Page 1

MICROFLOW-

INSTRUCTION MANUAL

Page 2

Page 3

MICRO FLOW- (FIRST EDITION REV 5)

May 2019

Part Number M-MFi-S-001-5P

COPYRIGHT

© Pulsar Process Measurement Limited, 2017 - 2019. All rights reserved. No part of this publication

may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language

in any form without the written permission of Pulsar Process Measurement Limited.

WARRANTY AND LIABILITY

Pulsar Process Measurement Limited guarantee for a period of 2 years from the date of delivery that it

will either exchange or repair any part of this product returned to Pulsar Process Measurement Limited

if it is found to be defective in material or workmanship, subject to the defect not being due to unfair

wear and tear, misuse, modification or alteration, accident, misapplication or negligence.

DISCLAIMER

Pulsar Process Measurement Limited neither gives nor implies any process guarantee for this product

and shall have no liability in respect of any loss, injury or damage whatsoever arising out of the

application or use of any product or circuit described herein.

Every effort has been made to ensure accuracy of this documentation, but Pulsar Process Measurement

Limited cannot be held liable for any errors.

Pulsar Process Measurement Limited operates a policy of constant development and improvement and

reserves the right to amend technical details as necessary.

The MicroFlow-i shown on the cover of this manual is used for illustrative purposes only and may not

be representative of the actual MicroFlow-i supplied.

TECHNICAL ENQUIRIES

Please contact Pulsar Process Measurement Limited for technical support.

COMMENTS AND SUGGESTIONS

If you have any comments or suggestions about this product, then please contact:

Pulsar Process Measurement Limited

Pulsar Process Measurement Inc.

Cardinal Building

Enigma Commercial Centre

Sandy’s Road

Malvern

Worcestershire

WR14 1JJ

United Kingdom

PO Box 5177

Niceville

FL 32578-5177

USA

Tel: + 44 (0) 1684 891371

Fax: + 44 (0) 1684 575985

Tel: + 1 850 279 4882

Fax: + 1 850 279 4886

Web Site: https://www.pulsar-pm.com

e-mail: info@pulsar-pm.com (general

information)

e-mail: support@ pulsar-pm.com (product

support)

Web Site: https://www.pulsar-pm.com

e-mail: info.usa@pulsar-pm.com (general

information)

e-mail: support.usa@ pulsar-pm.com (product

support)

Pulsar® is a registered trademark of Pulsar Process Measurement Ltd in the UK, USA and China.

Page 4

Page 5

Contents

Chapter 1 Start Here… ....................................................................................................................... 1

About this Manual ........................................................................................................................................... 1

About the MicroFlow-i ................................................................................................................................... 2

Benefits ............................................................................................................................................................ 3

Functional Description .................................................................................................................................... 4

Product Specification....................................................................................................................................... 5

EU Declaration of Conformity ....................................................................................................................... 6

Chapter 2 Installation .......................................................................................................................... 7

Unpacking ........................................................................................................................................................ 7

Power Supply Requirements ........................................................................................................................... 7

Cable Requirements ........................................................................................................................................ 7

Information specific to Hazardous Area Installation ..................................................................................... 8

Limitations on use.................................................................................................................................... 8

Hazardous Area Specific Power Supply and barrier Requirements ...................................................... 9

Location ......................................................................................................................................................... 11

Mounting ........................................................................................................................................................ 11

Angled Mounting Bracket ..................................................................................................................... 12

MicroFlow-i sensor ............................................................................................................................... 14

Mounting sensor to a bracket ................................................................................................................ 15

Terminal Connection Details ........................................................................................................................ 18

Chapter 3 Locating the MicroFlow-i sensor...................................................................................... 19

Locating the MicroFlow-i ..................................................................................................................... 19

Installing the Sensor............................................................................................................................... 22

Preparation for Operation .............................................................................................................................. 23

General Maintenance..................................................................................................................................... 23

Sensor Maintenance. ..................................................................................................................................... 24

Chapter 4 Understanding how the MicroFlow-i operates .................................................................. 27

MicroFlow-i HART compatible ................................................................................................................... 27

4 – 20 mA Device .......................................................................................................................................... 27

Chapter 5 MicroFlow-i HART PC .................................................................................................... 29

Software installation ...................................................................................................................................... 29

Connecting to MicroFlow-i HART PC ........................................................................................................ 30

Flow Tab ........................................................................................................................................................ 32

Configuration Tab ......................................................................................................................................... 33

Parameter Get/Set .................................................................................................................................. 33

MicroFlow-i Manual Setting ................................................................................................................. 34

4 – 20mA Trim ...................................................................................................................................... 35

Trace Tab ....................................................................................................................................................... 36

Comport ......................................................................................................................................................... 38

Language ........................................................................................................................................................ 38

Tools menu .................................................................................................................................................... 38

Info ................................................................................................................................................................. 39

Exit ................................................................................................................................................................. 39

Chapter 6 Parameter Listing and Descriptions .................................................................................. 40

Parameter Access........................................................................................................................................... 40

Device Information Parameters .................................................................................................................... 40

Processing Parameters ................................................................................................................................... 41

MicroFlow-i Firmware Upgrade .................................................................................................................. 44

MicroFlow-i HART Firmware Upgrade ...................................................................................................... 46

Chapter 7 Troubleshooting ............................................................................................................... 48

Chapter 8 Parameter record .............................................................................................................. 49

Chapter 9 Disposal ............................................................................................................................ 50

Page 6

Page 7

Page 1

Chapter 1 Start Here…

Congratulations on your purchase of a Pulsar MicroFlow-i. This quality system

has been developed over many years and represents the latest in high technology

flow monitoring.

It has been designed to give you years of trouble free performance, and a few

minutes spent reading this operating manual will ensure that your installation is as

simple as possible.

About this Manual

It is important that this manual is referred to for correct installation and

operation.

There are various parts of the manual that offer additional help or information as

shown.

Tips

TIP

At various parts of this manual

you may find tips to help you.

Additional Information

Additional Information

At various parts of the manual, you will find sections

like this that explain specific things in more detail.

References

See also text in Bold as these may be references to other parts of this or another

manual.

Drawings

It should be noted that drawings or pictures shown in this manual may not be to

scale.

Page 8

Page 2

About the

MicroFlow-i

The MicroFlow-i is a 2-wire loop-powered non-contacting velocity sensor,

with hazardous area approval. The sensor provides reliable flow velocity

measurements using short pulses of micro-waves, which are transmitted by an

enclosed antenna. When reflected off a moving surface, the signal experiences

a shift in frequency characteristics. The reflected signal is captured by the onboard microprocessor via the antenna, and analysed to determine the velocity.

The MicroFlow-i’s compact and versatile design makes it easy to install and

ideal for confined spaces. Housed in a robust enclosure coupled with a fully

encapsulated microwave antenna, it provides an effective fit-and-forget flow

velocity solution.

Perfect for remote monitoring or when there is no mains power available, due

to its low power consumption. To access flow velocity data, use Pulsar’s

MicroFlow-i HART PC or HART protocol.

Overall the device has outstanding stability, accuracy and repeatability.

Page 9

Page 3

Benefits

Combined with the ease of programming there are many other benefits to using

the MicroFlow-i, these are listed below:

• Non-contact velocity measurement.

• Loop powered and ideal for remote monitoring.

• Low-power consumption.

• Hazardous area approval (Ex ia) for Zone 0.

• ‘See through’ capability for enclosed plastic pipes and concrete (not

reinforced) channels.

• Suitable for abrasive and aggressive materials.

• Resilient to liquid vapour, wind or temperature.

• No minimum liquid level required for measurement

• Maintenance free.

• No interruption to operational flow.

• Can be installed in addition to existing in process contact measuring

devices.

• Easily setup using MicroFlow-i HART PC.

• The sensor is capable of monitoring flow of very shallow liquid,

mitigating the constraint associated with in-liquid techniques.

Page 10

Page 4

Functional Description

Based upon state-of-the-art micro-wave sensing technology, the MicroFlow-i

integrates Pulsar’s innovative and award winning DSP (Digital Signal Processing)

platform, offering you a cost effective solution with excellent reliability and

performance.

The Pulsar MicroFlow-i has been designed to provide maintenance free

performance. The MicroFlow-i i is also intrinsically safe (Ex ia) for Zone 0.

The MicroFlow-i can be mounted via a rear 1” BSP to M20 thread adapter

(supplied with unit). The MicroFlow-i is loop powered and gives a 4 to 20mA

output which is proportional to the flow velocity. A ‘fault condition’ alarm will

give out a reading of either 3.8mA or 22mA.

The 2 wire sensor can either be used in digital HART mode or as 4-20mA loop

powered device. The MicroFlow-i loop powered version can be set up using a

HART modem with either proprietary HART software such as Pact ware or Pulsar

MicroFlow-i HART PC software.

Boot up time from power up to stable reading: cold boot 8.5 seconds, warm boot

4 seconds (if within 12 hours from last start up).

Page 11

Page 5

Product Specification

Physical

Sensor body material Valox 357

Mounting Connection Via 1” BSP back mounted thread, 45o Angled

Mounting bracket and M20 thread adaptor

(optional).

Mounting angle: 45° optimum and mounted at the centre line

of the channel with clear uninterrupted view

Sensor body dimensions Diameter 90mm x height 140mm (3.54in x 5.51in)

Sensor body weight Nominal 0.7kg (1.54 lbs)

Transducer cable extensions 2 core screened

Maximum separation Up to 1000m (3280ft)

Environmental

Enclosure protection IP68

Max. & min. temperature (electronics) -20 ºC to +60 ºC (-4°F to +140°F)

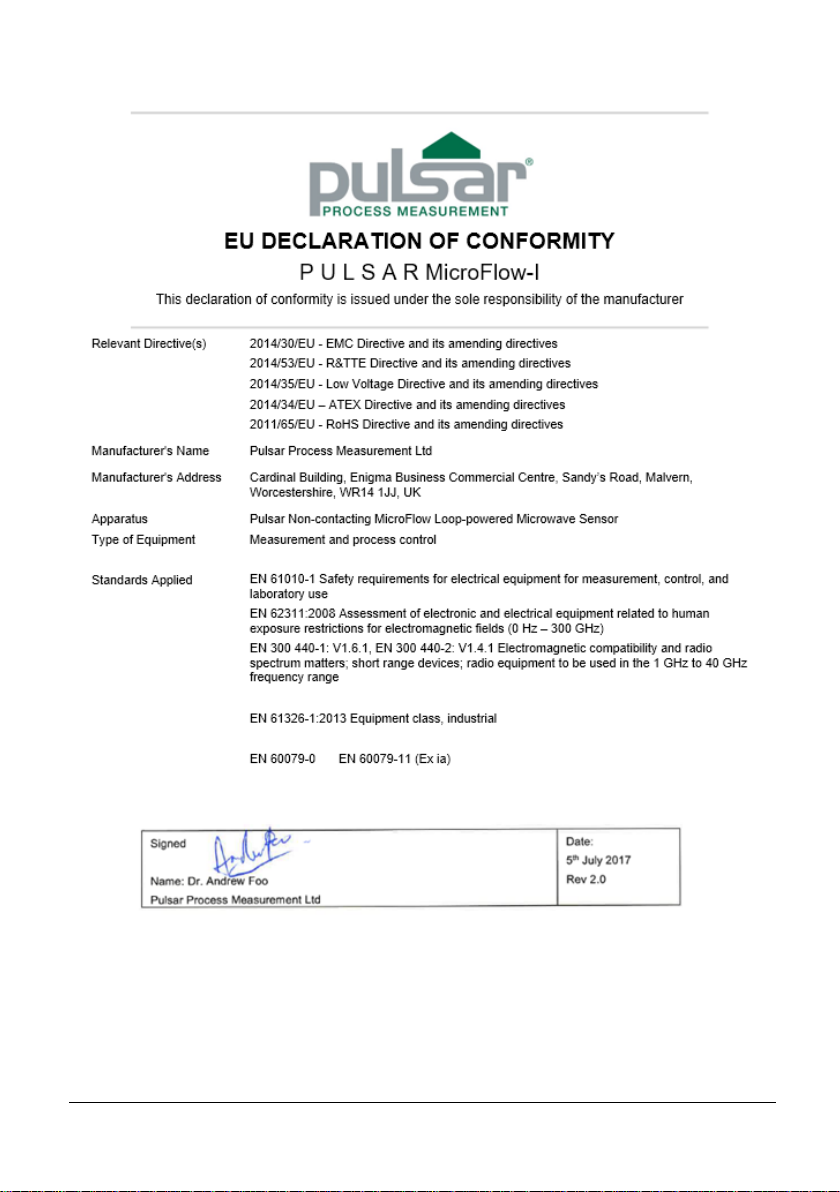

Approvals

ATEX CML 16ATEX2331X, IECEx CML 16.0105X

II 1 G Ex ia IIC T4 Ga

II 1 D Ex ia IIIC T1350C Da

CE and Radar Approval See EU Declaration of Conformity

Performance

Velocity Range 0.2 – 6.0 m/s (0.66 – 19.7 ft/s)

Accuracy The greater of ± 1.5% or 0.05 m/s (0.1ft/s)

Optimum installation Install at an angle of 45° in line with flow. For

more information, see ‘Locating the MicroFlow-i

sensor’ section of this manual

Maximum channel width per sensor 1.5m (4.92ft)

Radar K-Band (ISM)

Transmitter Power <15 dBm

Beam width 20° inclusive

Outputs

Communication HART compatible, 4-20mA loop powered

Programming

PC programming MicroFlow-i HART PC

Programming security via passcode

Programmed data integrity Via non-volatile memory

PC setup and monitoring software compatible Win 7, Win 8, Win 10

Supply

Operating Voltage 10 – 28VDC

Power Consumption Start up = 20mA. Average current = 60µA per

hour when one velocity measurement is

performed every 15 minutes

Pulsar Process Measurement Limited operates a policy of constant development and improvement

and reserve the right to amend technical details as necessary.

Page 12

Page 6

EU Declaration of Conformity

Page 13

Page 7

Chapter 2 Installation

Unpacking

Power Supply Requirements

The MicroFlow-i can operate from a DC supply of 10 to 28V. In all cases the unit

typically consumes 0.52W of power and will typically draw less than 22mA.

Cable Requirements

The MicroFlow-i comes with a fitted integral cable, if this cable is extended then

the total capacitance must not exceed the limits for the voltage applied, and the

hazardous area it is installed in.

The HART modem and PC or HART programmer are used to set up the

operation parameters for the MicroFlow-i sensor. The output can either be as a

4-20mA current giving flow velocity or as a digital signal via a HART master.

The MicroFlow-i cable is a twisted pair with an overall cable screen. The

twisted pair are red and black, connect the red to +ve and the black to the -ve.

The screen should go to signal ground.

Important Information

All shipping cartons should be opened carefully. When using a box cutter,

do not plunge the blade deeply into the box, as it could potentially cut or

scratch equipment components. Carefully remove equipment from each

carton, checking it against the packing list before discarding any packing

material. If there is any shortage or obvious shipping damage to the

equipment, report it immediately to Pulsar Process Measurement Limited.

Important Information

If the equipment is installed or used in a manner not specified in this

manual, then the protection provided by the equipment may be impaired.

Page 14

Page 8

Information specific to Hazardous Area Installation

(Reference European ATEX Directive 2014/34/EU)

The following instructions apply to equipment covered by certificate number CML

16ATEX2331X

1. The equipment may be used with flammable gases and vapours with apparatus

groups IIC, IIB, and IIA with temperature classes; T4 ambient temperature

range -20oC to +60oC.

2. The equipment is only certified for use in ambient temperatures in the range -

20oC to +60oC and should not be used outside this range.

3. Installation shall be carried out in accordance with the applicable code of

practise by suitably trained personnel.

4. Repair of the equipment shall be carried out in accordance with the acceptable

code of practise.

5. Certification as detailed in drawing number D-804-1200 (Ex ia).

6. If the equipment is likely to come into contact with aggressive substances, then

it is the responsibility of the user to take suitable precautions that prevent it

from being adversely affected, thus ensuring that the type of protection is not

compromised.

Aggressive Substances: e.g. such as acidic liquids or gases that may attack

metals or solvents that may affect polymeric materials.

Suitable precautions: e.g. regular checks as part of routine inspections or

establishing from the materials data sheet that it is resistant to specific

chemicals.

7. The certificate number has an ‘X’ suffix that indicates that the following

special condition of certification applies. In the case of the MicroFlow-i

sensor, due to the housing and labels being non-conductive plastic care needs

to be taken with regards to electrostatic charge. The equipment shall not be

installed if the conditions are conductive to the build-up of electrostatic charge.

Additionally, the equipment should only be cleaned with a damp cloth.

Limitations on use

1. The MicroFlow-i must be routinely inspected to avoid the build-up of dust

layers when installed in Zone 21 & Zone 22.

2. Electrostatic hazard – The MicroFlow-i must only be wiped with a damp or

antistatic cloth.

3. The outer enclosure is made from Valox357U, consider the performance of

this material with respect to chemicals that may be present in the hazardous

area.

Page 15

Page 9

Hazardous Area Specific Power Supply and barrier Requirements

The MicroFlow-i operates from a DC supply of 10 – 28VDC and will typically

draw less than 22mA. When connecting sensor to the PC software with a HART

modem, it is recommended to use a supply of at least 18VDC.

The MicroFlow-i cable is a twisted pair with overall cable screen. The twisted

pair is red and black, connect the red to +ve and the black to -ve. The screen

should go to signal ground.

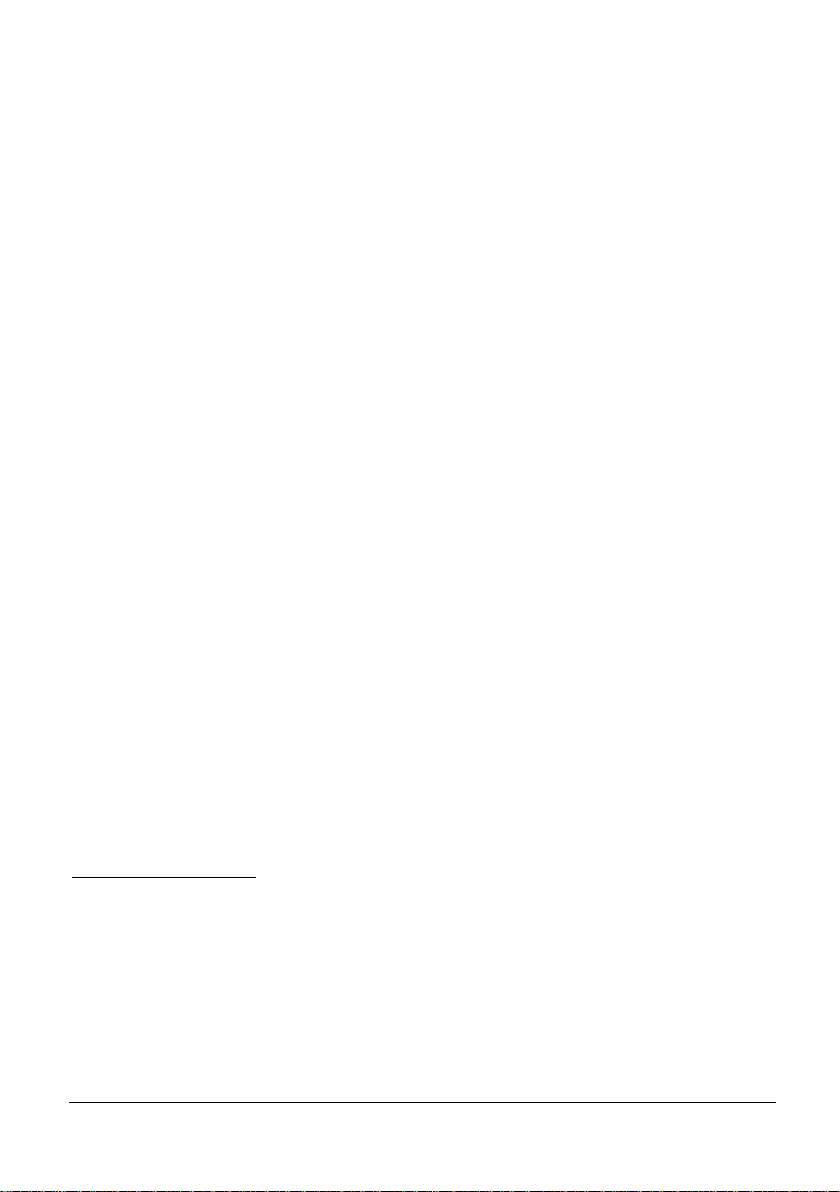

Typical wiring for the MicroFlow-i:

Important Information

In the case of the Ex ia version, the sensor must be powered from an

approved I.S. safety barrier or approved I.S. power supply with the

following limits:

Uo <= 28V, Io <= 162mA, Po <= 1.03W

V

24VDC

I.S. EARTH

PSU/SENSE

LOAD/SENSE

HAZARDOUS

AREA

SAFE AREA

SINGLE ZENNER BARRIER

Ex ia Version 4-20mA mode

SINGLE ZENNER BARRIER

CURENT SENSED IN +ve

Ui<=28V

Li<=162mA

Pi<=1.03W

+

-

Page 16

Page 10

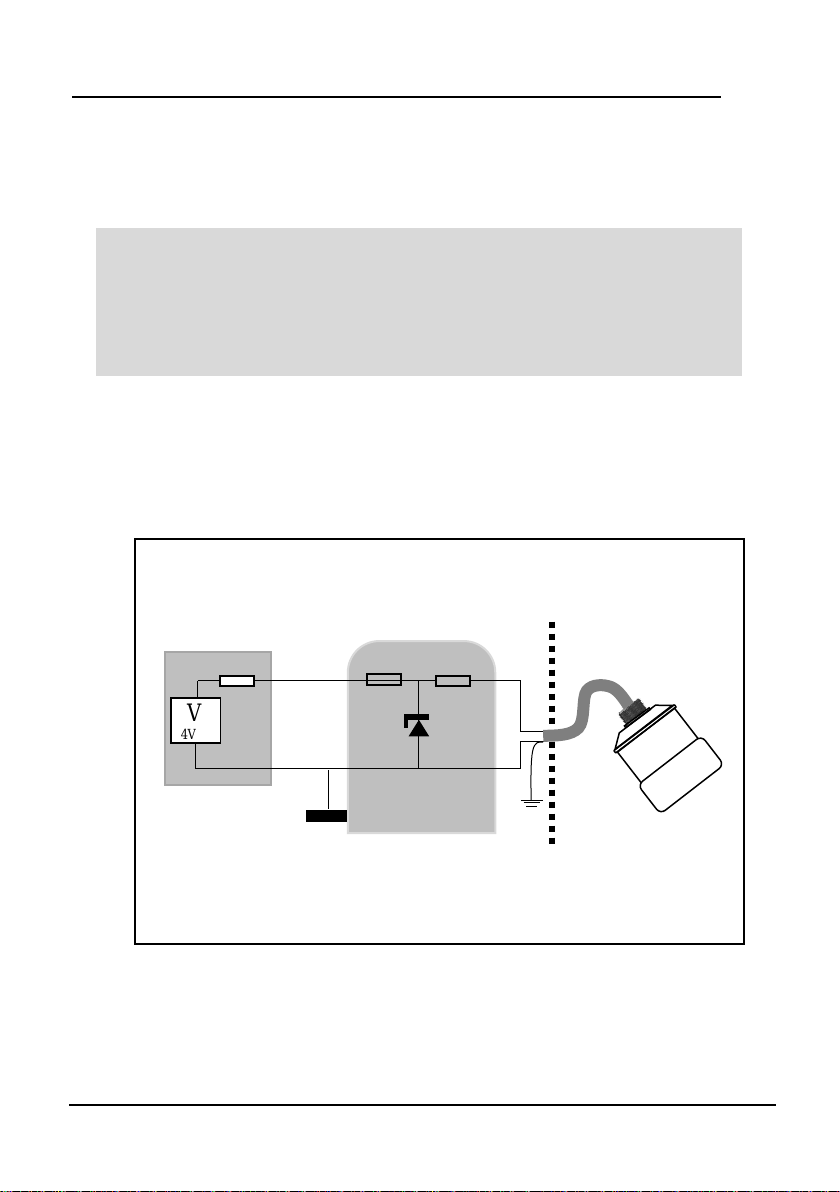

V

24VDC

I.S. EARTH

PSU/SENSE

LOAD/SENSE

HAZARDOUS

AREA

SAFE AREA

DUAL ZENNER BARRIER

Ex ia Version 4-20mA mode

DOUBLE ZENNER BARRIER

CURENT SENSED IN +ve

Ui<=28V

Li<=162mA

Pi<=1.03W

+

-

V

PSU/SENSE

HAZARDOUS

AREA

SAFE AREA

GALVANIC ISOLATOR

Ex ia Version 4-20mA mode

GALVANIC ISOLATOR

Ui<=28V

Li<=162mA

Pi<=1.03W

CURRENT

SENSE

+

-

Page 17

Page 11

Location

When choosing a location to mount the bracket and MicroFlow-i, note the

following:

• For optimum readings, it is recommended that the MicroFlow-i should be

positioned at a 45° angle to the surface of the material being measured.

• The mounting surface must be vibration-free.

• The ambient temperature should be between -20ºC and 60ºC.

Mounting

For the best results it is highly recommended to use the MicroFlow-i angled

bracket, which is available from your Pulsar distributor, which will ensure that the

MicroFlow-i can be correctly installed. The bracket can be used if the MicroFlow-

i sensor is to be mounted on its own in a specific location or along with a Pulsar

dBi or dB level transducer. Please see ‘Angled Mounting Bracket’ for

dimensions of this bracket, please note that the drawing is not to scale.

‘Mounting sensor to a bracket’ illustrates how you would install the sensor to

one of Pulsar’s angled brackets.

The MicroFlow-i angled bracket should be mounted by marking and drilling the

holes suitable for fixing your screws/bolts (length to suit your application) and

then fixing the bracket in place.

Important Information

When installing the MicroFlow-i it is recommended that it is mounted at

least 1m away from moving persons or machinery.

All electronic products are susceptible to electrostatic shock,

so follow proper grounding procedures during installation.

Page 18

Page 12

Angled Mounting Bracket

Part number: dBA0008MF

45

o

Side view

176mm

22mm

22mm

R20mm

12mm

100mm

Top view

100mm

Page 19

Page 13

Important Information

Using a spirit level, ensure that the Mounting Bracket is level before

attaching the sensor to the bracket.

R20mm

4 off 12mm

14mm

100mm

60mm

20mm

20mm

100mm

60mm

26mm

Rear view

Page 20

Page 14

MicroFlow-i sensor

The dimensions of the sensor body are shown below in Fig.1 and Fig.2:

BOTTOM

90 mm

1” BSP

78 mm

39mm

140 mm

To obtain the most accurate results, ensure the device is mounted at

a 45° angle to the surface being measured.

45°

Surface of measurement

73 mm

M i

Green ‘Dot’ to be

positioned on top of sensor.

Fig.1

Fig.2

Page 21

Page 15

Mounting sensor to a bracket

Mounting the sensor to the 45° angled bracket is done via an adapter and M20 nut, as

shown in Fig.3:

For correct installation, we recommend that the adapter is threaded on the cable, and

carefully screwed onto the MicroFlow-i before fitting to the bracket. This will reduce

the risk of any ’twisting’ in the cable.

Ensure that the sensor is tightened and the dot is in the correct position.

Important Information

When fixing the sensor to the adapter, ensure that care is taken when

pulling the sensor cable through. And once attached to the adapter, and

the M20 nut is tightened, the green dot should be central to the

movement of flow as shown in Fig.4.

Bracket

Adapter

Fig.3

Cable

M20 Nut

Green dot to be

displayed on top

Page 22

Page 16

Care should be taken not to overtighten the sensor when everything is connected,

as seen in Fig.5 below, as this could cause damage to the housing.

Central to the movement

of flow in channel.

Fig.4

Fig.5

305mm

215mm

129mm

Page 23

Page 17

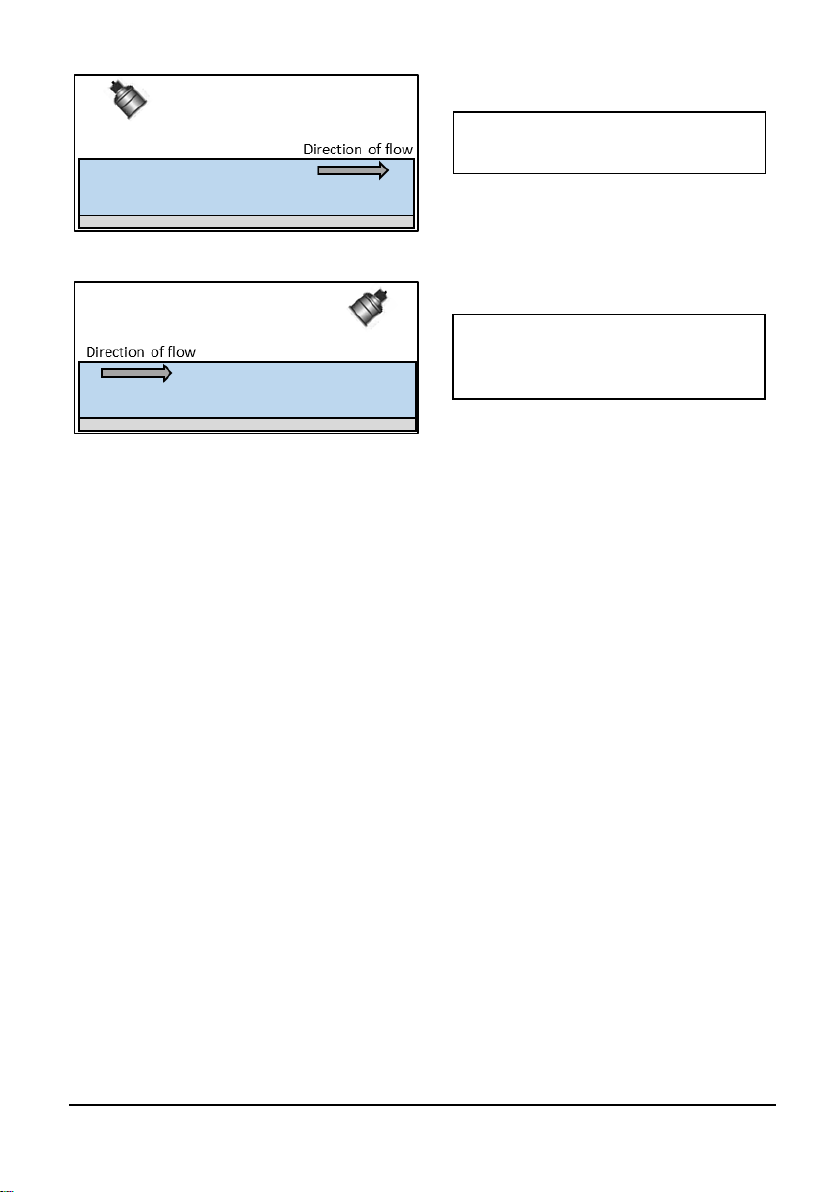

When the sensor is mounted on the bracket with dB or dBi series level

transducer, you can position the bracket in a way where the MicroFlow-i is

obtaining measurements following the direction of the flow, or facing the

direction of flow. Fig.6 and Fig.7 illustrate the correct positioning of the devices

according to the direction of flow:

Green dot to be

displayed on top

Direction of flow

Fig.6

Direction of flow

Fig.7

Green dot to be

displayed on top

Page 24

Page 18

Terminal Connection Details

Terminal Connections

Power

The MicroFlow-i operates from a DC voltage supply of 10-28 volts, and should

be installed and connected in accordance with ‘Chapter 2–Power supply

requirements’ and the instructions below. When wiring the MicroFlow-i you

should use a twisted pair cable. The wire coding is shown below for ease of use

when connecting the MicroFlow-i to monitor flow velocity:

You can also use Pulsar’s MicroFlow-i HART PC software to interrogate and

obtain readings from the device. Please refer to Chapter 6 MicroFlow-i HART

PC for more details on how to use it.

Important Information

If the equipment is installed or used in a manner not specified in this

manual, then the protection provided by the equipment may be impaired.

Bootlace

Ferrules

MicroFlow-i cable

110 mm

Heat Shrink

Power +10-28 VDC (Red cable)

0 Volts (Black cable)

Screen (Green cable)

Page 25

Page 19

Chapter 3 Locating the MicroFlow-i sensor

For optimum accuracy install the MicroFlow-i where the flow is not turbulent.

An ideal location for the sensor is in the centre of a long straight channel.

Vertical drops, baffles, curves or junctions can cause the velocity profile to be

distorted.

To obtain optimum results in velocity readings, the MicroFlow sensor requires

surface ripples to be present to provide a reliable measurement. If there are not

any surface ripples within the sensors field of view under ant flow conditions,

then an alternative measurement point should be found, or ripples created.

Locating the MicroFlow-i

• If the width of the channel exceeds 1.5m. Multiple MicroFlow-i sensors

are required to be used in conjunction with the Ultimate Controller with

firmware version 1.5.2 and later.

• When a level measurement transducer is used and mounted on the same

bracket as the MicroFlow-i. Take into account, the ‘blanking’ distance of

the transducer when mounting the bracket for the application.

• Ensure that there is an unobstructed path between the sensor and the surface

of the moving liquid being measured.

• Position the sensor at a height of 250mm above maximum liquid level or up

to two times the channel width from the minimum liquid level, whichever is

greater. As shown in Fig.8 below:

• A = Minimum 250mm above Maximum Liquid level.

• B = Maximum 3m above Minimum Liquid Level.

Important Information

If the maximum water height exceeds 2x width of the channel OR

If the maximum water height in channel is less than 50% of the

width of the channel. Please consult Pulsar product support for

assistance.

Fig.8

B

A

Max Liquid

Level

Min Liquid

Level

MicroFlow

Page 26

Page 20

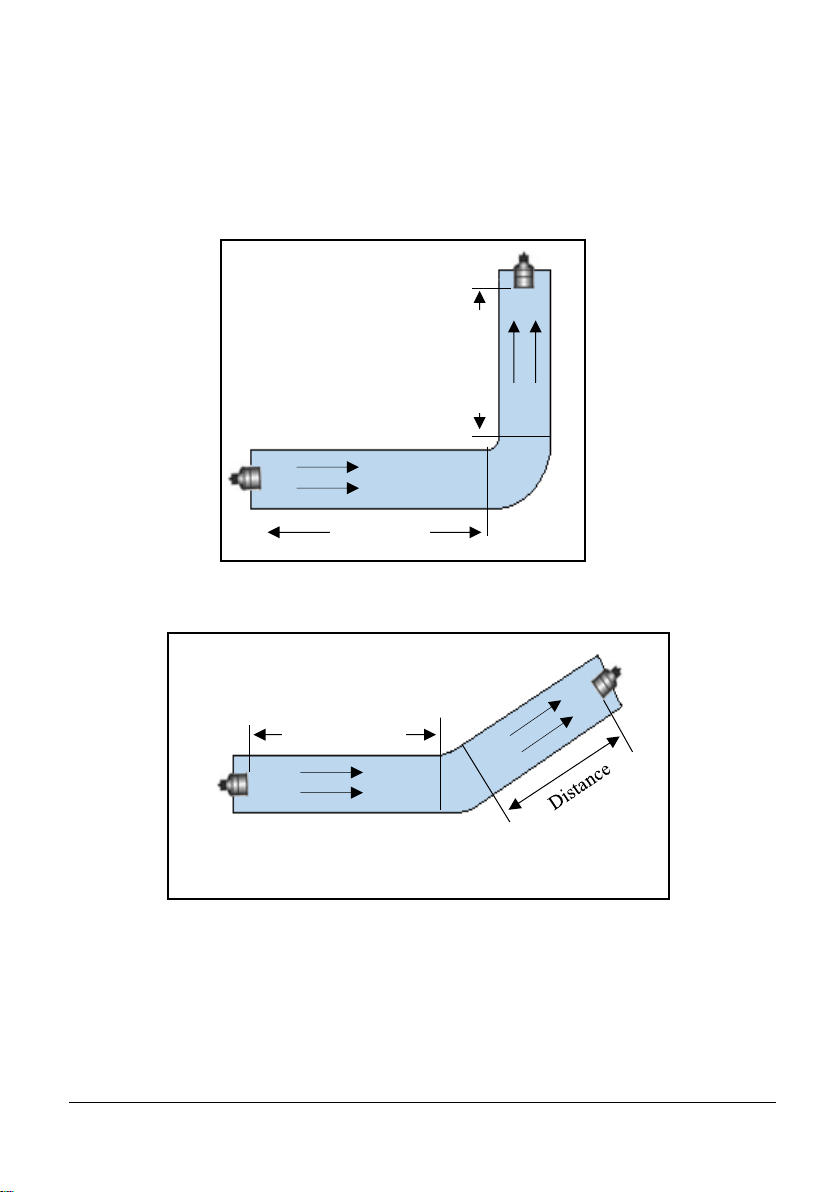

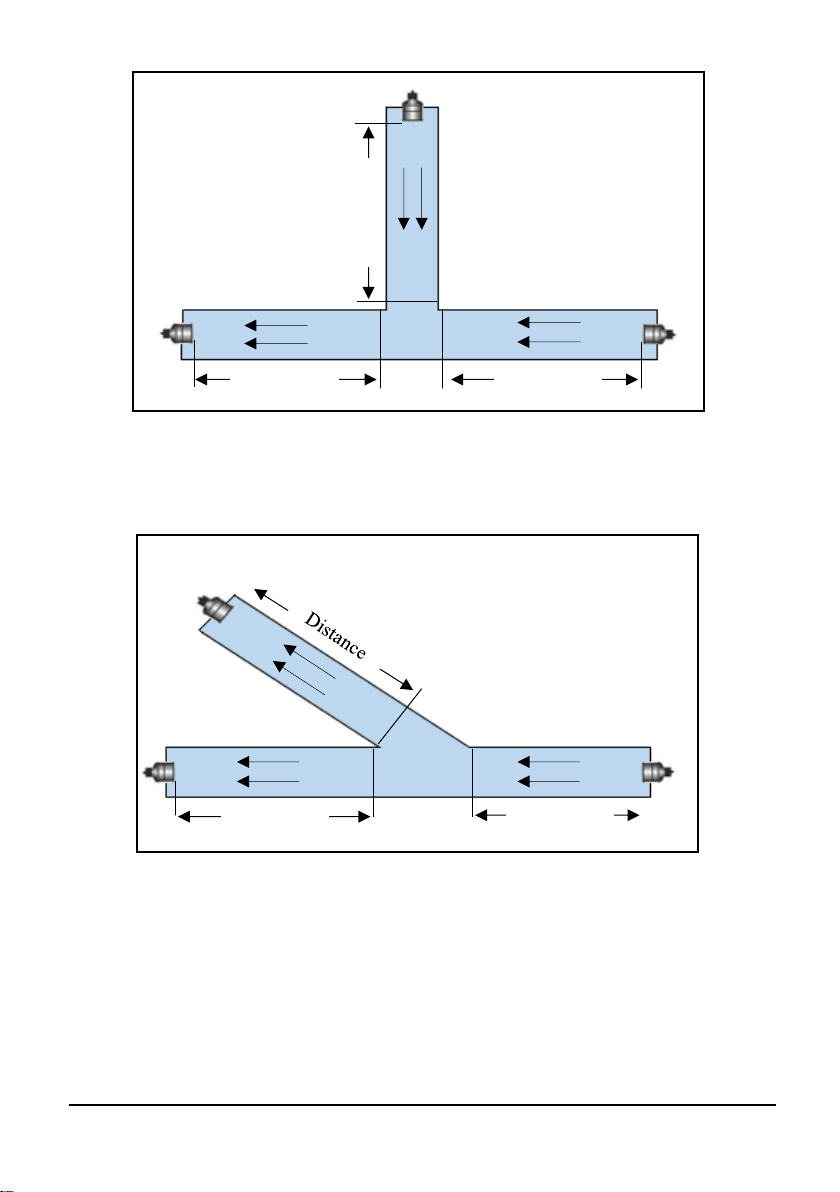

• In the instance where there are vertical drops, baffles, curves or

junctions. The sensor should then be positioned on a straight part of

the channel, at a minimum distance that is at least five times the width

of the channel before a bend, in order to obtain optimal velocity

readings. Examples of positioning the sensor are shown in diagrams 1 - 4

below:

Distance

Distance

Diagram 1

Distance

Diagram 2

Page 27

Page 21

Diagram 4

Diagram 3

Distance

Distance

Distance

Distance

Distance

Page 28

Page 22

Installing the Sensor

• The sensor is supplied with a 1” BSP to M20 thread adapter. The Sensor

housing is designed to accept a 1” BSP female threaded coupler for pipe or

conduit.

• Ensure that the sensor is positioned at a 45° angle to the surface of the

measured application, as this will achieve the best results. An example of

this is shown in the diagram below:

• When using one of the Pulsar Angled Mounting Brackets, secure the bracket

using the correct size screws/bolts/U-bolts (12mm diameter thread).

• Tighten the sensor into the bend, and then screw the thread adapter onto the

bracket using the nut supplied. CAUTION: extreme over-tightening may

crack or cause damage to the unit or bracket.

• Position the sensor so the green ‘dot’ that is shown on the label between the

two green arrows is on the top of the device, and is central to the movement

of flow in the channel.

• If desired, the sensor cable may be extended up to a maximum of 1000m.

Install the sensor cables in grounded metal conduit. Do not run in cable trays

or duct banks with variable frequency drives or other high voltage sources.

• When extending cable for a MicroFlow-i sensor, ensure that all wiring in any

junction /connector boxes are correct.

• Attention should also be taken, when mounting the unit, to ensure that strong

windy conditions are avoided wherever possible to prevent abnormal

operation.

• The sensor can be positioned to obtain readings following the direction of the

flow. Or it can be positioned to measure the oncoming flow as seen below:

45°

Surface of measurement

Green dot to be

displayed on top

Page 29

Page 23

Preparation for Operation

Before switching on, ensure that the following is checked:

✓ The MicroFlow-i is mounted correctly and is secure as outlined in

Chapter 3 – Locating the MicroFlow-i sensor.

✓ All wiring is correct.

✓ The power supply is correctly installed.

General Maintenance

There are no user serviceable parts inside MicroFlow-i. If you experience any

problems with the unit, then please contact Pulsar Process Measurement for

advice.

To clean the equipment, wipe with a damp cloth. Do not use any solvents on the

enclosure.

MicroFlow-i obtaining readings

following the direction of the flow.

MicroFlow-i obtaining readings

from the oncoming direction of the

flow.

Page 30

Page 24

Sensor Maintenance.

Procedure for the Removal of a MicroFlow-i Sensor

From time to time it may be necessary to remove the sensor for cleaning or

maintenance purposes, the below procedure is to ensure that this is done carefully

with regard for the health and safety of the operator involved, and without damage

to the sensor.

If it is necessary to replace the sensor for any reason, the following procedure

should be followed:

• Disconnect the power supply to the sensor.

• Remove any fittings that the sensor may be attached to, allowing the cable to

be pulled through with ease.

• If using a Pulsar angled bracket, the sensor head is mounted onto the end of

the bend via its process fitting, this should be carefully unscrewed in an

anticlockwise direction. Ensure that the sensor is not dropped or knocked as

this can cause damage to the unit.

• When replacing the sensor, care must be taken not to over tighten the unit as

this can cause damage. Hand tight is sufficient.

• Ensure that the green dot has been positioned in the direction of the flow of

the vessel, this will obtain optimum velocity readings that are available.

Please refer to ‘Fig.3’ in ‘Chapter 2-Installation’ section on how to do this.

• When the sensor has been replaced for the application, and re-connected to a

controller and the power re-applied, the unit will re-initialise and will begin

the process of acquiring flow and velocity readings.

• When refitting or replacing a sensor, ensure that it is installed in accordance

with ‘Chapter 2-Mounting a sensor to a bracket’.

• When replacing the sensor for a new one, you can use MicroFlow-i HART

PC to upload any changed parameters from your old sensor to the new sensor.

Allowing continued use of the sensor which is setup for your application.

The correct PPE should be worn on site when performing maintenance on the

system, if in doubt please contact your site Health and Safety Officer for further

advice.

Important Information

Before attempting to remove the sensor for cleaning or any other

purpose, the power to the unit should be disconnected.

Page 31

Page 25

To remove the sensor, first loosen any glands, couplers etc. that may connect it to

the Mounting Bracket, and then lift the sensor body onto a safe place. Taking care

not to damage the sensor housing or cable whilst performing this removal.

The sensor can then be safely inspected for damage or material fouling and can be

carefully cleaned with a damp cloth to remove any foreign debris.

Important Information

Care should be taken when removing and cleaning so as to not damage

the device.

Page 32

Page 26

This page is left blank intentionally

Page 33

Page 27

Chapter 4 Understanding how the MicroFlow-i operates

In order to initially set up the MicroFlow-i (if required) to obtain readings from

your application, it is advised to do this using MicroFlow-i HART PC.

Once the MicroFlow-i has been powered up, you can now begin to obtain flow

velocity from the sensor.

MicroFlow-i HART compatible

The MicroFlow-i uses a unique protocol which enables it to be compatible to any

HART controller that it is connected to, the HART address is ‘0’.

4 – 20 mA Device

The MicroFlow-i can be used as an ‘out of the box’ 4 – 20mA device, this is the

case, by default when you switch the sensor on. The 4 – 20mA output is

proportional to the flow velocity being seen, with respect to the maximum range

of the sensor up to 6 m/s (19.7 ft/s).

Important Information

For further information on how to set up the sensor as a mA device,

please contact your local Pulsar distributor.

To enable the MicroFlow-i to work successfully, ensure

that the power is disconnected prior to a connection being

made.

Page 34

Page 28

This page is left blank intentionally

Page 35

Page 29

Chapter 5 MicroFlow-i HART PC

The software that accompanies the MicroFlow-i can be used to access and change

all parameters via the HART modem, test, obtain and record trace readings from

a sensor. To utilise the features of the software, a USB HART modem which is

available from Pulsar (as shown in Fig.9 below), is required to communicate

between the sensor and your machine.

Software installation

Insert the CD that accompanies the MicroFlow-i sensor into your PC/Laptop. If

you do not have a CD drive on your laptop, then this software can be downloaded

from the Pulsar Process Measurement website: www.pulsar-

pm.com/support/downloads/software.aspx and choose to download MicroFlow-i

HART PC from the list which will then be downloaded onto your machine.

When setting up the HART modem for the first use, you will need to install the

necessary drivers for it to operate correctly with your OS. These drivers can be

installed from your installation disc. Run the MicroFlow-i HART PC Setup.exe

from the CD, or from the downloaded file from our website to install the

MicroFlow-i HART PC software correctly, which will automatically install the

necessary drivers for your HART modem. Once downloaded, a shortcut icon will

be created onto your Desktop for ease of use. Double click on this icon to launch

the program.

Important Information

For optimum installation insert your HART modem to your PC whilst

installing MicroFlow-i HART PC, where your PC should then assign

the modem to a Com Port. Or if you have an internet connection,

upon inserting the USB of the HART modem for the first time,

Windows updates should install this onto your computer for you.

Once the driver’s installation has completed, remove the HART

modem from your machine. Your modem is ready to be used when

a connection to MicroFlow-i PC is required.

Fig.9

Page 36

Page 30

Connecting to MicroFlow-i HART PC

When connecting to the software using the HART modem, power to the sensor

can be obtained from a 10-28VDC source.

To enable the MicroFlow-i to work correctly please ensure that the sensor is wired

as shown in the picture below:

To enable the sensor to work correctly, the power (red) cables from the supply and

to the MicroFlow-i must be wired in series with the 250 Ohm resistor (as seen in

the above picture).

Once the sensor is connected to the HART modem, insert the USB into the

PC/laptop ready for use. You can now use MicroFlow-i HART PC to change

settings of the sensor to suit your application.

To make a connection to the MicroFlow-i sensor, supply power to the sensor and

then select the button which will change to ‘Scanning’ and

the following pop-up windows will appear during an initial connection:

Important Information

Ensure that power to the sensor is switched ‘OFF’ before removing

cables and any connection is made.

Power (+) to MicroFlow-i

(Red cable)

0V to MicroFlow-I (Black cable)

Power (+) from supply

(Red cable)

0V from supply

(Black cable)

250 Ohm resistor

Connector

Connector

Page 37

Page 31

Once the MicroFlow-i parameters have been retrieved successfully, the status

condition will then appear as below:

Page 38

Page 32

If the sensor fails to connect to the software, please check that the Comport has

been correctly set (details of how to do this is outlined in this chapter). After

launching the program and connecting to the MicroFlow-i, the device’s

parameters will be automatically extracted once a connection is established.

Once connected you can now view the information received from the sensor on

the Software’s individual tabs: Flow, Configuration and Trace.

appears after a connection is established, selecting this will then

disconnect the MicroFlow-i.

Flow Tab

The above picture is an example of the default screen of MicroFlow-i HART PC,

which is the Flow tab. The dial on the left displays the linear flow velocity of a

maximum up to 6m/s (19.7 ft/s). While the numerical display on the right shows

the velocity flow rate and the current mA reading.

Signal Strength

The signal strength gives an indication of the actual strength of the velocity signal

detected. A level of higher than 70% is desired for reliable operation.

Page 39

Page 33

Stability

The stability level is an indication of the consistency of flow reading, as derived

from the combination of signal strength and statistical fluctuations of the flow

reading. A high level of stability would indicate optimum condition, and relatively

healthy flow within the channel and indicate higher levels of repeatability and

better flow tracking. The stability does not necessarily indicate the accuracy of

the flow reading, as this is subject to calibration.

Configuration Tab

Parameter Get/Set

This feature allows you to obtain and change parameter values from the list

available. Further information of these parameters and their values can be found

in Chapter 7 – Parameter Listing and Descriptions.

Get:

This will read and display the current ‘Value’ of the parameter selected, along with

‘Units’ of measurement where used, and a brief description of the parameter

selected. Select the desired parameter from the drop down ‘Parameter’ box and

select ‘Get’

Page 40

Page 34

Default:

When selected, this will display the current parameters default value. Selecting

‘Set’ will change the parameters value to that of its default value.

Set:

Allows the value of the selected parameter to be changed. Select the desired

parameter from the drop down ‘Parameter’ box, enter the required value and select

‘Set’. The value box will turn green when the change of parameter value has been

successfully carried out.

MicroFlow-i Manual Setting

The option for manually setting the parameters can be done by utilising the Manual

Setting terminal, as shown below:

This feature is also available when the sensor has been set into ‘Program mode’,

where all if the MicroFlow-i parameters can be queried by entering the parameter

address in the Parameter field and then clicking on the ‘Get’ button. The

MicroFlow-i will then reply with the current value of that parameter.

Selecting ‘Get’ will read and display the current value of the MicroFlow-i

parameter selected. When ‘selected, within the terminal box you will see a

command appear, example <</p102 as the software queries the chosen parameter.

The unit will reply with the parameter and its current value, example: ==/p102:120

Selecting ‘Set’ allows the value of the selected MicroFlow-i parameter to be

changed, both the address and value must be entered before clicking on the button.

<</p102:100 will show the parameter number and the value you have changed in

the manual setting box. And ==/p102:140 will appear when the change of the

parameter and its value is complete. The appropriate access levels are required for

setting parameters.

The values need to be valid and within the allowed range for that particular

parameter for the change to be successful. Please refer to ‘Chapter 7 Parameter

listing and Descriptions’ in this manual, on the parameters available and the

range each one can be set between. If a parameter has been incorrectly set, choose

the parameter from the options in ‘Parameter Get/Set’ and select the default button

to display the default value for that parameter. Pressing set will revert the

parameter to its default value.

Page 41

Page 35

4 – 20mA Trim

This feature is only available to use when the sensor has been set to ‘Run mode’,

the options will then no longer be greyed out and will now be available to use.

If the device connected to the mA output is out of calibration, and is unable to be

calibrated. Then the low and high current levels can be calibrated by altering ‘Set

4mA’ (Low Trim) and ‘Set 20mA’ (High Trim). It is advised that to carry out

calibration, that a Digital Multi Meter (DMM) is used, so that 4mA or 20mA

respectively are shown on the device.

Calibrating 4mA

To calibrate the 4mA, type in ‘4’ in the ‘Constant mA’ value box and press ‘Send’.

If the low value reading is incorrect, then it can be trimmed using the ‘Set 4mA’

option. Enter the offset directly into the value box and then select the ‘Set 4mA’

button to enable you to get the expected result (reading).

Calibrating 20mA

To calibrate the 20mA, type in ‘20’ in the ‘Constant mA’ value box and press

‘Send’. If the high value reading is incorrect, then it can be trimmed using the

‘Set 20mA’ option. Enter the offset directly into the value box and then select ‘Set

20mA’ button to enable you to get the expected result (reading).

Resume mA

When calibration is complete, to release the constant mA reading select ‘Resume

mA’ which will return you to normal measurement/mA output readings. If this is

not selected when calibration is complete, then your mA output will not be

updated.

Page 42

Page 36

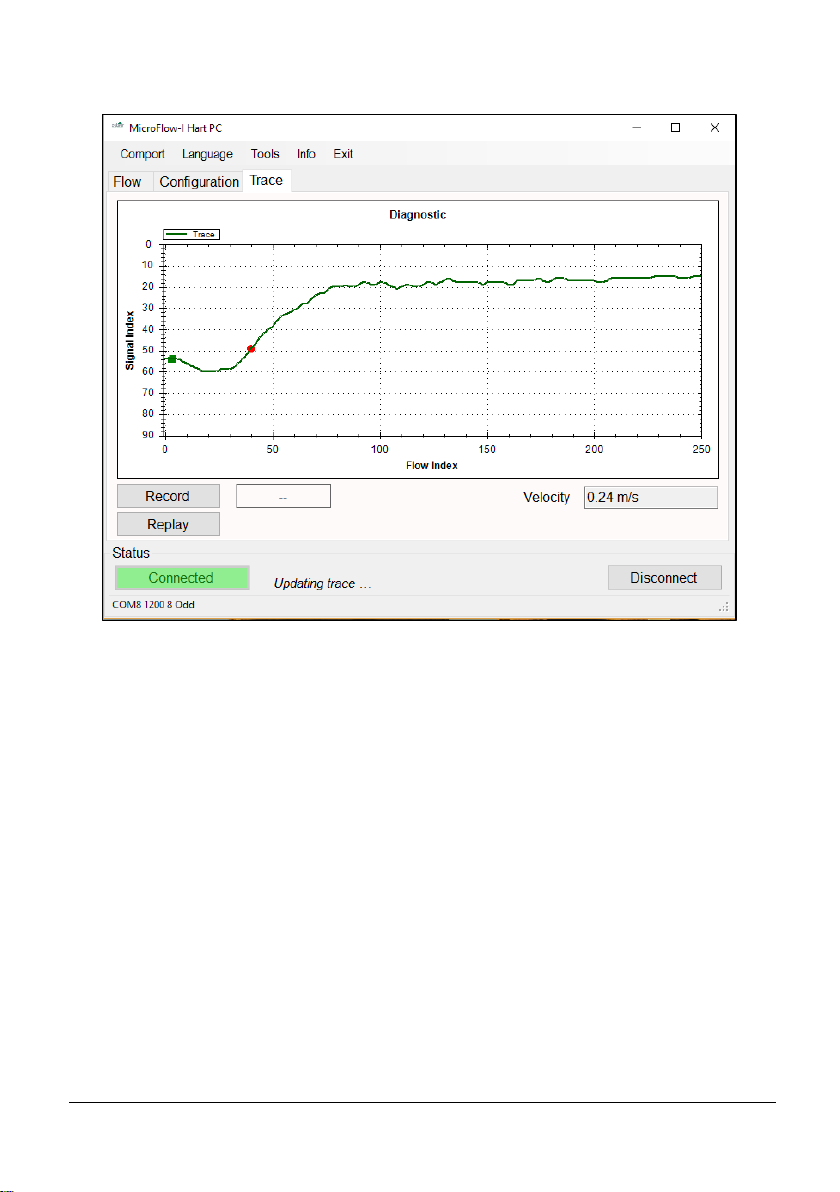

Trace Tab

Upon opening the trace tab, the information at the bottom of the screen will scroll

through Measurement in progress, Updating mA, Updating Trace. Once the trace

has updated the diagnostic traces from the sensor will be displayed. You are also

able to see the current velocity measurement obtained by the sensor.

The vertical axis is related to the signal strength, while the horizontal axis is related

to the detected flow.

When a signal is received, the ‘green square indicator’ will move down from 10

on the vertical axis. The further the ‘green square indicator’ moves from 10, the

larger the strength of the received signal. During flow condition, the ‘green

square indicator’ will normally be within the range of 30 to 70. Under no-flow

conditions the ‘green square indicator’ will remain at 10.

When flow is detected, the ‘red circle indicator’ will move horizontally to

indicate flow detection. The ‘red circle indicator’ should stay at 0 under no-flow

conditions, and move along the horizontal axis when flow is detected.

Under flow condition, the line should still approach and flatten out at just below

the signal index 10 line. If the trace remains flat or the indicators struggle to

remain stable during flow, then increase the ‘Gain’ (P102) setting.

Page 43

Page 37

You can zoom in by clicking and holding the mouse to draw a box over the

region to zoom in on. Zooming out can be done by right clicking on the chart and

selecting “Undo All Zoom”.

Record Traces

To record traces and the current velocity, select the button and enter

a site ID when prompted to do so. The record button will then change to green

whilst the software is recording the data from the sensor. A new trace will be

recorded when Updating Trace…. is shown in the status box.

Replay Traces

To replay trace and velocity data, the sensor needs to be disconnected from the

software. Select the button and a prompt will appear to choose the

data file you wish to play. The replay button will change to green whilst the

software is replaying the data. During replay select the replay button again to stop.

Important Information

Traces will only be recorded whilst the trace screen is displayed.

Upon leaving the trace screen, a message will appear to inform you

of this. Returning to the trace screen will resume recording of the

trace data.

Record

Replay

Page 44

Page 38

Comport

If MicroFlow-i PC fails to connect to the sensor, the status condition will appear

as below:

You will need to change the communications port that is being used. To do this,

select ‘Comport’ from the top menu bar and the Comm Port setup window will

appear, as seen below:

From the drop down box select the Comport that has been assigned to your HART

modem, then press select and then close. Comport assignments can be viewed in

the Device Manager area of Microsoft Windows.

Your Comport information will then appear at the bottom of the MicroFlow-i

HART PC: .

Language

This menu allows you to select the language you wish to view the information on

the software in the language option selected.

Tools menu

This menu option allows you to choose the following options:

Convert Logs to CSV

This allows you to export a saved data file (.MLG only) into CSV format. And

once opened in Excel, the information recorded in this file can be viewed and each

section is labelled at the top of the row: Date, Time, Velocity (m/s), Signal

Strength and Stability. This information from the MicroFlow-i can then be

placed into a chart/graph format.

COM 8 1200 8 Odd

Page 45

Page 39

Change Work Folder

This will allow you to select the default folder for where the trace data files are to

be saved to.

Run HART Bootloader Control

This function allows you to reprogram the sensor with HART firmware, and

should only be accessed by service personnel or under the guidance of Pulsar

service engineers.

Run Bootloader Control

This function allows you to reprogram the sensor with MicroFlow-i firmware, and

should only be accessed by service personnel or under the guidance of Pulsar

service engineers.

Set Program mode

This allow you to interrogate the sensor and make changes to its parameters, and

also view traces from the sensor. Whilst in program mode, the mA output will

automatically change to high (20mA) allowing the change of parameters to be

completed quickly and efficiently. However, the MicroFlow-i will continue to

monitor and display any change in velocity and mA readings on the Flow tab.

Set Run mode

This mode is used once the MicroFlow-i has been set up in program mode. It is

also the default mode that the sensor is in when a connection is made for the first

time to a device, or after a power failure. In run mode no parameters can be

changed and all current readings are reported, and you are able to adjust the 4 –

20mA Trim.

Info

This menu option allows you to choose the following options:

PC Software

This allows you to view the current version of MicroFlow-i HART PC being

used.

MicroFlow-i Firmware

When connected to a MicroFlow-i sensor, the information regarding the firmware.

Hardware and serial number currently connected is displayed here.

Exit

Disconnects the sensor (leaving it in program mode) and closes MicroFlow-i

HART PC.

Page 46

Page 40

Chapter 6 Parameter Listing and Descriptions

Parameter Access

All of the MicroFlow-i parameters have factory default values which the user

receives upon first use, or when the sensor is reset. The parameters consist of two

main types: Device information and Processing parameters.

Device parameters are read only and cannot be set by the user, such as the serial

number of the sensor. Processing parameters can be queried and set, there is also

an associated access level required for setting, either ‘User’ or ‘Service’. Upon

connection to a MicroFlow-i, the access level is defaulted to ‘User’.

The parameters are always stored and entered as whole numbers, please refer to

the individual parameter for its individual value range.

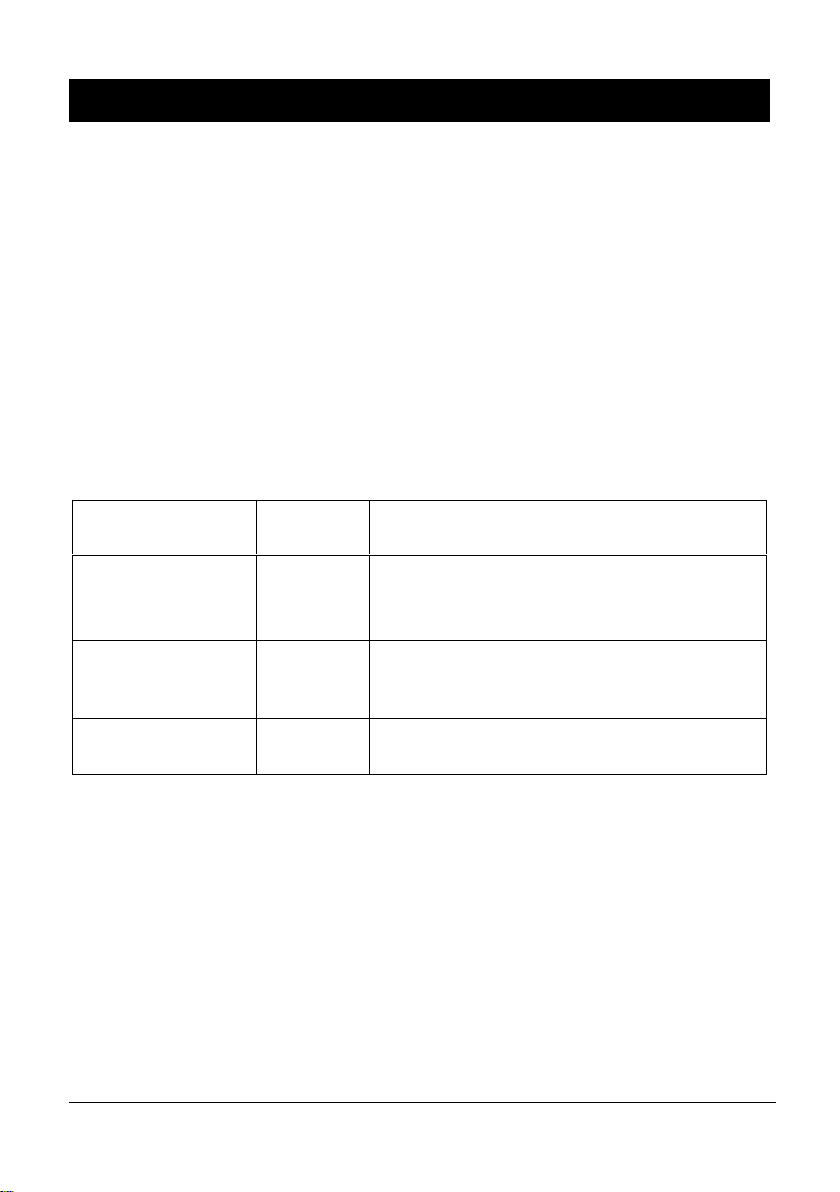

Device Information Parameters

These parameters are read-only.

Name

Parameter

No.

Description

Serial Number

240

&

241

Registers 240 & 241 form a 32-bit number.

Register 240 = Most significant 16-bit.

Register 241 = Least significant 16-bit.

Firmware ID

261

A number associated with the version of

firmware that is currently programmed onto the

sensor.

Hardware ID

262

A number associated with the version of

hardware that is currently used with the sensor.

Page 47

Page 41

Processing Parameters

These parameters relate to the detection and processing of the flow velocity signal.

Name

Parameter

No.

Options

Default

Notes

Gain

102

100 - 1600

120

Used to enter a fixed gain

(sensitivity) value, a higher

number means higher gain.

Quick response

Damping Factor

104

10 – 999

750

When P113=1, this damping

factor will be applied. When

P113=0, measurement will

only be damped by P109 the

main damping factor.

Cal Factor

108

1 – 500

100

In percentage terms, default

is 100, for 100%. 50%

would half and 200% would

double.

High/Main

Damping

109

0 - 28

0

This sets the damping factor

by adding to P104. A higher

number represents more

damping.

Step Response

Mode

113

0 = Off

1 = On

1

When turned off, no damping

by pass will be performed.

Low Damping

Persist

115

1 – 100

2

This is the number of

measurements that the sensor

acquires, before switching

into damping mode.

High Damping

Persist

116

1 - 100

1

This is the number of

measurements that the sensor

acquires, before switching

into Step Response Mode.

No Signal

Persist

117

1 – 100

2

This is the number of nonmeasurement to persist

before the sensor sees a state

of no signal.

Signal Present

Persist

118

1 - 100

2

This is the number of

measurements that need to

persist for there to be a signal

present state.

Page 48

Page 42

Minimum Flow

Cut Off

120

10-4000

150

In units of mm/s velocity for

user input, to set the

minimum flow velocity

present.

Response

125

0=Instant

1=Moderate

2=Damped

Instant

Changing this to ‘Instant’

will automatically calibrate

parameters in the sensor to

track measurements faster.

This is recommended for

Pumped flow. ‘Damped’ is

recommended when there is

natural flow, as

measurements will be

tracked at a slower pace.

Multipoint

Calibration @

0.2 m/s

152

5 - 500

100

In percentage terms, default

is 100, for 100%. 50%

would half and 200% would

double.

Multipoint

Calibration @

0.4 m/s

153

5 - 500

100

In percentage terms, default

is 100, for 100%. 50%

would half and 200% would

double.

Multipoint

Calibration @

0.8 m/s

154

5 - 500

100

In percentage terms, default

is 100, for 100%. 50%

would half and 200% would

double.

Multipoint

Calibration @

1.5 m/s

155

5 - 500

100

In percentage terms, default

is 100, for 100%. 50%

would half and 200% would

double.

Multipoint

Calibration @

3.0 m/s

156

5 - 500

100

In percentage terms, default

is 100, for 100%. 50%

would half and 200% would

double.

Multipoint

Calibration @

5.0 m/s

157

5 - 500

100

In percentage terms, default

is 100, for 100%. 50%

would half and 200% would

double.

Multipoint

calibration

mode

158

0 = Off

1 = On

Off

Turns Multipoint calibration

on and off.

Page 49

Page 43

Simulated Flow

Mode

288

0 = Off

1 = On

Off

Switch simulated flow on or

off.

Simulated Flow

Velocity mm/s

289

0 – 4000

0

This sets the flow velocity in

mm/s, which can be used to

simulate velocity and mA

readings.

Sensor Reset

297

7 = Default

0

This resets all MicroFlow-i

parameters to their default

values. (It does not affect

any mA Trims applied).

Both P834 and P835 are used for spanning the mA output, by default the 4-20 mA

output span is 0 – 6 m/s. Below are some examples of the parameters use:

Example 1: 0 – 3m/s span over 4 – 20 mA.

Set P835 to 3 (m/s).

Example 2: 0 – 6m/s span over 4 – 12mA. Set P835 to 12 (m/s).

Example 3: 0 – 6m/s span over 20 – 4 mA. Set P834 to 6 (m/s) and

set P835 to 0 (m/s).

Example 4: 0 – 6m/s over 8 – 20 mA. Set P834 to -2 (m/s).

Important Information

After using simulated flow, ensure that simulation mode (P288) is

switched ‘OFF’ before disconnecting the sensor from the software

and power cycling the unit.

If using the MicroFlow-i on an application where Flow type is

changed to ‘Fast’, this will reduce the damping to obtain better

results. If there is natural flow and ‘Slow’ is chosen, then damping is

increased to obtain better results.

Page 50

Page 44

MicroFlow-i Firmware Upgrade

Firmware upgrades are performed in ‘Bootloader’ mode, and require service level

access. Note: It is advised that reprogramming is carried out by Pulsar service

personnel. Also all flow measurement and output operation will be halted when

the sensor is in the ‘Bootloader’.

Please follow these steps to reprogram a sensor MicroFlow-i firmware:

1. Please ensure that the sensor is connected to a PC via the HART modem.

Prior to reprogramming, you will need the MicroFlow-i firmware file, and

the COM port number of the modem.

2. Establish a connection to the sensor.

3. You will require Service access to Run Bootloader Control.

4. Select Tools > Run Bootloader Control, which will then open up the

Bootloader control interface window as seen in Fig.10.

5. Once connected click ‘Load Hex file’, and choose the firmware file you are

using to upgrade the sensor.

6. Click ‘Erase-Program-Verify’, and wait for the process to finish.

7. When the ‘Verification Successful’ message is displayed, click ‘Run

firmware’ and the Bootloader Interface will close down.

8. Select the ‘Search’ button on the software, and the sensor will reconnect to

MicroFlow-i HART PC with the new HART firmware installed.

Important Information

It is important to know that it takes approximately 60 minutes to

reprogram a sensor with MicroFlow-i firmware successfully.

Page 51

Page 45

Important Information

Do not switch off supply to the unit or close the software down

during the firmware upgrade.

Fig.10

Page 52

Page 46

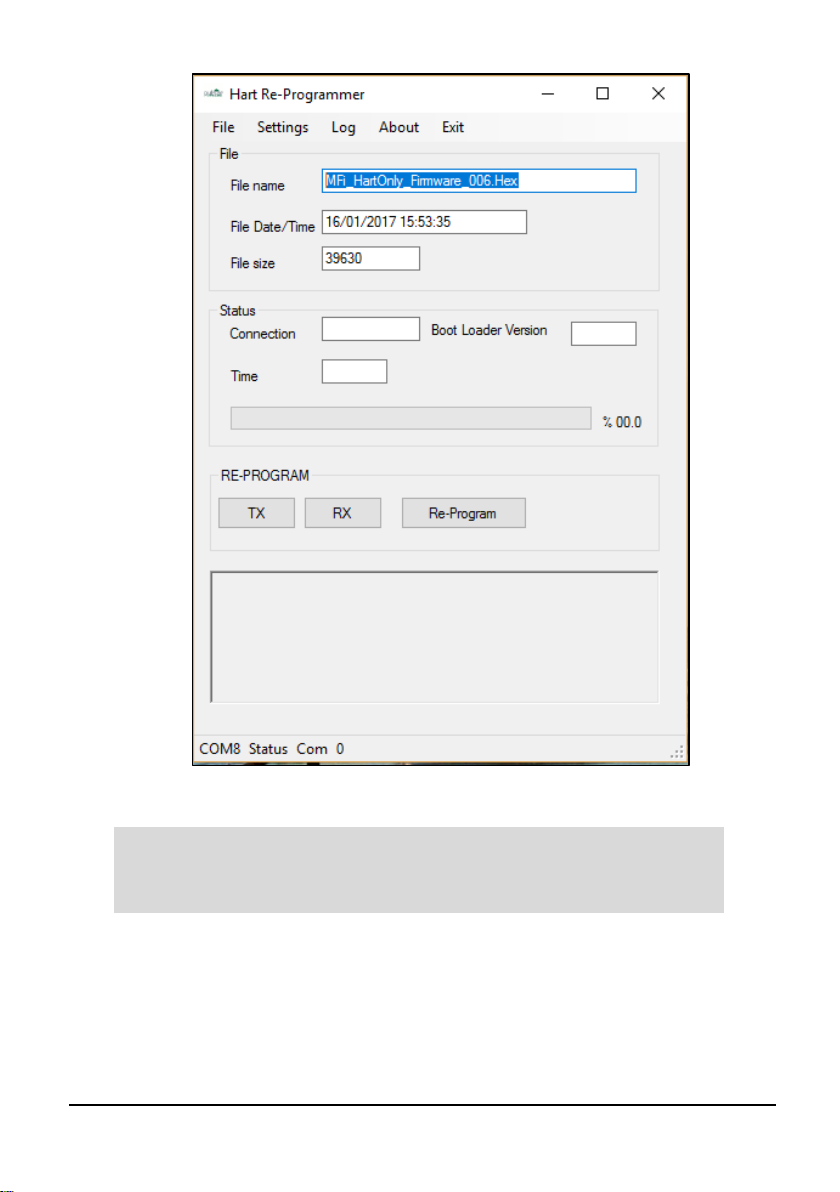

MicroFlow-i HART Firmware Upgrade

1. Please ensure that the sensor is connected to a PC via the HART modem.

Prior to reprogramming, you will need the HART firmware file, and the

COM port number of the modem.

2. Establish a connection to the sensor.

3. You will require Service access to Run HART Bootloader Control.

4. Select Tools > Run HART Bootloader Control, which will then open the

Bootloader control interface window as seen in Fig.11.

5. Once connected click File’, and choose the firmware file you are using to

upgrade the sensor.

6. Click ‘Re-Program’, turn the sensor off and on again when prompted to do

so by the Bootloader control and then wait for the process to finish.

7. When the ‘Program File OK now rebooting’ message is displayed, you can

close the HART Bootloader and reconnect to the PC software.

8. Select the ‘Search’ button on the software, and the sensor will reconnect to

MicroFlow-i HART PC with the new HART firmware installed.

Page 53

Page 47

Important Information

Do not switch off supply to the unit or close the software down

during the firmware upgrade.

Fig.11

Page 54

Page 48

Chapter 7 Troubleshooting

This section describes many common symptoms, with suggestions as to what to

do to resolve them.

Symptom

What to Do

Current velocity reads zero,

but you know that there is flow

movement.

Ensure that the sensor is mounted

correctly in accordance with Chapter

2.

Current velocity reading is

higher/lower than known

movement of flow.

Check that the sensor is mounted

correctly. Adjust the Gain (P102) or

Damping (P109) parameters to obtain

correct measurements.

Unable to connect to

MicroFlow-i HART PC.

Check that wiring to the modem is

correct. Close MicroFlow-i HART

PC software, cycle power on the

sensor and re-open the software.

Ensure that the correct Com port has

been set and retry connection.

Sensor remains at a high mA

out reading (20mA)

Ensure that Simulation mode (P288) is

set to 0 = Off

Ensure that ‘Resume mA’ has been

selected if in Run mode.

Important Information

If you experience any issues with our equipment, then please contact

your local Pulsar Distributor for assistance.

Page 55

Page 49

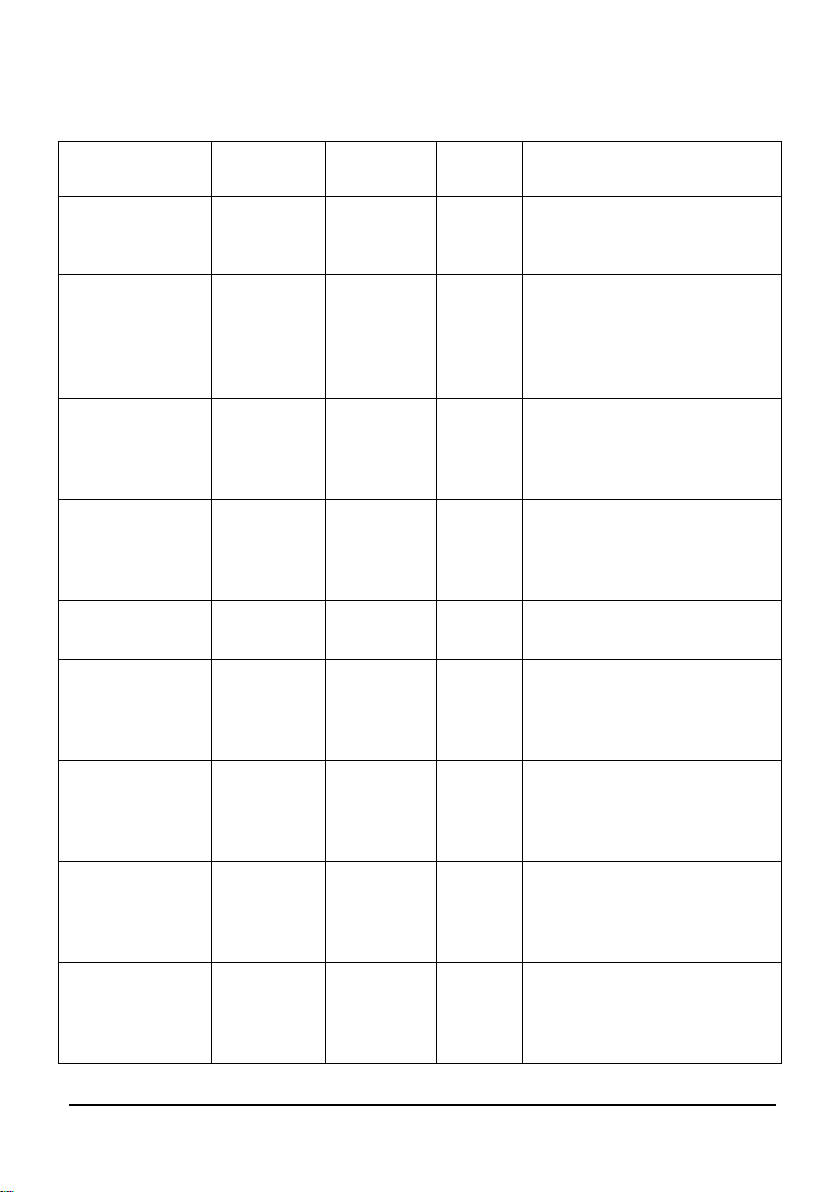

Chapter 8 Parameter record

Device Information Parameters

Processing Parameters

Parameter Details

Entered Values

No.

Description

Default

1 2 3 4 5

P240

&

P241

Serial No.

Read Only

P261

Firmware ID

Read Only

P262

Hardware ID

Read Only

Parameter Details

Entered Values

No.

Description

Default

1 2 3 4 5

P102

Gain

120 P104

Quick Resp Damp Factor

800

P108

Cal Factor

100

P109

High/Main damping

0 P113

Step response

0 = Off

P115

Low damping persist

2

P116

High damping persist

1 P117

No signal persist

2

P118

Signal present persist

2

P120

Minimum Flow cut off

150 (mm/s)

P125

Response

0 = Slow

P152

Multi Cal point 1 at 0.2 m/s

100

P153

Multi Cal point 2 at 0.4 m/s

100 P154

Multi Cal point 3 at 0.8 m/s

100

P155

Multi Cal point 4 at 1.5 m/s

100

P156

Multi Cal point 5 at 3.0 m/s

100 P157

Multi Cal point 6 at 5.0 m/s

100

P158

Multi Cal mode On/Off

0 = Off

P834

Low velocity for mA Span

0

P835

High velocity for mA Span

6

Page 56

Page 50

Chapter 9 Disposal

Incorrect disposal can cause adverse effects to the environment.

Dispose of the device components and packaging material in accordance with regional

environmental regulations including regulations for electrical \ electronic products.

Transducers

Remove power, disconnect the Transducer, cut off the electrical cable and dispose of

cable and Transducer in accordance with regional environmental regulations for

electrical \ electronic products.

Controllers

Remove power, disconnect the Controller and remove battery (if fitted). Dispose of

Controller in accordance with regional environmental regulations for electrical \

electronic products.

Dispose of batteries in accordance with regional environmental regulations for

batteries.

EU WEEE Directive Logo

This symbol indicates the requirements of Directive 2012/19/EU regarding the

treatment and disposal of waste from electric and electronic equipment.

Loading...

Loading...