Pulsafeeder PULSAlarm Pulsa, PULSAlarm Pulsar, PULSAlarm PulsaPro Installation, Operation & Maintenance Instructions Manual

PULSAlarm®

Installation, Operation &

Maintenance Instructio n

Models: Pulsa, Pulsar, PulsaPro

DEMKO 12 ATEX 1204081X

II 2 G Ex d IIB T5 Gb

II 2 D Ex tb IIIC T100°C Db IP66

IECEx UL 14.0118X

Ex d IIB T5 Gb

Ex tb IIIC T100°C Db IP66

Bulletin: IOM-PUL-1007 Rev E

THIS DOCUMENT CONTAINS CHARACTERISTICS CONTROLLED BY U.L. FILE # E186527; CHANGES REQUIRE AGENCY

APPROVAL.

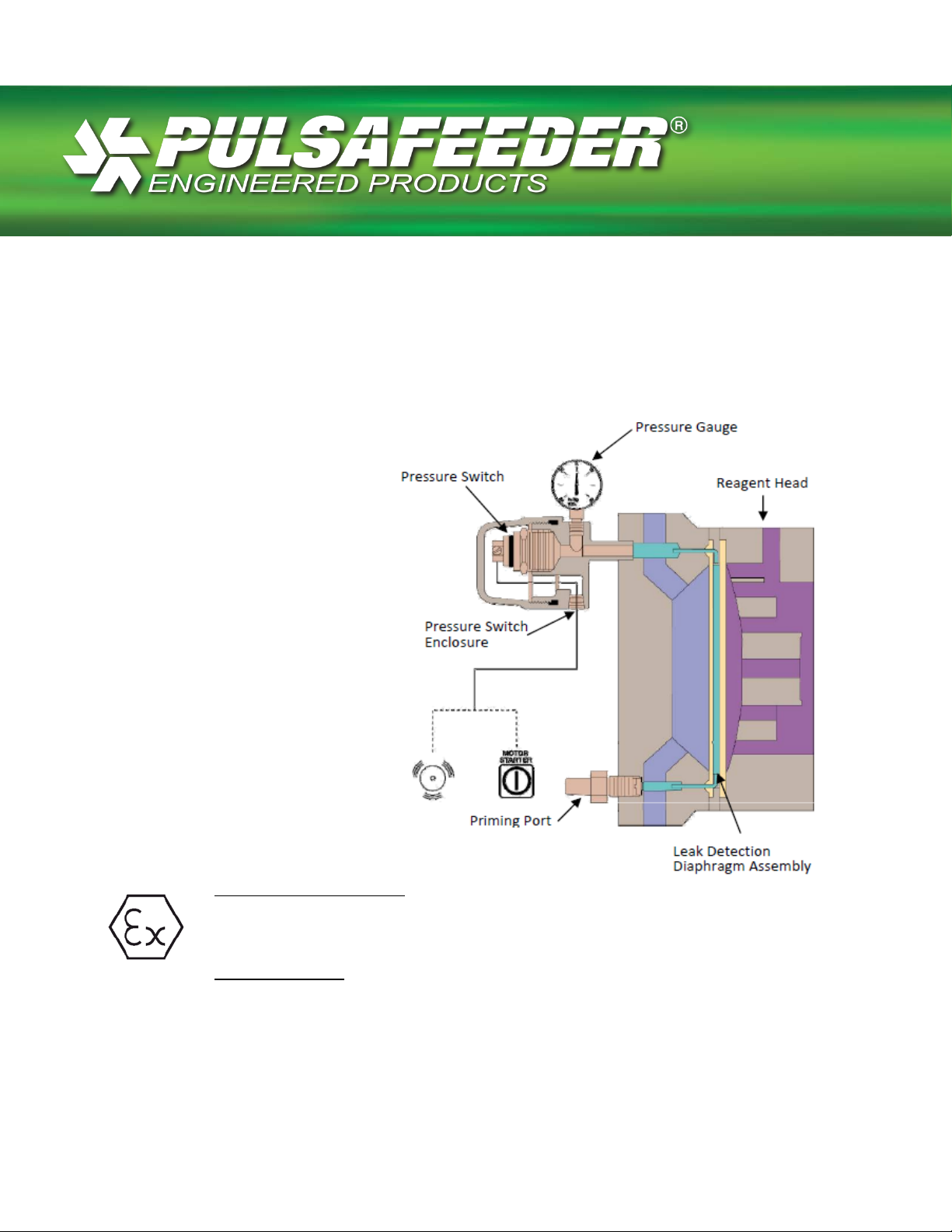

LEAK DETECTION

Pulsafeeder Factory Service Policy

Should you experience a problem with your Pulsafeeder pump, first consult the

troubleshooting guide in your pump operation and maintenance manual. If the problem

is not covered or cannot be solved, please contact your local Pulsafeeder Sales

Representative or Pulsafeeder Technical Service Department for further assistance.

Trained individuals are available to diagnose your problem and arrange a solution.

Solutions may include purchasing a replacement unit or returning the PULSAlarm to the

factory for inspection and repair.

All returns require a Return Material Authorization (R.M.A.) number to be issued by

Pulsafeeder. Parts purchased to correct a warranty issue may be credited after

examination of the original parts by Pulsafeeder personnel. Parts returned for warranty

considerations which are good will be sent back freight collect.

Any field modifications will void the warranty. Out-of-warranty repairs will be subject to

Pulsafeeder's standard bench fees and testing costs associated with replacement

components.

This document describes product features controlled by IECEx / ATEX

requirements. Those features, and this document, cannot be changed without

notification or approval of the appropriate agency.

Copyright

Copyright © 2006 - 2015 Pulsafeeder, Inc. All rights reserved.

Information in this document is subject to change without notice. No part of this

publication may be reproduced, stored in a retrieval system or transmitted in any form or

any means electronic or mechanical, including photocopying and recording for any

purpose other than the purchaser’s personal use without the written permission of

Pulsafeeder.

2

Safety Considerations:

• Read and understand all related instructions and documentation before attempting to

install or maintain this equipment

• Observe all special instructions, notes, and cautions.

• Act with care and exercise good common sense and judgment during all installation,

adjustment, and maintenance procedures.

• Ensure that all safety and work procedures and standards that are applicable to your

company and facility are followed during the installation, maintenance, and operation of

this equipment.

Notice

Information and specifications in this document are subject to change without notice.

Trademarks

Pulsa Series® and PULSAlarm® are registered trademarks of Pulsafeeder, Inc.

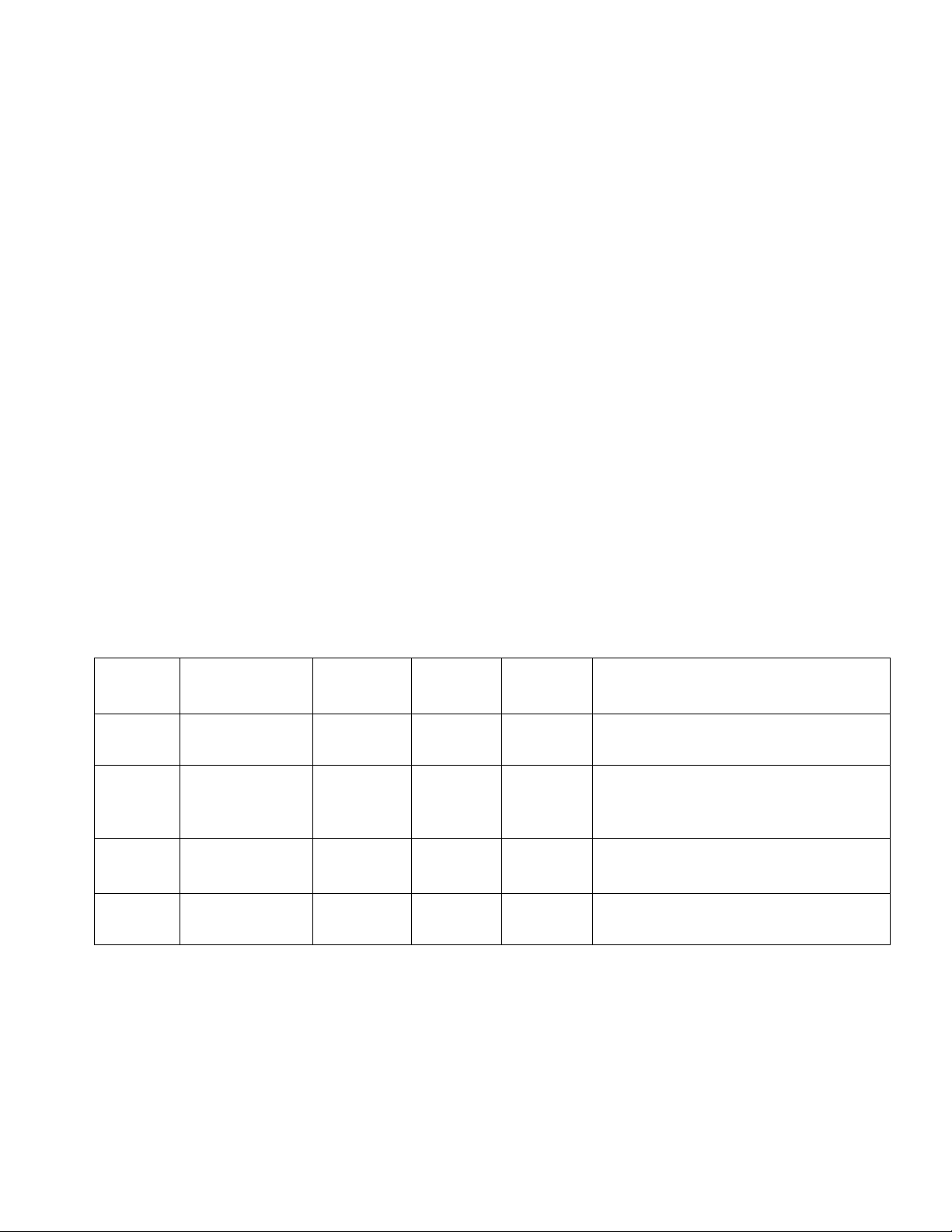

Revision History

Revision Implemented

By

B Engineering 04/27/2007 Technical

C Engineering,

Quality,

Compliance

D Engineering 03/03/2016 Technical

E Technical Service 05/31/2017 Aftermarket

Revision

Date

04/07/2015 Technical

Approved

By

Service

Service

Service

Manager

Approval

Date

04/27/2007 Material reference to “PTFE”

04/07/2015

03/03/2016

06/02/2017 Modify switch trip point settings and rem ove

Reason

Remove references to PULSAlarm®

Vacuum offering. Add ATEX and IECEx

information, general updates.

Modify temperature and code

information on front and back cover only

paragraph 7.4 for vacuum system priming.

3

Table of Contents

Contents

1.0 Conventions ........................................................................................................................ 5

2.0 Introduction ......................................................................................................................... 6

3.0 Foreword .............................................................................................................................. 6

4.0 ATEX / IECEx Nameplate and Marking ............................................................................... 7

5.0 Description and Theory of Operation ................................................................................. 9

5.1

PULSAlarm® Reagent Head .......................................................................................... 10

5.2

PULSAlarm® Leak Detection Diaphragm .................................................................... 10

5.3

Diaphragm Construction ............................................................................................. 11

6.0 Electrical ............................................................................................................................ 12

7.0 Setup for Pressure ............................................................................................................ 13

8.0 Pressure fill chamber ........................................................................................................ 17

9.0 Maintenance ...................................................................................................................... 19

9.1

Switch Setpoint Adjustment ........................................................................................ 19

10.0 PULSAlarm® Diaphragm Maintenance .................................................................... 20

11.0 PULSAlarm® Diaphragm Removal .......................................................................... 20

12.0 Inspection .................................................................................................................. 21

12.1 PULSAlarm® Diaphragm Reinstallation .................................................................. 21

4

A

Tips have been included within this bulletin to help the operator run the

1.0 Conventions

For the remainder of this bulletin, the following conventions are in effect.

WARNING DEFINES A CONDITION THAT COULD CAUSE DAMAGE TO BOTH THE

EQUIPMENT AND THE PERSONNEL OPERATING IT

IN ALL CASES WHERE THE WARNING SYMBOL IS MARKED IN ORDER TO FIND OUT THE

NATURE OF THE POTENTIAL HAZARDS AND ANY ACTIONS WHICH HAVE TO BE TAKEN

TO AVOID THEM

.

. THIS MANUAL MUST BE CONSULTED

CAUTION,

POSSIBILITY OF ELECTRIC SHOCK

Notes are general information meant to make operating the equipment

easier. For information on overall pump operation and maintenance, refer to

the

Installation, Operation, and Maintenance manual specific to the model

of pump in

PULSAlarm® ® leak

question. The information in this bulletin pertains only to the

detection system supplied as an option on

Pulsafeeder PULSA/PULSAR Series pumps

equipment in the most efficient manner possible. These “Tips” are drawn

from the knowledge and experience of our staff engineers, and input from

the field.

5

2.0 Introduction

The PULSAlarm® ® is a microprocessor based stroke length control device for use with

the PULSA diaphragm-metering pump. It has been designed to operate in a variety of

industrial environments.

3.0 Foreword

The pumps to which these “instructions” refer to are designed for use in industrial areas

and therefore cannot be treated as retail products. The present documentation gives

instructions to be used by qualified personnel only. It must be used in compliance with

the regulations, laws and technical standards in force and cannot, under any

circumstances, take the place of plant standard or additional regulations, including any

which are not legally enforceable, which have been issued with the scope of ensuring

safety.

Equipment with special manufacturing or constructive variances may differ in details with

respect to this description.

In case of any difficulty, please contact PULSAFEEDER, INC. Technical Service.

The PULSAlarm® is rated for NEMA 7 locations as identified on the nameplate.

The PULSAlarm® complies with both ATEX and IEC IECEx standards.

The following standards apply to this product:

IEC 60079-0 6

IEC 60079-1 6

IEC 60079-31 1

EN 60079-0:2012+A11:2013

EN 60079-1:2007

EN 60079-31:2009

th

Edition

th

Edition

st

Edition

6

4.0 ATEX / IECEx Nameplate and Marking

All pumps bear a standard rating nameplate on which it is possible to read, apart

from functional data, all data required for universal identification.

Conduit connections

Conduit connections can carry fluids and vapors into the PULSAlarm®

causing damage and void the warranty. Care should be taken when

installing conduit to protect against fluid/vapor entry. In accordance with

any applicable codes provide sealed entries and conduit drains near the

point of entry as required. For installation purposes, the conduit glands on

the PULSAlarm® are .50-14 NPT.

To reduce the risk of ignition of hazardous atmospheres, conduit runs must

have a sealing fitting connected within 18 inches of the enclosure for

Division applications. For Zone applications, a seal shall be installed within

50 mm of the enclosure.

7

Loading...

Loading...