Page 1

XP Peristaltic Pump Installation, Operation

and Maintenance Manual

7 Day Electronic Timer

REV. A PN J63143 - 1 -

Tested and Certified by WQA

against NSF/ANSI 61-Section 8.

and CSA B483.1

Page 2

TABLE OF CONTENTS

1. Introduction..................................................................................................... 3

2. Safety Instructions .......................................................................................... 3

3. Technical Specifications ................................................................................. 4

4. Installation ...................................................................................................... 5

5. Operation ....................................................................................................... 6

5.1. 7 Day Electronic Timer............................................................................. 6

5.2. General .................................................................................................. 11

6. Maintenance ................................................................................................. 11

6.1. Tubing Assembly Removal .................................................................... 12

6.2. Tubing Assembly Installation and Lubrication ........................................ 13

6.3. Pools and Spas ...................................................................................... 15

7. Policies and Procedures ............................................................................... 16

7.1. Manufacturers Product Warranty ........................................................... 16

7.2. Returns .................................................................................................. 16

7.3. Credits ................................................................................................... 17

I. Pump Assembly and Wiring Diagram ........................................................ 18

Maintenance Record ....................................................................................... 19

REV. A PN J63143 - 2 -

Page 3

1. Introduction

Thank you for your purchase of the Chem-Tech Series XP peristaltic pump from

Pulsafeeder. We appreciate your decision to purchase a Pulsafeeder product.

Please take this time to become familiar with your pump and the number of

accessories that shipped with your product.

The shipping box contains the following items:

1) Peristaltic pump comprising of: a) pump head and tube assembly, b)

Snap-on rear rain guard (this can be found in the sealed bag that shipped

with the product).

2) Instruction Manual.

3) Factory Replacement tube

4) Suction and Discharge tubing set (15-feet of ¼-inch OD Polyethylene

Tubing).

5) Injector Valve

6) Strainer w/ Ceramic Weight.

2. Safety Instructions

READ AND UNDERSTAND ALL INSTRUCTIONS PRIOR TO USE. Failure to

follow or understand instructions can/may lead to serious injury or death.

• WARNING: Secure chemicals & metering pumps, making them inaccessible

to children & pets.

• WARNING: DO NOT PUMP FLAMMABLE LIQUIDS.

• WARNING: To reduce the risk of electrical shock-before maintenance, repair,

or moving always disconnect the power to the pump by unplugging from wall

outlet.

• WARNING: Do not tamper with, cut the plug or ground lug off the electrical

cord. Consult a licensed electrician for proper installation.

• WARNING: Always wear protective clothing, including gloves and safety eye

protection, when working on or near chemical metering pumps, consult

chemical manufacture for protective equipment recommendations.

• WARNING: Always make sure the voltage on the pump data plate matches

the installation voltage before plugging the pump into a wall outlet or hooking

up to an electrical supply. If you are unsure have a licensed electrician

inspect and install your pump.

• WARNING: Always depressurize system and drain the chemical prior to

installation or maintenance.

• WARNING: Read and fully understand the section on tube replacement.

Failure to do so may lead to serious injury.

• WARNING: DO NOT MODIFY PUMP, as this poses a potentially dangerous

situation and voids the warranty.

• WARNING: If the injection point is lower than the chemical tank and pump,

install an anti-siphon valve.

REV. A PN J63143 - 3 -

Page 4

• WARNING: All pumps are factory tested with water. Remove tubing and

thoroughly dry if the chemical being pumped will react with water (for

example: sulfuric acid).

• WARNING: Only finger tighten plastic connections (Do not use a wrench).

• WARNING: Consult licensed plumber and electrician before installation to be

sure to conform to local codes.

• CAUTION: Inspect tubing regularly for cracking or deterioration and replace

as necessary. (Always wear protective clothing and safety eye protection

when inspecting tubing.)

• CAUTION: KEEP FINGERS AWAY FROM ROTATING PARTS.

• CAUTION: If the pump is exposed to direct sunlight, use a U.V. resistant

tubing.

• CAUTION: Follow directions and warnings provided with the chemical from

the chemical manufacturer. The user is responsible for determining the

chemical compatibility with the chemical feed pump.

• CAUTION: Consult with local health officials and qualified water conditioning

specialists when treating potable water

• CAUTION: For accurate volume output, the pump must be calibrated under

all operating conditions.

3. Technical Specifications

Refer to the data plate located on the back of the peristaltic pump. Note that the

data plate will be located behind the back splash cover if installed. Please make

note of the Electrical Rating, Feed Rate and Maximum Pressure of the pump.

Use this information to complete the top three lines in Table 1 (below) by. For

example, if the Electrical Rating indicated on the data plate of the pump is

230V/60 Hz fill in the first line of the table below. Keep this information handy for

future reference and part replacement.

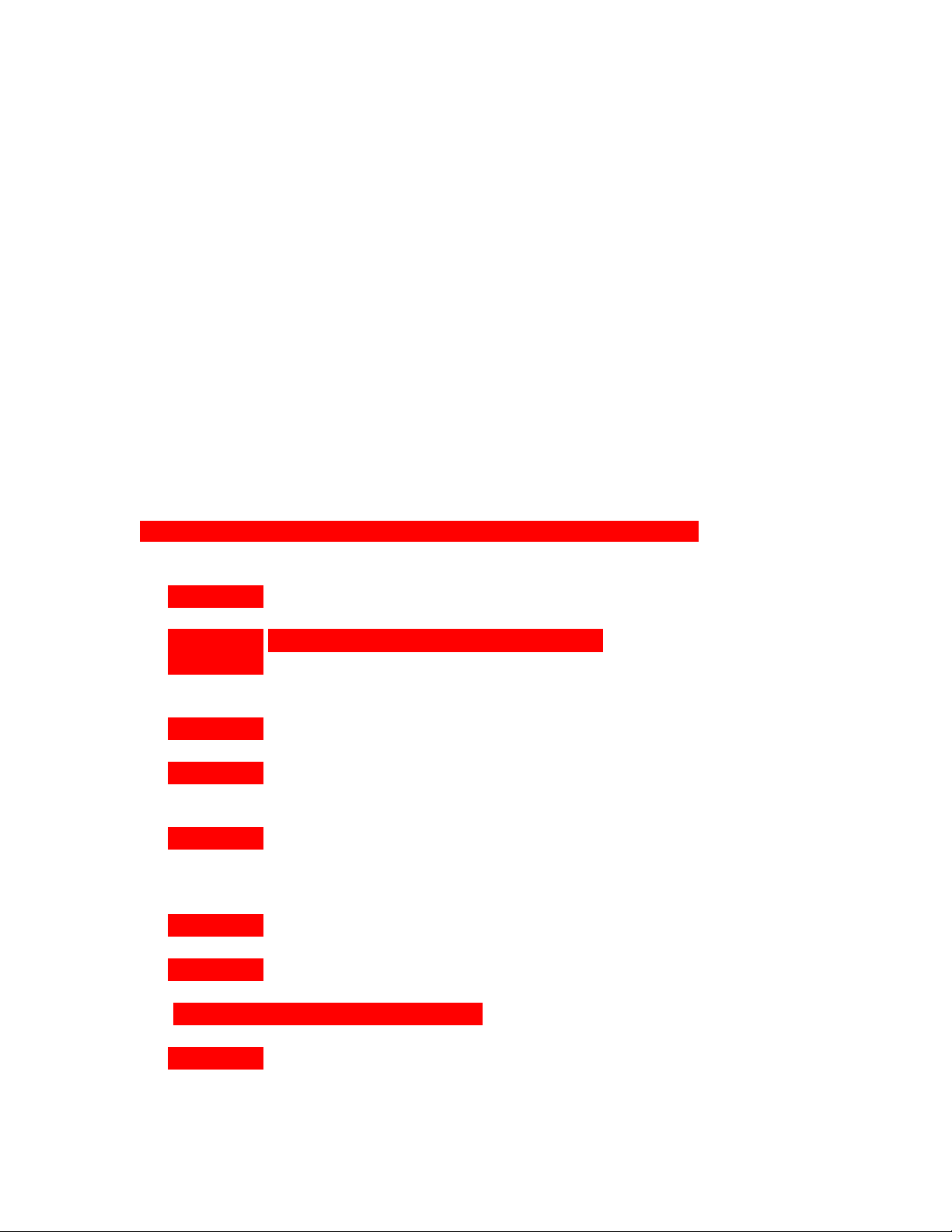

Figure 1 provides a quick reference for installation dimensional requirements.

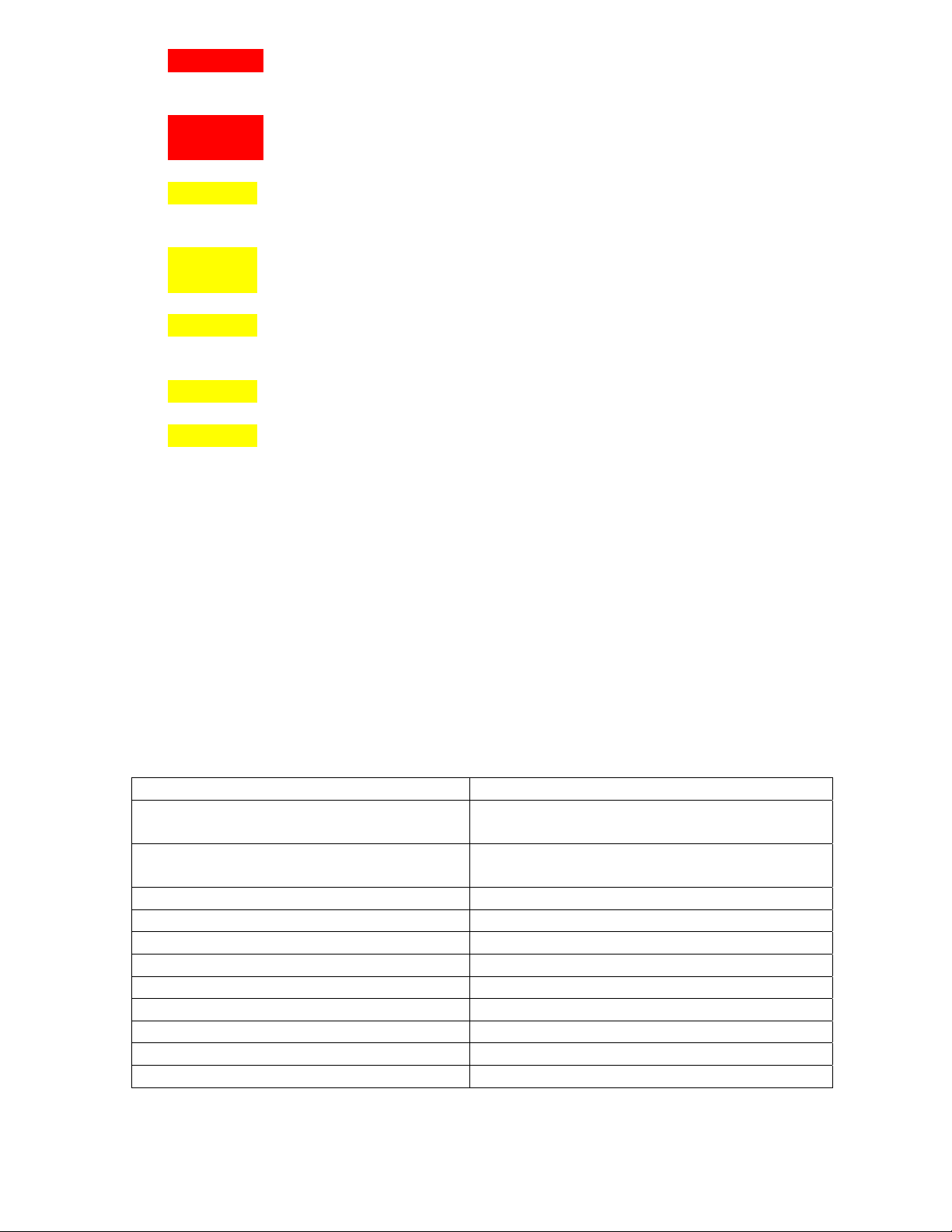

Table 1: Technical Specifications

Electrical Rating

Feed Rate (GPD)

Feed Rate (LPH)

Maximum Pressure (PSI)

Maximum Pressure (Bar)

Maximum Ambient Temperature 104OF (40OC)

Pump Safety Rating ETL,CETL, ETL

, NSF 50*

SAN

Enclosure Rating NEMA 3R (IP31)

Pump Head PVC

Pump Head Tubing Norprene

Injection Fitting PVC

Strainer Polypropylene

Suction/Discharge Tubing Polyethylene

Pump Housing ABS or Polycabonate/PBT/15%GF

*Except 50GPD (7.9 LPH) and 80GPD (12.6 LPH) Feed Rate pumps.

REV. A PN J63143 - 4 -

Page 5

Figure 1: Pump Dimensions

4. Installation

Vertical

Mount

NOTE: For pumps operating in swimming pool

installations the pump is to be supplied by an isolating

transformer or through a residual current device (RCD).

1) The pump can be installed either vertically or

horizontally (See Figure 2). Make sure to secure the

pump on a flat level surface that will support 50-lbs

(22kg) and secure with four .25-in (6mm) screws in the

holes provided. The guard snaps into the back of the

pump via three tangs -- see Figure 1. The pump

should be mounted with no less than 1.75-in

(44mm) of clearance around the venting on both

the front and the rear of the pump. Locate the

pump so there is direct access to the power cord plug.

The pump is rated for indoor use only. For applications that are subject to

splashing, make sure the pump is mounted horizontally level with splash guard in

place. Vertical mountings require the purchase of optional hood (J63004).

Select a location that does not subject the timers LCD to direct sunlight.

2) Verify the electrical requirements for the pump as listed on the name plate

and connect to an appropriate electrical source in compliance with local codes for

the specific application.

3) Relieve the system pressure and drain the piping run where the injection

fitting is to be installed. See Figure 2 for reference. The injection fitting must

not be installed in a dead end pipe or a deeply recessed tee. It should be

installed so as to place the tip at the center of the fluid stream as indicated

in Figure 2. The injection fitting is supplied with .25-in NPT threads. If necessary

drill a .44-in (11mm) diameter hole and using care not to tap to deeply, tap for

.25-in NPT.

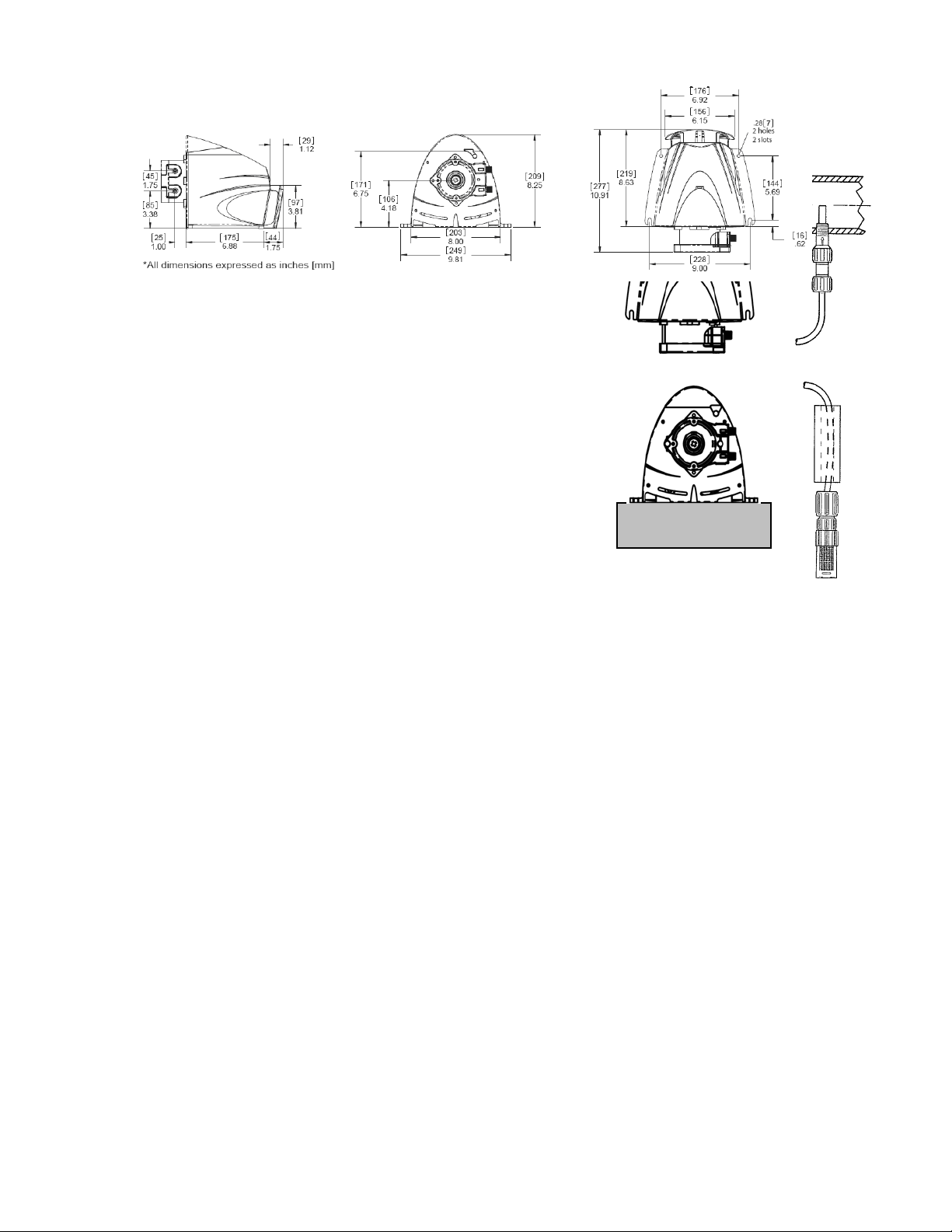

Figure 2: Injector Placement

Horizontal

REV. A PN J63143 - 5 -

Page 6

4) Apply Pipe tape to the injection fitting threads and install into piping system.

Do not remove the plastic sleeve on the tip of the fitting; it is a functional

part – see Figure 4.

CAUTION: Inspect the piping system and eliminate piping cross-connections to

prevent feeding chemical to areas not needing treatment.

To install tubing remove the compression fitting’s coupling nut and slide onto

tubing. Place tubing onto fitting and hand tighten the coupling nut. NOTE:

Immerse tubing in hot water to soften prior to pushing on to fitting. Hand-tighten

only, do not use wrenches.

Figure 4: Injector valve

5) Referring to Figure 5 slide ceramic strainer weight on

suction tubing first then remove the coupling nut from the

strainer and slide onto tubing next. Push the end of the

tubing onto the strainer and hand tighten the coupling nut.

Hand-tighten only, do not use wrenches. Note: Immerse

tubing in hot water to soften prior to pushing on fitting.

6) Install the strainer so it is off the bottom of the chemical

container (1 to 2-inches (25-50mm)) and measure suction tubing length required.

Cut tubing ends square and install on suction fitting of the pump. Hand-tighten

only, do not use wrenches.

Figure 5: CeramicWeighted Strainer

5. Operation

WARNING: Always make sure the voltage on the pump data plate matches the

installation voltage before plugging the pump into a wall outlet or hooking up to

an electrical supply. If you are unsure, have a licensed electrician inspect and

install your pump.

5.1. 7 Day Electronic Timer

CAUTION: Before plugging your pump into a wall outlet take a moment and

locate the control panel of your pump. The control panel is located on top of the

pump. The pump is equipped with a 3-position mode selector switch in the upper

left side of the control panel. Verify the switch in is the off-position before

plugging your pump into a wall receptacle – see Figure 6.

REV. A PN J63143 - 6 -

Page 7

P

1..Ph

Figure 6

As previously mentioned the mode selector switch has three positions. The offposition is the right side position of the switch. The switch also provides a

manually-on function in the far left side position. This function is very useful

when priming and/or replacing worn tubing in the pump. The middle position sets

the pump in the automatic (Timer) mode.

REV. A PN J63143 - 7 -

Page 8

PUMP TIMER PROGRAMMING INSTRUCTIONS

1. Read all instructions first.

2. When programming or re-programming, use the program work sheet to set up the desired

program before entering the steps into the timer. Seeing the program on paper may avoid

errors and will make it easier to put the correct steps into the timer.

3. When re-programming, it is always best to use the ‘R’ reset button and re-program all cycles.

4. Avoid program sequences which overlap another program. Programs which start while

another program is in the ‘ON’ sequence will not activate.

5. An ‘EEE’ on the screen indicates an error in program sequence. To correct, push the ‘R’

reset button; reset time of day and day of week; then re-program.

6. Do not attempt to re-program while the timer is in the ‘ON’ sequence

unless the ‘R’ recessed reset button is pressed first and all sequences

are reprogrammed.

7. Do not press the ‘ ’ button while in the ‘time of day’ ( ) set mode. This may

cause an error in the time keeping program which will cause hours: minutes to

count in seconds. If this condition occurs, slide the programming selector

switch to the ‘ ’ position, press the ‘ ’ button and the ‘h’ button

at the sametime

of day is corrected, slide the programming selector switch back to the ‘RUN’

position.

8. Do not reset the time of day during an active cycle.

Wait to reset during an ‘OFF’

cycle or use ‘R’ reset button and follow the complete

instruction from the beginning.

9. All programming errors may be corrected by moving the right side button to the ‘RUN’

position and depressing the ‘R’ reset button. This will clear all memory, both ‘time of day’

and all programs. All desired programs and ‘time of day’ must be re-entered. Begin again at

step #1.

Setting Time of Day:

1. With the programming selector switch in ‘RUN’

position, push recessed reset button, ‘R’

(0:00 will flash on the display).

2. Slide the programming selector switch to the left

to the ‘ ’ time of day’ position, (0:00 will appear

on the display).

2a. Use the ‘ 1..7’ button to set ‘day of week’ using

‘1' as Monday. Put the day indicator ‘▲’ under

the day of week.

2b. Use the ‘h’ button to set hour. ‘P’ will appear on

the left side of the display to indicate P.M.

2c .Use the ‘m’ button to set minutes.

, then use the ‘h’ button to correct the time. When the time

P

1..

h

REV. A PN J63143 - 8 -

Page 9

3. Slide the programming selector switch to center, ‘RUN’ position to check time setting. The

colon’;’ will flash. Be certain that minutes do not change with each flash of the colon. If

NOTE 2. Check the clock after completion of the time setting procedure. If the clock changes

Setting Programs: (refer to program worksheet (page 10) for guidance)

Running the Pump

this condition occurs, an error has been made. Begin again at step #1.

NOTE: 1 Setting the time in the above sequence will clear all programs, reset the

programs as required. (Skip step #1 to correct the time setting without clearing

programs).

minutes with each flash of the colon, an error has occurred. To correct this condition,

slide the programming selector switch to the ‘ ’ position. Push the ‘ ’ button and the

‘h’ button at the same time, then push the ‘h’ button to advance the hours to the

correct time of day. Slide the programming selector switch back to the ‘RUN’ position.

4. Slide programming selector switch right to program ‘ ’ position. (Screen will show “0:00

1 ) This indicates that you are setting the first event which is the ‘ON’ time for first cycle.

5. Use the ‘1...7 ‘button to set the desired day(or days) of the week. Put the day indicator ‘▲’

under the day or days) you want to run this program. Pressing the ‘ 1..7’ button once will

put the day indicator ‘▲’ under Sunday (7), pressing again will move the day indicator ‘▲’

to Monday (1). Continue pressing the button to advance day by day to Saturday (6).

Press again to get multiple day programs.

Once All weekdays (1 thru 5)

Twice = Weekend only (6 and &7)

3 Times = Every day except Sunday (1 thru 6)

4 Times = Every day (1 thru 7)

5a. Use the ‘h’ button to set hour, remember to set the time in A.M. or P.M. as required.

5b. Use the ‘m’ button to set minutes.

6. Push the program button; ’ to enter the data and set ‘ON’ time. The display will change

to ‘0:00 2' ready for you to set ‘OFF’ time for first program.

7 Use the ‘1...7’ button to set the day or days of the week for the ‘OFF’ cycle (refer to 5a

sequence). Day or days should match the day or days used in previous ‘ON’ cycle setting.

7b. Set ‘OFF’ time for first program using the ‘h’ and ‘m’ buttons.

8. After setting time to desired ‘OFF’ time, press the ‘ ’ button. This completes Program 1.

‘0:00 3 ‘ will appear on the display ready to set the ‘ON’ time for next program.

9. If further programs are desired, continue setting program using Steps #5 thru #8.

9a.If programming is complete, slide the program selector switch back to the ‘RUN’

position. All programs are now active.

10. To review program settings slide program selector switch to the ‘ ’ position. The display

will show ‘xx:xx 1 ’ indicating the first ‘ON’ cycle, day and time. Press the ‘ ’ button

again and the display will show ‘xx:xx 2’ the first ‘OFF’ cycle day and time. Continue

pressing the ‘ ’ button to step thru the ‘ON’ and ‘OFF’ cycles of the rest of the program.

After cycle 8 ‘xx:xx 8’ is passed the display will return to the first cycle. The program

selector switch may be returned to the ‘RUN’ position at anytime during review.

:

11. Position the mode selector switch (‘I’, ‘AUTO’, and ‘O’) to the position desired.

Position ‘I’ = Pump will run continuously, regardless of the program.

Position ‘AUTO’ = Pump will follow the program sequence.

Position ‘O’ = Pump will always remain off regardless of the program.

REV. A PN J63143 - 9 -

Page 10

12. Skip cycle button; ‘ may be used when you want to skip all program sequences

P

P

programmed for the next day. Press the ‘ ’ button once, the ‘ ’ will appear in the lower

right corner of the display. This will stop all program cycles from running the next calendar

day (the day indicator ‘▲’ will flash during the day which is being skipped).

PROGRAM WORKSHEET

(SYMBOLS ON TIMER MAY VARY)

PROGRAM

1 ON 1

1 OFF 2

2 ON 3

2 OFF 4

3 ON 5

3 OFF 6

4 ON 7

4 OFF 8

5 ON 9

5 OFF 10

6 ON 11

6 OFF 12

7 ON 13

7 OFF 14

8 ON 15

8 OFF 16

P

1

234567

1..P h

DAY(or DAYS)

P

1..Ph

P

1..Ph

P

P

1..P h

1..P h

P

P

1..Ph

1..Ph

P

P

1..Ph

1..Ph

P

P

1..P h

1..P h

REV. A PN J63143 - 10 -

Page 11

5.2. General

DANGER: DO NOT ATTEMPT TO FEED CHEMICALS WITHOUT FIRST

CONSULTING YOUR CHEMICAL FEEDER DEALER OR CHEMICAL

SUPPLIER. To avoid running out of chemical, follow a regular schedule of

monitoring chemical supply.

CAUTION: Inspect peristaltic tubing frequently and replace when deterioration

becomes apparent. Peristaltic tubing will eventually wear and break if neglected.

This occurrence will cause chemical spillage and a potential for personal injury or

damage to equipment. Always refer to chemical manufacturers

recommendations with regards to safety and handling of hazardous or corrosive

chemicals. Always wear protective clothing and safety glasses when working

near chemical feed systems.

WARNING: Do not expose the pump or tubing to pressure exceeding the

pressure rating on the pump nameplate.

1) Make sure the mode selector switch is in the off position...

2) Fill the chemical tank with the chemical to be fed.

3) Slide the model selector switch all the way to the left in the on position and

make sure the programming selector switch is in the run position

6. Maintenance

NOTE : To get actual feed rates for specific settings, the output must be verified

by measuring the volume output. Use the flow chart Figure #6, as a guide. To

get the actual feed rate for specific settings, each pump must be calibrated for its

flow. As with any peristaltic pump output varies tubing condition. It is

recommended that feed rates be verified at every tubing change and after every

250-hour. More critical applications require more frequent verification.

NOTE: NO USER SERVICEABLE COMPONENTS ARE INSIDE THE

ENCLOSURE. IF THE POWER SUPPLY CORD BECOMES DAMAGED, IT

MUST BE REPLACED BY PULSAFEEDER, ITS REPRESENTATIVE, OR A

SIMILARLY QUALIFIED TECHNICIAN IN ORDER TO AVOID A HAZARD.

REV. A PN J63143 - 11 -

Page 12

6.1. Tubing Assembly Removal

Always wear protective clothing and safety glasses when working on the

chemical pump and refer to the chemical manufacturers’ safety precautions.

1) Remove the power to the pump and place the mode selector switch in the Off

position.

2) Relieve the system pressure and the drain discharge and suction tubing.

3) Loosen coupling nuts and remove the tubing from suction and discharge

ports. See figure 7a.

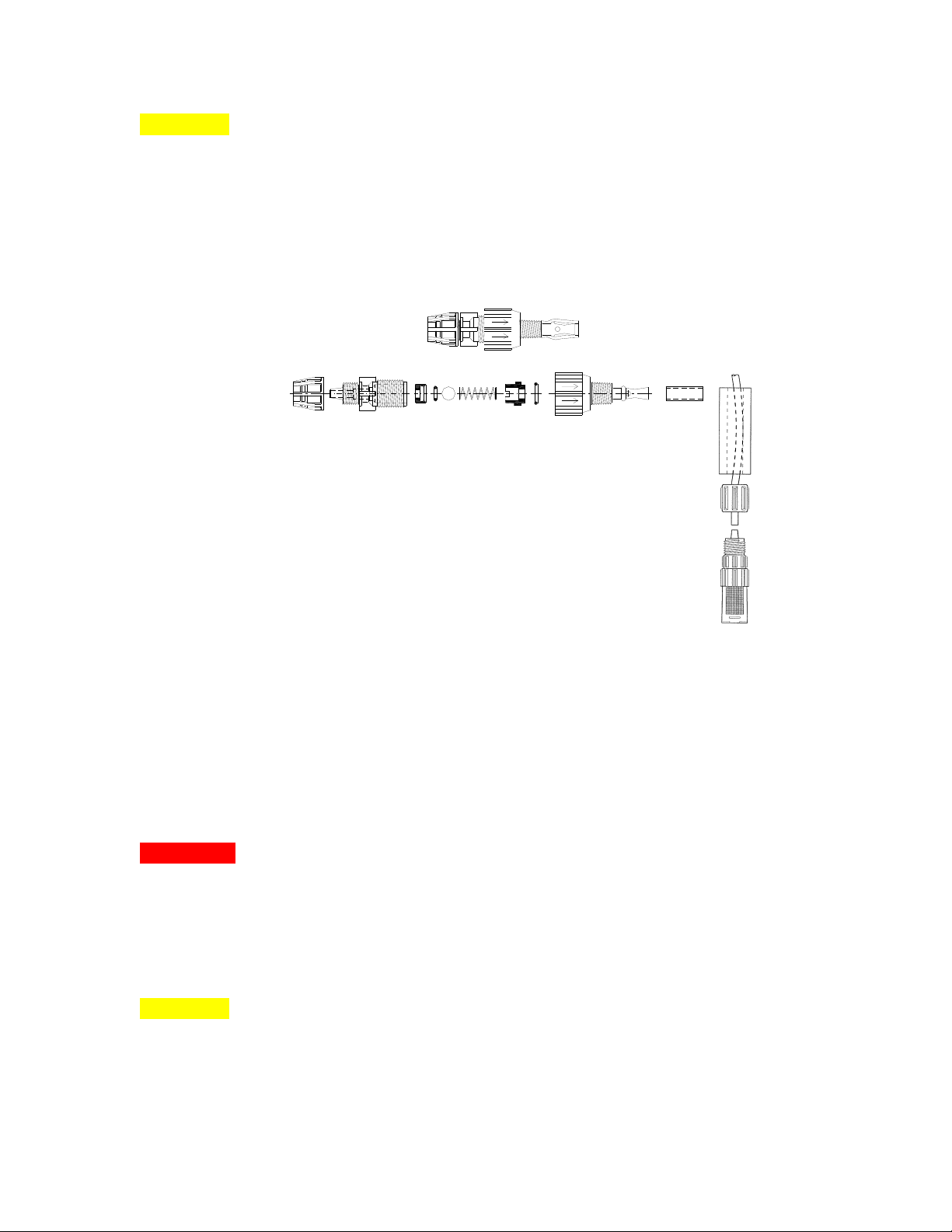

Figure 7a: Pump Head Assembly with Front Cover Attached

Figure 7b: Pump Head Assembly with Front Cover Removed

4) Remove the two thumb screws holding on the pump head cover and remove See figure 7b above.

REV. A PN J63143 - 12 -

Page 13

5) Remove pump head tube assembly by removing both connector fittings and

pulling tubing straight out of the pump head. Tubing may retain a small amount

of chemical. If the rotor assembly is removed, go to step #8.

6) Remove rotor assembly by pulling straight out of pump head. NOTE bearing

lubrication every 500-hours; see section 6.2, “Tubing Assembly Installation and

Lubrication”.

7) Clean any tubing debris from the rotor assembly and pump head.

6.2. Tubing Assembly Installation and Lubrication

WARNING: When using the pump to load tubing the mode selector switch must

be in the Off (“O”) position to prevent accidental motor starting. Caution must be

used to keep fingers away from rotating parts.

Figure 8: Pump Head w/ Rotor Assembly Removed

NOTE: Lubrication of rotor assembly should be performed at least once a year

(residential service). Clean front and rear rotor bearings and surfaces with a

clean shop cloth (item. No. 8, in assembly drawing on pg. 17). Lubricate with a

PTFE thickened, medium viscosity, synthetic grease intended for plastic parts.

Ref. Grease Kit (P/N J30257) – see Figure 8.

1) Reinstall the rotor assembly by aligning the cross in the rotor to the drive shaft

cross and fully insert into pump head.

2) With the programming selector switch in the run position, slide the mode

sector switch all the way to the left into the on position and align the rotor

assembly as shown in Figure 9a.

Lube all roller (3)

and bearing

surfaces (2)

REV. A PN J63143 - 13 -

Page 14

Note position of tube and

rotor’s cut-away guide

slot.

Figure 9a: Rotor Alignment at Start of Tube Installation

3) Insert one connector end of the tubing assembly into the bottom retaining slot

in the pump head. Insert the tube through the guide slot in the rotor. Using

caution, intermittently jog the mode selector switch to from the on and off

positions and feed the tube around the pump head as the guide slot rotates. Be

very careful not to get any objects (fingers, ties, hair, etc.) close to the

rotors and pump head as severe pinch points exist, see Figure 9b. Keep

hands and fingers away from the rotor assembly while feeding the new

tube.

WARNING: Note severe pinch points between rollers and pump housing

When the rotor is positioned as in Figure 9c, set the mode selector switch all the

way to the right into the off position. Insert the other connector into its retaining

slot.

4) Align the pump head cover bearing bore with the rotor shaft and press into

place.

5) Loosely reinstall the two thumb screws.

REV. A PN J63143 - 14 -

Figure 9b: Feeding the New Tube

Page 15

Figure 9c: Finishing the New Tube Installation

6) Using the mode selector switch, run the pump for several revolutions and then

fully tighten the thumb screws hand tight.

7) Return the pump to service by following the procedures in the installation

section.

6.3. Pools and Spas

Pumps carrying the “ETL Sanitation” (tested to NSF Standard-50) marks are

listed for swimming pools, spas and hot tubs, and when proper materials are

selected, are capable of handling but not limited to the following chemical

solutions:

12.0% ALUMINUM SULPHATE, 5.0% SODIUM CARBONATE,

2.0% CALCIUM HYPOCHLORITE, 10.0% SODIUM HYDROXIDE,

12.5% SODIUM HYPOCHLORITE, 10.0% HYDROCHLORIC ACID.

To meet the requirements of the “ETL Sanitation Mark” qualification, 1) Replace

the peristaltic tubing (as described above), 2) Grease the rotor bearing and 3) Oil

the three rotor rollers at intervals of 500-hours operation time (actual running

time).

REV. A PN J63143 - 15 -

Page 16

7. Policies and Procedures

7.1. Manufacturers Product Warranty

PULSAFEEDER warrants equipment of its manufacture to be free of defects in

material or workmanship. Liability under this policy extends for 24-months from

the date of shipment. The manufacturer’s liability is limited to repair or

replacement of any failed equipment or part which is proven defective in material

or workmanship upon manufacturers’ examination. This warranty does not

include removal or installation costs and in no event shall the manufacturers

liabilities exceed the selling price of such equipment or part.

The manufacturer disclaims all liability for damage to its products through

improper use, installation, maintenance or attempts to operate such products

beyond their functional capacity, intentionally or otherwise, or any unauthorized

repair. Replaceable elastomeric parts, including peristaltic tubing, are covered for

12 months. The manufacturer is not responsible for consequential or other

damages, injuries or expense incurred through the use of its products.

The above warranty is in lieu of any other warranty, either expressed or implied.

The manufacturer makes no warranty of fitness or merchantability. No agent of

ours is authorized to provide any warranty other than the above.

For warranty and service matters within the European Union, contact the seller

or:

Pulsafeeder, Inc

Units 12 and 13, Edison Road

Highfield Industrial Estates

Eastbourne,, East Sussex BN23 6PT

7.2. Returns

The Customer Service Department will issue a Return Authorization (RA) number

for all returns.

The following information will be required:

1. Billing and a ship-to address.

2. Model and serial number.

3. Contact name and phone number.

4. Reason for return.

5. Purchase order (where applicable).

6. RA number on outside of the carton.

7. Type of chemical that was pumped.

REV. A PN J63143 - 16 -

Page 17

All material must be returned freight prepaid. All merchandise must be properly

packaged and free of any corrosive, toxic or otherwise hazardous chemical. All

items returned must reference Return Authorization number.

7.3. Credits

No equipment will be accepted beyond six months after date of shipment from

the factory. Only unused and undamaged equipment will be accepted for return

to stock. All credits are based on acceptance of materials as new and unused by

our inspection personnel. A restocking fee will apply. All equipment returned for

credit must have a RA number and be returned freight prepaid.

REV. A PN J63143 - 17 -

Page 18

Appendix

I. Pump Assembly and Wiring Diagram

REV. A PN J63143 - 18 -

Page 19

Maintenance Record

Date Maintenance Performed

REV. A PN J63143 - 19 -

Page 20

EC Declaration of Conformity

We, Pulsafeeder Inc., declare under sole responsibility that the Series XP

metering pump, to which this declaration relates, is in sole conformity with

relevant sections of the applicable EC standards and other normative documents

listed on this document. If changes are made to the product which is covered by

this declaration of conformity, the declaration of conformity is no longer valid.

- Application of Council Directive: 73/23/EEC and 93/68/EEC

- Standard to Which Conformity is Declared: IEC/EN 60335-2-41

REV. A PN J63143 - 20 -

Loading...

Loading...