Page 1

BULLETIN CC-08

Calibration Columns

Calibration Columns

Purpose

Neptune Calibration Columns provide a

fast, easy and economical means of checking

the flow rate of your chemical metering pump.

The most accurate test of metering pump flow rate

is to measure the drawdown rate on the suction side

while leaving the discharge undisturbed in its normal

steady state operating condition. Pump flow rate

verification on a periodic basis or after maintenance

is important to system accuracy.

The Calibration Column can also be used to determine

if check valves are worn or dirty.

It is recommended to size the Calibration Column for a

minimum of 30 seconds with a scale that will produce

an easily readable differential within the test period.

Features

• Rugged PVC construction with slip on top

caps for top filling and easy cleaning

• Shielded glass models available for acids

and strong chemicals

• Calibration scales are protected from harsh

chemical by Mylar lamination

B

Specifications

A

FOR USE SCALE DIMENSIONS

UP TO INCREMENTS ABC

C (INLET

& OUTLET)

MODEL

NUMBER

CC 100 100 ml. 3 gph 1 ml. 14" 1-5/8" 1/2" FNPT

CC 250 250 ml. 7 gph 2 ml. 15" 2-1/4" 1/2" FNPT

CC 500 500 ml. 16 gph 5 ml. 15-5/8" 2-3/4" 3/4" FNPT

CC 1000 1000 ml. 30 gph 5 ml. 26-3/8" 2-3/4" 3/4" FNPT

CC 4000 4000 ml. 120 gph 20 ml. 31-1/2" 5" 2" FNPT

CAPACITY WITH PUMPS GRADUATION

Page 2

Installation Instructions

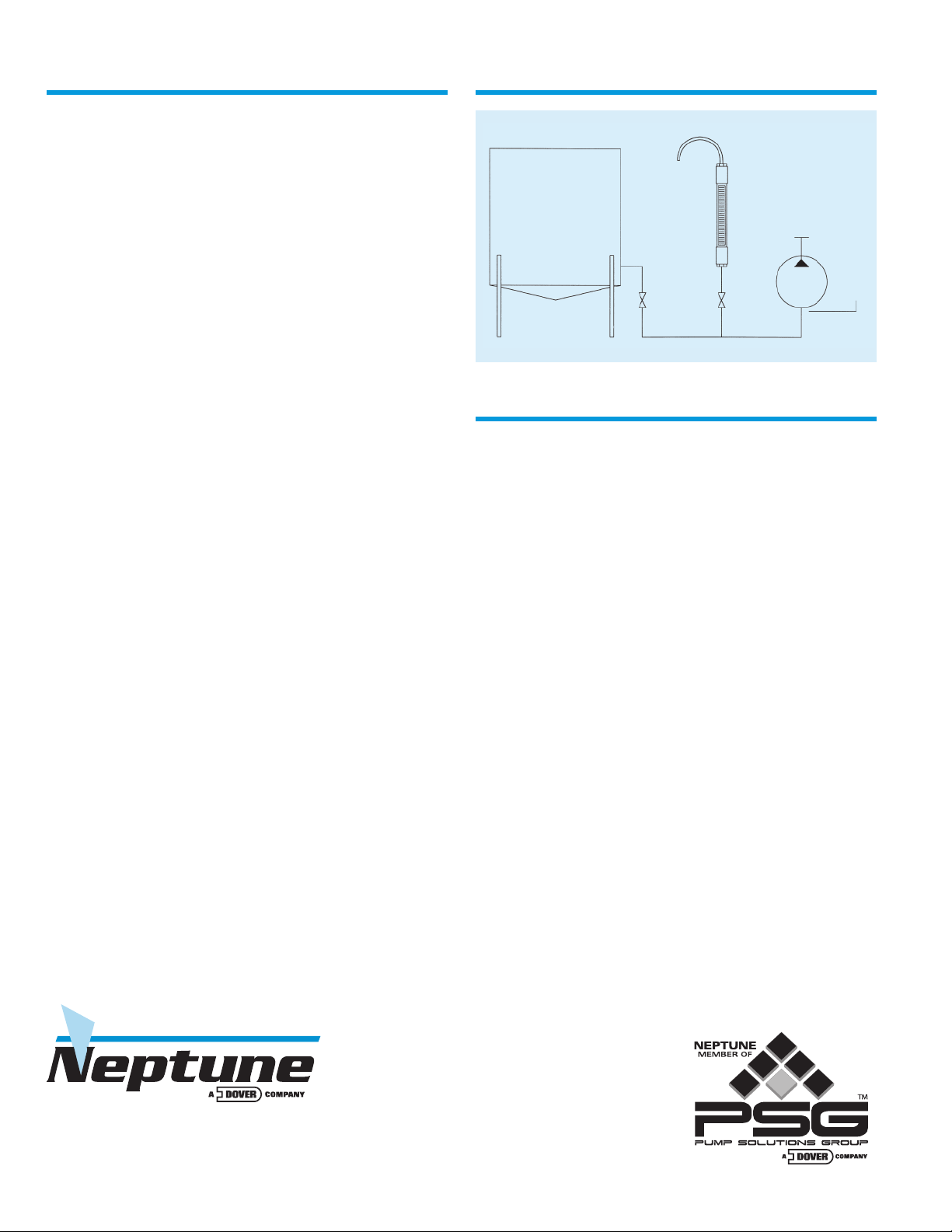

The recommended installation is shown below:

1. Install the Calibration Column in the suction line

of the Chemical Feed Pump. The column should be

installed in a vertical position.

2. Two (2) Ball Valves are required and must be

installed as shown in the adjacent drawing. Valves

are not included.

3. The column should be installed so it will be filled

regardless of the level of the tank. It is recommended

that the top connection of the column be connected

to a vent tube that is as high as the liquid level in the

tank to prevent accidental spillage in the event of a

valve malfunction or if the isolation valve is accidentally left open. Do not install any valve in this overflow

line, as the test tube must be vented to atmosphere

at all times.

CAUTION: Top cap is not glued to allow cleaning. Top

cap must be glued when vent is piped back to tank.

CAUTION: If the vent is not piped back to the tank

a “U” tube should be installed on the top of the column to prevent accidental splash-up for operator protection. Remember, the head in a tall tank can cause

the column to fill rapidly resulting in a squirt from the

small vent connection on the top of the column.

NOTE: When viewing the pump’s performance on a

calibration cylinder, each stroke of the pump should

steadily draw the liquid down to a dead stop and

then drawdown again. “Bouncing” in the column at

the end of the suction stroke is an indication of dirt

or clogging in the valves or possibly wear.

Recommended Installation

OVERFLOW PROTECTION LINE

RESERVOIR

CALIBRATION COLUMN

VALVE A

VALVE B

NEPTUNE

PUMP

UMP

P

UCTION

S

Operating Instructions

A stopwatch or wristwatch with sweep second hand

is required.

1. With the pump operating normally, Valve A is open

and Valve B is closed. Open Valve B slightly so the

column fills slowly with liquid.

2. When the liquid level reaches the zero division mark,

close Valve A (any division mark may be used as a

starting point, however, by filling to the zero mark,

you may measure over a longer period of time, enabling you to get a better calibration). Do not fill above

the zero division mark unless top cap is glued and

vent is piped to tank.

3. Allow liquid level to drop for a period of at least

30 seconds and note the mark on the column to

which the level has dropped. Re-open Valve A.

CAUTION—

IMPORTANT INSTALLATION NOTES:

a. This unit must be vented to atmosphere when in use.

b. Never use this device on discharge side of pump.

c. This device is intended for verification of metering

pump flow rate only.

d. Maximum Pressure = 25 psig

Maximum Temperature = 140°F

e. Not suitable for all chemicals. Consult Factory. Shielded

glass models available for acids and strong chemicals.

SOLD BY:

P.O. Box 247 • Lansdale, PA 19446-0247

Tel: 215-699-8700 • Fax: 215-699-0370

Toll-Free Tel: 1-888-3NEPTUNE (1-888-363-7886)

Toll-Free Fax: 1-800-255-4017

Web Site: http:// www.neptune1.com

E-mail: pump@neptune1.com

© 2008 Neptune Chemical Pump Company All Rights Reserved Bulletin CC-08 P/N ZL107028 Printed in U.S.A.

4. Each column has two scales. The left hand scale

shows the volume of the column in ml. Dividing the

volume pumped by the time to pump gives you the

flow rate. The right hand scale is direct reading in

gallons per hour for a 1 minute test. If the test time is

exactly 1 minute, the drop in the column indicates the

flow rate. Double the number on the right hand scale

for a 30 second test.

5. When the gauge is not in use, Valve B must be closed.

6. Valve A must remain open at all times except when

testing the pump rate.

Loading...

Loading...