Pulsarlube MS60, MS125, MS250 User Manual

Product upgrades may occur without prior notice for quality purposes.

Note: The MS Relay Box was designed for the Pulsarlube MS unit only.

Product warranty will be null &void if any other type of unspecified adapter or converter is used.

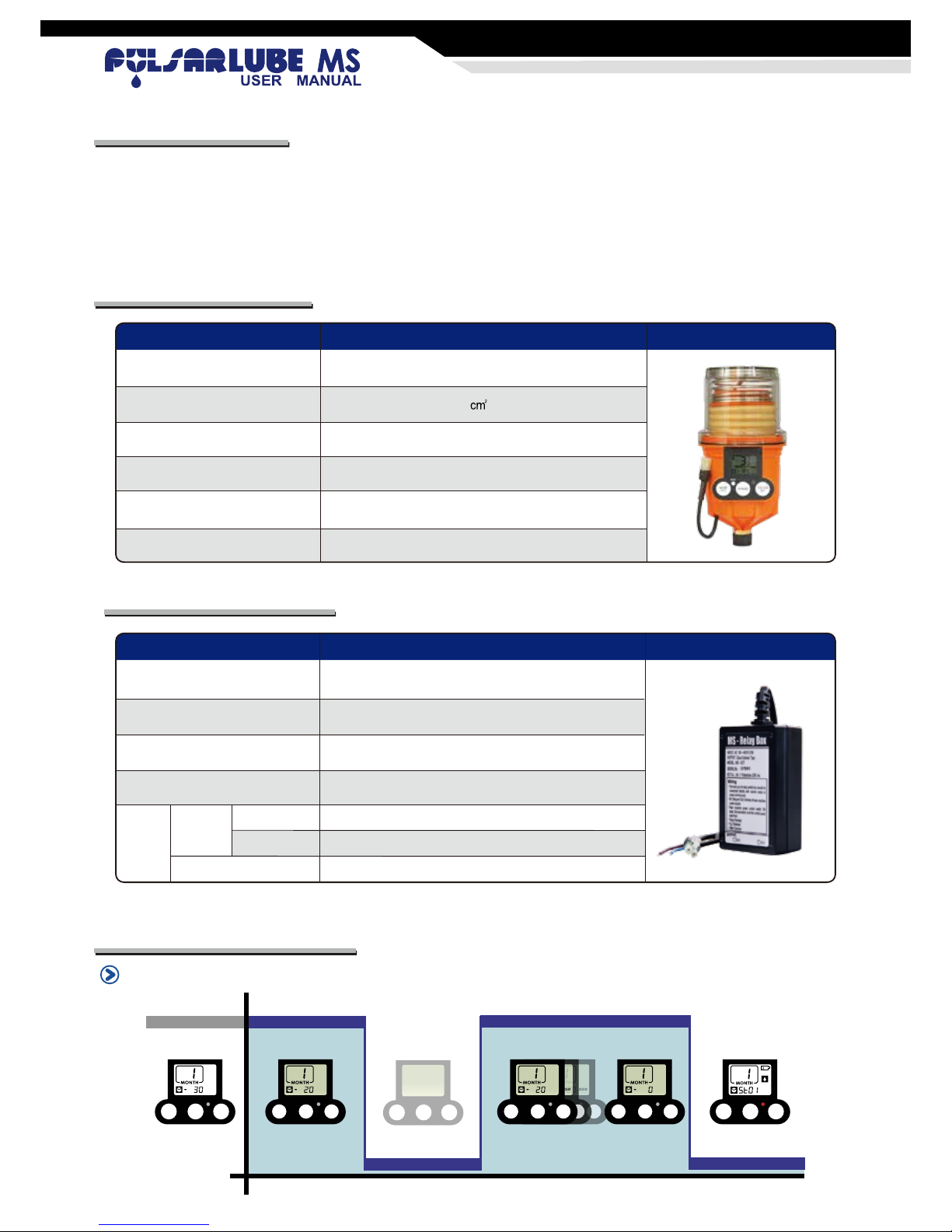

The MS functioning process

O

perating Principles

M

ain Unit specification

R

elay Box Specifica

tions

O

perating the Pulsarlube MS

Pulsarlube MS (Machine Synchronized Lubricator)

10 20 30

1) Month setting

2) Working for 10 days

4) Working again for 20 days

5) Finished

Total days

LCD RED LED Signal

lamp blinking

40

250

250

250

250

3) Off for 10 days

Power on

250 250 250

Models Available 60ml, 125ml, 250ml

Operating Pressure 30Kgf/

(425psi)

Operating Temp Range

Multi Point Lubrication Up to 8 points

Power Source DC 4.5V Replaceable Alkaline Battery

Other Functions Same as the Pulsarlube M lubricator

Item Description Image

Voltage Rate Input

Main Unit Side

Input

Output

AC 100~480V, 0.5W

50 ~ 60Hz

Voltage Rate Output Signal (Open collector Type)

Power ON Indicator Red LED

Relay Box Dimensions (mm) 85(D) x 49(W) x 32(H)

1M

4.5M

90mm

Item Description Image

Wire

Length

Power

Supply

Side

Doc No. 1082-000 REV. 140203

The Pulsarlube MS unit turns “On” or “Off” in synchronization with the equipment on which it is installed. It will

dispense the preset amount of grease as long as the machine is operating. If the equipment is not operating,

then the Pulsarlube MS unit goes into “stand-by mode” and does not dispense lubrication until the machine

operates again.

The MS unit is not an externally powered unit. It operates on its own battery.

Battery should be replaced simultaneously with grease pouch. The MS unit will turn ON/OFF

through a Relay Box in accordance with the related equipment power signal.

-15˚C~60˚C (5˚F~140˚F)

Pulsarlube MS (Machine Synchronized Lubricator)

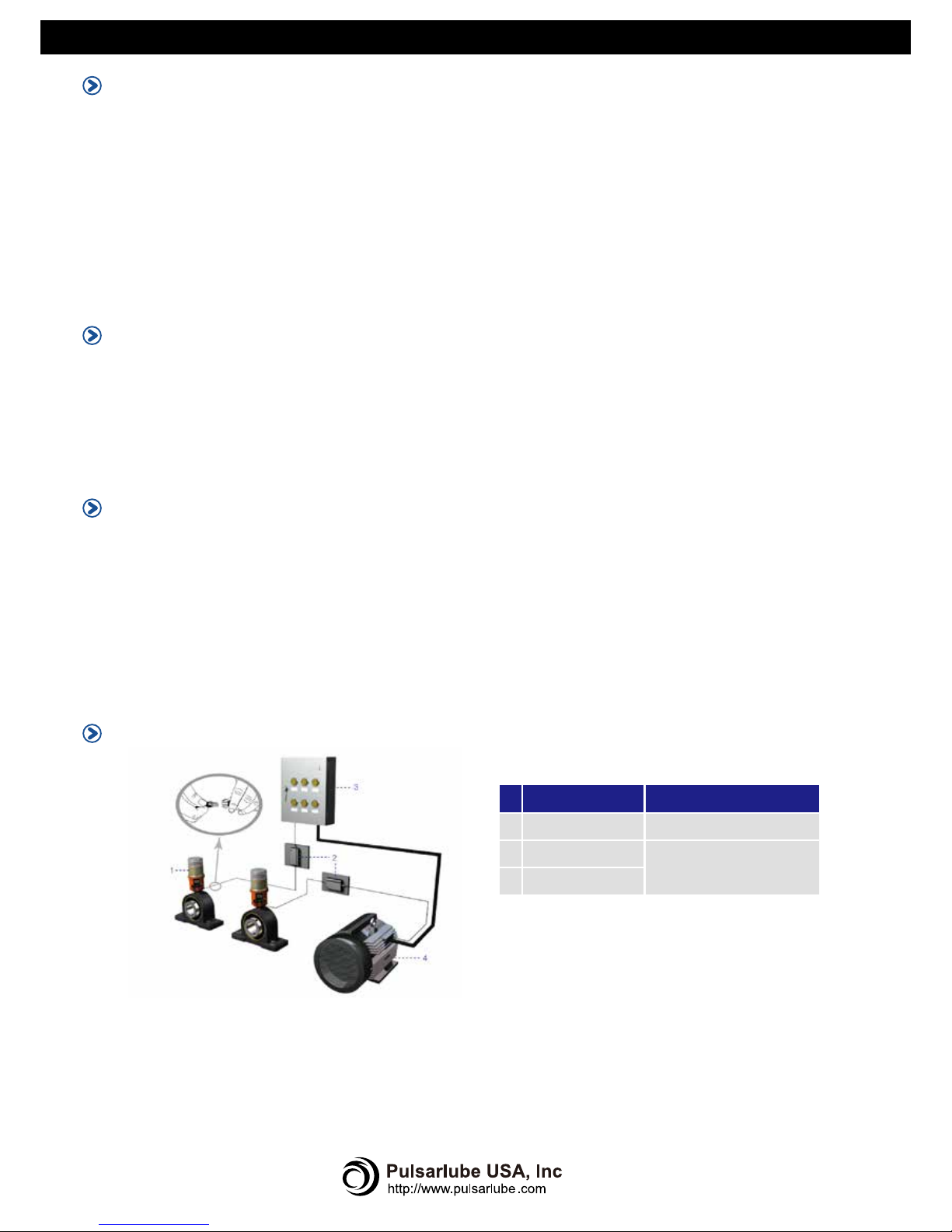

Pulsarlube MS Installation

1. Please install the unit in a convenient location for easy access.

2. Direct or remote mount unit to the bearing/s as you would a Pulsarlube M unit.

3. Connect Male end of Relay Box to the Female end coming from the main body of MS unit.

4. Connect Relay Box wiring to equipments’ power cable

5. It is not necessary to check for wire polarity (+), (-) for the AC power source.

6. Turn POWER button ON and program lubricator by pressing MODE button.

7. Please make sure that red LED blinks once turning power on.

1

2

3

4

How the MS unit time control programming works (Example: 1 Month Set Mode)

1. If the MS unit is programmed for 1 Month, the # “1” (month) will blink and 30 days will display on the LCD.

2. After 10 days in operation, the “1” will continue to blink and 20 days will display on the LCD. (20 days remaining)

3. MS Unit will go into “stand-by mode” for the amount of time equipment is OFF; in this case = 10days.

LCD will not display during stand-by; however CPU will maintain all data at all times via battery pack back up.

4. If equipment is turned ON i.e. after 10 days, the MS unit will re-activate and dispense for the remaining 20 days.

5. After 40 days (30 days in operation, 10 days in “stand-by mode”); a red LED warning light will be blinking.

6. Please make sure to replace “both” grease pouch and battery pack to avoid lubricator malfunction.

7. After changing service pack, please press “POWER” button and press “MODE” button to program desired setting.

Note !

• The MS unit rate input power is DC 4.5 Voltage.

• The MS unit can be turned off at any time by pressing the “POWER” button for 2 seconds.

• The MS unit will go into stand-by mode 6~7 seconds after equipment has been turned off.

• The equipment that the MS unit is connected to must be ON while programming the lubricator.

System Connection

Safety Instructions

Please read all safety and operating instructions before using Relay Box. Also, please keep this information for

future references.

• Water and Moisture. The Relay Box should never be used in, or near water or any other chemicals due to

the risk of fatal shock.

• Heat. Never locate the Relay Box near a heat source.

• Dangerous Entry. Care should be taken that no foreign objects or liquids fall or are spilled inside Relay Box.

• Ventilation. Please maintain Relay Box in a well ventilated area to avoid overheating.

• Flammability. Keep Relay Box away from flammable and combustible chemicals.

• Vibration. Keep Relay Box away from high vibration areas.

• Service. The user should not attempt to service the Relay Box beyond what is described in the user manual.

All other servicing should be referred to qualified personnel.

▶ Wiring Options

- Relay Box can be connected directly to the power cable.

- MC (Magnet Coil) Terminal of main machine power source

- Main machine power control switch ON lamp Terminal which is on the control panel case front

- Relay Terminal

- PLC Terminal

- Other Terminal

▶ Equipment

Automatic Lubricator MS series

AC 100 ~ 480 Volt

Connect wire to main machine

power

Relay Box

Control Panel

Electric Motor

Loading...

Loading...