Page 1

OPERATING &

INSTRUCTION

MANUAL

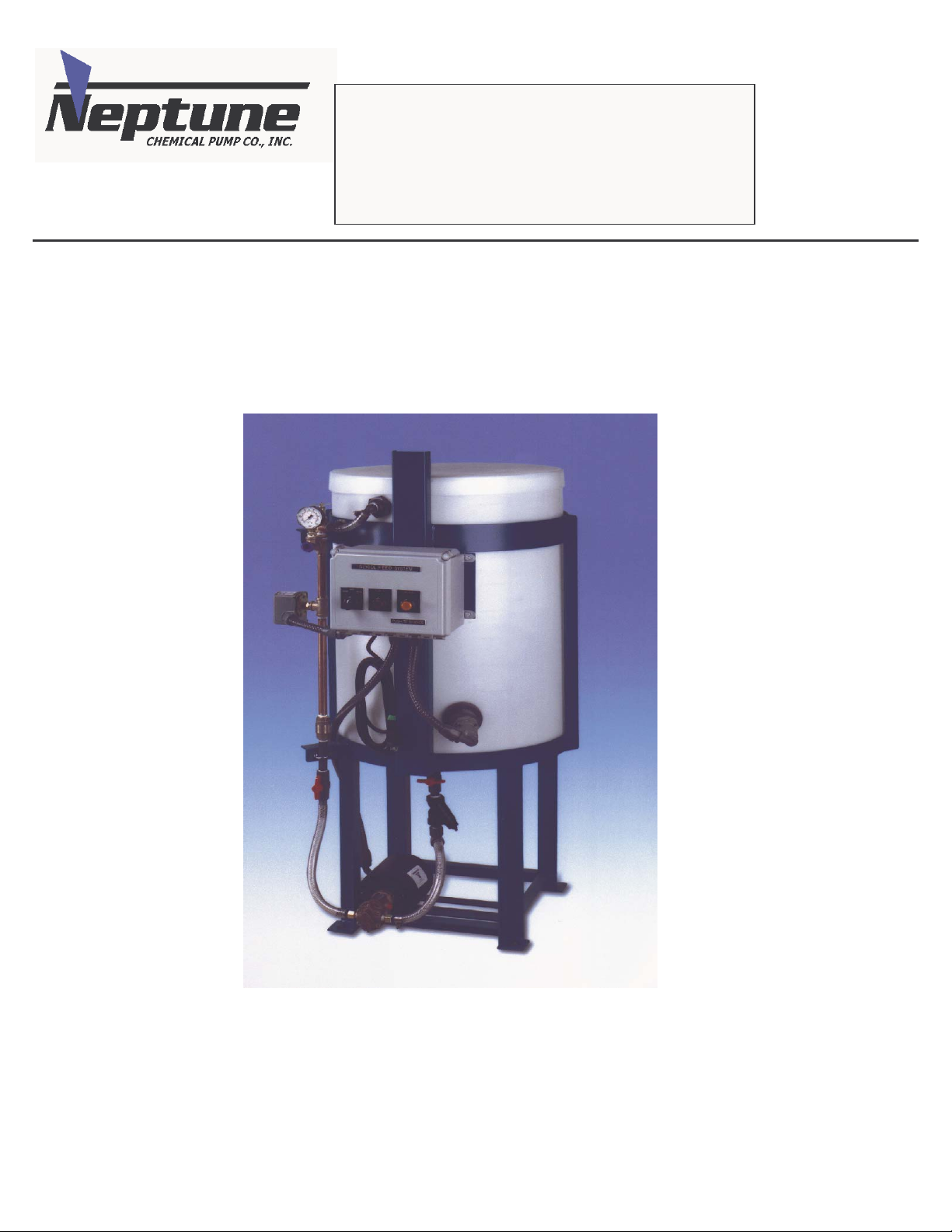

NEPTUNE

GLYCOL FEED SYSTEM

Models G-50-1, G-50-1A, G-50-2A, G-100-1A, G-100-2A

Lansdale, PA 19446 Tel: 215-699-8700 Fax: 215-699-0370

REV NO 6 – 01/08/04

ZL106838

Page 2

I.

GENERAL DESCRIPTION

Neptune Chemical Pump Company’s Glycol Feed System is intended for the automated

addition of glycol into closed loop chille d and hot water syste ms. The Glyco l Feed System

automatically maintains pressure in the loop by adding glycol solution to make up for

losses, which occur due to leakage.

Glycol addition is controlled by a pressure switch with adjustable low and high set points.

When the pressure in the loop reaches the low set point, the pump begins to feed glycol

into the system until the high set point pressure is achieved and stops the pump.

I.

MODELS

The Model G-50-1 or G-100-1 is provided with a 50 or 100 gallon polyethylene tank

mounted in a steel frame, 1.5 gpm bronze rotary gear pump (optional 3.0 gpm pump), float

switch and NEMA 4X control panel. The control panel features a HAND/OFF/AUTO

selector switch for the pump motor, ON indication light for the pump, LOW tank level

indication light and power cord with plug (115V, 60c). The pump suction piping includes

a PVC ball valve and cast iron “Y” strainer. The pump discharge assembly includes a PVC

ball valve, brass check valve, pressure switch, bronze relief valve and pressure gauge.

The Model G-XX-1A is identical to the G-XX-1 and has the addition of an audible

alarm, as well as light for low level tank indication.

The Model G-XX-2A is capable of feeding glycol to two separate closed loop systems

and includes two separate pumps, as well as suction and discharge assemblies.

The LP designation at the end of a model number (ex. G-XX-1-LP) indicates that a 3.0

gpm pump has been provided in place of our standard 1.5 gpm pump.

All glycol systems are provided with a dry contact for remote alarm.

Page 3

II.

OPERATION

The glycol feeder is provided with a control panel with HAND/OFF/AUTO selector

switch.

When the panel is switched to the AUTO position, the pump is actuated via the pressure

switch, which is mounted in the discharge assembly and sensing the pressure in the loop.

The pressure switch is pre-set to start the pump at 12 psi and stop the pump when 30 psi in

the loop is achieved. The adjustment range for the standard pressure switch is 10-45 psi to

start the pump and 20-60 psi to stop the pump. The minimum differential pressure

between the cut in and cut out set points is 10 psi and the maximum is 30 psi. The float

switch in the bottom of the ta nk will stop t he pump if the glyc ol solution in the tank gets to

low leve l.

The MANUAL position of the selector switch in the panel will allow the pumps to run and

inactivate both the pressure switch and the level switch.

PLEASE READ THIS

The initial settin g of the pre ss ur e swit ch is crit ica l

to the proper operation of the glycol feeder.

WARNING

The pressure relief valve is factory set at 60 psi.

DO NOT operate the glycol feeder above 100 psi.

If your application requires a higher operating

pressure, consult the factory.

Page 4

TROUBLESHOOTING

PROBLEM

Pump is running but is 1. The motor rotation is incorrect. The

not pumping anything proper rotation of the motor is counter-clockwise when

Pump is not running when 1. The low level float switch may be

HOA switch is in the AUTO actuated. The low light will be on a nd

position the audible alarm will sound on some

PROBABLE CAUSE

looking at the motor shaft. Check the wiring diagram

on the motor or t he a tta ched motor diagram for prop e r

wiring.

2. On simplex single pump systems – Model G-XX-1 and

G-XX-1A. The motor should be wired for 115V

counter-clockwise rotation. See further information on

the pump, which is attached.

3. Duplex or two pump systems, Model G-XX-2A, require

one pump motor to be wired counter-clockwise and the

other in a clockwise rotation. Looking at the front of

the Model G-XX-2A, the control panel facing you, the

pump motor on the left should be wired counterclockwise and the pump motor on the right should be

wired for a clockwise rotation.

models. Add glycol to the tank until

the leve l s w it c h is sa tisf ie d.

2. The pressure switch in the discharge piping has been

satisfied. The press u re s w itch is factory set to ac tuate

the pump at 12 psi and shut-off at 30 psi. See pressure

switch information for pressure switch adjustment,

which can be found on the inside cover of the pressure

switch.

Page 5

Page 6

Page 7

Page 8

Bronze Rotary Gear Pumps

Installation, Operation, and Maintenance Instruction

INTRODUCTION

Congratulations for choosing an Oberdorfer pump,the Industry Standard for quality since 1890.

Construction

Bronze Rotary Gear stan dard pump hou sings and h elical gears are made of top q u ality bronze. Shafts ar e st ainless steel. Pump s are availab le

with br on ze bearings and gr ease fittings or with carbon bea r ings whi ch require n o lu brication. Dynamic seal arr angem en ts inclu d e packing,

lip, or mechanical seal s for a variety of ap plicat ion requirement s. S tatic cover o- r ing seal s eli minate g asket probl ems.

Application Range

Bronze Rotary Gear pump s are of the ext ernal gear positive displacement t ype, d isplacing a fini te volume of flu id with each shaft revolution.

As such, capaci ty varies in direct pr op ortion t o p um p sp eed . They are s u ited to han d le clear lubricat in g an d n on-lubricating fl ui ds, with PH

ranging from 4 to 11, and temperatures to 400F. These pumps handle viscous fluids to 100,000 cps (462000 SSU) at reduced shaft speeds, with

flow rates to 175 GPM (662 LPM), differential pressures to 150 psig (10.3 BAR), and suction lift capability to 20 feet (6.1 meters ) for new

pumps.

Field Inspection

Bronze Rotary Gear pum ps may be rea dily insp ec ted in the field usually without re moval from the dr ive or s ystem p lumbing. S imply rem ove

the cover screws to pull the cover. Before attempting an inspection, follow safety precautions and be sure to read and understand this

manual.

New Pump Receipt Inspection

Upon r ecei pt, check for obvious s hipping damage and complet eness to p urchase order requ irements. Shorta g es or d amage shoul d be reported

immediately to the carrier and to your Oberdorfer distributor. Occasionally during shipment, possible misalignment or other damage

inclu ding cra cked mechan ical sea l fa ces can occur . As such, cust om ers ar e ad vi s ed to test th e pump with water in a conven ient location prior

to installin g in to the intended s ystem .

Storage

If the pump is to be stored prior to installation, it is recommended that it be left in the original shipping carton with all shipping plugs in

place an d stored in a dry environment avoid ing temperatur e variati ons. Contact the mot or manufacturer for s p ecific motor s t or age

informa tion .

Records

These instru ctions sh ould be kept in a convenient locat ion for ready r eference. The man ua l should be read carefu lly by pers ons responsible

for installation, operation, and maintenance of the equipment. For ease of reference, a copy of the order should be kept with the manual.

Write d own the pump model number as shown on the pump nam etag, and th e date the uni t wa s placed into service.

Page 9

BRONZE ROTARY GEAR PUMP INSTRUCTIONS continued …….

INSTALLATION

Site Preparatio n

Choose a site that a llows easy acces s t o the pum p for mainten ance. Con s i der prot ect ion from th e element s. Guard against drip s and spray

from nearby equipment. Ch oos e a sol id founda tion for mounting. If noi s e is a concern, consider a rubber pad under the pum p base to

dampen.

Flow Direction

Gear pumps will perform equally wel l in eith e r dir ec tion howeve r care mu s t be tak en for pump s equipped wi th in tegr a l pressure relief valves.

To change flow direction effectively reversing the suction and discharge ports, simply switch driver rotation by following motor wiring

diagram instructions and change the location of the relief valve as shown below. Most pump motor units are factory supplied with

counterclockwise shaft rotation (when viewing the pump from the shaft end).

Suction Plumbing

Suction side plumbing considerations are key to desirable pump performance. Minimize head loss by assuring sufficient pipe size (especia lly

important for highly viscous services). Generally the same size pipe as the pump ports is adequate. For long runs (beyond 3 feet) or visc ou s

fluids, use one or two pipe sizes larger. Strive to keep the lines as short and straight as possible. If flexible lines are used, they shoul d be

selected to prevent wall col lapse. To keep th e pum p fr om bei ng starved or running dry, be sure there is s u fficient fl u id supply. A flooded

suction is generally preferred . S uctio n l ifts over 3 vert i cal feet and l ong hor izontal ru ns (bey ond 3 l ineal fee t ) req uire a foot or check valve

below the level of the liquid being pumped. When taking suction from a tank or vessel, position the inlet above the maximum expected level

of solids. Use full-bore ball valves or gate valves to minimize restriction. Suction strainers should be properly sized to minimize press ure

drop and positioned for easy cleaning access. If st ar t-up scr eens are used , be su re they ar e r emoved prior to pla cin g the system in to regular

operation. Orient lines so as to prevent formation of air pockets. Be sure all joints are tight. Flush out all suction lines prior to installing the

pump.

General Piping

For further eas e of m aintenance, use union fittings t o connect the pump to the s ystem. In stall a di s ch ar g e pr iming tee for conven ience. D o not

spring the piping to connect the pump. Use piping supports or hangers as required. When necessary, provide for thermal expansion and

contraction to avoid placing strain on the pump.

Alignment

Proper alignmen t is key to seal an d bearin g p er forman ce. Improp er alignment can lea d t o premature pump failure. Ch eck th e alignment

carefu lly between the p um p an d th e dr ive.

Belt Drive

Though alignment is not as critical as direct connected, ensure that the pump and motor shafts are parallel and in line. For units suitable for

belt drive, be sure that the belt tension is adequate (per the belt manufacturer’s recommendation) but do not overtighten. For heavy pulley

loads, models are equipped with external ball bearing supports. A single 1/2” (A or 4L section) V-belt is satisfactory for drive speeds up to 1

HP 3450 RPM. For larger drive sizes, double-V belts are recommended. Install guards around all moving parts in accordance with OSHA to

prevent per son al injury.

Fasteners

Unless the pump has been shipped directly from the factory, it is recommended to check all bolts and nuts for tight-ness to eliminate pos s ib le

lea kag e problems or destructive vibration.

Pressure Relief

Discharge lines should be fitted with properly sized line pressure relief valves to protect both the pump and the system. Pumps equipped with

integral internal bypass relief valves are intended as a safety device against intermittent overpressurization. They are not designed for

continuous us e an d can lead to overheatin g . In these in st ances, a line press ure reli ef va l ve is required. The r elief outlet should be piped back

to the suction vessel.

Page 10

BRONZE ROTARY GEAR PUMP INSTRUCTIONS continued …….

Flow By-Pass

When a flow b y-pa s s syst e m is used t o c ontrol ou tput from th e pump, the bypa ssed fluid shoul d be direct e d back to t he suc tion vessel to

avoid recirculation heat build-up. In cases where this is not possible, connect to the suction at least 10 pipe diameters length away from the

pump inlet. Provisions for cooling should be made in the event of recirculation heat build-up.

Pump Driver Mounting

Adapter kits (including bracket, coupling components, and hardware) are available for Bronze Close Coupled Gear pumps allowing

conn ectivit y to NE MA an d IEC motor fra mes. Assem bly instructions are included with each kit. A da p terless mot ors, car bon ator mounts, and

electric clut ches are a va il able for som e models. Base mount ki t s (includin g ba sep late, cou p ling comp onents, coup ling guard, and hardware )

are ava ilable for Bronze Ped es tal Gear p um p s . C on t act your Ober d orfer rep resent ative for a d ditional informa tion.

OPERATION

Pre-Startup

Prior to start-up, recheck installation as described above. Verify desired rotation by jogging the motor and make corrections if necessary.

Before initia l s tartup, pre-wet the gears an d ma k e s ure the pump is ad eq u ately primed. Failure t o do so could cau se immediat e damage to

pump comp onents. M ake sure tha t d ischar g e val ves a re open.

Startup

Start pump and check for proper operation. Adjust packing (if applicable) as necessary, allowing adequate time to run in. Do not overtighten

the packing el s e da mage to the pa cking and th e shaft can occur. A proper ly packed and adju sted packing nut will leak at abou t 10 drops

every 3 to 5 minutes. Tighten packing nut only while shaft is rotating. Lip and mechanical seal versions require no adjustment. If the pump’s

bearing areas or seal area runs hot, shut the pump down and determine the cause. For units equipped with integral pressure relief valve, th e

factory settin g is usual ly 50 psig. It is recommended that the setting shou l d be 5 p s ig abo ve t he oper ating pr ess ure in the discharge line. To

incr ease the set p oint, turn th e b y-pass val ve a d ju s ting s cr ew cl ockwise. If start-up screens were u s ed , be sure they are remo ved prior to

placing the system into regular operation. Depending on suction conditions, it may be necessary to reprime the pump for subsequent restarts.

MAINTENANCE

Frequency

Since each installation differs, the frequency and extent of pump maintenance is best established based upon past performance. Keeping

detailed main tenance records of past per formance aids in determin in g futur e preventa tive main tenance intervals. During routi ne operating

inspections, pay particular attention to seal and bearing areas of the pump. Consult the motor manufacturer for motor maintenance

instructions.

Changing Applications

Verify that all wetted parts of the pump are compatible with the new fluid to be handled and that the motor is adequately sized. Check with

your Oberdorfer distributor if in doubt.

Inspect for Wear

If you r Bronz e Gear Pump exhibi ts reduced flow, an inabi lity to maintain pre s s ure, is noisy or per forms ot her wise abnormally, first refer to

the T roubleshooting M a trix on back . If th e probl em persis ts, th e pump shoul d be i nsp e cted for wear or damage. Oberdorfe r Bronze Gear

pump int erna ls may be rea dily insp e c ted in the fi e ld u s ually without removal fr om th e drive or syst e m pl umbin g. Sim ply r e move the cover

screws to pull the cover. Full pump removal and complete disassembly may be needed for a comprehensive inspection. Contact your local

authorized d istributor or th e O berdorfer fa ctory.

BRONZE ROTARY GEAR PUMP INSTRUCTIONS continued …….

Page 11

Mechanical Seals

Pumps eq u ip p ed with mech anical seals are of the standard pusher bellows type or wedge style. Th ey can be expected to provi d e long and

trouble free se rvi ce provided :

1) Seal materials are compatible with pumped fluid and properly applied to the service.

2) Adequate cooling and lubrication is provided

3) Dry running is avoided

4) Abra sives are kept away from the seal ar ea

5) Pump an d dr iver are pr operly aligned

Detai led mechanical s eal inspect ion and rep lacement instr u ctions are included with Ober d orfer Repair Kits.

Lip Seals

Pumps eq u ip p ed with lip seals are of the metal cased, spr in g energized, sing le lip style. These ar e in tended to provide min i mum friction drag

with positive sealing and again should be maintenance free provided the same conditions for mechanical seals are met as well as:

6) Avoid s courin g of the shaft in the lip sea l area due to contamin ated abrasives

7) Avoid excessive seal lip contact pressure on the pump shaft due to excessive pump pressure.

These are rea di ly replaceable by pres s i ng out the old seal and pressing in a new r ep lacement .

Packing

Pumps equipped with teflon or graphoil packing require periodic adjustment as described above in the Startup section to avoid excessive

leakage. Eventually all the packing in the pump will become deteriorated and will have to be replaced.

Recommended Spares

Repair k its are ava ilable for all Oberdorfer Bron ze Gear Pump s. Each ki t com es with det ailed ins tr u ctions. F or the proper kit, contact your

Oberdorfer Di s tr ibutor or th e fa ctory.

Page 12

PRESSURE SWITCH INSTRUCTIONS

SQUARE D

Commercial Pressure Switch

Class 9013, Model FSG29J99

Model FSG29J99

CUT-OUT RANGE 20-60 PSI

ADJUSTABLE RANGE 10-30 PSI

CUT-IN RANGE 10-45 PSI

PRESSURE CONNECTION : ¼” NPT EXTERNAL

ECHNICAL TERMS

T

Operating Points ( S et ting s)

Every pressure swit c h has two operating points; one on risi ng pr essure and one of falling pressure. The operat ing point on rising

pressure is refer r ed to as the TRIP POINT or cut out for pumps and compressors and the operating point on falli ng pressure i s

referred to as the RESET POI NT or c ut in f or pumps and compressor s. These operating points are called the SETTINGS of the

switch.

— TRIP POINT (rising pressure )

— RESET POINT (falling press u re)

Differential

The differenti al is the difference in pressure between the trip point (cut-out) and the reset point (cut-in). It can be adjusta ble or

nonadjustable (f ixed).

Example: Cut-in 30 psi

Range

The range is the pressure lim its within which the operating points (settings) can be adjusted. The range of the Class 9013

pressure switch is referenced to the operating point on rising pressure (trip point). The differenti al subtr ac ts from the trip point

setting. During the normal operating cycle, system pressure should nev er ex c eed the upper lim it of the range when using a

diaphragm actuated switch. This will greatly r educ e the life of the diaphragm.

Maximu m Allowable Pressure

Maximum allowable pr essure is the pr es sure t o whic h a switc h c an be subj ec ted without causing a c hange in operating

characteri stic s, shift in settings, or dam age to t he dev ice. P r essure surges may occur in a system duri ng the start up of a

machine or from valv e operation. Surges are not normally detrimental to the life of a switch if t he surge is within the maximum

allowable pressure rating of the switch. Di aphr agm actuated switches should not be subjected t o more than 10 surges per day.

More frequent surges will greatly reduce the lif e of t he diaphr agm .

Cut-out 50 psi

Differential 20 psi (50-30 psi)

Page 13

PRESSURE SWITCH INSTRUCTIONS continued …..

SET POINT ADJUSTMENTS

The pressure switch is set at the factory to the operati ng point(s) marked on the outside of the switc h housi ng. Before

readjusting t he switc h, cyle it to determine act ual oper ating points.

Non-Adjustable Differential

The range adjustment nut ( Item H, Figure 3 ) or knob ( Item C, Figure 3 ) adjusts both setpoints by t he same amount.

To adjust the operating points :

1. Place a flat blade screwdriver in a range adjustment nut slot.

2. Rotate the nut to the left t o inc r ease the oper ating points or to the right to dec r ease t he oper at ing set points.

Adjustable Differential

The range adjustment nut or knob determines the decreasing setpoi nt. The adjusti ng screw ( Item J, Figure 3 ) determines the

increasing setpoi nts. To adjust the operati ng points :

1. Adjust the decreasi ng setpoint ( see steps 1 and 2 above ).

2. Turn the adjusting scr ew cl oc k wise ( t o r aise the increasing setpoint ). This adjustment does not aff ect the

decreasing setpoint.

FIGURE 3

Page 14

INSTALLATION INSTRUCTIONS LL-3 (L-30N)

LIQUID LEVEL SWITCH

MODEL L30N LIQUID LEVEL SWITCH

INSTALLATION AND OPERATING INSTRUCTIONS

Installation:

The L-30 liquid level switch is supplied with a 1-1/2” or 1-1/4” X 1 bushing threaded in place

with 2 to 3 wraps of teflon tape, which must be intact or renewed if bushing and switch are

separated before assembly in tank. Care must be exercised when threading the bushing

into plastic or metal fittings. Apply a minimurn of 2 to a maximum of 3 wraps of teflon tape

to threads of bushing - this is especially important if unit is to be used in metal fittings where

coarse

METAL THREADS could gall plastic if not lubricated. The plastic bushing CAN BE

CRACKED if the main body of the flow switch is tightened into it FIRST. Cracking will not

occur if the bushing is FIRST tightened into the pipe or tank fitting and THEN the L-30 body

is tightened into the bushing.

Thus:

1). Teflon tape thread and tighten plastic bushing into pipe or tank fitting.

2). Teflon tape thread and tighten L-30 switch into PLASTIC bushing by applying wrench to

hexagon section. Repeat steps I and 2 until ARROW on

body points to UPWARD and

threads are, leak tight.

Plumbers'tools such as pipe wrenc hes are not recom m en de d. If possibl e us e a "Ridgi d"

typ e wrench where the smooth jaws closely fit the hexagon section.

Electrical Wiring:

1). Remove gland nut, grommet and switch cover.

2). Strip outerjacket of electrical cord back

3). Slip on terminals are

individual conductors supplied with each switch. approximately 1-1/4". Strip insulation

from back approximately 1/4". Remove from switch terminals and

and crimp on or solder to electrical leads.

4). Feed electrical cable throu gh gla nd nut, gr om m et and s witch cov er as sho wn.

Page 15

MODEL L30N LIQUID LEVEL SWITCH

INSTALLATION AND OPERATING INSTRUCTIONS

5). Apply slip on terminals to appropriate contacts of micro switch. Slide cover down

cable and fasten to body of switch with four screws provided. Slide grommet down cable

until outer jacket is level with small end of grommet per illustration page 2. Push

grommet into tapered end of cover. Hold cable jacket to prevent rotation and thread

gland nut firmly on to cover.

Fig. 1: Wiring schematic for power applied to load when liquid level is less than set point

(power to load inter ru pte d when l evel increa ses to ab ove set point).

Fig. 2: Wiring schematic for power applied to load when liquid level is greater than set

point (power to load interrupted when level decreases to below set point).

Figure 1 Figure 2

Microswitch actuation point may be monitored by an audible click or with an OHM meter

before connecting line power to the terminal strip or by monitoring the voltage supplied to

the load through the microswitch.

Loading...

Loading...