Your Pump House Condensate Pump is designed as an automatic condensate

removal

pump for pumping away room temperature condensate water dripping

from

air conditioner/refrigeration evaporative coils. The pump is controlled by a

float/switch

mechanism which turns the pump on to discharge the water when

approximately

55mm depth of water collects in a tank. The pump automatically

switches

off when the tank drains to approximately 30mm deep.

The

Pump House Condensate Pump you have purchased is a high quality

product

that has been engineered to give you long and reliable service.

This

pump is carefully packaged, inspected and tested to ensure safe operation

and

delivery. When you receive the pump, examine it carefully to determine

there

are no broken or damaged parts that may have occurred during

shipment.

If damage has occurred, please contact your supplier. They will

assist

you in replacement or repair, if required.

READ

INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO INSTALL,

OPER

ATE OR SERVICE THE PH-2L PUMP. KNOW THE PUMP APPLICATION,

LIMITATIONS AND POTENTIAL HAZARDS. PROTECT YOURSELF AND OTHERS

BY OBSERVING ALL SAFETY INFORMATION. FAILURE TO COMPLY WITH

INSTRUCTIONS COULD RESULT IN PERSONAL INJURY AND/OR PROPERTY

DAMAGE! RETAIN INSTRUCTIONS FOR FUTURE REFERENCE. INSTALLATION

AND

CONNECTIONS ARE TO BE MADE BY A QUALIFIED PERSON.

SAFETY GUIDELINES

DO NOT USE TO PUMP FLAMMABLE OR EXPLOSIVE FLUIDS SUCH AS

PETRO

L, FUEL OIL, KEROSENE, ETC. DO NOT USE IN EXPLOSIVE

ATMOSPHERES. PUMP SHOULD BE USED WITH LIQUIDS COMPATIBLE

WITH

PUMP COMPONENT MATERIALS.

DO

NOT HANDLE PUMP WITH WET HANDS OR WHEN STANDING ON WET

OR

DAMP SURFACE, OR IN WATER. THIS PUMP IS SUPPLIED WITH AN

EARTHING

CONDUCTOR AND/OR EARTHING TYPE ATTACHMENT PLUG. TO

REDUCE

THE RISK OF ELECTRICAL SHOCK, BE CERTAIN THAT IT IS

CONNECTED

TO A PERMANENT EARTH.

FOR

INSTALLATIONS WHERE PROPERTY DAMAGE AND/OR PERSONAL

INJURY

MIGHT RESULT FROM AN INOPERATIVE OR LEAKING PUMP DUE TO

POWER

CUTS, DISCHARGE LINE BLOCKAGE, OR ANY OTHER REASON, A

BAC

KUP SYSTEM(S) AND/OR ALARM SHOULD BE USED.

SUPPORT THE PUMP AND PIPING WHEN ASSEMBLING AND WHEN

INS

TALLED. FAILURE TO DO SO MAY CAUSE PIPING TO BREAK, PUMP TO

FAIL, MOTOR BEARING FAILURES, ETC.

INSTALLATION

1. Carefully unpack the pump. Remove the cardboard packing from the motor

cover

air slots. Carefully slide the packing away from the pump. This

packing

is used to prevent switch movement during shipment (Fig. 1).

INTRODUCTION

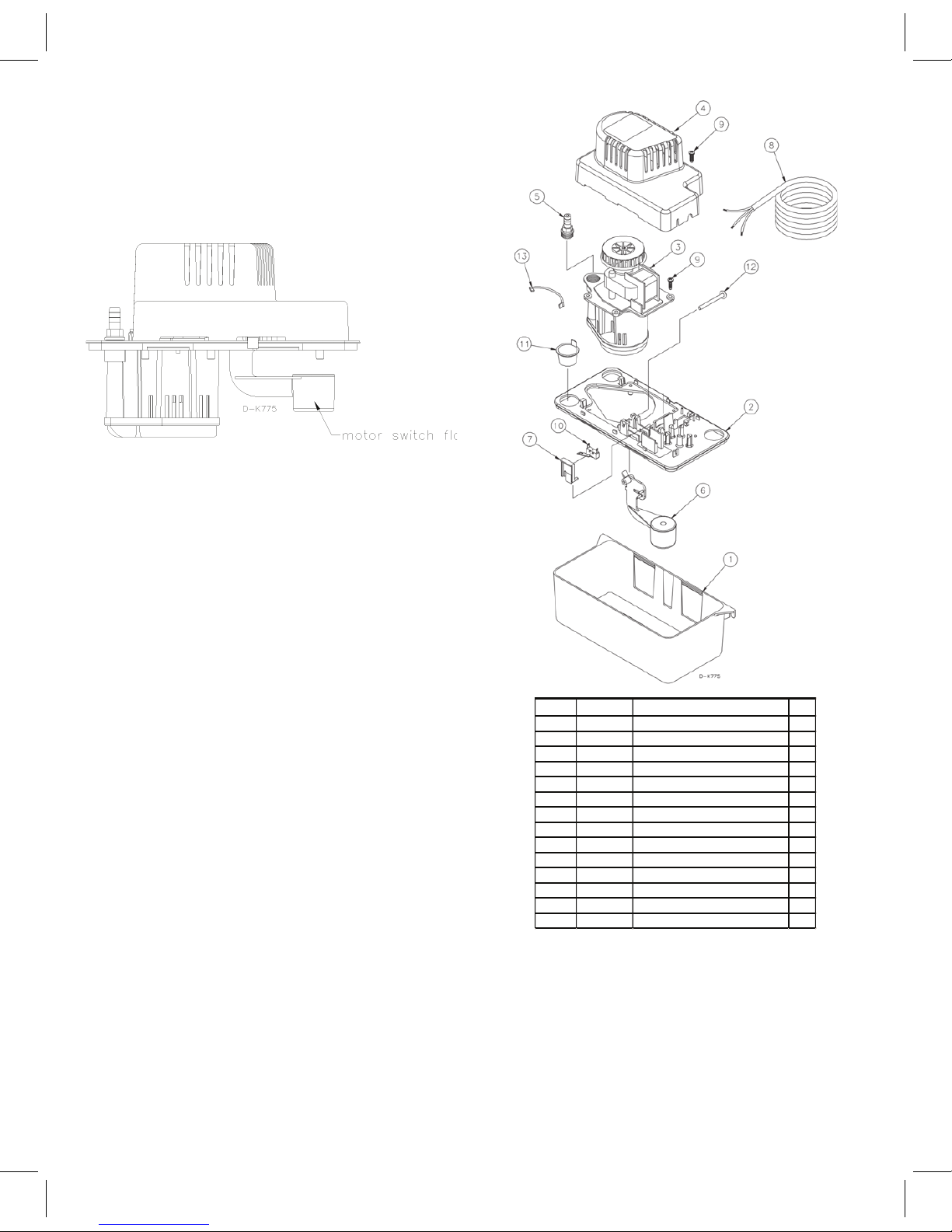

2. Mounting the pump: The tank has two slots provided to mount the unit

on a vertical surface such as an adjacent wall. The slots are located on

the

ends of the tank (Fig. 2). Pump must be level and the inlet must be

below the coil drain. Conduit fittings are not compatible with the plastic

pump housing.

3.

The pump should not be installed in a manner that will subject it to

splashing

or spraying.

4.

This pump is not intended for use inside air plenums.

ELECTRICAL CONNECTIONS

1. Shut off electrical power at fuse box before making any connections. All wiring

must

comply with local codes.

2. Line

voltage: Connect pump to voltage specified on label located on

pump.

Wiring is as follows:

Live

(Line) - Brown

Neutral

- Blue

Earth

- Yellow/Green

3. If fused plug is used, a 1.0 amp fuse is recommended.

WATER DRAIN CONNECTIONS

Inlet Water Connections

1.

Position pump beneath a/c or refrigeration condensate drain so that

condensate

water flows into pump inlet freely (use any of the three

openings

provided).

2.

The pump will accept up to three drain lines, although care should be

used

to make certain that total inflow does not exceed outflow of pump.

If

more water drains into the pump than the rated output of the pump,

tank

may overflow.

3.

Keep plugs in unused pump inlet openings to prevent debris from falling

into

the pump tank.

Outlet

Water Connections

1.

Connect 3/8" I.D. tubing to the discharge adapter (item 5, figure 4). For best

results, secure tubing with clamps (not provided) but do not pinch collapse

or

otherwise restrict the tubing.

2.

Tubing should rise vertically but not exceed the maximum shut off head

(pumping

height) of 4.8 metres above the pump.

3.

At highest point angle tubing horizontally and create a downward slope

to

drainage point. Do not sharply bend or twist the tubing in a way that

might

result in collapse or restriction of the tubing. Creating a

downward

slope will allow water to drain by gravity and keep tubing

empty

of water.

4. If it is not possible to create a downward slope, try to create an inverted “U”

trap

directly above the pump at the highest point.

1

CONDENSATE

REMOVAL PUMP

PH-2L

Figure 1.

Figure 2.

Remove cardboard insert.

Check Valve

Mounting Slots

COMMISSIONING & MAINTENANCE

1. Before servicing the pump, disconnect the electric power at the fuse box.

2. Upon commissioning, check for debris in the drain pan. Remove any

material that might block the drain line or drain into the pump tank.

3. It is recommended that the pump be checked every six months for proper

operation. Most important is to check for debris blocking the pump

discharge adapter/check valve. Check for proper free movement of pump

float (Figure 3) and switch and check for free, unrestricted movement of

motor and fan.

4. Clean the holding tank and float with warm water and mild soap. Rinse

completely when finished.

5. Check the inlet and outlet piping. Clean as necessary. Be sure there are no

kinks in the outlet line that would inhibit or restrict flow.

TESTING

1. Turn on power.

2. Remove motor/tank cover assembly and hold level.

3. Test motor switch by raising motor switch float with finger (Figure 3). Motor

should turn on just before float contacts underneath side o f cover.

4. Replace motor/tank cover assembly on tank.

2

Figure 3.

ITEM P/N Description QTY

1 14940690 Tank 1

2 154411

Tank, Cover 1

3 154493 Motor,Plate,Volute , Assy 1

4 14940097 Cover, Motor 1

5 154715 Check Valve 1

6 154452 Float Arm 1

7 154471 Sw itch Holder 1

8 951089 Wiring Harness A

ssy ,

230V, 6FT. 1

9 902414 Tapping Screw 5

10 950337 Sw itch 1

11 929602 Drain Hole Plug 2

12 154455 Float Pivot Pin 1

13 951941 Lead Wire Assy 1

14 154037 1/4" ID Tubing Adaptor (Not Shown) 1

Motor Switch Float

Form 998389 — 09/2006

Figure 4.

Loading...

Loading...