Pulsar EN54M-2A7, EN54M-5A7-17, EN54M-3A7-17, EN54M-2A7-17, EN54M-3A17-40 User Manual

...

USER MANUAL

EN

Edition: 2 from 04.04.2019

Supersedes the edition: 1 from 14.02.2019

Modules

EN54M series

v.1.0

Power supply modules for built-in

fire alarm systems and smoke

and heat control systems.

www.pulsar.pl EN54M RED POWER plus

2

GENERAL SAFETY RULES

Before installation, read the instruction manual to avoid errors that

can damage the device and give you an electric shock.

Before installation, cut off the voltage in the 230 V power-supply circuit.

To switch power off, use an external switch, in which the distance between the

contacts of all poles in the disconnection state is not less than 3mm.

The shock protection circuit shall be done with a particular care: the yellow and green

wire coat of the power cable should be connected to the terminal marked with

the grounding symbol on the PSU enclosure. Operation of the PSU without the

properly made and fully operational shock protection circuit is UNACCEPTABLE! It

can cause damage to the equipment or an electric shock.

The device should be transported without batteries. This has a direct impact on the

safety of the user and the device.

Installing and connecting the power supply must be carried out without batteries.

When connecting batteries to the power supply, pay particular attention to the correct

polarity. If necessary, it is possible to permanently disconnect the battery from the

power supply systems by removing the F

BAT

fuse.

The power supply is adapted to be connected to a power distribution network with an

effectively earthed neutral conductor.

Ensure a free, convection air flow around the enclosure. Do not cover the ventilation

openings.

www.pulsar.pl EN54M RED POWER plus

3

TABLE OF CONTENTS

1. PSU FEATURES. .................................................................................................................................... 4

2. FUNCTIONAL REQUIREMENTS OF POWER SUPPLY MODULES. ........................................ 5

3. TECHNICAL DESCRIPTION. ............................................................................................................. 6

3.1. GENERAL DESCRIPTION. ....................................................................................................................................................... 6

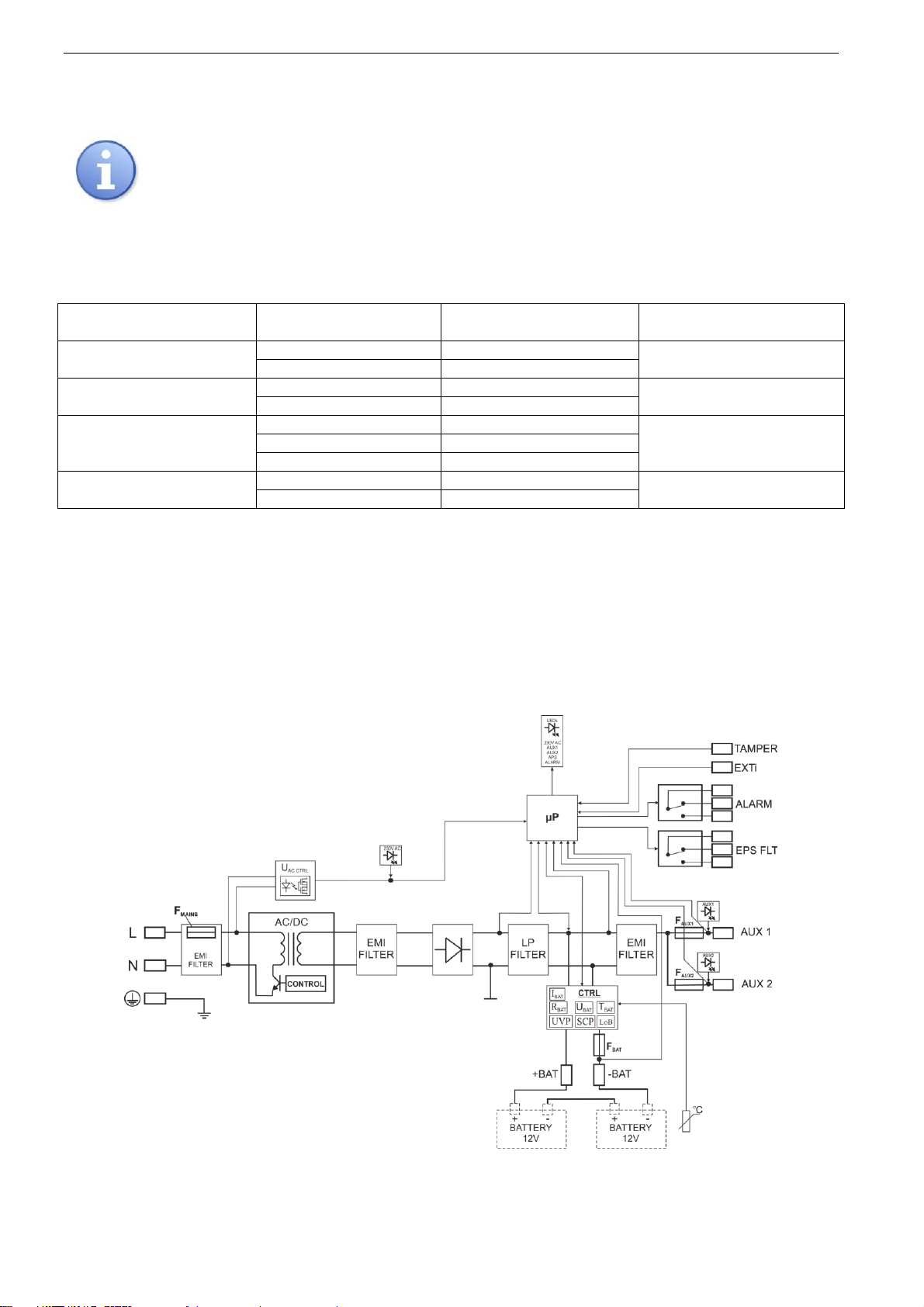

3.2. BLOCK DIAGRAM. ................................................................................................................................................................ 6

3.3. DESCRIPTION OF COMPONENTS AND POWER SUPPLY TERMINALS. ........................................................................................ 7

3.4. DIMENSIONS OF POWER SUPPLY MODULES. .......................................................................................................................... 8

4. INSTALLATION. ................................................................................................................................... 9

4.1. REQUIREMENTS. .................................................................................................................................................................. 9

4.2. INSTALLATION PROCEDURE. ................................................................................................................................................ 9

4.3. PROCEDURE FOR CHECKING THE POWER SUPPLY MODULE AT THE PLACE OF INSTALLATION. ............................................ 10

5. FUNCTIONS ......................................................................................................................................... 11

5.1. TECHNICAL OUTPUTS. ........................................................................................................................................................ 11

5.2. INPUT OF COLLECTIVE FAILURE: EXTI. ................................................................ .............................................................. 12

5.3. INDICATION OF THE ENCLOSURE OPENING - TAMPER. ..................................................................................................... 13

5.4. PSU OVERLOAD. ................................................................................................................................................................ 13

5.5. SHORT-CIRCUIT OF THE PSU OUTPUT. ............................................................................................................................... 13

5.6. ADDITIONAL MODULES. ..................................................................................................................................................... 13

5.6.1 Extending the number of PSU outputs - EN54C-LB4 and EN54C-LB8 fuse modules. ................................................ 13

5.6.2 Cooperation with electric actuators - EN54C-LS4 and EN54C-LS8 sequential modules. .......................................... 14

6. RESERVE POWER SUPPLY CIRCUIT. .......................................................................................... 15

6.1. BATTERY DETECTION. ....................................................................................................................................................... 15

6.2. PROTECTION AGAINST SHORT-CIRCUIT OF THE BATTERY TERMINALS. ............................................................................... 15

6.3. PROTECTION AGAINST REVERSE BATTERY CONNECTION. ................................................................................................... 15

6.4. DEEP DISCHARGE BATTERY PROTECTION UVP. ................................................................................................................. 15

6.5. BATTERY TEST. ................................................................................................................................................................ .. 15

6.6. MEASUREMENT OF THE RESISTANCE OF THE BATTERY CIRCUIT. ........................................................................................ 15

6.7. BATTERY TEMPERATURE MEASUREMENT. ......................................................................................................................... 15

6.8. STANDBY TIME. ................................................................................................................................................................. 16

7. TECHNICAL PARAMETERS. .......................................................................................................... 17

Table 4. Electrical parameters. ............................................................................................................................................ 17

Table 5. Mechanical parameters. ......................................................................................................................................... 18

Table 6. Safety of use. ........................................................................................................................................................... 18

Table 7. Recommended types and sections of installation cables. ....................................................................................... 18

8. TECHNICAL INSPECTIONS AND MAINTENANCE. .................................................................. 19

www.pulsar.pl EN54M RED POWER plus

4

Built-in power supply module

In accordance with standards: EN 54-4,

EN12101-10

27,6 V DC uninterruptible power supply

available versions with 2 A/3 A/5 A/10 A current

efficiencies

available versions with space for 7 Ah – 65 Ah

batteries

independently protected outputs AUX1 and AUX2

DIN rail mounting using additional EN54M-DIN1

bracket (optional equipment)

cooperation with EN54C-LB4 and EN54C-LB8 fuse

modules (optional equipment)

cooperation with EN54C-LS4 and EN54C-LS8

sequential modules (optional equipment)

optical indication – LED panel EN54M-LED (option)

high efficiency (up to 89%)

low level of voltage ripple

microprocessor-based automation system

measurement of the resistance of the battery circuit

automatic temperature-compensated charging

automatic battery test

two-stage battery charging process

accelerated battery charging

monitoring of the continuity of the battery circuit

monitoring of the battery voltage

monitoring of charging and maintenance of the

batteries

deep discharge battery protection (UVP)

battery overcharge protection

the LoB low battery voltage indication

battery output protection against short-circuit and

reverse connection

output voltage control

fuse monitoring of AUX1 and AUX2 outputs

relay output of collective failure ALARM

EPS relay output indicating 230 V power loss

the EXTi input of external failure

protections:

SCP short-circuit protection

OLP overload protection

OVP overvoltage protection

Surge protection

convection cooling (forced only in the EN54M-

10Axx)

warranty - 3 years from the production date

1. PSU features.

www.pulsar.pl EN54M RED POWER plus

5

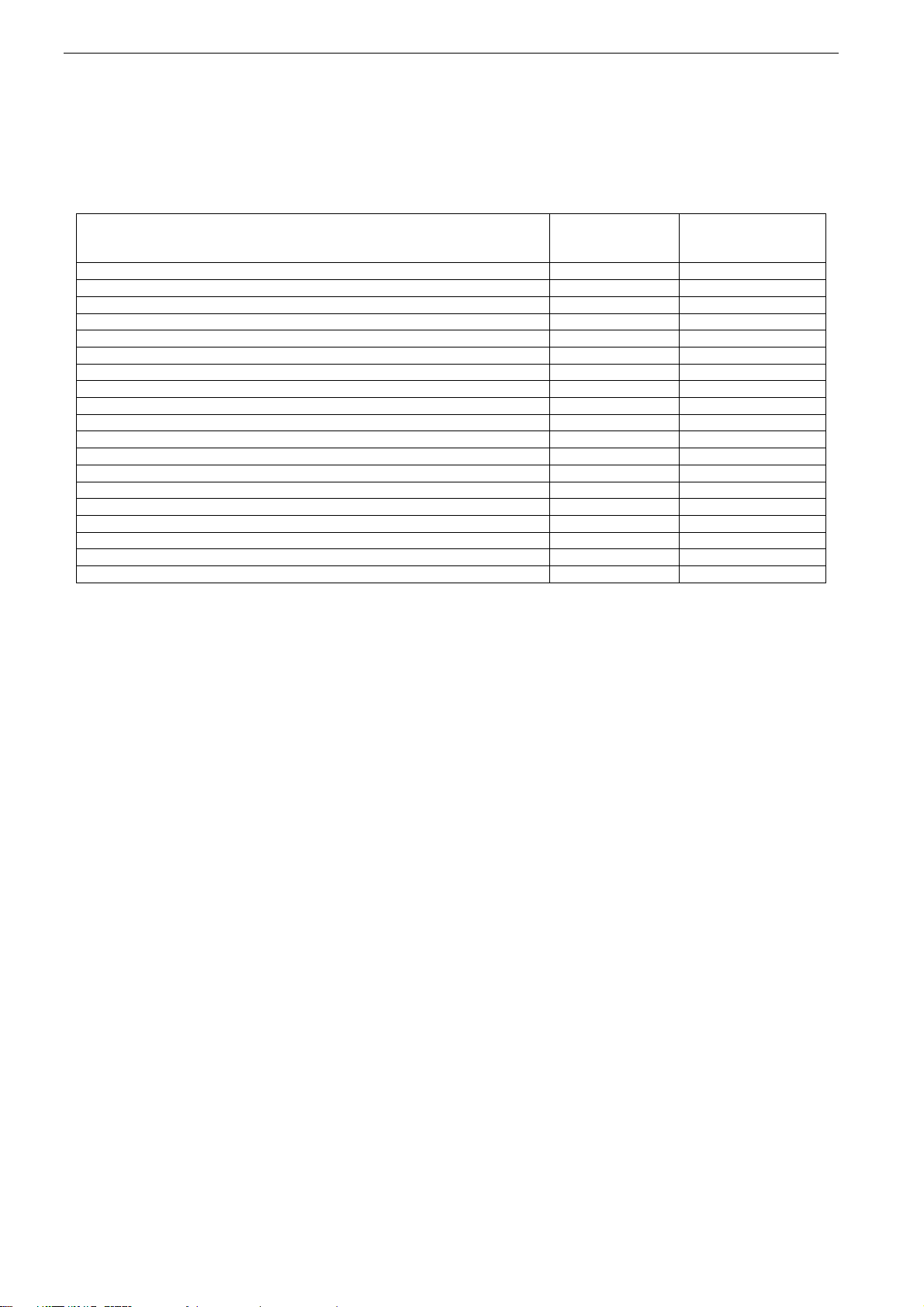

Functional requirements

Requirements

according to

standards

Power supplies

EN54M series

Two independent power sources

YES

YES

External Power Supply failure indication

YES

YES

Two independent power supply outputs protected against short-circuit

YES

YES

Temperature-compensated battery charging

YES

YES

Measurement of the resistance of the battery circuit

YES

YES

Low battery indication

YES

YES

Recharging the battery to 80% of the rated capacity within 24 hours

YES

YES

Deep discharge battery protection

YES

YES

Short-circuit protection of battery terminals

YES

YES

Charging circuit failure indication

YES

YES

Short-circuit protection

YES

YES

Overload protection

YES

YES

Output of collective failure ALARM

YES

YES

EPS technical output

YES

YES

Low output voltage indication

-

YES

High output voltage indication

-

YES

Indication of power supply failure

-

YES

Overvoltage protection

-

YES

Input of an external failure indication EXTi

-

YES

2. Functional requirements of power supply modules.

Buffer power supply modules for fire alarm systems has been designed in accordance with the following

standards:

- EN 54-4:2001+A1:2004+A2:2007 Fire detection and fire alarm systems.

- EN 12101-10:2007 Smoke and heat control systems.

www.pulsar.pl EN54M RED POWER plus

6

Built-in power supply

module model

Battery

Continuous operation

Imax a

Instantaneous operation

Imax b

EN54M-2A7

EN54M-2A7-17

7,2 Ah

1,6 A

2 A

7÷20 Ah

1,2 A

EN54M-3A7-17

EN54M-3A17-40

7÷20 Ah

2,2 A

3 A

17÷45 Ah

1,2 A

EN54M-5A7-17

EN54M-5A17-40

EN54M-5A40-65

7÷20 Ah

4,2 A

5 A

17÷45 Ah

3,2 A

40÷65 Ah

2,4 A

EN54M-10A17-40

EN54M-10A40-65

17÷45 Ah

8,2 A

10 A

40÷65 Ah

7,4 A

3. Technical description.

3.1. General description.

The power supply modules are designed for mounting in an additional housing. In order to meet

the requirements of the EN54-4 + A1 + A2 and EN12101-10 + AC standards, the enclosure must be of

appropriate construction. IP30 protection class is required.

Buffer power supply modules has been designed for an uninterrupted supply of fire alarm systems,

smoke and heat control systems, fire protection equipment and fire automatics requiring stabilized voltage of

24 V DC (±15%). The power supplies are fitted with two independently protected AUX1 and AUX2 outputs,

which provide a voltage of 27,6 V DC and the total current efficiency depending on the version:

In case of power loss, the PSU switches to battery power, providing uninterruptible power supply.

The power supply modules units works with maintenance-free lead acid batteries made with AGM

technology or gel technology.

3.2. Block diagram.

The power supply modules has been manufactured based on a high-efficiency system of AC/DC

converter. Applied microprocessor circuit is responsible for the full diagnostics of the PSU parameters and

batteries. The figure below shows a flowchart of the power supply, along with selected functional blocks which

are essential for the proper functioning of the unit.

Fig. 1. Block diagram of the PSU module.

Loading...

Loading...