Pulsar DTS-i 180 UG III Training Manual

Dealer Development Center

2

Dealer Development Center

1

The Engine and Frame serial numbers are used

to register the vehicles. They are the only

means of identifying your particular vehicle

from the other of the same model and type.

These serial numbers may be needed by your

dealer when ordering the parts. In the event of

theft, the investigating authorities will require

both these numbers in addition to the model,

type and any special features of your vehicle

that can help identifications.

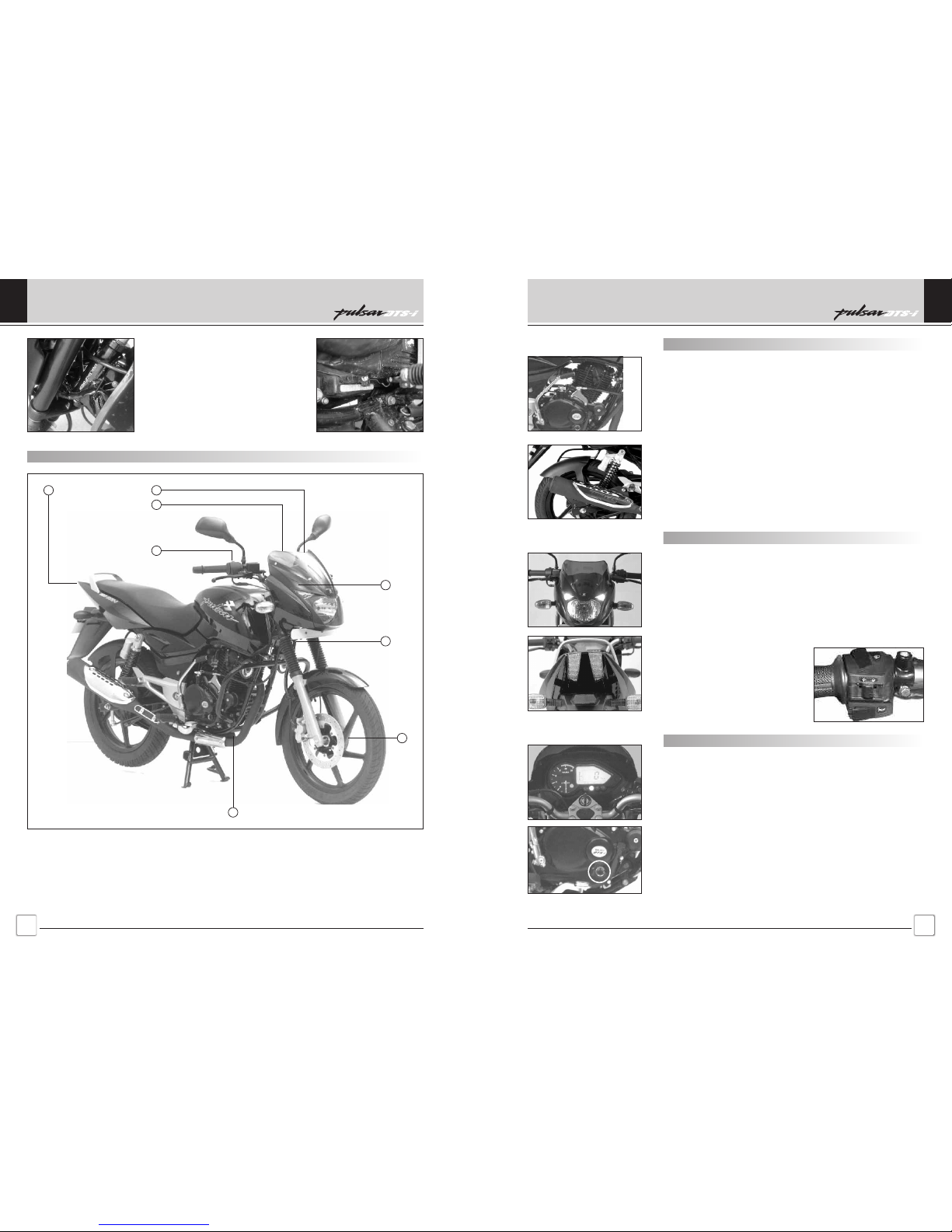

Location of Parts

1

2

3

4

5

6

7

8

Pulsar DTS-i UG-III-180cc Training NotesPulsar DTS-i UG-III-180cc Training Notes

1. Control Switch RH

2. LCD Speedo Console

3. Control Switch LH

4. Body Control Unit

(Placed inside Head Light fairing)

5. Hall Sensor for Indicator

6. Vehicle Speed Sensor

7. ExhausTEC

8. Tail Light LED display

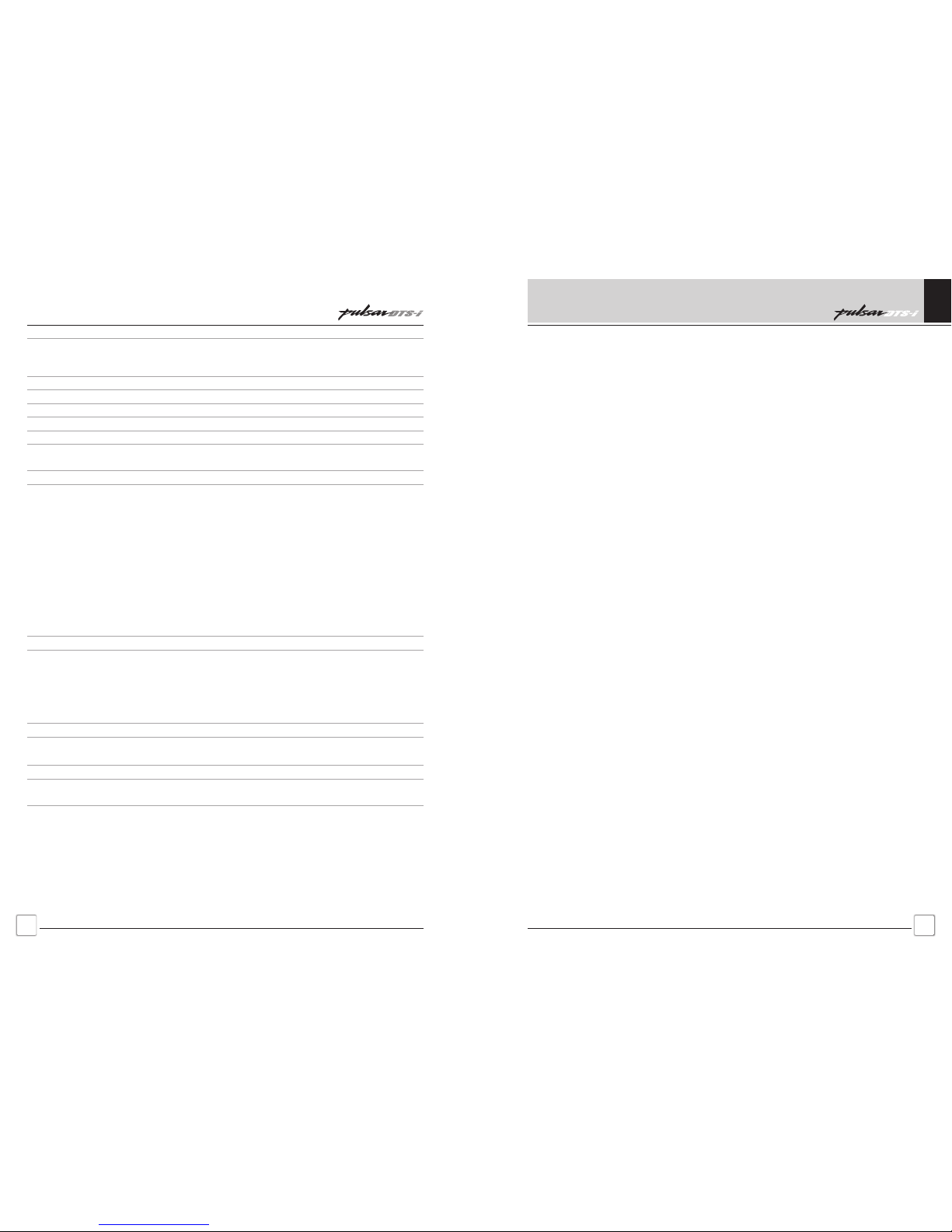

Refined engine power delivery by optimization of Exhaus TEC

location and revised ignition timing with intelligent CDI

New clutch & revamped gear shifting mechanism that gives

smooth, positive, virtually friction-free gear shift feel

New Bigger twin foam filter with an optimized intake system to

provide better torque

Optimized valve timing and Roller rocker with NR bearing for

friction reduction that improves drivability.

LED tail lamp that consumes negligible power & require zero

maintenance

Stainless steel silencer that overcomes rusting problem

All sensor type electrical switches that enables switches to

function for the life of the bike. Absolutely no maintenance in

absence of mechanical contacts.

Performance :

Style :

Stylish fairing and head lamp assembly with owleye

A new black mask that separates headlamp from parking lights

adds to aesthetics.

Clear lens indicator with amber bulbs.

New age, sharp and attractive 2 Row Tail lamp with LED lights

New seat cowl to match stylish LED tail lamp.

Louver type LH & RH covers with wire mesh gives sturdy look.

Ergonomically designed self-letting switches

Convenience and Comfort

LCD Speedo Console with digital fuel gauge (12 level indicator)

Digital speed display, odometer and two trip meter with resetting

provision.

Self-canceling indicators After completion of turn, the indicator

will be switched off automatically.

Engine oil level window for easy to monitor level.

Maintenance free battery once a year electrolyte top up.

In addition to Fuel gauge, Reserve indicator bulb is provided that

glows continuously till the petrol filled to main level.

Self check provision for Tachometer for its functioning

Identification Data

Salient Features

Dealer Development Center

4

Salient Features

Dealer Development Center

3

Pulsar DTS-i UG-III-180cc Training NotesPulsar DTS-i UG-III-180cc Training Notes

Day night mode of Speedo console

The turn Indicator, neutral, high beam, and side stand Indicator bulb

glow brightly in the day for clarity, and Intensity reduces during night to

reduce irritance to the rider's eye

High RPM warning lamp when engine reaches to 9000 RPM

automatically Red LED bulb starts blinking. This enables the rider to

control the speed to avoid damages if any that may take place to

engine components.

Engine cut-off at 10000 RPM Spark gets cut-off at 10000 RPM

to bring down the engines RPM for safety.

LED illumination for tell-tale icons on electrical switches that glows in

the night for positive access of individual functions.

Safety :

Engine and Transmission

Type : Four stroke DTS-i, Natural air cooled.

No. of cylinders : One

Bore : 63.50 mm.

Stroke : 56.40 mm.

Engine displacement : 178.60 cc.

Compression ratio : 9.5 + 0.5:1

Idling Speed : 1400 + 100 rpm.

Max. net power : 12.15 kW (16.51 Ps) at 8000 rpm.

Max. net torque : 15.22 Nm at 6000 rpm.

Ignition System : Microprocessor controlled digital C.D.I.

0

Ignition Timing : 10 BTDC at 1500 rpm.

0

: 28 BTDC at 3500 rpm.

Fuel : Unleaded petrol

Carburettor : UCAl-MIKUNI BS29, Side Drought, CV Type.

Spark Plug : 2 Nos. Champion RG4HC, Bosch UR3DC (Resistive)

Spark Plug Gap : 0.7 to 0.8 mm.

Lubrication : Wet sump, Forced.

Starting : Kick start / Electric start.

Clutch : Wet, Multidisc type.

Transmission : 5 speed constant mesh.

Primary Reduction : 3.47 : 1 (66/19)

Gear Ratios: 1st gear : 26.93 : 1 (36/13)

2nd gear : 18.31 : 1 (32/17)

3rd gear : 13.43 : 1 (29/21)

4th gear : 10.54 : 1 (26/24)

5th gear : 8.98 : 1 (24/26)

Final drive ratio : 2.80 : 1 (43/15)

CHASSIS & BODY

Frame Type : Double cradle.

Suspension Front : Telescopic front fork with DU bush (Stroke 135mm)

Rear : Trailing arm with coaxial hydraulic cum gas filled

adjustable shock absorbers, and triple rate coil springs.

Brakes Front : Mechanically expanding shoe and drum type.

Hydraulically operated disc type.

Rear : Mechanically expanding shoe and drum type.

Tyres Front : 2.75 x 17, 41 P

Rear : 100/90 x 17, 55 P

2

Tyre Pressure Front : 1.75 kg/cm (24.5 Psi)

2

Rear Solo : 2.00 kg/cm (28.0 Psi)

2

Rear Pillion : 2.25 kg/cm (32.0 Psi)

Rims (Alloy Wheels) Front : 1.60 x 17

Rear : 2.15 x 17

Technical Specifications

Frequently Asked Questions (FAQ’s)

Dealer Development Center

6

Technical Specifications

Dealer Development Center

5

Fuel Tank Capacity : 15 liters Full

: 3.2 liters Reserve

: 2.0 liters Usable reserve

CONTROLS

Steering : Handle Bar

Accelerator : Twist grip type on RH side of handle bar

Gears : Left foot pedal operated

Clutch : Lever operated on LH side of handle bar

Brakes Front : Lever operated on RH side of handle bar

Rear : Pedal operated by right foot

ELECTRICALS

System : 12 V (AC+DC)

Battery : 12V 9Ah

Head Lamp : 35/35 W-HS1

Pilot Lamp : 5W - 2 Nos.

Tail/Stop lamp : LED

Turn signal lamp : 10 W (2 Nos.)

Turn signal pilot lamp : LED

Side stand indicator lamp : LED

Hi beam indicator lamp : LED

Neutral indicator lamp : LED

Speedometer lamp : LED display

Rear number plate lamp : 5 W

Horn : 12V DC

DIMENSIONS

Length : 1990 mm.

Width : 750 mm.

Height : 1090 mm.

Wheel base : 1320 mm.

Turning circle radius : 2180 mm. (Minimum)

Ground clearance : 165 mm. (Minimum)

WEIGHTS

Vehicle kerb weight : 143 kg.

Gross vehicle weight : 273 Kg.

PERFORMANCE

Maximum speed : 125 km/h with single rider (68kg)

0

Climbing ability : 28% (16 Maximum)

Notes:

• Values given babove are nominal and for guidance only, 15% variations is allowed to cater for

production and measurement variation.

• All dimensions are under UNLADEN condition.

• Definitions of terminologies wherever applicable are as per relevant IS/ISO standards.

• Specifications are subject to change without notice.

Pulsar DTS-i UG-III-180cc Training NotesPulsar DTS-i UG-III-180cc Training Notes

Ï What are the special features of 'PULSAR DTS-i 180 UG III '? OR

Ï What is so special in this 'PULSAR DTS-i 180 UG III '?

B Pulsar UGIII is next version of Pulsar breed. It is loaded with lots of unique &

contemporary features and that distinguishes the Pulsar not only in the category of Power,

Performance & Style but also for Comfort, Convenience & Safety from the competition.

B Apart from refining the power delivery, it is loaded with the features that are meant for

cars. So, here is the Comfort, Convenience & Safety of the 4 wheels (cars) available on 2

wheels.

B The major changes / features are

Enhanced Performance

• Refined engine power delivery by optimization of ExhausTEC location, bigger & twin

Air Filter element, optimized valve timing, reduced engine friction etc.

• Stainless steel silencer that lasts long & overcomes rusting.

• All sensor type electrical switches that function for the life of the bike. Absolutely no

maintenance in absence of mechanical contacts.

Enhanced Style

• Stylish fairing & Headlamp assembly with owl eye, new black mask to separate

headlamp from parking lights

• New age, sharp & attractive 2 Row Tail lamp with LED lights

• Louver type LH & RH covers with wire mesh gives sturdy look.

• Ergonomically designed self-letting switches

• Absolutely no maintenance in absence of mechanical contacts.

Enhanced Comfort & Convenience

• Loaded with Digital Technology like LCD Speed/Odo display, digital fuel meter, Digital

trip meter that enables to count two trips.

• Car like self canceling indicator switches that keeps rider free from switching off the

indicators after turn.

• Apart from digital fuel meter, warning light for low fuel level is provided.

• Self check provision for tachometer to ensure proper functioning.

• Oil level inspection window that indicates oils level at a glance.

Enhanced Safety

• Engine cut-off at 10000 RPM Spark gets cut-off at 10000 RPM

• High RPM warning lamp when engine reaches to 9000 RPM automatically Red LED

bulb starts blinking.

• Day night mode of Speedo console, LED illumination for tell-tale icons on electrical

switches that glows in the night for positive access.

Ï How does the digital Speedo work?

B Front wheel of the bike has a sensor & magnet unit. The sensor counts no. of pulses w.r.t.

wheel rotation & logically calculates number of wheel rotation & gives input to the display

unit in the speedo console and the LCD display indicates accurate speed, odo reading &

trip meter readings.

Dealer Development Center

8

Frequently Asked Questions (FAQ’s)Frequently Asked Questions (FAQ’s)

Dealer Development Center

7

Pulsar DTS-i UG-III-180cc Training NotesPulsar DTS-i UG-III-180cc Training Notes

Ï What are the advantages / Benefits of the digital speedometer apart from giving

accurate reading?

B This system is totally contact less & no mechanical transmission of drive from wheel to

speedometer is available. Thus this system is totally maintenance free & lasts for the life of

the bike.

Ï How the digital fuel indicator meter works? OR How one can understand the available

fuel level in the fuel tank? OR How to read the graphical bar of the fuel meter?

B Graphic bar with 12-segment display is provided in the speedo console for indicating fuel

level in the tank. If the all the 12 segments of a bar graph are 'ON', that indicates that the

fuel tank is full.

B As the float gauge in the tank starts lowering down due fuel level coming down, the

segments of the bar graph starts diminishing with corresponding drop in fuel level.

B When the petrol level comes down to below four liters, all the segments of the bar will

vanish.

B Apart from LCD graph bar, a red warning light also has been provided in the console that

glows continuously when the petrol level falls down to reserve. And it will be 'ON' till petrol

is filled above reserve level.

Ï When the digital fuel meter is available, why the red warning light is provided?

B While the LCD graphical bar segments indicates the petrol level in the fuel tank, the red

warning light continuously reminds the rider to fill the petrol.

Ï Why two trip meter reading option is given? How is it useful?

B It is just to enable the rider to count reading for two different trips unlike only single trip in

case of conventional type.

B It is like this - on selecting 'Trip1' its will indicate the distance covered in first trip that is

set for. In continuation, on selecting 'Trip2', it will indicate the distance covered in the

second trip. Then if one wants to know the cumulative distance covered in first & second

trip, it can be found in 'Trip1' mode. For this one has to just press/select 'Trip1' mode.

B This is an added advantage taken from digital technology!

Ï What do Self-canceling Indicators switches means?

B In conventional type of switches, the rider has to manually depress or turn knob of

indicator switch for putting 'OFF' the indicator bulbs. In case of this Self-canceling'

switches the indicator goes off automatically after the rider takes a turn & brings the

handle bar straight. This feature is similar to cars. That means, rider do not have to press

or turn the switch to cancel the indicators.

Ï What if one switches ON the indicator and do not physically take a turn? Will it work

in such situation?

B Yes. Of course. When the rider selects a right or left turn indicator, but changes his mind

and physically do not take a turn, the indicators turn 'OFF' automatically after pre-set time.

For this a timer function is incorporated in the system. And the timing for this timer is set

around 80 seconds.

Ï What does non-contact Handlebar switches mean?

B The control switches on both sides of the handlebar are conventional to look at, in terms

of switch operations & knob position etc. But the key & distinguishing difference is the

principle of functioning that means these switches do not function on the basis of physical

contact for ON & OFF. These are on non-contact sensor based.

B This feature will have any wear and tear & hence its life would be more than the life of the

bike. These are absolutely maintenance free as far as wear & tear is concerned.

B The other feature, in these switches is the Illumination of the tell-tale icons that is lit up

with LEDs inside the switch body. This gives the icons a pleasant bluish white glow that

can be seen in the night clearly & coolly.

Ï The tail lamp assembly seems to be too special. What is so in that?

B Yes. The tail lamp is unique on this vehicle and no other competitor's vehicle has this

feature. It consists of 16 (8) nos. of LED bulbs with bi-filaments.

B The specialties of LED bulbs are

- Consume very low current

- Glow brightly

- Last far long

- Totally maintenance free

B So, the LED tail lamp apart from delivering fantastic performance, it adds to aesthetics.

Ï What is this bi-filament bulb?

B Bi-filament bulb means these LED bulbs have two filaments in each bulb. One filament of

lower wattage for parking lights & another for brake lighting, which is of little higher

wattage.

Ï If so much so electrical /electronic appliances are loaded, it may affect on Battery?

B Absolutely not. In fact, all the bulbs & backlit bulbs in the Speedo console (except Head

Lamp bulb & pilot bulbs) are of LED type. Few of them works on AC & few are on DC i.e.

battery. So there is hardly any drain on the battery as compared to conventional type of

bulbs.

B Moreover, the Battery of this new Pulsar 180 is special & maintenance free.

Ï What is this maintenance free Battery?

B The battery is new development in DC system on two wheelers (in fact, such batteries are

introduced in cars earlier than bikes) it is different than the conventional one in the material

composition it is made up of. The main features of this new battery are

- Electrolyte level checking is required at every one year instead of every fortnight

- The unique vent mechanism that do not allow loss of electrolyte

- No drainpipe unlike in conventional type battery. So no chances of spillage of electrolyte.

B So, in all it is almost maintenance free battery. Moreover, the LED bulbs, & disable

function of cranking after 3 successive self starts attempts, will further only enhance the

life of the battery.

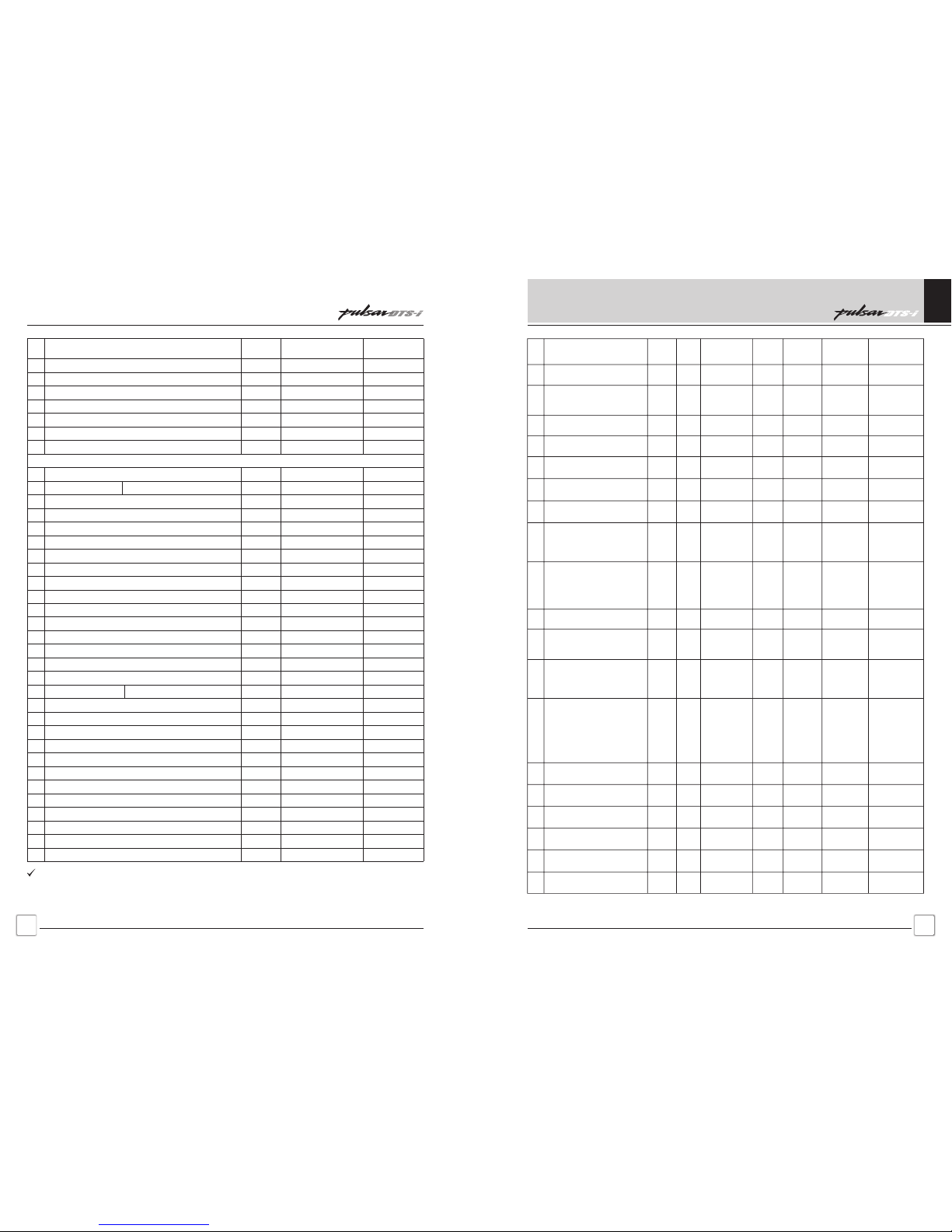

Pre Delivery Inspection Checklist

Dealer Development Center

10

Dealer Development Center

9

Pulsar DTS-i UG-III-180cc Training NotesPulsar DTS-i UG-III-180cc Training Notes

Ï What is that disabling of cranking after 3 successive attempts?

B A protective device has been incorporated in the system that allows rider to attempt self-

start option (pressing of self-start button) for starting only three times at times. After third

attempt the battery power supply gets cut-off to the self-starter motor, thus avoid rider

from further cranking of engine by self-start.

B This is mainly to protect the battery from over draining by excess attempts of pressing of

self-start button to start the engine.

B However, one can again use the self-start option after 15 seconds after third attempt.

Ï How come so many features are managed accurately & what is the guarantee of no

malfunctioning of these features?

B It is needless to say that the digital technology that works with sensors & chips works

accurately. To control all the functions of these electronics features, an intelligent device

has been installed in the electrical system. This is called BCU (Body Control Unit)

Ï What exactly is BCU (Body Control Unit)? How it controls all these functioning?

B BCU (Body Control Unit) is a device that integrates & controls major of all electrical /

electronic functions on the vehicle. It is an intelligent device that works on microchip base.

B In the eventuality of electrical overloads or short circuits, the built in intelligent protection

circuit takes the control of the situation & prevent future damages on other electronic

parts. For example:- During night, suppose one of the Head light filament blows OFF then

there is a possibility of an accident due to sudden darkness.. To rescue, here the BSU

plays an important role. It switches over the Headlight to the other beam automatically

without manual shifting of any switches.

B It also checks & inspects the fused circuit religiously for any corrections and thus riders'

safety is ensured.

Ï Are these type of product features available in Pulsar150cc also?

B Presently not. But as in all sphere of life, technology also proliferates. When that happens

you may find similar features in Pulsar 150cc also.

Ï Can one alter the current Pulsar model & incorporate these features?

B` No. It is not possible. Physically lot of changes are there that are not easily

accommodated in the existing Pulsar.

1

2

3

4

5

6

7

8

9

10

11

Sl. Check

PDI done by BAL/

Service Engg.

PDI Done by

Dealer

Check Points for PDI

LOCK OPERATION

STEERING LOCK NOT WORKING/JAM

SIDE COVER LOCK NOT WORKING

PAINT FINISH -

OVER FLOW (Samples / photographs)

FUEL TANK DEFECTS

LEAKAGE

BLISTERS

RUSTY

OTHERS

(Specify)

FUEL COCK OPERATION - HARD / LEAKAGE

FRONT / REAR WHEEL OFFSET

WHEEL

FR. WHEEL TYRE -Free rotation.

FRONT WHEEL RUNOUT (SPECIFY)

REAR WHEEL RUN OUT (SPECIFY)

SILENCER - BAFFLE NOISE

SWITCHES

RH switch operations

LH Switch operations

IGNITION SWITCH SHORT

LIGHTS:-

Side indicator blinking.

HEAD LIGHT

HORN :-

DISTORTED/WEAK SOUND(DO NOT SET)

Tripmeter - 1/2 working -Resetting

Odometer working

Auto - Calibration of RPM meter

Fuel level indication

Reserve indication (by red lamp)

Red lamp blinking after crossing Engine RPM 9000

Auto-switch off of Ind lamps(H bar straight for > 2 sec)

Head light / tail light illumination after 3 seconds

SPEEDO Needle flickering.

LED functioning - Speedounit - Both side indication,

Side stand, Neutral, Hi beam, RES ind lamp

TAIL/BRAKE LED

Speedo :

SPEEDO NOT SENSING.

Frequently Asked Questions (FAQ’s)

PDI SOP

Dealer Development Center

12

Pre Delivery Inspection Checklist

Dealer Development Center

11

Sl. Check

PDI done by BAL/

Service Engg.

PDI Done by

Dealer

Check Points for PDI

12

FLAT SPOT (GIVE CO %)

13

DRIVE CHAIN slack (mention amont of play)

14

BRAKE OPERATION - FRONT/REAR

FRONT BRAKE

REAR BRAKE EFFECTIVENESS

BRAKE LIGHT REMAINING ON CONTINUOUSLY.

15

GAP AT THE REED SWITCH AND MAGNETO.

CHECK POINTS FOR PDI

16

17

18

19

20

21

22

23

24

LOOSE PARTS

KICK BOSS BOLT

ENGINE MOUNTING BOLT

ENGINE NOISE

CHAIN TENSIONER / TIMING CHAIN

ENGINE OIL LEAKAGE

DRAIN BOLT

MAGNETO COVER

CRANKCASE JOINT

OIL FILLING PLUG

OHC COVER

TAPPET COVER

BENJO BOLT

CHAIN TENSIONER 'O' RING

OIL LEVEL INDICATOR WINDOW

OIL FILTER COVER

CLUTCH OPERATION

HARD

CLUTCH JUDDERING

PLATING DEFECTS

HANDLE BAR

ENGINE OPENING DURING PDI (If any)

(Give engine no & reason for engine opening)

FRAME OPENING DURING PDI (If any)

(Give chassis no & reason for chassis opening)

OTHER DEFECTS :

MINOR ADJUSTMENTS

TRANSIT DAMAGES (Send photographs)

TAPPET NOISE

Marked if the ok observed

Pulsar DTS-i UG-III-180cc Training NotesPulsar DTS-i UG-III-180cc Training Notes

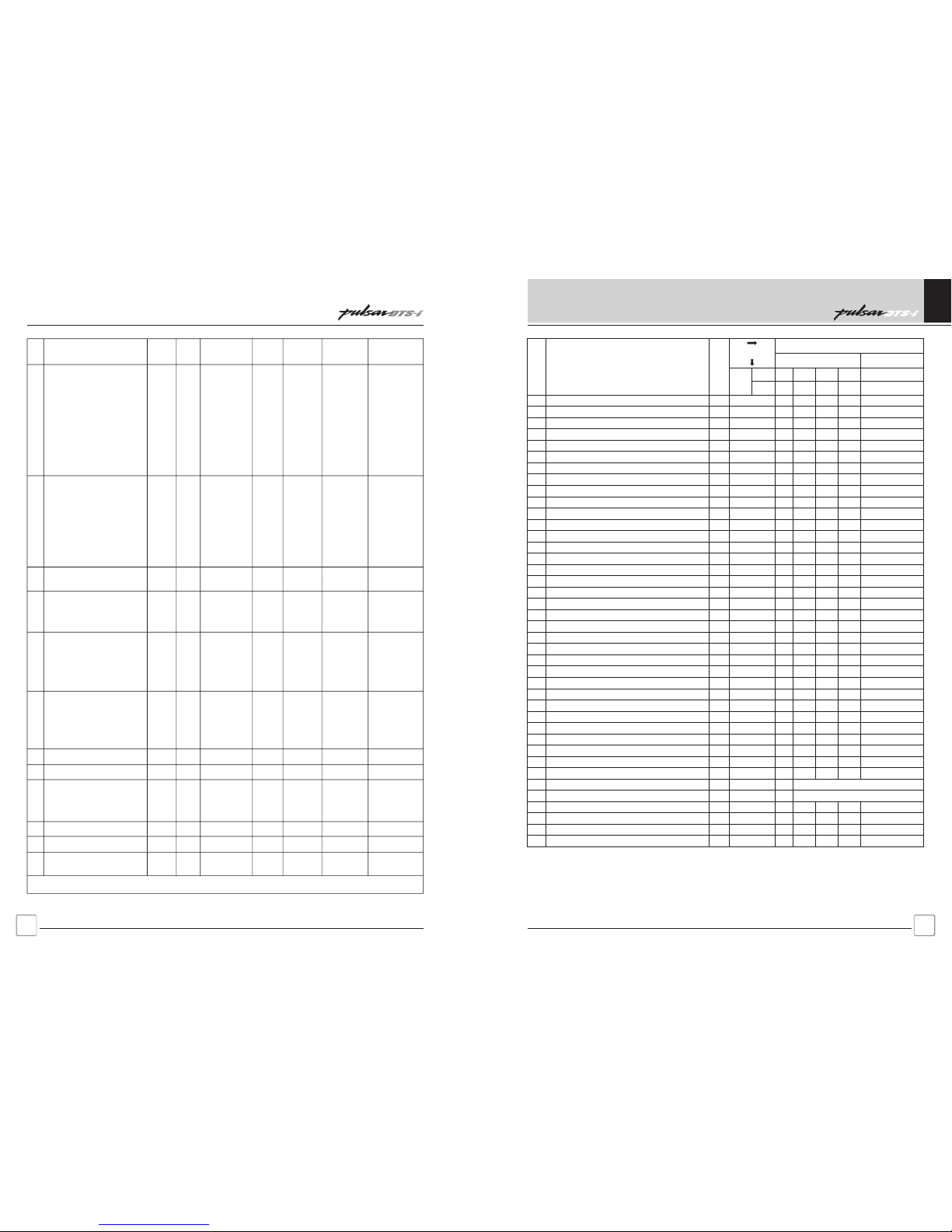

Description

Position

SMM GP Tools

Special

Tools

PNR & its

Attachment

Consumables

Sr.

No.

1

Identify & Park Vehicle on

Work Bay

0.80

2

Remove the Thermocol and

additional packing if any. Study

PDI card and Work content.

0.50

3

Open Petrol tank cap

& pour petrol

0.50

Petrol, Waste

Cloth

Measuring Jar,

Funnel

12-13 Ring

Spanner

Check for smooth operation of

fuel cock lever

Check and correct tyre inflation

pressure - Front Wheel

Check front brakes for efficient

working & Adjust if required.

Check clutch cable operation &

Adjust if required.

Check & top up engine oil level,

if required.

0.10

0.20

0.10

0.30

0.10

4

8

7

5

6

RH

RH

12-13 OE

Spanner

Front

/ RH

Pencil Type

Pressure Gauge

Front

9

Check Battery voltage, fill /

top-up electrolyte, apply

petroleum jelly, connect

terminals properly.

LH

0.60

Screw Driver,

Distilled water

Filler, 10mm

‘T’ Spanner

Cloth, Fine

Polish Paper,

Petroleum

Jelly,

Distilled Water

10

Inspect Rear Shock Absorber

setting & correct if necessary.

RH/LH

0.10

11

Check Rear brakes for efficient

working & adjust if required.

Rear

0.10

14-15 No.

O.E. Spanner

12

Check and Correct tyre inflation

pressure - Rear Wheel.

Rear

0.20

Pencil Type

Pressure Gauge

13

Lubricate chain and Check /

Adjust chain slackness if required.

LH

0.40

20-22, 24-27

Ring Spanner,

10-11 No. OE

Spanner,

Torque Wrench,

Socket Set,

Oil Can

Cloth,

SAE 90 Oil

14

Check Choke lever operation

LH

0.05

10-11 No.

OE Spanner

15

Check Accelerator cable free play

LH

0.05

8 & 10 No.

OE Spanner

10-11 No.

OE Spanner

16

Check & Adjust TPS

LH

0.10

17

Check gear shifter lever operation

LH

0.05

8 No.

‘T’ Spanner

18

Check & Adjust steering and

Handle bar for free movement.

RH /

Front

0.20

12-13, 16-17

Ring Spanner

M & T / Service

Shop Equipments

Lifter Bay

Air Gun

Analogous/Digital

type Pressure

gauge, Air filling

Valve

Hydrometer,

Battery Charger,

Battery Tester

Cloth,

Graphite Grease,

Fine Polish Paper

Analogous/Digital

Type Pressure

Gauge, Air Filling

Valve

Air gun

Fork Spanner

19

Check front mudguard alignment

wrt Front Wheel

Front

0.05

Periodic Maintenance & Lubrication Chart

Dealer Development Center

14

PDI SOP

Dealer Development Center

13

Description

Position

SMM

GP Tools

Special

Tools

PNR & its

Attachment

Consumables

M & T / Service

Shop Equipments

Sr.

No.

20

Check all important nut bolts for

torque and tightness,

• Handle bar mounting bolt

• Stem lower & upper bracket bolts

• Stem of bolts

• Front axle nut

• Cylinder head nuts

• Engine foundation bolts

• Trailing arm bolts

• Silencer cover shield bolts

• Both LH/RH engine mtg. bolts

LH/RH

4.00

12-13, 14-15,

16-17, 20-22

Ring Spanner,

22 mm Box

Spanner with

Handle Ratchet

Pistol Grip

PNR

21

Check the following and

lubricate if necessary

• Rear brake lever

• Rear brake pedal / cam

• Pillion foot rest

• Center stand

• Side stand

• Kick lever boss

• Clutch lever

RH/LH

FRONT

REAR

1.00

Oil Can

SAE

20W40 Oil

22

OE accessories fitment Mirrors RH & LH

LH/RH

1.15

17mm

OE Spanner

23

OE accessories fitment Leg guard

LH/RH

3.25

10-12 No.

OE Spanner

and 12 No.

Box Spanner

Pistol Grip

PNR

24

Start vehicle, Check operation of

electrical like- Head light, Tail light,

Brake light, Side stand indicator,

Horn, Speedometer, Odometer,

Side indicators, Parking and

Pass light working.

LH/RH

0.35

25

Check Idling and CO%.

LH/RH

0.60

Small

Screw driver

CO-HC Analyzer;

Tachometer,

Proper Exhaust

Sealing

Arrangement

of Silencer

26

Trip meter working

LH/RH

0.10

27

Check all locks for proper operation

LH/RH

0.50

28

Test drive the vehicle, check digital

speedometer working. Study the

job card and verify work done.

Take vehicle out and park.

1.30

29

Clean/Wash the veh. before delivery

1.00

17.75

Total SMM

30

Repair for any other defects seen

or observed during test drive.

Expected Output in 480 Minutes / Man / 27 Vehicles

Pulsar DTS-i UG-III-180cc Training NotesPulsar DTS-i UG-III-180cc Training Notes

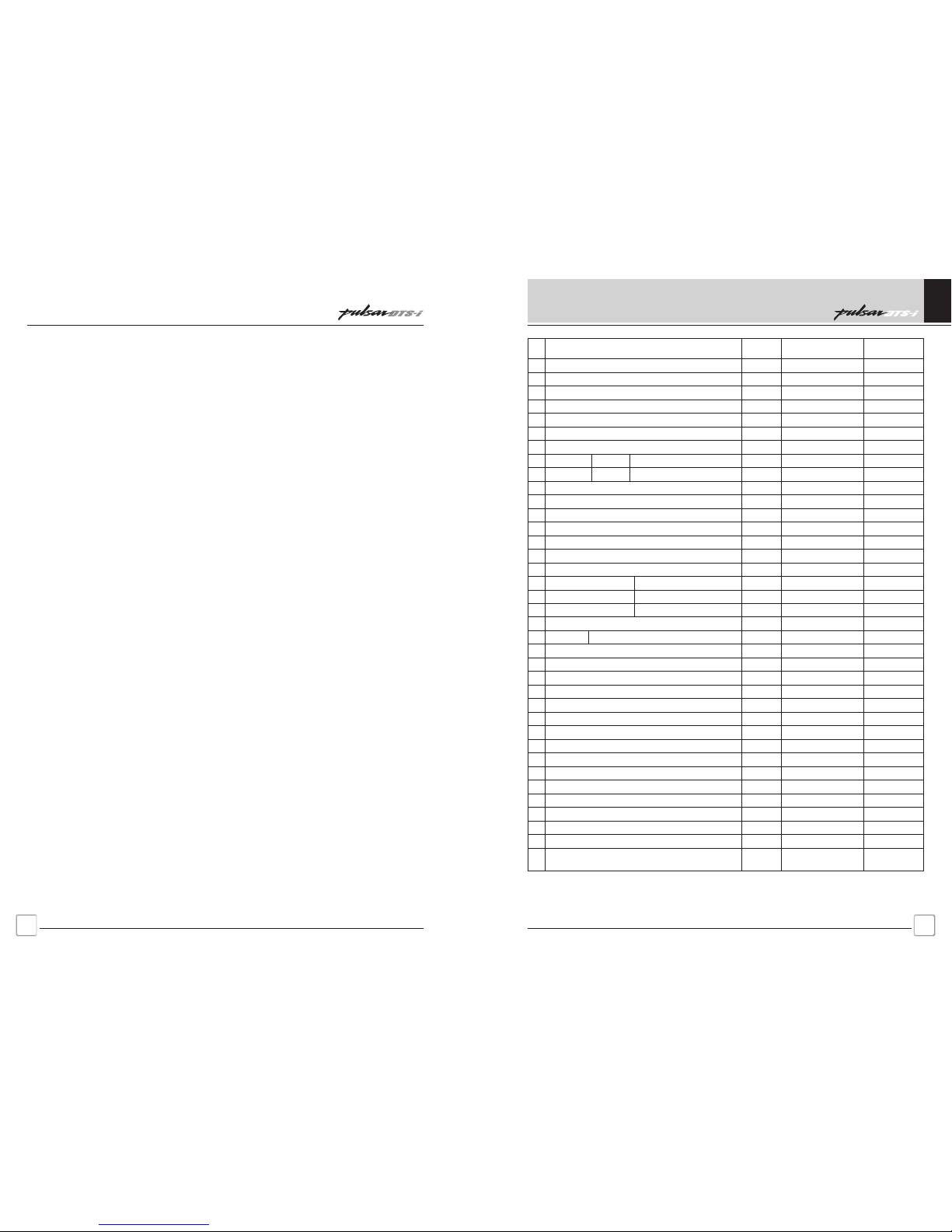

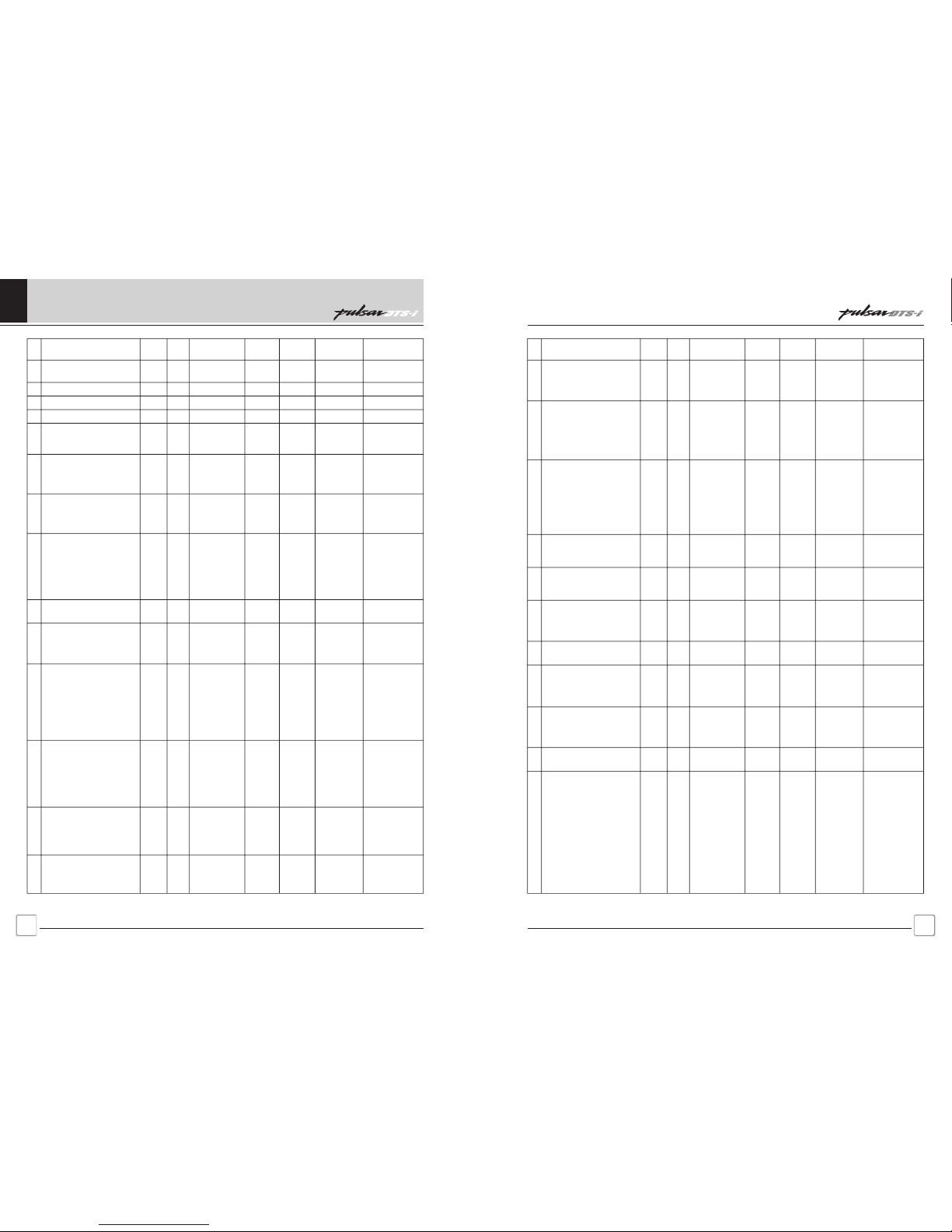

1. Servicing llll l

2. Idle speed / CO% C,A llll l

3. Valve tappet clearance A l Every 5000 kms

4. Engine oil (SAE 20W50 of API SG+JASO MA) R ll Every 5000 kms

5. Oil strainer / Centrifugal filter CL Every 10000 kms

6. Air cleaner element V CL llll l

7. Air cleaner element R Every 10000 kms

8. Carburettor CL,A llll l

9. Fuel system leakages C,R llll l

10. Fuel pipes R Every Year

11. Spark plug / gap CL,A llll l

12. Spark plugs (2 Nos.) R Every 10000 kms

13. Battery electrolyte level C,A llll Every Year

14. Brake light switch C,A llll l

15. Clutch play C,A llll l

16. Throttle play C,A llll l

17. Rear brake pedal play C,A llll l

18. Brake lining or pad wear C,R llll l

19. Brake fluid level / top up C 1 Month llll l

20. Brake fluid change R Every 10,000 kms.

21. Steering play C,A llll l

22. All fasteners tightness C,T llll l

23. Engine mounting silent blocks R Every 20,000 kms.

24. Tyre tread wear C,R lll l

25. General lubrication L llll l

26. Steering stem bearing L,R 1 year Every 10000kms

27. Wheel bearing C,L 1 year Every 10000kms

28. Master cylinder cup and Dust seal R Every 2 years

29. Caliper piston seal and Dust seal R Every 2 years

30. Swing arm pivot pin L l Every 5000kms.

31. Front fork C,L ll l

32. Front fork oil R Every 10000kms

33. Front brake hose C,R 2 years

2

34. Rr. Shock Absorber- Check gas pressure 7.0+0.5 Kg/cm Every 10000kms

35. Drive chain L Every 500 kms.

36. Drive chain slack A l Every 2500 kms.

37. Drive chain wear / Remove & Lubricate C,R l Every 5000kms.

38. Engine compression pressure C Every 10000kms

39. Cylinder head de-carbonising & valve lapping CL Every 30000kms

40. Valve oil seals R Every 30000kms

Sr.

No.

Operation

Whichever

comes first

750 2,500

RECOMMENDED FREQUENCY

Initial

Subsequent

5,000 7,500 Every 2,500km

Kms.

Days

OR

30~45

105~120

195~210

285~300

Every 90 days

l : Indicates operation to be performed.

« : More frequent cleaning may be required when driving in dusty condition.

Note: Parts / Lubricants to be replaced as per Periodic Maintenance and

Lubrication Chart are mandatory and the same are chargeable to customer.

A - Adjust

CL - Clean

C - Check

L - Lubricate

T - Tighten

R - Replace

Dealer Development Center

16

Dealer Development Center

15

Pulsar DTS-i UG-III-180cc Training NotesPulsar DTS-i UG-III-180cc Training Notes

Description

LH/RH

Side

SMM GP Tools

Special

Tools

Consumables

M & T / Service

Shop Equipments

Sr.

No.

1

Wash vehicle thoroughly.

Both

To be done by

washing boy

PNR

2

Identify the Vehicle

0.30

3

Bring vehicle & position on bay

0.50

4

Raise the lift

0.30

5

Start veh. & Warm up. Remove

RH/LH side covers, Seat,

Petrol Tank & keep properly.

LH/RH

0.70

12-13 No.

Ring Spanner,

12mm Socket

Pistol Grip

PNR

6

Drain Engine Oil

LH

1.30

16mm Socket,

Extension,

Tommy

& Plastic Tray

Cloth

Oil Draining

Equipment

7

Clean Air filter.

(Replace - if necessary)

RH

3.00

8mm

‘T’ Spanner

Cloth,

20W40 Oil,

Diesel, Air

Filter Element

Filter Cleaning

Stand, Air Gun

8

Drain Carburetor.

(Overhaul - if required)

LH

1.30

Phillips Screw

Driver, Screw

Driver, 10mm

Nylon Brush,

Plastic Tray,

10-11 & 14-15mm

OE Spanner

Float

Gauge

Cloth, Diesel

Air gun

9

Check Accelerator and adjust

LH

0.40

8-9, 10-11

OE spanner

10

Clean, Check & Adjust

(Replace - if necessary)

LH

2.40

Spark Plug

Spanner, Plug

Cleaner,

Wire Brush

Filler

Gauge

0.01~1mm

Cloth, Fine

Polish Paper,

Spark Plug

Spark Plug

Cleaner and

Tester, Air Gun

11

Check & Adjust tappet

clearance. (if required) During

4th Servicing or after 5000 Km

whichever is later.

LH

8-9 No. Ring

Spanner, 24-27

OE Spanner,

14 mm Box

Spanner with

Handle Ratchet,

Spark Plug

Spanner

Filler

Gauge

0.01~1mm

Tappet

Holder

Cloth

12

Check

• Side bolts of Front fork

• Engine foundation bolts

• Side stand

• RSA top and bottom nuts

14-15, 16-17,

20-22 Ring

Spanner, 12 mm

Box Spanner with

Handle Ratchet,

12-13 No.

OE Spanner

Pistol Grip

PNR

0.60

LH/RH

13

Adjust chain slackness &

Lubricate. Remove and Clean,

If required.

LH /

Rear

3.90

10mm ‘T’

Spanner, 20-22,

24-27 Ring

Spanner, 10-11

OE Spanner

Cloth,

SAE 90 Oil

Air gun

14

Check/ Adjust

Rear

0.50

20-22, 24-27 Ring

Spanner, 10-11,

14-15 OE Spanner

Cloth, Graphite

Grease, Fine

Polish Paper

Air Gun

Periodic Service SOP

Periodic Service SOP

Description

LH/RH

Side

SMM GP Tools

Special

Tools

Consumables

M & T / Service

Shop Equipments

Sr.

No.

PNR

15

Check & Adjust

Rear tyre air pressure.

Rear

0.40

Pencil Type

Pressure Gauge

Analogous /

Digital Type

Pressure Gauge,

Air Filling Valve

16

Check Battery, Top-up distilled

water. Clean terminals & apply

petroleum jelly. Route cables

properly and fit terminal caps

properly. Recharge battery if

required.

LH

1.80

Screw Driver,

Distilled Water

Filler, 10mm

‘T’ Spanner

Cloth, Fine

Polish Paper,

Petroleum Jelly

Distilled Water

Hydrometer,

Battery Charger,

Battery Tester

17

Clean oil strainer.

(Replace - if required) After

1 Year or 10000 Km

whichever is later.

RH

8 No. Box

Spanner, 12-13

OE Spanner,

12-13 Ring

Spanner, 8mm ‘T’

Spanner. Plastic

Tray, Phillips

Screw Driver

Pistol Grip

PNR

Diesel, cloth,

Clutch Cover

Gasket,

Oil Strainer

18

Check clutch and Adjust.

RH

0.30

12-13 OE

Spanner, Small

Screw Driver

19

Fill engine oil.

RH

1.35

6” Combination

Pliers, Measuring

Jar 1Liter, Funnel

Cloth, Oil 20W50

of API SG +

JASO MA grade

Oil Dispenser

20

Clean, Check & Adjust

RH spark plug.

RH

2.40

Spark Plug

Spanner,

Plug Cleaner,

Wire Brush

Filler

Gauge

0.01~1mm

Cloth, Fine

Polish Paper,

Spark Plug

Spark Plug

Cleaner and

Tester, Air Gun

21

Check and Top-up

brake fluid level.

Front

1.00

Phillips

Screw Driver

Cloth,

Oil Dot-4

Check/ Adjust

Front

0.50

12-13

Ring Spanner,

5 & 10 mm

Allen Key

Cloth, Fine

Polish Paper

Air Gun

22

23

Check & Adjust front tyre

air pressure.

Front

0.40

Pencil Type

Pressure Gauge

Analogous /

Digital Type

Pressure Gauge,

Air filling Valve

24

Check and Adjust steering.

Front

0.80

16-17 No.

Ring Spanner

Fork

Spanner

25

Check

• Engine foundation bolts

• Front axle nut

• Side bolts of Front fork

• Handle bar bolts

• RSA top and bottom nuts

• Swing arm axle nut

• Silencer protective cover

screws / bolts

• Rear view mirror

RH

10-11, 12-13,

14-15, 16-17,

20-22 No.

Ring Spanner,

22 mm Box

Spanner with

Handle Ratchet

Pistol Grip

PNR

1.30

Service Wise Part Kit

Dealer Development Center

18

Dealer Development Center

17

Pulsar DTS-i UG-III-180cc Training NotesPulsar DTS-i UG-III-180cc Training Notes

Description

LH/RH

Side

SMM GP Tools

Special

Tools

Consumables

M & T / Service

Shop Equipments

Sr.

No.

PNR

26

Lubricate

• Clutch lever

• Rear Brake pedal

• Rear Brake Cam

• Pillion Foot Rest

• Center Stand

• Side Stand

• Kick lever boss pin

Grease Gun

LH/RH

Oil Can

0.80

20W40 Oil,

Graphite

Grease, Cloth

27

Refit RH, LH side covers,

Seat, Petrol tank

LH/RH

0.50

12-13 No.

Ring Spanner,

12mm Socket

Pistol Grip

PNR

28

Check and Clean fuel line &

Clean petrol tank.

(Replace fuel pipe - if required)

LH

0.50

Air Gun

29

Check all Meters for proper

functioning & Correct, if reqd.

Front

0.50

30

Start vehicle, Check & Adjust

the following.

RH

Head light.

Tail light.

Brake light.

Horn

Speedo, Pass, Parking light

Side Indicators - Front & Rear

Front

Screw Driver

Rear

Phillips

Screw Driver

RH/Rear

Front

Front

Both

0.95

30

Tune Engine & Carburetor.

LH

2.00

Small

Screw Driver

CO-HC

Analyzer,

Tachometer,

Proper Exhaust

Sealing

Arrangement

of Silencer

31 Study Job Card. Verify work. 1.00

32

Lower the Lift

0.30

33

Take vehicle out and park

0.50

32.50

Sub Total

34

Carry out any additional work

as indicated by the Customer

or as required.

10.00

42.50

Total SMM

Expected Production / 480 minutes / Man / 11

35

Test Ride of the Vehicle

if required and park.

1.5

To be Carried

out by Expert

36

Clean the vehicle at the

time of delivery.

1

Will be done

by Delivery boy

PNR = Pneumatic Nut Runner

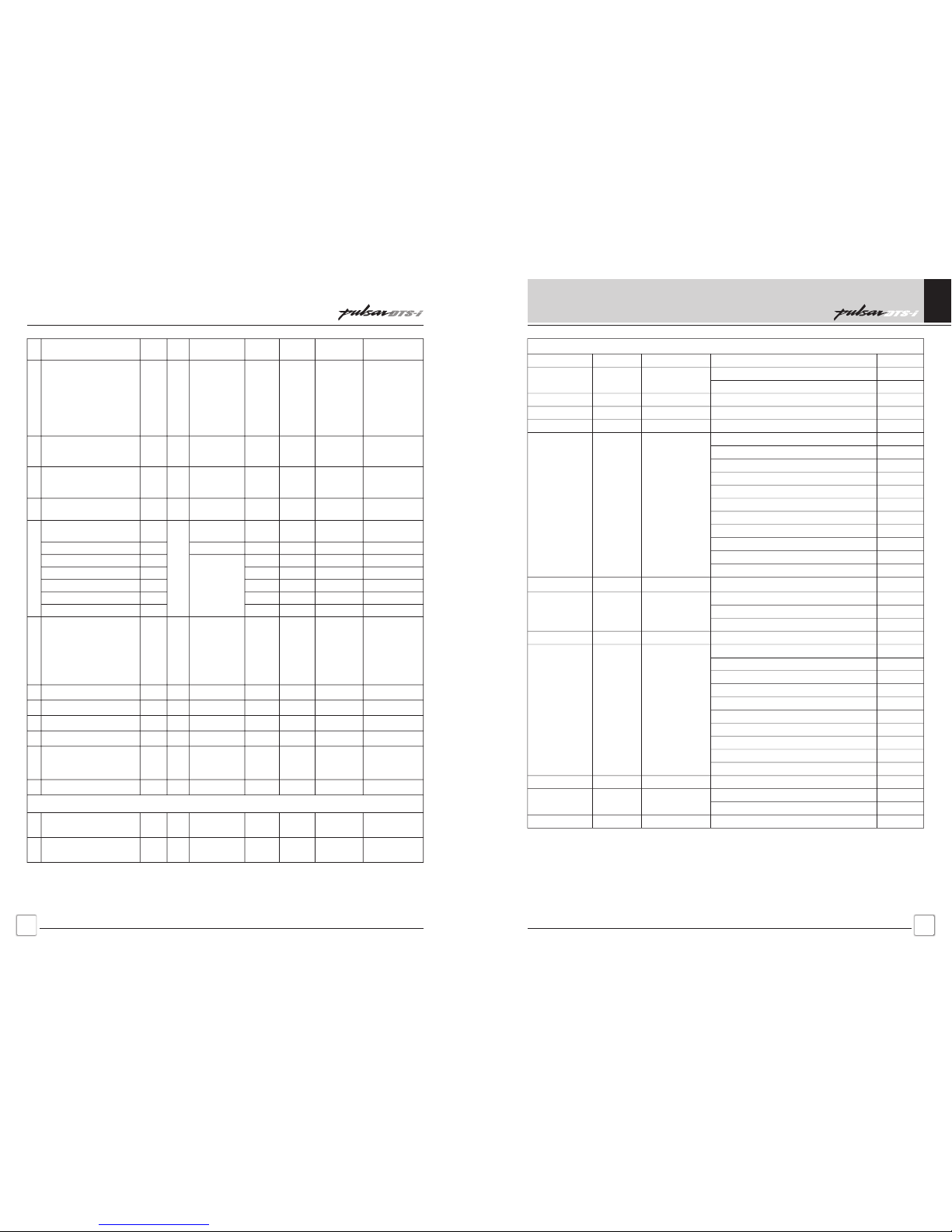

Type of Service

Part Name

Quantity

Periodic Part Replacement Kit for Free Services

Days Kms. Limit

1st Free

500~750

Engine oil 1000 ml.

30~45

Clutch cover gasket

1

2nd Free

2000~2500

NIL NIL

105~120

3rd Free

4500~5000

Engine oil 1000 ml.

195~210

1st Paid

2nd Paid

NIL

Engine oil

NIL

1000 ml.

285~300

375~390

Clutch cover gasket

1

Air filter foam element

1

Spark plug

2

2

Fork oil 330 ml.

Drive chain lock & link set

1

Brake shoes (if worn out)

1

1

7000~7500

9500~10000

Starter clutch bush

Fork oil seal

Cylinder head gasket (If required)

1

Front disc pad inspect / replace (If worn out)

1

3rd Paid 12000~12500

NIL

NIL465~480

4th Free

14500~15000

Engine oil

1000 ml.

555~570

4th Paid

Drive chain lock & link set

Steering cone kit

1

1

615~630

NIL NIL

Engine oil 1000 ml.

Clutch cover gasket 1

330 ml.

Air filter foam element 1

Spark plug 2

Brake shoes (if worn out) 1

1

17000~17500

Front disc pad inspect / replace (If worn out)

Fork oil

5th Paid

705~720 19500~20000

Clutch plate

1

Rear brake damper

1

Drive chain lock & link set

1

6th Paid 22000~22500

NIL

NIL795~810

7th Paid

8th Paid

Carburettor insulator

Chain sprocket kit

1

1

885~900

975~990

NIL NIL

24500~25000

27000~27500

Periodic Service SOP

Schedule Maintenance

Dealer Development Center

20

Dealer Development Center

19

Pulsar DTS-i UG-III-180cc Training NotesPulsar DTS-i UG-III-180cc Training Notes

Cleaning

The vehicle must be cleaned periodically using pressurized water.

Before cleaning the vehicle cover the important parts like Ignition

switch, Silencer Tail end, CDI unit, H.T. coil with plastic bags. Don’t

apply the jet of water directly on electrical parts such as Switches,

Ignition unit, Coils etc. otherwise they may get damaged.

Brushing with kerosene and wiping dry with clean rag is advisable for

external cleaning of the engine. All painted surfaces should be washed

with water. Do not use kerosene or hard detergent soap on painted

surfaces as it damages the paint and turns it dull.

After washing, dry the vehicle with compressed air and carry out the

lubrication as recommended

Caution : Water may enter on the brake liners during washing & brake

slippage may occur. Ensure that brake liners are dry before driving the

vehicle.

Periodic Maintenance

Periodic maintenance (in accordance with the periodic maintenance

chart) of a vehicle is most important to prolong vehicle life, trouble

free running and ensure your safety while driving.

Engine Oil Level Checking

• Park the vehicle on level surface on center stand to check the oil

level.

• Inspect the oil level through oil inspection window

• It should be in between upper and lower mark

• Top up if required

Recommended Oil Grade and Qty

Grade SAE 20W50 of API ‘SG’ + JASO ‘MA’

Quantity Drain & Refill 1000 ml.

Engine Overhaul 1100 ml.

Oil Strainer Cleaning

Remove :

• Drain engine oil.

• Clutch cover

• Oil pump mounting bolts (A)

(3 Nos.)

• Pump with strainer.

• Clip (B) and take out ‘Oil

Strainer’ from oil pump.

Note : It is most vital to adhere to recommended frequency of oil change

for the purpose of long life of critical engine components for details refer

Periodic Maintenance Chart.

Upper

Level Mark

Lower

Level Mark

B

A

Service Wise Part Kit

Type of Service

Part Name

Quantity

Periodic Part Replacement Kit for Free Services

Days Kms. Limit

9th Paid

1065~1080

Engine oil 1000 ml.

Clutch cover gasket

1

4

Air filter foam element

1

Spark plug

2

Valve oil kit

1

1

29500~30000

Cylinder head gasket

Cylinder head stud copper washer

Use always Genuine Bajaj Auto parts & recommended lubricants.

(Engine oil: SAE 20W50 API ‘SG’ + JASO ‘MA’ grade)

Brake shoes (If worn out)

1

Front disc pad inspect / replace (If worn out)

1

Steering cone kit

1

Fork oil 330 ml.

Drive chain lock & link set

1

Notes :

Loading...

Loading...