BULLETIN PZ- 08

Series PZ / PZi / PZiG

Series PZ / PZi / PZiG

Pulse Metering Pumps

Pulse Metering Pumps

US Patent #6,283,717

The Power of Intelligent Pumps Expands!

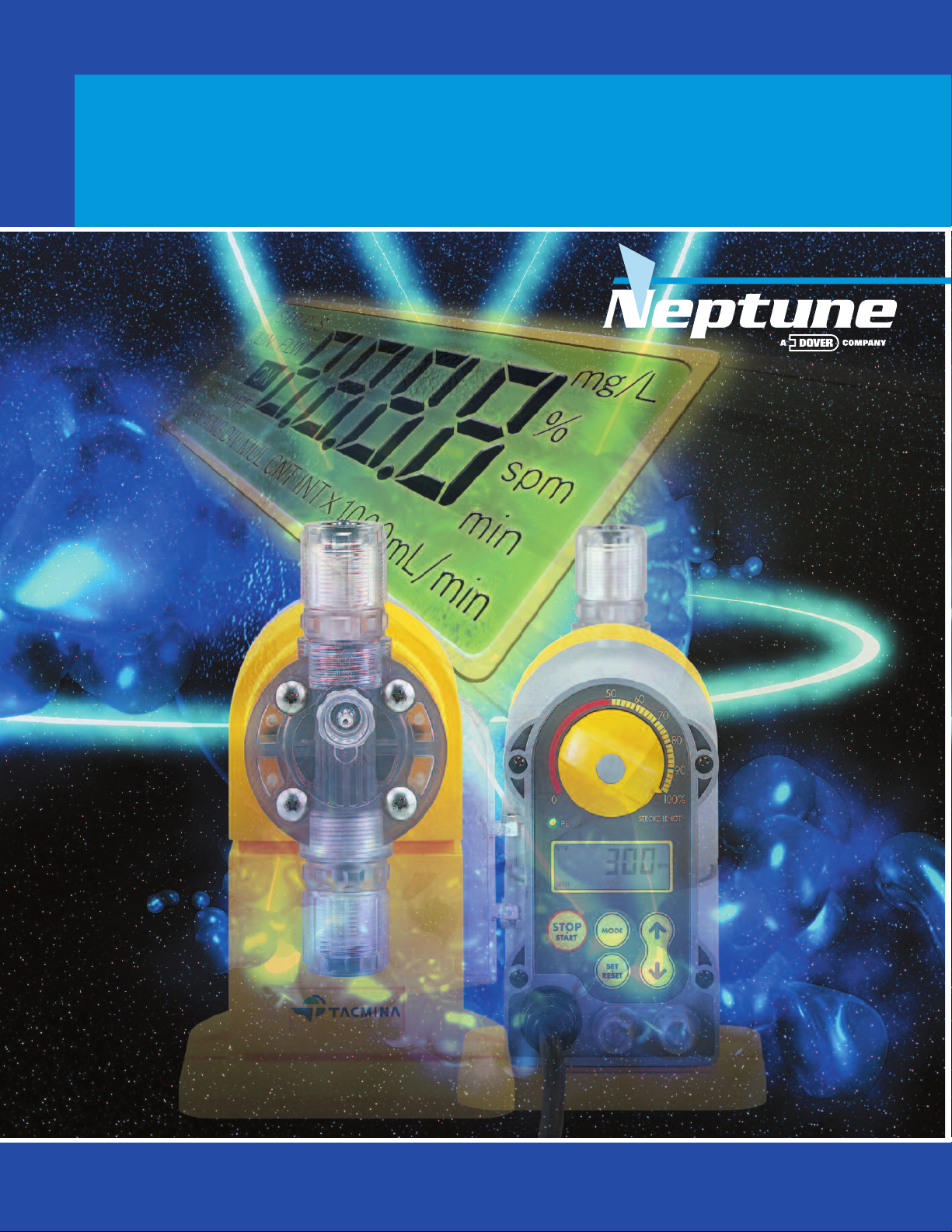

TYPE PZ

(manual)

TYPE PZi4

(automatic)

Features

• PZ Models (Speed only is adjustable from 15 to 300 SPM) ៚ ————

Manual control • PZD & PZi Models

• Enter desired flow directly in ml/min. — ៚ — ៚៚

Calibration • Calibrate pump flow to actual condition of chemical,

function pressure, viscosity, etc.

Control input • External interlock (Examples: level switch, remote start, reset) ——៚៚៚

Operation

display

Signal input

4-pin connector

Signal output

8-pin connector

Alarms • Alarm display, output and action (run, pause or stop) can be selected ———៚៚

Other

functions

NOTES: 1. PZi4 and PZi8 Models in sizes -31 / -61 / -12: 50% to 100% stroke length adjustment.

PZi4 and PZi8 Models in sizes -32 / -52 plus all PZD and PZiG Models: 20% to 100% stroke length adjustment.

2. PZi8 only when used with Flow Checker shown on page 5.

3. PZi4 has one analog input and one high speed digital pulse input; PZi8 and PZiG have one analog input and two high speed digital pulse inputs. See page 9.

4. Two separate configurable outputs, either open collector (alarm, error, run) or pulse (operational sync or end of cycle).

5. Sizes -31 / -61 / -12 only.

• Indicates speed and status ——៚៚៚

• Indicates speed, feed rate

• Pulse signal Frequency-divide 1/1 to 1/9999, Multiply 1 to 9999 (See pg.6) ——៚៚៚

3

• Analog signal Shift function, Proportional band function (See page 6) ——៚៚៚

• pH Control/Residual Chlorine Control (See page 8) ————៚

• Alarm output (Level switch, injection monitor2)———៚៚

4

• Operation pulse signal (Synchronous pulse output for each stroke) ———៚៚

• Operation progress signal

• Two point level control (See page 9) ———៚៚

• Power supply for flow checker ———៚ —

• Interval operation (Repeat cycle program, see page 9)

ON time: 1 to 999999 minutes / OFF time: 1 to 999999 minutes

• Counter (Countdown batch injection, see page 9)

1 to 9999 strokes (X1, X10, X100, X1000)

•

Head can be turned 90° to allow base to be mounted to a vertical wall5៚ — ៚៚—

(Adjust speed 1 to 300 SPM plus stroke length adjustment1)

2

, status and other operational data ———៚៚

(Time or number of strokes remaining in program)

TYPE PZi8

(programmable)

ANUAL EXTERNAL PROGRAMMABLE

M

TYPE

CONTROL INPUT INPUTS/OUTPUTS

PZ PZD PZi4 PZi8 PZiG

— ៚៚៚៚

— ៚ — ៚៚

———៚៚

———៚៚

———៚៚

MODEL NUMBER SELECTION–

The complete model number consists of three parts: TYPE + SIZE + MATERIAL CODE

TYPE – Specify PZ or PZD for manual control; specify PZi4 for external input; specify PZi8 for programmable models.

The largest models are the PZiG Series, available in full programmable type only.

SIZE – Size code selects the capacities per the charts on page 3. Sizes -31, -61 and -12 are available for type PZ.

Higher capacity sizes -32 and -52 are available for type PZD. All five sizes are available for types PZi4 and PZi8.

The very high PZiG capacities are shown in a separate chart.

MATERIAL CODE – Select from charts on page 4.

Example – The complete model for a pump with a Kynar liquid end with

Viton seals rated at 160 ml/min capable of accepting a 4-20mA input would be:

Type PZi4 + Size -61 + Material code -FFC

The complete model number becomes

PZi4-61-FFC

2

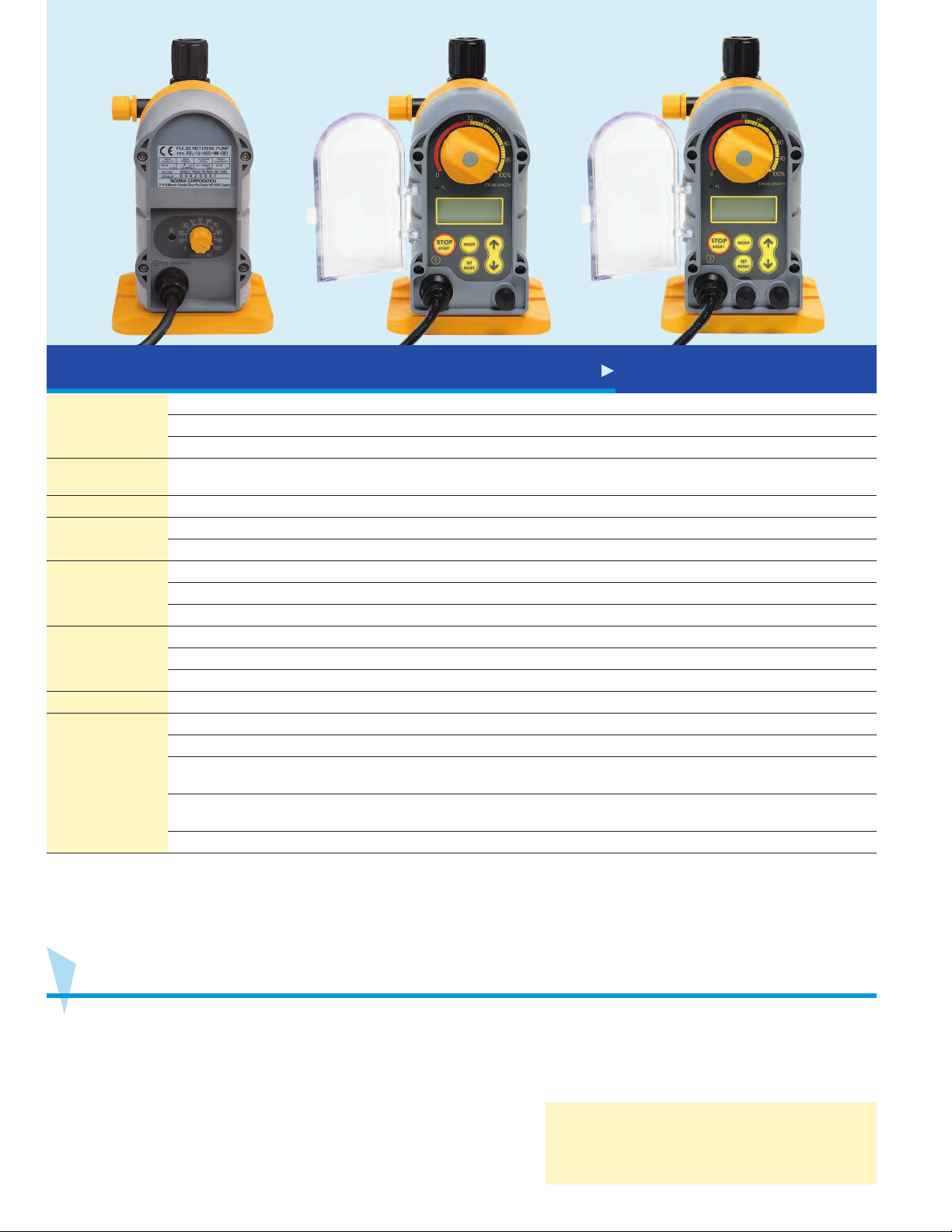

Type PZD /PZi-32 /52 High Capacity Models

PZD Series pumps offer higher capacities. These models feature

an extra large keyboard and the injection rate can be entered

directly in milliliters per minute.

The injection rate can be set three ways by direct entry of:

– Stroke speed: 1 to 300 spm

– Percentage: 1 to 100%

– Injection rate: ml/min.

• Onboard calibration measures the

High Capacity models are

available in material codes

VFC, VEC, SS and FTC only.

VFC model is shown.

actual discharge volume under the exact

operating condition of the specific installation and chemical,

then stores that value to insure the correct injection rate.

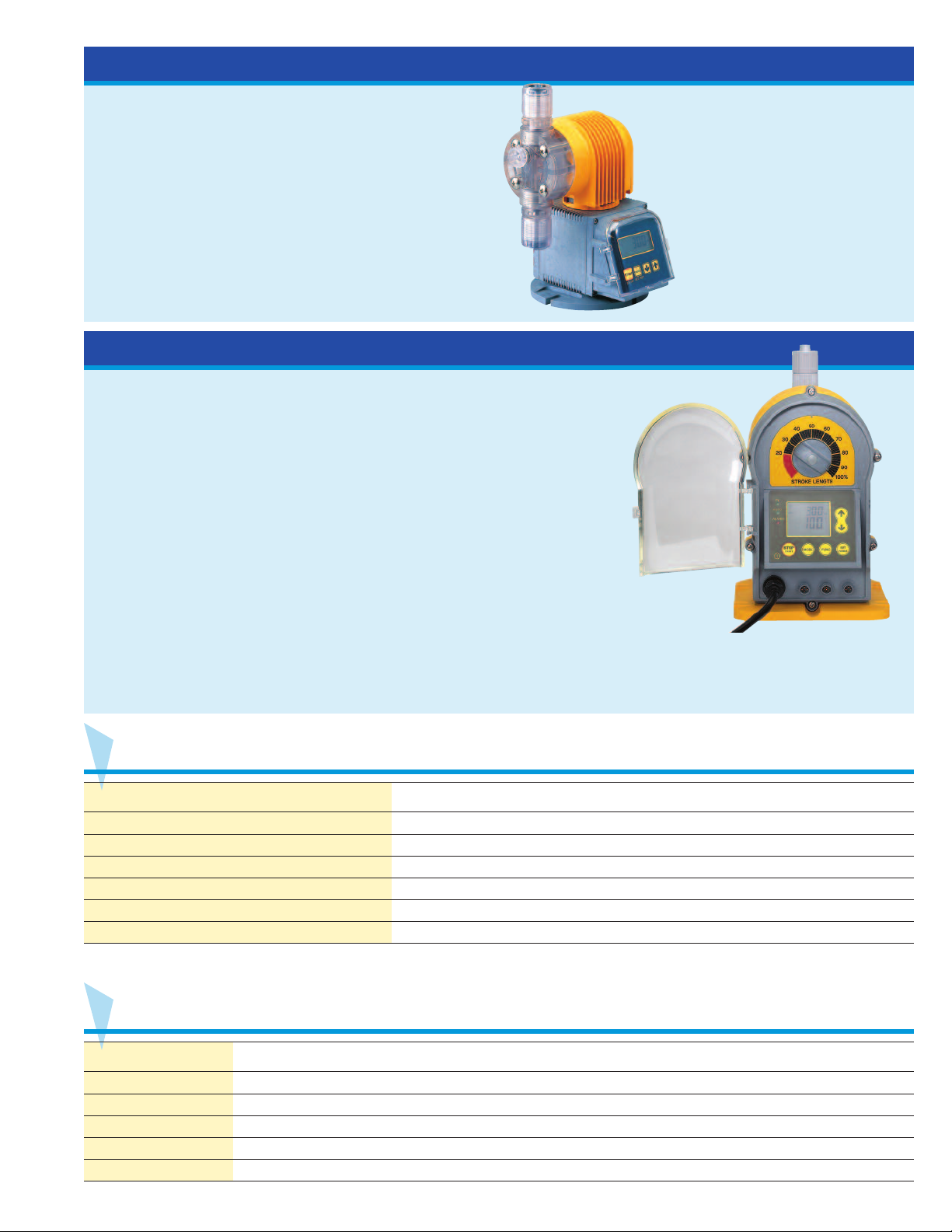

Type PZiG Programmable Large Volume Models

PZiG Models offer capacities typically requiring motor driven pumps. Special models

easily handle viscosities of 1000 CPS (up to 4000 CPS at reduced volume).

Powerful onboard controls allow proportional flow rate, pH and residual chlorine control

by direct analog connection eliminating the PID Controller and Inverter (plus the control

panel to house them), that are required by similar sized motor driven pumps.

The injection rate can be set three ways by direct entry of:

– Stroke speed: 1 to 300 spm

– Percentage: 1 to 100%

– Injection rate: ml/min.

• Manual stroke length adjustment 20% to 100%.

Control Functions also include (see pages 8 & 9):

• Onboard calibration measures the actual discharge volume under the

exact operating condition of the specific installation and chemical, then stores

that value to insure the correct injection rate.

• Multi-pump proportional flow rate injection from

a single direct flowmeter signal (pulse/analog).

• Two point level switch control (see page 9)

Note: Install a pulsation

dampener for discharge lines

greater than 7 feet to achieve

maximum pressure capability.

PZiG

with VTCF

Liquid Head

• Batch injection • Interval injection

• Proportional control with shift and proportional band function.

• Two line LCD screen displays injection rate and/or operational progress.

• Manual stroke length adjustment

20% to 100%.

• Set points can be easily viewed

on the LCD.

• Pump head may be rotated to

face in any of the three positions

other than where the keypad

and display are located.

• Pump head can be decoupled

from the controller base for

remote mounting.

Head can be turned 90° to allow base to be

TYPE & SIZE SELECTION CHART: PZ / PZD / PZi4 / PZi8

MANUAL EXTERNAL PROGRAMMABLE MAX. CAPACITY MAX. PRES. DWG./ STROKE MAX. PWR. AVG. PWR.

MODEL INPUT MODEL

PZ-31-HP

PZ-31 PZi4-31 PZi8-31 12 0.5 30 140 page 7 1.0 200 15

PZ-61 PZi4-61 PZi8-61 24 1.0 60 115 page 7 1.0 250 18

PZ-12 PZi4-12 PZi8-12 38 1.6 100 60 page 7 1.0 250 18

PZD-32 PZi4-32 PZi8-32 137 5.7 360 45 page 7 1.5 500 30

PZD-52 PZi4-52 PZi8-52 204 8.5 540 30 page 7 1.5 500 30

NOTES:1PZi4 models include 2-meter cable with 4-pin connector on one end; PZi8 models include separate 2-meter signal cables, one each with 4-pin and 8-pin connector end.

2

PZi4-31-HP

2

High Pressure models are available as PZ-31, PZi4-31 or PZi8-31 only; available in FEC or SS only. Refer to Material Code Chart on page 4.

TYPE & SIZE SELECTION CHART: PZiG

PROGRAMMABLE MAX. CAPACITY MAX. PRESSURE DRAWING/ STROKE MAX. POWER AVG. POWER

MODEL GPD GPH ML/MIN. PSI CURVE LENGTH (MM) (VA) (WATTS)

PZiG-300 130 5.4 340 140 page 7 1.5 750 100

PZiG-500 200 8.4 530 100 page 7 1.5 750 100

PZiG-700 288 12.0 760 60 page 7 1.5 750 100

PZiG-1000 380 15.8 1000 45 page 7 1.5 750 100

PZiG-1300 495 20.6 1300 30 page 7 1.5 750 100

1

2

MODEL

PZi8-31-HP

1

GPD GPH ML/MIN. PSI CURVE LENGTH (MM) (VA) (WATTS)

2

10.5 0.44 28 220 page 7 1.0 200 15

Available Only in Programmable Models

(See page 8 for Direct Connection of pH and Residual Chlorine Control Instruments)

mounted to a vertical wall (-31 / -61 /-12 only).

3

Variety of Liquid End Materials

Variety of Liquid End Materials

Standard

odel: PVC

M

៑

(VFC/VEC)

• General chemical

applications

• Valve seats and

O-rings are

available in

®

Viton

or EPDM

• Built-in relief valve

Universal

Model: PVDF ៑

FFC/FEC/FTC)

(

• For most chemicals

and highly corrosive

chemicals

• Valve seats and

O-rings are available

®

in Viton

or Teflon

• Built-in relief valve

, EPDM

®

Chlorine Model:

្ Acrylic (CL)

• Transparent pump

head allows visual

check of valves

• Reduced head volume

and upward sloping

ports vent gas away

from diaphragm

• Improved pump efficiency

for countering gas lock

• Built-in relief valve

MATERIALS CHART: PZ / PZD / PZi4 / PZi8

Chlorine Model:

្ Acrylic (ARPZ)

• CL model with

automatic air release

mechanism

• Derate

capacity

5% for

air release

models

Adapters for NPT

connection are available

Stainless Steel

odel (SS)

M

• For solvents and other

chemicals where plastics

To specify pump, choose the type from

the chart on page 2 plus the size from

the chart on page 3 (ex: PZi4-31).Then

add the appropriate material code from

the chart below (ex: PZi4-31-FFC).

Complete instructions regarding Model

Number Selection are on page 2.

៓

are not suitable

TRIM 5/8" OFF OF THIS SIDE TO CLEAR HOLE DRILL

MATERIAL PUMP TUBE VALVE CHECK FOOT VALVE BACKPRESSURE SUCTION DISCHARGE

CODE HEAD JOINT SEAT BALL

DIAPHRAGM

& STRAINER INJECTION ASSEMBLY CONNECTION – TUBE* CONNECTION – TUBE*

VFC PVC PVC Viton Ceramic PTFE PVC PVC 3/8" Tube – Soft PVC23/8" Tube – PE

VEC PVC PVC EPDM Ceramic PTFE PVC PVC 3/8" Tube – Soft PVC23/8" Tube – PE

1

CL

Acrylic PVC Viton Ceramic PTFE PVC PVC 3/8" Tube – Soft PVC 3/8" Tube – PE

ARPZ1Acrylic PVC Viton Ceramic PTFE PVC PVC 3/8" Tube – Soft PVC 3/8" Tube – PE

SS 316SS N /A EPDM 316SS PTFE Not Included Not Included 3/8" MNPT – None 3/8" MNPT – None

1

FFC

FEC

PVDF PP Viton Ceramic PTFE PVDF – Molded PVDF – Molded 3/8" Tube – PE

1

PVDF PP

4

EPDM Ceramic PTFE PVDF – Molded PVDF – Molded 3/8" Tube – PE

FTC PVDF PVDF Teflon Ceramic PTFE PVDF – Molded PVDF – Machined 3/8" Tube – FEP

1

Not available in -32 or -52 size codes.

2

PZ-32 and PZ-52 Models – 18x12 mm Soft PVC Tube for VFC and VEC Models; 15 x12 mm PTFE Tube for FTC Models

3

Ceramic Weight Included

4

220 psi Model PZ/PZi-31-FEC – 1/4" Tube Joint and Tube – PP

3

3

*NOTE: 3/8" Tube is 3/8" OD x 1/4" ID;

Adapters for NPT connection are available

2,3

3/8" Tube – PE

3/8" Tube – PE

3/8" Tube – FEP

PZiG with ៑

MATERIALS CHART: PZiG

MATERIAL PUMP VALVE CHECK DIA-

CODE HEAD SEAT BALL PHRAGM

STRAINER INJECTION DISCHARGE

VTCE PVC EPDM Ceramic Teflon Not Included Not Included 1/2" FNPT

VTCF PVC Viton Ceramic Teflon Not Included Not Included 1/2" FNPT

VTCF-V1PVC Viton Ceramic Teflon Not Included Not Included 3/4" FNPT

FTCT PVDF Teflon Ceramic Teflon Not Included Not Included 1/2" FNPT

FTCT-A2PVDF Teflon Ceramic Teflon PVDF PVDF 15 x12 PTFE

1

High Viscosity Model rated 1000 to 4000 cps. Consult factory for applications greater than 2000 cps.

2

Only these models include Foot Valve Strainer, Antisiphon Check Valve,

plus 15 x12 mm Teflon Suction and Discharge Tubing. Tubing rated 75 psi max.

BACKPRESSURE SUCTION/

ASSEMBLY CONNECTION

VTCF Liquid Head

2

2

2

4

2

4

3-3/8'' (85)

2-3/8'' (60)

2-5/8'' (66)

LED: RED

2'' (50)

2

LED: GREEN

2'' (48)

1

-1/2'' (39)

6'' (149)

NCLUDED WITH

I

EACH PUMP:

Feed Verification

Feed Verification

F

oot Valve Strainer*

Back Pressure/Check Valve

Injector with Quill*

Suction, Discharge and

Air Release Tubing*

Foot Valve

Strainer

Back Pressure

Injector

Power Cord with 3-Prong Plug

Signal Cable with Multi-Pin Connectors

(one with PZi4 & two with PZi8 & PZiG models)

*except some PZiG models (see page 4)

Model FC-1

FLOW CHECKER

The Model FC-1 Flow Checker output provides

vital information for water treatment programs

requiring feed verification to manage chemistry

and monitor drum inventory.

• The flow checker mounts directly to the discharge

of PZ and PZi metering pumps.

• The flow checker is an oval gear flow meter

which measures the pump output and transmits

one pulse for each 1 ml of flow.

(shown with

PZi8 type

pump)

• Flow checker output can be connected to

Model PZi8 Pumps for instantaneous indication

MATERIAL SELECTION CHART

PUMPING LIQUID CONCENTRATION RECOMMENDED

(in alphabetical order)

Acetic acid 50% VFC/FFC

Acetic acid concentrated 24°C FTC

Aluminum sulfate — VEC

Amine* — SS

Aqueous ammonia — VEC

Calcium/Sodium

hypochlorite

Caustic soda — VEC

Ferric/Ferrous chloride — VFC

Ferric/Ferrous sulfate — VFC

Hydrochloric acid 10% to conc. VFC

Hydrogen peroxide 30% VFC

Nitric acid 10% VFC

Nitric acid 30% to conc. FTC

Phosphoric acid 10% to conc. FTC

Poly-aluminum

chloride (PAC)

TRIM 5/8" OFF OF THIS SIDE TO CLEAR HOLE DRILL

Potassium

permanganate

Sulfuric acid to 40% VFC/FFC

Sulfuric acid concentrated FTC

*Boiler compounds with small amounts of Amine – FEC

12% CL/AR

— VEC

— VEC

TYPE

CAUTION – ALL MODELS

• Ambient temperature: 32 to 104°F (0 to 40°C)

Pumped liquids:

Temperature: 32 to 104°F (0 to 40°C),

Viscosity: 100 CPS max. except as noted

• This pump is designed for outdoor use. Avoid

installing pump in a location where service life

could be shortened (i.e., where it is exposed to

direct sunlight or driving rain).

• This pump cannot pump liquids containing a slurry.

• A relief valve should be installed on the discharge

side, if the pump does not have a built-in relief

valve and the discharge piping has a shutoff valve.

5

of pump output displayed on the pump LCD.

• Connect the flow checker output to your

controller or PLC (external power supply

required if not used with PZi8 type pump).

DIMENSIONS ៓

inches (mm)

FLOW CHECKER SELECTION CHART

MODEL NO. MATERIAL USE w/ PUMP MODEL†

FC-1P-P-N1 Ryton* PZ or PZi-31

FC-1N-P-N1 Noryl** PZ or PZi -31

FC-1P-P-N2 Ryton* PZ or PZi-61 or -12

FC-1N-P-N2 Noryl** PZ or PZi -61 or -12

† Not available for larger models.

LIQUID-END MATERIALS

PART MODEL MODEL

NAME FC -1P-ᔤ FC -1N- ᔤ

Body Ryton* Noryl**

Ball Check Ceramic Ceramic

Ball Guide/Joint PVC PVC

Valve Seat/O-Ring EPDM Fluororubber

* Ryton: PPS — Polyphenylene-sulfide (for general chemicals)

** Noryl: PPO — Polyphenylene-oxide (for sodium hypochlorite)

SPECIFICATIONS

Pulse constant 1mL/pulse

Accuracy ±3% (Depends on nature of chemical,

flow rate, temperature and back pressure.)

Normal operating pressure 140 psi (10 Kg/cm2)

Momentary maximum 200 psi (14 Kg/cm

operating pressure

Temperature 32–104°F (0–40°C) (Liquid should not freeze.)

Liquid viscosity 1 to 50 cps

Output Open collector (Collector capacity: 30V, 30mA)

Power requirement 4.5 to 25VDC (20mA Max.)*

Green LED lights for each pulse output. Red LED on when the power is ON.

NOTES: 1. Use flow checker only for clear liquids.

2. Pressure loss is 0.5 Kg/cm

+ 5V Power Supply provided on board PZi8 Models.

*

2

(at maximum flow rate using water).

2

)

Advantages

Digital settings from 15 to

•

300 pulses per minute on

PZ models and from 1 to 300

pulses per minute on PZi and

PZD models

• High stroking speed

ensures more uniform

distribution of chemical at

low feed rates

• Pump delivery is constant

at any voltage from 94 to

264 VAC single phase and

is not affected by voltage

fluctuations

• Outdoor use—pump is water

and UV resistant. Equivalent

to IEC specification IP65.

Dust proof, wash down

duty (with proper electrical

connection).

Cross Sectional view applies to PVC, Kynar and Type CL Heads;

does not apply to Material Codes ARPZ, SS or any PZiG Liquid Heads.

ome models use single check balls.

S

Applications

• Injection of chemicals to boilers and cooling towers

• Chlorine sterilization for food plants, small-scale water-supply

systems, buildings and swimming pools

• Injection of nutrients and disinfectants in the livestock industry,

such as poultry and hog producers, as well as for hydroponic

cultivation

• Very low flow rate injection of low viscosity liquids for any

application (100 CPS max. except high viscosity models)

ANALOG SIGNAL INPUT

DC4(0) to 20mA input

1. Proportional band function

The proportional band can be adjusted within a range of ±1% to ±999%.

Pump response to increasing input signal is easily reversed from min. 4mA

and max. flow at 20mA to max. flow 20mA and min. flow at 4mA.

0mA to 20mA range on PZi8 models.

300

1%

50%

150

Pump stroke (spm)

30

0

4(0) 12 20

4.16

2. Shift function

Shift can be set within the range ±100%

allowing a min. preset flow at 0 (4mA)

signal or allowing no flow until the input

signal exceeds a preset value.

6

100%

200%

999%

Analog input (mA)

PZi4 /PZi8 / PZiG

300

270

150

–50%

–1%

Pump stroke (spm)

0

4(0) 12 20

100%

Pump operation

0

4(0) Signal 20mA

–100%

4.16

Analog input (mA)

(A)

–999%

–200%

(B)

PULSE SIGNAL INPUT

1. Frequency-division (1/1 to 1/9999 adjustable)

Example: 1/6 frequency-division

Signal

Pump operation

2. Multiplication (1 to 9999 adjustable)

Example: 5 times multiplication

(A) Pulses 5 times—next 5 strokes at normal operating speed.

Signal

Conventional products

(A)

(B) Pulses 5 times evenly spaced over one minute.

PZi

(B) Injection is more uniform.

PZi4 /PZi8 / PZiG

500

400

300

200

100

0

50 100 150 200 250 300

0.15MPa

(1.5kgf/cm

2

)

1.0MPa

(10kgf/cm

2

)

(pulse/min)

Discharge volume (ml/min)

700

600

500

400

300

200

100

0

50 100 150 200 250 300

0.15MPa

(1.5kgf/cm

2

)

0.7MPa

(7kgf/cm

2

)

(pulse/min)

Discharge volume (ml/min)

1200

1000

800

600

400

200

0

50 100 150 200 250 300

0.15MPa

(1.5kgf/cm

2

)

0.3MPa

(3kgf/cm

2

)

(pulse/min)

Discharge volume (ml/min)

1600

1400

1200

1000

800

600

400

200

0

50 100 150 200 250 300

0.15MPa

(1.5kgf/cm

2

)

0.2MPa

(2kgf/cm

2

)

(pulse/min)

Discharge volume (ml/min)

800

900

700

600

500

400

300

200

100

0

50 100 150 200 250 300

0.15MPa

(1.5kgf/cm

2

)

0.4MPa

(4kgf/cm

2

)

(pulse/min)

Discharge volume (ml/min)

EXTERNAL DIMENSIONS

40

45

35

30

25

20

15

10

5

0

50 100 150 200 250 300

0.2MPa

(2kgf/cm

2

)

1.0MPa

(10kgf/cm

2

)

(pulse/min)

Discharge volume (ml/min)

80

70

60

50

40

30

20

10

0

50 100 150 200 250 300

0.2MPa

(2kgf/cm

2

)

0.8MPa

(8kgf/cm

2

)

(pulse/min)

Discharge volume (ml/min)

400

350

300

250

200

150

100

50

0

50 100 150 200 250 300

0.1MPa

(1kgf/cm

2

)

0.3MPa

(3kgf/cm

2

)

(pulse/min)

Discharge volume (ml/min)

600

500

400

300

200

100

0

50 100 150 200 250 300

0.1MPa

(1kgf/cm

2

)

0.2MPa

(2kgf/cm

2

)

(pulse/min)

Discharge volume (ml/min)

120

100

80

60

40

20

0

50 100 150 200 250 300

0.2MPa

(2kgf/cm

2

)

0.4MPa

(4kgf/cm

2

)

(pulse/min)

Discharge volume (ml/min)

A

5-1/8

[130]

4-5/8

[118]

B

E

2-3/4

[70]

4-5/16 [110]

6-1/2 [165]

1/4

[6]

3-7/16

[

87]

C

D

A

B

C

D

5

-7/8 [150]

E

4-5/8 [118]

6-7/8 [175]

F

3

-7/16

[87]

3-7/16

[

87]

1/4

[6]

R3

6

[155]

1-1/2

[38]

1-1/4

[32]

6-11/16

[170]

D

E

F

B

C

6-1/2

[165]

6-11/16

[170]

A

5-11/16

[145]

3-15/16

[100]

3/8

[9]

R4.

5

Dimensions are shown in inches (mm).

*The mounting slots

llow mounting from

a

-7/16" (87) to

3

-5/16" (110) centers.

4

MODELS PZ/PZi-31/61/12

MATERIAL ABCDE

FC/VEC 4

V

FC/FEC/FTC 4

F

3

⁄4 (

3

⁄4 (

CL 31⁄4 (83) 8 (204) 27⁄8 (73) 3 (76) 11⁄4 (32)

RPZ 3

A

1

⁄4 (

SS 31⁄4 (83) 75⁄8 (194) 21⁄2 (64) 21⁄2 (64)3⁄4 (19)

1

120) 8

206) 3 (76) 3 (76)

⁄8 (

120) 9 (228) 3

83) 8 (204) 2

7

⁄8 (

7

⁄8 (

7

98) 3

98)

⁄8 (

73) 3 (76) 2

11

17)

⁄16(

1

1

17)

⁄16(

1

57)

⁄4 (

PERFORMANCE CURVES

Type PZ, PZi4 or PZi8 Type PZD or PZi

SIZEᔤ-31

SIZEᔤ-61

*The mounting slots

llow mounting from

a

-7/16" (87) to

3

-5/16" (110) centers.

4

MATERIAL AB C DEF

VFC/VEC 4 (102) 95⁄8 (244) 31⁄2 (88) 31⁄2 (88) 1 (25) 33⁄8 (86)

TC 4 (102) 10

F

SS 4 (102) 9 (227) 31⁄4 (83) 27⁄8 (72) 1 (24) 31⁄2 (89)

MATERIAL A B* C* D* EF

VTCE & VTCF

300/500 57⁄8 (150) 105⁄8 (270) 4 (100) 4 (100) 2 (50) 93⁄4 (247)

700 57⁄8 (150) 101⁄4 (260) 31⁄2 (90) 31⁄2 (90) 2 (50) 93⁄4 (247)

1000/1300 57⁄8 (150) 101⁄2 (265) 33⁄4 (95) 33⁄4 (95) 21⁄8 (54) 10 (253)

FTCT

300/500 57⁄8 (150) 111⁄4 (285) 41⁄2 (115) 37⁄8 (97) 2 (50) 93⁄4 (247)

700 57⁄8 (150) 111⁄4 (285) 41⁄2 (115) 37⁄8 (97) 2 (50) 93⁄4 (247)

1000/1300 57⁄8 (150) 113⁄4 (298) 5 (128) 5 (128) 21⁄8 (54) 10 (253)

Conditions: Clean water, Room temperature

SIZEᔤ-12

MODELS PZD/PZi-32/52

1

256) 4 (101) 3

⁄8 (

1

7

83)

⁄4 (

22) 3

⁄8 (

MODELS PZiG-300/500/700/1000/1300

*For high viscosity liquid end type VTCF-V (all sizes):

5

B = 11

⁄8 (294) C = 47⁄8 (124) D = 47⁄8 (124)

SIZEᔤ-32

SIZEᔤ-52

1

83)

⁄4 (

PZiG-300

PZiG-500

PZiG-700

PZiG-1000

PZiG-1300

7

PZiG

PZiG for

alkali use

PZiG

Discharge volume (%)

Main piping

flow rate (%)

100

100

0

Alkali injection amount

pH

100 (%)

76.5

0

Acid injection amount

pH

100 (%)

147.57

0

Chemical injection amount

Residual chlorine

concentration

100 (%)

1mg/L0.5

0

Motor-driven

pump

Motor-driven

pump

Motor-driven pump

INVPID

D

SC

DIS

Inverter

<50:1 control>

Alkali tank

PZiG for

acid use

Acid tank

PH

AG

PIDPID

INV INV

AG

RM

RM

Example: On-site pH control

Example: Disinfection using electrolytic sodium hypochlorite in swimming pools

PH

PZiG setting

for alkali use

PZiG setting

for acid use

*The pH 6.5 to 7.5 range is set as the dead band.

P

P

INVPID

Control panel

PID controller

Residual chlorine meter

Inverter

Control panel

Electrolytic sodium

hypochlorite

generating unit

Agitator

PID controller

Servo motor

Servo controller

PID controller

Inverter

pH meter

Display

Flow meter

Example: Any additive injected proportional to flow in a line

Current

system

Current

system

Current

system

PZiG

system

PZiG

system

PZiG

system

Motor-driven

pump

S

tatic mixer

<300:1 control>

8

Programmable Models PZi8 & PZiG Control System Examples

YOUR SYSTEM IS ENHANCED BY OUTSTANDING CONTROLLABILITY

Proportional Flow Rate Control – Models PZi8 & PZiG

Flow meter signals are received directly according to the flow rate of the main piping and the discharge volume is automatically controlled.

Advantage

This eliminates the need for control devices, which have been needed up until now, and reduces the cost of devices.

Cost benefits: Digital panel meters, PID controllers and inverters are no longer required.

Advantage

pH Control – Model PZiG only

Control signals from the pH meter are received and chemicals are automatically injected

according to the preset pH value.This simplifies the configuration of the control devices.

Cost benefits: Two PID controllers and two inverters are no longer required.

Advantage

Sterilization – Model PZiG only

Automatic control is possible on the pump unit merely by receiving signals directly from the residual chlorine meter and setting the target residual chlorine value.

Cost benefits: Control panels (PID controllers and inverters) are no longer required.

8

ulti-liquid Proportional Flow Rate

PZiG

C

PZiG

B

PZiG

A

Flow meter

(pulse/analog)

Sodium

h

ydroxide

Sodium

h

ypochlorite

Polyaluminum

c

hloride

PZiG

system

PZiG

Alarm

PZiG

system

PZiG

F

Start signal

Discharge completed display

PZiG

system

PZiGP

Stop signal

PZiG

system

P

M

Injection – Models PZi8* & PZiG

Multiple PZiGs inject different chemicals according to preset

Advantage

*Input is

connected to

one PZi8 pump:

Multiple PZi4

pumps would

follow the pulse

output of the

PZi8 pump.

Note:

Multiple PZiG pumps take pulse or analog signal directly:A single PZi8 pump would

take a pulse or analog signal directly and slave a second or third pump to its output.

values while calculating the signal from a single flow meter.

This eliminates the need for a signal distributor.

-point Level Switch-based Control

2

– Models PZi8 & PZiG

A 2-point level control enables output of an alarm at

Advantage

the liquid level “low limit” and stops pump operation at

the “low-low limit.”

Batch Injection (counter)*

– Models PZi8 & PZiG

Pump operation starts on command signal. Operation auto-

Advantage

matically stops and operator is notified of completion when

a preset count is reached. Maximum number of pulses 9999x1,

x10, x100 or x1000 (555 hours max. run time).**

*Calibration function assures accuracy greater than ordinary pumps in these applications (see page 3).

**Pump operation can be interrupted by a remote signal at any time; program resumes when restarted.

CONTROL VARIATIONS – Models PZi8 & PZiG

Adjustment range

Analog input 4~20 mADC (110 ohm) 1

Number of inputs Digital input high speed (125 Hz max.) Open collector 2

Basic specifications

Other Power supply output +5VDC (10 mA max.) 1

LCD display Display unit selection (%, mL, spm)

Manual operation Manual mode

Run mode

Automatic operation Pulse signal 1 to 9999 times

Digital input low speed (10 Hz max.) Open collector 2

Analog mode Analog signal 4~20 mADC

Count mode Number of strokes 1~9999 (x1, 10, 100, 1000)

Interval mode ON/OFF time 1 to 9999 mins / 1 to 9999 mins

Stroke speed 1~300 spm (1 spm step)

Stroke length adjustment 20~100%*

Pulse signal 1/1~1/9999

*50~100% for sizes -31/-61/-12

Interval Injection (repeat cycle)*

– Models PZi8 & PZiG

The pump is repeatedly started and stopped by a preset

Advantage

timed program. ON time and OFF interval can be easily

set from 1 to 9999 minutes respectively.**

Stop input

Control input

Inputs

Control output Operation sync pulse output

Outputs

Alarm output

1. Output in sync with solenoid operation.

2. Output when operation for preset count is completed.

3. Alarm display, alarm output and pump operation can

be selected in response to an alarm condition.

Level switch input

Alarm reset input

Start/reset input

Operation signal output

End signal output

Analog input error alarm

Inpule pulse buffer overflow alarm

Level error alarm

Injection monitor error alarm

1

2

3

3

3

3

9

Quality

Quality

Accessories

Accessories

POLYETHYLENE SOLUTION

TANKS & AGITATORS

by Neptune

by Neptune

CORPORATION

STOPS

MODEL

CS2-75-PVC

Use: Injection of

chemicals pumped

by metering pumps

into tanks, mains,

cooling towers and

process systems.

Request Bulletin CS

ATERIAL SIZE DIMENSIONS

ODEL OF CONST. (A) BCD

M

CS2-75-PVC CPVC3⁄4

CS2-100-PVC CPVC 1" NPT 71⁄4

Kynar, 316 SS and C-20 also available.

M

" NPT 73⁄4

"51⁄4

"61⁄4

" 2"

"11⁄2

For PZ Series Pumps

(Top Mounted)

• Self Supporting

• For Corrosive or Non-Corrosive

Solutions

• Molded cover will accept

“PZ” Series Pumps and

Neptune Economy Agitators

• 30 or 50 Gallon Sizes

TANKS

ODEL SIZE HEIGHT DIA. MAX. WEIGHT

M

ST-30 30 Gal. 23" 22" 19 lbs.

ST-50 50 Gal. 321⁄2

AGITATORS – P

MODEL DESCRIPTION WEIGHT

N-316-30

A

AN-316-50

N-E-30

A

AN-E-50

"

" 22" 20 lbs.

VC suction tubing protector pipe included

16SS shaft and propeller, fits 30-gallon

3

polyethylene tank; 19" long shaft

316SS shaft and propeller, fits 50-gallon

olyethylene tank; 29" long shaft

p

Epoxy-coated shaft and impeller, fits 30gallon polyethylene tank; 19" long shaft

Epoxy-coated shaft and impeller, fits 50gallon polyethylene tank; 29" long shaft

MODEL

4 lbs.

1

14 lbs.

4 lbs.

1

14 lbs.

ST-50

NIMBLE SKID

FLEXIBLE PUMP PACKAGES

PORTABLE

MINI-TANK FEEDERS

Mini-tank system offers portability and economy.

Compact 23

fits through doorways, in elevators and allows

installation in small areas.Tank removes

from base for ease of

transport and handling.

• Total weight: 40 lbs.

plus pump

• Use with electronic or

motor driven pumps

• 8" manway standard

Request Bulletin FDP/CFS

P.O. Box 247 • Lansdale, PA 19446-0247

Tel: 215-699-8700 • Fax: 215-699-0370

Toll-Free Tel: 1- 888-3NEPTUNE (1- 888-363-7886)

Toll-Free Fax: 1-800-255-4017

Web Site: http:// www.neptune1.com

E-mail: pump@neptune1.com

1

⁄2" wide, 36" long, 29" high size

MODEL DESCRIPTION

30 Gallon System includes polypropylene suction piping

MT-30

with isolation valve and “Y” strainer (pump not included)

MT-30T 30 Gallon Molded Tank and Base Only

OPTIONS AND ACCESSORIES

MT-CC Calibration Column

MT-CT Containment Basin

MTA 1/ 20 HP Mixer

Specifications and dimensions for the products in this bulletin are subject to change without notice.

Nimble Skids offer a complete chemical

feed system ready for use with bulk

or semi bulk tanks.

Standardized

design with a

menu of options

allows design

flexibility and

rapid delivery

at an affordable cost.

MODEL

MT-30

SOLD BY:

© 2008 Neptune Chemical Pump Company All Rights Reserved Bulletin PZ-08 P/N ZL107971 Printed in U.S.A.

Controls and

Automation

are available.

Request

Bulletin FDP/CFS

Loading...

Loading...