Page 1

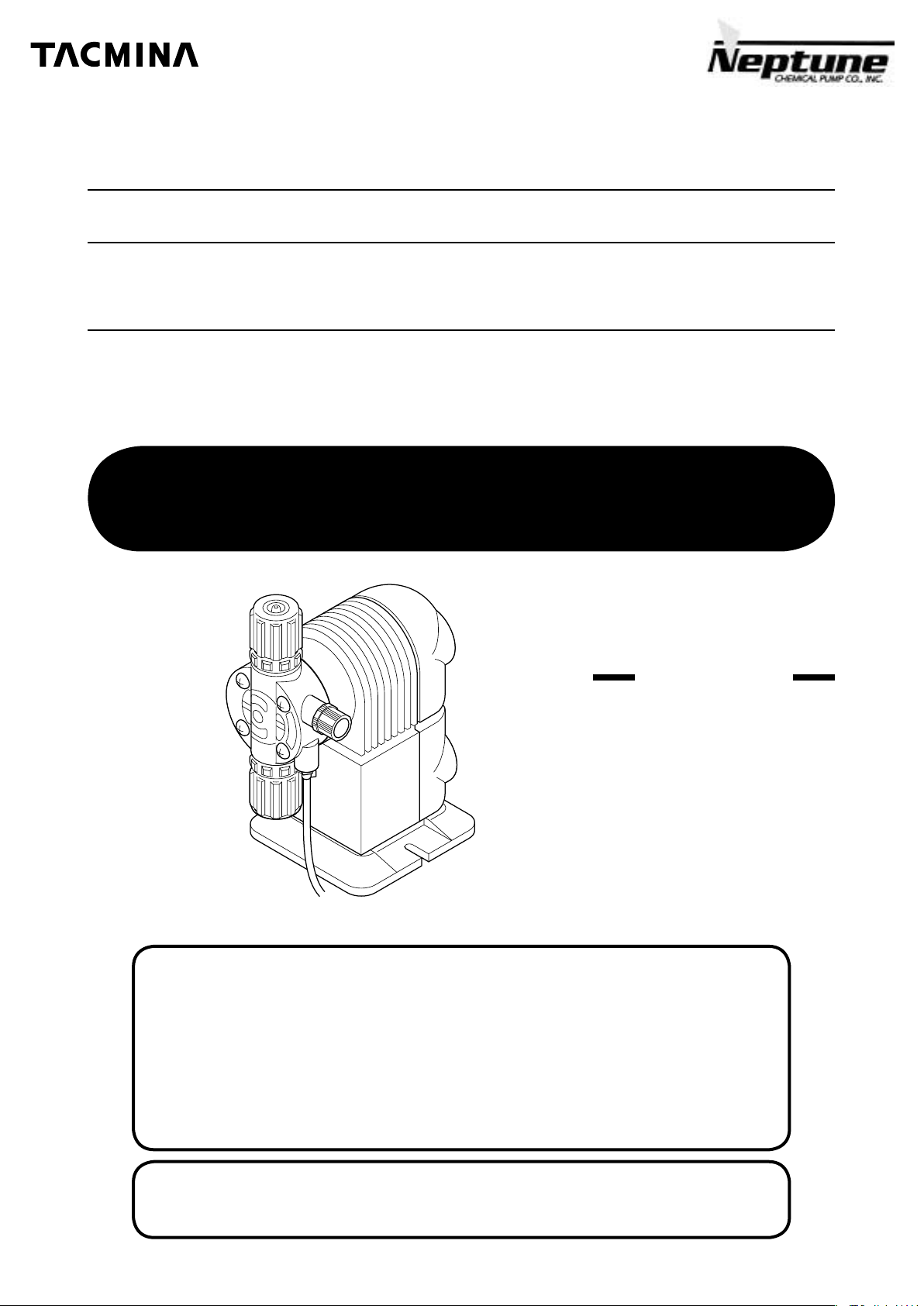

Solenoid-driven Diaphragm Metering Pump

PZ Series

OPERATION MANUAL

Please read this OPERATION MANUAL carefully before use.

Operating the pump incorrectly in disregard of these instructions

may lead to death, injury and/or cause property damage.

Applicable Models

PZ-31/61/12

ARPZ-31/61/12

This illustration is for PZ-31

7 Thank you for purchasing this TACMINA product. Please read this

OPERATION MANUAL carefully in order to ensure that you will use the

product safely and correctly.

7 Be sure to keep this OPERATION MANUAL in a place where it will be

easily available for reference.

7 If the product you purchased conforms to special specifications not

described in this OPERATION MANUAL, handle the product according to

details of separate meetings, drawings and approved documents.

7

TACMINA accepts no liability whatsoever for any damage caused by

malfunction of this product and other damage caused by use of this product.

www.tacmina.com

Page 2

How to operate the pump safely

In order to ensure that the pump will be operated correctly and safely, this OPERATION MANUAL contains some

guidelines for the user in the form of important safety precautions and considerations which, depending on their

seriousness, are categorized as set forth below. Be absolutely sure to heed these precautions and considerations.

WARNING

!

• This is used to indicate a condition or action which may result in death or serious injury if the instructions given

are ignored and the operations are performed incorrectly.

CAUTION

!

• This is used to indicate a condition or action which may result in injury and/or damage to personal property if

the instructions given are ignored and the operations are performed incorrectly.

IMPORTANT

• This is used to indicate a condition or action which must be established or carried out in order to maintain the

performance and service life of the equipment.

NOTE

• This is used to indicate supplementary information.

Conditions of Use

WARNING

!

• This pump cannot be used in explosion-proof regions or in explosive or combustible atmospheres.

CAUTION

!

• This pump must be used for the purpose of transferring or injecting liquids only. Using it for any other purpose may

result in accidents and/or malfunctions.

• This pump cannot be used to transfer or inject any liquids containing slurry.

• This pump’s discharge volume cannot be adjusted by operating the valve on its discharge pipe.

• The characteristics of this pump are such that pulsation will arise. If pulsation threatens to be a problem, install an

air chamber or some other device for reducing the effects of pulsation.

• Do not use the pump outside the following usage ranges. Doing so may cause malfunctions.

Ambient temperature

Ambient humidity

Temperature of liquid

Viscosity of liquid

Altitude of installation location

Transport and store the pump at temperatures within the −10°C to +50°C range. Do not subject the pump to strong impacts.

*

✽

Install the tank at a position higher than the pump (so that the pipe is connected to force the chemicals downward).

✽ The volume and viscosity of the liquids that can be pumped differ according to the conditions under which the pipes are

connected and the properties of the chemicals to be pumped.

0 to 40 °C*

35 to 85%RH

0 to 40 °C (no freezing)

Less than 50 mPa • s

Less than 1,000 m

Installation, Piping & Connections

WARNING

!

•

This pump does not have explosion-proof specifications. Do not install it in explosion-proof regions or in explosive or combustible atmospheres.

• Install the pump in a location that cannot be accessed by anyone but control personnel.

!

• If this pump has been dropped or damaged, consult your vender or a TACMINA representative. Using a dropped or

damaged pump may result in accidents and/or malfunctions.

• Do not install the pump where there is a risk of flooding or where there are high levels of moisture or dust. Doing so

may cause electric shocks and/or malfunctions.

•

This pump has a water-proof construction (equivalent to IP65 under IEC standards). However, it is made of plastic so make every attempt to

avoid installing it in a position that will shorten its service life (such as a position where it will be exposed to direct sunlight, wind or rain).

• Connect the pipes to the pump properly.

• Do not connect the pipes above a passageway. Do not install the pipes where the chemical may splash onto people

even if the hose/tube should break.

• When using a pump with a relief-valve function, always attach a hose for relief purposes, and lead the end of the

pipe back to a tank or other container.

CAUTION

1

Page 3

• When using a pump without a relief-valve function, be absolutely sure to install a relief valve on the pipe right

outside the pump on the discharge side. If the user has forgotten to open the valve or foreign matter is clogged

inside the pump’s discharge-side pipe, this may cause the pressure to rise above the pump’s specifications range,

liquid to gush out, the pipes to become damaged and/or the pump to malfunction, all of which are dangerous.

• When using the pump in cold regions, the chemical may freeze inside the pump head or pipes, possibly damaging

the pump and its surroundings. Be absolutely sure to install a heating unit or heat-insulating unit.

• The water used for the shipment tests may be left on the liquid-end parts (the parts that come into contact with the

liquid) of the pump. If the pump is to be used for chemical that may harden or give off gas if it reacts with water, be

absolutely sure to dry off the liquid-end parts prior to use.

• When the hoses/tubes become very hot, their ability to withstand pressure will deteriorate. When using hoses/tubes

available on the market, be absolutely sure to use the ones which are resistant to chemical and which can withstand

the temperatures and pressures under which the pump will be used.

•

The durability of a hose/tube differs significantly depending on the chemicals with which it is used, on the temperatures

and pressures and on the presence of ultraviolet rays. Inspect the hoses/tubes, and replace them if they have deteriorated.

Electrical Wiring

!

• This pump cannot be used in explosion-proof regions or in explosive or combustible atmospheres.

• Take steps to ensure that the power will not be turned on during the course of work. Hang a sign on the power

switch indicating that work is in progress.

• Do not operate the pump with wet hands. Doing so may result in electric shocks.

• Securely ground the protective earth terminal, and be absolutely sure to install a ground fault circuit interrupter.

Otherwise, you may receive electric shocks.

• Do not attempt to disassemble the pump body or the circuit parts.

!

• The wiring must be done by a qualified electrician or somebody with electrical knowledge.

•

Connect the wires after checking the supply voltage. Do not connect the wires to a power supply that is not within the rated voltage range.

WARNING

CAUTION

Operation & Maintenance

!

• Ensure that nobody other than the operators and control personnel will operate the pump.

• Take steps to ensure that the power will not be turned on during the course of work. Hang a sign on the power

switch indicating that work is in progress.

• Do not operate the pump with wet hands. Doing so may result in electric shocks.

•

When trouble has occurred (such as when smoke appears or there is a smell of burning), shut down the pump’s operation

immediately, and contact your vender or a TACMINA representative. Otherwise, a fire, electric shocks and/or malfunctions may result.

• Do not attempt to disassemble the pump body or the circuit parts.

• During the air releasing, chemical may suddenly gush out from the pipes and other parts. Lead the end of the airrelease hose bank to the tank or other container, and secure it so that it will not become disconnected.

•

A situation in which the valve inside the pipe at the discharge side of the pump is shut off or becomes blocked with foreign matter

is dangerous in that it may lead to an excessive rise in pressure that will exceed the pump’s specification range, causing liquid to

gush out, the pipe to be damaged and the pump itself to malfunction. Prior to operating the pump, check the valves and pipes, etc.

WARNING

CAUTION

!

• When working on the liquid-end parts of the pump, wear protective gear suited to the chemical concerned (such as

rubber gloves, a mask, protective goggles and work overalls that are resistant to chemical).

• Before attempting to maintain or repair the pump, release the pressure in the discharge pipe, discharge the liquid in

the pump head, and clean the liquid-end parts.

• The vibration of the pump may cause the hoses/tubes to become loose and disconnected. Before starting

operation, secure the hoses/tubes and check their tightness.

• While the pump is operating, the pump’s surfaces may become hot, reaching a temperature of 60°C or more.

• Idling the pump for prolonged periods of time can lead to malfunctions.

Other Precautions

CAUTION

!

• Do not attempt to remodel the pump.

• Install a protective barrier or other preventive action to cope with a chemical spill just in case one occurs. Also take

steps to ensure that the pump will not get wet from the chemical.

• When it comes time to dispose of the pump, entrust its disposal to an industrial waste disposal company whose

operations have been authorized in accordance with applicable laws and regulations.

2

Page 4

Page 5

Introduction

Contents

Checking out the product

Accessories list

Description of product

Names of the parts

............................................................................................................................

.......................................................................................................................

............................................................................................................

.................................................................................................................

Installation

Installing the product

Piping

Connecting

Electrical wiring

............................................................................................................................................

✽

The instructions differ according to the model. Find the model concerned in the table on page 9, and read the instructions given.

✽ The instructions differ according to the model. Find the model concerned in the table on page 14, and read the instructions given.

..................................................................................................................................

...................................................................................................................

..........................................................................................................................

Operation

Operating precautions

Air releasing

Discharge-volume setting

Procedure for prolonged shutdown of operation

................................................................................................................................

...............................................................................................................

..........................................................................................................

Maintenance

....................................................................

5

5

7

7

8

9

InstallationOperationMaintenance

14

23

25

26

28

28

Maintenance precautions

Replacing the diaphragm

Replacing the valve seats and check balls

Replacing the relief valve

..........................................................................................................

..........................................................................................................

..........................................................................................................

Troubleshooting

Troubleshooting

.........................................................................................................................

Specifications

Model code

Liquid-end material

Specification

Performance curve

External dimension

..................................................................................................................................

....................................................................................................................

...............................................................................................................................

.....................................................................................................................

....................................................................................................................

Others

Consumables

Spare parts & options

Explanation of terms

After-sales services

..............................................................................................................................

................................................................................................................

..................................................................................................................

...................................................................................................................

..............................................................................

29

30

31

35

37

39

42

43

47

49

51

53

53

54

Troubleshooting

Specifications

Others Introduction

4

Page 6

Checking out the product

After unpacking the pump, check the following.

• Is the pump the one that was ordered?

• Do the details on the pump’s nameplate match what was ordered?

• Is all the accessories supplied?

✽ Check the supplied accessories against the “Accessories list” below.

• Has the pump sustained any damage from vibration or impact during transit?

• Have any of the screws come loose or fallen out?

Introduction

Every care is taken by TACMINA in the shipment of its pumps, but if you

come across anything untoward, please contact your vender or a TACMINA

representative.

Accessories list

Model for injection of general chemicals: PZ-31/61/12-VEC/VFC/FEC/FFC/FTC

Liquid-end Material VEC/VFC

Model 31 61 12

Hose/tube

Relief/air-release hose (1m, installed) Soft PVC hose (4×6)

INSULOK (spare) for relief/air-release hose 1 piece

Anti-siphon check valve 1 set (R1/2)

Foot valve 1 set

Pump-mounting nuts/bolts 2 sets (M5×30)

Operation manual 1 copy

Discharge side (3m) PE tube (1/4"×3/8")

Suction side (2m) PVC braided hose (1/4"×3/8")

Liquid-end Material FEC/FFC

Model 31 61 12

Tube (5m) PE tube (1/4"×3/8")

Relief/air-release hose (1m, installed) Soft PVC hose (4×6)

INSULOK (spare) for relief/air-release hose 1 piece

Anti-siphon check valve 1 set (R1/2)

Foot valve 1 set

Ceramic weight 1 set

Pump-mounting nuts/bolts 2 sets (M5×30)

Operation manual 1 copy

Liquid-end Material FTC

Model 31 61 12

Tube (5m) FEP tube (1/4"×3/8")

Relief/air-release hose (1m, installed) Soft PVC hose (4×6)

INSULOK (spare) for relief/air-release hose 1 piece

Anti-siphon check valve 1 set (R1/2 or R3/8)

Foot valve 1 set

Ceramic weight 1 set

Pump-mounting nuts/bolts 2 sets (M5×30)

Operation manual 1 copy

5

Page 7

Accessories list

Model for injection of boiler chemicals: PZ-31-FEC (PP)

Liquid-end Material FEC (PP)

Model 31

Tube

Relief/air-release hose (1m, installed) Soft PVC hose (4×6)

INSULOK (spare) for Relief/air-release hose 1 piece

Anti-siphon check valve 1 set (R1/2)

Foot valve 1 set

Ceramic weight 1 set

Pump-mounting nuts/bolts 2 sets (M5×30)

Operation manual 1 copy

Model for injection of sodium hypochlorite: PZ-31/61/12-CL

Hose/tube

Air-release hose (1m) Soft PVC hose (4×6)

Anti-siphon check valve w/ duck-bill cap 1 set (R1/2)

Foot valve 1 set

Pump-mounting nuts/bolts 2 sets (M5×30)

Operation manual 1 copy

Discharge side (3m) PP tube (1/8"×1/4")

Suction side (2m) PE tube (1/4"×3/8")

Liquid-end Material CL

Model 31 61 12

Discharge side (3m) PE tube (1/4"×3/8")

Suction side (2m) PVC braided hose (1/4"×3/8")

Introduction

Model w/ automatic air-release function for injection of sodium hypochlorite: ARPZ-31/61/12

Liquid-end Material CL

Model 31 61 12

Hose/tube

Air-release hose (1m) Soft PVC hose (4×6)

Anti-siphon check valve w/ duck-bill cap 1 set (R1/2)

Foot valve 1 set

Pump-mounting nuts/bolts 2 sets (M5×30)

Operation manual 1 copy

Discharge side (3m) PE tube (1/4"×3/8")

Suction side (2m) PVC braided hose (1/4"×3/8")

6

Page 8

Description of product

This is a solenoid-driven diaphragm metering pump with liquid-end parts which are resistant to chemicals and with a

compact body. It can be operated on any supply voltage from AC 100V to AC 240V (±10%). Its discharge capacity has

been adjusted so that it will remain constant over the supply voltage range.

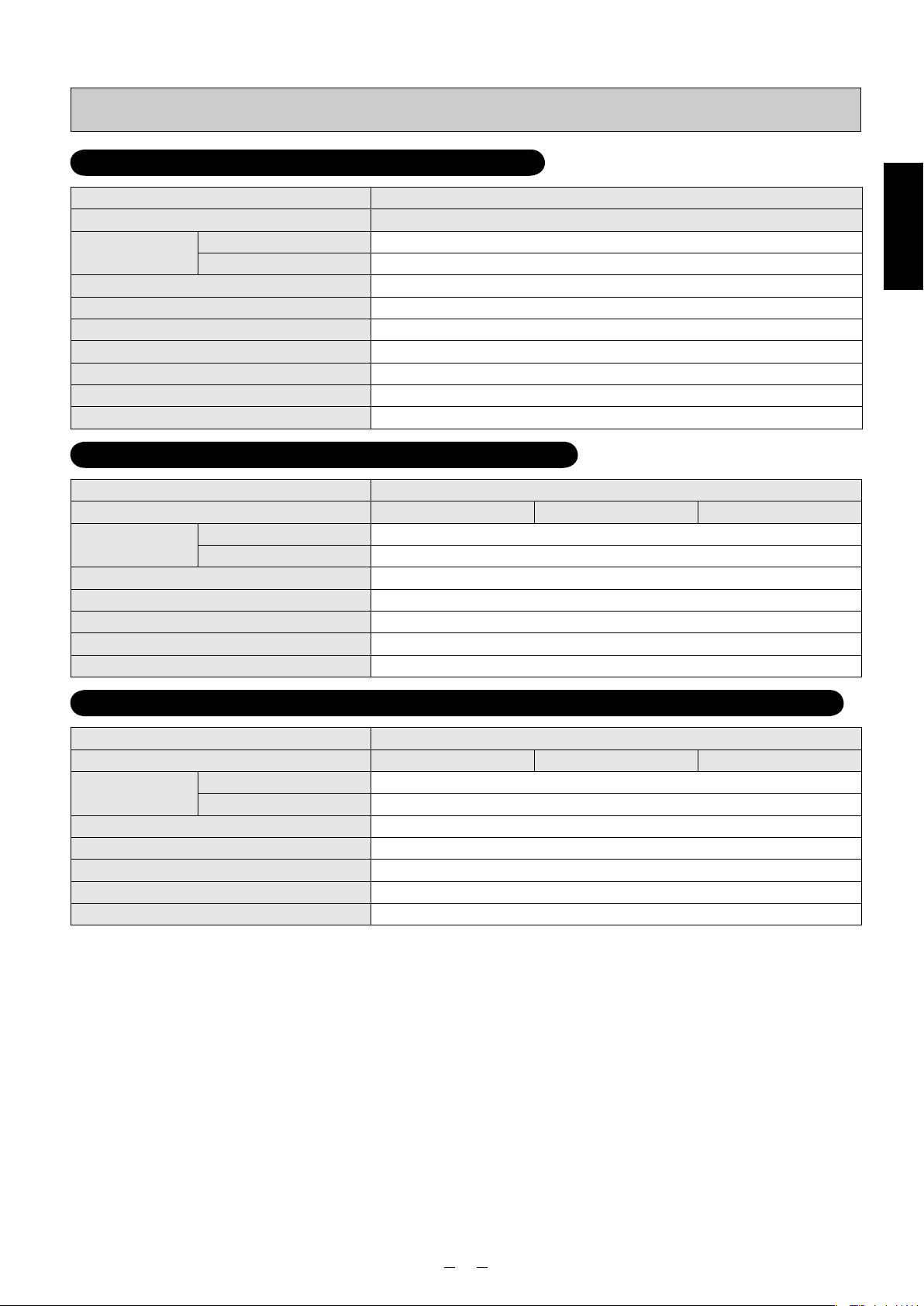

Names of the parts

Introduction

Model for injection of general chemicals: PZ-31/61/12-VEC/VFC/FEC/FFC/FTC

Model for injection of boiler chemicals: PZ-31-FEC (PP)

Pump head

Discharge-side joint

Relief valve

Suction-side joint

Relief/air-release port

✽ The shapes of pump heads and joints differ slightly depending on the liquid-end material and connection type.

Model for injection of sodium hypochlorite:

PZ-31/61/12-CL

Discharge-side joint

Air-release knob

Suction-side joint

Air-release port

Cable ground

Model w/ automatic air-release funtion

injection of sodium hypochlorite: ARPZ-31/61/12

Air-release joint

Discharge-side joint

Suction-side joint

for

7

Page 9

Installing the product

WARNING

!

• This pump does not have explosion-proof specifications. Do not install it in explosion-proof regions or

in explosive or combustible atmospheres.

• Install the pump in a location that cannot be accessed by anyone but control personnel.

!

• Do not install the pump where there is a risk of flooding or where there are high levels of moisture or

dust. Doing so may cause electric shocks and/or malfunctions.

• This pump has a water-proof construction (equivalent to IP65 under IEC standards). However, it is made

of plastic so make every attempt to avoid installing it in a position that will shorten its service life (such

as a position where it will be exposed to direct sunlight, wind or rain).

CAUTION

Installation location

• Avoid installing the pump in a location exposed to direct sunlight or wind and rain. Although it features a water-proof

construction (equivalent to IP65 under the IEC standards), direct sunlight may cause the temperature of the metal

parts to rise, ultraviolet rays may cause the plastic parts to deteriorate, and sand, dust, and rainwater may damage or

corrode the pump body. When installing the pump outdoors, it is recommended that an awning or cover be installed to

protect the pump from the elements and extend its service life.

• Install the pump in a location where the ventilation is good and where the chemical will not freeze.

• Provide adequate space around the pump to facilitate maintenance and inspections.

• Place the pump in a level location, and secure it so that it will not vibrate. Installing the pump at an angle may result in

discharge trouble or in the inability of pump to discharge.

Installation

Mounting bolt positions

Use the pump-mounting bolts (×2) provided to secure the pump.

✽ The pump can be installed at any pitch ranging from 87 to 110 mm.

8

Page 10

Piping

!

• Connect the pipes to the pump properly.

• Do not connect the pipes above a passageway. Do not install the pipes where the chemical may splash

onto people even if the hose/tube should break.

• When using a pump with a relief-valve function, always attach a hose for relief purposes, and lead the

end of the pipe back to a tank or other container.

• When using a pump without a relief-valve function, be absolutely sure to install a relief valve on the

pipe right outside the pump on the discharge side. If the user has forgotten to open the valve or foreign

matter is clogged inside the pump’s discharge-side pipe, this may cause the pressure to rise above

the pump’s specifications range, liquid to gush out, the pipes to become damaged and/or the pump to

malfunction, all of which are dangerous.

•

When using the pump in cold regions, the chemical may freeze inside the pump head or pipes, possibly

damaging the pump and its surroundings. Be absolutely sure to install a heating unit or heat-insulating unit.

•

Installation

When the hoses/tubes become very hot, their ability to withstand pressure will deteriorate. When using

hoses/tubes available on the market, be absolutely sure to use the ones which are resistant to chemical

and which can withstand the temperatures and pressures under which the pump will be used.

•

The durability of a hose/tube differs significantly depending on the chemicals with which it is used, on the temperatures

and pressures and on the presence of ultraviolet rays. Inspect the hoses/tubes, and replace them if they have deteriorated.

IMPORTANT

• Install a pressure gauge on the discharge-side pipe in order to measure the pressure at the discharge

side of the pump.

• Install the pump as close as possible to the tank. If the suction-side pipe is too long, cavitation* may

occur, possibly making it impossible to maintain the pump’s metering capability.

* Refer to the “Explanation of terms” on page 53.

CAUTION

■Pulsation

• The occurrence of pulsation will cause the pump’s hoses/tubes to vibrate. Secure the hoses/tubes so that they will not

swing about.

• In order to reduce pulsation, the installation of a damper is recommended. Ask a TACMINA representative for more

information.

■Pipe length

• An excessively long hose/tube may result in increased pressure loss, may cause the pressure to exceed the pump’s

allowable pressure, or may give rise to overfeed and/or cause pipe vibration.

• The pump comes with a 5-meter-long hose/tube for both the discharge side and suction side. If the pressure loss

exceeds the pump’s maximum discharge pressure, thicker pipes will be required. Provide details on the (1) viscosity

of the liquid, (2) length of the pipes (how they are positioned) and (3) specific gravity of the liquid to a TACMINA

representative.

■During maintenance

• When disconnecting the hose/tube for maintenance or other purposes and then reconnecting the same hose/tube, cut

about 10 mm off the end of the hose/tube before reconnecting.

• When conducting maintenance, release the pressure of the discharge hose/tube.

■When curving a hose/tube

• Provide a sufficient margin so that the hose/tube will not bend instead of curve round.

• Take steps to ensure that the hose/tube will not bend, rub against other parts, be cut or stepped on. Such actions can

damage the hose/tube.

• Take steps to minimize the number of tight curves in the pipes, joints and other parts that may restrict the flow.

The piping procedure will be described by pump type.

Model Series Page

Model for injection of general chemicals PZ-31/61/12-VEC/VFC/FEC/FFC/FTC 10

Model for injection of boiler chemicals PZ-31-FEC (PP) 11

Model for injection of sodium hypochlorite PZ-31/61/12-CL 12

Model w/ automatic air-release function for injection of

sodium hypochlorite

ARPZ-31/61/12 13

9

Page 11

Piping

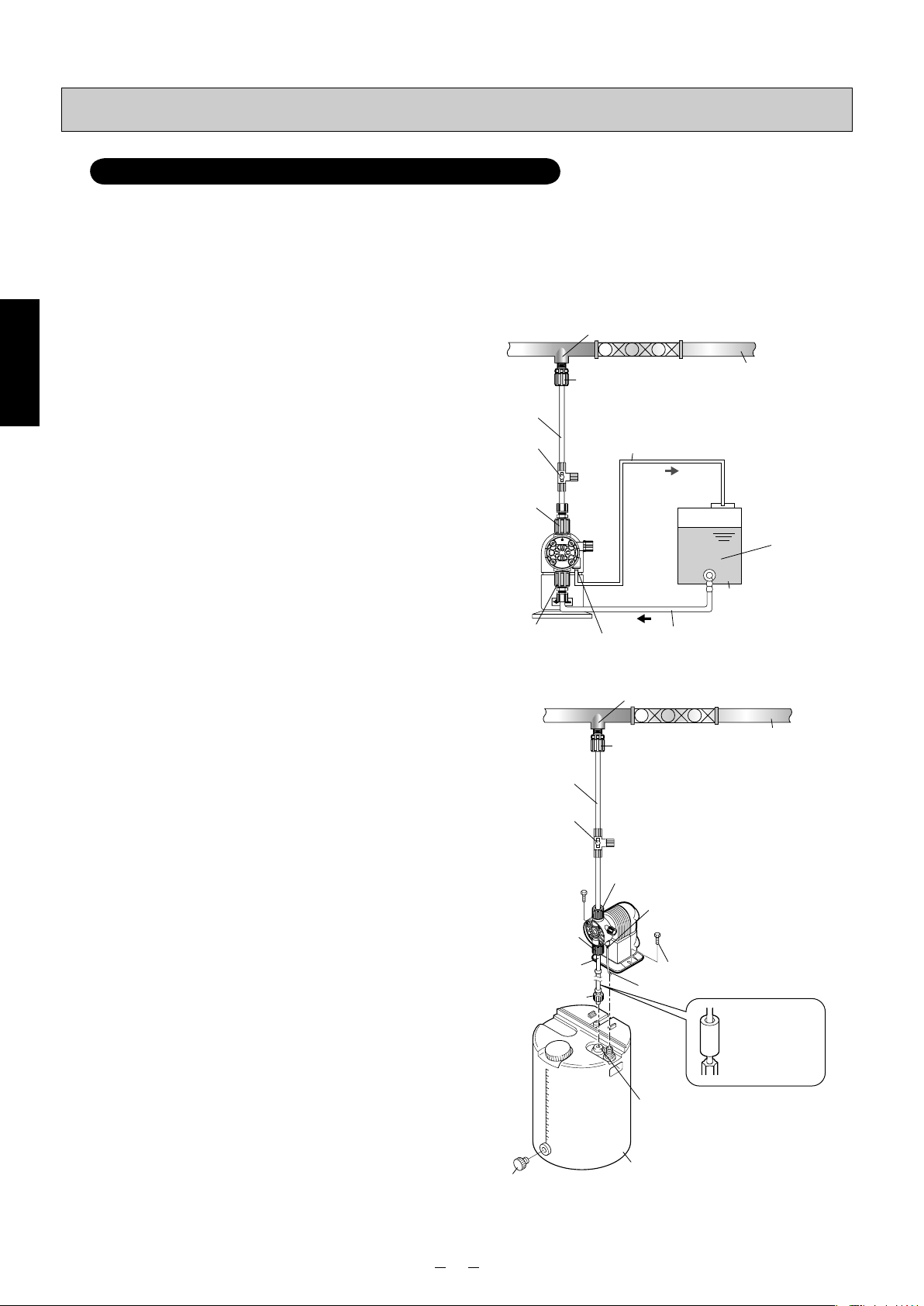

Model for injection of general chemicals: PZ-31/61/12-VEC/VFC/FEC/FFC/FTC

Installation is described with an example using PZ-31-VEC and TACMINA tank.

• If the valve has not been opened or clogging by foreign matter has occurred inside the pipe at the discharge side of

the pump, the chemical will gush out from the relief/air-release port. Therefore, always have a relief/air-release hose

installed, and lead its end back into the tank or other container.

• Install a valve for releasing abnormal pressure that has built up inside the discharge-side pipe. The 3-way valve on the

washing water line may be used instead.

■ When installing the pump

below the tank

(1)

Connect the suction valve of the tank and the suctionside joint of the pump using the hose/tube.

(2) Connect the discharge-side joint of the pump and

main pipe (injection point) using the tube. When

doing this, attach the anti-siphon check valve at the

injection-point side end of the tube.

(3) Return the end of the relief/air-release hose which

has already been attached to the relief/air-release

port to the tank or other container.

✽ It is also recommended that a valve, meter, etc. be

installed to make it easy to carry out maintenance

and other such jobs.

■ When installing the pump

above the tank

(1) Using the pump-mounting bolts provided, secure the

pump to the prescribed position on top of the tank.

(2) Pass the suction-side hose/tube with foot valve and

ceramic weight (tube only) attached through the

hole in the suction-pipe cover on top of the tank, and

connect it to the suction-side joint of the pump. At

this time, adjust the length of the hose/tube and cut

it so that the foot valve is 30 mm higher than the bottom of the tank.

(3) Connect the discharge-side joint of the pump and

main pipe (injection point) using the tube. When

doing this, attach the anti-siphon check valve at the

injection-point side end of the tube.

(4) Return the end of the relief/air-release hose which

has already been attached to the relief/air-release

port to the tank or other container.

✽ Installing the pump above the tank is not recommend-

ed for chemicals in which air bubbles tend to form.

✽ This pump’s static suction head is −1.5 m for water.

Its suction capability may decrease when the valve

seats inside the pump head are dry.

✽ Be absolutely sure to connect the foot valve provided

to the end of the suction-side hose/tube to prevent

dirt or foreign matter from entering the pump head

and valve seat area.

✽ It is also recommended that a valve, meter, etc. be

installed to make it easy to carry out maintenance

and other such jobs.

Dischargeside pipe

3-way valve

Dischargeside joint

Suction-side joint

Dischargeside pipe

3-way valve

Suction-side joint

Suction-side pipe

Foot valve

Drain cock

Injection point

Anti-siphon check valve

Relief/air-release hose

UP

PVC

Relief/air-release port

Injection point

Anti-siphon check valve

Discharge-side joint

Relief/air-release port

Pump-mounting bolts (2 sets)

Relief/air-release hose

Tank

Tank

Suction-side pipe

When a PE or FEP tube is

to be used for the suction

side pipe (FEC/FFC/FTC

only), attach the ceramic

weight (supplied) to

straighten the tube.

Suction-pipe cover

Main pipe

Installation

Suction valve

Main pipe

10

Page 12

Piping

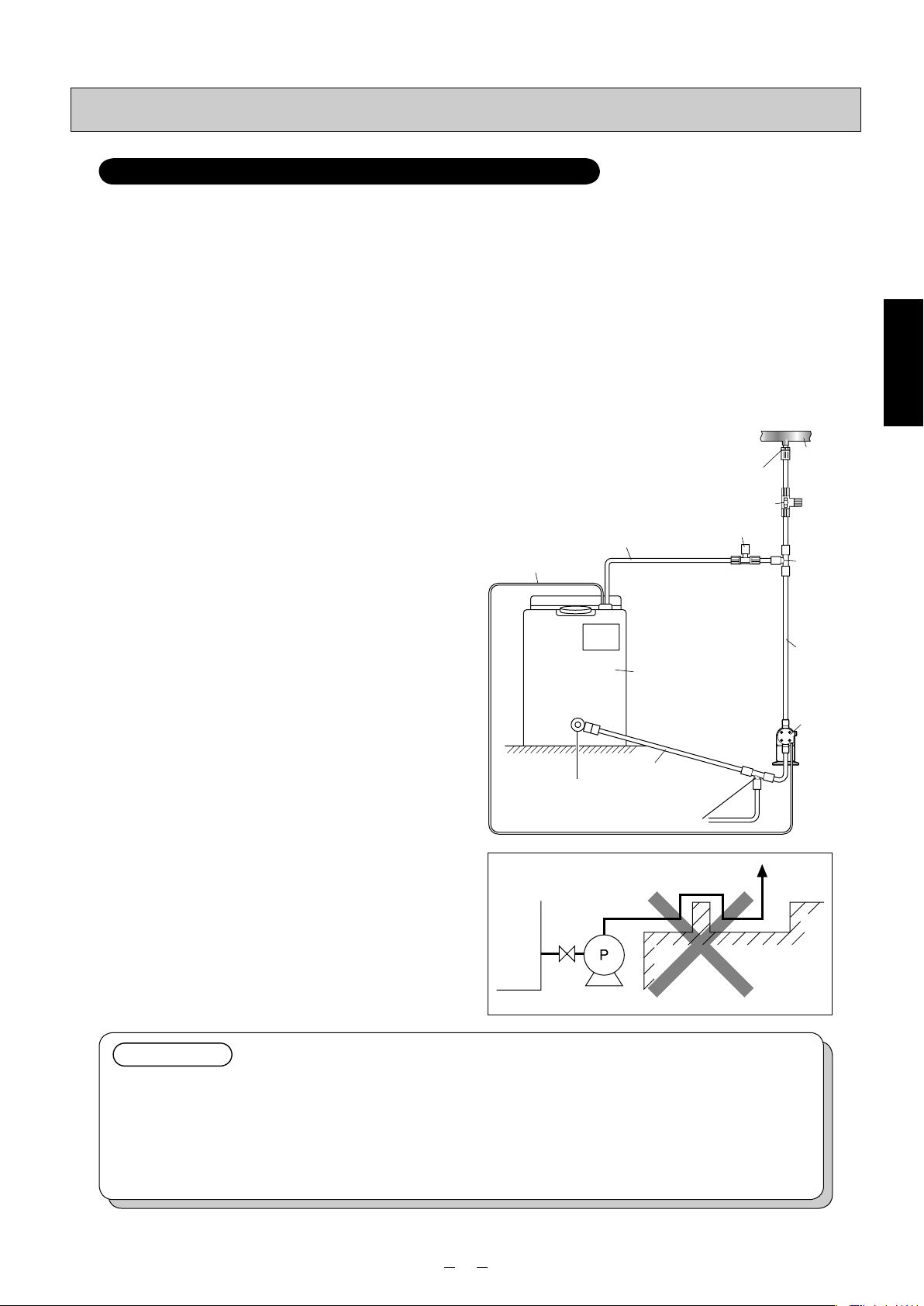

Model for injection of boiler chemicals: PZ-31-FEC (PP)

Installation is described with an example using PZ-31-FEC (PP) and TACMINA tank.

• If the valve has not been opened or clogging by foreign matter has occurred inside the pipe at the discharge side of

the pump, the chemical will gush out from the relief/air-release port. Therefore, always have a relief/air-release hose

installed, and lead its end back into the tank or other container.

• Install a valve for releasing abnormal pressure that has built up inside the discharge-side pipe. The 3-way valve on the

washing water line may be used instead.

■ When installing the pump

below the tank

(1)

Connect the suction valve of the tank and the suctionside joint of the pump using the tube.

Installation

(2) Connect the discharge-side joint of the pump and

main pipe (injection point) using the tube. When

doing this, attach the anti-siphon check valve at the

injection-point side end of the tube.

(3) Return the end of the relief/air-release hose which

has already been attached to the relief/air-release

port to the tank or other container.

✽ It is also recommended that a valve, meter, etc. be

installed to make it easy to carry out maintenance

and other such jobs.

■ When installing the pump

above the tank

(1) Using the pump-mounting bolts provided, secure the

pump to the prescribed position on top of the tank.

(2) Pass the suction-side tube with foot valve and

ceramic weight attached through the hole in the

suction-pipe cover on top of the tank, and connect

it to the suction-side joint of the pump. At this time,

adjust the length of the tube and cut it so that the

foot valve is 30 mm higher than the bottom of the

tank.

(3) Connect the discharge-side joint of the pump and

main pipe (injection point) using the tube. When

doing this, attach the anti-siphon check valve at the

injection-point side end of the tube.

(4) Return the end of the relief/air-release hose which

has already been attached to the relief/air-release

port to the tank or other container.

✽ Installing the pump above the tank is not recommend-

ed for chemicals in which air bubbles tend to form.

✽ This pump’s static suction head is −1.5 m for water.

Its suction capability may decrease when the valve

seats inside the pump head are dry.

✽ Be absolutely sure to connect the foot valve provided

to the end of the suction-side hose to prevent dirt

or foreign matter from entering the pump head and

valve seat area.

✽ It is also recommended that a valve, meter, etc. be

installed to make it easy to carry out maintenance

and other such jobs.

Injection point

Anti-siphon check valve

Dischargeside pipe

3-way valve

Dischargeside joint

UP

PVDF

Suction-side joint Suction-side pipe

Suction-side joint

Suction-side pipe

Drain cock

Relief/air-release port

Dischargeside pipe

3-way valve

Foot valve

Relief/air-release hose

Tank

Injection point

Anti-siphon check valve

Discharge-side joint

Relief/air-release port

Pump-mounting bolts (2 sets)

Relief/air-release hose

Suction-pipe cover

Tank

Main pipe

Suction valve

Main pipe

Attach the ceramic

weight (supplied) to

straighten the tube.

11

Page 13

Piping

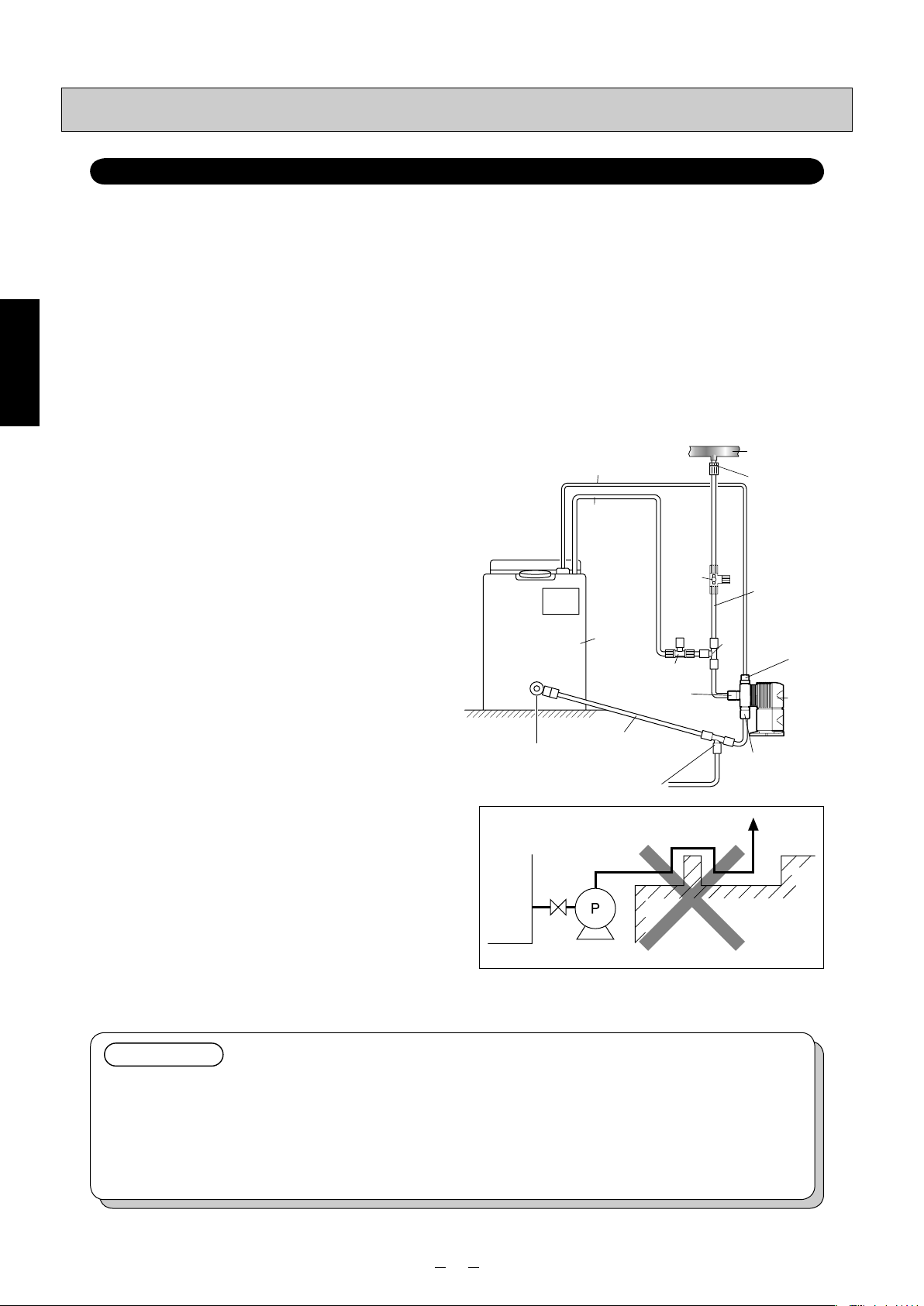

Model for injection of sodium hypochlorite: PZ-31/61/12-CL

Installation is described with an example using PZ-31-CL and TACMINA tank.

• It is extremely dangerous for the user to forget to open the valve or for there to be the clogging of foreign matter inside

the pump’s discharge-side pipe. Be absolutely sure to install a relief valve, which will automatically release abnormally

high pressure levels, on the discharge-side pipe.

• Install a valve for releasing abnormal pressure that has built up inside the discharge-side pipe. The 3-way valve on the

washing water line may be used instead.

• To prevent gas lock and other such types of trouble, be absolutely sure to use the pump with a push-in pipe (when the

pump is to be placed lower than the tank).

• In order to prevent gas lock caused by gases generated and building up inside the pipes, make the pipe connections

as short as possible.

■ When installing the pump

below the tank

✽ Do not install the pump above the tank.

(1)

Connect the suction valve of the tank and the suctionside joint of the pump using the hose. When doing

this, tilt the pipe at a downward gradient so that no air

will be trapped inside the pipe.

(2) Connect the tube to the discharge-side joint of the

pump.

(3) Attach a 3-way joint to the discharge-side tube (near

the pump’s discharge-side joint), and install a relief

valve. Return the end of the relief pipe to the tank or

other container.

(4) Connect the end of the other discharge-side tube

extending from the 3-way joint to the main pipe

(injection point). When doing this, attach the antisiphon check valve with duck-bill cap at the injection-point side end of the tube.

(5) Attach one end of the air-release hose to the air-

release port, and return the other end to the tank or

other container.

✽ If it is unavoidable for the pump to be placed higher

than the tank, be absolutely sure to connect the foot

valve supplied to the end of the suction-side hose

to ensure that no dirt or foreign matter will be mixed

inside the pump head or valve seat.

✽ It is also recommended that a valve, meter, etc. be

installed to make it easy to carry out maintenance

and other such jobs.

Anti-siphon

check valve

w/ duck-bill cap

3-way valve

Relief valve

Air-release hose

Suction valve

Relief pipe

Ta nk

Suction-side pipe

(downward gradient)

Draining of washing water

<Example of unacceptable installation>

Main pipe

3-way joint

Dischargeside pipe

Metering

pump

Installation

Metering pump

IMPORTANT

<Washing water line>

• It is recommended that a washing water line be provided in the piping.

(A 3-way valve for releasing abnormally high pressure levels may be used instead.)

<Sodium hypochlorite>

•

Take steps to use up the sodium hypochlorite in as short a period as possible (10 to 20 days in hot weather).

• When diluting sodium hypochlorite, use (1) pure water (purified water), (2) water that has been passed

through a water softener or (3) city water that has been purified.

12

Page 14

Piping

Model w/ automatic air-release function for injection of sodium hypochlorite: ARPZ-31/61/12

Installation is described with an example using ARPZ-31 and TACMINA tank.

•

Unlike other models, this pump has a discharge-side joint at the front of the pump head and an air-release side joint on its top.

• It is extremely dangerous for the user to forget to open the valve or for there to be the clogging of foreign matter inside

the pump’s discharge-side pipe. Be absolutely sure to install a relief valve, which will automatically release abnormally

high pressure levels, on the discharge-side pipe.

• Install a valve for releasing abnormal pressure that has built up inside the discharge-side pipe. The 3-way valve on the

washing water line may be used instead.

• To prevent gas lock and other such types of trouble, be absolutely sure to use the pump with a push-in pipe (when the

pump is to be placed lower than the tank).

• In order to prevent gas lock caused by gases generated and building up inside the pipes, make the pipe connections

as short as possible.

Installation

■ When installing the pump

below the tank

✽ Do not install the pump above the tank.

(1)

Connect the suction valve of the tank and the suctionside joint of the pump using the hose. When doing

this, tilt the pipe at a downward gradient so that no air

will be trapped inside the pipe.

(2) Connect the tube to the discharge-side joint of the

pump.

(3) Attach a 3-way joint to the discharge-side tube (near

the pump’s discharge-side joint), and install a relief

valve. Return the end of the relief pipe to the tank or

other container.

(4) Connect the end of the other discharge-side tube

extending from the 3-way joint to the main pipe

(injection point). When doing this, attach the antisiphon check valve with duck-bill cap at the injection-point side end of the hose/tube.

(5) Attach one end of the air-release hose to the air-

release port, and return the other end to the tank or

other container.

✽ If it is unavoidable for the pump to be placed higher

than the tank, be absolutely sure to connect the foot

valve supplied to the end of the suction-side hose

to ensure that no dirt or foreign matter will be mixed

inside the pump head or valve seat.

✽ It is also recommended that a valve, meter, etc. be

installed to make it easy to carry out maintenance

and other such jobs.

Air-release hose

Relief pipe

3-way

valve

Tank

Relief valve

Discharge-side joint

Suction valve

Draining of washing water

Suction-side pipe

(downward gradient)

<Example of unacceptable installation>

Main pipe

Anti-siphon

check valve

w/ duck-bill cap

Dischargeside pipe

3-way

Air-release joint

joint

Suction-side joint

Metering

pump

Metering pump

IMPORTANT

<Washing water line>

• It is recommended that a washing water line be provided in the piping.

(A 3-way valve for releasing abnormally high pressure levels may be used instead.)

<Sodium hypochlorite>

•

Take steps to use up the sodium hypochlorite in as short a period as possible (10 to 20 days in hot weather).

• When diluting sodium hypochlorite, use (1) pure water (purified water), (2) water that has been passed

through a water softener or (3) city water that has been purified.

13

Page 15

Connecting

The connection procedure will be described by pump type.

Model Liquid-end material Hose/tube Page

Discharge side : PE tube

Suction side : PVC braided hose

14

Model for injection of general chemicals

PZ-31/61/12-VEC/VFC

PZ-31/61/12-FEC/FFC PE tube

16

PZ-31/61/12-FTC FEP tube

Model for injection of boiler chemicals PZ-31-FEC (PP)

Model for injection of sodium hypochlorite

Model w/ automatic air-release function

for injection of sodium hypochlorite

PZ-31/61/12-CL

ARPZ-31/61/12

Discharge side : PP tube

Suction side : PE tube

Discharge side : PE tube

Suction side : PVC braided hose

Discharge side : PE tube

Suction side : PVC braided hose

18

20

21

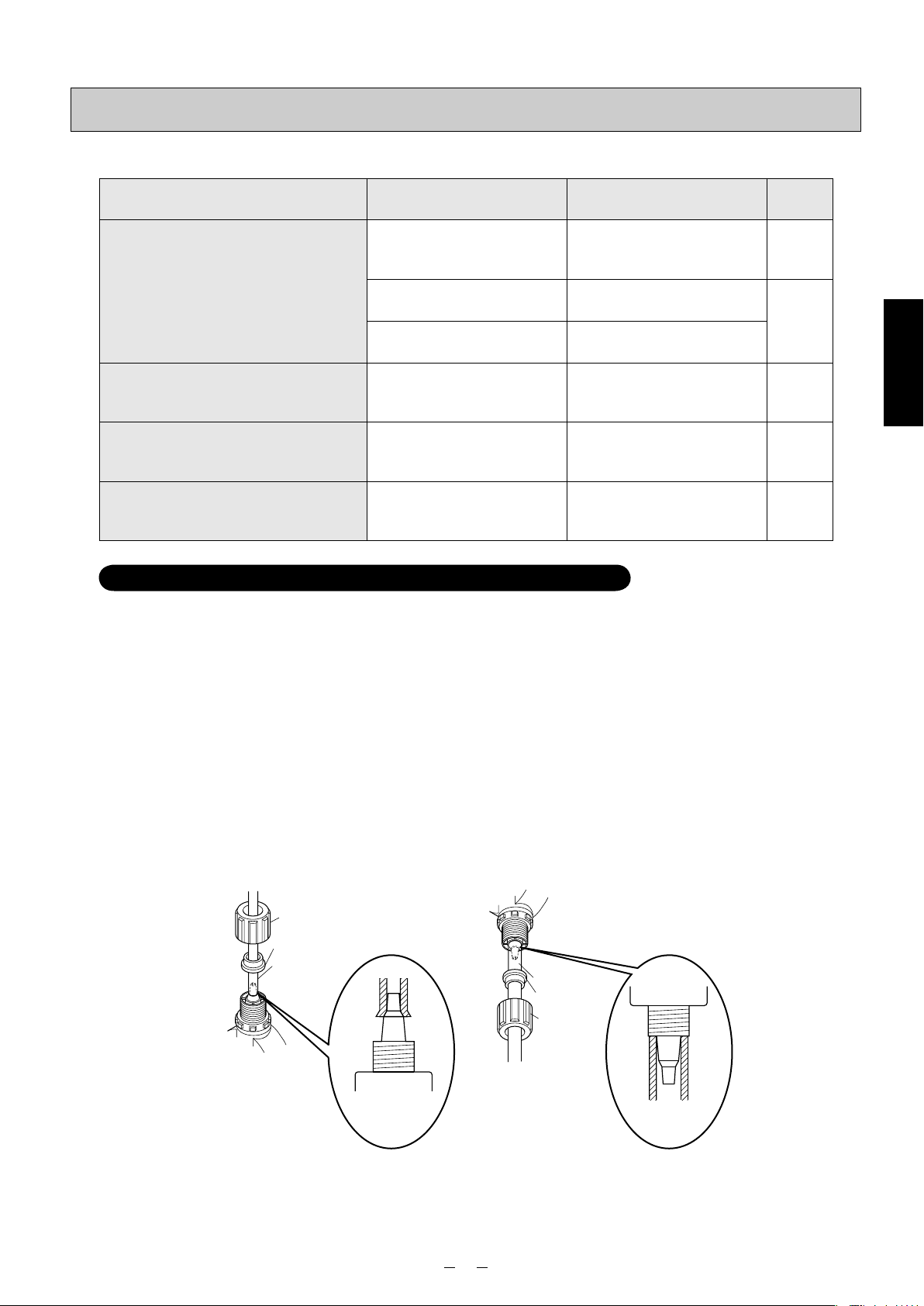

Model for injection of general chemicals: PZ-31/61/12-VEC/VFC

■PVC braided hose/PE tube

• When bending the hose/tube, provide sufficient leeway in the bending so that the hose/tube will not break. Also ensure that it will not be rubbed against or trodden on.

• Insert the hose/tube firmly so that it will not become disconnected, and tighten the nuts securely. Do not excessively

tighten the nuts. Doing so may damage or break the joint.

• If the temperature of a liquid or ambient temperature is higher than room temperature, the tightening force will be reduced, and the hose/tube may become disconnected. After operation has started, tighten up the nuts as appropriate.

• When tightening the nuts, hold the hose/tube to prevent it from being twisted. The joints and other areas may be loosened by the return force of the hose/tube.

• The pump comes with a 5-meter long hose/tube for both the discharge side and suction side. When longer hose/tube

is used, the pressure loss may exceed the pump’s maximum discharge pressure so thicker hose/tube will be required.

Provide details on the (1) viscosity of the liquid, (2) length of the pipes (how they are positioned) and (3) specific gravity of the liquid to a TACMINA representative who will select the appropriate hose/tube size.

• When disconnecting the hose/tube for jobs such as maintenance and then afterwards re-connecting the same hose/

tube, cut about 10 mm off the end of the hose/tube before re-using them.

Installation

Nut

Retaining ring

PE tube

PE tube

(1/4”×3/8”)

14

PVC braided hose

Retaining ring

Nut

PVC braided hose

(1/4”×3/8”)

Page 16

Connecting

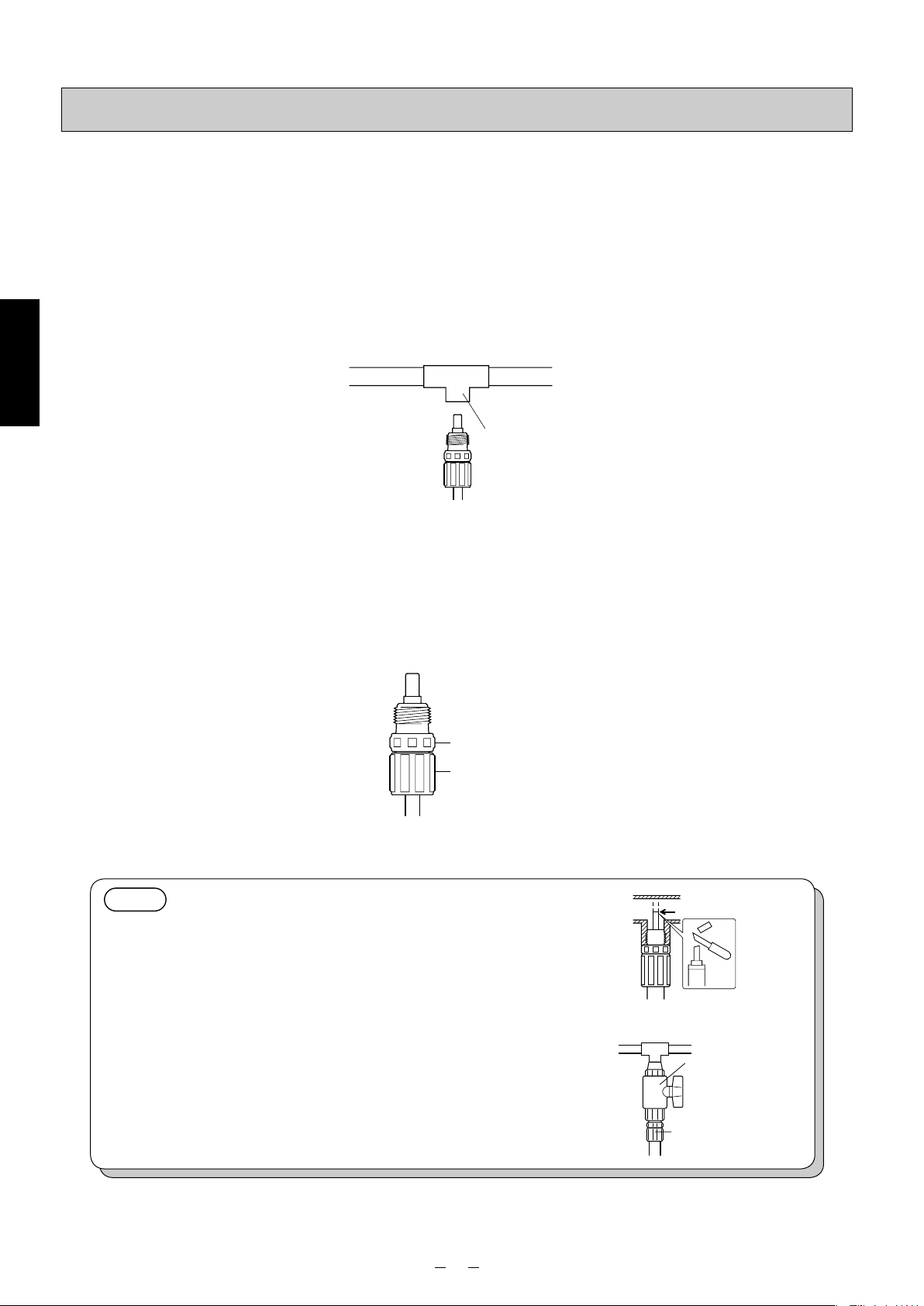

■Anti-siphon check valve

This pump is provided with an anti-siphon check valve. Use this valve at the injection point unless there is a good reason not to do so. Be absolutely sure to install it in the following cases.

• When the injection point is open to the atmosphere and liquid is to be injected at a position lower than the level of the

liquid in the tank (prevention of siphoning)

• When the liquid is to be injected inside the suction-side pipe of a volute pump, etc.

• When a chemical greatly exceeding the pump’s rated discharge volume is being fed (prevention of overfeed)

✽ Even with a rising pipe, overfeed may occur if the pipe is too long.

(1) The anti-siphon check valve has an R1/2 external thread. Provide an Rc1/2 internal thread at the injection point.

Installation

(2)

Wind sealing tape around the external thread of the anti-siphon check valve, and screw the valve into the injection point.

✽ If it is hard to screw the valve in, grasp the nozzle grip using a tool such as pliers, and tighten the valve gently.

✽ When connecting the tube with the anti-siphon check valve already mounted on it to the main pipe, be absolutely

sure to hold the valve body and turn the nut. If the nut is turned without holding the body, the threaded part on the

nozzle may be damaged.

Main pipe

Injection point

(Rc1/2)

Nozzle grip

Nut

NOTE

<When injecting liquid into a pipe with a small diameter>

If the end of the anti-siphon check valve is too long, cut it off

so that the end will be positioned at the center of the main pipe

where the chemical is to be injected prior to use.

<For maintenance>

It is recommended that the tube be attached to the main pipe

through a valve to enable the anti-siphon check valve to be

replaced or cleaned, etc.

✽ Use a valve made of materials which will resist any corrosion

resulting from the chemical used.

Valve

Anti-siphon

check valve

15

Page 17

Connecting

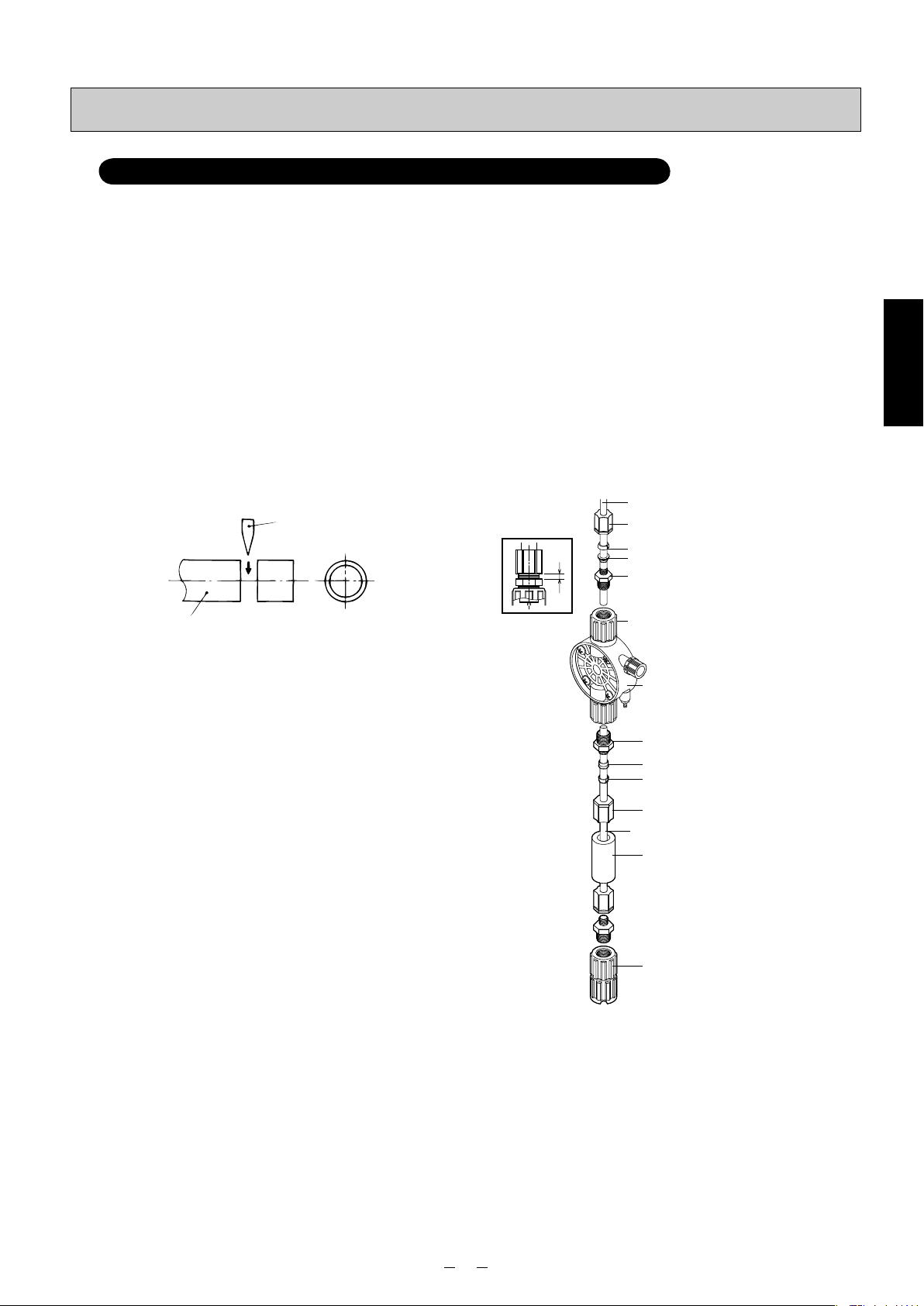

Model for injection of general chemicals: PZ-31/61/12-FEC/FFC/FTC

■PE/FEP tube

• When bending the tube, provide sufficient leeway in the bending so that the tube will not break. Also ensure that it will

not be rubbed against or trodden on.

• Insert the tube firmly so that it will not become disconnected, and tighten the nuts securely. Do not excessively tighten

the nuts. Doing so may damage or break the joint.

• If the temperature of a liquid or ambient temperature is higher than room temperature, the tightening force will be

reduced, and the tube may become disconnected. After operation has started, tighten up the nuts as appropriate.

• When tightening the nuts, hold the tube to prevent it from being twisted. The joints and other areas may be loosened

by the return force of the tube.

• The pump comes with a 5-meter long tube for both the discharge side and suction side. When longer tube is used, the

pressure loss may exceed the pump’s maximum discharge pressure so thicker tube will be required. Provide details

on the (1) viscosity of the liquid, (2) length of the pipes (how they are positioned) and (3) specific gravity of the liquid

to a TACMINA representative who will select the appropriate tube size.

• When disconnecting the tube for jobs such as maintenance and then afterwards re-connecting the same tube, cut

about 10 mm off the end of the tube before re-using it.

(1) Cut the end of the tube at right angles using a sharp

blade.

blade

a

PE/FEP tube (1/4”×3/8”)

Nut (A)

Grip (B)

⎫

Sleeve (C)

Tube-fitting body (D)

⎬

Installation

tube

(2) Wrap sealing tape around the tube-fitting body (D),

and screw the body into the discharge-side joint

using a tool. (The tube-fitting body is already mounted in place before shipment.)

(3)

Pass the tube through the nut (A), grip (B) and

sleeve (C), and insert its end until it touches the

back end of the tube-fitting body (D) on the inside.

(4) Tighten the nut (A) by hand.

(5) Using the tool, tighten the nut (A) in such a way that

the gap (area “a” in the figure) between the tube-

fitting body (D) and nut (A) is approximately 1.5 mm.

✽ Bear in mind that the joint may break if the nut (A)

is tightened too much.

Discharge-side joint

⎭

Pump head

Tube-fitting body

Sleeve

Grip

Nut

PE/FEP tube (1/4”×3/8”)

Ceramic weight (E)*

Foot valve

* The tube is packed in the form of a coil. Attach the

ceramic weight (E) and straighten out the tube so that

the liquid inside the tank will be sucked up through it.

16

Page 18

Connecting

■Anti-siphon check valve

This pump is provided with an anti-siphon check valve. Use this valve at the injection point unless there is a good reason not to do so. Be absolutely sure to install it in the following cases.

• When the injection point is open to the atmosphere and liquid is to be injected at a position lower than the level of the

liquid in the tank (prevention of siphoning)

• When the liquid is to be injected inside the suction-side pipe of a volute pump, etc.

• When a chemical greatly exceeding the pump’s rated discharge volume is being fed (prevention of overfeed)

✽ Even with a rising pipe, overfeed may occur if the pipe is too long.

• Take care when handling an anti-siphon check valve which is made of PVDF since it is fragile in the face of impact.

(1) The anti-siphon check valve for the FEC/FFC type has an R1/2 external thread whereas the FTC type has R1/2 and

R3/8 external threads. Provide an Rc1/2 or Rc3/8 internal thread at the injection point that fits the anti-siphon check

valve.

Installation

FEC/FFC (w/ PE tube)

(2)

Wind sealing tape around the external thread of the anti-siphon check valve, and screw the valve into the injection point.

✽ If it is hard to screw the valve in, grasp the nozzle grip using a tool such as pliers, and tighten the valve gently.

✽ When connecting the tube with the anti-siphon check valve already mounted on it to the main pipe, be absolutely

FEC/FFC (w/ PE tube)

FTC (w/ FEP tube)

Main pipe

Injection point

(Rc1/2)

sure to hold the valve body and turn the nut. If the nut is turned without holding the body, the threaded part on the

nozzle may be damaged.

Main pipe

Injection point

(Rc1/2 or Rc3/8)

FTC (w/ FEP tube)

Nozzle grip

Nozzle grip

Nut

Nut

NOTE

<

When injecting liquid into a pipe with a small diameter

If the end of the anti-siphon check valve is too

long, cut it off so that the end will be positioned at

the center of the main pipe where the chemical is

to be injected prior to use.

<For maintenance>

It is recommended that the tube be attached to

the main pipe through a valve to enable the antisiphon check valve to be replaced or cleaned, etc.

✽

Use a valve made of materials which will resist

any corrosion resulting from the chemical used.

>

Example: FEC/FFC

Example: FEC/FFC

17

Valve

Anti-siphon

check valve

Page 19

Connecting

Model for injection of boiler chemicals: PZ-31-FEC(PP)

■PP/PE tube

• When bending the tube, provide sufficient leeway in the bending so that the tube will not break. Also ensure that it will

not be rubbed against or trodden on.

• Insert the tube firmly so that it will not become disconnected, and tighten the nuts securely. Do not excessively tighten

the nuts. Doing so may damage or break the joint.

• If the temperature of a liquid or ambient temperature is higher than room temperature, the tightening force will be

reduced, and the tube may become disconnected. After operation has started, tighten up the nuts as appropriate.

• When tightening the nuts, hold the tube to prevent it from being twisted. The joints and other areas may be loosened

by the return force of the tube.

• The pump comes with a 5-meter long tube for both the discharge side and suction side. When longer tube is used, the

pressure loss may exceed the pump’s maximum discharge pressure so thicker tube will be required. Provide details

on the (1) viscosity of the liquid, (2) length of the pipes (how they are positioned) and (3) specific gravity of the liquid

to a TACMINA representative who will select the appropriate tube size.

• When disconnecting the tube for jobs such as maintenance and then afterwards re-connecting the same tube, cut

about 10 mm off the end of the tube before re-using it.

(1) Cut the end of the tube at right angles using a sharp

blade.

blade

a

PP tube (1/8”×1/4”)

Nut (A)

Grip (B)

⎫

Sleeve (C)

Tube-fitting body (D)

⎬

Installation

tube

(2) Wrap sealing tape around the tube-fitting body (D),

and screw the body into the discharge-side joint

using a tool. (The tube-fitting body is already mounted in place before shipment.)

(3)

Pass the tube through the nut (A), grip (B) and

sleeve (C), and insert its end until it touches the

back end of the tube-fitting body (D) on the inside.

(4) Tighten the nut (A) by hand.

(5) Using the tool, tighten the nut (A) in such a way that

the gap (area “a” in the figure) between the tube-

fitting body (D) and nut (A) is approximately 1.5 mm.

✽ Bear in mind that the joint may break if the nut (A)

is tightened too much.

Discharge-side joint

⎭

Pump head

Tube-fitting body

Sleeve

Grip

Nut

PE tube (1/4”×3/8”)

Ceramic weight (E)*

Foot valve

* The tube is packed in the form of a coil. Attach the

ceramic weight (E) and straighten out the tube so that

the liquid inside the tank will be sucked up through it.

18

Page 20

Connecting

■Anti-siphon check valve

This pump is provided with an anti-siphon check valve. Use this valve at the injection point unless there is a good reason not to do so. Be absolutely sure to install it in the following cases.

• When the injection point is open to the atmosphere and liquid is to be injected at a position lower than the level of the

liquid in the tank (prevention of siphoning)

• When the liquid is to be injected inside the suction-side pipe of a volute pump, etc.

• When a chemical greatly exceeding the pump’s rated discharge volume is being fed (prevention of overfeed)

✽ Even with a rising pipe, overfeed may occur if the pipe is too long.

• Take care when handling an anti-siphon check valve which is made of PVDF since it is fragile in the face of impact.

(1) The anti-siphon check valve for the FEC(PP) type has an R1/2 external thread. Provide an Rc1/2 internal thread at

the injection point that fits the anti-siphon check valve.

Installation

FEC (w/ PP tube)

(2)

Wind sealing tape around the external thread of the anti-siphon check valve, and screw the valve into the injection point.

✽ If it is hard to screw the valve in, grasp the nozzle grip using a tool such as pliers, and tighten the valve gently.

✽ When connecting the tube with the anti-siphon check valve already mounted on it to the main pipe, be absolutely

FEC (w/ PP tube)

Main pipe

Injection point

(Rc1/2)

sure to hold the valve body and turn the nut. If the nut is turned without holding the body, the threaded part on the

nozzle may be damaged.

Nozzle grip

Nut

NOTE

<

When injecting liquid into a pipe with a small diameter

If the end of the anti-siphon check valve is too

long, cut it off so that the end will be positioned at

the center of the main pipe where the chemical is

to be injected prior to use.

<For maintenance>

It is recommended that the tube be attached to

the main pipe through a valve to enable the antisiphon check valve to be replaced or cleaned, etc.

✽

Use a valve made of materials which will resist

any corrosion resulting from the chemical used.

>

Example: FEC (w/PP tube)

Example: FEC (w/PP tube)

19

Valve

Anti-siphon

check valve

Page 21

Connecting

Model for injection of sodium hypochlorite: PZ-31/61/12-CL

■PVC braided hose/PE tube

• When bending the hose/tube, provide sufficient leeway in the bending so that the hose/tube will not break. Also

ensure that it will not be rubbed against or trodden on.

• Insert the hose/tube firmly so that it will not become disconnected, and tighten the nuts securely. Do not excessively

tighten the nuts. Doing so may damage or break the joint.

•

If the temperature of a liquid or ambient temperature is higher than room temperature, the tightening force will be

reduced, and the hose/tube may become disconnected. After operation has started, tighten up the nuts as appropriate.

• When tightening the nuts, hold the hose/tube to prevent it from being twisted. The joints and other areas may be loos-

ened by the return force of the hose/tube.

• The pump comes with a 5-meter long hose/tube for both the discharge side and suction side. When longer hose/tube

is used, the pressure loss may exceed the pump’s maximum discharge pressure so thicker hose/tube will be required.

Provide details on the (1) viscosity of the liquid, (2) length of the pipes (how they are positioned) and (3) specific gravity of the liquid to a TACMINA representative who will select the appropriate hose/tube size.

• When disconnecting the hose/tube for jobs such as maintenance and then afterwards re-connecting the same hose/

tube, cut about 10 mm off the end of the hose/tube before re-using them.

Nut

Retaining ring

PE tube

PVC braided hose

Retaining ring

Installation

PE tube

(1/4”×3/8”)

Nut

PVC braided hose

(1/4”×3/8”)

■Anti-siphon check valve w/ duck-bill cap

This pump is provided with an anti-siphon check valve with duck-bill cap. Use this valve at the injection point unless

there is a good reason not to do so. Be absolutely sure to install it in the following cases.

• When the injection point is open to the atmosphere and liquid is to be injected at a position lower than the level of the

liquid in the tank (prevention of siphoning)

• When the liquid is to be injected inside the suction-side pipe of a volute pump, etc.

• When a chemical greatly exceeding the pump’s rated discharge volume is being fed (prevention of overfeed)

✽ Even with a rising pipe, overfeed may occur if the pipe is too long.

(1) The anti-siphon check valve with duck-bill cap has an R1/2 external

thread. Provide an Rc1/2 internal thread at the injection point.

(2) Wind sealing tape around the external thread of the anti-siphon check

valve with duck-bill cap, and screw the valve into the injection point.

✽ If it is hard to screw the valve in, grasp the nozzle grip using a tool such

as pliers, and tighten the valve gently.

✽ When connecting the tube with the anti-siphon check valve with duck-

bill cap already mounted on it to the main pipe, be absolutely sure to

hold the valve body and turn the nut. If the nut is turned without holding

the body, the threaded part on the nozzle may be damaged.

Main pipe

Duck-bill cap

✽

Do not remove this.

Injection point

(Rc1/2)

Nozzle grip

Nut

NOTE

<For maintenance>

It is recommended that the tube be attached to the main pipe through a

valve to enable the anti-siphon check cap with duck-bill cap to be replaced

or cleaned, etc.

✽ Use a valve made of materials which will resist any corrosion resulting

from the chemicals used.

20

Valve

Anti-siphon

check valve

with duck-bill cap

Page 22

Connecting

Model w/ automatic air-release function for injection of sodium hypochlorite: ARPZ-31/61/12

■PVC braided hose/PE tube

• Unlike other models, this model has a discharge-side joint at the front side

of the pump head and an air-release joint on its top.

• When bending the hose/tube, provide sufficient leeway in the bending so

that the hose/tube will not break. Also ensure that it will not be rubbed

against or trodden on.

• Insert the hose/tube firmly so that it will not become disconnected, and

tighten the nuts securely. Do not excessively tighten the nuts. Doing so

may damage or break the joint.

• If the temperature of a liquid or ambient temperature is higher than room

temperature, the tightening force will be reduced, and the hose/tube may

Installation

become disconnected. After operation has started, tighten up the nuts as

appropriate.

• When tightening the nuts, hold the hose/tube to prevent it from being twisted. The joints and other areas may be loosened by the return force of the

hose/tube.

•

The pump comes with a 5-meter long hose/tube for both the discharge side

and suction side. When longer hose/tube is used, the pressure loss may

exceed the pump’s maximum discharge pressure so thicker hose/tube will

be required. Provide details on the (1) viscosity of the liquid, (2) length of

the pipes (how they are positioned) and (3) specific gravity of the liquid to a

TACMINA representative who will select the appropriate hose/tube size.

• When disconnecting the hose/tube for jobs such as maintenance and then

afterwards re-connecting the same hose/tube, cut about 10 mm off the end

of the hose/tube before re-using them.

Air-release joint

Pump head

Discharge-side joint

Suction-side joint

Retaining ring

Nut

PE tube

PE tube

(1/4”×3/8”)

■Soft PVC hose (for air release)

(1) Firmly insert the supplied soft PVC air-release hose

as far as the base of the air-release joint on the top

of the pump head.

(2) Firmly tighten up the nut so that the hose will not

become disconnected.

(3) Return the other end of the hose to the tank or other

container.

PVC braided hose

(1/4”×3/8”)

Air-release hose

(soft PVC)

Nut

Air-release

joint

Retaining ring

Nut

PVC braided hose

Return to the tank

or other container.

Nut

Air-release joint

Air-release hose

21

Page 23

Connecting

■Anti-siphon check valve w/ duck-bill cap

This pump is provided with an anti-siphon check valve with duck-bill cap. Use this valve at the injection point unless

there is a good reason not to do so. Be absolutely sure to install it in the following cases.

• When the injection point is open to the atmosphere and liquid is to be injected at a position lower than the level of the

liquid in the tank (prevention of siphoning)

• When the liquid is to be injected inside the suction-side pipe of a volute pump, etc.

• When chemicals greatly exceeding the pump’s rated discharge volume are being fed (prevention of overfeed)

✽ Even with a rising pipe, overfeed may occur if the pipe is too long.

(1) The anti-siphon check valve with duck-bill cap has an R1/2 external

thread. Provide an Rc1/2 internal thread at the injection point.

(2) Wind sealing tape around the external thread of the anti-siphon check

valve with duck-bill cap, and screw the valve into the injection point.

✽ If it is hard to screw the valve in, grasp the nozzle grip using a tool

such as pliers, and tighten the valve gently.

✽ When connecting the tube with the anti-siphon check valve with duck-

bill cap already mounted on it to the main pipe, be absolutely sure to

hold the valve body and turn the nut. If the nut is turned without holding the body, the threaded part on the nozzle may be damaged.

NOTE

<For maintenance>

It is recommended that the tube be attached to the main pipe through a

valve to enable the anti-siphon check valve with duck-bill cap to be replaced

or cleaned, etc.

✽ Use a valve made of materials which will resist any corrosion resulting

from the chemicals used.

Main pipe

Duck-bill cap

✽

Do not remove this.

Injection point

(Rc1/2)

Nozzle grip

Nut

Valve

Anti-siphon

check valve

with duck-bill cap

Installation

22

Page 24

Electrical wiring

!

• This pump cannot be used in explosion-proof regions or in explosive or combustible atmospheres.

• Take steps to ensure that the power will not be turned on during the course of work. Hang a sign on the

power switch indicating that work is in progress.

• Do not operate the pump with wet hands. Doing so may result in electric shocks.

• Securely ground the protective earth terminal, and be absolutely sure to install a ground fault circuit

interrupter. Otherwise, you may receive electric shocks.

• Do not attempt to disassemble the pump body or the circuit parts.

!

• The wiring must be done by a qualified electrician or somebody with electrical knowledge.

• Connect the wires after checking the supply voltage. Do not connect the wires to a power supply that is

not within the rated voltage range.

Installation

Power cable (2m) is already attached.

Example of wiring

● When operating the pump in tandem

with an irrigation pump, etc.

Power supply

AC200V

3-phase

WARNING

CAUTION

GFCI

CB MC1

CP

CB

MC2

Operation signals

SS1

SS2

TH

PE

Automatic

Off

Manual

X

Automatic

Off

Manual

PE

●When running the pump on its own

Irrigation

pump

U

V

W

MC1

OL

PL1

MC2

PL2

TH

P

Irrigation

pump

PZ/ARPZ

Power supply

AC100~240V

PZ/ARPZ

GFCI

CP

PZ/ARPZ

PE

GFCI : Ground fault circuit interrupter

CB : Circuit breaker

MC1, 2 : Electromagnetic contactor

TH : Thermal relay

CP : Circuit protector

SS1, 2 : Selector switch

OL : Overload relay

PL : Pilot lamp

IMPORTANT

• Be absolutely sure to use a commercial power source (the power

supplied by an electric power company) for supplying the power.

<Power sources that cannot be used>

Power sources in which an AC power regulator is installed

Power sources on the output side of an inverter

• Since a high voltage is generated when the power is cut off or in

other such circumstances and this may result in trouble, do not

take the power from the same terminals as the induction motor of

U

V

W

Power supply

PE

Irrigation

pump, etc.

P

PZ/ARPZ

an irrigation pump, etc.

NOTE

• A circuit protector (CP) is ideal as the injection pump’s overcurrent protection device from the

standpoint of its operating duration and breaking current characteristics. (5A, medium-speed type)

• The circuit protector (CP) shown as the recommended protection device can also be used as the power

switch, thus simplifying the wiring connections.

•

The thermal relay (TH) used for the motor is not appropriate for protecting the pump from the standpoint

of its characteristics.

23

Page 25

Electrical wiring

Recommended protection devices

(1) Circuit protectors

Manufacturer Model

Mitsubishi Electric CP30-BA2P1-M3A

Fuji Electric

Matsushita Electric Works BAC201305

(2) Lightning arrestors

Manufacturer For AC 100V For AC 200V

M-System Co. MA-100 MA-200

(3) Line filters, sealed transformers

CP32D/3

Installation

(4) EMC filter

Manufacturer

TDK

Aihara Electric Co. SPB-300E sealed transformer

Manufacturer

TDK ZAC2205-00U

ZMB2202-11 noise filter

Model

Model

24

Page 26

Operating precautions

• Ensure that nobody other than the operators and control personnel will operate the pump.

• Do not operate the pump with wet hands. Doing so may result in electric shocks.

• When trouble has occurred (such as when smoke appears or there is a smell of burning), shut down the

• A situation in which the valve inside the pipe at the discharge side of the pump is shut off or becomes

•

• The vibration of the pump may cause the hoses/tubes to become loose and disconnected. Before

•

• Idling the pump for prolonged periods of time can lead to malfunctions.

Check the following points.

Operation

Before operation

Check location Details of check Notes

Tank

Pipes

Valves

Power supply

!

pump’s operation immediately, and contact your vender or a TACMINA representative. Otherwise, a fire,

electric shocks and/or malfunctions may result.

blocked with foreign matter is dangerous in that it may lead to an excessive rise in pressure that will

exceed the pump’s specification range, causing liquid to gush out, the pipe to be damaged and the

pump itself to malfunction. Prior to operating the pump, check the valves and pipes, etc.

!

When working on the liquid-end parts of the pump, wear protective gear suited to the chemical concerned

(such as rubber gloves, a mask, protective goggles and work overalls that are resistant to chemical).

starting operation, secure the hoses/tubes and check their tightness.

While the pump is operating, the pump’s surfaces may become hot, reaching a temperature of 60°C or more.

WARNING

CAUTION

Check whether the amount of liquid is sufficient.

If it is not, replenish it.

Check whether any pipes have become disconnected or damaged.

If so, re-connect or make repairs.

Check that the valves are open.

If a valve is closed, open it.

Check that the pump is connected properly to the

prescribed power supply.

Take special care in cases where the chemicals or processes involved would be adversely affected if air were sucked in.

−

Closed valves can cause dangerous situations in which the pressure

rises excessively, liquid gushes out and/or the pipes are damaged.

If it is not, the electronic circuits and solenoids

may burn out.

During operation

Check location Details of check Notes

Pump head

Joints/pipes Check for liquid leaks and looseness.

Discharge-side

pressure

• When using the pump for the first time

•

When resuming operation after a prolonged shutdown of operation

• When the pump is gas-locked

• When the tank is empty

• When using the pump for the first time

• When changing the discharge volume

• When shutting down operation for a prolonged period

•

When resuming operation after a prolonged shutdown of operation

Check whether any liquid is leaking from the hole underneath the auxiliary ring at the back of the pump head.

Check the pressure gauge on the discharge side.

If liquid is leaking, it may mean that the diaphragm is damaged.

Inspect the diaphragm.

If liquid is leaking or there is a loose joint, replace

or tighten it.

If liquid still leaks, inspect the O-rings in the joint concerned.

If the gauge shows an abnormal value, a pipe or

valve may be blocked.

Inspect the pipes.

Air releasing

(page 26)

Discharge-volume setting

(page 28)

Procedure for prolonged

shutdown of operation

(page 28)

25

Page 27

Air releasing

WARNING

!

• During the air releasing, chemical may suddenly gush out from the pipes and other parts. Lead the end

of the relief/air-release hose bank to the tank or other container, and secure it so that it will not become

disconnected.

IMPORTANT

• When using the pump for the first time or when the chemical container has been replaced, proceed with

the task of air releasing prior to operating the pump.

Type Page

Model for injection of general chemicals PZ-31/61/12-VEC/VFC/FEC/FFC/FTC

Model for injection of boiler chemicals

Model for injection of sodium hypochlorite

Model w/ automatic air-release function for injection of

sodium hypochlorite

PZ-31-FEC (PP)

PZ-31/61/12-CL

ARPZ-31/61/12 27

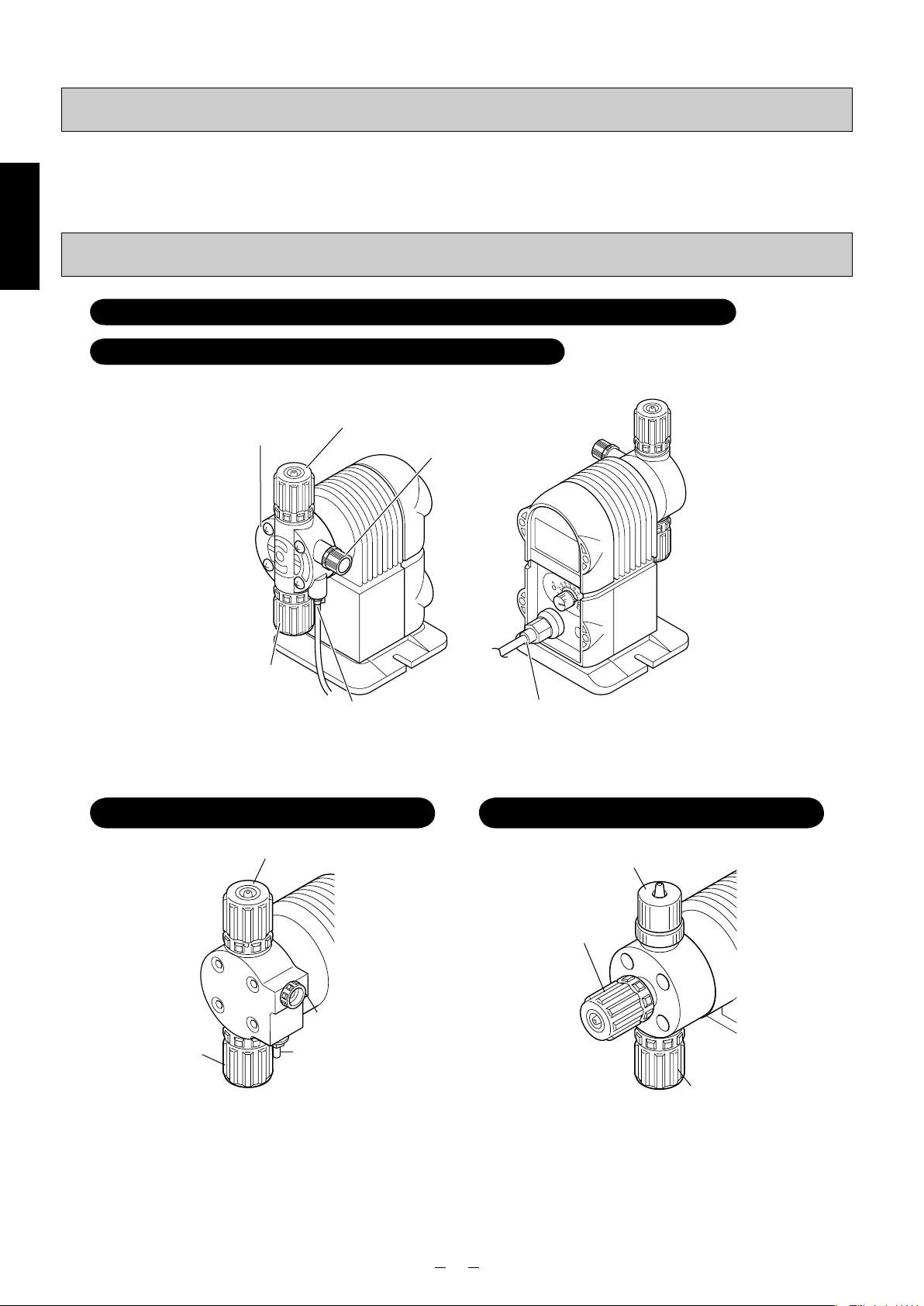

Model for injection of general chemicals: PZ-31/61/12-VEC/VFC/FEC/FFC/FTC

Model for injection of boiler chemicals: PZ-31-FEC (PP)

(1) Before proceeding with the air releasing, check that the end of the relief/air-release hose has been led back to the

tank or other container.

(2) Turn off the pump’s power, and release the pressure inside the discharge-side pipe.

(3) Set the discharge volume to the maximum level. (See page 28)

(4) Turn on the pump’s power to start operating the pump.

(5) Rotate the air-release knob clockwise by about 90 degrees.

The presence of a gap between the knob and retaining nut is now visible.

26

27

Operation

Air-release knob

Gap

Retaining nut

(6) After a few moments air will exit from the relief/air-release port together with the liquid.

(7) After all the air has been released, turn the air-release knob further in the clockwise direction until a clicking sound

is heard.

(8) Shut down the pump.

IMPORTANT

• Under no circumstances must the air-release knob be turned counterclockwise.

NOTE

• If it is difficult to release the air, keep turning the air-release knob clockwise until a clicking sound is

heard repeatedly.

26

Page 28

Air releasing

Model for injection of sodium hypochlorite: PZ-31/61/12-CL

(1) Insert the air-release hose provided into the air-release port.

(2) Return the other end of the air-release hose to the tank or other container, and secure it firmly.

(3) Turn off the pump’s power, and release the pressure inside the discharge-side pipe.

Operation

(4) Set the discharge volume to the maximum level. (See page 28)

(5) Turn on the pump’s power to start operating the pump.

(6) While operating the pump, turn the air-release knob counterclockwise for 1 to 1-1/2 turns.

Airrelease

port

Air-release hose

Air-release knob

(7) After a few moments air will exit from the air-release port together with the liquid.

(8) After all the air has been released, turn the air-release knob clockwise, and tighten it securely.

(9) Shut down the pump.

NOTE

• If it is difficult to release the air completely, repeatedly open and close the air-release knob.

Model w/ automatic air-release function for injection of sodium hypochlorite: ARPZ-31/61/12

(1) Before proceeding with the air releasing, check that the end of the air-release hose has been led back to the tank or

other container.

(2) Turn off the pump’s power, and release the pressure inside the discharge-side pipe.

(3) Set the discharge volume to the maximum level. (See page 28)

(4) Turn on the pump’s power to start operating the pump.

(5) After a few moments air will exit from the air-release port together with the liquid.

(6) After all the air has been released, shut down the pump.

27

Page 29

Discharge-volume setting

• The stroke speed can be adjusted by turning the stroke-speed adjustent dial located at the back of the pump.

50

40

30

PL

20

10

0

SPEED(%)

Adjustable range of stroke speed: 15 to 300 strokes/min

✽ When the dial is moved while the pump is stopped, the dial setting may shift during pump operation. If this happens,

adjust the dial again.

60

70

80

90

100

Operation

Procedure for prolonged shutdown of operation

Follow the steps below when shutting down the pump for a prolonged period.

To shut down the pump

(1) Operate the pump so that clean water or cleaning fluid is sucked in and discharged for about 30 minutes to

clean the inside of the pump head.

(2) Turn off the power completely.

(3) Place the cover over the pump to protect the pump from the build-up of dust and corrosive environments.

To resume operation

(1) Check the inside of the tank for any sediment that may have accumulated, and check for signs of trouble such

as cloudy liquid. If the liquid quality has deteriorated, clean the inside of the tank, and replace all the existing

liquid with fresh chemical.

(2) Check the valve seat areas and check balls inside the joints for dirt and other foreign matter.

(3) Check the items in the section “Before operation” on page 25.

28

Page 30

Maintenance precautions

!

• Ensure that nobody other than the operators and control personnel will operate the pump.

• Take steps to ensure that the power will not be turned on during the course of work. Hang a sign on the

power switch indicating that work is in progress.

• Do not operate the pump with wet hands. Doing so may result in electric shocks.

• When trouble has occurred (such as when smoke appears or there is a smell of burning), shut down the

pump’s operation immediately, and contact your vender or a TACMINA representative. Otherwise, a fire,

electric shocks and/or malfunctions may result.

• Do not attempt to disassemble the pump body or the circuit parts.

!

• When working on the liquid-end parts of the pump, wear protective gear suited to the chemical

concerned (such as rubber gloves, a mask, protective goggles and work overalls that are resistant to

chemical).

• Before attempting to maintain or repair the pump, release the pressure in the discharge pipe, discharge

the liquid in the pump head, and clean the liquid-end parts.

Check the following points.

WARNING

CAUTION

Routine inspections

• Check whether the level of the chemical in the tank is high enough.

• Check the pump for chemical leakage.

• Check that the pressure gauge on the pump discharge side indicates a normal value.

Periodic inspections

Maintenance

•

At the 10,000-hour mark after starting the pump operation

• When discharge trouble has occurred (reduced discharge

volume)

• When chemical is leaking from around the pump head

•

At the 10,000-hour mark after starting the pump operation

• When discharge trouble has occurred (reduced discharge

volume)

When trouble has occurred

• When the relief-valve function has been activated

• When trouble has occurred during operation

Replacing the diaphragm

(see the page 30)

Replacing the valve seats

and check balls

(see the page 31 to 34)

Replacing the relief valve

(see the page 35)

Troubleshooting

(see the page 37 to 38)

29

Page 31

Replacing the diaphragm