Pulsar ULTRA TWIN Instruction Manual

ULTRA TWIN (UL)

INSTRUCTION MANUAL

ULTRA TWIN (UL) (FIRST EDITION REV 1)

June 2011

Part Number M-192-6-001-1U

COPYRIGHT

© Pulsar Process Measurement Limited, 2005 -11. All rights reserved. No part of this publication may be

reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language in any

form without the written permission of Pulsar Process Measurement Limited.

WARRANTY AND LIABILITY

Pulsar Process Measurement Limited guarantee for a period of 2 years from the date of delivery that it

will either exchange or repair any part of this product returned to Pulsar Process Measurement Limited if

it is found to be defective in material or workmanship, subject to the defect not being due to unfair wear

and tear, misuse, modification or alteration, accident, misapplication or negligence.

DISCLAIMER

Pulsar Process Measurement Limited gives nor implies any process guarantee for this product, and shall

have no liability in respect of any loss, injury or damage whatsoever arising out of the application or use

of any product or circuit described herein.

Every effort has been made to ensure accuracy of this documentation, but Pulsar Process Measurement

Limited cannot be held liable for any errors.

Pulsar Process Measurement Limited operates a policy of constant development and improvement and

reserves the right to amend technical details as necessary.

TECHNICAL ENQUIRIES

Please contact Pulsar Process Measurement Limited for technical support.

COMMENTS AND SUGGESTIONS

If you have any comments or suggestions about this product, then please contact:

Pulsar Process Measurement Limited

Pulsar Process Measurement Inc.

Cardinal Building

Enigma Business Centre

Sandy’s Road

Malvern

Worcestershire

WR14 1JJ

United Kingdom

PO Box 5177

Niceville

FL 32578 - 5177

USA

Tel: + 44 (0) 1684 891371

Fax: + 44 (0) 1684 575985

Tel: + 1 850 279 4882

Fax: + 1 850 279 4886

Web Site: http://www.pulsar-pm.com

e-mail: info@pulsar-pm.com (general

information)

e-mail: support@ pulsar-pm.com (product

support)

Web Site: http://www.pulsar-pm.com

e-mail: info.usa@pulsar-pm.com (general

information)

e-mail: support.usa@ pulsar-pm.com (product

support)

Contents

Chapter 1 Start Here… ......................................................................................................................................... 1

About this Manual ........................................................................................................................................... 1

About the Ultra Twin ...................................................................................................................................... 2

Functional Description .................................................................................................................................... 2

Product Specification....................................................................................................................................... 4

EC Declaration of Conformity ........................................................................................................................ 6

Wall Mount .............................................................................................................................................. 6

Fascia Mount ........................................................................................................................................... 7

Chapter 2 Installation............................................................................................................................................ 9

Power Supply Requirements ........................................................................................................................... 9

Safety Symbols ................................................................................................................................................ 9

Location ......................................................................................................................................................... 10

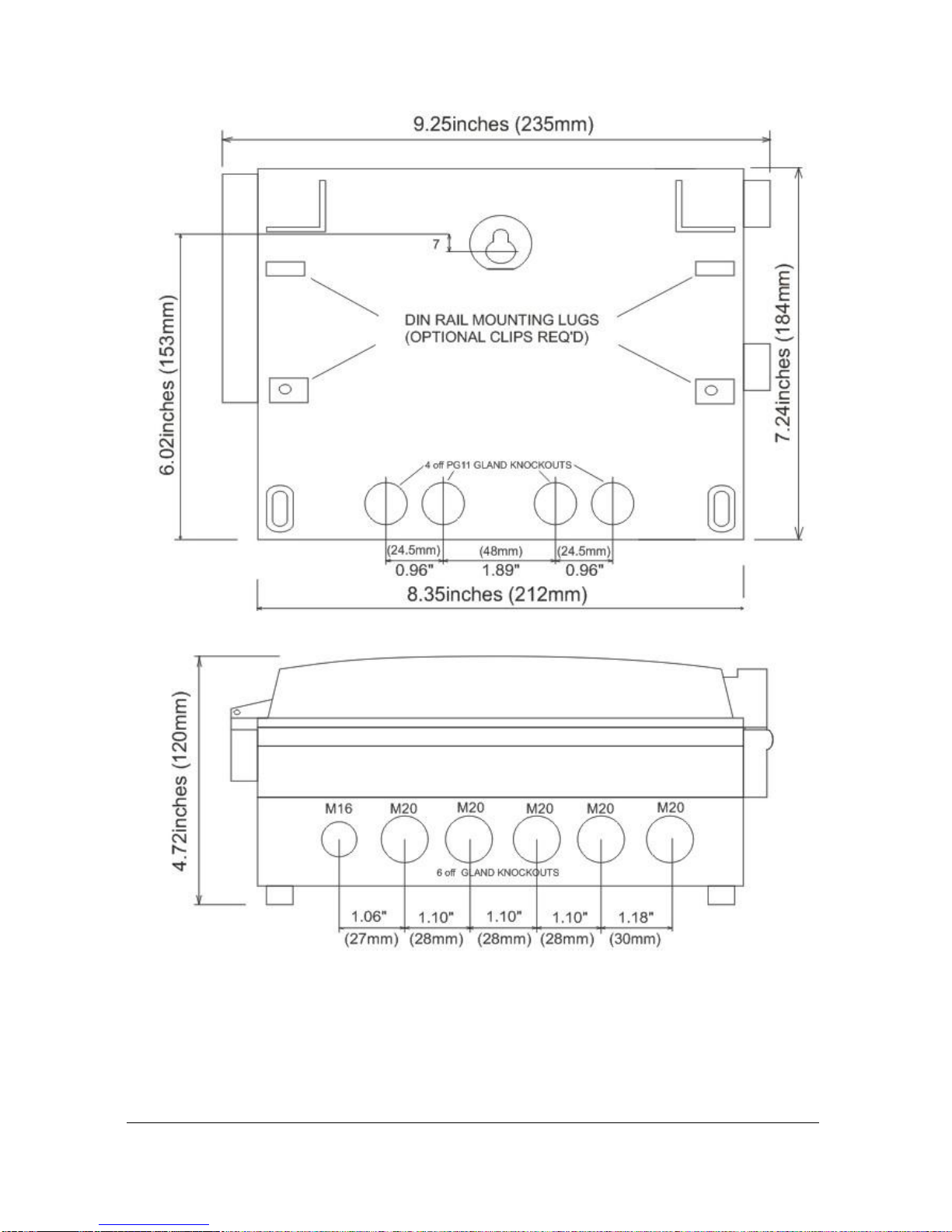

Dimensions .................................................................................................................................................... 11

Wall mount ............................................................................................................................................ 11

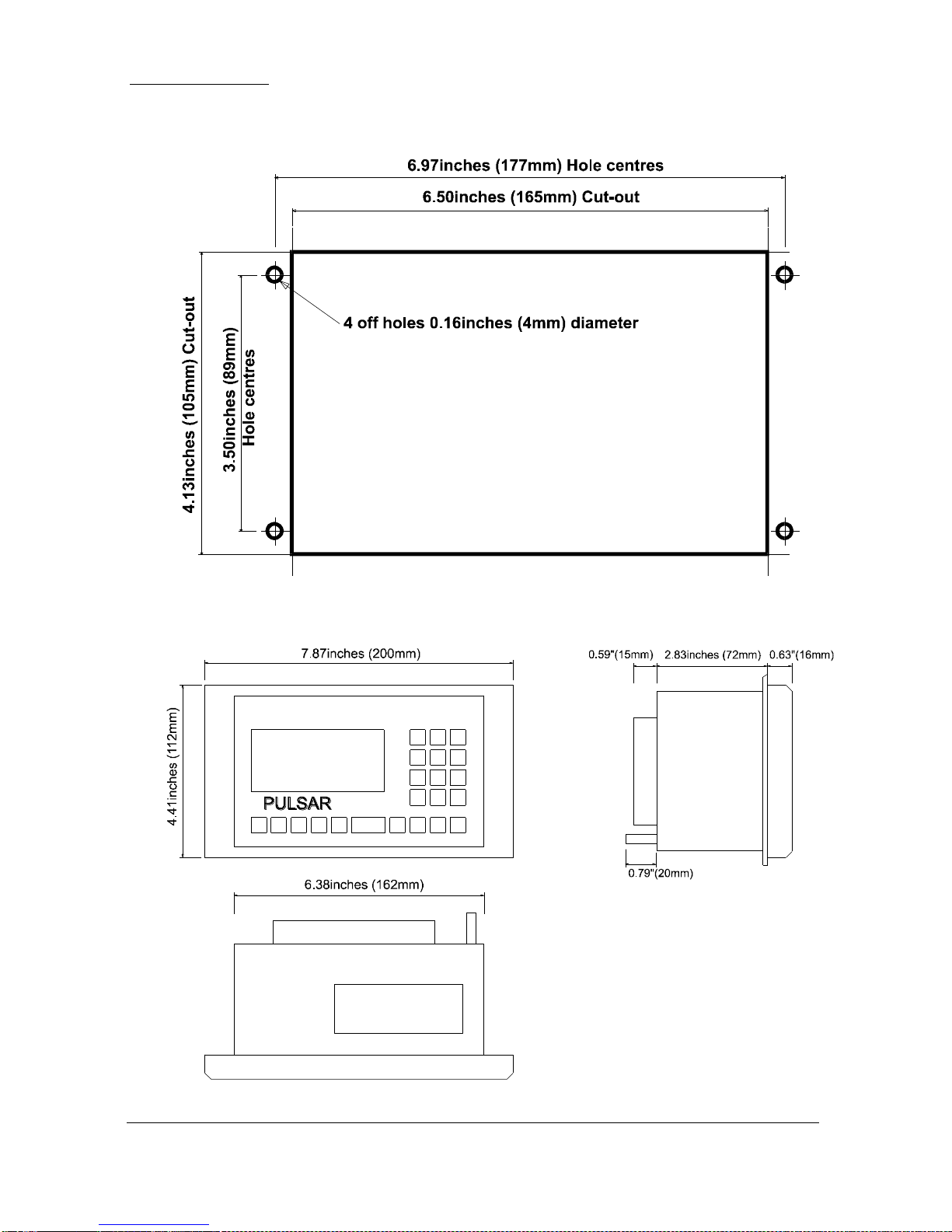

Fascia Mount ......................................................................................................................................... 14

Terminal Connection Details ........................................................................................................................ 15

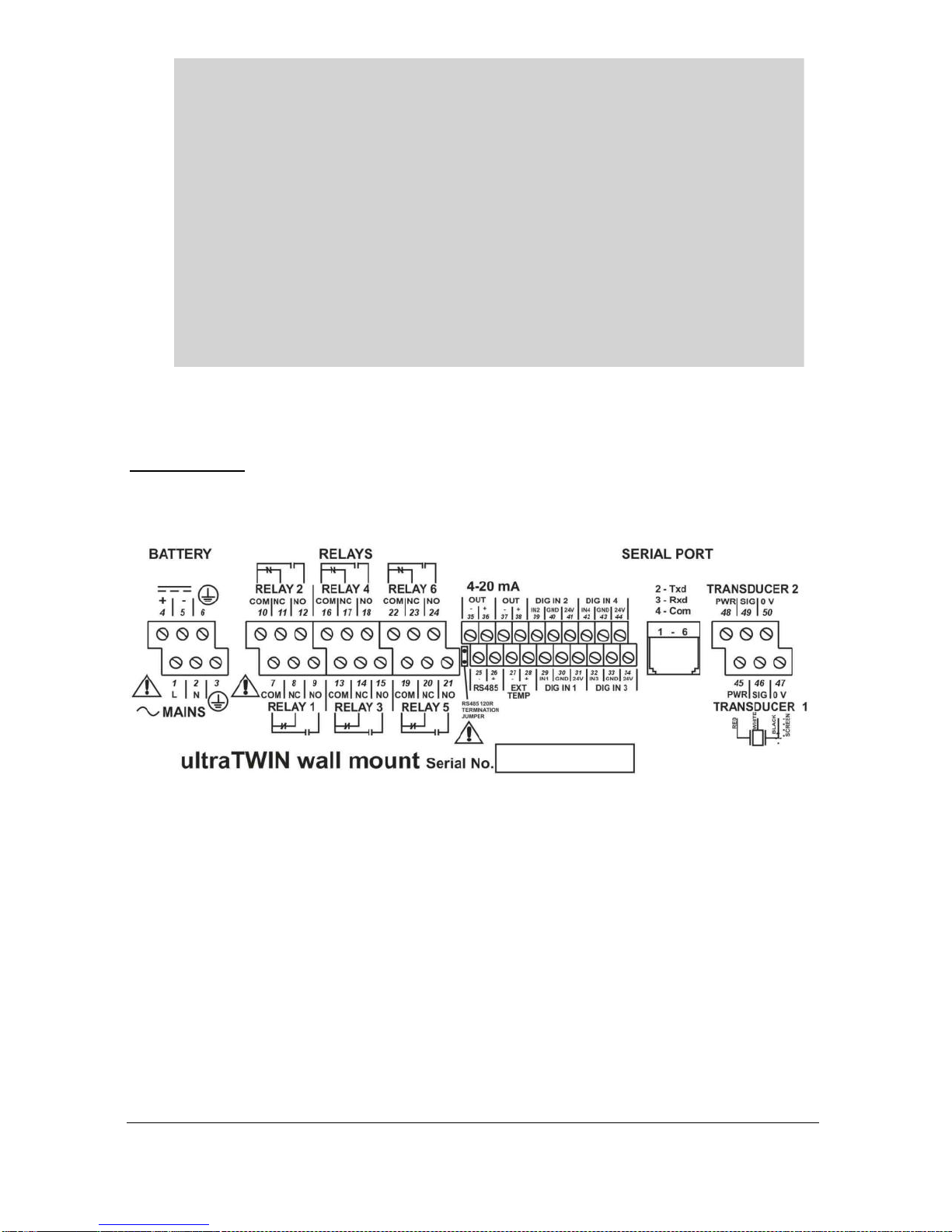

Wall Mount ............................................................................................................................................ 15

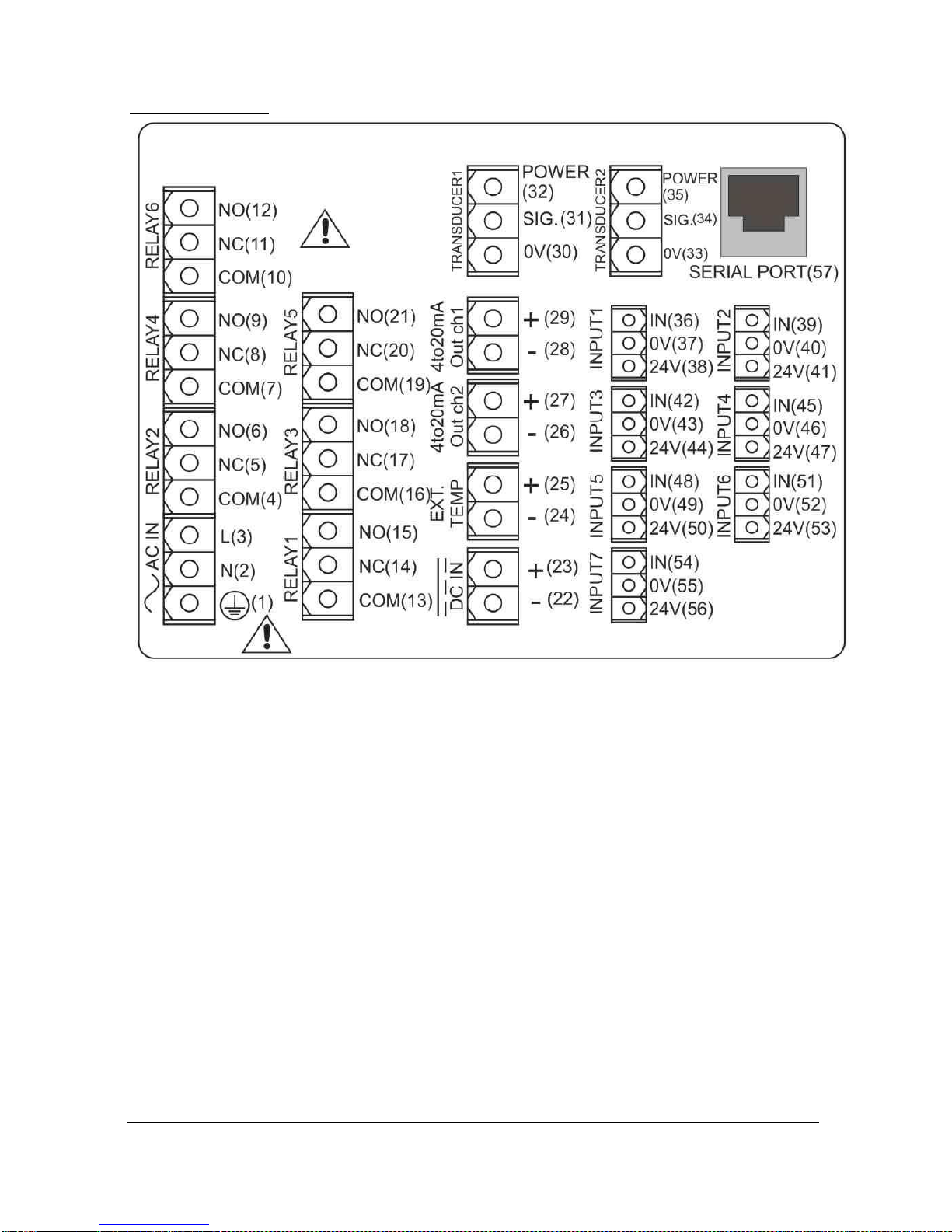

Fascia Mount ......................................................................................................................................... 16

Fuse Location ................................................................................................................................................ 22

Wall mount ............................................................................................................................................ 22

Fascia mount .......................................................................................................................................... 22

Preparation for Operation .............................................................................................................................. 23

Maintenance ................................................................................................................................................... 24

Chapter 3 How To Use Your Ultra Twin ......................................................................................................... 25

Operating the Controls .................................................................................................................................. 25

Display ................................................................................................................................................... 25

Run Mode .............................................................................................................................................. 27

Program Mode ....................................................................................................................................... 27

How to Access Program Mode ..................................................................................................................... 28

Test Mode ...................................................................................................................................................... 33

Using the RS232 Serial Interface .................................................................................................................. 34

Parameter Defaults ........................................................................................................................................ 36

Factory Defaults ..................................................................................................................................... 36

Chapter 4 Quick Set-up Guide ............................................................................................................................. 37

Level or Volume ............................................................................................................................................ 38

Example 1 Level Monitoring with Alarms .......................................................................................... 44

Example 2 Level Monitoring and Control (up or down) ..................................................................... 46

Example 3 Volume Application ........................................................................................................... 48

Example 4 : Differential Control........................................................................................................... 50

Pump .............................................................................................................................................................. 54

Example 1 Sump Control (pump down) ............................................................................................. 59

Example 2 Reservoir Control (pump up) ............................................................................................. 61

Flow ............................................................................................................................................................... 63

Exponential Devices ...................................................................................................................................... 70

Point of Measurement ........................................................................................................................... 71

Calculations ............................................................................................................................................ 73

Example 1 ‘V’ Notch Weir ................................................................................................................. 74

BS3680 Flumes ............................................................................................................................................. 76

Point of Measurement ........................................................................................................................... 76

Calculations ............................................................................................................................................ 77

Example 2 BS3680 U-Throated Flume ............................................................................................... 79

BS3680 Thin Plate Weirs .............................................................................................................................. 81

Point of Measurement ........................................................................................................................... 81

Calculations ............................................................................................................................................ 81

Example 3 BS3680 Rectangular Weir ................................................................................................. 83

BS3680 Rectangular Broad Crested Weir .................................................................................................... 85

Point of Measurement ........................................................................................................................... 85

Calculations ............................................................................................................................................ 85

Special Devices .............................................................................................................................................. 86

Point of Measurement ........................................................................................................................... 86

Calculations ............................................................................................................................................ 87

Universal Calculations .................................................................................................................................. 88

Point of Measurement ........................................................................................................................... 88

Calculations ............................................................................................................................................ 88

Chapter 5 Parameter Guide .............................................................................................................................. 89

Menu System Diagrams ................................................................................................................................ 89

Top Level Menu .................................................................................................................................... 89

Application Menu .................................................................................................................................. 90

Relays Menu .......................................................................................................................................... 91

Pump “Advanced” ................................................................................................................................. 92

Digital Inputs.......................................................................................................................................... 93

Data Logs ............................................................................................................................................... 94

Volume Menu ........................................................................................................................................ 95

OCM Menu ............................................................................................................................................ 96

Display ................................................................................................................................................... 97

mA Output 1 Menu ............................................................................................................................... 98

mA Output 2 Menu ............................................................................................................................... 98

Compensation ........................................................................................................................................ 99

Stability Menu........................................................................................................................................ 99

Echo Processing Menu ........................................................................................................................ 100

System Menu ....................................................................................................................................... 101

Device Comm Menu ........................................................................................................................... 102

Test Menu ............................................................................................................................................ 103

Parameter Listing ......................................................................................................................................... 104

Application Parameters ............................................................................................................................... 104

System Units ........................................................................................................................................ 104

Operation .............................................................................................................................................. 104

Dimensions .......................................................................................................................................... 106

Relay Parameters ......................................................................................................................................... 108

Alarms .................................................................................................................................................. 109

Pumps ................................................................................................................................................... 117

Control.................................................................................................................................................. 121

Miscellaneous ...................................................................................................................................... 126

Common Parameters ........................................................................................................................... 128

Pump “Advanced” Parameters ................................................................................................................... 129

Pump Run On ...................................................................................................................................... 129

Starting ................................................................................................................................................. 129

Stopping ............................................................................................................................................... 130

Pump Exercising .................................................................................................................................. 130

Wall Cling ............................................................................................................................................ 131

Digital Inputs ............................................................................................................................................... 132

About Digital Inputs ............................................................................................................................ 132

Digital Input Parameters .............................................................................................................................. 138

Common Par. ....................................................................................................................................... 138

Digital Inputs........................................................................................................................................ 140

Data Log Parameters ................................................................................................................................... 143

Totaliser Audits .................................................................................................................................... 143

Temperature ......................................................................................................................................... 143

Pump Logs ........................................................................................................................................... 144

Volume......................................................................................................................................................... 145

Conversion ........................................................................................................................................... 146

Breakpoints .......................................................................................................................................... 150

Tables ................................................................................................................................................... 151

OCM Parameters ......................................................................................................................................... 152

PMD Setup........................................................................................................................................... 152

Dimensions .......................................................................................................................................... 155

Calculations .......................................................................................................................................... 158

Breakpoints .......................................................................................................................................... 159

Tables ................................................................................................................................................... 159

Average Flow ...................................................................................................................................... 160

Display Parameters ...................................................................................................................................... 160

Options ................................................................................................................................................. 160

Failsafe ................................................................................................................................................. 162

Auxiliary .............................................................................................................................................. 163

Totaliser ................................................................................................................................................ 165

Bargraph ............................................................................................................................................... 167

mA Output 1 Parameters ............................................................................................................................. 168

Range ................................................................................................................................................... 168

Operaton ............................................................................................................................................... 169

Setpoint ................................................................................................................................................ 170

Limits ................................................................................................................................................... 170

Trim ...................................................................................................................................................... 171

Failsafe ................................................................................................................................................. 171

Allocation ............................................................................................................................................. 172

mA Output 2 Parameters ............................................................................................................................. 173

Range ................................................................................................................................................... 173

Operation .............................................................................................................................................. 174

Setpoint ................................................................................................................................................ 175

Limits ................................................................................................................................................... 175

Trim ...................................................................................................................................................... 176

Failsafe ................................................................................................................................................. 176

Allocation ............................................................................................................................................. 177

Compensation Parameters ........................................................................................................................... 178

Offset .................................................................................................................................................... 178

Temperature ......................................................................................................................................... 178

Velocity ................................................................................................................................................ 179

Stability Parameters ..................................................................................................................................... 180

Damping............................................................................................................................................... 180

Indicator ............................................................................................................................................... 180

Rate....................................................................................................................................................... 180

Filters .................................................................................................................................................... 181

Echo Processing Parameters ....................................................................................................................... 182

Transducer 1 Status ............................................................................................................................. 182

Transducer 2 Status ............................................................................................................................. 183

System Parameters ...................................................................................................................................... 184

Passcode ............................................................................................................................................... 184

Backup ................................................................................................................................................. 184

System Information ............................................................................................................................. 185

Date & Time ........................................................................................................................................ 186

LED Colour ......................................................................................................................................... 186

Watchdog ............................................................................................................................................. 187

Daylight Saving Time ......................................................................................................................... 188

Device Comm. ............................................................................................................................................. 191

RS232 Set Up ...................................................................................................................................... 191

RS 485 Set Up (Optional) ................................................................................................................... 191

Remote Alarm...................................................................................................................................... 192

Test Parameters ............................................................................................................................................ 193

Simulation ............................................................................................................................................ 193

Test Setup ............................................................................................................................................. 194

Hardware .............................................................................................................................................. 195

Chapter 6 Troubleshooting .............................................................................................................................. 197

Parameter Record .............................................................................................................................................. 199

Page 1

Chapter 1 Start Here…

Congratulations on your purchase of a Pulsar Ultra Twin. This quality

system has been developed over many years and represents the latest in high

technology ultrasonic level measurement and control.

It has been designed to give you years of trouble free performance, and a

few minutes spent reading this operating manual will ensure that your

installation is as simple as possible.

About this Manual

It is important that this manual is referred to for correct installation and

operation.

There are various parts of the manual that offer additional help or

information as shown.

Tips

TIP

At various parts of this

manual you will find tips to

help you.

Additional Information

Additional Information

At various parts of the manual, you will find

sections like this that explain specific things in

more detail.

References

See Also

References to other parts of the manual

Page 2

About the

Ultra Twin

Ultra Twin has two independent points of measurement, the wallmount

model provides a dedicated display to each point of measurement, whilst the

fascia model, whilst in RUN, will show detail of one point of measurement

in the main display line, with the second point being displayed on the

auxillary display line. In both models the display will provide information

relevant to the point of measurement selected whilst in RUN and

PROGRAM mode.

Ultra Twin combines premium specification with high performance in a

most versatile system which is quickly configurable offering a choice of

applications in any combination, between the two points of measurement, of

three specific applications i.e. level or volume measurement, pump control

or flow measurement.

Functional Description

Ultra Twin sends a transmit pulse to the transducer(s), which emits an

ultrasonic pulse perpendicular to the transducer face, and the returned echo

is sent back to the Ultra Twin. The time taken to receive the echo is

measured and the distance from the transducer face to the surface being

monitored is calculated.

Page 3

Ultra Twin can measure from zero to 131 feet (40m) from the transducer to

the surface being monitored, dependent on the application chosen and

transducer used.

Six user-definable relays can be programmed to activate alarms, pump

starters, or other control equipment, and can be allocated to either point of

measurement. Also provided are four user definable digital inputs on the

wallmount model and seven on the fascia mount model, which can be

allocated to either point of measurement. There is an isolated 4-20 mA

output for each point of measurement that can be connected to a recorder or

PLC, to monitor level space, distance, volume, OCM head or flow

(dependant on the application chosen), independently from that shown on

the display. There is an RS232 port, so that the Ultra Twin can be operated

remotely by a PC or other equipment.

Ultra Twin can be programmed either by the built-in keypad (standard), or

by PC via the RS 232 Serial Interface (optional).

All parameters are stored in non-volatile memory, so are retained in the

event of power interruption. A second backup copy of all parameters can

also be retained in the Ultra Twin memory, in case an alternative set of

parameters needs to be stored.

The system utilises the unique DATEM software (Digital Adaptive

Tracking of Echo Movement). This is a proven digital mapping technique

developed especially for the Pulsar Ultra range, which gives the system

unequalled ability when identifying the “true target level” in the face of

competing echoes from pipes, pumps or other obstructions. Coupled with

the powerful, long-range abilities of the ‘all new’ dB transducer range, the

Ultra Twin lives up to its reputation as the most reliable ultrasonic level

measurement system available.

The Pulsar Ultra Twin ultrasonic level controller has been designed to

provide maintenance-free fit and forget performance.

Page 4

Product Specification

Physical

Wall Mount

Overall Outside dimensions 9.25 x 7.24 x 4.72 inch

(235 x 184 x 120 mm)

Weight Nominal 2.2lbs (1 kg)

Enclosure material/description Polycarbonate, flame resistant to

UL94-5V

Cable entry detail 10 cable entry knock outs, 5 x M20,

1 x M16 underside

4 x PG11 at rear

Fascia Mount

Outside dimensions 7.87 x 4.41 x 4.25 inch

(200 x 112 x 108 mm)

Weight Nominal 2.8lbs (1.3kg)

Enclosure material/description Stainless Steel back, Polycarbonate

UL94-V0 front and bezel

Transducer cable extensions 3-conductor 20AWG screened

Maximum separation 3,280 ft (1000 metres)

Environmental

Mounting - Wall Mount Indoor/Outdoor

- Fascia Mount Indoor

Relative Humidity (IP Rating)

- Wall Mount IP65 (NEMA 4X) when closed IP20

when open

- Fascia Mount (IP64 from front of panel) <35oC

(95oF) at 93% relative humidity

Pollution Degree 2

Altitude 2000m maximum

Max. & min. temperature (electronics) -4oF to 120oF (-20 ºC to +50 ºC)

Flammable atmosphere approval Safe area: compatible with approved

dB transducers (see transducer spec'

sheet)

Approvals

UL Certificate Number E257330

CE approval See EC Declaration of Conformity

Performance

Accuracy 0.25% of the measured range or

0.24" (6 mm) (whichever is greater)

Resolution 0.1% of the measured range or 0.08"

(2 mm) (whichever is greater)

Max. range Dependant on application and

transducer (maximum 131ft (40m)

dB40)

Min. range Dependent upon application and

transducer (minimum zero dB Mach3)

Rate response fully adjustable

Page 5

Echo Processing

Description DATEM (Digital Adaptive Tracking of

Echo Movement)

Outputs (x2)

Analogue output Isolated (floating) output (to 150V) of

4-20 mA or 0-20 mA into 500 (user

programmable and adjustable) 0.1%

resolution

Digital output Full Duplex RS232

Volt free contacts, number and rating 6 form "C" (SPDT) rated at 5A at 115V

AC

Digital Inputs

Wall Mount x4 Min. Input Voltage 4.5VDC

Fascia Mount x7 Max. Input Voltage 30VDC (Max Current

3mA)

24VDC Input Supply maximum total

current 24mA.

Displays

Wallmount x2 6 digits plus 12 character text, plus

Fascia Mount x1 bargraph with direction indicators,

remote communicator identifier, and

program/run/test mode indicators

Programming

On-board programming By integral keypad

PC programming via RS232

Programming security Via passcode (user selectable and

adjustable)

Programmed data integrity Via non-volatile RAM, plus backup

Supply

Power supply 115V AC + 5% / -10% 50/60 Hz,

dc 18 - 30V (If using a battery then

24V minimum 1AH, dependant on life

required, externally fused with 1A fast

blow fuse.

10W maximum power (typically 6W)

Overvoltage Category II

Fuses

Mains (F1) 125 mA T at 115 VAC

DC (Battery) (F2) 1A Thermal (self resetting after power

removed). Not user replaceable

Transducer (F3, F5 Ch.1 & F4, F6 Ch. 2) Littelfuse 242 series 100mA Part No.

0242.100. This fuse is not user

replaceable and has a 4000A breaking

capability to comply with certification

of the Exm version of dB series

transducers.

Pulsar Process Measurement Limited operates a policy of constant development and

improvement and reserve the right to amend technical details as necessary.

Page 6

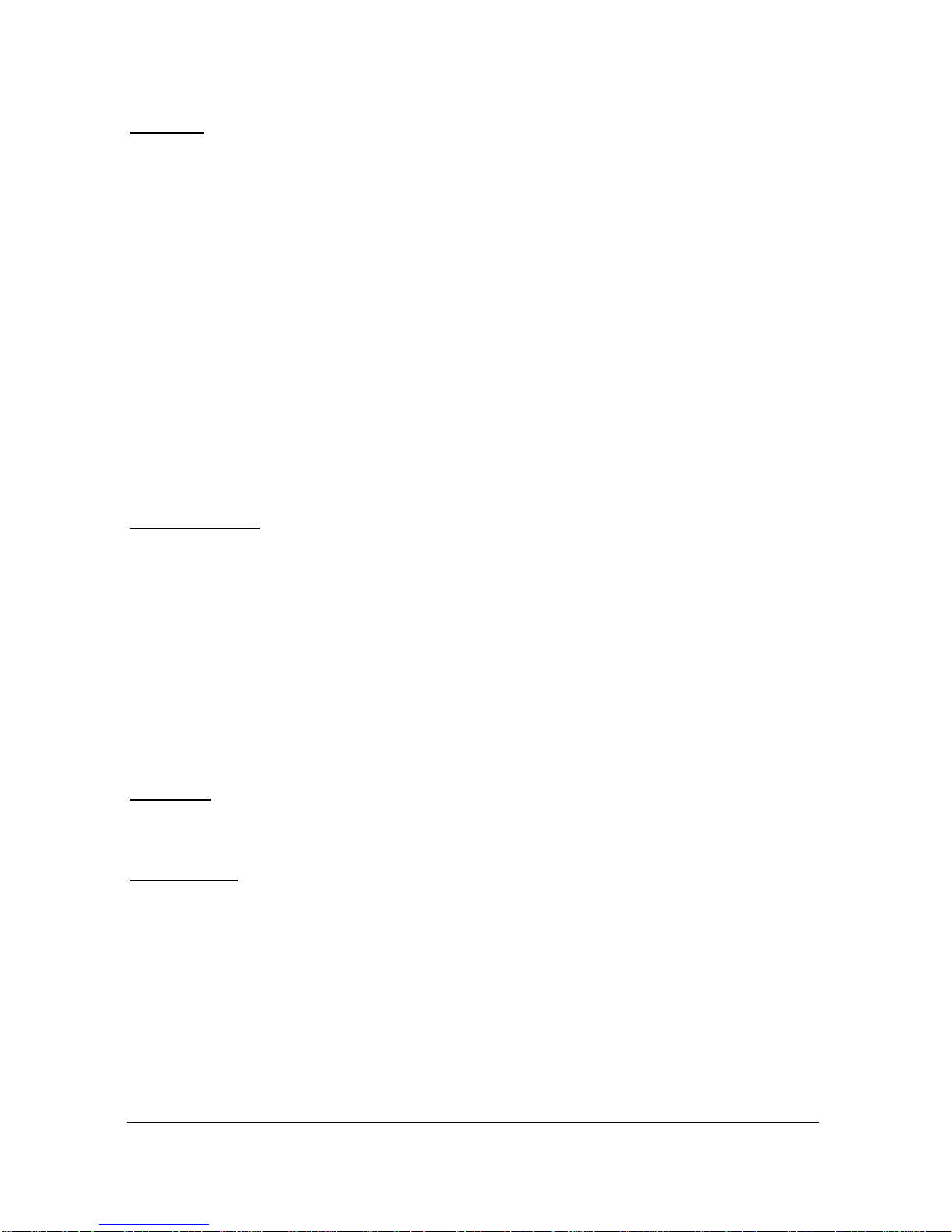

EC Declaration of Conformity

Wall Mount

Page 7

Fascia Mount

Page 8

This page left blank intentionally

Page 9

Chapter 2 Installation

Power Supply Requirements

The Ultra Twin can operate from AC supply or from a DC battery and is

designed for use in temperatures between -4oF to +140oF (-20oC to +50oC).

The AC is 115 +5% / -10% 50/60Hz. The DC is 18-30V. In all cases the

Ultra Twin will typically consume 6W of power, with a maximum of 10W.

If Ultra Twin has both an AC and DC supply available then the AC supply

source will be automatically sensed and used, should the AC supply be

removed for any reason then the DC supply will take over.

The AC and DC wiring should be completed using either 16 – 14AWG

(1.5–2.5mm2) stranded or 16 – 14AWG (1.5–4mm2) solid wire, with all

terminals being tightened to 4.5in. lbs. (0.5Nm).

An external supply isolator/circuit breaker (AC or DC) must be fitted near to

the unit and labelled to identify the instrument to which it refers.

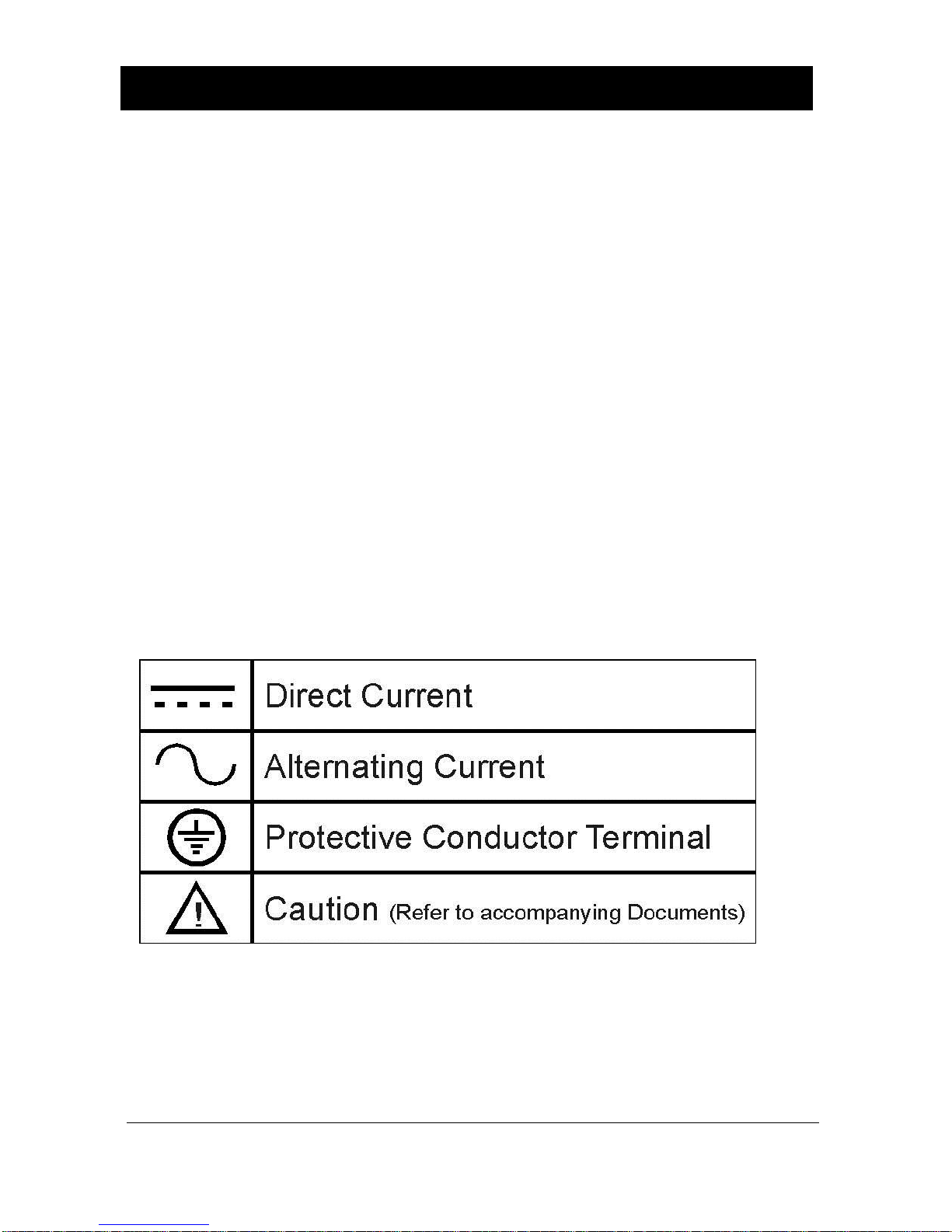

Safety Symbols

Detailed below are descriptions and meanings of safety/warning symbols

that are used on the Ultra Twin and in this manual.

Page 10

Location

All electronic products are susceptible to electrostatic

shock, so follow proper grounding procedures during

installation.

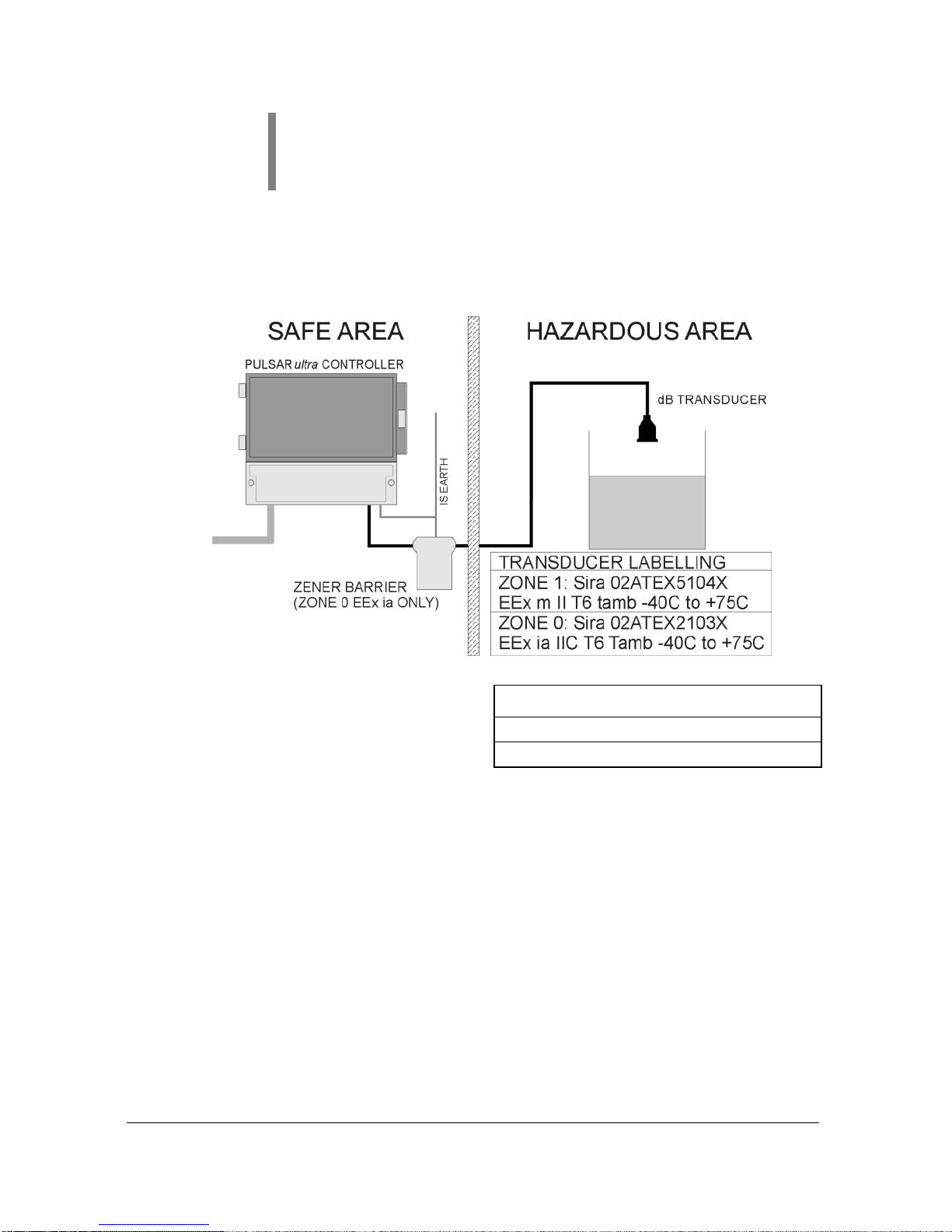

Ultra Twin must be mounted in a non-hazardous (safe) area, and the

transducer fitted in the hazardous area.

When choosing a location to mount the enclosure, bear in mind the following:

Ensure that the Ultra Twin is installed in a “Safe”, non-hazardous,

area.

For a clear view of the LCD display it is recommended that it is

mounted at eye level.

The mounting surface is vibration-free.

The ambient temperature is between -4oF and 140oF (-20ºC and

50ºC).

There should be no high voltage cables or inverters close by.

FM APPROVED TRANSDUCERS

Class I, Div. 1, Group A, B, C & D

Class II, Div. 1, Group E, F & G

Page 11

Dimensions

Wall mount

The dimensions of the wall fixing holes are as shown below.

The Ultra Twin should be mounted by drilling three holes suitable for size 8

screws (length to suit your application), and fixing the top screw in place.

Hang the unit on this and fix the two remaining screws by removing the

terminals access cover to access the pre drilled holes.

Page 12

The full dimensions of the enclosure are as shown below

.

Page 13

Cable Entry

There are 6 cable gland knock-outs on the base of the wall mount Ultra

Twin (5 x 0.79" (20mm), 1 x 0.63" (16mm)) and 4 on the rear (4 x 0.73"

(18mm)). Select which ones you wish to use, and remove them by using a

circular cutter, such as a tank cutter. Take care not to damage the circuit

board inside while undertaking this. Do not use a hammer, as this may cause

damage to the enclosure.

It is recommended that you use suitable cable glands to ensure that the

ingress rating is maintained and that they be tightened to the manufacturers

recommended settings.

Important Information

All cable glands should be tightened to the manufacturer’s specifications.

The terminal compartment cover screws should be tightened to 1.48lb

in.(2Nm)

Care should be taken not to over tighten the screws.

Page 14

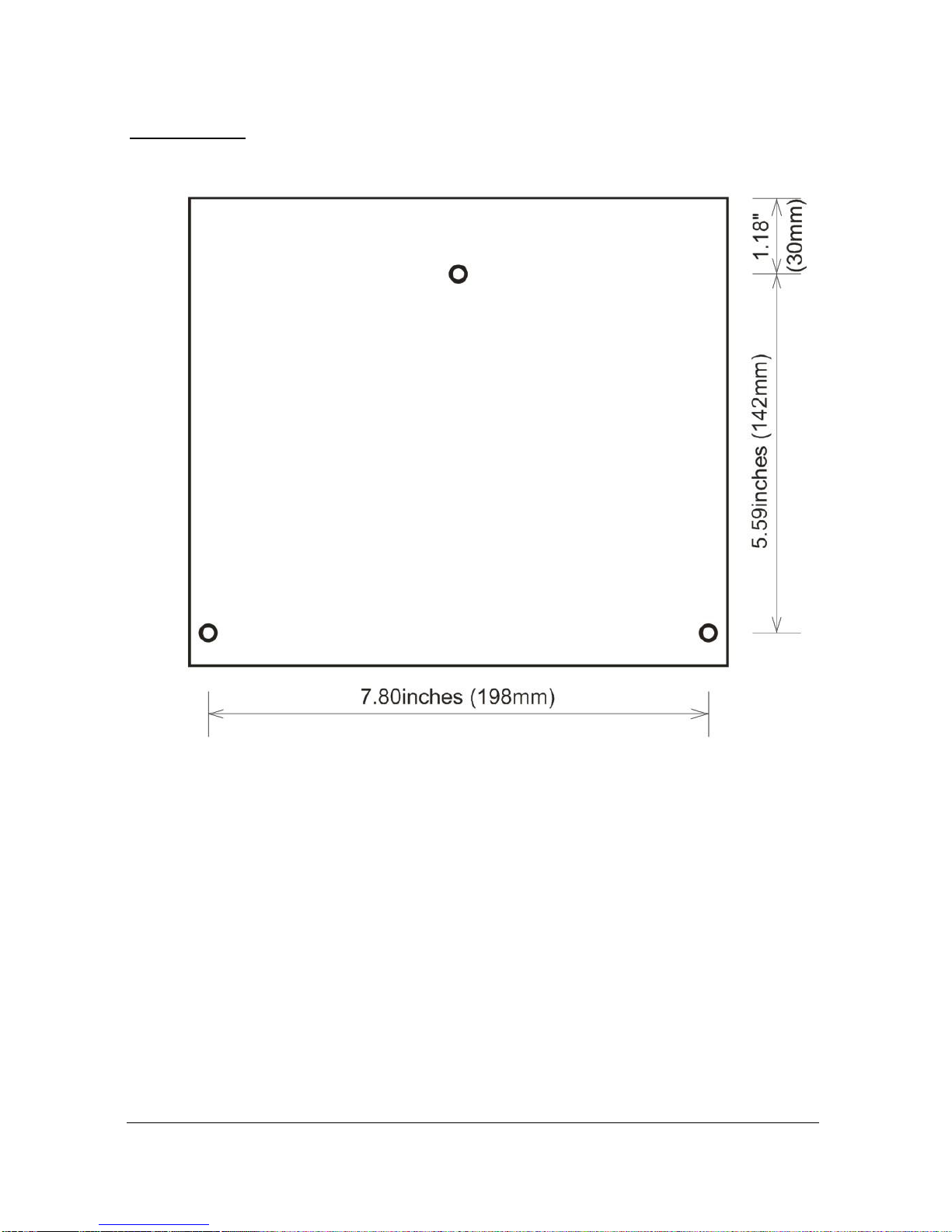

Fascia Mount

The Fascia mount Ultra Twin should be installed by cutting a hole in the

panel, as detailed below, and securing the unit with the fixings supplied.

The full dimensions of the Fascia mount enclosure are as shown below.

Page 15

Important Information

When mounting the fascia mount unit in to a panel, in order to

maintain the panel IP rating the panel should be of smooth/painted

finish and be machined, as per the details contained in this manual.

Fit the unit through the hole then, using the components supplied

place a plain washer then a spring washer followed by an elongated

nut to each of the 4 off M3 threaded studs and tighten to 2.5lb in.

(0.28Nm)

Care should be taken not to overtighten the screws.

Terminal Connection Details

Wall Mount

The terminal strip is as detailed below. There is also a wiring diagram inside

the terminals access cover.

Page 16

Fascia Mount

Page 17

Terminal Connections

Important Information

All terminal connection screws should be tightened to 4.5in.lbs.

(0.5Nm).

Care should be taken not to overtighten the screws.

Power

The Ultra Twin can operate from mains AC and automatically from DC or

battery backup in the event of power failure, or can be operated permanently

from DC or batteries.

Important Information

The protective earth must be connected prior to any other cabling

taking place. This is connected to terminal 3, on all wall mount

units, and should be tightened to 4.5in.lbs. (0.5Nm). In the case of

the fascia unit the earth should be connected to the stud at the rear of

the enclosure and tightened to 7.4lbF (10Nm).

The AC and DC wiring should be completed using either 16 – 14AWG

(1.5–2.5mm2) stranded or 16 – 14AWG (1.5–4mm2) solid wire.

An external supply isolator/circuit breaker (AC or DC) must be fitted near to

the unit and labelled to identify the instrument to which it refers.

Page 18

Transducer

The transducer should be installed, and connected, in accordance with the

installation instructions contained in the Transducer User Guide.

The entire range of, standard dB transducers are certified for use in

hazardous areas and different models, for each, are available for use in Zone

1 or Zone 0.

Wire the transducer to the Ultra Twin’s transducer terminals, terminal

numbers will depend on the unit type, as follows:

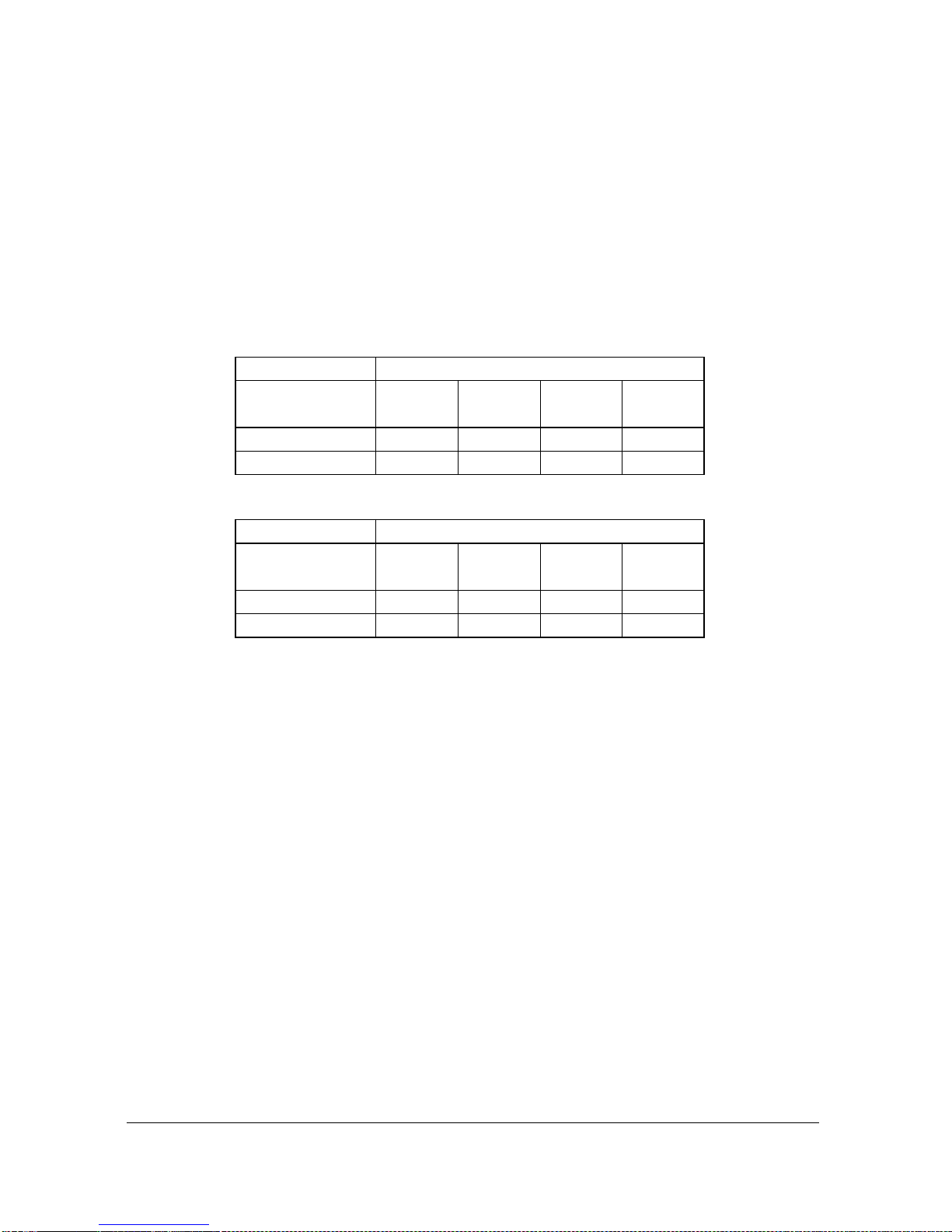

Transducer 1

Terminal Connection Details

Unit Type

Red

Power

White

Signal

Black

0 volts

Green

Screen

Wall Mount

45

46

47

47

Fascia Mount

32

31

30

30

Transducer 2

Terminal Connection Details

Unit Type

Red

Power

White

Signal

Black

0 volts

Green

Screen

Wall Mount

48

49

50

50

Fascia Mount

35

34

33

33

If splicing, it is recommended using a junction box with standard twisted,

shielded pair at 20 AWG.

When using 2-core screened extension cable, the Black and Green wires of

the transducer should be connected to the screen of the extension cable,

which in turn should be connected to the relevant 0 volts terminal.

Page 19

When installing a transducer in a hazardous area use an approved

transducer, from the Pulsar dB range, suitable for the proposed application.

FM

For EEx m (Zone 1) applications a transducer certified to FM Class I Div 1

Group A, B, C & D, ClassII Div 1 Group E, F & G, Class III is used, and

must be supplied via a 1500A breaking fuse, which is fitted as standard to

the blackbox level controller.

Restrictions do not use in the presence of these groups of Chemicals,

Aliphatic Hydro Carbons, Ketones or Esters

For EEx ia (I.S.) a transducer certified to FM Class I Div 1 Group A, B, C

& D, ClassII Div 1 Group E, F & G is used, which must be connected to

the blackbox via an external Zener barrier.

ATEX

For EEx m (Zone 1) applications a transducer certified to Sira

02ATEX5104X is used, and must be supplied via a 4000A breaking fuse,

which is fitted as standard to the blackbox level controller.

For EEx ia (Zone 0) a transducer certified to Sira 02ATEX2103X is used,

which must be connected to the blackbox via an external Zener barrier.

See transducer label for certification details.

Page 20

Important Information

Please note that if the output of the ultrasonic transducers used with

the Ultra Twin are capable of emitting sound pressure levels in excess

of 85dBA (above a reference sound pressure level of 20µPA), then the

Ultra Twin must be located remote from the transducer such that a

sound pressure level of 85dBA is not exceeded when standing at the

Ultra Twin in the operators position.

Important Information

When using the Ultra Twin to measure the differential level

between the two points of measurement then transducer one must

be located on the upstream side of the application.

Relay Outputs

The six relays can be programmed for a variety of alarms, pump control, or

other process functions and allocated to either point of measurement. The

relay contacts are all rated at 5A at 115V AC.

Wiring should be completed by using suitable cable, to meet the specified

115V AC 5A contact rating, up to maximum size of 14AWG.

All connections should be such that the short circuit capacity of the circuits

to which they are connected, is limited by fuses rated so that they do not

exceed the relay rating.

Digital Inputs

Where the Ultra Twin is required to provide power for a Device Input the

appropriate Digital Input should be wired between the 24VDC supply

terminal and the IN terminal. (TOTAL maximum current available, for all

digital inputs, four on Wall Mount model and seven on Fascia Mount model,

from the 24VDC supply is 24mA). When Device Inputs are self powered,

connection of the device should be made between the Common terminal and

the IN terminal. (Minimum Input voltage 4.5VDC, Maximum Input voltage

30VDC with a maximum current of 3mA).

Current Output

There are two mA Outputs which are fully assignable, both outputs are an

isolated (floating) mA output, of 4 - 20mA or 0 - 20mA, and the load should

not exceed 500.

Page 21

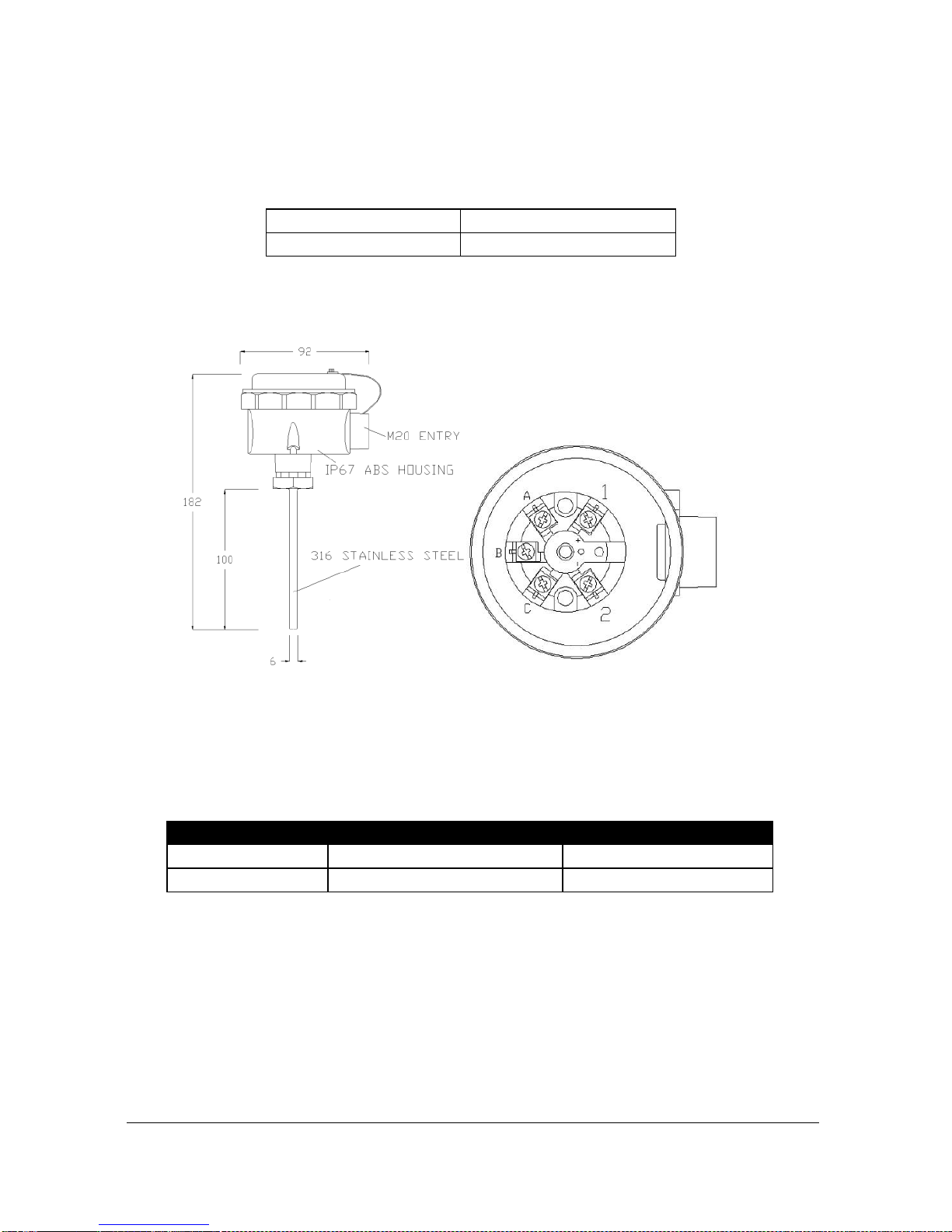

Temperature Input

The external temperature sensor allows more localised compensation of the

measured distance due to changes in temperature.

There are two models, Type A and Type B as follows:

Type A

-25ºC to 50ºC

Type B

-25ºC to 125ºC

The temperature sensor should be placed close to the point of measurement.

The unit is connected as follows:

Description

Temperature Sensor

Ultra Twin

Power Supply

Terminal 1

Terminal 27

Return

Terminal 2

Terminal 28

Temp Source (P1-852, P2-852), should be set to option 4 or 5 depending on

the sensor range, set 4 for type A and 5 for type B (see above), the range is

specified on the label of the sensor.

RS232 Serial Interface

If required, you can connect to the serial interface, to operate your Ultra

Twin remotely.

Page 22

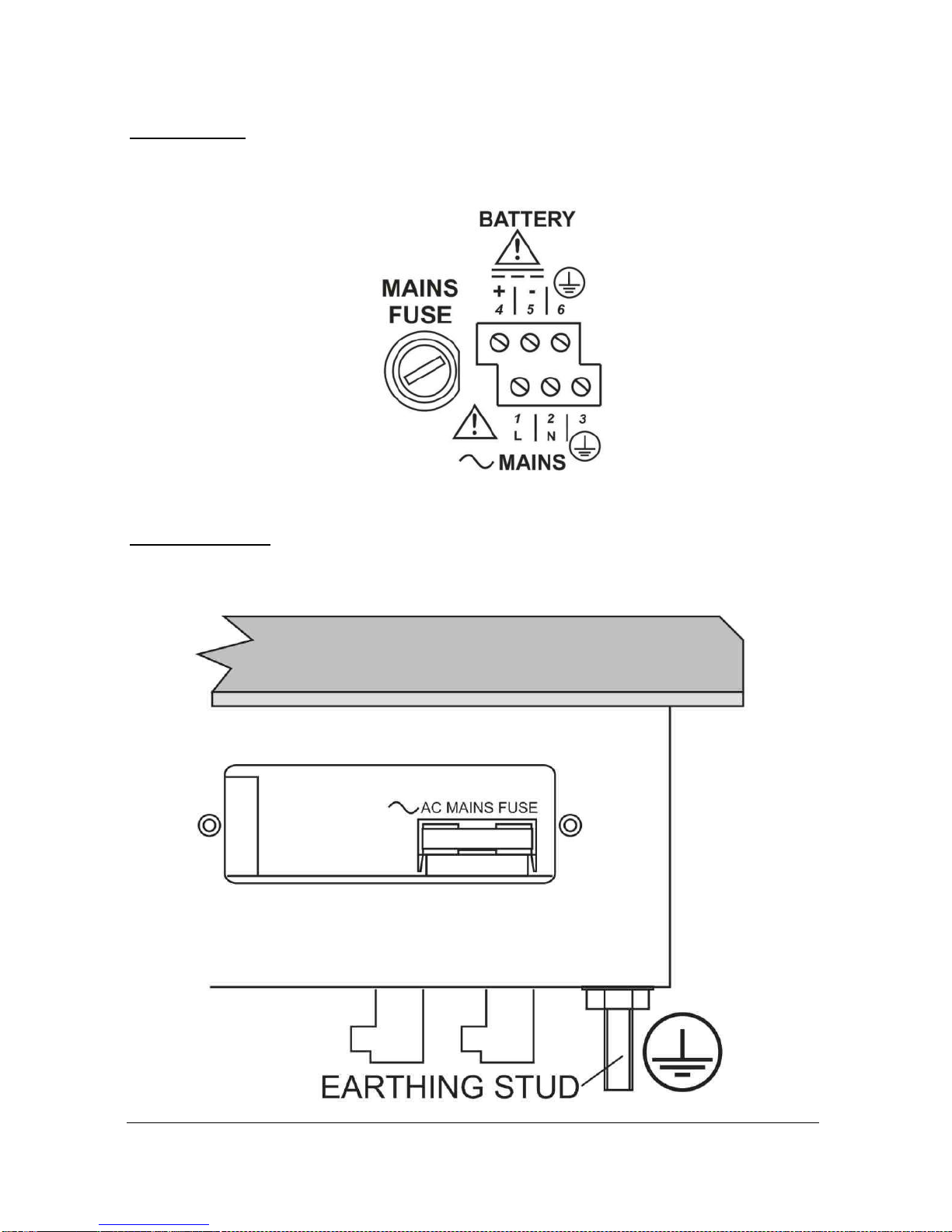

Fuse Location

Wall mount

The mains fuse is located, inside the terminal compartment, to the left of

the mains terminals, as illustrated below.

Fascia mount

The mains fuse is located under the removable cover at the bottom of the

unit, as illustrated below.

Loading...

Loading...