall no

damage

s caused by

rnings in

aintenance

610 shall no

caused b

parts.

service until

y, that are n

be held lia

o equipme

failure to re

this Instal

anual.

be held lia

the use o

all of

ted in

le for

t or

d and

ation,

le for

non-

DESC

The

axially s

pump. T

suction,

opposed

GENE

Thes

familiariz

use. Op

these in

reliability

instructio

SAFE

SAFET

The follo

the use

hazards,

Thi

where no

a high ris

T

and ca

instructio

result in l

IPTION

WD is an

lit, betwee

e PWD is

ide dischar

ouble sucti

AL

instruction

tion with th

rating the p

tructions is

in service

s may not

Y

SYMBO

wing symb

Non-obs

physical in

symbol in

-complianc

to personal

is symbol i

ution whe

s would aff

ss of life an

PI 610 type

bearing,

a horizontal

e, double v

n impeller d

are intende

product and

roduct in co

important to

and avoid

take into

ls are to be

rvance wo

ry, damage

icates elect

of instructio

safety or the

dicates dan

e non-co

ct personal

involve so

BB1 design

single stag

ly split, sid

lute, with a

sign.

d to facilitat

its permitte

pliance wit

help ensur

risks. Th

ccount loca

observed b

ld result i

or delays.

ical hazard

s will involv

loss of life.

er, warning

pliance o

safety, coul

e risk to saf

l

he PWD u

hou

ing designs:

lations; en

reg

obs

rved by all,

pro

uct. Always

ope

ations perso

req

irements, a

law

/regulations.

ope

ation and

dam

age the equi

This sym

fluid where

toxi

wou

ld affect per

loss

of life.

This

sphere zon

atm

in s

fety instruc

the

azardous a

expl

sion.

Ball

Slee

Slee

ilizes three

adial – Ball

e Radial – B

e Radial – T

ure such

including t

coordinate

nnel, and fol

pplicable s

personal s

ment or pro

ol indicates

non-complia

onal safety

ymbol ind

according t

ions where

ea would c

hoices of b

hrust

all Thrus

ilting Pad Th

regulations

ose installin

epair activit

ow all plant

fety and

fety and

erty.

hazardous

nce of instru

nd could re

icates exp

ATEX. It is

non-complia

use the risk

aring

ust

are

g the

with

afety

ealth

ould

nd or

ctions

ult in

losive

used

ce in

of an

Page 6

Model: P

f 28

D Rev. B_1

/2/2015

o

W

R

Alwa

e

v

s

y

s

r

o

e

y

v

n

n

Alw

c

n

o

e

e

Y

n

n

n

H E F G H

e

/

T

p

p

u

m

u

e

e

h

v

E

e

h

o

h

h

n

t

e

z

E

y

n

o

e

e

o

h

e

o

p

.

w

m

n

n

e

n

t

n

t

d

y

s

d

r

g

,

y

s

d

t

d

d

w

e

a

e

y

s

e

s

r

r

t

r

t

n

e

r

A

e

u

a

y

f

c

W

r

r

s

A

c

A

s

e

n

m

e

f

d

d

w

g

a

R

t

o

A

a

g

e

o

h

d

i

u

u

p

c

r

r

m

i

d

o

k

m

m

d

g

s

t

e

b

n

m

m

o

w

ff

o

o

t

r

s

y

a

o

e

)

t

t

a

d

t

GENE

AL SAFE

Y

procedur

when ser

Thi

and ma

warning.

Thi

are unde

connecti

pressuriz

potentiall

or corrosi

precautio

equipme

avoid ex

surfaces.

by gas a

suction,

minimum

when s

potential

SAFET

ys follow

s, on all

icing this eq

equipment

startup a

unit is a pr

pressure. N

ns while t

d.

This

hazardous,

e product.

s should b

t.

ays keep t

essive dust

Pay attenti

d vapors in t

Never run

r closed disc

Never ru

flow, or if no

Never us

rvicing this

xplosion ha

EQUIPM

roper lock

otential ene

ipment.

ay be rem

tomatically,

ssure vessel

ver try to tig

is unit is

unit could

flammable,

xtreme cauti

used when

e work are

buildup on

n to the ris

e work area

a pump

arge valve.

a pump

properly pri

heat or a

equipment,

ard.

NT

out tag ou

rgy sources

tely operate

without an

and content

ten any flui

running o

be pumpin

xplosive, hot

n and safet

servicing thi

a clean an

otentially ho

ks presente

ith a close

dry, belo

ed.

open flam

due to

pum

p, for whi

con

ulting Pump

or p

oper lubricat

gua

ds in place.

safe

ty devices in

the

isks of electr

elec

rical acciden

arisi

ng from co

mac

hinery/parts/

ry low temp

or v

to p

otect onesel

dB(

). Surroun

nois

sho

ld be worn

Imp

ct between

rust

steel can c

Neve

Neve

Never ope

Never ope

void all ele

lway

Be awar

Noise pro

exceeding

Use only

r change t

h it was

orks 610.

r run this un

ion.

ate this eq

ate this eq

talled and o

trical dange

ic shock or a

bear in

ts, and burn

of any an

tact with

aterials tha

ratures. Ta

or others.

uced by pu

ing environ

85 dB(A).

hen require

ood workin

light metal

use a spark

e service

esigned,

t without su

ipment with

ipment with

erational.

s. Pay atten

c flash haza

ind the ri

njuries.

all risk of

r in proxim

t are at ver

e necessary

p is less th

ent may pr

Hearing prot

.

non-rusted

(aluminum

f this

ithout

icient

ut all

ut all

ion to

ds.

k of

injury

ity of

high

steps

n 85

duce

ction

tools.

and

Use safet

equipme

regulatio

equipme

In other

personn

required:

Page

Model: P

t according

s at all times

t. This includ

ead Protecti

ye Protectio

oot Protecti

loves

earing Prot

hazardous

l protectiv

7

f 28

D Rev. B_12

and perso

to the us

when worki

es:

ve Gear

n

ction

environmen

equipme

2/2015

al protectiv

rs compan

g around thi

s, additiona

t may b

Flame

l

Respira

Breathin

Hazard

Etc.

of fire extin

use

nearest fire

the

Electrical c

fied electric

certi

first aid

The oper

etardant Clo

ors

g Apparatus

us Environm

kit should b

tor should

uishers and

quipment to

nnections

ians in co

hing

ent Monitors

available.

e familiar wi

ote the loca

the work are

ust be ma

pliance wi

th the

ion of

.

e by

h all

W

n

Y

e

n

r

o

e

e

y

u

t

n

t

e

n

i

d

h

p

Y

v

n

v

Alw

n

y

/

U

m

A

u

s

k

z

a

m

u

o

t

o

p

n

f

a

y

o

l

p

a

x

m

U

p

g

o

y

s

F

a

g

o

a

e

a

e

I

d

m

y

m

p

y

s

a

r

e

H

o

n

e

i

s

R

y

n

s

s

y

s

e

r

y

t

a

e

0

s

d

t

o

o

s

r

n

c

K

g

d

d

u

oPum

a

e

e

o

d

d

A

o

r

s

o

s

k

c

c

h

a

s

e

r

e

a

A

y

e

e

c

t

m

i

p

x

c

s

v

e

f

v

d

d

n

p

p

y

a

p

.

i

c

o

e

a

v

a

e

t

o

e

e

u

e

u

y

t

r

w

t

w

internatio

al, nation

al, state,

and loca

l reg

lations.

SAFET

Th

precautio

explode,

over-pres

to avoid

leaking fi

under pr

Op

unit in an

could ca

damage

modificati

provided

question

equipme

represen

accepted

These m

liquid ca

explosion

impellers,

aid in the

manual.

leaking,

electric s

fumes,

PRECA

operator

s to prevent

ny press

upture, or di

surized. Ta

ver-pressuri

Do not try

tting or con

ssure.

rating, inst

way that is

se death, s

o the equip

on to the eq

by PumpW

regarding

t, please c

ative before

This ma

methods

thods must

rapidly exp

and injur

propellers,

r removal un

If the

o not oper

ock, fire, e

hysical har

TIONS BE

ust be aw

physical inju

re-containin

charge its c

e all necess

ation.

to loosen o

nection whil

lling, or m

ot covered i

rious perso

ent. This

ipment or us

rks 610.

he intende

ntact a Pu

roceeding.

ual clearl

or disasse

be adhered

nd and resu

. Never a

r their retaini

ess explicitl

ump/motor i

te as it m

plosion, libe

, and/or

ORE WO

re of safet

y.

device ca

ntents if it i

ry measure

tighten an

the unit i

intaining th

n this manua

nal injury, o

includes an

e of parts no

f there is

us of th

pWorks 61

identifie

bling units

to. Trappe

lt in a violen

ply heat t

ng devices t

stated in thi

damaged o

y cause a

ation of toxi

nvironmenta

K IS STA

l

.

l

RTED

dam

age. Corre

ng back it ba

putti

Do not c

ut the

with

pWorks 610

Provide a

are

, for exampl

Make sure

plac

and secure

Make sure

retr

at.

Make sure

fall

ver and inju

Make sure

goo

condition.

Make sur

rate

for unit

rra

ngement Dr

before you h

cool

Make sur

ughly clean

thor

Disconnect

ene

gizing sour

equi

pment.

Check the

e electric ha

or u

llow all s

t/repair the

ck into servi

ange the

pproval of

representati

uitable barri

, a guard rail

that all sa

.

that you ha

that the pro

e people or

that the lifti

lifting equi

weight. R

wings.

stem and pu

andle them.

that the

d.

and lock

es before

explosion ris

nd tools.

problem pr

e.

ervice appli

an auth

e.

r around th

.

ety guards

e a clear p

uct cannot

amage prop

g equipmen

ment is pr

efer to G

mp compon

roduct has

out tag o

you servic

k before yo

or to

ation

rized

work

re in

th of

roll or

rty.

is in

perly

neral

nts to

been

t all

this

weld

SAFET

without p

inspectio

protectio

Model: P

PRECA

Ne

er weld to t

roper weld

s and testin

Ne

er work alon

ays wear pr

.

Sta

clear of su

D Rev. B_12

TIONS W

he exterior

rocedures a

.

tective cloth

pended load

2/2015

ILE WOR

f the casin

d post wel

ng and han

.

ING

with

ut any warn

disa

semble the

wor

ing pressure

Always lift

This equip

Properly

Do not e

he product b

ent may st

ng.

clean com

ump.

ceed the m

of the pump

its lifting de

rtup automa

onents afte

aximum allo

vice.

ically,

you

able

W

e

r

a

D

n

d

p

U

a

u

h

e

e

e

e

v

e

A

o

e

d

A

s

n

A

m

f

s

p

b

N

a

n

o

/

n

p

e

U

a

r

c

G

s

n

m

h

w

y

r

l

a

A

e

s

n

s

v

k

h

a

0

e

r

n

a

g

d

o

E

s

g

h

e

n

o

O

u

a

o

b

u

r

a

o

N

o

G

m

e

h

r

s

e

e

s

o

,

r

U

t

,

d

n

a

s

g

e

e

T

r

e

t

-

o

f

h

s

d

d

A

d

s

e

s

o

a

o

U

d

c

w

I

z

T

l

c

u

h

n

y

s

w

r

r

w

u

V

A

c

g

r

R

t

c

u

n

s

r

n

a

p

s

e

n

e

D

c

a

c

t

p

a

f

o

r

g

e

p

n

I

p

m

f

e

o

V

y

g

o

g

s

o

a

u

s

o

l

v

n

e

g

d

y

e

h

p

e

Do

remove

pressuriz

Make su

system

not open a

any plugs

d.

e that the

nd that pr

y vent or d

while the

ump is isol

ssure is rel

rain valve o

system i

ted from th

ieved befor

sembly of

disa

disc

inst

nnect pipin

Never ope

lled

the pump,

.

ate a pump

coupling

remove plu

without a pr

s, or

perly

uard.

HAZAR

Whe

liquids ca

the liqui

limiting

HOT S

Hot

buildup.

surfaces,

pump c

temperat

catastrop

due to a

surface t

could exc

Ther

should b

PERSO

OUS LIQ

the pump

re must be t

by approp

ersonnel a

RFACE I

urfaces ca

Under nor

such as t

sing, are

re of an

ic failure of

loss of lub

mperatures

eed this leve

fore, dust

limited to

NNEL QU

IDS

is handlin

ken to avoi

iate sitting

cess and

NITION T

ignite du

al operatin

e bearing

ell below

dust bu

this unit wer

ication or a

of the housi

.

buildup on

maximum

LIFICATI

hazardou

exposure t

f the pump

by operato

MPERAT

t and dus

conditions

ousings an

the ignitio

ildup. If

to occur, a

loss of flow

gs or casin

any surfac

f 1/8”. If th

NS AND

train

expl

appl

RE OF D

buil

shut

pro

follo

utili

and

avai

pur

RAINING

ing. If the

sive, strict

ied.

ST LAYE

up exceeds

down and

edures and

ed.

t is the res

e safety eq

sleeve beari

emperature

lable by cu

hased and in

liquid is fl

safety pro

his, the unit

leaned. Pro

safety prec

ponsibility o

ipment to m

g temperatu

monitorin

tomer requ

stalled.

mmable an

edures mu

should be pr

er lockout t

utions sho

the end u

nitor the pr

es.

devices

st if not a

d /or

t be

perly

g out

ld be

er to

duct,

are

ready

Thes

Ex-appro

atmosph

ll w

by certifi

authorize

installatio

ll u

electric c

character

present i

ny

must con

Standard

Pum

responsi

CE A

It is

equipme

of the w

are the p

ed product

res:

rk on the pr

d electricia

mechanic

s in explosi

ers must

urrent and t

istics of the

hazardous

aintenance

orm to Intern

.

Works 61

le for work

D ATEX

legal requir

t put into se

rld shall co

rsonnel req

in potenti

duct must

s and Pum

. Special r

e atmosphe

now about

e chemical

gas, the v

reas.

for Ex-appr

ational and

shall n

done by u

MARKIN

ment that

vice within c

form with t

irements fo

lly explosiv

e carried ou

pWorks 610

les apply t

es.

the risks o

and physica

por, or bot

ved product

ational

t be hel

ntrained an

S AND

achinery an

rtain region

e applicabl

l

PPRO

thorized pe

una

in t

e operatio

mai

tenance of

carr

out the wo

que

tion do not

kno

ledge and

instr

uction must

ator m

ope

man

ufacturer/su

ing. Alway

train

ations and h

ope

follo

all pla

appl

icable saf

lations.

reg

ALS

TE

X Marking

where appli

and,

tromagnetic

Ele

sonnel. All

, installatio

the unit mu

rk involved.

lready poss

skill, appro

be provided

ay co

plier to p

coordinate

alth and sa

t safety r

ty and h

irectives c

able, Low

Compatibilit

ersonnel in

, inspectio

st be qualifi

f the person

ess the nec

riate trainin

. If require

mission

rovide appl

repair activit

ety personn

equirements

alth laws

vering Mac

oltage Equi

(EMC), Pr

olved

and

ed to

nel in

ssary

and

, the

the

icable

with

l, and

and

and

inery

ment,

ssure

Model: P

D Rev. B_12

2/2015

Loading...

Loading...