Service instruction

K 101, K 151, K 200, K 250, K 300

(M50 Motors)

K 101/151/200/250/300.58.0404.Eng/Digital

2 (15)

K 101/151/200/250/300.58.0404.Eng/Digital

SERVICE INSTRUCTION

K 101, 151, 200, 250, 300

Table of Contents

Introduction.............................................................................................................................3

Cross-sectional drawing........................................................................................................4

Nameplate..................................................................................................................4

Safety Precautions................................................................................................................4

Minimizing Environmental Impact..........................................................................................5

General Maintenance.............................................................................................................5

Disassembling

Removal from the Wet Well....................................................................................................6

Disassembling the Volute.....................................................................................................6

Adding and Changing the Oil..................................................................................................6

Changing the Cooling Liquid..................................................................................................7

Inspection of Terminal Board Area.........................................................................................7

Disassembling the Terminal Housing....................................................................................8

Disassembling the Cooling Jacket.........................................................................................8

Disassembling the Impeller....................................................................................................8

Disassembling the Seal Cartridge..........................................................................................8

Changing the Stator Unit........................................................................................................8

Disassembling the Stator.......................................................................................................9

Disassembling the Rotor and Bearings...............................................................................10

Assembling

Mounting...............................................................................................................................10

Mounting the Bearings.........................................................................................................10

Mounting the Rotor in the Oil Housing.................................................................................11

Mounting the Stator...........................................................................................................11

Mounting the Seal Cartridge.................................................................................................11

Mounting the Impeller.........................................................................................................12

Mounting the Cooling Jacket................................................................................................12

Mounting the Cable Seal......................................................................................................12

Mounting the Terminal Housing............................................................................................12

Mounting the Cover..............................................................................................................12

Mounting the Motor Unit to the Volute..................................................................................13

Adjusting the Wear Ring.......................................................................................................13

Testing.............................................................................................................................13

Recycling in Case of Scrapping the Pumps........................................................................13

Wiring Diagram.....................................................................................................................14

Torque Rating........................................................................................................................15

3 (15)

K 101/151/200/250/300.58.0404.Eng/Digital

SERVICE INSTRUCTION

K 101, 151, 200, 250, 300

This service manual covers pumps K 101, K 151, K 200, K 250 and K 300 with M50 motors in

the following designs:

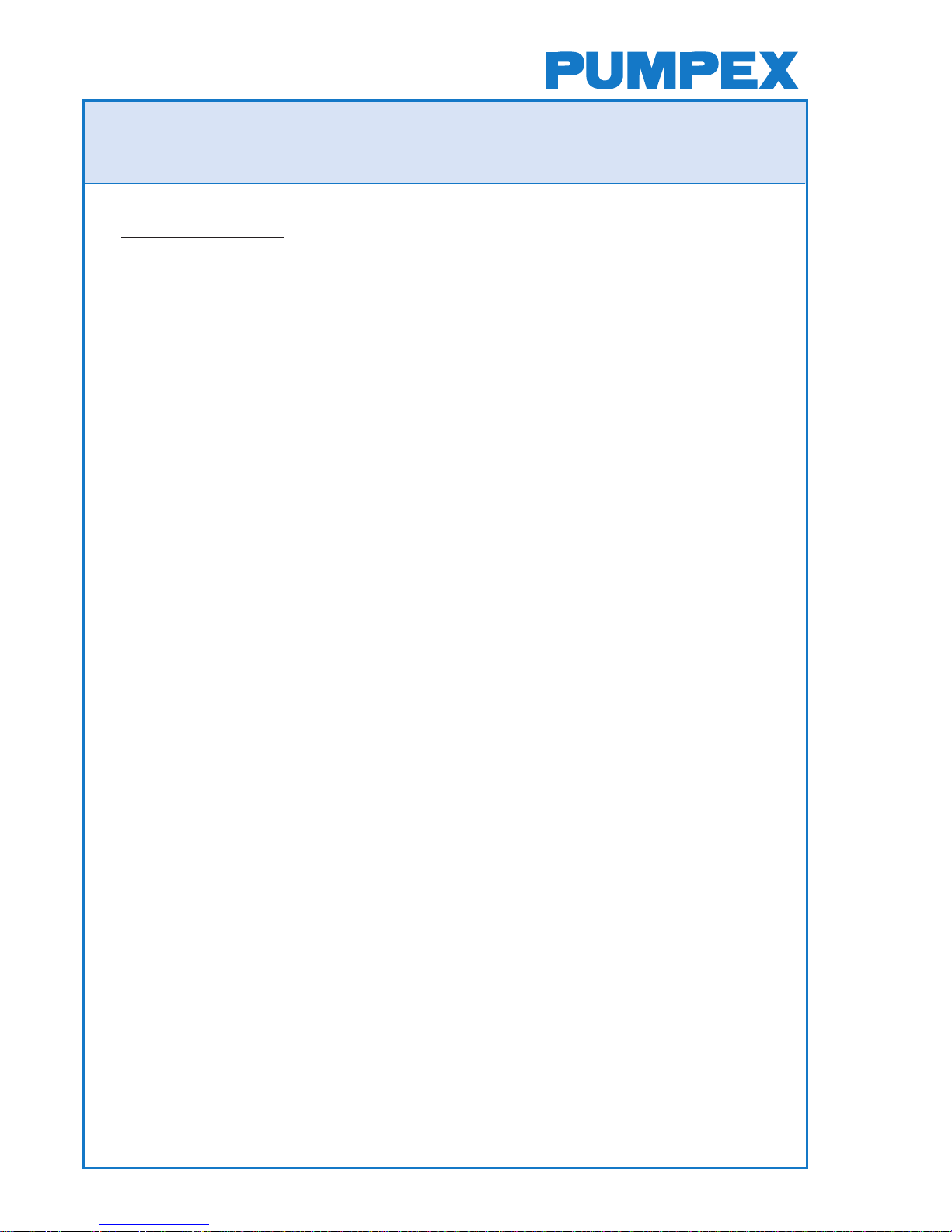

Type F Wet Pit Installation

Installed on a guide rail system with a quickrelease base elbow, the base elbow is bolted

to the floor of the sump. The volute is equipped

with an adapter to be connected to the

discharge elbow.

Two twin guide rails are mounted to the

discharge elbow to steer the pump into the

right position when hoisted up and down. In

case of Wet Pit Installation, the driving units

lack an internal, closed loop cooling system.

Type T, Vertical Dry Pit Installation

Type H, Horizontal Dry Pit Installation

Installed with a suction pipe. The pump is

supported by an adjustable fabricated steel

stand, mounted at the factory.

The height of the stand is sufficient for the

standard suction elbow to be used on a flat

floor. The pump volute is drilled or threaded on

the connection-flange and equipped with studs

on the suction-flange. The motors are equipped

with a maintenance-free internal, closed loop

cooling system.

Type P, Wet Pit Portable

Installation

A version of the pump which is suitable for

temporary installations. The pump is

equipped with a fabricated round steel stand

and a discharge spigot

for a hose or threaded

connection. The minimum

water level in the wet

well for continuous

operation should not be

below ¾ of the motor

housing.

For continuous operation

at water levels below the

abovementioned level,

an internal cooling jacket is recommended.

Intermittent operation down to a water level

below the top edge of the volute is not

acceptable.

4 (15)

K 101/151/200/250/300.58.0404.Eng/Digital

SERVICE INSTRUCTION

K 101, 151, 200, 250, 300

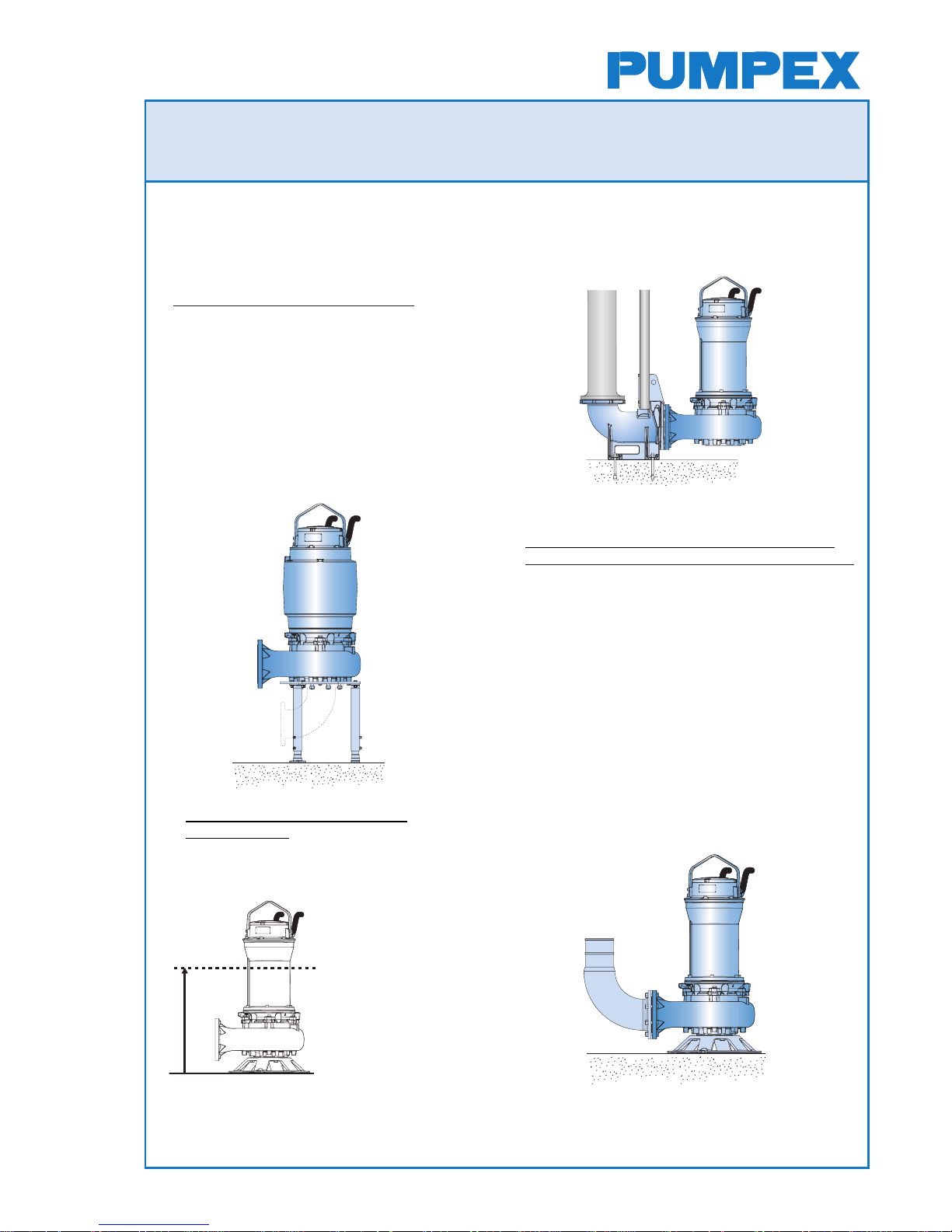

○○○○○○

○○○○○○○○○○○○

○○○○○○

○○○○○

○○○

○○○○○○

○○○○○○○○○○

○○○

○○○○○○○

○○○○

Box 5207 S - 12118 JOHANNESHOV SWEDEN

5

6

7

8

9

1

2

3

4

K 101

No 10119999 P.2 45 kW

3 Ph 50 Hz

U 400 V Y n 1465 rpm Class F IP68

I 81 A 717 kg

20 m

Volute

EcoCool

TM

Internal Closed

Loop Cooling

System

Impeller

SmartSeal

TM

Seal Cartridge

Stator Unit

Rotor

Optimizer

TM

Adjustable Wear Ring

Cable Seal

Guide Rails

Discharge Elbow

Safety Precautions

Notice: When performing repairs, the safety instructions in the Service instruction under the

Installation and Operating Instructions, especially the section entitled ”Safety”, must be

observed. When performing any work, appropriately sized and adequately dimensioned hoists

and other tools should be used. Do not work under a suspended load.

Before doing any maintenance or repairs to the pump, make sure that it is isolated from the

power supply and ensure that no one can reconnect it while being worked on. Never move

or lift a pump by using the cable.

If the pump has been working in sewage or similar substance, before working on it, use a

power or steam hose to clean it, and observe personal hygiene precautions.

Electrical work on the pumps should only be performed by qualified personnel.

1 Type of pump

2 Serial Number

3 Working voltage

4 Rated current

5 Rated power

6 Speed of rotation

Notice! Standard nameplate

7 Frequency

8 Winding Class

9 Weight

5 (15)

K 101/151/200/250/300.58.0404.Eng/Digital

SERVICE INSTRUCTION

K 101, 151, 200, 250, 300

Minimizing the Environmental Impact

A life cycle analysis shows that the larger part of the environmental impact caused by

pumps arises in the operating phase. In the five categories of environmental impact, the

operating phase constitutes the major part. The operating phase is vitally important,

especially in the case of greenhouse gases discharging. This is due to the energy that the

pump is using while in operation.

Therefore, it is important to operate the pump with as little energy as possible, which, in turn,

helps to reduce the operating costs.

Points to be Observed:

1. Choose a pump that has the best efficiency and the duty point should be as near as

possible to the best efficiency.

2. Do not choose a pump that is too big.

3. Adjust the wear ring against the impeller when the flow significantly decreases.

4. Change the parts if it is not possible to adjust the pump flow to the original value.

General Maintenance Advice

Before assembling, all parts should be carefully checked.

Parts being reused must be in perfect condition and carefully cleaned before fitting.

The pump and its electrical cables must be disconnected from any power source

by a qualified electrician before any inspection or service is performed!

6 (15)

K 101/151/200/250/300.58.0404.Eng/Digital

SERVICE INSTRUCTION

K 101, 151, 200, 250, 300

Oljeavtappning

Motor

Oljepåfyllning

○○○○○○○

DISASSEMBLING

Removal from the Wet Well

Hoist the pump from the sump and rinse it clean.

Disassembling the Volute

The motor unit is connected to the volute with six

bolts. Loosen the locking screws, turn the latch bolts

90

o

and lift off the motor unit from the volute.

(Fig. 1-2)

Adding and Changing the Oil

The oil housing of PUMPEX wet pit pumps is filled

with oil at the plant.

Type of Oil:

White Oil (e.g. Enerpar M002 or Similar).

Oil Amount:

4 dl (0.9 US pints) F - T – P installation

5 dl (1.1 US pints) H - installation

Remove the plug marked ”oil out” and slant the pump

slightly forward. Let the old oil pour out through the

groove under the plug. Then loosen the plug marked

”oil in” to facilitate the oil draining out. Gather the old

oil in the can. Fasten the plug so that the lower, not

the top O-ring gasket becomes sealed.

Fill new oil in "oil in" and fasten the plugs.

Inspect the motor housing to see if it is dry by

removing the screw marked ”motor”. Tilt the pump

slightly. If water, oil or other debris is present in the

motor housing, a full dismantling is required. (Fig. 3)

Fig 1

Fig 2

Fig 3

QuickLock

TM

Latch Bolts

Oil filling

Oil out

Motor

7 (15)

K 101/151/200/250/300.58.0404.Eng/Digital

SERVICE INSTRUCTION

K 101, 151, 200, 250, 300

Changing the Cooling Liquid

First disassemble the motor unit from the volute.

Pump Without Cooling Jacket:

Loosen the cooling liquid plug down on the cooling plate. Open

the plugs on top of the oil housing and let the old water pour out.

Replug the lower plug on the cooling plate. Slowly fill the new

cooling liquid into one of the holes on top of the oil housing. Let

both plugs on the top open to avoid air bubbles which will obstruct

the filling.

Note! Do not forget to tighten the plugs after filling is

complete.

Pump Without Cooling Jacket - Cooling Liquid, Quantity:

5.5 l (11.6 US pints)

30% Propylene glycol DOWCAL ® 20

Pump With Cooling Jacket:

Loosen the cooling liquid plug down on the cooling plate. Open

the plugs on top of the cooling jacket and let the old water pour

out into a can. Replug the lower plug on the cooling plate. Slowly

fill the new cooling liquid into the hole marked ”in” on top of the

cooling jacket. Let both plugs on the top open to avoid air bubbles

to obstruct the filling.

Note! Don´t Forget to Tighten the Plugs after Filling is

Complete.

Inspection of the Terminal Board Area

Remove the four screws that hold the cover in place. Lift the

cover carefully. To make it easier, the cable cover can be

loosened so that the O-ring gasket does not continue to seal.

Pump With Cooling Jacket - Cooling Liquid, Quantity:

Motor Liter US pints

50Hz:

22kW-4, 30kW-4 18.5kW-6 49.5 105

37kW-4, 45kW-4, 22kW-6, 30kW-6

37kW-6, 15kW-8 44.0 93

60Hz:

25kW(33Hp)-4, 35kW(47Hp)-4, 22kW(29Hp)-6 49.5 105

43kW(57Hp)-4, 52kW(69Hp)-4, 25kW(33Hp)-6

35kW(47Hp)-6, 43kW(57Hp)-6, 17kW(23Hp)-8

22kW(29Hp)-8, 25kW(33Hp)-8, 35kW(47Hp)-8 44.0 93

(30% Propylenglykol DOWCAL® 20)

8 (15)

K 101/151/200/250/300.58.0404.Eng/Digital

SERVICE INSTRUCTION

K 101, 151, 200, 250, 300

Disassembling the Terminal Housing

Disassemble cover as instructed above.

Remove the six screws that hold the terminal housing in place.

Loosen the cables coming out of the motor unit from the terminal

block. The cable lugs have to be removed before cables can be

pulled through the cable seals. Lift the housing carefully.

Note! Always Check how the Cables are Connected

Inside the Block.

Disassembling the Cooling Jacket

Disassemble terminal housing as instructed above. Use the two

M10 holes on the top of the cooling jacket to lift off the cooling

jacket. If needed, use eyebolts for help.

Note! If only the Bearing and the Seal Have to be

Disassembled, the Cooling Jacket May Stay in Place then Disassemble Only the Terminal Housing as

Described Above.

Disassembling the Impeller

The impeller is bolted to the shaft with a flat key and a bolt.

Securing the impeller with a pipe or similar tool, remove the

impeller bolt with a wrench (Fig. 4). To loosen the impeller, it

often helps to pry with a couple of strong screwdrivers between

the impeller and the cooling plate.

Disassembling the Seal Cartridge

Disassemble volute and impeller as instructed above, and empty

the pump of cooling liquid and oil. Lay the motor unit on its side.

Remove the four screws that holds the seal cartridge. The

cartridge can be removed from the oil chamber by inserting two

M8 screws (40 mm (1

9

/16") long) into the ”jacking holes” in the

cartridge or a M8 threaded plug, which will force the cartridge

from the housing (Fig. 5).

Changing the Stator Unit

If the motor protection trips repeatedly, the stator has to be

overhauled. Disconnect the pump from the electric box. Check

the isolation resistance of the motor at the loose end of the cable.

Use a megger.

Fig 4

Fig 5

9 (15)

K 101/151/200/250/300.58.0404.Eng/Digital

SERVICE INSTRUCTION

K 101, 151, 200, 250, 300

Stator med

urpressningsverktyg

If using a 500 V megger the insulation resistance shall exceed

0.5 megaohm. This applies to phase-to-phase readings as well

as between each phase to ground. If the insulation resistance is

less than 0.5 megaohm, the stator should be dried in an oven.

Also check the resistance in the stator. Disconnect the stator

cables from the terminal block and measure directly at the stator

cables.

Note! Notice How the Cables are Connected on the

Terminal Block.

Also check the circuit with the three built-in thermal overload

switches using a buzzer or a bell. If the circuit is open, probably

one of the overload switches is defective.

If the stator still cannot be used, it has to be replaced. Disconnect

the stator from the outgoing cables and disassemble it. Order an

exchange stator unit from the nearest Pumpex Service Center.

Disassembling the Stator

Disassemble the terminal housing as instructed above.

Remove the six screws that hold the stator casing. Use three

M16 screws and thread them into the three threaded holes at the

lower flange so that the stator unit is lifted up from the oil housing.

Gently, with a hoist (recommend Eyebolt M16),lift the stator

casing from the rotor/shaft. Note! Disconnect the cable from the

moisture sensor in the oil housing before the stator is totally lifted

up. Put the stator unit on a distance tube.

Place the pressure tool on the stator and pull the stator out of the

casing (Fig. 6).

Note! Record the Distance from the lower edge of the

Stator Housing to the Edge of the Stator Before the

Stator is Pressed Out.

Stator with

Pressure Tool

Fig 6

10 (15)

K 101/151/200/250/300.58.0404.Eng/Digital

SERVICE INSTRUCTION

K 101, 151, 200, 250, 300

Disassembling the Rotor and Ball Bearings

The rotor is mounted in the motor unit with an upper and two

lower bearings. Install the eyebolt (M16) into the drilled hole in the

shaft (Fig.7).

Carefully lift out the rotor with the upper bearing from the oil

housing. Bearings that have been in contact with water or are

damaged should

always be replaced.

Fasten the rotor in a vice with soft jaws. Clean the shaft and

lubricate it. Place the withdrawing tool on the upper bearing and

make sure it pulls the inner ring. Remove the bearing.

If the lower bearings are on the shaft, pull them off with your

hands. Pick up the lower bearings if they are still in the oil

housing.

ASSEMBLING

Mounting

While mounting the motor unit, be extremely careful and make

sure everything is clean. Clean all O-ring grooves and all other

contact surfaces carefully. Use a wire brush when necessary.

Lubricate all O-rings with oil or grease to prevent the O-rings

from getting stuck or damaged when remounting. Also, lubricate

all threads on the screws to facilitate disassembling when

servicing next time.

Mounting the Ball Bearings

Check that the shaft is straight and the key slot is not damaged.

Polish deep scratches and burrs off. Push the upper bearing into

place. If a press is not available, heat the bearing to 100-120°C

(212-248°F) in an oilbath.

Wipe off the shaft contact surfaces of the bearing and mount it.

Mount the lower bearings in the oil housing by using a pipe with

the same external diameter as the bearing external diameter in

order to keep the bearings in place in the oil housing when the

rotor is mounted (Fig. 8).

NB! Do not Forget to Refill the Bearings with Grease.

Fig 7

Fig 8

11 (15)

K 101/151/200/250/300.58.0404.Eng/Digital

SERVICE INSTRUCTION

K 101, 151, 200, 250, 300

Stator med

inpressningsverktyg

Mounting the Rotor in the Oil Housing

Heat the oil housing before mounting the rotor (Fig. 9). Lift the

rotor carefully in place with help of an eyebolt (Fig.10).

Mounting the Stator

Push the stator in with the pressure tool (Fig. 11).

Note! Remember the Measurement taken from

”Dismounting the Stator”.

Pull the cables from the stator through the cable seals on the

terminal housing. Connect the cables onto the terminal block

according to the wiring diagram on page 14. Put the terminal

housing with the O-ring in their place.

Let the oil housing with rotor cool down so that the bearings will

take hold. Erect the oil housing and clean all contact surfaces

between the oil housing and the stator unit with a wire brush.

Lubricate and mount a new O-ring in the oil housing. The stator is

now ready to be mounted on the oil housing. Note that space is

required for the shaft end when it sticks out after mounting.

Lift the stator unit with a lift device and carefully lower it over the

rotor. Do not forget to reconnect the cable to the moisture sensor

in the oil housing. Check that the rotor does not damage the

windings or the stator core. Fasten the stator with the six screws.

Note! Be sure that the Cooling Channel Holes in the

Stator Housing are in line with Cooling Channels/Plugs

in the Oil Housing.

Mounting the Seal Cartridge

Put down the motor unit. Lubricate the shaft and all four O-rings

on the seal unit (three external on the seal housing and one

internal in the seal sleeve).

Push the seal unit onto the shaft, and carefully place it in position.

Do not use hard striking tools. Tighten the seal unit by

fastening the four screws.

NOTE! If the Seal is Mounted, Never Run the Motor

Without Having the Impeller Mounted. This Can Cause

Damage to O-rings in the Seal.

Stator with the

Pressure Tool

Fig 11

Fig 10

Fig 9

12 (15)

K 101/151/200/250/300.58.0404.Eng/Digital

SERVICE INSTRUCTION

K 101, 151, 200, 250, 300

Mounting the Impeller

Turn the shaft so that the key slot is upward. Put the key in its

groove and push the impeller onto the shaft. Lock the impeller to

prevent it from rotating with a pipe or similar tool and fasten the

impeller washer and screw (Fig.12). For the torque rating, see

page 15.

Mounting the Cooling Jacket

Lubricate the O-ring on the oil housing and the O-ring on the

upper inside of the cooling jacket. Lower the cooling jacket over

the stator housing. The cooling jacket can be placed optionally so

that the filling holes are in suitable position.

Mounting the Cable Seal

If water has gotten through the cable seal to the terminal board,

the cable seals have to be replaced. The cable seal should be

replaced after every disassembly of the cable gland. Measure

the cable diameter with a slide gauge and compare it to the holes

in the cable seal and the washers so that the dimensions are

identical.

Pull the seal onto the cable with one washer on each side (Fig.

13). Pull the cable through the cover so that the cable and its

cover extends through the cable gland and into the terminal area

when tightening the cable lead-in. After tightening, the strain relief

clamp is fastened. Turn the clip´s long pin down to prevent the

cable lead-in from unthreading.

Mounting the Terminal Housing

Pull the cables through from the stator unit and fasten the

terminal housing with six screws.

Remember that the Ground Cable by Safety Standards

Should be Longer than the Other Cables.

Ensure that the cables are not pinched. Connect the cables

according to the wiring diagram on page 14.

Mounting the Cover

Grease the O-ring on the cover and fasten it with four screws. In

order to facilitate mounting the cover, one of the cable covers can

be loosened so that air can be pressed out and release the

pressure. Tighten the loosened cable cover.

Fig 13

Fig 12

13 (15)

K 101/151/200/250/300.58.0404.Eng/Digital

SERVICE INSTRUCTION

K 101, 151, 200, 250, 300

Mounting the Motor Unit to the Volute

Turn the latch bolts so that the motor unit runs free down to the

upper edge of the volute. Turn the latch bolts in and fasten the

screws alternately. For the torque rating see page 15.

Adjusting the Wear Ring

Lay the pump down on its side and check the clearance in

between the impeller and wear ring. The clearance should be

0.7 mm (

1

/32") maximum. The wear ring is placed on the bottom

side of the volute and is fastened by three screws placed

horizontally (Fig. 14).

Loosen these screws and adjust with the three vertically placed

screws. When necessary, strike carefully with a hammer or

plastic club. When the distance is adjusted, the horizontally

placed screws can be tightened. In case of T/H installation, the

wear ring can be adjusted with three vertically placed screws

from the inside of the volute. This requires, nevertheless, that the

motor unit has been dismounted from the volute.

Note! This Applies Only if Using a Channel Impeller. If

using a Vortex Impeller, do not Adjust the Wear Ring!

Testing

Connect the cables to the electric mains and start the pump. The

arrow on the cover indicates the direction of rotation. The starting

reaction will be in the opposite direction.

Note! Always Check the Lifting Handle and Screws Each

Time the Pump is Lifted Up from the Pit.

Recycling in Case of Scrapping the Pumps

The pump can be disassembled to the material level. Wear parts

made of rubber/ steel have to be treated so that the steel can be

recycled. The cable has to be treated so that the copper can be

recycled. The most positive environmental impact is achieved

when the copper is recycled. Recycling the original components

is profitable. Aluminium, copper, stainless steel, cast iron and

ductile iron should be recycled. White oil should be submitted for

burning and other materials for discarding.

Fig 14

14 (15)

K 101/151/200/250/300.58.0404.Eng/Digital

SERVICE INSTRUCTION

K 101, 151, 200, 250, 300

ÄY

1

2

Y/Ä

3

THERMAL PROTECTION WINDING

MOISTURE SENS. OIL CHAMBER

MOISTURE SENSOR TERMINAL BOARD AREA

Star/Delta starting

THERMAL PROTECTION WINDING

MOISTURE SENS. OIL CHAMBER

MOISTURE SENSOR TERMINAL BOARD AREA

Direct on-line starting

THERMAL PROTECTION WINDING

MOISTURE SENS. OIL CHAMBER

MOISTURE SENSOR TERMINAL BOARD AREA

Direct on-line starting

Wiring Diagram

15 (15)

K 101/151/200/250/300.58.0404.Eng/Digital

SERVICE INSTRUCTION

K 101, 151, 200, 250, 300

Torque Rating

Cable Gland: A specific torque value cannot be given for the cable gland. Tighten it until

the rubber offers resistance, and thereafter, one more full rotation.

Size [Nm] [lb-ft]

M6 7 5.2

M8 17 12.5

M10 33 24.3

M12 57 42.0

M14 91 67.1

M16 140 103.3

Size [Nm] [lb-ft]

Impeller Bolt

198 146

(M16 Bumax)

Latch Bolt

187 138

(M16 A4-80)

Loading...

Loading...