Page 1

TC–10B

FREQUENCY-PROGRAMMABLE

ON/OFF CARRIER

TRANSMITTER/RECEIVER

System Manual

CC44–VER06

(Replaces CC44–VER05)

Technologies, Inc.

4050 N.W. 121st Avenue

Coral Springs, FL U.S.A. 33065

1–800–785–7274

www.pulsartech.com

Printed October 2003

Page 2

Technologies, Inc.

Page 3

1

Product Description

2

Applications and Ordering Information

3

Installation

4

Test Equipment

5

Installation/Adjustment Procedures

6

Signal Path

7

Design Verification Tests

8

Maintenance

9

Power Supply Module

10

Keying Module

11

Transmitter Module

12

10W PA Module

13

RF Interface Module

14

Universal Receiver Module

15

Receiver (solid state) Output Module

16

Universal Checkback Module

17

Optional Voice Adapter Module

TC–10B

System Manual

Table

of

Contents

Page 4

Page ii October 2003

Technologies, Inc.

Important Change Notification

This document supersedes the TC–10B Frequency-Programmable On/Off Carrier Transmitter/ Receiver

System Manual CC44–VER05. The following list shows the most recent publication date for each chapter.

Publication dates in bold type indicate changes to that chapter. For these chapters, the specific pages that

have changed are listed for easy reference. Note that only significant changes, i.e., those changes which

affect the technical use and understanding of the document and the TC–10B equipment, are reported.

Changes in format, typographical corrections, minor word changes, etc. are not reported. Note also that in

some cases text and graphics may have flowed to a different page than in the previous publication due to

formatting or other changes. The page numbers below show the current pages on which the reported

changes appear.

Each reported change is identified in the document by a change bar, || placed to its immediate left and/or

right, as shown on this page.

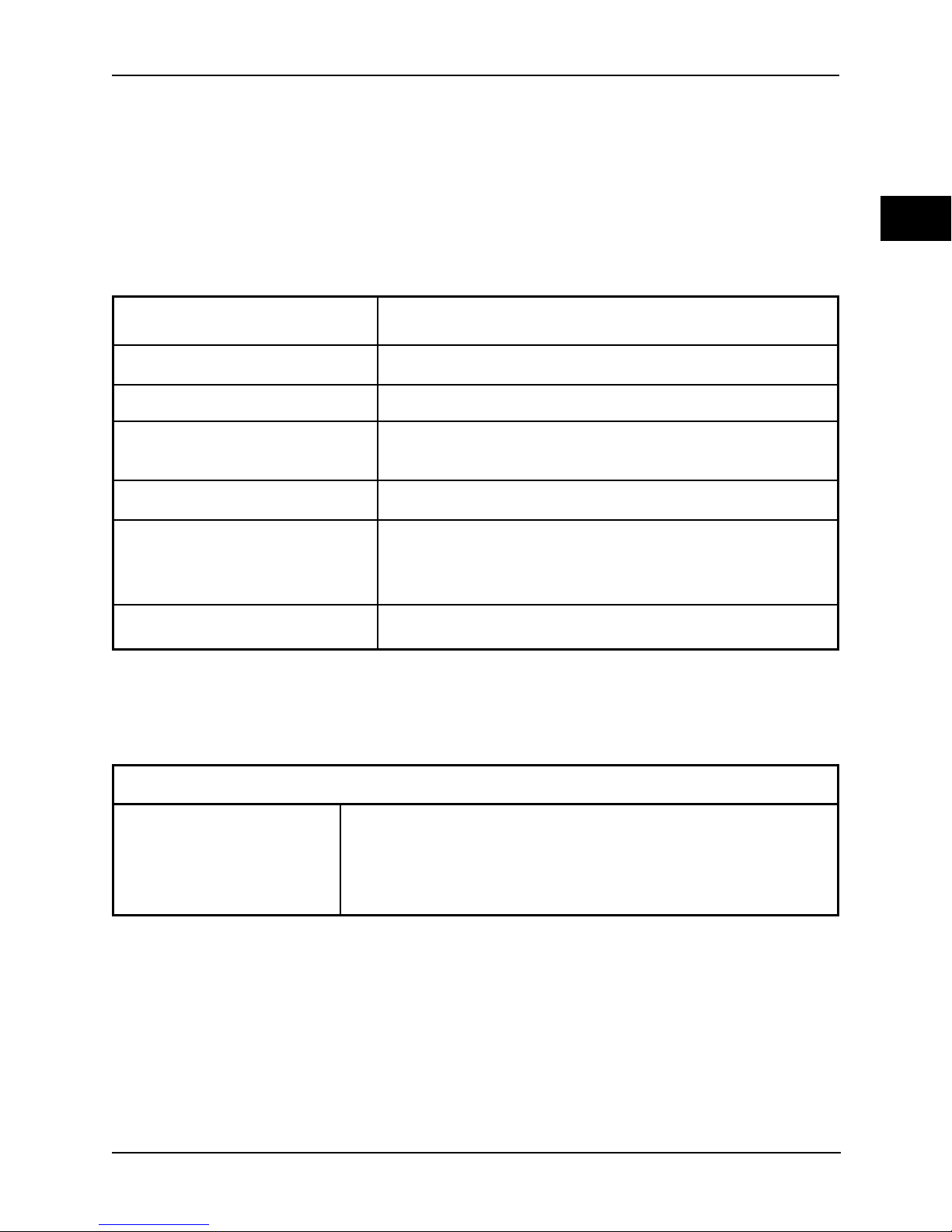

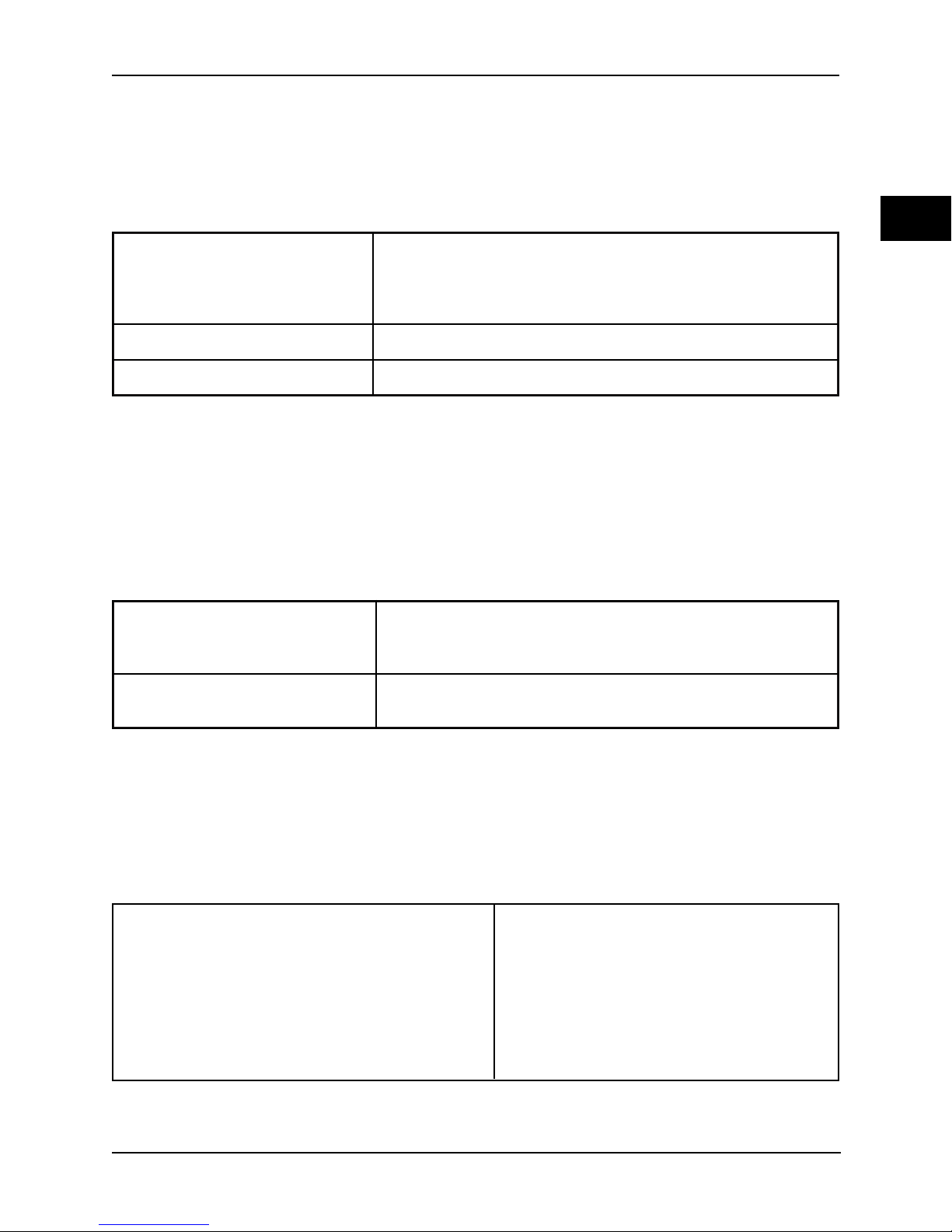

Chapter Number & Title Publication Date Pages with Changes

|| Front Section October 2003 ii, v

1. Product Description October 2000

|| 2. Applications and Ordering Information October 2003 2-6, 17, 20

3. Installation October 2002

4. Test Equipment October 2000

5. Installation/Adjustment procedures October 2002

6. Signal Path October 2002

7. Design Verification Tests October 2002

8. Maintenance September 1996

9. Power Supply Module January 1996

10. Keying Module January 1996

11.Transmitter Module October 2002

12. 10W PA Module October 2002

13. RF Interface Module January 1996

14. Universal Receiver Module October 2002

15. Receiver (solid state) Output Module April 1997

||16. Universal Checkback Module October 2003 16-2, 4, 6, 7, 9, 11, 14, 37,

38, 39, 42, 43

17. Optional Voice Adapter Module October 2000

Page 5

October 2003 Page iii

TC–10B System Manual

W

e recommend that you become acquainted with the information in this manual before energizing your TC–10B system. Failure to do so may result in injury to personnel or damage to

the equipment, and may affect the equipment warranty. If you mount the carrier set in a

cabinet, it must be bolted to the floor or otherwise secured before you swing out the equipment, to

prevent the installation from tipping over.

You should not remove or insert printed circuit modules while the TC–10B is energized. Failure to

observe this precaution can result in undesired tripping output and can cause component damage.

PULSAR does not assume liability arising out of the application or use of any product or circuit

described herein. PULSAR reserves the right to make changes to any products herein to improve reliability, function or design. Specifications and information herein are subject to change without notice.

All possible contingencies which may arise during installation, operation, or maintenance, and all

details and variations of this equipment do not purport to be covered by this manual. If you desire

further information regar ding a particular installation, operation, or maintenance of equipment, please

contact your local Pulsar Technologies, Inc. representative.

Copyright ©

By Pulsar Technologies, Inc. U.S.A.

Published 2002

ALL RIGHTS RESERVED

PULSAR does not convey any license under its patent rights nor the rights of others.

!

IMPORTANT

ESD Warning!

YOU MUST BE PROPERLY GROUNDED, TO PREVENT DAMAGE FROM

STATIC ELECTRICITY, BEFORE HANDLING ANY AND ALL MODULES OR

EQUIPMENT FROM PULSAR.

All semiconductor components used, are sensitive to and can be damaged by the

discharge of static electricity. Be sure to observe all Electrostatic Discharge (ESD)

precautions when handling modules or individual components.

Page 6

PREFACE

Scope

This manual describes the functions and features of the TC–10B Power Line Carrier T ransmitter/Receiver.

It is intended primarily for use by engineers and technicians involved in the installation, alignment,

operation, and maintenance of the TC–10B.

Equipment Identification

The TC–10B equipment is identified by the Catalog Number on the TC–10B chassis nameplate. You can

decode the Catalog Number using the information in Chapter 2.

Production Changes

When engineering and production changes are made to the TC–10B equipment, a revision notation

(Sub number) is reflected on the style number and related schematic diagram. A summary of all Sub

numbers for the particular release is shown on the following page.

Warranty

Our standard warranty extends for 60 months after shipment. For all repaired modules or advance replacements, the standard warranty is 90 days or the remaining warranty time, whichever is longer. Damage

clearly caused by improper application, repair, or handling of the equipment will void the warranty.

Equipment Return & Repair Procedure

To return equipment for repair or replacement:

1. Call your PULSAR representative at 1–800–785–7274.

2. Request an RMA number for proper authorization and credit.

3. Carefully pack the equipment you are returning.

Repair work is done most satisfactorily at the factory. When returning any equipment, pack it in

the original shipping containers if possible. Be sure to use anti-static material when packing the

equipment. Any damage due to improperly packed items will be charged to the customer, even

when under warranty.

Pulsar Technologies, Inc. also makes available interchangeable parts to customers who are

equipped to do repair work. When ordering parts (components, modules, etc.), always give the

complete PULSAR style number(s).

4. Make sure you include your return address and the RMA number on the package.

5. Ship the package(s) to:

Pulsar Technologies, Inc.

Communications Division

4050 N.W. 121st Avenue

Coral Springs, FL U.S.A. 33065

Page iv October 2003

Technologies, Inc.

Page 7

October 2003 Page v

TC–10B System Manual

Overview of this Publication

Chapter 1 – Product Description and specifications

Chapter 2 – Applications and related catalog numbers for ordering

Chapter 3 – Installation

Chapter 4 – Test equipment

Chapter 5 – Installation/adjustment procedures

Chapter 6 – Signal path

Chapter 7 – Design verification tests

Chapter 8 – Maintenance procedures

Chapters 9-17 – Module circuit descriptions and troubleshooting procedures

The TC–10B circuitry is divided into seven (7) standard modules. In addition, Universal Checkback, TTL

Transmitter and Voice Adapter modules are available as options. (See Figure 6-1, for a Functional Block

Diagram.)

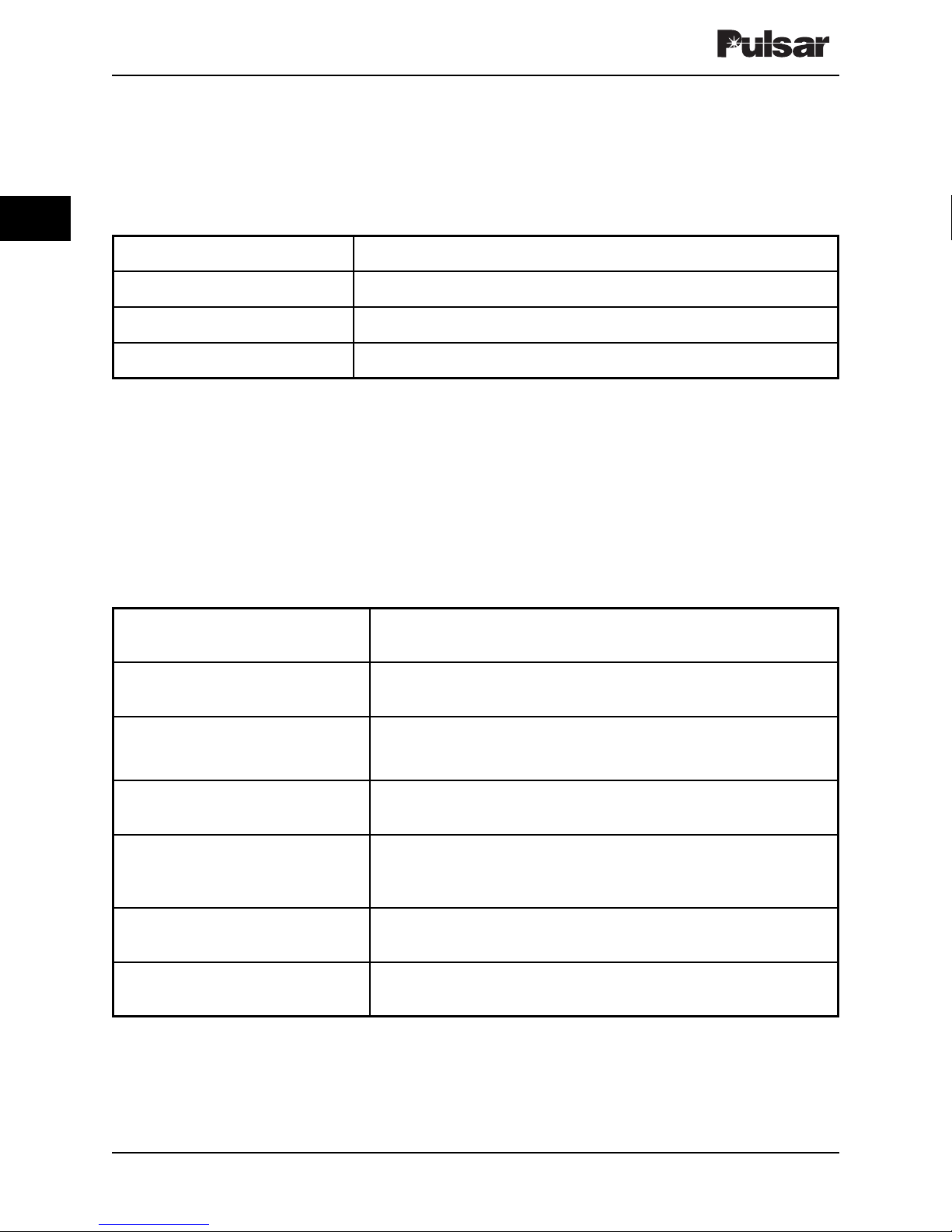

Contents of Carrier Set

The TC–10B carrier set includes the style numbers, listed below, with appropriate sub numbers representing revision levels. (To determine related style numbers, you may also refer to Table 2-3.)

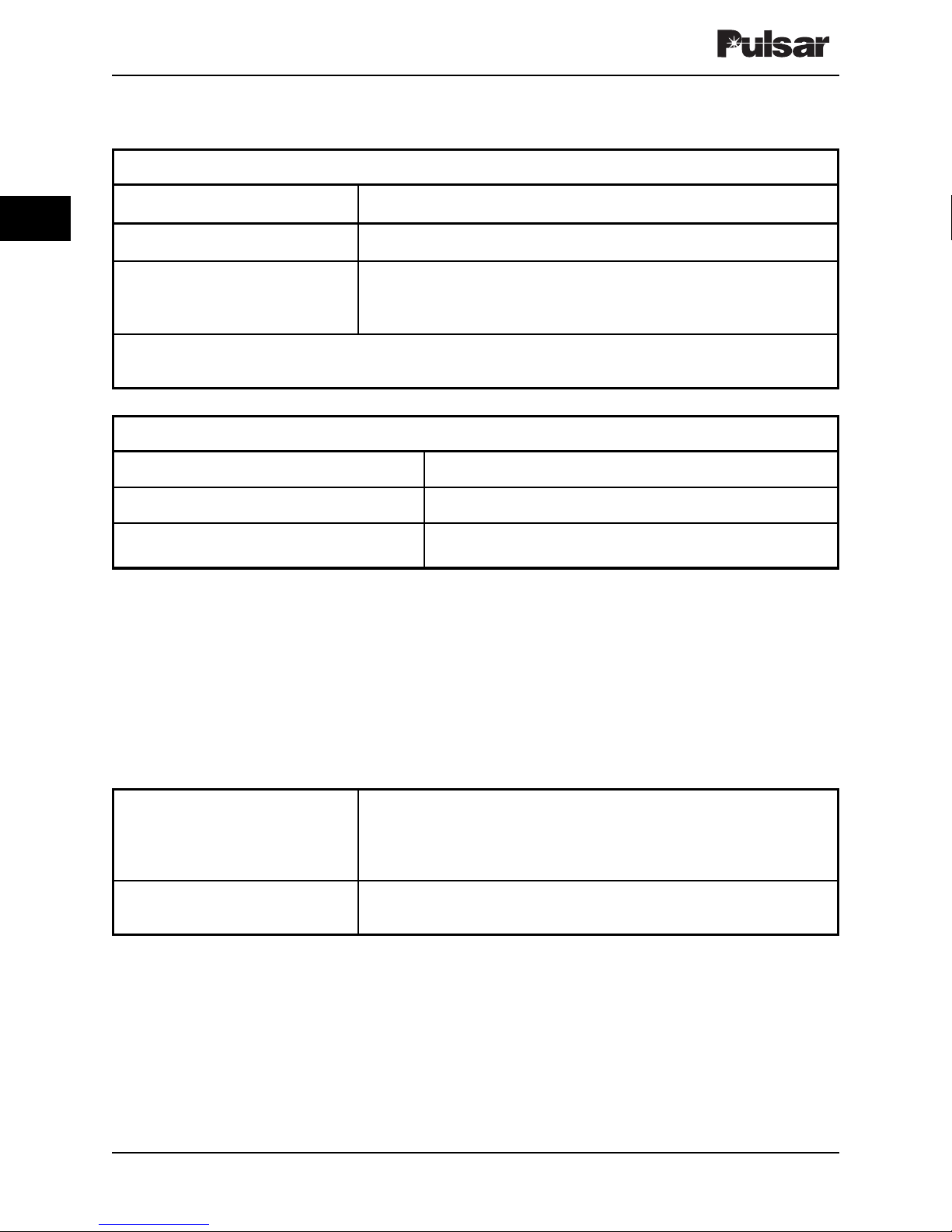

Module Style Sub Number

Power Supply 1617C38 GXX 03 ||

Keying 1606C29 G01 11

Transmitter 1610C01 G01 15 ||

TTL Transmitter 1610C01 G02 15 ||

10W PA 1606C33 G01 21

RF Interface 1609C32 G01 09

Universal Receiver C020-RXVMN-203 08 ||

Receiver Output CC20-RXSMN-001 02 ||

Universal Checkback CC20-UCBMN-001 07 ||

Voice Adapter C020-VADMN-001 04 ||

Trademarks

All terms mentioned in this book that are known to be trademarks or service marks are listed below.

In addition, terms suspected of being trademarks or service marks have been appropriately capitalized. Pulsar Technologies, Inc. cannot attest to the accuracy of this information. Use of a term in this

book should not be regarded as affecting the validity of any trademark or service mark.

IBM and PC are registered trademarks of the International Business Machines Corporation.

Page 8

FIGURES

Figure No. Page No.

1-1 TC–10B Chassis and Control Panels with Optional Universal Checkback

and Voice Adapter Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

2-1 Directional-Comparison Blocking, Basic Elements and Logic Diagrams . . . . . . .2-2

2-2 Phase-Comparison Blocking, Basic Elements . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

2-3 Single Phase Comparison Blocking, Current Only Operation . . . . . . . . . . . . . . .2-4

2-4 Single Phase-Comparison Blocking, Distance-Supervised Operation . . . . . . . . . .2-5

2-5 Simplified Application Schematic (Scheme A) . . . . . . . . . . . . . . . . . . . . . . . . .2-11

2-6 Simplified Application Schematic (Scheme B) . . . . . . . . . . . . . . . . . . . . . . . . .2-12

2-7 Simplified Application Schematic (Scheme C) . . . . . . . . . . . . . . . . . . . . . . . . .2-13

2-8 Simplified Application Schematic (Scheme D) . . . . . . . . . . . . . . . . . . . . . . . . .2-14

2-9 Simplified Application Schematic (Scheme E) . . . . . . . . . . . . . . . . . . . . . . . . . .2-15

2-10 Simplified Application Schematic (Scheme F) . . . . . . . . . . . . . . . . . . . . . . . . . .2-16

2-11 Simplified Application Schematic (Scheme G) . . . . . . . . . . . . . . . . . . . . . . . . .2-17

2-12 Simplified Application Schematic (Scheme H) . . . . . . . . . . . . . . . . . . . . . . . . .2-18

2-13 Simplified Schematic (Scheme K) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

2-14 Simplified Applications Schematic (Scheme L) . . . . . . . . . . . . . . . . . . . . . . . . .2-20

2-15 Receiver Output Typical Connections for Microprocessor based relays . . . . . . .2-21

2-16 Receiver Outputs w/External Resistors for Electro-mechanical relays . . . . . . . .2-21

3-1 Rear Panel – Mother Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2

3-2 Cable Termination Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-4

3-3 Mechanical Outline Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

3-4 Connection Drawing and Jumper Options (Sheet 1 of 2). . . . . . . . . . . . . . . . . .3-10

3-5 Connection Drawing and Jumper Options (Sheet 2 of 2). . . . . . . . . . . . . . . . . . .3-11

4-1 Extender Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-2

6-1 Interconnection and Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-6

9-1 Power Supply Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

9-2 Power Supply Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

9-3 Power Supply Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-4

10-1 Keying Module Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

10-2 Keying PC Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-5

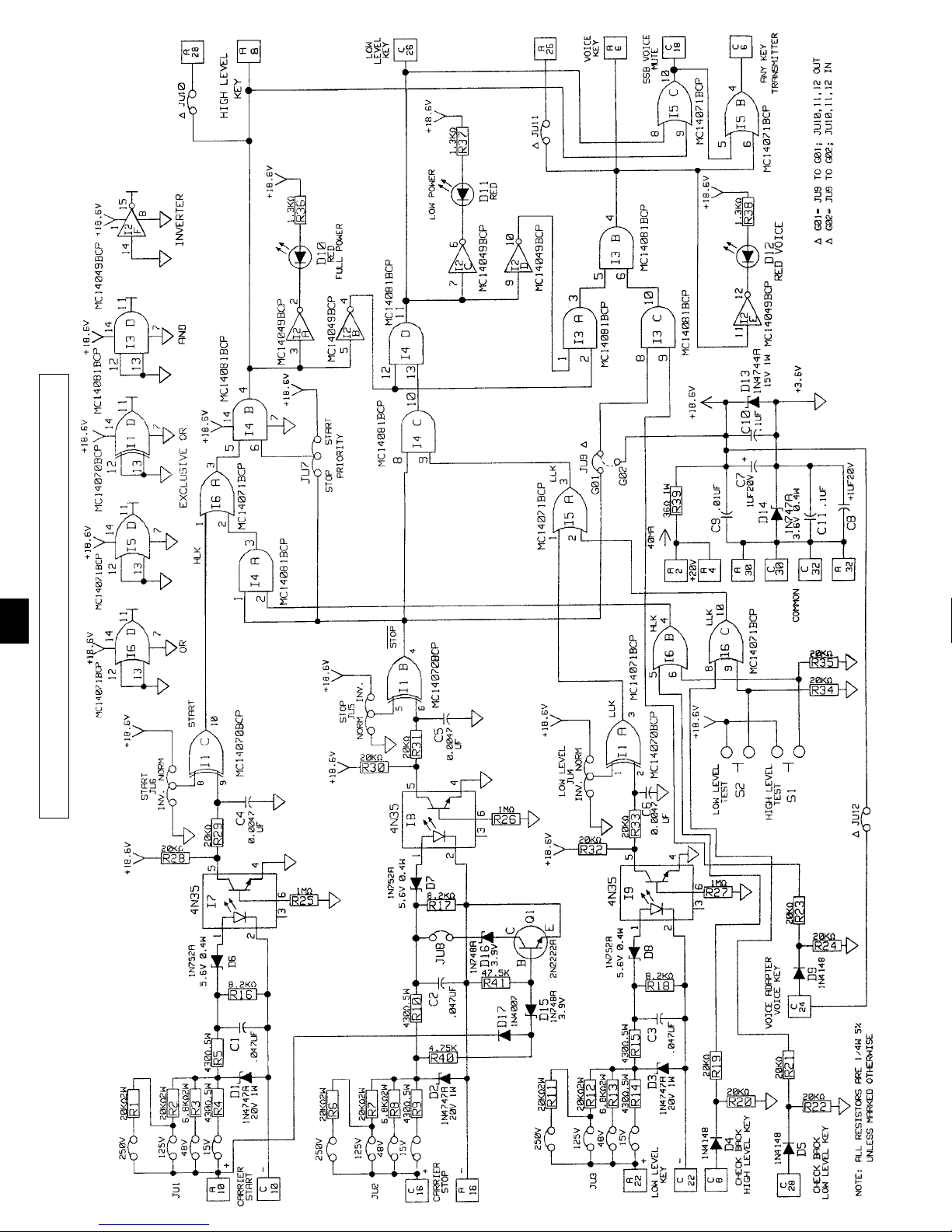

10-3 Keying Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-6

11-1 Transmitter Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

11-2 Optional TTL Module Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-4

11-3 Transmitter PC Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-6

Page vi October 2003

Technologies, Inc.

Page 9

11-4 Transmitter Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-7

11-5 Transmitter Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-8

11-6 TTLTransmitter PC Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-9

11-7 TTLTransmitter Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-10

12-1 10W PA Module Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

12-2 10W PA PC Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-4

12-3 10W PA Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-5

13-1 RF Interface Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-1

13-2 RF Interface PC Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-3

13-3 RF Interface Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-4

14-1 Universal Receiver Simplified Signal Flow Diagram . . . . . . . . . . . . . . . . . . . . .14-1

14-2 Universal Receiver Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-2

14-3 Universal Receiver Location of SW1 Dip switch & J3 . . . . . . . . . . . . . . . . . . .14-7

15-1 Receiver Output Module — Simplified Signal Flow Diagram . . . . . . . . . . . . . .15-1

15-2 Receiver Output Module Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-2

15-3 Receiver Output PC Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-6

15-4 Receiver Output Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-7

16-1 Universal Checkback as part of a TC-10B . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-4

16-2 Maximum Checkback Configuration with Timed Communications Mode . . . . . .16-5

16-3 Maximum Checkback Configuration with Coded Communications Mode . . . . .16-5

16-4 Universal Checkback Module Front panel Controls and Indicators . . . . . . . . . . .16-5

16-5 Initial Communication with the Checkback Module . . . . . . . . . . . . . . . . . . . . .16-12

16-6 Get Event Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-15

16-7 Example of a Remote Logon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-16

16-8 Universal Checkback Module –Timed Sequence (Master initiated) . . . . . . . . . .16-27

16-9 Universal Checkback Module –Timed Sequence (Remote 1 initiated) . . . . . . . .16-28

16-10 Universal Checkback Module simplified Component Layout . . . . . . . . . . . . . .16-42

16-11 Universal Checkback Module Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . .16-43

17-1 Voice Adapter Module — Simplified Signal Flow Diagram . . . . . . . . . . . . . . . .17-1

17-2 Voice Adapter Module Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-4

17-3 Voice Adapter Module PC Board (C020VADMN) . . . . . . . . . . . . . . . . . . . . . . .17-6

17-4 Voice Adapter Module Schematic (C030VADMN1 Sheet 1 of 2) . . . . . . . . . . . .17-7

17-5 Voice Adapter Module Schematic (C030VADMN2 Sheet 2 of 2) . . . . . . . . . . . .17-8

17-6 Connections for Remote Phone and External Alarm . . . . . . . . . . . . . . . . . . . . . .17-9

17-7 External Alarm Circuit for Use with Module Front Panel Jack . . . . . . . . . . . . .17-10

17-8 Handset Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-10

October 2003 Page vii

TC–10B System Manual

Page 10

TABLES

Table No. Page No.

1-1 Transmitter/Receiver Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

1-2 Keying Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

1-3 Receiver Output Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1-4 Alarm & Level Option Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1-5 Checkback Option Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

1-6 Voice Adapter Option Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1-7 Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

1-8 Altitude Dielectric Strength De-Rating for Air Insulation . . . . . . . . . . . . . . . . . . .1-7

1-9 Altitude Correction for Maximum Temperature of Cooling Air . . . . . . . . . . . . . .1-7

1-10 Power Requirement Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

1-11 Weight and Dimension Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8

2-1 Directional Comparison Schemes for External and Internal Faults. . . . . . . . . . . . .2-3

2-2 TC–10B Catalog Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-8

2-3 TC–10B Catalog Numbers/Module Style Numbers . . . . . . . . . . . . . . . . . . . . . . .2-9

2-4 Voice Adapter Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

2-5 Other TC–10B Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

2-6 External Resistor Requirements – Provided with Chassis, According to Voltage .2-10

3-1 Attenuator Override Jumper Sensitivity Levels . . . . . . . . . . . . . . . . . . . . . . . . . . .3-7

4-1 Recommended Test Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

7-1 Voltage Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-1

7-2 Universal Checkback Module DIP Switch Settings . . . . . . . . . . . . . . . . . . . . . . . .7-2

7-3 Voltage Levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-3

7-4 Keying Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-4

7-5 Level Detector and CLI Test Procedure Specifications. . . . . . . . . . . . . . . . . . . . .7-5

7-6 Receiver Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-6

9-1 1617C38 Styles and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-1

10-1 1606C29 Styles and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

11-1 1610C01 /Styles and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-1

Page viii October 2003

Technologies, Inc.

Page 11

TABLES, Cont’d

Table No. Page No.

12-1 1606C33 Styles and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

13-1 1609C32 Styles and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-1

14-1 Universal Receiver Style . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-1

14-2 Receiver System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-3

14-3 ON–OFF Frequency Spacing Specifications (Minimum) . . . . . . . . . . . . . . . . . .14-4

14-4 AM Receiver (SW1-1 set to the ON position . . . . . . . . . . . . . . . . . . . . . . . . . . .14-4

15-1 CC20-RXSMN-001 Styles and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-1

15-2 Output Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-3

15-3 Receiver Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-5

16-1 Universal Checkback Module Style and Description . . . . . . . . . . . . . . . . . . . . . .16-1

16-2 Universal Checkback Module DIPswitch settings . . . . . . . . . . . . . . . . . . . . . . .16-9

16-3 Factory Preset Configuration Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-10

16-4 Primary/Fallback Communications Options . . . . . . . . . . . . . . . . . . . . . . . . . . .16-24

16-5 Test and General Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-37

16-6 Output States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-37

16-7 Test and Communications Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-38

16-8 Programmable Output Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-38

16-9 Times and Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-38

16-10 Information Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-38

16-11 Clearing Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-39

16-12 Action commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-39

16-13 Logon commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-39

16-14 Help commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-39

16-15 Networking Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16-40

17-1 C020-VADMN Styles and Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-1

17-2 Voice Adapter Module Electrical Characteristics . . . . . . . . . . . . . . . . . . . . . . . . .17-3

17-3 DIPSwitch Setting Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-5

17-4 Default (Normal) Settings for TC-10B Operation . . . . . . . . . . . . . . . . . . . . . . . .17-5

October 2003 Page ix

TC–10B System Manual

Page 12

Technologies, Inc.

Page 13

1.1 Standard Features

The TC–10B frequency-programmable power-line-carrier set offers the following features as standard:

• Programmable over 30–535kHz (in 0.5kHz steps) with direct frequency readout

• Frequencies are easily field-selectable by rotary switches (transmitter) -or- push button (receiver)

•Wideband (1,600Hz) receiver for use with all blocking systems

• Narrow band (800Hz) receiver for use with directional-comparison blocking systems where there

is a need to improve signal-to-noise ratio (SNR)

• High receiver sensitivity: 22.5mV....(Standard setting)

5mV....(High-sensitivity setting)

• Universal keying/receiver output

• 300-2,000Hz range audio channel for maintenance Voice Channel

• Built-in low/high level carrier test switches

•dc-to-dc isolated power supply

• 48, 125, and 250Vdc versions available

1.2 Standard Nomenclature

The standard nomenclature for PULSAR carrier protection equipment is as follows:

Cabinet – contains fixed-racks, swing-racks, or open racks

Rack – contains one or more chassis (e.g., the TC–10B)

Chassis – contains several printed circuit boards, called modules (e.g., Transmitter or Receiver)

Module – contains a number of functional circuits (e.g., Oscillator or Synthesizer)

Circuit – a complete function on a printed circuit board

1.3 TC–10B Chassis

The TC–10B chassis specifications include standard dimensions of:

Height – 5.25” (133.35 mm), requiring 3 rack units, each measuring 1.75” (44.45 mm)

Width – 19.00” (482.6 mm) Depth – 13.50” (342.9 mm)

Each chassis is notched for mounting in a standard relay rack.

Copyright © 2003 Pulsar Technologies, Inc.

Chapter 1. Product Description

1

Page 14

1.4 TC–10B Modules

The TC–10B circuitry is divided into standard modules with optional Voice Adapter, TTL Transmitter and

Universal Checkback modules available, as shown on the Functional Block Diagram (Fig. 6-1). Circuit

descriptions, complete with schematic diagrams, are shown in Chapters 9 through 17 with Sub Numbers

that indicate appropriate revisions for each module, as follows:

Chapter

Module

Schematic

9. Power Supply 1617C38-2

10. Keying 1606C29-7

11. Transmitter 1355D71-8

12. 10W PA 1606C33-20

13. RF Interface 1609C32-8

14. Universal Receiver not user serviceable

15. Receiver Output (Solid State) CC30-RXSMN

16. (Optional) Universal Checkback not user serviceable

17. (Optional) Voice Adapter C030-VADMN

Page 1–2 October 2003

TC–10B System Manual

NOTE

See Chapter 2, Applications and Ordering Information, for ordering information. See Chapter 3,

Installation, for a summary of jumper controls.

Technologies, Inc.

Page 15

1.5 SPECIFICATIONS

The TC–10B meets or exceeds all applicable ANSI/IEEE standards.

1.5.1 Transmitter/Receiver

Table 1-1 lists the Transmitter/Receiver specifications for the TC–10B.

October 2003 Page 1–3

Chapter 1. Product Description

1

Table 1–1. Transmitter/Receiver Specifications.

Frequency Range 30–535 kHz in 0.5 kHz (500Hz) steps, transmitter selection in

100Hz steps

4-Wire Receiver Input Impedance 5,000

Ω or 1,000Ω

RF Output Impedance 50, 75 or 100Ω (nominal unbalanced)

Output Power • 10 watts (max)

• 100 watts (with optional external amplifier)

Frequency Stability ± 10Hz (typical)

Nominal Receiver Bandwidths • Narrow band: (800Hz at 3db points)

• Wide band (1600Hz at 3db points)

• On-Off Phase Comparison (3,500Hz at 3db points)

Harmonic Distortion 55db below full power

Receive Sensitivity

Narrow Band

or • 22.5 mV (min) to 70V (max) Standard setting

Wide Band

•5 mV (min) to 17V (max) High setting

Page 16

Page 1–4 October 2003

TC–10B System Manual

Channel Speed at 15dB Margin, Solid State Output

Narrow Band (800Hz) 3.8ms (pickup) 6.0ms (dropout) typical

Standard (Wide) Band (1,600Hz) 2.4ms (pickup) 3.8ms (dropout) typical

Phase Comparison Band (3,500Hz) 1.3ms (pickup) 1.5ms (dropout) typical

Minimum Channel Spacing

1.5.2 Keying

Table 1-2 shows the TC–10B keying specifications.

Carrier Start, Carrier Stop All optically isolated for operation at 15V, 48V, 125V, or

Auxiliary (Reduced Power) 250Vdc, strappable for either presence or absence of voltage

Keying for keying, as well as carrier start or stop priority (maximum

burden is 20 mA).

Manual Keying Recessed push button switches for carrier start and auxiliary

keying.

Table 1–1. System Specifications (Cont’d).

Table 1–2. Keying Specifications.

Wideband 4 kHz

Narrow band 2 kHz

With Voice Adapter 4 kHz

(both Narrow band

and Wideband)

An external hybrid or other device offering at least 20db rejection of the adjacent channel

must be used in the application

Technologies, Inc.

Page 17

October 2003 Page 1–5

Chapter 1. Product Description

1

1.5.4 Alarm & Level Option

Table 1-4 shows Alarm & Level Option specifications for the TC–10B.

1.5.3 Receiver Outputs

Table 1-3 shows the TC–10B Receiver Output Specifications.

Two independent relaying Both outputs (fully isolated) provide up to 1 A transistor switch

outputs for microprocessor relaying or 200 mA(into 24Ω), 20mA (into

2,200Ω); will operate from any battery supply (20 to 280Vdc)

One receive alarm output One Form A100VA, 125Vdc (maximum)

One carrier level output (optional)

0–100 µA for external indicator

Table 1–3. Receiver Output Specifications.

Alarm Contacts (dc Power Loss, Form Aor B contacts (field strappable) rated 100VA; 0.5 sec

RF “ON”, and Receive at Margin; of dropout delay

3 separate relays)

Carrier Level Indication Meter –20db to +10dB

Reading

Table 1–4. Alarm & Level Option Specifications.

Table 1–5. Universal Checkback Option Specifications.

• PC interface for controlling settings and operation • Automatic checkback tests done either

• On-line help periodically or at user specified times

• User selectable encoded or timed carrier • Loopback test capability

• Three user programmable outputs • Remote communications

• Optional timed communications fallback • Automatic clock synchronization

• Optional low power tests • Optional carrier recovery

1.5.5 Universal Checkback Options

Table 1-5 shows Universal Checkback Option specifications for the TC–10B.

Page 18

Page 1–6 October 2003

TC–10B System Manual

Ambient temperature range of -20 to +60°C (derated per Table 1-9) (ANS C37.90.)

air-contacting equipment

Relative humidity Up to 95% (non-condensing) at 40°C (for 96 hours cumulative)

(ANS/UL 508)

Altitude • Up to 1,500 m (without derating)

• Up to 6,000 m (using Table 1-8 and Table 1-9)

SWC and FAST Transient All external user interfaces meet SWC and FAST Transients of

ANS C37.90.1 and IEC 255-6

Dielectric Only isolated inputs and outputs, and all alarms: 2,500Vdc from

each terminal to ground, derated per Table 1-8.

(IEC 255-5)

Center conductor of coaxial 3,000Vdc impulse level, using 1.2 x 50ms impulse

cable to ground

Electro-Magnetic Interference IEEE Trial-Use-Standard P734/D5/R4 (ANS C37.90.2).

Compatibility:

Table 1–7. Environmental Specifications.

Modulation Amplitude Modulation with compandor

Transmission Half-Duplex

Frequency Response 300Hz to 2 kHz

Signaling Carrier alarm

Table 1–6. Voice Adapter Option Specifications.

1.5.6 Voice Adapter Option

Table 1-6 shows the TC–10B Voice Adapter Option specifications.

1.5.7 Environmental

Table 1-7 shows the TC–10B environmental specifications.

Technologies, Inc.

Page 19

October 2003 Page 1–7

Chapter 1. Product Description

1

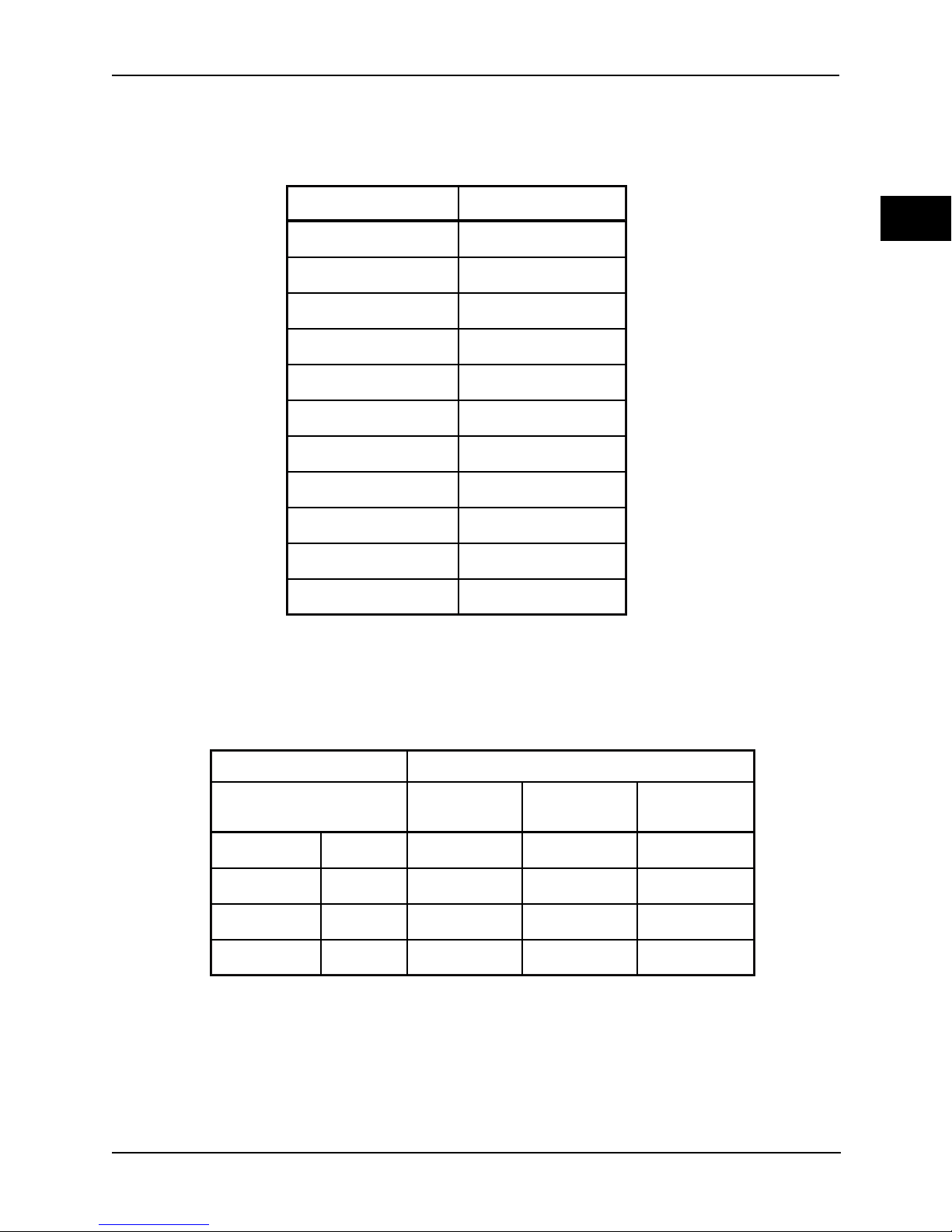

Temperatures (Degrees C)

Altitude (Meters) Short-Time Long-Time Difference

From Usual

Usual 1,500 55 40 —

Unusual 2,000 53 38 2

Unusual 3,000 48 33 7

Unusual 4,000 43 28 12

Table 1–9.

Altitude Correction For Maximum

Temperature Of Cooling Air (ANS C93.5).

Altitude (Meters) Correction Factor

1,500 1.00

1,800 0.97

2,100 0.94

2,400 0.91

2,700 0.87

3,000 0.83

3,600 0.79

4,200 0.74

4,800 0.69

5,400 0.64

6,000 0.59

Table 1–8.

Altitude Dielectric Strength

De-Rating for Air Insulation

Page 20

Page 1–8 October 2003

TC–10B System Manual

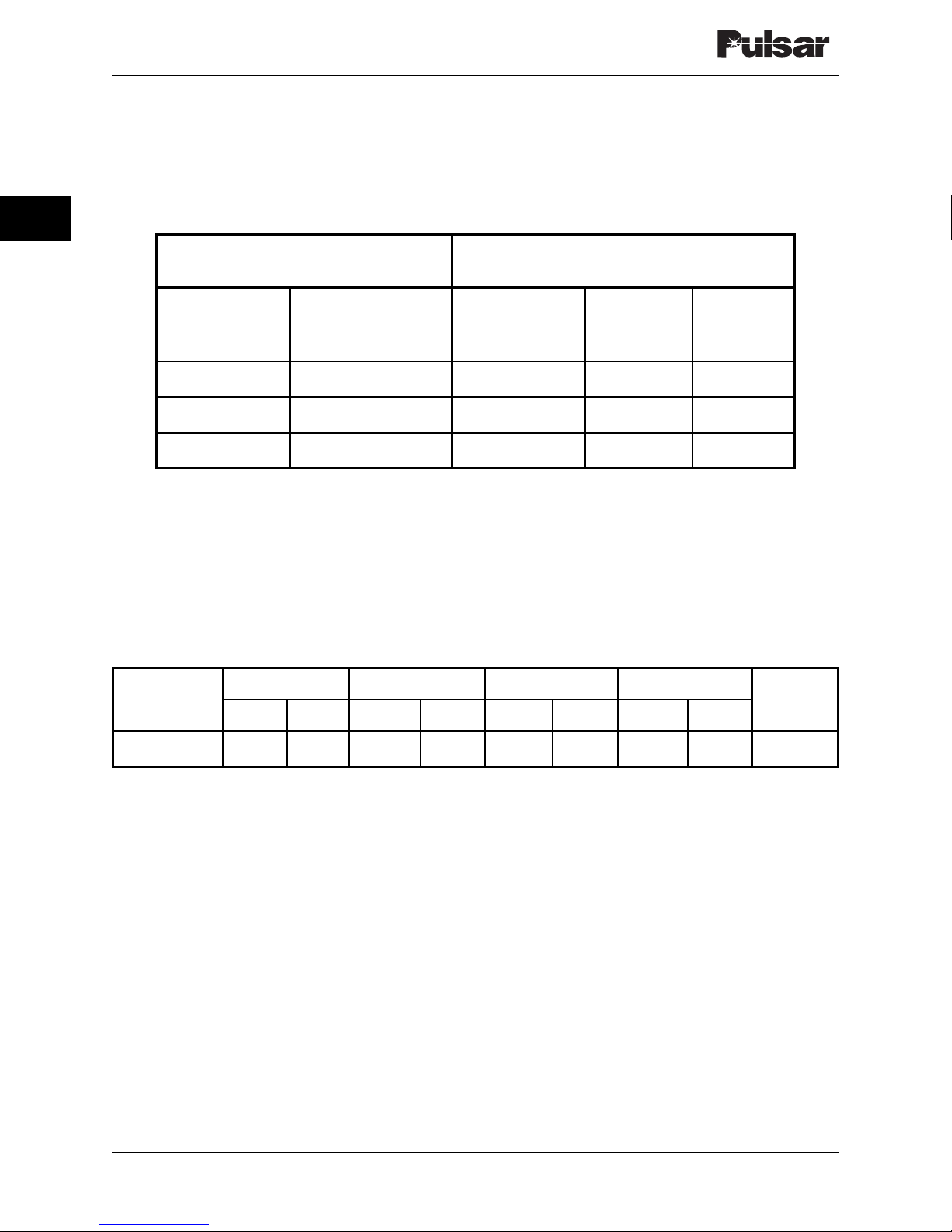

1.5.8 Power Requirements and Dimensions

Table 1-10 shows the TC–10B power requirement specifications.

Table 1-11 shows the TC–10B weight and dimension specifications.

Transceiver Supply Current (Amps)

At Nominal Voltage

Nominal Permissible

Battery Voltage Receive/ 1 Watt 10 Watt

Voltage Range Standby Transmit Transmit

48/60Vdc 38–70Vdc .630 .940 1.600

110/125Vdc 88–140Vdc .240 .360 .600

220/250Vdc 176–280Vdc .120 .180 .300

Table 1–10. Power Requirement Specifications.

Equipment Net Weight Height Width Depth Rack

lbs Kg inches mm inches mm inches mm Space

Transceiver 21 9.53 5.25 133.4 19.00 482.6 13.50 342.9 3 RU

Table 1–11. Weight and Dimension Specifications.

Technologies, Inc.

Page 21

1

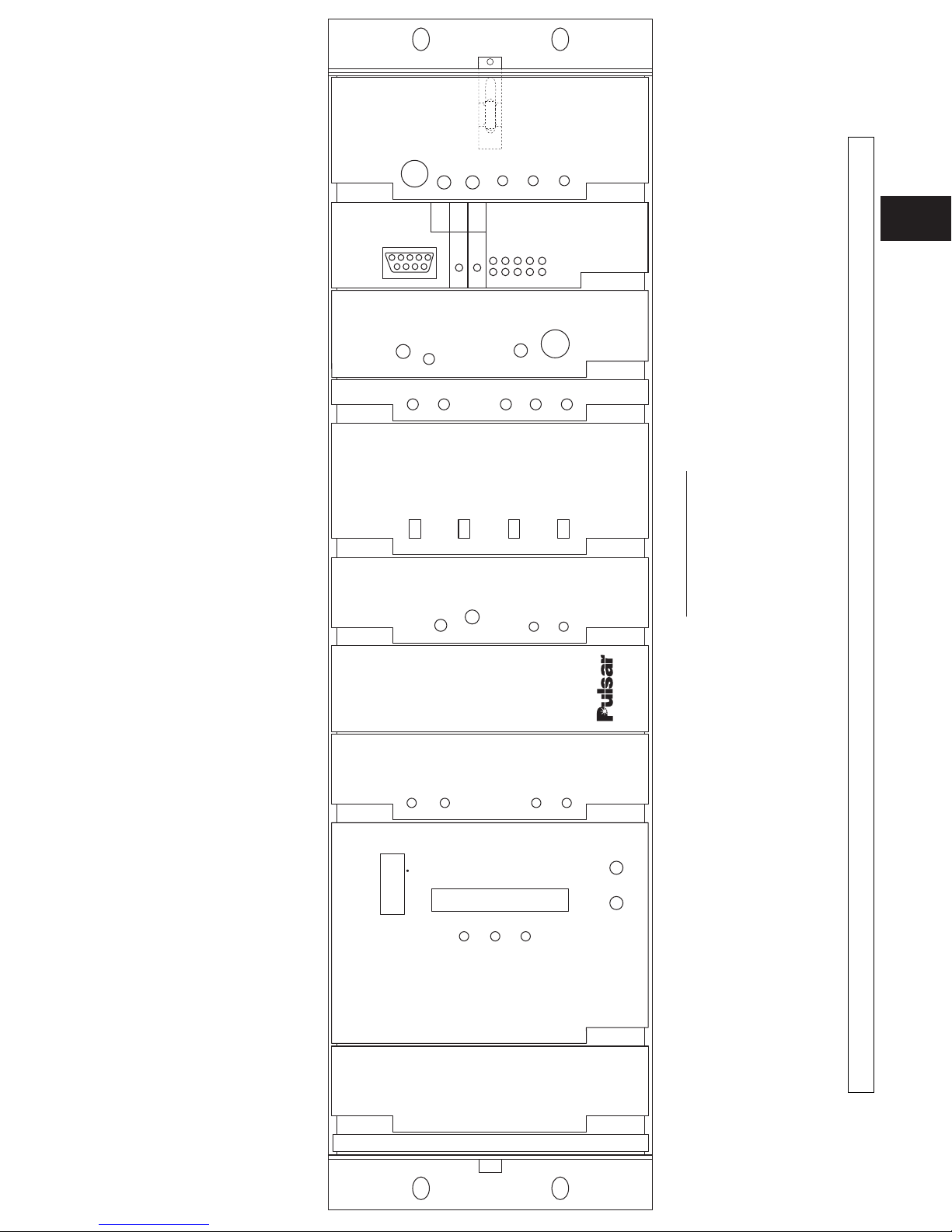

Figure 1–1. TC–10B Chassis and Control Panels with Optional Universal Checkback and Voice Adapter Modules. (1354D16A)

POWER SUPPLY

POWER

INPUT

OUTPUT

+20V

COMMON

–20V

POS. 22

LOOP

HOLD

2 SEC

PC

INTERFACE

CHECKBACK

POS. 20

CALLING

P.B .

T

ALARM

E

S

HL

VOICE ADAPTER

POS. 18

KEY

POS. 17

RECOVER

MAJOR ALRM1MINOR ALRM2RECOVERY3REMOTE LOGON

ALARM

CHECK

RST

TST

T

LL

HL

4

AUDIO

RECEIVE

E

Y

K

LL

CHECK OK

C

PRGM

SET

HANDSET

I

N

G

V

POS. 14

POS. 12

POS. 10

POS. 8

TRANSMITTER

10W POWER AMP

TC–10B

RF INTERFACE

UNIVERSAL RECEIVER

F

POWER

ON-OFF

LINE

kHz

R

E

Q

TRANSMIT

LINE

CARRIER

LINE

COM

+10

U

INPUT

+5

E

N

LEVEL

C

SET

0

Y

X

1

0

0

H

Z

INPUT

COMMON

CC44

RCVR

–15

BLOCK DIAG.

RCVR

COM

–20

1353D16

Technologies, Inc.

AM: MARGIN DETECT

MANUAL

CAT. NO.

S1A1WVAS

–5 dB

–10

SET

LOWER

FRONT VIEW

MADE IN U.S.A.

SIGNAL

FSK: LOW NOISE

CANCEL / RAISE

POS. 3

RCVR OUTPUT

POS. 1

Page 22

Page 1–10 October 2003

TC–10B System Manual

USER NOTES

Technologies, Inc.

Technologies, Inc.

Page 23

2.1 Protective Relay

Applications Using

ON/OFF Carriers

The TC–10B carrier set is particularly suitable for

the following types of protective relay systems:

• Directional-Comparison Blocking

• Phase-Comparison Blocking

• Current Only

• Distance Supervised

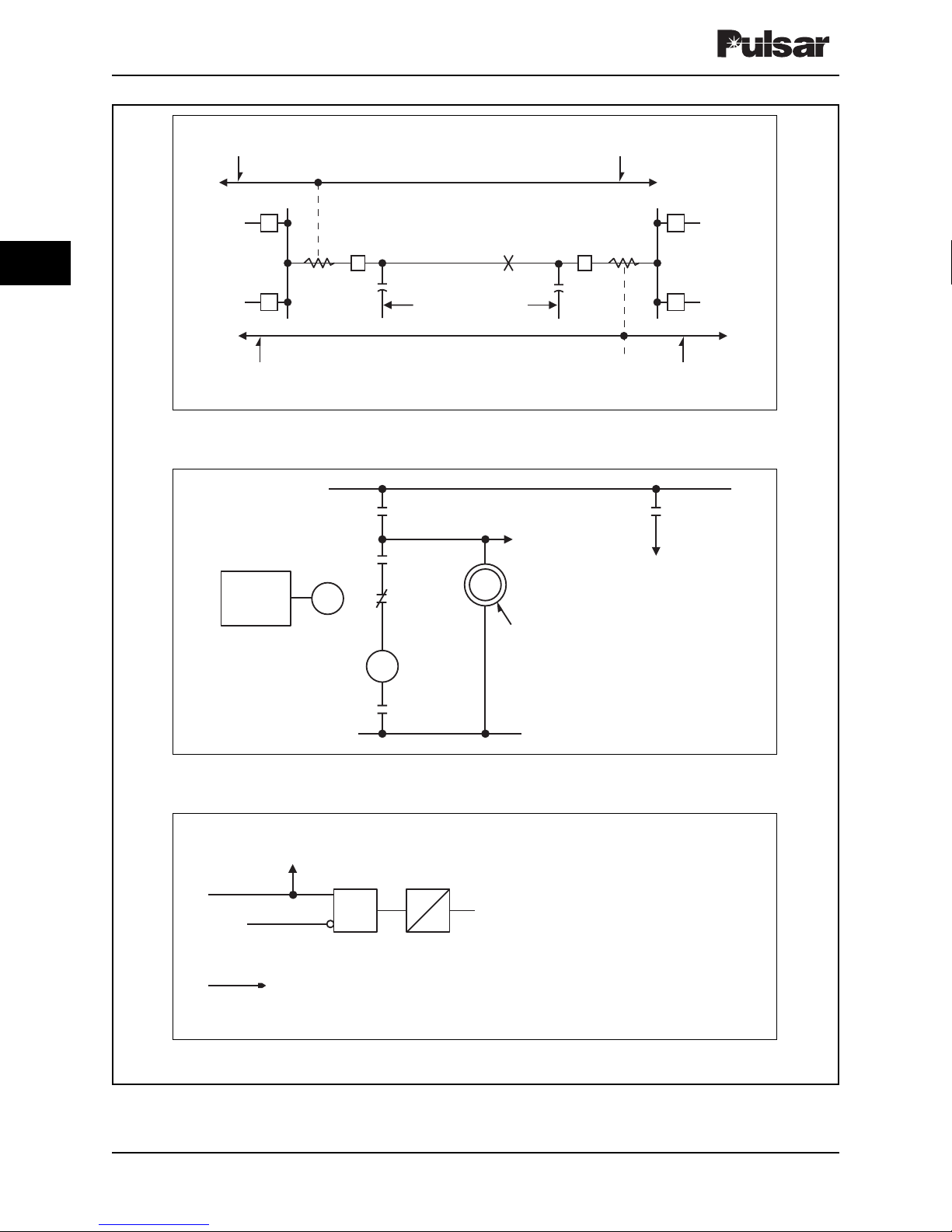

2.1.1 Directional-Comparison

Blocking

The basic elements for directional-comparison

blocking systems are shown in Figure 2-1a and

Figure 2-1b. At each terminal, the phase and

ground trip units (P) must be directional and set to

overreach the remote terminal; that is, they must

be set to operate for all internal faults. Nominal

settings of the distance units are 120 to 150

percent of the line. The start units (S) must reach

farther, or be set more sensitively, than the remote

trip units. Thus S

1 must be set more sensitively

than P

2 or reach farther behind bus G. Likewise,

S

2 must be set more sensitively than P1 or reach

farther behind bus H. In any case, the S and P

relays should be similar in type. If the trip unit (P)

is a directional overcurrent ground relay, the start

(S) ground relay should be a similar non-directional overcurrent unit. The same principle applies

for the phase relays.

When the TC–10B ON-OFF power line carrier is

used with these schemes, except for possible

auxiliary functions, no signal is normally trans-

mitted, since the S units operate only during fault

conditions.

Operation of the directional-comparison scheme

(shown in Figure 2-1a and Figure 2-1b) is internal

faults. Subscript 1 indicates relays at station G for

breaker 1; subscript 2, relays at

station H for breaker 2. (Figure 2-1c shows a

solid-state logic version of Figure 2-1b.)

The schemes shown are still widely used for their

flexibility and reliability. Since the communication channel is not required for tripping, internal

faults that might short and interrupt the channel

are not a problem. Over tripping will occur,

however, if the channel fails or is not established

for external faults within the reach of the trip fault

detectors. Since the carrier transmitter is normally

OFF, or non-transmitting, channel failure cannot

be detected until the system is tested or until an

external fault occurs. This limitation can be

overcome by using the optional TC–10B

checkback system with the TC–10B carrier.

2.1.2 Phase-Comparison Blocking

Basic elements of the phase-comparison systems

are shown in Figure 2-2. The system uses a

composite sequence current network to provide a

single-phase voltage output proportional to the

positive, negative, and zero sequence current

input. Sensitivity to different types of faults

depends on the weighting factors or constants

designed into the sequence current network.

Adjustments to the network are provided.

A squaring amplifier in the controlling relay

converts the single-phase voltage output to a

square wave. The positive voltage portion corresponds to the positive half-cycle of the filter

voltage wave and the zero portion corresponds to

the negative half-cycle. The square wave is used

to key the TC–10B, transmitting to the remote

terminal. The square wave from the remote

terminal is compared to the local square wave,

which has been delayed by an amount equal to the

absolute channel delay time. This comparison of

the local and remote square waves at each

Copyright © 2003 Pulsar Technologies, Inc.

Chapter 2. Applications and Ordering Information

2

Page 24

Page 2–2 October 2003

TC–10B System Manual

Technologies, Inc.

2-1a – Basic Elements for directional-comparison blocking systems.

2-1c – Solid State Logic (per Terminal).

Figure 2–1. Directional-Comparison Blocking, Basic Elements and Logic Diagrams.

2-1b – Contact Logic (per Terminal).

Breaker 1 Channel

Start Fault Detectors (S1)

G

Protected Line

1 2

Breaker 2 Trip Fault Detector (P2)

F

I

Power Line Carrier

Channel

Breaker 1 Trip

Fault Detector (P1)

H

Breaker 2 Channel

Start Fault Detectors (S2)

S

Initiate

Channel

Signal

Channel

Signal

Receiver

RR

P

CS

RR

Trip

Coil

Stop Channel

Signal if

Initiated

Locally

CS

Pick-up

Approximately

13–16 Ms

F

E

52a

Stop Channel Signal if

Initiated Locally

Timer

P

S From

AND

X

Trip

O

Remote Terminal

Via Channel

S Initiate Channel Signal

X – Nominally Between 6–16 Ms

Note: (P) Operation or (S) Signal

Provides an Input 1 on Circuit.

Page 25

terminal determines whether a fault

is internal or external.

Fault detectors are used to determine

whether a fault has occurred and to

supervise tripping. The fault

detectors must be overreaching, i.e.,

set sensitively enough to operate for

all internal phase and ground faults.

Because overcurrent fault detectors

are normally used, voltage transformers are not required. Such a

scheme is current only. Fault

detectors should be set above

maximum load, yet operate for all

internal faults. Distance fault

detectors, which require voltage

transformers, are used on heavyloaded or long lines when distance

supervision is required.

October 2003 Page 2–3

Chapter 2. Applications and Ordering Information

2

Table 2–1. Directional Comparison Schemes for External and Internal Faults.

* For external faults, the CS unit or timer x/o assure that a blocking signal is established.

SCHEME FOR EXTERNAL AND INTERNAL FAULTS

Type of Fault Events at Station G Events at Station H

External (FE)

For external faults, the

CS unit or timer x/o

assure that a blocking

signal is established.

P1operates; S1does not see

fault. Blocking signal received

from station H. RR back

contacts open (or 1 signal

negates AND).

No trip.

S2operates to key transmitter.

Blocking signal sent to station

G. P2does not see fault.

No trip.

Internal (FI) P1operates; S1may or may not

operate, but P1operation

prevents transmission of a

blocking signal.

Breaker 1 tripped.

P2operates, S2may or may not

operate but P2operation

prevents transmission of a

blocking signal.

Breaker 2 tripped.

Figure 2–2. Phase-Comparison Blocking, Basic Elements.

G

1 2

Protected Line

Sequence

Network

Squaring

Amplifier

Three Phase

and Neutral

Single Phase

Output

Delay

Circuit

Channel

Comparison

Circuit

Trip Breaker 1 Trip Breaker 2

Sequence

Network

Squaring

Amplifier

Delay

Circuit

Comparison

Circuit

H

Three Phase

and Neutral

Single Phase

Output

Page 26

Page 2–4 October 2003

TC–10B System Manual

Technologies, Inc.

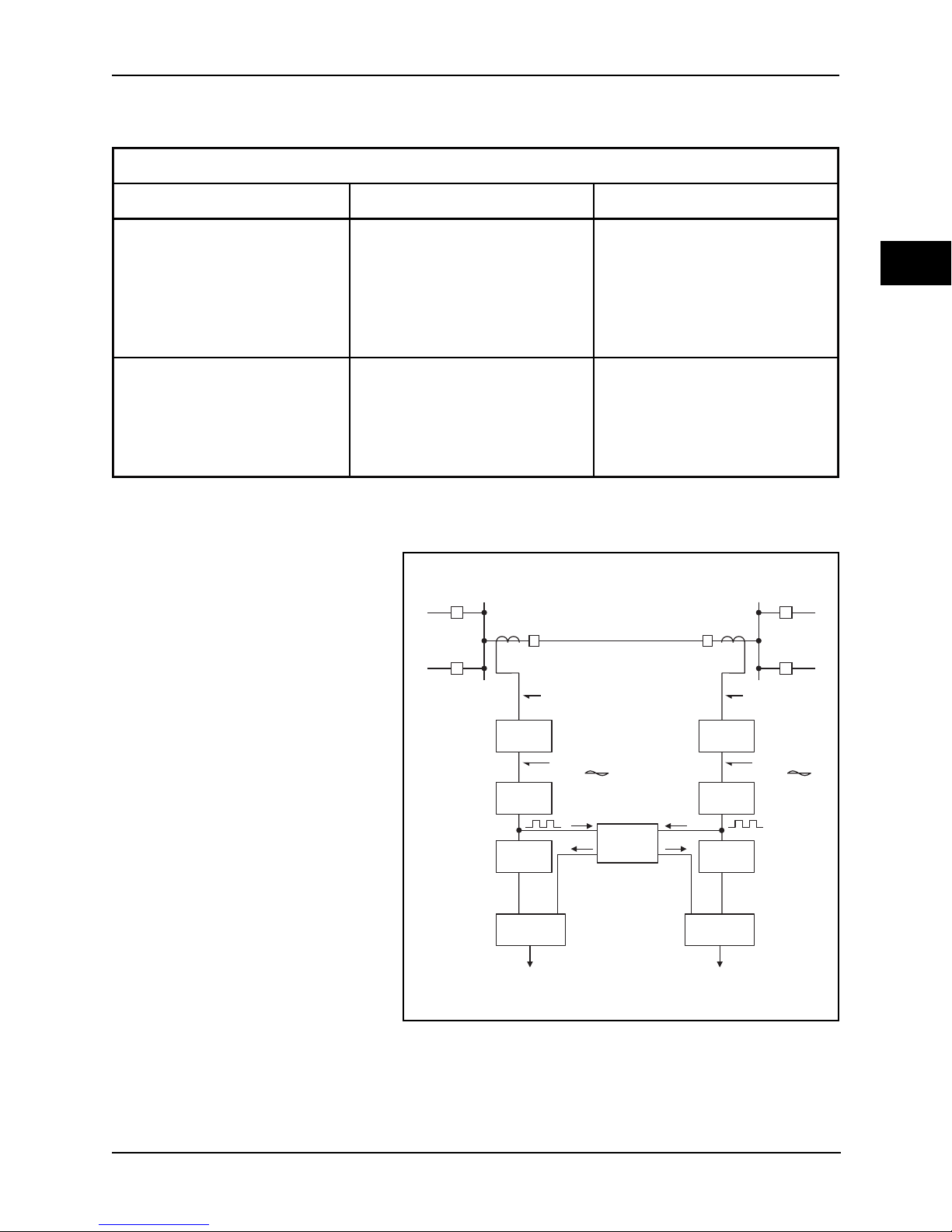

2.1.3 Single PhaseComparison

Blocking, Current

Only

In the current only system, the

TC–10B is used with two overcurrent fault detectors (FD

l and FD

2).

FD

1, the carrier start unit, is set

more sensitively than FD

2 and

permits the local square wave

signal to key the “ON/OFF” carrier

transmitter. FD2, set with a higher

pickup than FD1, is used to arm the

system for tripping. For transmission lines less than 100 miles long,

the FD

2

pickup is set at 125 percent

of FD

1. For lines longer than 100

miles, the FD

2 pickup is set at 200

percent of FD

1. On a three-terminal

line, FD

2 is set at 250% of FD1,

provided the line length between

any two breakers is less than 100

miles. Phase-Comparison cannot

occur until FD

2 operates. The

purpose of the two fault detectors is

to coordinate the comparison of the

local and remote square waves with

the keying of the carrier square

wave. The carrier must be started

before the comparison is allowed

to ensure that the remote square

wave has been received.

The basic operation of the system is

shown in Figure 2-3. FD

1

and FD2at

both terminals operate for an

internal fault (F

I

). The square wave

inputs to the AND from the local

currents are essentially in phase

with those transmitted via the

channel from the remote terminal.

The local square wave turns the

carrier “ON” and “OFF” to provide

the square wave receiver output for

the remote terminal.

A flip flop is energized if the inputs

to the AND continue for 4ms,

providing a continuous trip output

supervised by FD2 operation. The 4ms correspond to a phase

angle difference of 90°, on a 60-Hz base, between the currents at

the two terminals. The currents at the two ends of the line may

be out of phase by up to 90° and still trip. This is a blocking

system, since the receipt of a signal from the channel prevents

tripping. The carrier signal, therefore, does not have to be transmitted through the internal fault. No received signal puts a “1”

on the AND input. With the remote terminals open, this system

provides sensitive instantaneous overcurrent protection for the

entire line. As is characteristic of blocking systems, the channel

is not required for tripping on internal faults.

For an external fault, such as F

E in Figure 2-3, blocking is essen-

tially continuous, since the remote wave input to the AND is

out-of-phase with the local square wave. The secondary ct

currents are essentially out-of-phase for an external fault. The

currents can, however, be in-phase by up to 90

° on a 60-Hz base

and still block.

Figure 2–3.

Single Phase Comparison Blocking, Current Only Operation.

G

FI& F

E

1 2

Fault Detecting Logic

(Figure 2–2)

Transmitter

Receiver

Receiver

Output

Local

Input

Arming Arming

Internal Fault (FI)

(at Terminal G*)

Local Input

to AND

Receiver

Output

Receiver Input

to AND

AND Output

Trip Output

* Equivalent operation and same trip output at Station H.

Comparison Circuit

Basic Logic

4

0

AND AND

Trip Breaker 1 Trip Breaker 2

0

0

0

0

Protected Line

Channel

1

0

1

1

1

F

I

Fault Detecting Logic

(Figure 2–2)

Transmitter

Receiver

Comparison Circuit

Basic Logic

4

0

External Fault (FE)

(at Terminal G*)

0

0

1

0

0

H

F

E

F

I

F

Receiver

Output

Local

Input

1

11

0

0

0

E

Page 27

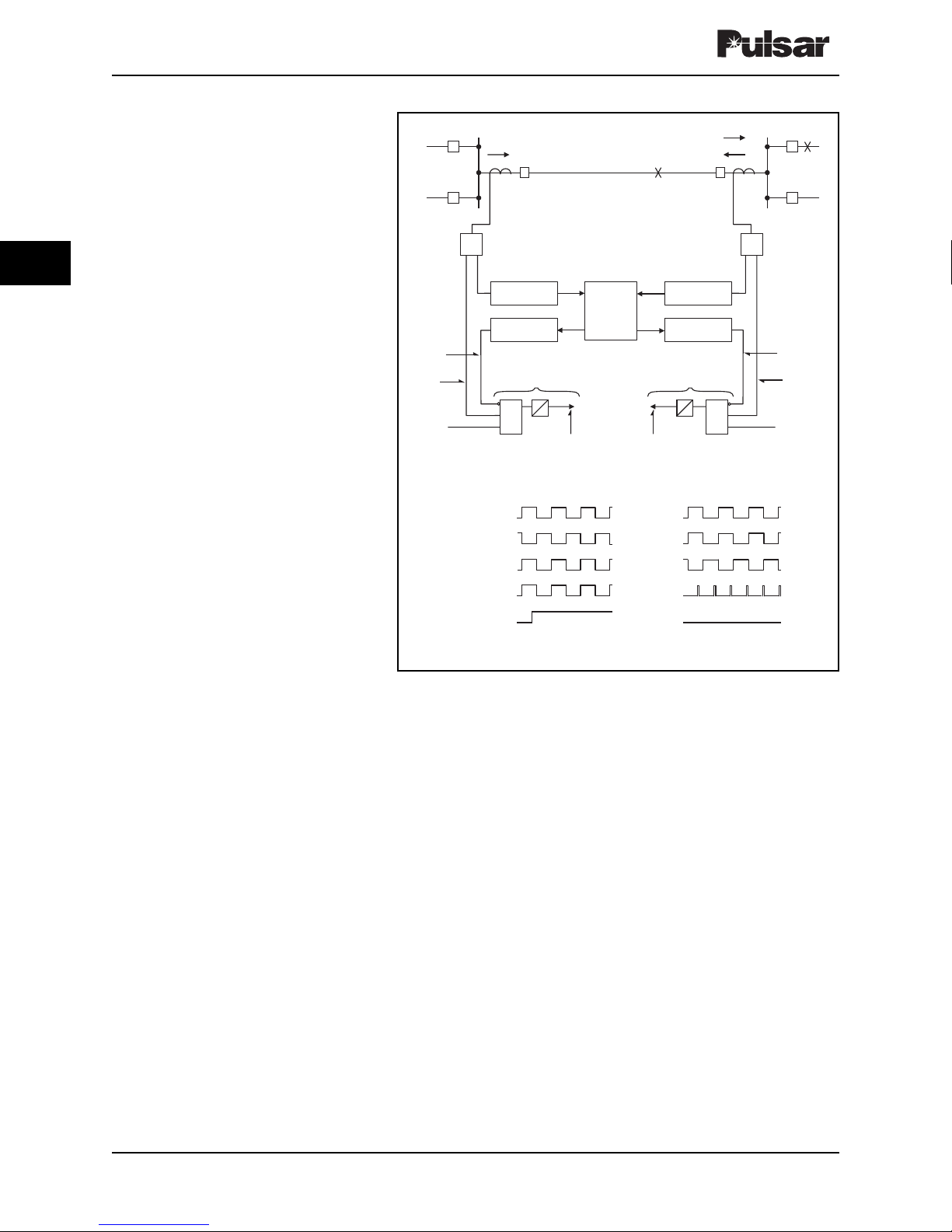

2.1.4 Single-Phase, Distance-

Supervised Comparison

Blocking

A distance-supervised scheme should be used

if the minimum internal three-phase fault

current is less than twice the maximum load

current. Twice maximum load current allows

FD

l to operate positively on the minimum

internal three-phase fault, yet reset when an

external fault is followed by a maximum load

current flowing through the line. The TC–10B

operates in the same manner as when used

with the current-only scheme, except for the

fault detection and arming techniques.

Two sequence current networks and two

distance relays supplement the two overcurrent fault detectors.

One sequence current network responds only

to negative and zero sequence currents,

detecting all phase-to-phase and ground faults

(but not three-phase faults). The output of this

adjustable network operates the conventional

overcurrent FD

l and FD2

fault detectors. The

two distance relays operate only for threephase faults. Thus, FD

2 provides the arming

function for all unbalanced phase and ground

faults, through the adjustable filter, and one of

the distance relays (21P) provides arming for

all three-phase faults.

The second and non-adjustable sequence

current network operates through the squaring

amplifier, providing the local square wave and

the carrier-keyed square wave required for

phase comparison. This signal is keyed by FD

1

and the second distance relay (21S) to provide

the carrier start functions. This second

network responds to positive, negative, and

zero sequence currents. Separate networks

provide greater sensitivity: with phase-tophase faults, for example, more than twice the

sensitivity is gained.

October 2003 Page 2–5

Chapter 2. Applications and Ordering Information

2

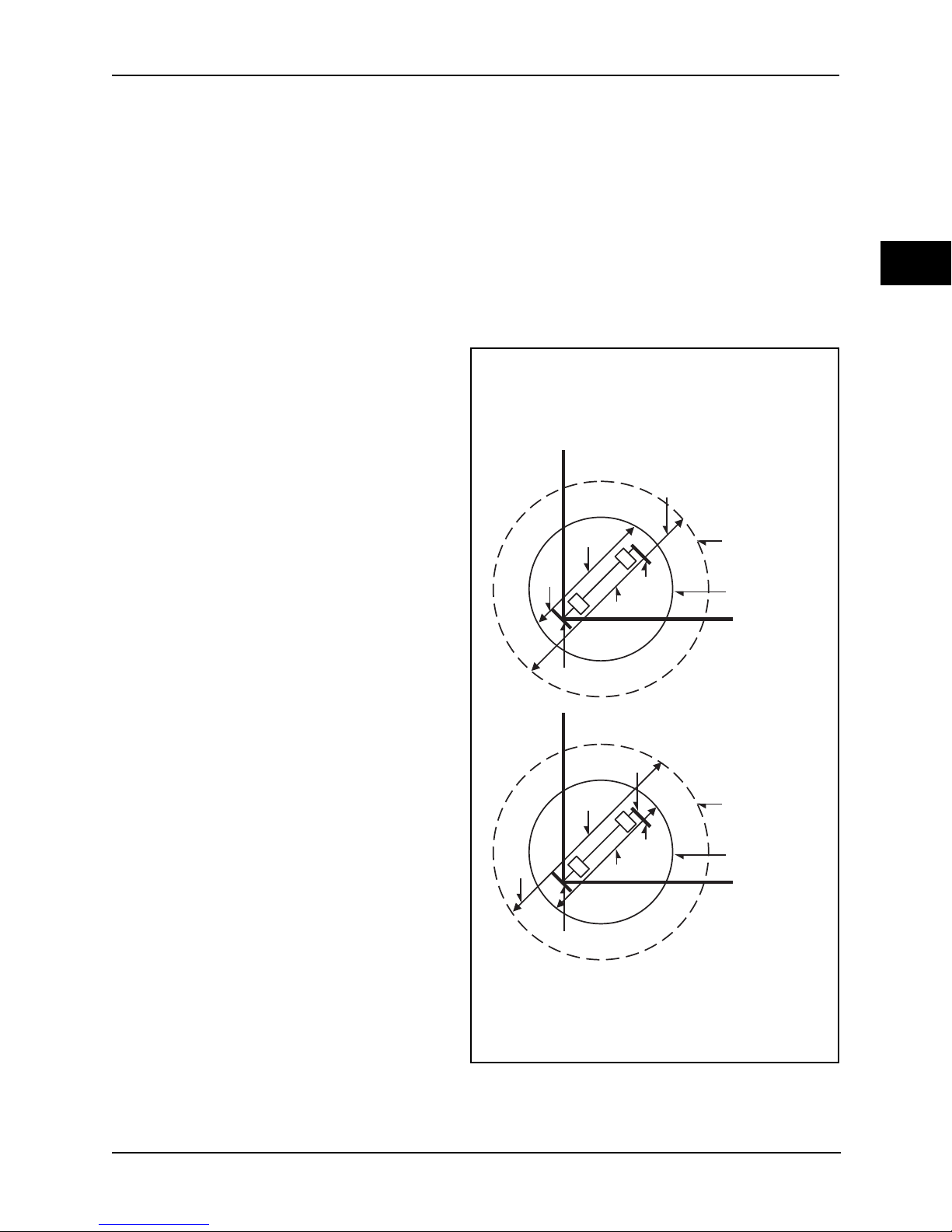

Figure 2–4. Single Phase-Comparison Blocking,

Distance-Supervised Operation.

The setting coordination of FDl and FD2 overcurrent

units is the same as for the current-only system.

Settings for the two three-phase distance units are

shown in Figure 2-4. Both 21S and 21Pdistance relays

must be set to overreach both the local and remote

terminal buses; 21S must be set further than 21P, as

shown.

X

Z

C

Z

Z

C

Bus G

A

2

Bus H

1

Z

A

X

21 S at Breaker

21 P at Breaker

R

Z

C

Bus H

Z

A

2

Z

C

1

Z

A

21 S at Breaker

21 P at Breaker

R

Bus G

Page 28

|| 2.1.5 Phase Comparison Relaying

and 20V Auxilliary Power

Supply

|| When ordering a TC-10B for use with phase

comparison relaying, a 20V auxilliary power

supply is provided.

The majority of interfaces between the relay and

the communications equipment are done at the

station battery. If the control battery is 125Vdc,

then the carrier output will be powered up with

125Vdc to provide station battery voltage to the

relay. However, in phase comparison relay

systems, the ratio, of the on and off state, of the

carrier circuit ouptut and the on and off state of the

relay’s keying circuit is critical to provide a square

wave that closely represents the power system ac

wave. Therefore, based on the type of inputs used

on the relay system at the point it interfaces with

the carrier system, this will determine what

voltage level is acceptable. This criticality is on

the order of 500 or less microseconds.

Due to the capacitors typically applied to output

circuits to dampen surges, the higher the voltage

applied, the longer it will take to dissipate the

energy . Therefore, to dissipate this ener gy quickly,

to adhere to the timing requirements for a secure

phase comparison relay system, the use of the

auxilliary 20V power supply is necessary.

Different relay manufacturers’ input circuits may

vary and can conceivably decay fast enough not to

hinder the security of the relay system operation.

However, the energy dissipated will also generate

a significant amount of heat. By utilizing the

auxilliary supply, mounted on the rear of the

carrier unit, it will allow that heat to be outside of

either unit.

Pulsar strongly recommends the application of the

auxilliary power supply for two reasons; decay

time of the energy, and the heating caused by the

dissipation of energy.||

2.2 Special Application

Considerations

Because the TC–10B is “ON/OFF” modulated,

only one frequency (f

C

) is required for line protec-

tion. When applied to three terminal lines, phase

cancellation will occur when two or more transmitters are keyed simultaneously. To prevent this,

you should offset transmitters by ±100Hz, using

the thumbwheel frequency programming

switches. The three frequencies should be:

•f

C

•fC- 100Hz

•f

C

+ 100Hz

When using the TC–10B with the SKBU-1 PhaseComparison, you must offset the transmitter

frequencies from the center frequency by 100 Hz

for all applications. In a two-terminal application,

set the transmitter at one end 100Hz above the

center frequency, and the transmitter at the other

end 100Hz below the center frequency. Thus, the

two transmitters are spaced 200Hz from each

other. For a three terminal line, you should offset

the transmitter as described in the above

paragraph.

The TC–10B does not have an adjustable filter or

hybrid attached to the output of the transmitter.

If you are using the TC–10B in an application

where no other power line carrier equipment is

attached to the power line, then no further action

is required. However, in the application of

Single Comparator Phase Comparison

relaying, the TC–10B is to be operated in the

four-wire mode (see RF Interface Module),

with an external skewed hybrid between transmitter and receiver.

If you are applying the carrier set with other transmitters, coupled through the same tuning

equipment, you must apply a hybrid or a series LC

unit to the transmitter output to isolate the other

transmitters from the TC–10B transmitter. This

will avoid the problems of intermodulation distortion. We suggest that you use a hybrid if the

frequency spacing between all transmitters is

within the bandwidth of the hybrid (usually 6%).

Check the manufacturers instructions for the

actual spacing limitations of the hybrid you are

using. If you cannot use a hybrid, then you may

use a series LC unit to isolate the transmitters. In

this case, the transmitters must have spacing such

that the LC you are using will attenuate the

Page 2–6 October 2003

TC–10B System Manual

Technologies, Inc.

Page 29

external frequencies by at least 20dB (if the other

frequency is a 10 watt transmitter), and 30dB (if

the other frequency is a 100 watt transmitter).

2.3 Ordering Information

The TC–10B carrier is functionally compatible

with earlier type carrier equipment (e.g., KR, TC,

TC-10, TC-10A). That is, you may use the

TC–10B with these other carrier types at the

opposite end of the line, with or without voice

function. You may use the same telephone handset

unit with any of these ON-OFF carrier sets.

You may use the TC–10B carrier set with the

following types of relay systems:

• All Directional-Comparison Blocking

Systems

• Phase-Comparison Blocking Systems,

e.g., SKBU-1 (Requires 45-Vdc power

supply — please see Table 2-5.)

Simplified schematics of typical electro-mechanical systems are shown in Figure 2-5 through

Figure 2-13 (schemes A thru K). These schemes

indicate the different jumper positions required for

particular applications. Simplified connections

between the TC–10B and a microprocessor based

relay are shown in Figure 2-14 (Scheme L).

Figure 2-15 shows the output circuit for microprocessor based relays (1 amp maximum output).

Figure 2-16 shows the resultant output circuit for

48, 125, and 250Vdc systems.

Two variations of TC–10B are available:

(1) Plug-in Voice Adapter Module with signaling

as a push-to-talk maintenance voice channel (see Chapter 17). Atelephone jack is provided

on the Voice Adapter Module, but you may

also use a remote jack or hookswitch. (See

Figure 18-4, Scheme J, for the connection

diagrams.)

(2) Plug-in Universal Checkback Module for

periodic testing of the carrier channel at

programmable intervals (see Chapter 17).

(See Figure 3–3 for connection diagrams.)

The equipment identification number (catalog

number) is located in the middle of the front panel

(just to the left of the 10W PA Module). The

TC–10B catalog number comprises eight (8) characters, each in a specific position. This number

identifies the unit's technical characteristics and

capabilities, as well as any optional modules

installed in the unit.

Table 2-2 provides a complete listing of the

options for ordering a TC–10B, as well as a

sample catalog number. To order one or more

TC–10Bs, simply identify the features and

optional modules you want for each chassis. For

example, the typical catalog number shown in

Table 2-2 — S1A1WVAS— orders a

TC–10B with the following features:

Basic TC–10B Transmitter/Receiver

Power Output: 10 watt

Universal Checkback: Universal Checkback

Module, PC programmable

dc/dc Converter Power Supply: 110/125Vdc

battery input

Bandwidth (Filter Range): Wideband filter

Voice Adapter: Voice Adapter Module with

signaling

Alarm and Carrier Level Indication: with loss-

of-dc-power alarm relay, R.F. output alarm

relay, received-carrier-level-margin alarm

relay, detect alarm, instrument indicating

carrier level (-20dB to +10dB), carrier level

analog output (0–100 µA) for external instrument

Outputs: Dual transistor-switched outputs (for

use with electro-mechanical carrier auxiliary

relays and microprocessor relays)

Table 2-3 provides a further breakdown of the

TC–10B catalog number by style numbers.

The accessories available for the TC–10B are

listed, along with their style numbers, in Table 2-4

and Table 2-5. To order an accessory, simply give

its style number.

October 2003 Page 2–7

Chapter 2. Applications and Ordering Information

2

Page 30

Page 2–8 October 2003

TC–10B System Manual

Technologies, Inc.

Table 2–2. TC–10B Catalog Numbers

Typical Catalog Number

S 1 A 1 W V A S

Catalog Number Position 12345678

Basic TC–10B Transmitter/Receiver

Solid state programmable transmitter/receiver assembly for

phase- or directional-comparison relaying, or supervisory control S

Self-Adjusting Receiver only V

Transmitter only X

Power Output

10 watt output * 1

Automatic Checkback

Universal Checkback, Personal Computer programmable A

No Checkback Module N

DC/DC Converter Power Supply

48/60Vdc battery input 4

110/125Vdc battery input 1

220/250Vdc battery input 2

Bandwidth (Filter Range)

Wideband filter W

Narrow band filter X

Voice Adapter

Voice Adapter Module with signaling V

No Voice Adapter Module N

Transmission Limitation Circuit T

Alarm and Carrier Level Indication

With loss-of-dc-power alarm relay, R.F.-output alarm relay,

received-carrier-level-margin alarm relay, carrier level A

analog output (0–100 µA) for external instrument

Outputs

Dual transistor-switched outputs (for use with electro-mechanical

carrier auxiliary relays and microprocessor relays) S

Transmitter only chassis N

Phase Comparison Output (20Vdc power supply included) P

Accessories TC–10B/TCF–10B Extender Board . . . . . . . . .Style # 1353D70G01

TC–10B to KR mounting kit . . . . . . . . . . . . . . .Style # 1355D61G01

*For 50 or 100 watt output, see document

CA44-VER03 (Linear Power Amplifier)

Page 31

2

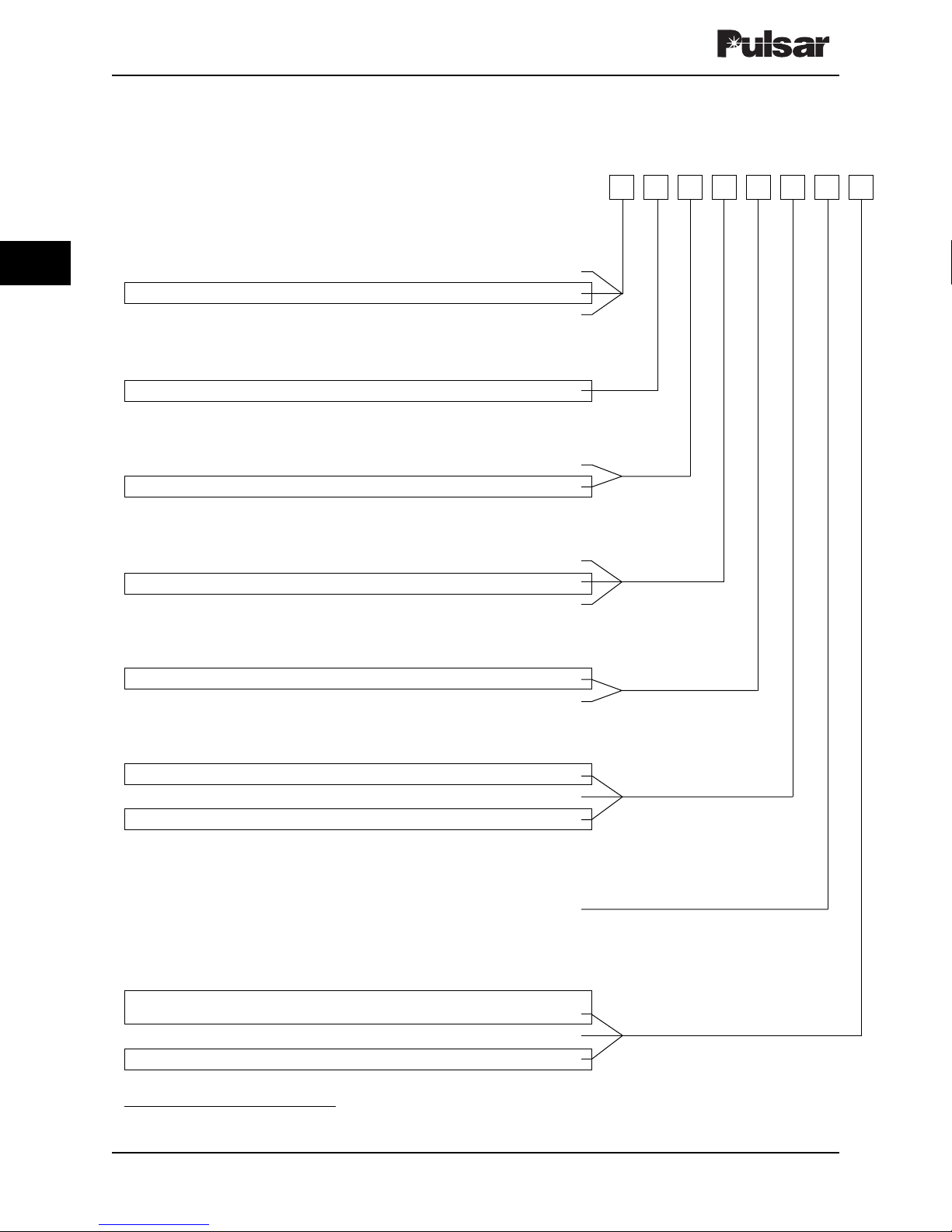

Table 2–3. TC–10B Catalog Numbers/Module Style Numbers.

SorN

S,NorP

A

A

S

1

1

W

V

A

S

V,NorT

WorX

4,1or2

AorN

10 Watts

Automatic Checkback

DC/DC Converter Power Supply

Bandwidth

Voice, Transmit Limiter

Alarm and Carrier Level Indication

Outputs

1

S,VorX

P

Basic Transmitter/Receiver

Position Description Style Number S V X A N 1 2 4 W X V N T S A N 1 2 4 W X V N T

1Receiver Output CC20-RXSMN-001 X X X

3Receiver C020-RXVMN-201 or 203 X X X

8RFInterface 1606C32G01 X X X X

12 10W Power Amp 1606C33G01 X X X

14 Transmitter 1610C01G01 X X X X

Transmitter w/TTL 1610C01G03 X X

17 Keying 1606C29G01 X X X

18 Voice Adapter C020-VADMN-001 X X

Blank Panel 1606C47H03 X X X X

20 Universal Checkback CC20-UCBMN-001 X X

Blank Panel 1606C47H03 X X

22 Power Supply 48Vdc 1617C38G01 X X

Power Supply 125Vdc 1617C38G02 X X

Power Supply 250Vdc 1617C38G03 X X

none 20V Aux. PS-48 to 20Vdc 1610C07G01 X

20V Aux. PS-125 to 20Vdc 1610C07G02 X

20V Aux. PS-250 to 20Vdc 1610C07G03 X

none Chassis Assy. 1353D63G01 X X

10 Nameplate 1496B80H03 X X

none Cover Assy. 1606C49G01 X X

none Resistor Assy. (250Vdc) 1355D01G02 X X

none Resistors (125Vdc) 01R3-3310-43M qty 2 X X

none P.S. Filter C020-BKPA1-001 X X

Page 32

Page 2–10 October 2003

TC–10B System Manual

Technologies, Inc.

Accessories for Voice Adapter Style Number

Sonalert (2,900Hz, 60–250Vdc) SC250J

Telephone Hookswitch 205C266G05

Assembly (panel mounting) with

Noise Canceling Handset

Telephone Handset, Push to Talk, 1353D88G01

Noise Canceling (single prong plug)

Telephone Jack, remote panel 715B674G03

mounting (single prong plug)

Other Accessories Style Number

45V power supply for use with

SKBU-1 Relaying System

48V to 45V 5303D49G05

125V to 45V 5303D49G06

250V to 45V 5303D49G07

Table 2–4. TC–10B Voice Adapter Accessories.

Table 2–5. Other TC–10B Accessories

Carrier Aux. Battery Resistor

Relay Voltage

20 mA (220Ω)48Not Required

20 mA (220Ω) 125 3500Ω, 5W

20 mA (220Ω) 250 9200Ω, 10W & 500Ω, 40W

200 mA (25Ω)48Not Required

200 mA (25Ω) 125 Not Required

200 mA (25Ω) 250 500Ω, 40W

Table 2–6. External Resistor Requirements — Provided with

Chassis, According to Battery Voltage.

Page 33

October 2003 Page 2–11

Chapter 2. Applications and Ordering Information

2

Figure 2–5. TC–10B Simplified Application Schematic – Scheme A (7833C63).

POS

JUMPER

TB6–1

TB6–2

TB7–5

TC–10B

TB6–4

TB6–5

TB7–1 (DC+)

AUTOMATIC CHECKBACK

(SEE FIGURE 6-1 FOR

CONNECTIONS)

TB6–6

TB6–7

TB6–8

TB6–9

TB1–1 (OUTPUT+)

TB4–3 (STOP+)

TB4–5 (LL+)

TB5–7

TB5–8

TB4–1 (START+)

DETECTOR

TB5–9

TB2–3

MARGIN

OUTPUT

TB2–4

TB2–5

TB7–6

TB1–3 (OUTPUT–)

RF OUTPUT

OUTPUT

TB2–6

TB3–1

TB1–8 (OUTPUT–)

ALARM

VOICE ADAPTER

TB3–2

TB5–1

TB4–6 (LL–)

JUMPERS

REMOTE PHONE CONNECTIONS

(SEE FIGURE 17-6)

TB5–2

TB5–3

TB5–4

TB5–5

TB7

–4

TB7

–3

TB2

–2

TB2

–1

TB4–4 (STOP–)

TB4–2 (START–)

TB7–2

(DC–)

BATTERY

VOLTAGE

MODULE

DC FAILURE

KEYING 48 JU1 15

KEYING 125 JU1 48

KEYING 250 JU1 125

ALARM

CLI

EXTERNAL

KEYING 48 JU2 48

KEYING 125 JU2 125

KEYING 250 JU2 250

KEYING 48 JU3 48

KEYING 125 JU3 125

KEYING 250 JU3 250

KEYING —JU4NORM

KEYING — JU5 NORM

KEYING —JU6 NORM

KEYING —JU7STOP

KEYING —JU8 IN

OUTPUT 48 JU1/JU2 48

OUTPUT 125 JU1/JU2 125/250

OUTPUT 250 JU1/JU2 125/250

SCHEME A

SIMPLIFIED K–DAR

UTILIZING COMMON

CARRIER SCHEMATIC

START/STOP CONTROL

1

BATTERY

POSITIVE

CARRIER

LOW

LEVEL

TEST

RC

R

Z1

TEST

CARRIER

Z2

CX

Z3

NOTE

Z5

Z4

CX

CX

PHASE AND

GROUND

+

MA

CARRIER

START

SQ

CSP

CSG

AL

PHASE AND

GROUND

CARRIER

0–30 mA

STOP

RRH

0–300 mA

BATTERY

NEGATIVE

OPTIONAL

IN KA–4

NOTE 1 – EXTERNAL RESISTORS ARE REQUIRED

FOR SOME SYSTEMS, AS SHOWN IN TABLE 2-6. THE

RESISTORS ARE SUPPLIED WITH ALL 125 AND 250

Vdc TC–10B CARRIERS.

NOTE 2 – SOME SCHEMES MAY NOT HAVE CARRIER

CONTINUATION (CX).

Page 34

Page 2–12 October 2003

TC–10B System Manual

Technologies, Inc.

Figure 2–6. TC–10B Simplified Application Schematic – Scheme B (7833C63).

POS

JUMPER

JUMPERS

BATTERY

VOLTAGE

MODULE

KEYING 48 JU1 48

KEYING 125 JU1 125

KEYING 250 JU1 250

KEYING 48 JU2 15

KEYING 125 JU2 48

KEYING 250 JU2 125

KEYING 48 JU3 48

KEYING 125 JU3 125

KEYING 250 JU3 250

KEYING — JU4 NORM

KEYING — JU5 NORM

KEYING — JU6 NORM

KEYING — JU7 STOP

KEYING — JU8 OUT

OUTPUT 48 JU1/JU2 48

OUTPUT 125 JU1/JU2 125/250

OUTPUT 250 JU1/JU2 125/250

TB6–1

TB6–2

TB7–5

TC–10B

AUTOMATIC CHECKBACK

TB6–4

TB6–5

TB7–1 (DC+)

CARRIER

LOW

LEVEL

(SEE FIGURE 6-1 FOR

CONNECTIONS)

TB6–6

TB6–7

TB6–8

TB1–1 (OUTPUT+)

TB4–5 (LL+)

TEST

TB6–9

TB5–7

TB7–6

TB5–8

TB4–3 (STOP+)

DETECTOR

TB5–9

TB2–3

TB4–1 (START+)

MARGIN

OUTPUT

OUTPUT

TB2–4

TB2–5

TB2–6

TB1–3 (OUTPUT–)

TB1–8 (OUTPUT–)

1

NOTE

RF OUTPUT

ALARM

TB3–1

TB3–2

TB4–6 (LL–)

+

AL

VOICE ADAPTER

REMOTE PHONE CONNECTIONS

TB5–1

TB5–2

TB5–3

TB4–4 (STOP–)

RRH

(SEE FIGURE 17-6)

TB5–4

TB4–2 (START–)

TB5–5

TB7

TB7

TB2

TB2

TB7–2

1000

–4

–3

–2

–1

(DC–)

DC FAILURE

BATTERY

RRT

ALARM

CLI

EXTERNAL

NEGATIVE

SIMPLIFIED

SCHEME B

HZ/HZM SCHEMATIC

4000

IOS

23

23

23

BATTERY

POSITIVE

4MFD

250

CBU

CSP CSO

CSO

CSA

CSA

CSA

CSG

CBU UNIT USED ONLY WHEN REMOTE TERMINAL

USES CONTACT OPENING CARRIER START

OPTIONAL

SCHEME SUCH AS KDAR.

NOTE 1 – EXTERNAL RESISTORS ARE REQUIRED

FOR SOME SYSTEMS, AS SHOWN IN TABLE 2-6. THE

RESISTORS ARE SUPPLIED WITH ALL 125 AND 250

Vdc TC–10B CARRIERS.

Page 35

October 2003 Page 2–13

Chapter 2. Applications and Ordering Information

2

Figure 2–7. TC–10B Simplified Application Schematic – Scheme C (7833C63).

TB6–1

TB6–2

TB7–5

TC–10B

TB6–4

TB6–5

AUTOMATIC CHECKBACK

(SEE FIGURE 6-1 FOR

CONNECTIONS)

TB6–6

TB6–7

TB6–8

TB6–9

TB5–7

TB5–8

DETECTOR

TB5–9

TB2–3

MARGIN

OUTPUT

TB2–4

TB2–5

RF OUTPUT

OUTPUT

TB2–6

TB3–1

VOICE ADAPTER

ALARM

TB3–2

TB5–1

JUMPERS

REMOTE PHONE CONNECTIONS

(SEE FIGURE 17-6)

TB5–2

TB5–3

TB5–4

TB5–5

TB7

–4

TB7

–3

TB2

–2

TB2

–1

POS

JUMPER

BATTERY

VOLTAGE

MODULE

DC FAILURE

KEYING 48 JU1 48

KEYING 125 JU1 125

KEYING 250 JU1 250

ALARM

CLI

EXTERNAL

125/250

125/250

JU1/JU2

JU1/JU2

250

125

OUTPUT

KEYING 48 JU2 48

KEYING 125 JU2 125

KEYING 250 JU2 250

KEYING 48 JU3 48

KEYING 125 JU3 125

KEYING 250 JU3 250

KEYING — JU4 INV

KEYING — JU5 NORM

KEYING — JU6 INV

KEYING — JU7 STOP

SIMPLIFIED

SCHEME C

KEYING — JU8 OUT

OUTPUT 48 JU1/JU2 48

OUTPUT

BATTERY

POSITIVE

TB7–1 (DC+)

CARRIER

LOW

LEVEL

TEST

CARRIER

HIGH

LEVEL

TEST

TB1–1 (OUTPUT+)

TB4–5 (LL+)

CARRIER

CARRIER

START

STOP

TB7–6

TB4–1 (START+)

TB4–3 (STOP+)

TB1–3 (OUTPUT–)

TB1–8 (OUTPUT–)

1

NOTE

TB4–6 (LL–)

TB4–4 (STOP–)

+

TB4–2 (START–)

R

CARRIER

TB7–2

(DC–)

AUX.

RELAY

RA

MA

0–30 mA

BATTERY

0–300 mA

NEGATIVE

OPTIONAL

NOTE 1 – EXTERNAL RESISTORS ARE REQUIRED FOR

SOME SYSTEMS, AS SHOWN IN TABLE 2-6. THE RESISTORS

GCY–GCX RELAYING

POSITIVE D.C. KEYING

ARE SUPPLIED WITH ALL 125 AND 250 Vdc TC–10B

CARRIERS.

Page 36

Page 2–14 October 2003

TC–10B System Manual

Technologies, Inc.

Figure 2–8. TC–10B Simplified Application Schematic – Scheme D (7833C63).

TB6–1

TB6–2

TB7–5

TC–10B

TB6–4

TB6–5

AUTOMATIC CHECKBACK

(SEE FIGURE 6-1 FOR

CONNECTIONS)

TB6–6

TB6–7

TB6–8

TB6–9

TB5–7

TB5–8

DETECTOR

TB5–9

TB2–3

MARGIN

OUTPUT

TB2–4

TB2–5

RF OUTPUT

OUTPUT

TB2–6

TB3–1

ALARM

TB3–2

TB5–1

REMOTE PHONE CONNECTIONS

VOICE ADAPTER

(SEE FIGURE 17-6)

TB5–2

TB5–3

JUMPERS

BATTERY

TB5–4

TB5–5

TB7

–4

TB7

–3

TB2

–2

TB2

–1

POS

JUMPER

VOLTAGE

KEYING 48 JU1 48

MODULE

ALARM

DC FAILURE

KEYING 125 JU1 125

KEYING 250 JU1 250

KEYING 48 JU2 48

KEYING 125 JU2 125

CLI

EXTERNAL

KEYING 250 JU2 250

KEYING 48 JU3 48

KEYING 125 JU3 125

KEYING 250 JU3 250

SIMPLIFIED

KEYING — JU4 INV

KEYING —JU5 NORM

KEYING — JU6 INV

SCHEME D

KEYING —JU7STOP

KEYING — JU8 OUT

125/250

JU1/JU2

125

OUTPUT

OUTPUT 48 JU1/JU2 48

125/250

JU1/JU2

250

OUTPUT

TB7–1 (DC+)

TB1–1 (OUTPUT+)

TB4–5 (LL+)

TB4–3 (STOP+)

TB4–1 (START+)

TB7–6

TB4–4 (STOP–)

TB4–2 (START–)

TB4–6 (LL–)

BATTERY

POSITIVE

TB1–3 (OUTPUT–)

NOTE

CARRIER

LOW

LEVEL

TEST

CARRIER

HIGH

1

LEVEL

TEST

TB1–8 (OUTPUT–)

TB7–2

R

R

CARRIER

CARRIER

CARRIER

(DC–)

AUX.

RELAY

START

STOP

RA

GCY–GCX RELAYING

NEGATIVE D.C. KEYING

+

MA

0–30 mA

0–300 mA

OPTIONAL

NOTE 1 – EXTERNAL RESISTORS ARE REQUIRED FOR

SOME SYSTEMS, AS SHOWN IN TABLE 2-6. THE RESISTORS

ARE SUPPLIED WITH ALL 125 AND 250 Vdc TC–10B

BATTERY

NEGATIVE

CARRIERS.

Page 37

October 2003 Page 2–15

Chapter 2. Applications and Ordering Information

2

Figure 2–9. TC–10B Simplified Application Schematic – Scheme E (7833C63).

TB6–1

TB6–2

TB7–5

TC–10B

TB6–4

TB6–5

AUTOMATIC CHECKBACK

(SEE FIGURE 6-1 FOR

CONNECTIONS)

TB6–6

TB6–7

TB6–8

TB6–9

TB5–7

TB5–8

DETECTOR

TB5–9

TB2–3

MARGIN

OUTPUT

TB2–4

TB2–5

RF OUTPUT

OUTPUT

TB2–6

TB3–1

VOICE ADAPTER

ALARM

TB3–2

TB5–1

JUMPERS

REMOTE PHONE CONNECTIONS

(SEE FIGURE 17-6)

TB5–2

TB5–3

TB5–4

TB5–5

POS

JUMPER

BATTERY

VOLTAGE

MODULE

TB7

–4

TB7

–3

TB2

–2

TB2

–1

KEYING 48 JU1 48

KEYING 125 JU1 125

KEYING 250 JU1 250

ALARM

DC FAILURE

EXTERNAL

KEYING 48 JU2 48

CLI

KEYING 125 JU2 125

KEYING 250 JU2 250

KEYING 48 JU3 48

KEYING 125 JU3 125

KEYING 250 JU3 250

KEYING — JU4 NORM

KEYING — JU5 NORM

KEYING — JU6 NORM

KEYING — JU7 STOP

SCHEME E

KEYING — JU8 OUT

125/250

JU1/JU2

125

OUTPUT

OUTPUT 48 JU1/JU2 48

125/250

JU1/JU2

250

OUTPUT

BATTERY

POSITIVE

TB7–1 (DC+)

CARRIER

LOW

LEVEL

TEST

CARRIER

HIGH

LEVEL

TEST

CARRIER

START

SUPV

TB1–1 (OUTPUT+)

TB4–5 (LL+)

TB4–1 (START+)

TB4–3 (STOP+)

TB7–6

CARRIER

STOP

TB4–6 (LL–)

TB4–4 (STOP–)

TB4–2 (START–)

TB7–2 (DC–)

TB1–3 (OUTPUT–)

TB1–8 (OUTPUT–)

1

NOTE

AUX.

CARRIER

RELAY

SIMPLIFIED SCHEMATIC

FOR CARRIER START/STOP

NORMALLY OPEN CONTACTS

NOTE 1

BATTERY

NEGATIVE

OPTIONAL

NOTE 1 – EXTERNAL RESISTORS ARE REQUIRED FOR

SOME SYSTEMS, AS SHOWN IN TABLE 2-6. THE RESISTORS

CARRIERS.

ARE SUPPLIED WITH ALL 125 AND 250 Vdc TC–10B

Page 38

Page 2–16 October 2003

TC–10B System Manual

Technologies, Inc.

Figure 2–10. TC–10B Simplified Application Schematic – Scheme F (7833C63).

TB6–1

TB6–2

TB7–5

TC–10B

TB6–4

TB6–5

TB7–1 (DC+)

AUTOMATIC CHECKBACK

(SEE FIGURE 6-1 FOR

CONNECTIONS)

TB6–6

TB6–7

TB6–8

TB6–9

TB1–1 (OUTPUT+)

TB4–5 (LL+)

TB5–7

TB4–1 (START+)

TB5–8

TB5–9

TB7–6

DETECTOR

OUTPUT

TB2–3

TB2–4

TB4–3 (STOP+)

MARGIN

OUTPUT

TB2–5

TB4–6 (LL–)

RF OUTPUT

TB2–6

TB3–1

TB4–4 (STOP–)

ALARM

TB3–2

TB4–2 (START–)

VOICE ADAPTER

REMOTE PHONE CONNECTIONS

TB5–1

TB5–2

TB1–3 (OUTPUT–)

TB7–2 (DC–)

(SEE FIGURE 17-6)

TB5–3

TB5–4

TB1–8 (OUTPUT–)

POS

JUMPER

JUMPERS

BATTERY

VOLTAGE

MODULE

TB5–5

TB7

–4

TB7

–3

TB2

–2

TB2

–1

KEYING 48 JU1 48

DC FAILURE

KEYING 125 JU1 125

KEYING 250 JU1 250

KEYING 48 JU2 48

KEYING 125 JU2 125

ALARM

CLI

EXTERNAL

KEYING 250 JU2 250

KEYING 48 JU3 48

KEYING 125 JU3 125

SIMPLIFIED SCHEMATIC

KEYING 250 JU3 250

KEYING —JU4 INV

KEYING — JU5 INV

FOR CARRIER START/STOP

NORMALLY CLOSED CONTACTS

KEYING — JU6 INV

125/250

125/250

JU1/JU2

JU1/JU2

250

125

OUTPUT

KEYING — JU8 OUT

OUTPUT 48 JU1/JU2 48

OUTPUT

KEYING — JU7 STOP

SCHEME F

1

AUX.

CARRIER

RELAY

NOTE 1

CARRIER

LOW

LEVEL

TEST

NOTE

SUPV

CARRIER

HIGH

LEVEL

TEST

CARRIER

STOP

BATTERY

NEGATIVE

OPTIONAL

NOTE 1 – EXTERNAL RESISTORS ARE REQUIRED FOR

SOME SYSTEMS, AS SHOWN IN TABLE 2-6. THE RESISTORS

ARE SUPPLIED WITH ALL 125 AND 250 Vdc TC–10B

CARRIERS.

BATTERY

POSITIVE

CARRIER

START

Page 39

October 2003 Page 2–17

Chapter 2. Applications and Ordering Information

2

Figure 2–11. TC–10B Simplified Application Schematic – Scheme G (7833C63).

TB6–1

TB6–2

TB7ñ5

TCñ10B

TB6–4

TB6–5

AUTOMATIC CHECKBACK

(SEE FIGURE 6-1 FOR

CONNECTIONS)

TB6–6

TB6–7

TB6–8

TB6–9

TB5–7

TB5–8

DETECTOR

TB5–9

TB2–3

MARGIN

OUTPUT

TB2–4

TB2–5

RF OUTPUT

OUTPUT

TB2–6

TB3–1

VOICE ADAPTER

ALARM

TB3–2

TB5–1

JUMPERS

REMOTE PHONE CONNECTIONS

(SEE FIGURE 17-6)

TB5–2

TB5–3

TB5–4

TB5–5

TB7

–4

TB7

–3

TB2

–2

TB2

–1

POS

JUMPER

BATTERY

VOLTAGE

MODULE

DC FAILURE

KEYING 48 JU1 48

KEYING 125 JU1 125

KEYING 250 JU1 250

ALARM

CLI

EXTERNAL

KEYING 48 JU2 48

KEYING 125 JU2 125

KEYING 250 JU2 250

KEYING 48 JU3 48

KEYING 125 JU3 125

SIMPLIFIED SCHEMATIC

KEYING 250 JU3 250

KEYING – JU4 NORM

KEYING – JU5 INV

KEYING – JU6 NORM

KEYING – JU7 STOP

SCHEME G

KEYING – JU8 OUT

125/250

JU1/JU2

125

OUTPUT

OUTPUT 48 JU1/JU2 48

125/250

JU1/JU2

250

OUTPUT

BATTERY

POSITIVE

TB7–1 (DC+)

TB1–1 (OUTPUT+)

CARRIER

LOW

CARRIER

HIGH

CARRIER

LEVEL

LEVEL

START

SUPV

TB4–5 (LL+)

TEST

TEST

TB4–1 (START+)

TB4–3 (STOP+)

TB7–6

CARRIER

STOP

TB4–6 (LL–)

TB4–4 (STOP–)

TB4–2 (START–)

TB7–2 (DC–)

TB1–3 (OUTPUT–)

TB1–8 (OUTPUT–)

1

NOTE

AUX.

CARRIER

RELAY

BATTERY

NOTE 1

NEGATIVE

N.O. CONTACTS FOR CARRIER START

OPTIONAL

NOTE 1 – EXTERNAL RESISTORS ARE REQUIRED FOR

SOME SYSTEMS, AS SHOWN IN TABLE 2-6. THE RESISTORS

N.C. CONTACTS FOR CARRIER STOP

ARE SUPPLIED WITH ALL 125 AND 250 Vdc TC–10B

CARRIERS.

Page 40

Page 2–18 October 2003

TC–10B System Manual

Technologies, Inc.