Page 1

OPERATING &

NSTRUCTION

I

M

NEPTUNE SERIES 7000

Mechanical “dia-PUMP”

Tel.: 215-699-8700 •FAX: 215-699-0370

ANUAL

MODEL 7000

CHEMICAL PUMP CO., INC.

204, Dekalb Pike,

Lansdale, PA 19446

ZL104440

Page 2

WARNING

LOCKOUTS ARE REQUIRED BEFORE

SERVICING THIS EQUIPMENT.

Shut off/Lockout pump Power before Servicing.

SAFETY INSTRUCTIONS:

Be certain pump isolation valves are

Closed and chemical is shut off.

Bleed pressure before servicing.

2

Page 3

SECTION PARAGRAPH PAGE

I

II

1

2

3

4

5

III NORMAL MAINTENANCE

6

PARTS LIST

IV 7 MOTOR OPERATING CONDITIONS 14

V TROUBLE SHOOTING CHART 14

DRAWINGS

GENERAL DESCRIPTION 4

LIMITED WARRANTY 5

PARTS ORDERING INSTRUCTIONS 6

INSTALLATION INSTRUCTIONS

GENERAL

SUCTION PIPING

DISCHARGE PIPING

INSTALLATION OUTDOORS

STARTUP PROCEDURE

MAINTENANCE

FOR 7000 SERIES PUMP

BALLOONED DRAWING 7000 PUMP

BASIC DIMENSION OF 7000 SERIES PUMP

TABLE OF CONTENTS

7

8

9

9

9

10

13

12

15

3

Page 4

SECTION I

GENERAL DESCRIPTION

The Neptune Series 7000 Mechanical Diaphragm metering pump is a reliable me tering pump of the Low-pressure

diaphragm type. Under constant conditions of temperature, pressure, and capacity adjustment settings, a +/- 2%

metered discharge volume is maintained. Rugged contoured composite diaphragm designed for high mete ring

accuracy over a full 10:1 turndown range.

A plunger reciprocating at a set fixed stroke, actuates a flexible, chemically inert, Teflon faced diaphragm, to create

pumping action. Screwing in and out a hand knob regulates the capacity of the pump. Screwing in (shortens the

stroke length) reduces the volume and screwing out increases it. A percentage of flow is read on the scale.

Precision-engineered liquid ends meters mild solutions, aggressive chemicals, high viscosity polymers (up to

5000cP) and slurries (hydrated lime slurries up to 4 lbs of /gallon of water, activated carbon slurries up to 1 lbs

/gallon of water)

Metering accuracy is maintained by the ball check valves at the suction and discharge of the pump. The use of screw

in cartridge ball check valves eases maintenance.

Temperature limitations on the plastic heads are 36 – 125°F (2 - 52°C)

Mechanical diaphragm pumps are positive displacement reciprocating pump s. Each pump consists of a power end

and a process end separated by mechanically operated Teflon faced diaphragm. Individual pumps will vary in

appearance due to various liquid ends; however, the basic principles of operation remain the same.

PLEASE READ THE INSTRUCTION MANUAL COMPLETELY BEFORE INSTALLING THE PUMP

4

Page 5

SECTION I

NEPTUNE CHEMICAL PUMP COMPANY

LIMITED WARRANTY

All Neptune Pumps are tested at the factory prior to shipment. Each part used in their construction has been carefully

checked for workmanship.

If the pump is installed properly, Neptune Chemical Pump Company, Inc. warrants to the purchaser of this product

for a period of twelve months from the date of first use or eighteen months from shipment, whichever occurs first, this

product shall be free of defects in material and/or workmanship, as follows:

1 Neptune Chemical Pump Company, Inc. will replace, at no charge, any part that fails due to a defect in

material and/or workmanship during the warranty period, FOB our factory, Lansdale, Pennsylvania. To obtain

warranty service, you must forward the defective parts to the factory for examination, freight pre-paid.

1 This warranty period does not cover any product or product part, which has been subject to accident,

misuse, abuse or negligence. Neptune Chemical Pump Company, Inc. shall only be liable under this

warranty if the product is used in the manner intended by the manufacturer as specified in the written

instructions furnished with this product.

Any express warranty not provided in this warranty document, and any remedy for breach of contract that, but for this

provision, might arise by implication or operation of law, is hereby excluded and disclaimed. Under no circumstances

shall Neptune Chemical Pump Company, Inc. be liable to purchaser or any other person for any charge for labor,

repairs, or parts, performed or furnished by others, nor for any incidental consequential damages, whether arising out

of breach of warranty, express or implied, a breach of contract or otherwise. Except to the extent prohibited by

applicable law, any implied warranty of merchantability and fitness for a particular purpose are expressly limited in

duration to the duration of this limited warranty.

Some states do not allow the exclusion or limitation of incidental or consequential damages, or allow limitations on

how long any implied warranty lasts, so the above limitations may not apply to you. This warranty gives you specific

legal rights, and you may have other rights, which may vary from state to state.

1

IMPORTANT

SHOULD IT BE NECESSARY TO SEND THE PUMP TO THE FACTORY FOR REPAIR OR MAINTENANCE

REBUILDING; DRAIN ALL OIL AND CHEMICAL FROM PUMP BEFORE SHIPPING. FAILURE TO DO SO CAN

CAUSE EXTENSIVE DAMAGE TO THE MOTOR.

SEE IMPORTANT NOTICE – RETURN GOODS AUTHORIZATION

1

IMPORTANT NOTICE

RETURN GOODS AUTHORIZATION

(1) All equipment returned to Neptune Chemical Pump Company, Inc. requires proper Returned

Goods Authorization Number (RGA) and tags.

(2) All equipment returned to the factory for repair or service must first be thoroughly flushed and have

all chemical contact areas neutralized.

(3) All equipment which has been in contact with chemicals must be accompanied by a copy of the

Chemical Product Material Safety Data Sheet (MSDS).

(4) Failure to comply with the above instructions will result in equipment being returned to sender,

freight collect, without service.

5

Page 6

SECTION I

PARTS ORDERING INSTRUCTIONS

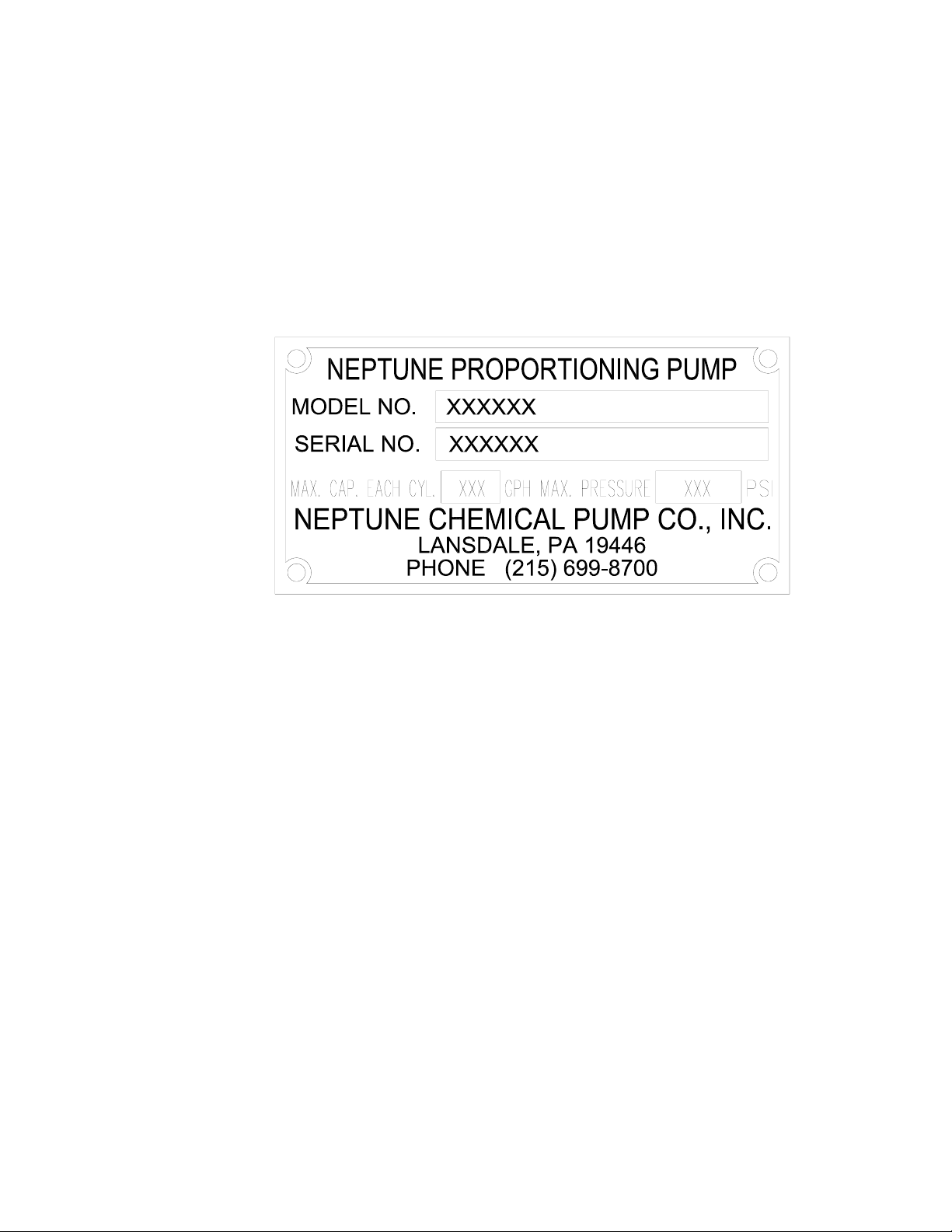

The complete model number and serial number of the pump must be furnished to insu re prompt and

accurate parts service. These numbers are found on the name plate (sample below) located on the side

of the pump.

Please refer to page number (13) for parts list. Ballooned drawing of the pumps can be found on pag es

(12) and (14).

Send all orders or inquiries for parts to:

Parts Department

Neptune Chemical Pump Company, Inc.

P.O. Box 247

Lansdale, PA 19446

Tel.: 215-699-8700

1 -888-3NEPTUNE (888-363-7886)

FAX: 215-699-0370

NOTE: PLEASE SUPPLY BOTH MODEL AND SERIAL NUMBERS.

6

Page 7

1.0 GENERAL

1.0.1 UNPACKING & INSPECTION

When unpacking a pump or chemical feed system, be certain that no parts are thrown away.

Examine the equipment for possible damage. If damage has occurred, file claim with the common

carrier within 24 hours. Neptune will assist in estimating the repair costs.

1.0.2 The Mechanical Diaphragm metering pumps should be located on a level surface. Three mounting

holes are provided to anchor the pump securely to the mounting surface. All piping to the pump

should be supported to prevent stress on the pump input and output fittings.

1.0.3 Before connecting the pump make sure that all fittings are completely clean by flushing thoroughly.

Foreign matters with sharp edges entering the pump can damage the diaphragm and severely limit

the life of the pump.

1.0.4 A “Y” STRAINER (AT LEAST ONE PIPE SIZE LARGER THAN SUCTION INLET SIZE OF THE

PUMP) MUST BE INSTALLED IN THE SUCTION LINE OF THE PUMP TO INSURE AGAINST

FOREIGN MATTER ENTERING THE PUMP

1.0.5 It is recommended that shut-off valves and unions be placed in the suction and discharge lines if

possible. Such an arrangement will facilitate servicing the pump.

1.0.6 The electrical supply to the pump must match the motor nameplate characteristics. The motor

rotation is counter clockwise when viewed from the top of the motor or looking down on the pump.

An arrow mark on the gearbox shows the rotation (See Figure 1)

On single-phase units, the rotation is set at the factory and must not be changed.

SECTION II

INSTALLATION INSTRUCTIONS

IMPORTANT

FIGURE 1

Please note Figure 1, indicating the correct rotation. Operation with the incorrect rotation will

damage the pump and motor.

1.0.7 Fill gearbox and pump by pouring the specified gear oil (drive lubricant) supplied through the

Breather (see note) at the rear of the pump. Pour fluid in slowly until it covers the worm gear.

PLEASE NOTE: Oil may be poured through breather. Snap off the breather top and remove the breather

sponge to fill oil and then reinstall sponge and breather top.

7

Page 8

The hydraulic fluid supplied by Neptune is:

EP Gear Oil, ISO #68, Norton Petroleum Corp., 290 Possum Park Road, Newark, DE 19711

(302) 731-8220 CAS No.64742-54-7, 64742-65-0 or 64741-8 8-4.

Common sources for hydraulic fluid are:

All piping systems should include:

1.1.1 A separate system relief valve to protect piping and process equipment, including the pump, from

*An external relief valve is required!!

1.1.2 Shutoff valves and unions (or flanges) on suction and discharge piping. This permits check valve

1.1.3 An inlet strainer, if the product is not slurry. Pump check valves are susceptible to dirt and other solid

1.1.4 Valve housings or other portions of the reagent head must not support piping weight, as the resulting

SUCTION PRESSURE REQUIREMENTS

2.0 SUCTION PIPING

2.0.1 The suction piping to the pump must be absolutely airtight for optimum operation any leakage in the

2.0.2 NEPTUNE RECOMMENDS THAT The Mechanical Diaphragm metering pumps BE OPERATED

Alternate Oils Manufacturer

Omala #68 Shell Oil

Mobil Gear #626 Mobil Oil

Sun EP #68 Sun Oil

Meropa #68 Texaco

excess process pressures.

inspection without draining long runs of piping. Shutoff valves should be of the same size as connecting pipe. Ball valves are preferred since they offer minimum flow restriction.

contaminants unless designed for that service, and any accumulation can cause malfunction. The

strainer should be located between the suction shutoff valve and the pump suction valve. It must be

sized to accommodate the flow rate and the anticipated level of contamination. A 100-mesh screen

size is recommended.

stresses can cause leaks. In piping assembly, use a sealing compound chemically compatible with

the process material.

Although Mechanical Diaphragm metering pumps have suction lift capability, a flooded suction is

preferable whenever possible. The pump should be located as clo se a s po ssible to the suction side

reservoir or other source.

The pump will self-prime with 10 ft (3 meters) of water suction lift (wetted valves, zero back pressure,

full stroke and speed, water like solutions). Once primed, the pump is capabl e of up to 10 feet (3

meters) of water suction lift.

All Mechanical Diaphragm metering pumps are designed for continuous service at the rated

discharge pressure. The discharge pressure must exceed suction pressure by at least 6 Psia (or

0.41 Bar). This can be achieved where necessary by the installation of a backpressure valve in the

discharge line.

suction line will reduce pumping capacity. Pipe should be one size larger than suction inlet size of

the pump. It is suggested that the suction piping be tested with low air pressure and a soap sol ution

to assure that no leaks exist. Limit the total length of the suction line to 5-8 feet for suction lift or 8-10

feet for flooded suction. Minimize bends, elbows, or other restrictions for better pumping efficiency.

WITH A FLOODED SUCTION, AS THIS WILL FACILITATE START UP AND INCREASE THE

SERVICE LIFE OF THE PUMP.

8

Page 9

2.0.3 It is recommended that all solution tanks be furnished with a low level cut off switch or low-level

alarm and cut off switch to prevent the pump from running dry. Although the pump can run dry for a

few minuets. OPERATION AGAINST A DRY SYSTEM FOR A PROLONGED PERIOD MAY CAUSE

DAMAGE TO THE PUMP DIAPHRAGM AND REDUCE THE OPERATING LIFE OF THE PUMP.

3.0 DISCHARGE PIPING

3.0.1 It is recommended that the Mechanical Diaphragm metering pump o perate against a suitable back

pressure to facilitate better operation of the check valves.

3.0.3 To protect the pump, it is recommended that an external relief valve as manufactured by Neptune

Chemical Pump Company, or equal, be placed in the discharge line of the pump to avoid over pressure.

3.0.4 Discharge piping should equal discharge port size.

NOTE: All parts must have a working pressure rating above the required set pressure.

3.0.5 Start and run the pump.

3.0.6 Adjust the required percentage of flow required.

Do not attempt to run the pump in excess of its nameplate rating.

4.0 INSTALLATION OUTDOORS

The Mechanical Diaphragm metering pump is a totally enclosed pump, which can be used o utdoors or

indoors. When installed outdoors, make sure that the pump is protected against extremes of nature as

follows:

4.0.1 Running of the pump when exposed to tropical sunshine with ambient temperature above 90°F

(32°C) would cause excessive oil and motor temperatures. The pump should be shaded and located

in such a way as to permit an ample degree of air circulation.

4.0.2 Under cold conditions, the pump should be insulated and a heater should be supplied in order to

maintain the hydraulic fluid at an ambient temperature above 36°F (2°C.)

5.0 START UP PROCEDURE

The following start up procedure is complete and does repeat instructions on filling the gearbox and pump.

5.0.1 Open suction and discharge valve. (See recommendation 1.0.5)

5.0.2 Set capacity indicator to zero by turning hand knob clockwise.

5.0.3 Adjust backpressure close to zero.

5.0.3 Start pump.

5.0.4 On initial start-ups: Check for proper motor rotation (Refer to Paragraph 1.0.6). Listen for any

abnormal motor or crank noises, and if present, refer to trouble shooting chart.

5.0.5 Adjust pump to required capacity by turning hand knob anticlockwise.

5.0.6 Adjust pressure to requirement.

CAUTION

9

Page 10

6.0 MAINTENANCE

Under normal conditions, the Mechanical Diaphragm metering pumps should not require any significant

amount of maintenance. It is advised that periodic visual observations be made of the oil level to make sure

that it is over the worm gear. The liquid end of the pump should also be inspected for leakage. These

observations should be made regularly.

The Gear oil should be drained and replaced when necessary, removing the drain plug at the side of the

pump. This change can be scheduled with the normal factory maintenance at seasonal periods.

6.1.0 OIL CHANGE

6.1.1 Disconnect the power source to the drive motor

6.1.2 Relieve all pressure from the piping system.

6.1.3 Drain the oil by removing the drain plug at the lower rear side of the gearbox.

6.1.4 Replace the drain plug.

6.1. 5 Remove breather on the gearbox cover. (Or snap off the breather top and remove sponge)

6.1.6 Fill with oil.

6.1.7 Replace breather. (Or snap on the breather top after replacin g sponge)

6.2.0 CHECK VALVE REMOVAL CLEANING AND REPLACEMENT.

Should the valves need cleaning, remove as follows:

6.2.1 Disconnect the power source to the drive motor.

6.2.2 Relieve all pressure from the piping system.

6.2.3 Close the inlet and outlet shutoff valves.

6.2.4 Loosen and remove the suction and discharge valve cartridges slowly to drain any

6.2.5 Clean valve cartridges with suitable solvent. Both valve cartridges are complete and

6.2.6 To replace reverse above procedures. Make sure that the port orientation is right.

SECTION III

NORMAL MAINTENANCE

The recommended oil change intervals are depende nt upon the operating environment and

level of pump usage.

trapped liquid.

integral units and should not be disassembled for cleaning. If the valves are found to be

worn and in need of replacement, an entire valve cartridge in either suction or discharge

should be ordered.

10

Page 11

6.3.0 LIQUID HEAD REMOVAL, INSPECTION, AND REINSTALLATION

CAUTION

If the diaphragm has failed, any process fluid would pass through the bleed hole located

behind the diaphragm. Handle any liquid with appropriate care.

Mechanical diaphragms should operate for approximately 2000 ho urs under normal operating

conditions; however, the accumulation of foreign material or debris and abnormal operating condition

or simply age can cause failure. Failure can also occur as a result of system over pressure. Periodic

diaphragm inspection and replacement are recommended.

6.3.1 Adjust the stroke setting to “0” percent and disconnect the power source to the drive

motor

6.3.2 Relieve all pressure from the piping system.

6.3.3 Take all precautions described under “Caution” to prevent environmental and personnel

exposure to hazardous materials.

6.3.4 Disconnect piping to the reagent head and drain any process liquid.

6.3.5 Place a pan underneath the pump head adaptor to catch any liquid leakage.

6.3.6 Remove all but two top reagent head bolt. Product will leak out between the pump head

adaptor and reagent head as the bolts are loosened.

6.3.7 Tilt the head and pour out any liquids retained by the check valves into a suitable

container, continuing to follow safety precautions as appropriate.

6.3.8 Remove the final bolt and rinse or clean the reagent head with an appropriate material.

6.3.9 Inspect the diaphragm and remove the diaphragm if necessary, by turning counterclockwise. The diaphragm must be replaced if it is cracked, separated, or obviously

damaged.

6.3.10 To install a diaphragm, first ensure that the critical sealing areas of diaphragm, reagent

head, and pump head are clean and free of debris. Then lubricate the elastomer side of

the diaphragm liberally, where it is in contact against the intermediate chamber wall and

backup plate, with a lubricant (silicone grease is preferred).

6.3.11 Thread the diaphragm (clockwise) fully onto the shaft.

6.3.12 Install the reagent head bolts and tighten in an alternating pattern to ensure an even

pressure on all bolts.

11

Page 12

MODEL 7000

(SHOWN WITH 316SS LIQUID HEAD)

12

Page 13

PARTS LIST

7000 MECHANICAL DIAPHRAGM PUMP

ITEM

NO.

1 Gear Box 1 004410

2 Worm Gear 18 SPM 1 004540

Worm Gear 37 SPM 1 004541

Worm Gear 72 SPM 1 004542

Worm Gear 117 SPM 1 004543

Worm Gear 144 SPM 1 004547

3 Thrust Collar 2 004419

4 Shaft Retainer 1 000289

5 1/4-20 x 1/2" Lg. Screws 3 100254

6 Shaft Retainer Gasket 2 106290

7 Retainer Cover 1 004415

8 #10-32 x 1/2” Lg. Screws 7 100358

9 Stroke Adjuster Disk 1 004414

10 Retaining Ring, External 1 106593

11* O-Ring 1 107600

12 Retaining Ring, Internal 1 106592

13* Oil Seal 1 106586

14 1/4-20 x 7/8" Lg. Screws 4 100197

15 Pump Head Adapter 1 004411

16 Spring 1 108023

17 Piston Rod 1 004412

18 Ball Bearing 1 100359

19 Gear Shaft 1 104444

20 Thrust Washers 1 100252

21 Back Cover Gasket 1 104443

22 #8-32 x 1/2” Lg. Screws 6 100578

23 Back Cover Plate 1 004420

24 #10-32 x 5/8” Lg. Screws 3 106106

DESCRIPTION

QTY.

PART

NO.

ITEM

NO.

25 Hand Knob 1 107652

26 Hand Knob Adapter 1 004418

27 Spring Pin 1 100305

28 Hand Knob Set Screw 1 105017

29 Control Stud 1 004417

30 Control Stud Holder 1 004416

31 Control Stud External O-Ring 1 100322

32 Control Stud Internal O-Ring 1 100417

33 Thumb Screw 1 107677

34* Diaphragm 1 108022

39 1/4” Lock Washers 3 100169

40 1/4-20 x 3/4” Lg. Screws 3 108140

41 Bearing Cup 1 100179

42 Bearing Cone 1 100180

43 Worm Spring Pin 1 100181

44 O-Ring 1 100244

45 Worm Shaft Cover 1 004422

46 Pump Mount Bracket 1 001415

47 Drain Plug 1 100332

48 Worm 18 SPM 1 003516

Worm 37 SPM 1 000170

Worm 72 SPM 1 000172

Worm 117 SPM 1 000169

Worm 144 SPM 1 002817

49 Fill/Vent Plug 1 000191

50 Capacity Indicating Scale 1 104441

51 Breather Vent 1 104447

52 Street Elbow 1 101757

DESCRIPTION

QTY.

PART

NO.

PARTS FOR 7000 PUMP HEADS

ITEM

NO.

35

Pipe Plug 1 101859 ------ ------

36* Check Valve 2 003321 003279 003332

37 Liquid Head 1 003276 004578 004579

38 Pump Head Screws 8 101174 107766 107766

Washers 8 ------ 106857 106857

DESCRIPTION

QTY.

N3

PART NO.

N5

PART NO.

PART NO

Note: PARTS MARKED WITH “*” ARE Recommended SPARE PARTS

N8

13

Page 14

SECTION IV

r

MOTOR OPERATING CONDITIONS

7.0 The normal temperature rise for standard motors is 40°C above ambient temperature and, thus, it might

appear that the motor is operating at a higher than normal temperature. This situation is normal.

As a precaution against motor overheating, it is recommended that the pump be located where adequate

ventilation is available, It is also recommended that a MOTOR STARTER WITH THE PROPER OVERLOAD

PROTECTION BE SUPPLIED AS AN ADDITIONAL SAFETY DEVICE.

SECTION V

TROUBLE SHOOTING CHART

SYMPTOMS CAUSES REMEDIES

. Pump Motor Will Not

Operate.

Open thermal overload device in starter. Reset.

Low liquid level in tank (where low level

D. Broken wire. Locate and repair.

E. Low voltage. Check for too light wiring.

Oil “frozen” in pump. Thaw out.

Pump Does Not Deliver

Rated Capacity

B. Leaky suction piping. Pressure test, repair or replace defective piping.

C. Excessive suction lift. Rearrange equipment location to reduce suction lift.

Liquid too close to boiling point. Lower temperature or increase suction pressure slightly.

A. Blown Fuse. Check for short circuit or overload

Fill tank.

cut-off is used).

A. Starved suction.

Look for blockage in suction line.

Replace suction piping with larger size.

Worn or dirty valves or seats, or both. Clean or replace.

Viscosity of liquid too high. Reduce viscosity by heating or other means.

2. Increase size of suction piping

3. Increase suction pressure slightly

Low discharge pressure. A minimum discharge pressure of 25 psi is required to insure proper

capacity control

ump delivers erratically. Leaky suction line. Repair or replace piping.

Worn or dirty valves or seats, or both. Clean or replace valve assembly.

Excessive excursion of ball valves from

seats (indicated by ball chatter).

Insufficient suction pressure Increase suction pressure.

Raise tank level.

Liquid too close to boiling point, Reduce temperature or raise suction pressure.

Leaky system relief valve. Repair or replace relief valve

Motor overheats

thermal overload

activates,

Overload caused by operating pump

5. Noisy Operation

1. In Pump Pump Valves. Valves must move to open and close, and they will make a clicking noise

2. In Gear Reduce

Oil level Low Flexible diaphragm punctured Replace diaphragm

Gearbox hot

Power supply does not match motor. Check power supply against motor nameplate data.

beyond rated capacity

Pounding noise at high discharge pressure Fluid compressibility causes reversal of load on gears at end of pressure

Gearbox temp. may rise to 150°F. and may

be caused by various reasons and should

not raise any concern.

Increase backpressure.

Check operating pressure against pump manufacturer data plate

maximum rating

as they operate. These noises are sometimes amplified by natural

resonances in piping system. They are usually indications of normal

valve functioning.

stroke, Not considered detrimental.

In case of excessive heat buildup, contact factory.

14

Page 15

7000 Dimensions with Metal Head

7000 Dimensions with Plastic Head

15

Page 16

MATERIAL SAFETY DATA SHEET Page 1 of 4

1. CHEMICAL PRODUCT AND COMPANY IDENTIFICATION

Product Name: EP 68 Gear Oil

Product Code:

Generic Name: Heavy-duty, Multi-grade Gear Oil

Chemical Family: Petroleum Hydrocarbons & Additives

Manufacturer: Scot Lubricants Emergency Telephone Numbers

1801 E. Tremont Street Information: 610-433-2527 8am-5pm - EST M-F

P.O. Box 326 C H EMTREC: 800-424-9300 24 hrs – every day

Allentown, PA 18105

2. CAUTION Summary of Hazards

May cause mild eye irritation and/or mild skin irritation and inflammation. Avoid eye contact and

prolonged and/or repeated skin contact.

HAZARD RATING

TOXICITY – 1 0=INSIGNIFICANT 1=SLIGHT

FLAMMABILITY – 1 2=MODERATE 3=HIGH

REACTIVITY – 1 4=EXTREME

3. Fire Fighting Measures

Flash Point (Method) Autoignition Temperature (Method) Flammable Limits in Vol

4. FIRST AID MEASURES

INHALATION: Move to fresh air

EYE CONTACT: Flush with water for at least 15 minutes. If irritation persists, obtain medical assistance.

SKIN CONTACT: Wash with soap and water until no odor remains. If redness or swelling develops, obtain

medical assistance. Wash clothing before reuse.

INGESTION; Practically non-toxic. Induction of vomiting not required. Obtain emergency medical attention.

Small amounts, which accidentally enter mouth, should be rinsed out until taste of it is gone.

5. FIRE FIGHTING MEASURES

FLASHPOINT (METHOD): 390°F Minimum COC; 201°C Minimum COC

FLAMMABLE LIMITS: Not established.

AUTO-IGNITION TEMP: 675°F Estimated; 359°C Estimated

EXTINGUISHING MEDIA: Water spray, dry chemical, carbon dioxide (CO2), foam.

FIRE FIGHTING INSTRUCTIONS: Avoid breathing smoke and vapor.

FIRE FIGHTING EQUIPMENT: Wear self-contained breathing apparatus and protective clothing. Use water

spray to keep fire-exposed containers cool.

HAZARDOUS COMBUSTION PRODUCTS: Normal combustion forms carbon dioxide and water vapor;

incomplete combustion can produce carbon monoxide.

Revision: 05/05/2007 NA= Not Applicable ND=No Data NE=Not Established

16

Page 17

EP 68 Gear Oil Page 2 of 4

6. ACCIDENTAL RELEASE MEASURES

SPILLS OR LEAKS: Contain spills, advise EPA, state agency, if required. Absorb on inert material, shovel,

sweep, or vacuum spill.

7. HANDLING AND STORAGE

NFPA Class IIIB Storage. Wash thoroughly after handling.

8. EXPOSURE CONTROLS/PERSONAL PROTECTION

VENTILATION: Ventilate as needed to comply with exposure limit. General Dilution ventilation acceptable.

PERSONAL PROTECTIVE EQUIPMENT –

EYE: Splash proof chemical goggles recommended to protect against splash of product.

GLOVES: Protective gloves recommended when prolonged skin contact cannot be avoided. The following glove

materials are acceptable: polyvinyl chloride (PVC); neoprene; nitrile; polyvinyl alcohol; viton.

RESPIRATOR:

Respiratory protection usually not needed unless product is heated or misted. Half-mask air purifying respirator with dust/mist

filters or HEPA filter cartridges is acceptable to 10 times the exposure limit. Full-face air purifying respirator with dust/mist

filters of HEPA filter cartridges is acceptable to 50 times the exposure limit. Protection by air purifying respirators is limited.

Use a positive pressure demand full-face supplied air respirator or SCBA for exposures above 50X the exposure limit. If

exposure is above IDLH (immediately dangerous to life and health) or there is the possibility of an uncontrolled release or

exposure levels are unknown, then use a positive pressure demand full-face supplied air respirator with escape bottle or SCBA.

Concentration in air determines protection needed. Use only NIOSH certified respiratory protection.

OTHER: If contact is unavoidable, wear chemical resistant clothing. The following materials are

acceptable as protective clothing materials: polyvinyl alcohol (PVA); polyvinyl chloride (PVC); neoprene;

nitrile; viton; polyurethane. Launder soiled clothes.9. PHYSICAL AND CHEMICAL PROPERTIES

9. PHYSICAL AND CHEMICAL PROPERTIES

APPEARANCE/ODOR: AMBER FLUID/SLIGHT ODOR .BOILING POINT: HIGH

VAPOR PRESSURE <0.0001 (MM HG @ 20°C) MELTING POINT: N/A

MOLECULAR WEIGHT: N/A (G/MOLE) PACKING DENSITY: N/A

SOLUBILITY IN WATER: NIL (% BY VOLUME) OCTANOL/WATER COEFF: N.D.

EVAPORATION RATE: 1000X SLOWER (ETHYL ETHER=1) ODOR THRESHOLD: N.D.

SPECIFIC GRAVITY: 0.86 (WATER=1) VAPOR DENSITY: 10+ (AIR=1)

VISCOSITY: 55 SUS @ 210°F 68 CST @ 40°C

10. STABILITY AND REACTIVITY

STABILITY: Stable

CONDITIONS TO AVOID: None known.

MATERIALS TO AVOID: Strong oxidizing agents.

HAZARDOUS POLYMERIZATION: Will not occur.

HAZARDOUS DECOMPOSITION: Combustion will produce carbon monoxide and asphyxiants

.

11. TOXICOLOGICAL INFORMATION

FOR THE PRODUCT –

INHALATION: Low acute toxicity. SKIN: Practically non-toxic if absorbed. Mild irritation with prolonged or

repeated contact. EYE: Mildly irritating on contact. ORAL: Practically non-toxic. Acute toxicity: estimated oral

LD50 in rats is: >15 g/kg. Estimated draize skin irritation score is: 2.10 out of 8.0

Revision: 05/05/2007 NA= Not Applicable ND=No Data NE=Not .Established

17

Page 18

EP 68 Gear Oil Page 3 of 4

11. TOXICOLOGICAL INFORMATION – cont’d

SEVERELY SOLVENT REFINED HEAVY PARAFFINIC PETROLEUM OIL: INHALATION: Low acute

toxicity. SKIN: Practically non-toxic if absorbed; may cause moderate irritation with prolonged and repeated

contact. EYE: Minimally irritating on contact. INGESTION: Practically non-toxic if swallowed.

CALCIUM SULFONATE: INHALATION/INGESTION: No data available. SKIN: Moderate irritant.

Cause allergic skin reaction in animals. EYE: Moderate to severe irritation.

BUTYLATED PHENOL: No data available for all routes of exposure.

ZINC DIALKYL DITHIOPHOSPHATE: INHALATION: Toxic hydrogen sulfide is generated when heated

above 155 deg. F. This can cause respiratory collapse, coma, or death. SKIN: Prolonged or repeated contact may

cause moderate irritation, redness, drying, cracking, and dermatitis. EYE: Irritant. ORAL: Harmful if swallowed.

ACRYLIC COPOLYMER: No data available for all routes of exposure.

2-ETHYLHEXANOL: INHALATION: Overexposure may cause nose/throat irritation, nasal discomfort and

discharge, chest pain, cough, headache, nausea, vomiting. SKIN: Irritant. Prolonged/repeated contact may cause

redness and swelling. Prolonged widespread absorption caused CNS (Brain) depression, stupor, and unconsciousness in animals. EYE: Severe irritant. May cause corneal injury. ORAL: Moderately toxic. May cause abdominal

discomfort, nausea, vomiting, diarrhea, unconsciousness, and other CNS (Brain) effects. Liver and kidney injury

(repeated ingestion). PREGNANT RATS: Skin contact up to 3 ml/kg. Maternal toxicity, but no birth defects; oral

dose 2 ml/kg. Embryo/fetal toxicity and possibly increased birth defects.

TOLUENE: INHALATION: Vapor harmful. Overexposure to high concentration will cause eye, nose, and throat

irritation. CNS (Brain) effects, dizziness, breathing difficulties, coma, and death. Reports of heart beat irregularities

from massive exposure. Prolonged overexposure can cause brain, liver, kidney effects and/or damage. ORAL:

Harmful or fatal if swallowed. PULMONARY ASPIRATION HAZARD: Can enter lungs and cause damage.

PREGNANT: May cause mental and/or growth retardation in children of female solvent abusers. Prolonged

breathing in rats was toxic to fetuses and mothers – 15000 ppm. No birth defects-5000 ppm. No effects 750 ppm.

12. ECOLOGICAL INFORMATION

ECOTOXICITY: No data available.

13. DISPOSAL INFORMATION

Follow federal, state, and local regulations. Not RCRA hazardous waste if uncontaminated. If “used”, RCRA

criteria (ignitability, reactivity, corrosivity, toxicity characteristics) must be determined. Do not flush to drain/storm

sewer. Contract to authorized disposal service.

14. TRANSPORTATION INFORMATION

DOT

PROPER SHIPPING NAME Petroleum Lubricating Oil

HAZARD CLASS Not regulated

ID NUMBER Not regulated

LABEL REQUIRED Not regulated

IMDG PROPER SHIPPING NAME N.D.

IATA PROPER SHIPPING NAME N.D.

Revision: 05/05/2007 NA= Not Applicable ND=No Data NE=Not Established

18

Page 19

EP 68 Gear Oil Page 4 of 4

15. REGULATORY INFORMATION

TSCA: This material complies with the TOXIC SUBSTANCES CONTROL ACT (15 USC 2601-2629) and is listed

in the TSCA Inventory.

SARA 302 THRESHOLD PLANNING QUANTITY N/A

SARA 304 REPORTABLE QUANTITY N/A

SARA 311/312 REPORTING Health Immediate (acute) No

Health Delayed (Chronic) No

Physical Fire No

Physical Sudden Release of Pressure No

Physical Reactive No

When a product and/or component is listed below, the regulatory list on which it appears is indicated.

ZINC DIALKYL DITHIOPHOSPHATE – NJ 01

TOLUENE – CA FL MA MN NJ PA 01 07

2-ETHYLHEXANOL – MA PA

01=SARA 313 02-SARA 302/304 03=IARC CARCINOGEN

04-OSHA CARCINOGEN 05=ACGIH CARCINOGEN 06=NTP CARCINOGEN

07=CERCLA 302.4 08=WHMIS CONTROLLED PROD.

10-OTHER CARCINOGEN

PA=PA RTK NJ=NEW JERSEY RTK CA=CALIFORNIA PR OP 65

MA=MASS. RTK MI=MICHIGAN 406 MN=MINNESOTA RTK

FL=FLORIDA RI=RHODE ISLAND IL=ILLINOIS

NY=NEW YORK WV=WEST VIRGINIA CT=CONNECTICUT

LA=LOUISIANA ME=MAINE OH=OHIO

16. OTHER INFORMATION

SCOT LUBRICANTS OF PA, INC.

1801 E. TREMONT STREET

P.O. BOX 326

ALLENTOWN, PA 18105

610-433-2527

The information on this form is furnished solely for the purpose of compliance with the OSHA Act, and shall not be

used for any other purpose. The information herein is given in good faith and is based on data considered accurate.

However, no warranty, expressed or implied, is made regarding the accuracy of these data or the result to be obtained

from the use thereof.

Revision: 05/05/2007 NA=Not Applicable ND=No Data NE=Not Established

19

Page 20

MAINTENANCE LOG

Pump Model___________________________

Strokes Per Minute______________________

Piston Diameter________________________

Spare Parts Kit #____________________________________________________________

NEPTUNE CHEMICAL PUMP CO., INC. Tel.: 215-699-8700 • FAX: 215-699-0370

DATE SERVICED BY MAINTENANCE PERFORMED

Serial #_______________________________

Maximum Flow________________________

Maximum Pressure_____________________

20

Loading...

Loading...