Page 1

BULLETIN No.: PulsaPro 900-IOM-2009 Rev. J

PulsaPro Control Addendum

INSTALLATION

OPERATION

MAINTENANCE

INSTRUCTIONS

Manufacturers of Quality Pumps,

Controls and Systems

Pulsafeeder, Inc.

2883 Brighton Henrietta Town Line Road

Rochester, New York, 14623

Email: pulsa@idexcorp.com

Telephone: ++1 (585) 292-8000

Fax: ++1 (585) 424-5619

pulsafeeder.com

Page 2

PulsaPro Series Guarantee

Should you experience a problem with your Pulsafeeder pump, first consult the troubleshooting

guide in your operation and maintenance manual. If the problem cannot be solved, please contact

your local Pulsafeeder Sales Representative, or our Technical Services Department for further

assistance.

Trained technicians are available to diagnose your problem and arrange a solution. Solutions

may include purchase of replacement parts or returning the unit to the factory for inspection and

repair. All returns require a Return Authorization number to be issued by Pulsafeeder. Parts

purchased to correct a warranty issue may be credited after an examination of original parts by

Pulsafeeder. Warranty parts returned as defective which test good will be sent back freight

collect. No credit will be issued on any replacement electronic parts.

Any modifications or out-of-warranty repairs will be subject to bench fees and costs associated

with replacement parts.

In addition, Pulsafeeder guarantees its

years from the date of shipment. All other material and workmanship are fully covered for a

period of one year. Any parts found to be defective within the above time span will be replaced

free of charge, F.O.B. our factory.

Equipment or accessories manufactured by others but purchased through Pulsafeeder, such as

electric motors, are guaranteed only to the extent of the original manufacturer.

Damages incurred from misuse, abuse, and/or improper protection during storage will be cause to

void this guarantee. Erosion, corrosion, or improper application of the equipment or related

piping by the buyer or any third party is also excluded.

The above guarantee is in lieu of any other guarantee, either expressed or implied. We make no

warranty of fitness or merchantability. No agent of ours is authorized to make any warranty other

than the above.

PulsaPro

Series drive assemblies for a period of five

Safety Considerations:

1. Read and understand all related instructions and documentation before attempting to install or

maintain this equipment

2. Observe all special instructions, notes, and cautions.

3. Act with care and exercise good common sense and judgment during all installation, adjustment,

and maintenance procedures.

4. Ensure that all safety and work procedures and standards that are applicable to your company and

facility are followed during the installation, maintenance, and operation of this equipment.

Copyright ©2009 Pulsafeeder, Inc. All rights reserved.

Information in this document is subject to change without notice. No part of this publication may be

reproduced, stored in a retrieval system or transmitted in any form or any means electronic or mechanical,

including photocopying and recording for any purpose other than the purchaser’s personal use without the

written permission of Pulsafeeder, Inc.

ii

Page 3

Table of Contents

1. INTRODUCTION ..................................................................................................................................... 1

1.1 General Description ................................................................................................................ 1

2. PRINCIPLES OF OPERATION ................................................................................................................... 1

2.1 Overall Operation .................................................................................................................... 1

2.2 Component Location ............................................................................................................... 2

2.2.1 Reagent Head Assembly ................................................................................................. 3

2.2.2 Pump Head/Piston Assembly ......................................................................................... 4

2.2.3 Control Assembly ............................................................................................................ 6

2.2.4 Gear Reducer Assembly ................................................................................................. 7

3. EQUIPMENT INSPECTION ....................................................................................................................... 8

4. STORAGE INSTRUCTIONS ...................................................................................................................... 8

4.1 Short Term ............................................................................................................................... 8

4.2 Long Term ................................................................................................................................ 8

5. INSTALLATION ...................................................................................................................................... 9

5.1 Location .................................................................................................................................... 9

5.2 Mounting .................................................................................................................................. 9

5.3 Piping System .......................................................................................................................... 10

5.3.1 Suction Pressure Requirements .................................................................................... 11

5.3.2 Discharge Pressure Requirements ................................................................................ 11

6. EQUIPMENT STARTUP ........................................................................................................................... 12

6.1 Lubrication ............................................................................................................................... 12

6.1.1 Oil Capacities ................................................................................................................... 12

6.1.2 Oil Fill ................................................................................................................................ 14

6.1.3 Oil Changes ...................................................................................................................... 16

6.2 Startup ...................................................................................................................................... 17

6.2.1 Output Adjustment .......................................................................................................... 17

6.2.2 Priming the Pump Head .................................................................................................. 18

6.2.3 Priming the Reagent Head .............................................................................................. 18

6.2.4 Motor Rotation ................................................................................................................. 19

6.2.5 Calibration ........................................................................................................................ 20

7. MAINTENANCE ...................................................................................................................................... 21

7.1 Wet End Removal, Inspection, and Reinstallation ............................................................... 22

7.2 Re-Priming the Pump Head .................................................................................................... 24

7.2.1 Re-Filling the Hydraulic System ..................................................................................... 25

7.2.2 Re-Priming the Hydraulic System .................................................................................. 25

7.3 Check Valves ........................................................................................................................... 26

7.3.1 Check Valve Removal ..................................................................................................... 27

7.3.2 Ball Valve – Inspection and Repair ................................................................................ 27

7.3.3 Disk Valve – Inspection and Repair ............................................................................... 27

7.3.4 Check Valve Reinstallation ............................................................................................. 28

7.4 Hydraulic Performance Valve (HPV) ...................................................................................... 29

7.4.1 HPV Removal and Replacement .................................................................................... 30

7.5 Hydraulic Bypass Valve (HBV) ............................................................................................... 31

7.5.1 PTP (Push To Purge) Valve ............................................................................................ 32

7.5.2 PTP Removal, Cleaning, and Reinstallation ................................................................. 33

7.5.3 Piston Seal ....................................................................................................................... 34

7.5.4 Piston Removal ................................................................................................................ 35

7.5.5 Piston Seal Reinstallation ............................................................................................... 35

7.6 Oil Seals ................................................................................................................................... 37

7.6.1 General Description......................................................................................................... 37

7.6.2 Motor Adaptor Oil Seal Removal and Replacement ..................................................... 38

7.7 Stroke Control Assembly ....................................................................................................... 40

7.7.1 Stroke Control Assembly Maintenance ......................................................................... 40

7.8 Motor Removal and Reinstallation ........................................................................................ 41

8. REPLACEMENT PARTS .......................................................................................................................... 42

8.1 PulsaPro Series KOPkit Program .......................................................................................... 42

iii

Page 4

8.2 Ordering KOPkits or Parts ...................................................................................................... 42

9. PULSALARM LEAK DETECTION PUMP HEAD ASSEMBLY ....................................................................... 43

9.1 PULSAlarm Leak Detection Diaphragm ................................................................................ 44

9.2 Leak Detection – Setup for Pressure ..................................................................................... 44

9.3 Pressure System Set-up and Priming ................................................................................... 45

9.4 PULSAlarm Leak Detection Diaphragm Maintenance ......................................................... 47

9.4.1 Leak Detection Diaphragm Removal ............................................................................. 48

9.4.2 Inspection ......................................................................................................................... 48

9.4.3 Leak Detection Diaphragm Reinstallation .................................................................... 48

10. TROUBLESHOOTING CHART................................................................................................................... 49

APPENDIX I – PIPING CALCULATIONS ........................................................................................................... 51

Suction Head Requirements .............................................................................................................. 51

System Back Pressure ........................................................................................................................ 53

Nomenclature ....................................................................................................................................... 53

APPENDIX II – OIL SPECIFICATIONS .............................................................................................................. 54

PULSAlube Universal 1HG ................................................................................................................. 54

APPENDIX III – BOLT TORQUE RECOMMENDATIONS/NOZZLE LOADS ............................................................. 55

Reagent Head and Tie-Bar .................................................................................................................. 55

Pump Head Bolts ................................................................................................................................. 55

Nozzle Loads ........................................................................................................................................ 56

APPENDIX IV DIMENSIONAL DRAWINGS ........................................................................................................ 57

APPENDIX V EC DECLARATION OF CONFORMANCE ...................................................................................... 62

P

ULSA PRO CONTROL ADDENDUM ............................................................................................................... 63

Conventions

For the remainder of this bulletin, the following Conventions are in effect.

A WARNING DEFINES A CONDITION THAT COULD CAUSE DAMAGE TO BOTH

THE EQUIPMENT AND THE PERSONNEL OPERATING IT

ATTENTION TO ANY WARNING

.

Notes are general information meant to make operating the equipment easier.

Tips have been included within this bulletin to help the operator run the

equipment in the most efficient manner possible. These “Tips” are drawn from

the knowledge and experience of our staff engineers, and input from the field.

iv

. PAY CLOSE

Page 5

1. Introduction

1.1 General Description

Diaphragm Metering pumps are positive displacement reciprocating pumps that combine the

high efficiency of the plunger pump with a sealed diaphragm that prevents product leakage.

Each pump consists of a power end and a process end separated by a hydraulically operated

diaphragm. Individual pumps will vary in appearance due to various liquid ends, accessories,

and multiplexing - however, the basic principles of operation remain the same.

2. Principles of Operation

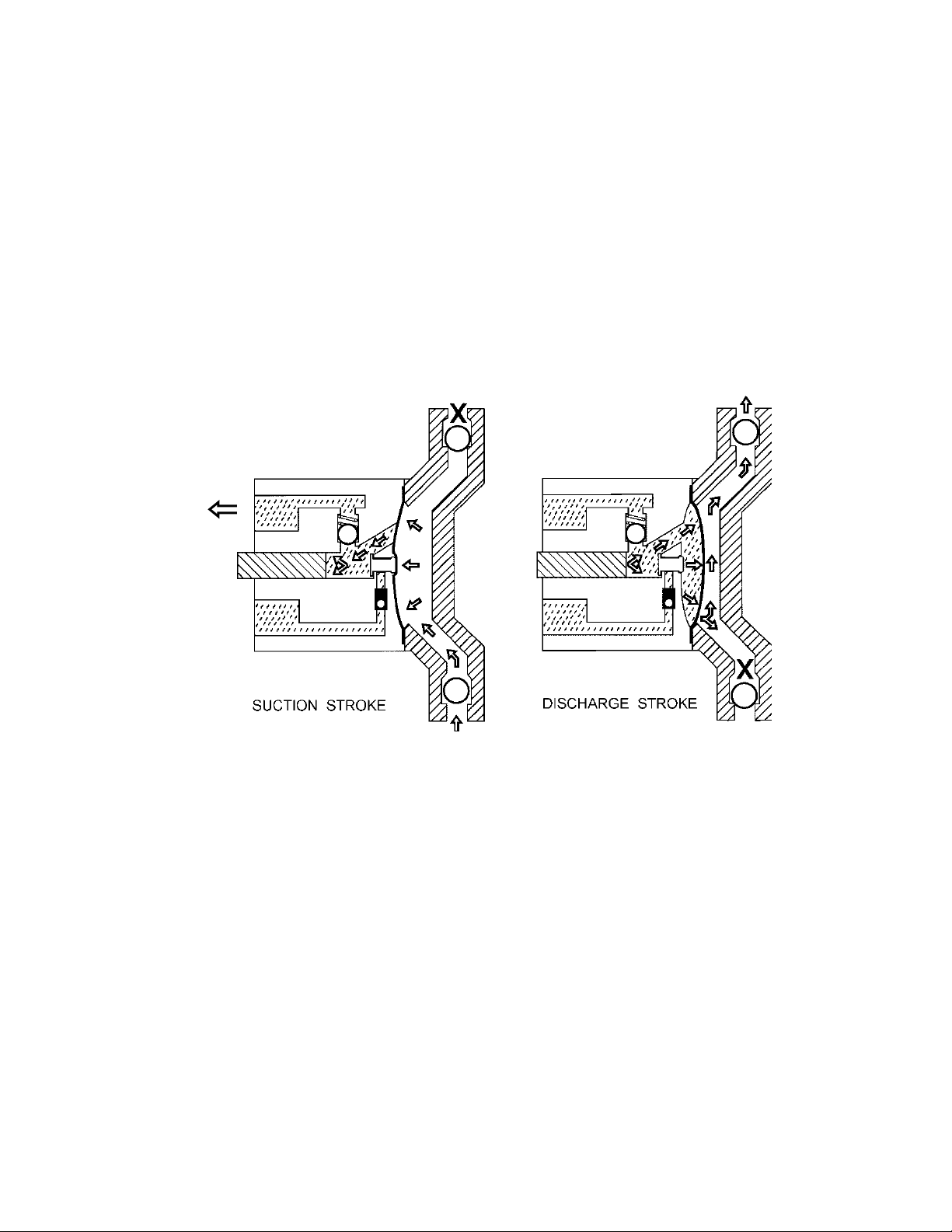

2.1 Overall Operation

Figure 1

A piston reciprocates within an accurately sized cylinder at a preset stroke length, displacing

an exact volume of hydraulic fluid. The hydraulic fluid acts against a sealed diaphragm,

which pumps the chemicals.

The piston and associated mechanisms are enclosed by a chamber called the Pump Head or

intermediate housing. This also acts as a hydraulic oil reservoir.

The diaphragm separates the hydraulic oil from the product pumped. The diaphragm moves

in exact response to the piston displacement. The diaphragm does no work, and acts only as a

separator.

The displacement of the oil is translated into an equal displacement of the chemical being

pumped. Therefore, piston retraction causes the product to enter through the suction check

valve. Piston advance causes the discharge of an equal amount of the product through the

discharge check valve.

1

Page 6

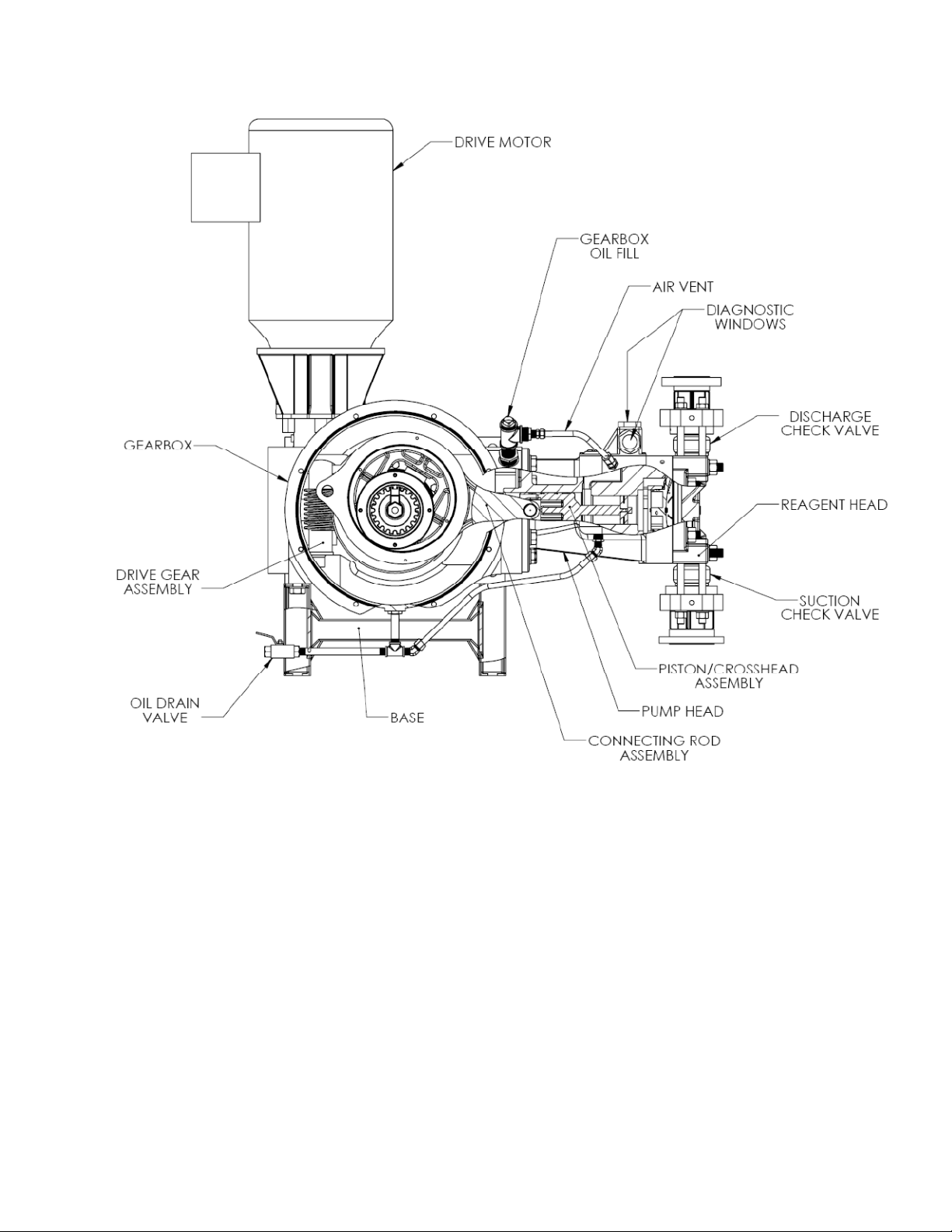

2.2 Component Location

Figure 2

2

Page 7

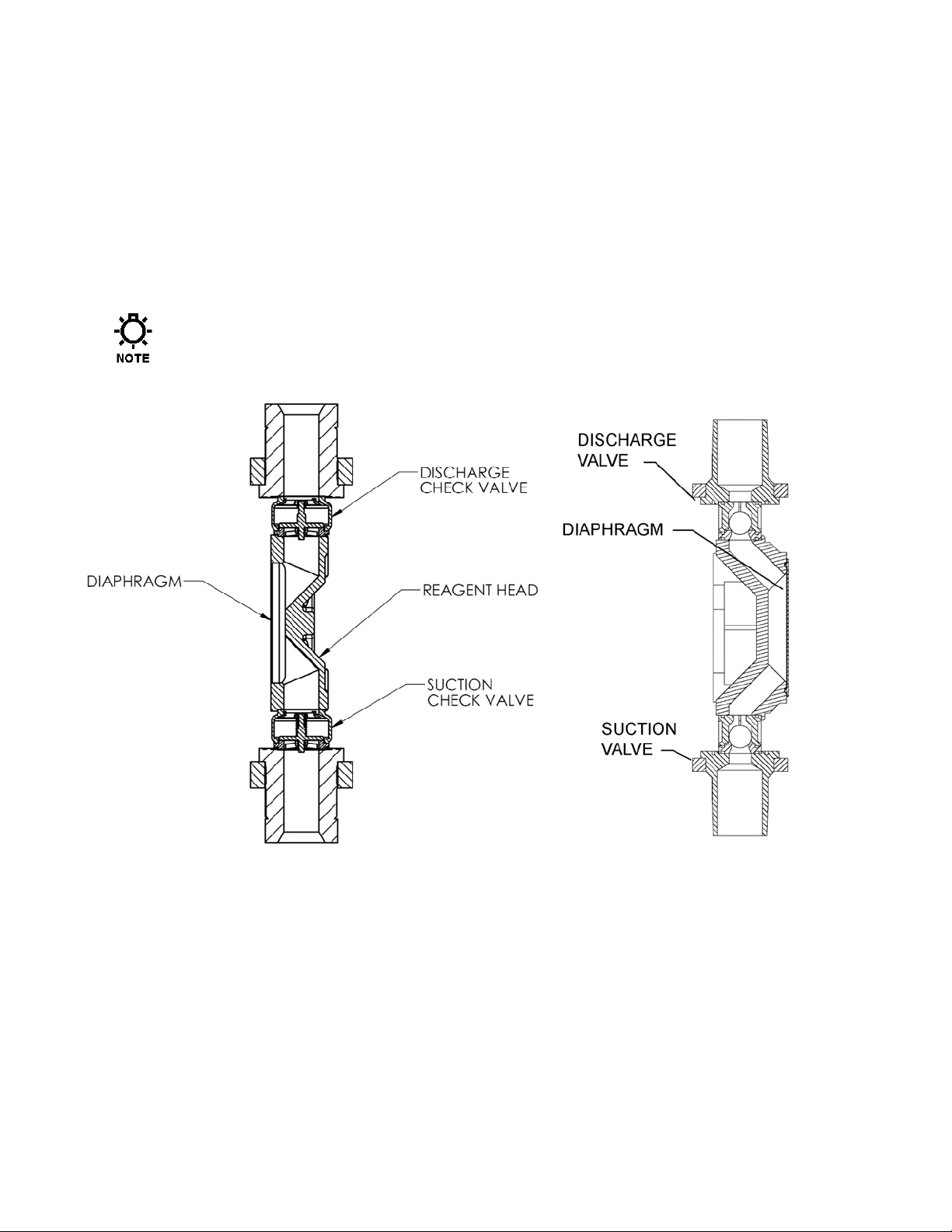

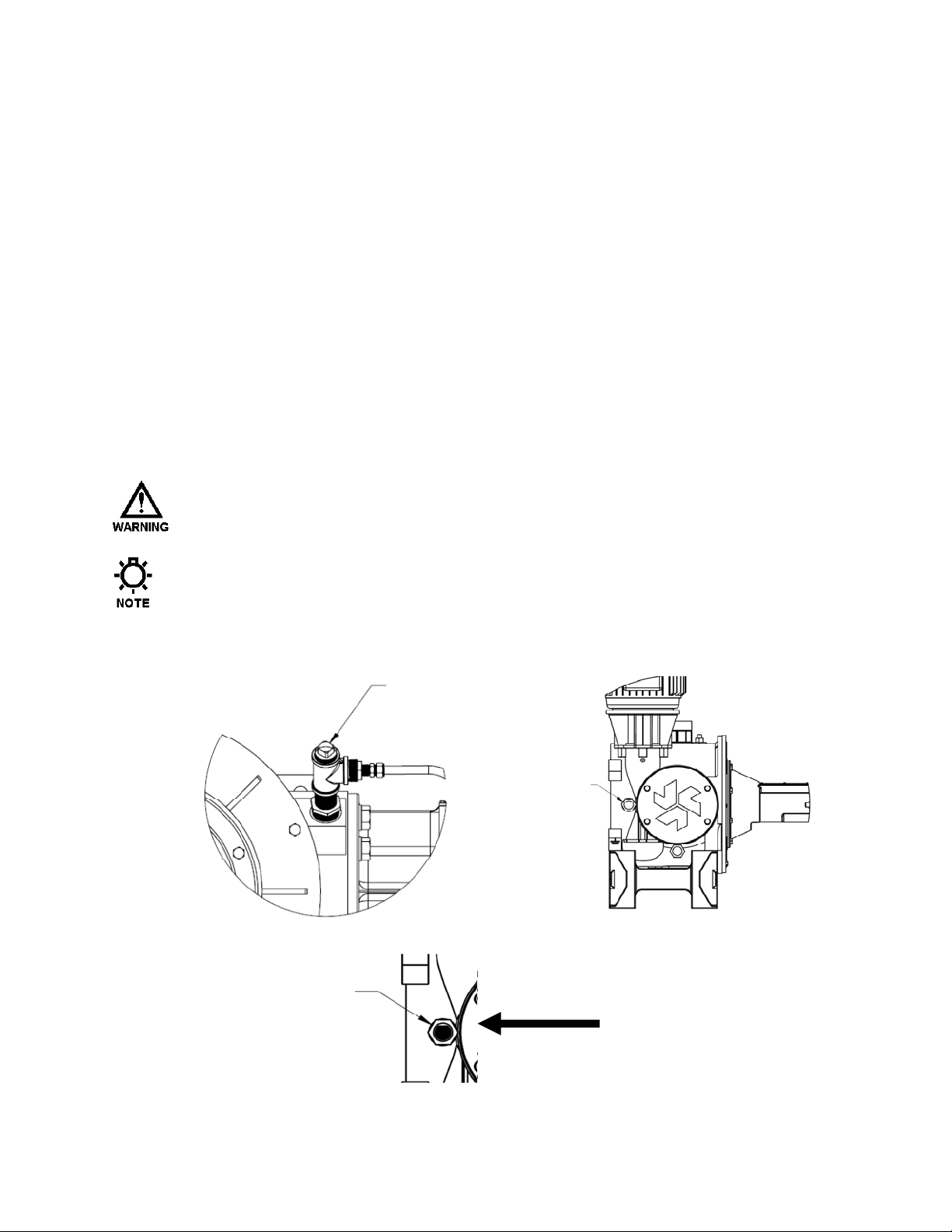

2.2.1 Reagent Head Assembly

The term Reagent Head Assembly refers to the pump components that come into direct

contact with the process fluid (or Reagent). The typical Reagent Head Assembly consists of

the following components:

a) Reagent Head

b) Diaphragm

c) Suction Check Valve

d) Discharge Check Valve

High flow pump models use disk valves.

DISK VALVE DESIGN BALL VALVE DESIGN

Figure 3

3

Page 8

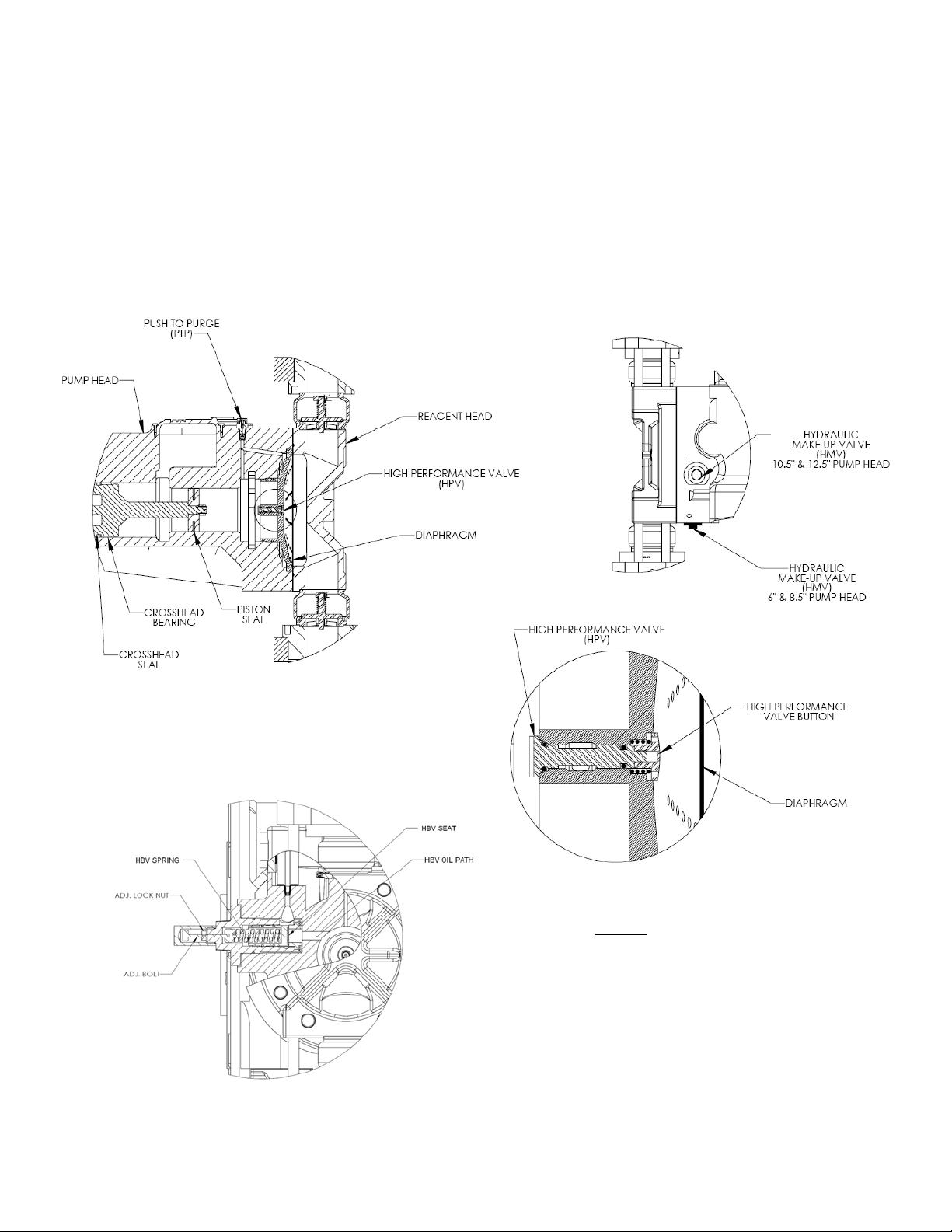

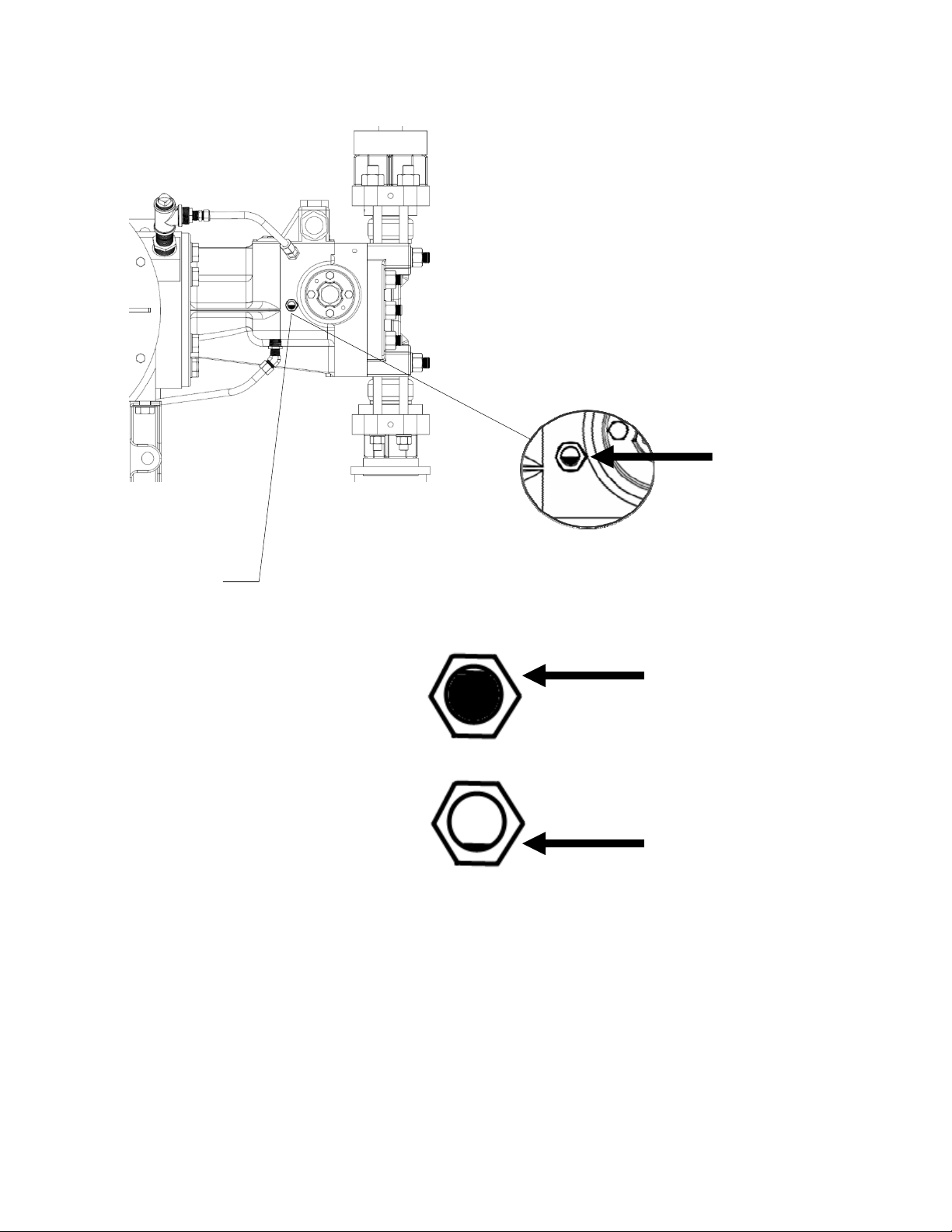

2.2.2 Pump Head/Piston Assembly

The pump head/piston assembly is installed on the intermediate housing. This assembly contains

the hydraulic system which consists of the pump head, cylinder, piston assembly, and four

hydraulic valves:

a) Push-To-Purge (PTP)

b) Hydraulic Performance Valve (HPV)

c) Hydraulic Makeup Valve (HMV)

d) Hydraulic Bypass Valve (HBV)

PTP

HBV

Figure 4

HMV

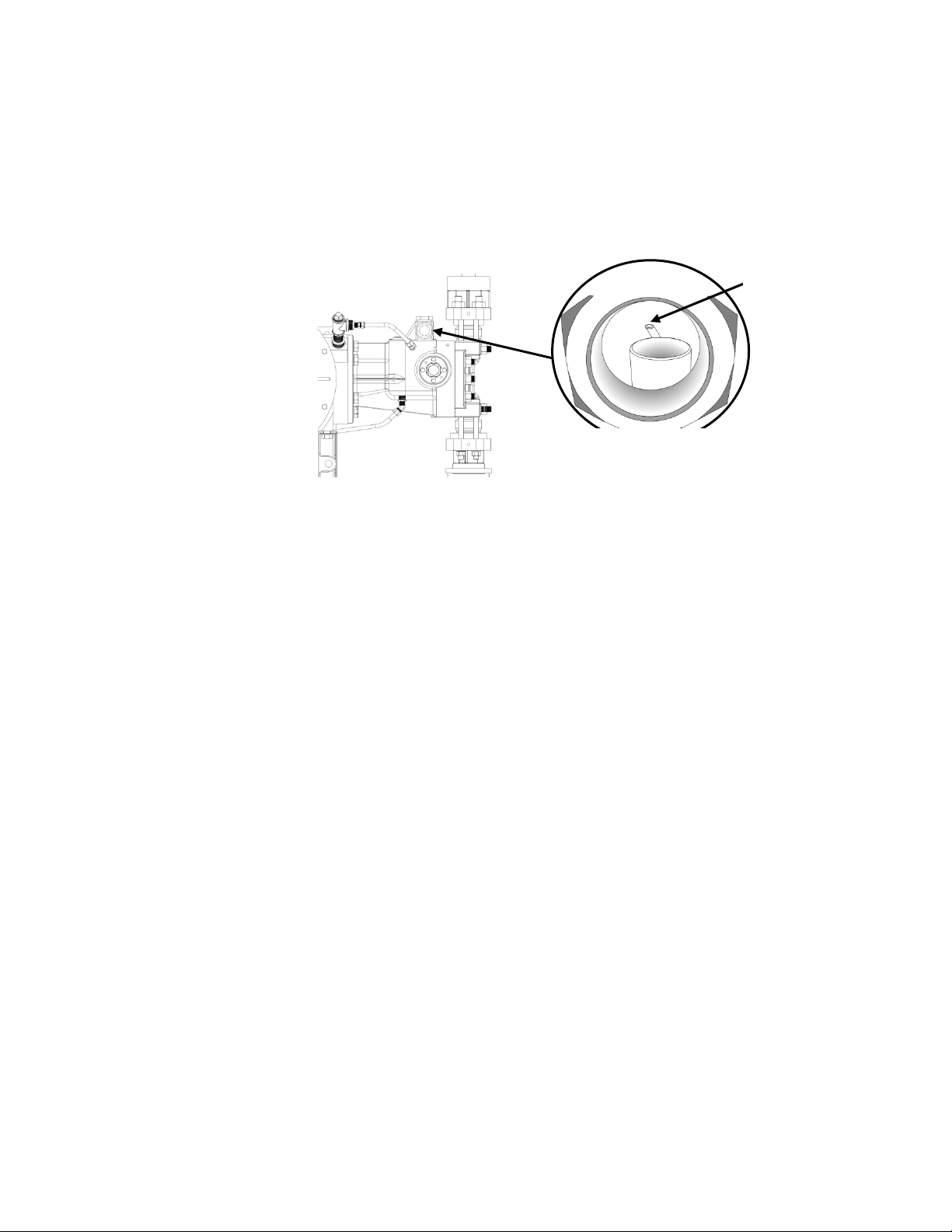

Detail A

HPV

Detail A

4

Page 9

2.2.2.1 Push to Purge (PTP)

The Push to Purge (PTP) valve is located at the top of the Pump Head. It

automatically removes air entrained in the hydraulic system. Pressing down on the

button at the top of the PTP overrides its automatic operation. This allows a small

amount of hydraulic fluid to bleed from the pump head to the reservoir every stroke.

Activating the PTP in this manner helps determine if the pump head is properly

primed and diaphragm integrity is maintained.

2.2.2.2 Hydraulic Performance Valve (HPV)

The Hydraulic Performance Valve (HPV) automatically maintains the hydraulic oil

that “connects” the piston to the diaphragm. During normal operation small amounts

of hydraulic fluid is lost past the piston seal and PTP. This causes the diaphragm to

move progressively closer to the button on the HPV valve (see Figure 4, Detail A).

Over time, the diaphragm will come into contact with this button. When this occurs, it

will push the HPV valve open allowing lost hydraulic fluid to be replenished.

2.2.2.3 Hydraulic Makeup Valve (HMV)

The Hydraulic Makeup Valve (HMV) works in conjunction with the HPV to assure

hydraulic oil flows in one direction (into the diaphragm/piston chamber) at the correct

pressure.

2.2.2.4 Hydraulic Bypass Valve (HBV)

The Hydraulic Bypass Valve (HBV) protects the pump from over-pressurizing by

relieving any excess pressure. It is typically set at 110% of the Pump’s discharge

pressure.

5

Page 10

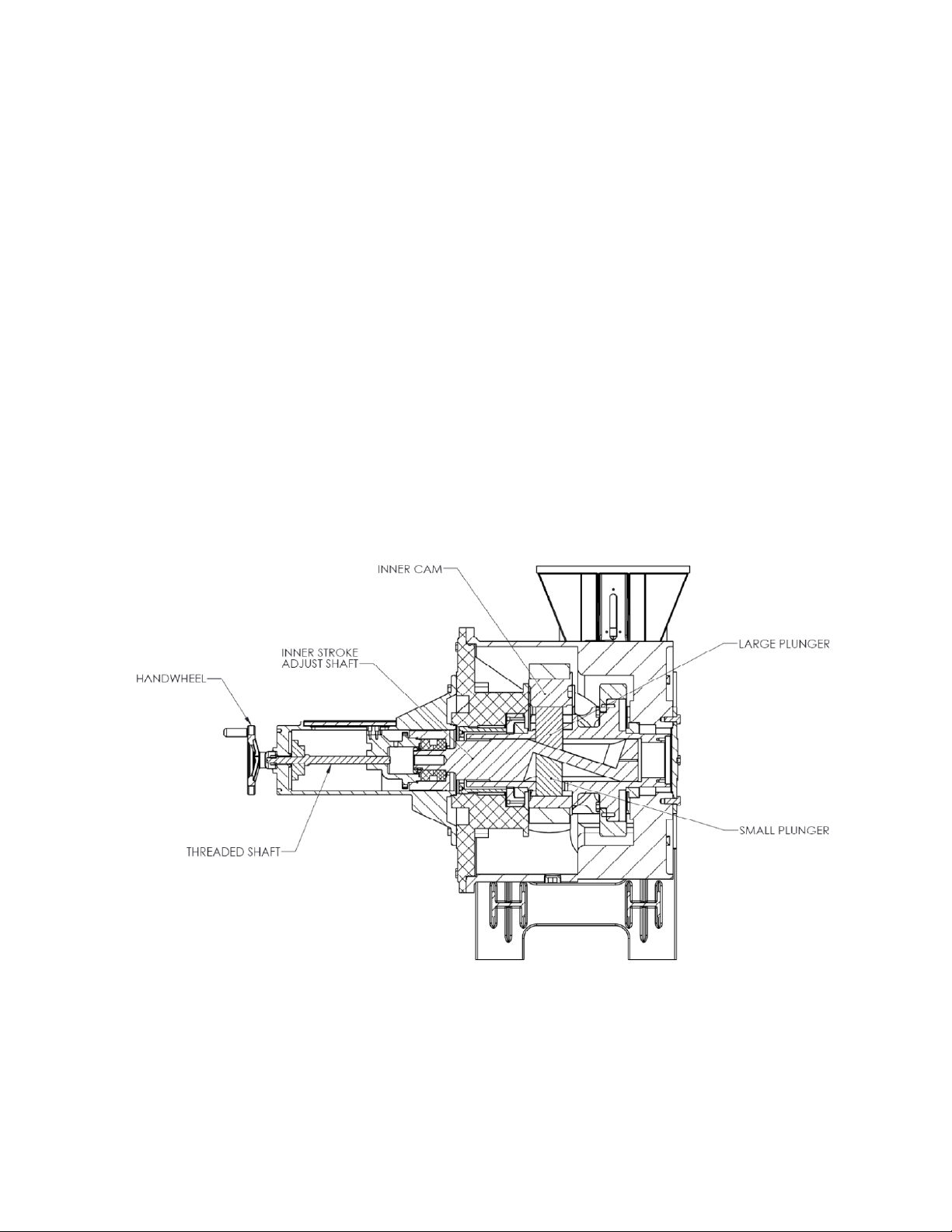

2.2.3 Control Assembly

The output of the

with each pump stroke. The Piston is attached to a rotating cam with a connecting rod. The

Control Assembly allows the throw of the cam to be adjusted (see Figure 5). The assembly

consists of the following parts:

e) Hand wheel

f) Threaded Shaft

g) Inner Stroke Adjust Shaft

h) Large and Small Plunger

i) Inner Cam

2.2.3.1 Operation

The output of the pump is varied by turning the Hand Wheel. The Hand Wheel turns a

threaded shaft. Depending on the direction of rotation, this either pulls the inner stroke

adjustment shaft towards the hand wheel or pushes it away. The inner stroke shaft includes

two opposite faces that are machined on an angle. A Large and Small Plunger ride on these

opposite faces. An Inner Cam rides over the plungers. As the position of the Inner Stroke

Adjustment Shaft changes, the Plungers shift from one side to the other causing the throw of

the cam to change.

PulsaPro 900

can be controlled by changing how far the piston moves

Figure 5

The stroke length setting is denoted by a 0 – 100% scale with 2.5% increments. The scale is

located on the top part of the stroke control housing under a clear sealed cover.

6

Page 11

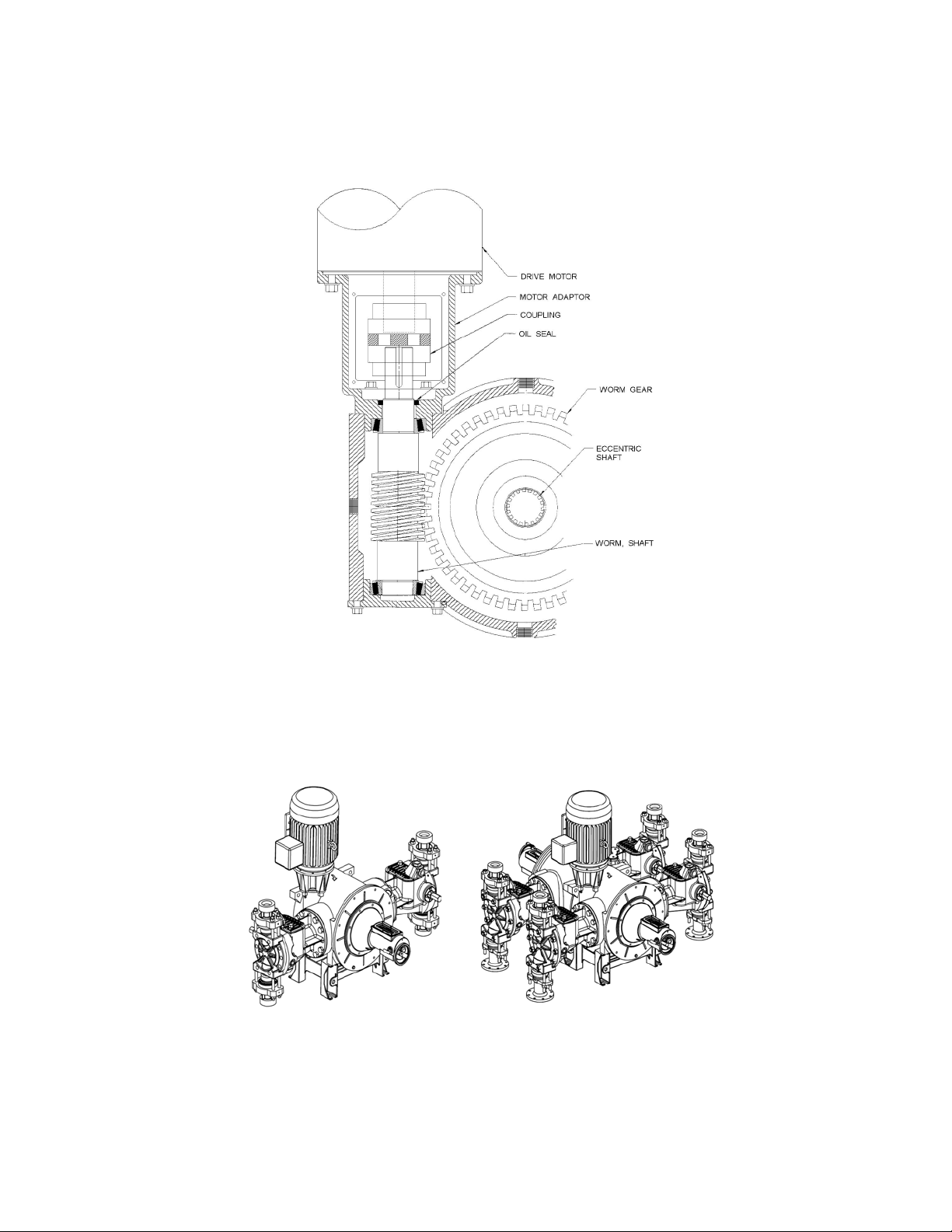

2.2.4 Gear Reducer Assembly

PulsaPro 900

adaptor that completely encloses a coupling. The motor drives a worm gear reduction that

turns an eccentric shaft assembly – converting the rotary motion into reciprocating motion.

pumps are driven by a standard C-face electric motor mounted to an

Figure 6

A single drive assembly can drive up to four Pump/Reagent Head assemblies. This is

referred to as multiplexing.

Figure 7

Whenever pumps are multiplexed the eccentric shafts are positioned to place a uniform load

on the drive. Before full disassembly always note the relative positions of the eccentric shafts

to each other so they can be reassembled back in the same orientation.

7

Page 12

3. Equipment Inspection

Check all equipment for completeness against the order and for any evidence of shipping

damage. Shortages or damage should be reported immediately to the carrier and your

PulsaPro

Representative.

4. Storage Instructions

4.1 Short Term

Storage of

recommended short-term storage procedures are:

a) Store the pump indoors at room temperature in a dry environment.

b) Prior to startup, inspect the pump head, and gearbox. Replenish oil as required to

c) Prior to startup, perform a complete inspection and then start up in accordance with the

PulsaPro

maintain operating levels. If water or condensation is present, change oil as described in

the Equipment Startup section.

instructions in this manual.

4.2 Long Term

Every twelve months, in addition to the above short-term procedures, power up the motor and

operate the pump for a minimum of one hour. It is not necessary to have liquid in the reagent

head during this operation, but the suction and discharge ports must be open to atmosphere.

After twelve months of storage, Pulsafeeder’s warranty cannot cover items that are subject to

deterioration with age such as seals and gaskets. If the pump has been in storage longer than 12

months it is recommended that all seals and gaskets be inspected and replaced as necessary

prior to startup. Materials and labor to replace this class of item under this circumstance are the

purchaser’s responsibility. For a continuance of the 5 year warranty after extended storage,

equipment inspection and any required refurbishing must be done by a Pulsafeeder

Representative.

Series pumps for up to 12 months is considered short-term. The

8

Page 13

5. Installation

5.1 Location

When selecting an installation site or designing a skid package, consideration should be given to

access for routine maintenance.

PulsaPro 900

covering to protect the pump from direct weather and sunlight is required. External heating

and/or the use of synthetic lubricants for the gearbox is recommended if ambient temperatures

below 20°C (0°F) or above 40°C (104°F) are anticipated. Check with the factory if you are

concerned with the suitability of the operating environment.

pumps are designed to operate indoors and outdoors. At a minimum, a

5.2 Mounting

The pump must be rigidly bolted to a solid and flat foundation to minimize vibration, which can

loosen connections. Bolt each base with a minimum of 1” diameter studs with flat and lock

washers in 4 locations per base (note: the quad configurations include 2 bases). The pump must

be level within 2°. This will assure that the oil is maintained at the proper level and that the

check valves can operate properly.

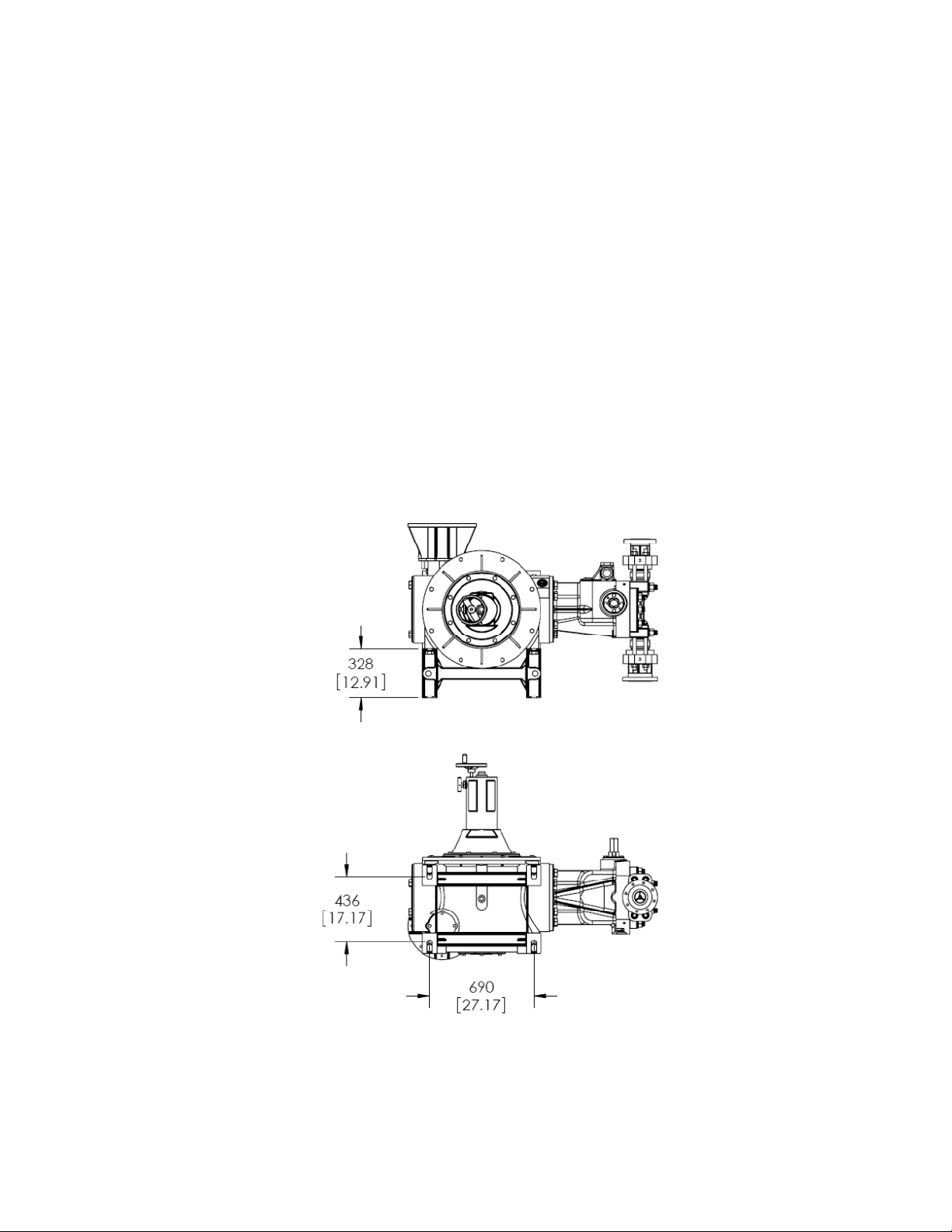

mm

[inch]

Figure 7

9

Page 14

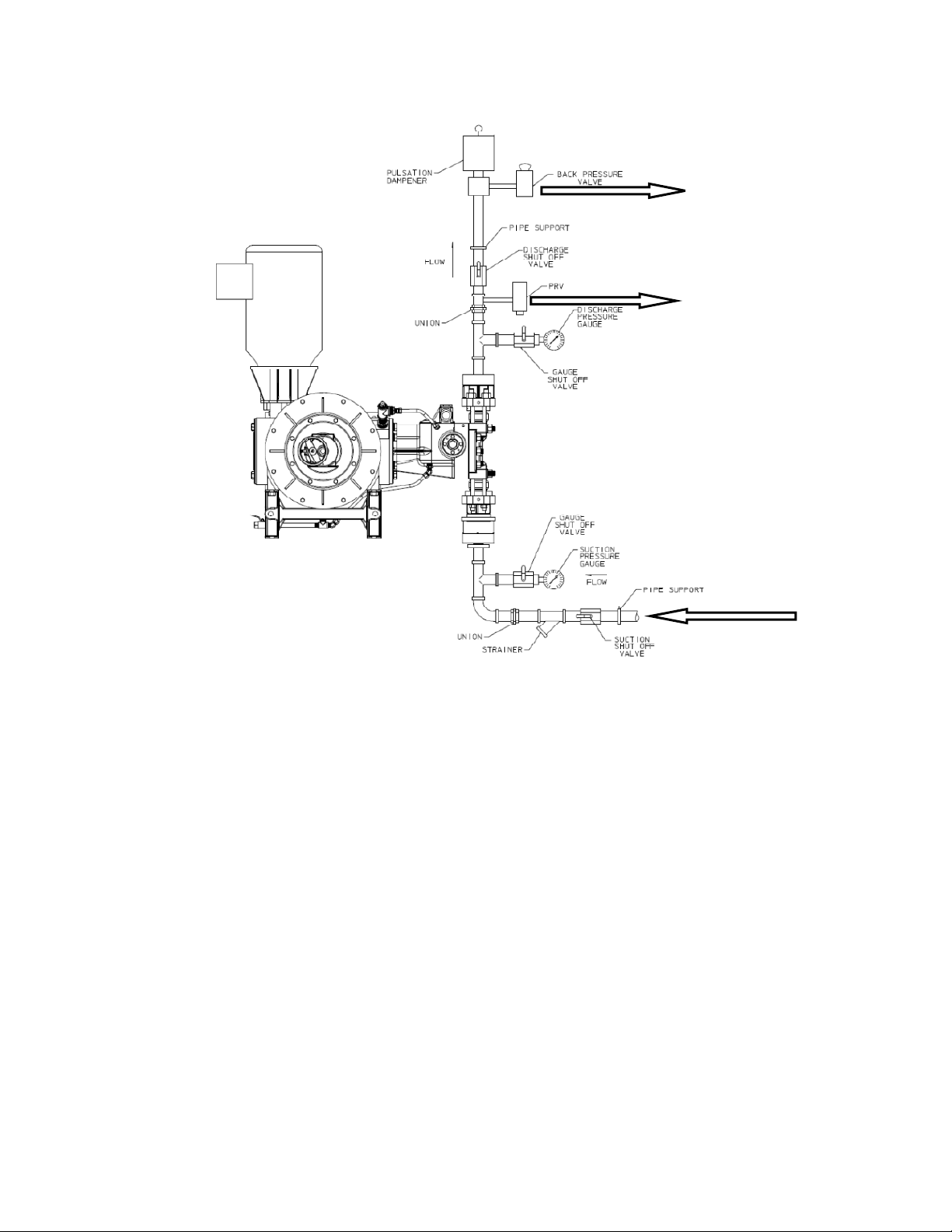

5.3 Piping System

DISCHARGE

RETURN TO TANK

FROM SUPPLY TANK

Figure 8A

All piping systems should include:

1. Shutoff valves and unions (or flanges) on suction and discharge piping.

a) This permits check valve inspection without draining long runs of piping.

b) Shutoff valves should be of the same size as connecting pipe.

c) Ball valves are preferred since they offer minimum flow restriction.

2. An inlet strainer, if the process fluid is not a slurry.

a) Pump check valves are susceptible to dirt and other solid contaminants unless designed

for that service, and any accumulation can cause malfunction.

b) The strainer should be located between the suction shutoff valve and the pump suction

valve.

c) It must be sized to accommodate the flow rate and the anticipated level of contamination.

d) 100 mesh screen is recommended.

3. Vacuum/pressure gauges in the suction and discharge lines in order to check system operation.

a) Gauges should be fitted with protective shutoff valves for isolation while not in use.

10

Page 15

4. A separate system relief valve to protect piping and process equipment, including the pump,

from excess process pressures.

a) The hydraulic bypass valve (HBV) in the pump is not intended to protect the system.

Piping weight must not be supported by valve housings or other portions of the reagent head, as

the resulting stresses can cause leaks. If appropriate, provide for thermal expansion and

contraction so that no excess force or movement is applied to the pump.

In piping assembly, use a sealing compound chemically compatible with the process material.

Users of sealing tape are cautioned to ensure that the entering pipe thread ends are not taped,

and that tape is removed from previously-used threads prior to re-use. Both new and existing

piping should be cleaned, preferably by flushing with a clean liquid (compatible with process

material) and blown out with air, prior to connection to the pump.

5.3.1 Suction Pressure Requirements

Although metering pumps have suction lift capability, all pump installations should be designed

to minimize lift for optimal performance. A flooded suction (i.e., suction fluid level higher than

the centerline of the pump) is preferable whenever possible. The pump should be located as

close as possible to the suction side reservoir or other source.

If suction lift is required, the minimum net positive suction pressure required (NPSH

psia (0.21 bar) above the Vapor Pressure of the Process Fluid. If this requirement is not met

the Process Fluid may cavitate inside the pump, degrading metering accuracy.

Likewise, if the suction pressure is low enough, it is possible to cavitate the hydraulic fluid used

to move the diaphragm in the pump. Therefore, suction pressure must also be maintained at a

minimum absolute value of 5 psia (0.34 bar) to ensure proper hydraulic system and pump

operation.

The suction pressure must not exceed 165 psia (11.38 bar) for pumps with TFE diaphragms.

Please consult the factory for higher suction applications.

Higher pressures may be possible with optional alternate diaphragm materials or

modified dish plates.

Refer to Appendix I for a complete explanation of Suction Pressure Requirements including

methods to calculate values for your system.

5.3.2 Discharge Pressure Requirements

All Pulsafeeder Metering Pumps are designed for continuous service at the rated discharge

pressure. If system suction pressure were to exceed system discharge pressure (a condition

sometimes described as “pumping downhill” or “flow-through”), excess flow would be

generated, resulting in a reduction in accuracy and loss of control over the metering process. To

prevent this condition, the discharge pressure must exceed the suction pressure by at least 25

psia (1.7 bar). This can be achieved where necessary by installing a backpressure valve in the

discharge line.

DISCHARGE PRESSURE MUST NEVER EXCEED THE HYDRAULIC BYPASS VALVE (HBV)

SETTING ON THE NAMEPLATE

PERFORMANCE

, DAMAGE THE PUMP AND VOID THE WARRANTY.

. EXCESSIVE DISCHARGE PRESSURE COULD IMPAIR

) is 3

R

Refer to Appendix I for a complete explanation of Discharge Pressure Requirements including

methods to calculate values for your system.

11

Page 16

6. Equipment Startup

6.1 Lubrication

PULSAPRO 900 PUMPS USE PULSALUBE UNIVERSAL 1HG OIL AS STANDARD FOR THE

PUMP HEAD AND GEARBOX

PERFORMANCE

, DAMAGE THE PUMP AND VOID THE WARRANTY.

6.1.1 Oil Capacities

. USE OF ALTERNATIVE LUBRICANTS COULD IMPAIR

The approximate amounts of oil required to fill the

Pulsalube Universal 1HG is standard oil supplied with all pumps unless

specified. Temperatures +40 – 280 °F

Total - Pump Head and Gear Box 25

PULSAlube Universal 1HG is available as follows:

• 1 quart (0.94 liters) Part #: 1HG-1QT

• 1 gallon (3.79 liters) Part #: 1HG-1GL

• 5 gallons (18.9 liters) Part #: 1HG-5GL

• 55 gallons (208.2 liters) Part #: 1HG-55GL

It is recommended that adequate supplies of Pulsalube Universal 1HG be on hand for

periodic changes and emergency requirements.

PulsaPro 900

94.6

to the specified level is:

Gallons

Liters

Pulsafeeder also offers oil options for extreme operating conditions.

Pulsalube Ultra 6HGS is Non-standard oil and is for special applications

Temperatures -40 – 400 °F

Total - Pump Head and Gear Box 25

94.6

PULSAlube Ultra 6HGS is available as follows:

• 1 gallon (3.79 liters) Part #: 6HGS-1GL

• 5 gallons (18.9 liters) Part #: 6HGS-5GL

• 55 gallons (208.2 liters) Part #: 6HGS-55G

12

Gallons

Liters

Page 17

13

Page 18

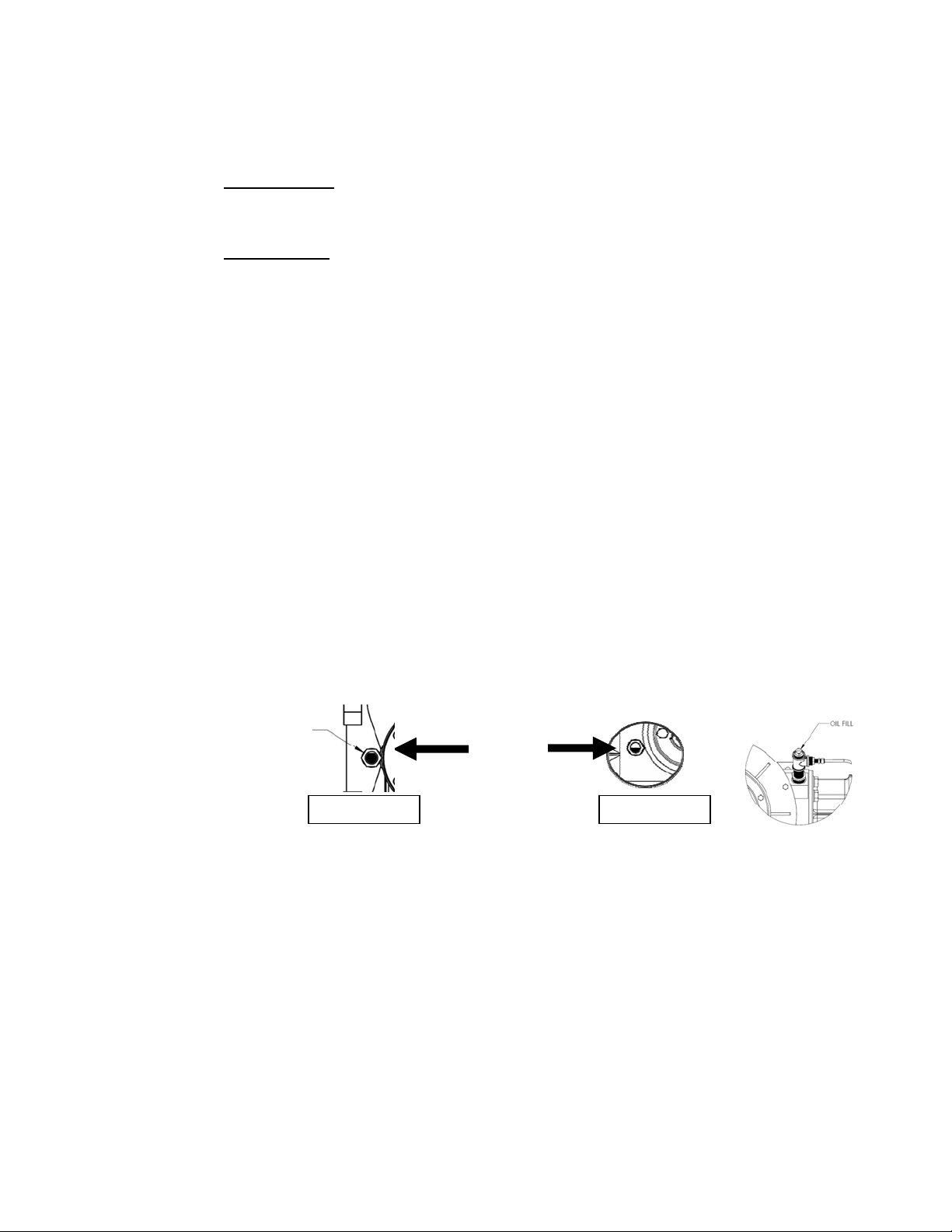

6.1.2 Oil Fill

The pump is shipped from the factory filled to the proper level with PULSAlube Universal

or Ultra. The oil is held within two main reservoirs – the Gear Box (located on the motor

end of the pump) and the Pump Head (located on the process fluid end of the pump). The

two reservoirs are connected to allow lubricant to flow between them to assure a constant oil

level across the entire pump.

Two sight glasses provide a visual confirmation of oil level. One is located in the Pump

Head next to the HBV valve. The second is located in the Gearbox below the motor on the

centerline. The construction and operating conditions of the pump can cause the oil level to

go up or down during operation – this is normal. The level should be set to the center of the

sight glass. During operation the level can increase or decrease from this position, but should

always be visible within the window. For reliable measurements shut the pump off, set the

Stroke Adjustment to 0% stroke and wait approximately 5 minutes before reading the sight

glass levels.

The oil fill is located on the top of the gearbox opposite the motor (see Figure 9A). To fill,

remove the cover and add PULSAlube Universal or Ultra. Because this one fill location

supplies two reservoirs, it is necessary to wait several minutes for the level to stabilize across

the entire pump.

DO NOT OVERFILL! OVERFILLING CAN CAUSE MALFUCTION AND MAY RESULT IN

DAMAGE NOT COVERED BY WARRANTY

During normal operation, the worm gear running behind the sight glass in the gearbox

will cause oil to cover the glass completely. This is normal and does not reflect the true

measure of oil level. Turn the pump off and set the Stroke Adjustment to 0% to check

the oil level properly.

.

Oil Fill

Rear Sight

Glass

Figure 9A: Gearbox Oil Level

Rear

REAR SIGHT GLASS

Sight

Glass

Proper Oil

Level with

Pump Off

14

Page 19

FRONT SIGHT

GLASS

Proper Oil

Level with

pump off

Maximum

Oil Level

Minimum

Oil Level

Figure 9B: Pump Head Oil Level – Maximum/Minimum Definition

15

Page 20

6.1.3 Oil Changes

6.1.3.1 Service Level Definition

The recommended oil change intervals are dependent upon the operating environment and

level of pump usage, classified as follows:

Normal service

Clean/dry atmosphere, an ambient operating temperature of 0°C to 40°C (32°F to

104°F), and up to 2,000 annual operating hours.

Severe Service

Humid atmosphere, an ambient operating temperature below 0°C (32°F) or above

40°C (104°F), and over 2,000 annual operating hours.

6.1.3.2 Oil Change:

The recommended oil change interval is 2 years for normal service and 1 year for severe

service. The first oil change should be done after six (6) months of continuous operation

(approximately 1,000 hours). The procedure is as follows:

1. Disconnect the power source to the drive motor (e.g., lockout/tagout the motor

disconnect).

2. Relieve all pressure from the piping system.

3. Set the Stroke Adjustment to 0% Stroke.

4. Remove the oil fill cap.

5. Drain the oil by opening the Oil Drain Valve at back of the Gearbox underneath the base.

6. Close the Oil Drain Valve.

7. Fill the Pump with 20 Gallons (75 Liters) of PULSAlube Universal or Ultra.

8. Wait for 10 minutes for the oil to level across the pump.

9. Slowly add more PULSAlube Universal or Ultra until the oil level centers on the

gearbox sight glass and the pump head sight glass.

Rear Sight Glass

10. Replace the Oil Fill Cap.

11. Set the Stroke Adjustment to the proper setting.

12. Remove Motor Starter Lockout/Tagout.

Proper Oil

Level with

pump off

GEAR BOX PUMP HEAD

16

Page 21

6.2 Startup

6.2.1 Output Adjustment

When starting up the pump for the first time, it is best to set the stroke adjustment to

0% output and then slowly increase the setting to 100%. This allows you to react to

any leaks that may be present in the piping system before they become severe.

PulsaPro 900

The

rear of the stroke adjust housing (refer to Figure 10). The hand wheel can be adjusted at any

point from 0 to 100%. It includes a stroke lock mechanism. Before making an adjustment

pull out the stroke lock handle and rotate it ¼ turn to hold it in the disengaged position. With

the stroke lock disengaged, crank the hand wheel in either direction to adjust the stroke length

to the desired setting – do not go below the 0% or above the 100% marks. After you have

completed your stroke length setting, re-engage the stroke lock by turning the stroke lock

handle ¼ turn.

Please be sure the stroke lock is then engaged during pump operation to prevent drift.

uses a hand wheel for manual stroke adjustment. It is mounted on the

Stroke

Adjustment

Stroke

Lock

Figure 10

17

Page 22

6.2.2 Priming the Pump Head

All pumps are shipped with a fully primed hydraulic system. However, during shipping,

handling and storage some air may accumulate in the hydraulic system resulting in reduced

performance. Generally this air will be automatically purged after a short run-in period. If

necessary, rapid purging may be accomplished by:

1. Fully depressing and holding the button on top of the PTP valve while the pump is

operating at any stroke length setting above 30%.

2. With the PTP button depressed, oil should begin to flow out of the small diagnostic port.

3. Hold the valve down for several seconds after the oil is clear of bubbles to ensure a good

prime.

If the pump fails to prime refer to Section 7.2.1, Re-Priming the Pump Head.

PTP

DIAGNOSTIC

PORT

DIAGNOSTIC WINDOW

6.2.3 Priming the Reagent Head

To prime the Reagent Head with the process fluid:

1. Open the suction and discharge line shutoff valves.

2. If the piping system design and the storage tank are such that the product flows due to

gravity through the pump, no priming is required.

In the event the discharge line contains a significant amount of pressurized air or other

gas, it may be necessary to lower the discharge pressure to enable the pump to self-prime.

3. If the installation involves a suction lift, it may be necessary to prime the reagent head

and suction line. Try priming the reagent head first.

a) Remove the discharge valve by unscrewing the four tie bar bolts and removing the

valve as a unit.

b) Fill the head through the discharge valve port with process (or compatible) liquid

c) Reinstall the valve and retighten the tie bar bolts.

4. Start the pump at the 100% stroke length setting to prime the pump. If this does not

work, it will be necessary to fill the suction line.

Filling of the suction line will necessitate the use of a foot valve or similar device at the

end of the suction line so that liquid can be maintained above the reservoir level.

a) Remove the suction valve assembly.

b) Fill the line

c) Replace the valve.

d) Remove the discharge valve assembly and fill the reagent head as described in Step 3

above.

18

Page 23

6.2.4 Motor Rotation

Verifying the proper rotation of the motor

a) To verify the correct shaft rotation of the motor you can remove the 3 screws to the

access cover or remove the large pipe plug on the side of the motor adaptor housing.

This will allow you visual sight of the motor coupling to verify rotation.

b) Another way to verify the proper motor rotation is to observe the rotation of the fan

on the motor.

Observing from the rear of the pump the Proper rotation of the input shaft of the

Pro 900 pump is

gearbox for proper rotation.

CLOCKWISE

. Please also refer to the arrow that is cast into the

19

Page 24

6.2.5 Calibration

All metering pumps must be calibrated to accurately specify stroke length settings to achieve

required flow rates.

Figure 11

A typical calibration chart is shown in Figure 11. Although output is linear with respect to

stroke length setting, an increase in discharge pressure decreases output uniformly, describing a

series of parallel lines, one for each pressure (only two are shown in the figure).

The theoretical output flow rate at atmospheric pressure is based on the displacement of the

hydraulic piston (the product of the piston cross-sectional area and stroke length) and the

stroking rate of the pump.

Whenever possible, calibration should be performed under actual process conditions (i.e., the

same or a similar process liquid at system operating pressure).

To assure a sound hydraulic system, run the pump for 15-20 minutes prior to calibration. This

will allow the PTP (automatic bleed) valve to purge any air from the system.

Allowing the pump to run for several hours prior to performing a calibration will

provide better results.

Procedure for constructing a calibration chart,

1. Measure the flow rate several times at three or more stroke settings (e.g., 25, 50, 75, and

100%).

2. Plot these values on linear graph paper.

3. Draw a best-fit line through the points.

For stable conditions, this line should predict stroke settings to attain required outputs.

20

Page 25

7. Maintenance

ALWAYS LOCKOUT/TAGOUT THE PUMP MOTOR BEFORE PERFORMING MAINTENANCE

OF ANY KIND

B

EFORE PERFORMING ANY MAINTENANCE REQUIRING REAGENT HEAD OR VALVE (WET

) DISASSEMBLY, BE SURE TO RELI EVE PRESSURE FROM THE PIPING SYSTEM.

END

WHERE HAZARDOUS PROCESS MATERIALS ARE INVOLVED , REND ER TH E PUMP SAF E TO

PERSONNEL AND THE ENVIRONMENT BY CLEANING AND CHEMICALLY NEUTRALIZING AS

APPROPRIATE

EQUIPMENT

Accurate records from the early stages of pump operation will indicate the type and levels of

required maintenance. A preventative maintenance program based on such records will minimize

operational problems. It is not possible to forecast the lives of wetted parts such as diaphragms

and check valves. Since corrosion rates and operational conditions affect functional material life,

each metering pump must be considered according to its particular service conditions.

.

. WEAR ALL REQUIRED PROTECTIVE CLOTHING AND USE PROTECTIVE

.

PulsaPro

maintenance program. It is recommended that KOPkits and PULSAlube oil be kept available at

all times.

Each

with the documentation package. The data sheet contains important information relating to the

application along with pump serial number, pump specifications (i.e., materials, piston size,

stroking rate, etc.).

Series KOPkits contain all replacement parts normally used in a preventative

PulsaPro

Series pump is provided with an individual specification data sheet included

21

Page 26

7.1 Wet End Removal, Inspection, and Reinstallation

IF THE DIAPHRAGM HAS FAILED, PROCESS FLUID MAY HAVE CONTAMINATED THE

PUMP OIL. HANDLE WITH APPROPRIATE CARE, CLEAN AND REPLACE OIL IF

REQUIRED

DUE TO THE SIZE AND WEIGHT OF WET END COMPONENTS, CARE MUST BE USED TO

SELECT THE PROPER TOOLS AND LIFTING EQUIPMENT FOR HEAVY LOADS

.

.

PulsaPro

foreign material or the entrapment of sharp particles between the diaphragm and dish cavity can

eventually cause failure. Failure can also occur as a result of hydraulic system malfunction or

chemical attack. Periodic diaphragm inspection and replacement is recommended.

Series diaphragms do not have a specific cycle life. However, the accumulation of

TAKE ALL PRECAUTIONS TO PREVENT ENVIRONMENTAL AND PERSONNEL EXPOSURE

TO HAZARDOUS MATERIALS

Figure 12

.

22

Page 27

Diaphragm Replacement procedure

1. Disconnect the power source to the drive motor (e.g., lockout/tagout the motor disconnect).

2. Relieve all pressure from the piping system.

3. Close the suction and discharge shutoff valves (refer to Figure 8A).

4. Disconnect piping to the reagent head and drain any process liquid, following material safety

precautions from the process liquid manufacturer.

5. Place a pan underneath the pump head to catch any oil leakage from the pump.

6. If the oil is known to be contaminated by process fluid (e.g., the diaphragm has ruptured, the oil

is discolored, etc.) drain the oil by opening the oil drain valve below the base at the back of the

pump.

7. Remove the suction and discharge check valves as described in Section 7.3.1. Pour out any

liquids retained by the check valves into a suitable container, continuing to follow safety

precautions as appropriate.

8. Attach lifting means (e.g., straps, rigging and hoist) to support the reagent head during removal.

9. Remove the 10 nuts that secure the reagent head to the pump head.

OIL MAY LEAK OUT BETWEEN THE PUMP HEAD AND REAGENT HEAD AS THE REAGENT

HEAD BOLTS ARE LOOSENED

10. Carefully slide the regent head straight off towards the end of the studs, please use caution not

to damage the threads.

11. Rinse or clean the reagent head with an appropriate material/method.

12. Remove and inspect the diaphragm. It may have taken a permanent convex or concave set as a

result of normal flexure and conformance to the dish plate. This condition is normal and is not

cause for replacement.

The diaphragm must be replaced if it is excessively deformed, dimpled, or obviously

damaged.

.

13. Ensure that the critical sealing areas of the diaphragm, reagent head, and pump head are clean

and free of debris.

14. When reinstalling a used diaphragm it is important to maintain the previous orientation relative

to the reagent head and pump head hole pattern.

15. Place the diaphragm into the circular groove in the reagent head press firmly around the outer

edge. The groove will hold the diaphragm in place until you install the reagent head to the

pump head.

16. Carefully move the reagent head into place over the studs.

17. Install the reagent head hold-down nuts finger tight (just in contact with the reagent head front

face).

18. Torque the nuts in an alternating pattern as defined in Appendix III. Initially torque the nuts to

one half the recommended value. Repeat the pattern, tightening the nuts to the specified value.

19. Re-install the suction and discharge check valves.

20. Re-install the suction and discharge piping.

21. Re-prime the pump following the procedure outlined in the next section.

23

Page 28

7.2 Re-Priming the Pump Head

The

PulsaPro

several components to protect its prime – the HPV, HBV and PTP – they will not automatically restore

hydraulic prime if the oil is drained from the hydraulic chamber (the space between the piston and the

diaphragm). This would commonly occur when the diaphragm is replaced for example. This procedure

describes how to efficiently re-prime the Pump Head.

Re-Priming the Pump Head is not required when performing a normal oil change. Typically

the Pump Head hydraulic chamber will retain its prime while you drain the oil using the

drain valve in the Gear Box.

This procedure may be helpful in cases where the system has experienced a severe upset (for

example, when a valve in the suction line is shut off for more than 30 minutes).

must maintain hydraulic prime to operate properly. While its Hydraulic System includes

RESERVOIR

PUSH TO PRIME (PTP)

RESERVOIR OIL LEVEL

Figure 13

HYDRAULIC CHAMBER

DIAGNOSTIC WINDOW

24

Page 29

7.2.1 Re-Filling the Hydraulic System

Use the following procedure to refill the Hydraulic System after Diaphragm/Piston service or

extreme system upset conditions:

1. Disconnect the power source to the drive motor (e.g., lockout/tagout the motor disconnect).

2. Check the Pump Head Oil Level (refer to Section 6.1.3 Oil Changes). Restore levels in the

Pump Head Reservoir if necessary.

3. Remove the PTP valve from the Pump Head carefully to access the Hydraulic Chamber. There is

an o-ring and copper gasket that need to be properly handled and protected from damage.

OIL MAY LEAK OUT FROM AROUND THE PTP VALVE. TAKE APPROPRIATE MEASURES

TO CAPTURE AND CONTAIN IT

4. Set the stroke length adjustment to 0%.

5. Using a small plastic funnel (or a kitchen style turkey baster), slowly pour PULSAlube Universal

1HG (or oil specific to your application) into the Hydraulic Chamber through the PTP valve port

until full. Make sure the neck of the funnel enters the small hole at the bottom of the threaded

bore. Failure to do so will result in the oil running through a small cross drilled hole into the

Reservoir instead of the Hydraulic Chamber.

6. Replace the PTP valve, ensuring that the flat copper gasket and o-ring are properly in place.

.

PTP

Cross Drilled Hole

O-Ring

Funnel Neck must

Enter Here

Copper Gasket

7.2.2 Re-Priming the Hydraulic System

Use the following procedure to re-prime the Hydraulic System:

1. Restore power to the pump.

2. Turn on the pump and slowly adjust the stroke length to 50%.

3. Allow the pump to operate for 30 minutes. During this time fully depress and

hold the PTP valve button for several seconds every 5 minutes. After

approximately 15 minutes oil should begin to flow out of the small diagnostic

port (refer to Figure 13) but may appear foamy. By the end of the 30 minute

period oil coming out of the diagnostic port should be clear of bubbles.

Depending on the system discharge flow and pressure oil may spurt from the

diagnostic port. This is normal.

4. Adjust the stroke length to 100%. Confirm the pump is making the proper flow and pressure

using external equipment - a flow meter and pressure gage for example.

5. If the pump is NOT making flow and pressure repeat this re-priming procedure.

6. If, after attempting a second re-prime, the pump still doesn’t make flow and pressure, repeat the

Re-Fill and Re-Prime procedures above.

OBSERVE

PTP FLOW

HERE

25

Page 30

7.3 Check Valves

Most fluid metering problems are related to check valves. Problems can be caused by solids

accumulation between the valve and seat, corrosion of seating surfaces, erosion, physical

damage due to wear or the presence of foreign objects.

There are two styles of check valves. Ball checks are used for lower flows. Disk checks are

used for higher flows.

The ball check valve incorporates a ball, guide, and seat. Flow in the unchecked direction

lifts the ball off the seat, allowing liquid to pass through the guide. Reverse flow forces the

ball down, sealing it against the sharp edge of the seat. The guide permits the ball to rotate

but restricts vertical and lateral movement in order to minimize “slip” or reverse flow. Ball

rotation prolongs life by distributing wear over the entire surface of the ball. Since ball return

is by gravity, the valve must be in the vertical position in order to function properly. Parts are

sealed by o-rings.

Figure 14

The disk valve functions in the same manner as the ball valve, except that the ball is replaced

by a spring-loaded guided disk. The seat may contain a captured o-ring to facilitate sealing.

26

Page 31

7.3.1 Check Valve Removal

TAKE ALL PRECAUTIONS TO PREVENT ENVIRONMENTAL AND PERSONNEL EXPOSURE

TO HAZARDOUS MATERIALS

1. Disconnect the power source to the drive motor (e.g., lockout/tagout the motor disconnect).

2. Relieve all pressure from the piping system.

3. Close the suction and discharge shutoff valves (refer to Figure 8A).

4. Loosen the suction valve tie-bar bolts and spring the suction piping slightly to drain any liquid

from the reagent head cavity. If the piping is closely connected it may be necessary to

disconnect a union or flange.

5. Remove the suction check valve assembly, holding it together as a unit.

6. Loosen the tie bar bolts on the discharge valve and spring the piping slightly to drain any liquid.

7. Remove the discharge check valve assembly, holding it together as a unit.

.

7.3.2 Ball Valve – Inspection and Repair

1. Disassemble both the suction and discharge check valves.

The ball seats should have sharp edges or a small chamfer and be free from dents or nicks.

2. Examine components for wear by holding the ball firmly against its mating seat in front of a

bright light to inspect for fit.

Observation of light between the ball and seat is cause for replacement of either or both

components.

3. Reassemble both valves using new parts as required. The o-rings should always be replaced.

7.3.3 Disk Valve – Inspection and Repair

1. Disassemble valves and inspect components for wear.

The seats and lower disk surfaces contacting the seats should remain flat and smooth.

Although it is normal for the o-ring in the seat to be flattened after significant use,

replacement is recommended as a part of valve maintenance.

2. The seat o-ring is captured by an internal lip in its groove in the seat. Removal requires the

following destructive procedure:

a) Position a small blade type screwdriver against the outer edge of the o-ring at an angle of

approximately 45 degrees.

b) Taking care not to damage the sides of the seat, drive the screwdriver into the o-ring.

c) Using the screwdriver, pry one section of the o-ring out of the groove.

d) Grip the O-Ring with pliers, and remove it from the seat.

3. To install the replacement seat o-ring; place it on the seat above the groove.

4. Position a flat metal object over the o-ring

5. Apply uniform light pressure using a hand arbor press.

The slight movement that accompanies seating can be easily felt through the press

handle.

DO NOT TRY TO INSTALL THE RING BY HAMMERING, AS THE SEATING WILL NOT BE

UNIFORM

IMPAIRED

6. Reassemble both valves using new parts as required. Sealing O-Rings should always be

replaced.

. THE RING MAY BE DAMAGED AND THE PUMP PERFORMANC E MAY BE

.

27

Page 32

7.3.4 Check Valve Reinstallation

1. Reinstall both valve assemblies, taking care to ensure that they are correctly oriented with balls

or disks above seats. Refer to Figure 14.

2. Tighten the tie bar bolts evenly, making sure the valve assemblies and tie bar are assembled

squarely. Refer to Appendix III for torque values.

For best results, always loosen the unions or flanges on either side of the system piping prior

to re-tightening the check valve assemblies. Retighten the unions or flanges after the check

valves are securely tightened into position.

3. Check for leaks and retighten tie bar bolts as necessary.

28

Page 33

7.4 Hydraulic Performance Valve (HPV)

During normal pump operation hydraulic fluid is continually discharged through the

automatic bleed valve and may also be lost past the piston seals. This causes the diaphragm

to be drawn further back on each successive suction stroke until it actuates the HPV. Once

the valve is actuated, oil is allowed to flow into the hydraulic system until the piston reaches

the end of the suction stroke. As the piston starts forward a Hydraulic Makeup Valve (HMV)

prevents oil from flowing back through the HPV, thereby allowing the valve to close as the

diaphragm moves forward. Through this process the diaphragm is continually maintained in

the proper operating position relative to the pump head dish plate. Since the HPV is

unaffected by the vacuum level in the pump head, oil cannot be inadvertently brought into the

hydraulic system which would result in over-extension and damage to the diaphragm. This

feature provides pump protection should the suction line become intermittently restricted or

closed.

PulsaPro 900

are factory preset and require no maintenance provided the oil remains clean. Should the

HPV require removal for cleaning or replacement follow the below procedure.

High Performance Valves (HPV) and Hydraulic Makeup Valves (HMV)

Figure 15

29

Page 34

7.4.1 HPV Removal and Replacement

1. Disconnect the power source to the drive motor (e.g., lockout/tagout the motor disconnect).

2. Relieve all pressure from the piping system.

3. Drain the oil from the eccentric box / pump head by opening the drain valve.

4. Remove the reagent head and diaphragm using the procedure outlined in Section 7.1.

5. The dish plate is held in the pump head by two sealing o-rings. Install screws into the two M4

x 0.7 threaded jacking locations to remove the HBV / Dish plate assembly properly. Tighten

them into the dish plate to jack it out of the pump head. Take care to prevent dropping the

dish plate on final removal.

Jacking

O-Rings

Locations

6. If cleaning of the valve is required, use a solvent compatible with Nitrile rubber and blow air

through the valve to remove all contaminants.

7. Inspect the O-Rings on the body of the valve for nicks or other damage and replace if

required.

8. Lubricate the O-Rings with PULSAlube Universal or Ultra and carefully insert the HPV

into the dish side bore of the pump head.

9. Rotate the valve and dish insert into the pump head until the hole on the back side of the outer

edge aligns with the alignment pin. Seat dish in counter bore.

ALIGNMENT PIN

30

Page 35

Figure 16

10. Reinstall the diaphragm and the reagent head using the procedure outlined in Section 7.1.

11. Close the Gearbox / Pump Head drain valve and fill with PULSAlube Universal or Ultra

hydraulic oil.

12. Re-prime the pump head.

7.5 Hydraulic Bypass Valve (HBV)

All

PulsaPro

designed to protect the pump against excessive hydraulic pressure encountered during system

upset (it will not limit or regulate system pressure). It is constructed of an adjustable spring

loaded valve ported into the hydraulic cavity of the pump head. The valve is factory-set at 10%

above the rated pump discharge pressure or as specified at the time of order.

Series pumps incorporate a Hydraulic Bypass Valve (HBV). This valve is

OBSERVE

HBV FLOW

HERE

ADJUST

HBV

HERE

Figure 17

The HBV is located on the left side of the pump head as you face the reagent head. Discharge

from this valve is visible through a large diameter tube located behind the diagnostic port that

faces the same side of the pump (refer to figure 17). Whenever discharge is visible, it indicates

the pressure in the pump discharge piping exceeds the HBV setting. After confirming the

discharge pressure is within the rated pressure of the pump it may be necessary to adjust the

HBV setting.

Adjusting the HBV Valve:

1. Remove the valve adjustment cover.

2. Loosen the locknut.

3. Tighten the adjustment bolt by turning clockwise (as seen facing the screw) to increase

the bypass pressure. Loosen the bolt by turning counterclockwise to decrease it.

4. Re-tighten the locknut after adjustment.

5. Re-install the valve adjustment cover.

Pump damage may occur during a system upset if the hydraulic bypass pressure is set higher

than 10% over the design pressure of the pump (refer to the nameplate rating). Conversely, if

31

Page 36

the setting is too low the valve will operate on each discharge stroke. This results in decreased

pumping capacity and will eventually affect the efficiency of the valve.

To check the hydraulic bypass pressure setting, install a gauge and a back pressure valve in the

pump discharge line. The gauge must be between the pump and the back pressure valve (for

convenience, locate the two as close to the pump as possible). With the pump operating at

maximum stroke length, gradually increase the discharge pressure and observe when the HBV

starts to operate through the diagnostic window. The cracking pressure of the valve must be at

least as high as the maximum pressure of the system but no more than 10% over the pump’s

rated pressure. After adjustment tighten the lock nut and reinstall the metal cover.

Periodic inspection of the valve seat is recommended. If it becomes worn or damaged leakage

will occur regardless of how tightly the valve is adjusted.

7.5.1 PTP (Push To Purge) Valve

OBSERVE

PTP FLOW

HERE

Figure 18

The PTP (Push to Purge) Valve is a gravity-operated disk check valve that automatically

removes gases from the hydraulic system. On each discharge stroke of the pump, pressure

generated by the piston lifts the disk off a lower seat. If accumulated gasses are present the

gasses flow around the disk and are vented to the reservoir. If there are no gasses present

then oil forces the disk to shut off against an upper seat – limiting the amount of fluid that

escapes. On each suction stroke, the disk returns (by gravity) to the lower seat to prevent

reentry of gas into the system. By this mechanism, under normal operation, a small amount

of oil is displaced with each discharge stroke. This oil is returned by gravity to the reservoir

where it is recycled. The PTP removes minute accumulations of gas long before they are

visible or detrimental to pump operation.

The PTP includes a spring-loaded button at the top of the valve that is used to accelerate the

purging of accumulated gasses in the hydraulics. Holding the button down momentarily

opens the disk valve so that large amounts of gas and hydraulic fluid can be instantly purged.

When the button is released, the valve returns to normal automatic operation. PTP operation

can be monitored by observing oil flow through the small tube behind the diagnostic window.

32

Page 37

7.5.2 PTP Removal, Cleaning, and Reinstallation

Any accumulation of solids can cause the valve to malfunction.

1. Disconnect the power source to the drive motor (e.g., lockout/tagout the motor disconnect).

2. Relieve all pressure from the piping system.

3. Slowly unscrew the valve to gradually relieve any residual hydraulic system pressure.

OIL MAY LEAK OUT FROM AROUND THE PTP VALVE. TAKE APPROPRIATE

MEASURES TO CAPTURE AND CONTAIN IT

4. Remove the valve and clean it by soaking in a petroleum based solvent.

Valve operation can be confirmed by blowing air through it in both directions and listening

for the “click” sound of disk-seat contact in both directions.

5. Verify that the copper gasket is installed at the bottom of the threaded hole in the pump head.

The copper gasket need not be replaced provided that it is sound and undamaged.

The elastomeric gasket around the upper portion of the valve assembly may be likewise re-

used.

This valve is not repairable and must be replaced if it continues to malfunction after

cleaning.

.

PTP BUTTON

O-Ring

Copper Gasket

Figure 18a

33

Page 38

7.5.3 Piston Seal

7.5.3.1 General Description

The piston assembly has 2 different design structures as shown in Figure 19. With proper

maintenance, piston seals should give you years of service.

Figure 19

Figure 20

34

Page 39

7.5.4 Piston Removal

Piston Removal Procedure:

1. Remove reagent head, and dish plate using the procedure defined in Section 7.4.1, HPV

Removal.

2. Remove the nut from the end of the cross head shaft assembly.

3. Set the stroke adjustment setting to 100%.

4. Rotate the Motor by hand (confirm lockout/tag out) until the piston achieves its full forward

position.

5. Continue Motor rotation until the cross head shaft is pulled from the hole in the center of the

piston assembly.

6. Hook the piston assembly through hole in center and pull the piston straight out of the piston

bore by exerting even tension.

7.5.5 Piston Seal Reinstallation

Piston Reinstallation Procedure:

It is important to apply an anaerobic thread locking compound (Loctite® 242™ Henkel

Corporation) to the threads of the hex nut and torque to 140 foot-pounds to prevent

loosening during operation.

Figure 21

35

Page 40

1. Apply PULSAlube Universal or Ultra hydraulic oil to all the piston assembly components. No

matter which piston size you have.

For 4 inch pistons and larger please follow these instructions:

1.1 Slide the smaller of the 2 o-rings over the threaded end of the cross head.

1.2 Install the spacer onto the threaded end of the cross head.

1.3 Install the piston cup with the outer lip facing away from the cross head.

1.4 Install the larger o-ring into the groove on the outside diameter of the Expander.

1.5 Install the expander onto threaded end of the cross head.

1.6 Assure all components slide back onto the threaded end of the cross head until they

bottom out (refer to Figure 21).

1.7 Please confirm that the expander with the o-ring on the outside diameter lies flat

inside the piston cup when fully pushed rearward. Proceed to Step 2 of this section.

For 3 inch pistons and smaller please follow these instructions:

1.1 Slide the smaller of the 2 o-rings over the threaded end of the cross head.

1.2 Install the seal retainer onto the threaded end of the cross head.

1.3 Install the seal onto the seal retainer. Make sure the seal is seated properly all the way

around the retainer.

1.4 Install the unitized piston.

1.5 Assure all components slide back onto the threaded end of the cross head until they

bottom out (refer to Figure 21).

1.6 Please double check the seal to assure it is seated properly to the seal retainer. Proceed

to Step 2 of this section.

2. Install the flat washer and lock washer onto the end of the threaded shaft.

3. Apply Loctite® 242 (™ Henkel Corporation) removable anaerobic thread locking compound to

the threads on the threaded end of the Cross head.

4. Hand tighten the Piston retaining nut onto the threaded end of the cross head.

5. Torque the nut to 140 foot-pounds. This will draw the piston onto the end of the cross head and

cause it to bottom out on the shoulder.

IT IS IMPORTANT TO USE THE CORRECT THREAD LOCKING COMPOUND AND TORQUE

THE PISTON RETAINING NUT

FAILURE OF THE PISTON ASSEMBLY AND RESULT IN DAMAGE THAT IS NOT COVER ED

UNDER WARRANTY

6. Replace the reagent head and diaphragm as described in Section 7.1, Wet End Removal,

Inspection and Reinstallation.

7. Fill the pump head with PULSAlube Universal or Ultra and prime the pump head as

described in Section 6 – Equipment Startup.

.

. FAILURE TO DO SO CAN RESULT IN CATASTROPHIC

36

Page 41

7.6 Oil Seals

7.6.1 General Description

The

PulsaPro 900

seals. Only one (the Worm Oil Seal) is dynamic and should be serviced at regular intervals.

Worm Oil

Seal

Rear Cover

Seal

Worm

Bearing

Cover

gear box has seven primary oil seals. Six of these are static o-ring

Pump

Head Seal

Sub-Cover

Seal

Main Cover

Seal

Figure 23

Eccentric

Cover Seal

37

Page 42

7.6.2 Motor Adaptor Oil Seal Removal and Replacement

7.6.2.1 Motor Adaptor Removal and Worm Oil Seal Replacement

1. Disconnect the power source to the drive motor (e.g., lockout/tagout the motor disconnect).

2. Attach required lifting device to the motor. Do not put any tension on the pump motor at this

time.

3. Remove the four Motor Attachment Bolts from the motor (refer to Figure 24).

4. Open the Access Panel by removing the three Access Panel Screws.

Figure 24

5. Remove the Motor and Upper Coupling assembly by lifting straight up.

6. Remove the four motor adapter bolts and lift the motor adapter from the gearbox.

7. Rotate the Lower Coupling Assembly by hand until the Coupling Setscrew is visible.

8. Loosen the Lower Coupling Setscrew.

9. Remove the lower coupling and coupling spider.

Figure 25

38

Page 43

Figure 26

10. Remove the four seal retainer bolts and seal retainer.

11. Remove the input shaft oil seal from the input shaft adjustment nut.

12. Lubricate the replacement input shaft seal with silicone grease or PULSAlube Universal or

Ultra.

13. Slide the input shaft adjustment nut onto the input shaft and begin tightening. The input shaft

adjustment nut should have about .002in (0.05mm) max end play.

14. Install the input shaft oil seal by pressing it into position. Be careful not to cut the seal on the

key way of the shaft.

15. Install the Motor Adaptor over the gearbox input shaft and then bolt in place.

16. Slip the Lower Coupling and Spider over the input shaft.

17. Position the coupling half flush to the end of the input shaft.

18. Tighten the coupling setscrew.

19. Lower the motor / Upper Coupling into position. As you are positioning the motor, it may be

necessary to rotate the Lower Coupling / Spider assembly to facilitate proper alignment.

20. Once the coupling is aligned, lower the motor assembly until full contact has been made with

the lower coupling.

21. Insert and tighten the motor mounting bolts that were removed in Step 3.

22. Restore power to the

PulsaPro 900

pump assembly.

39

Page 44

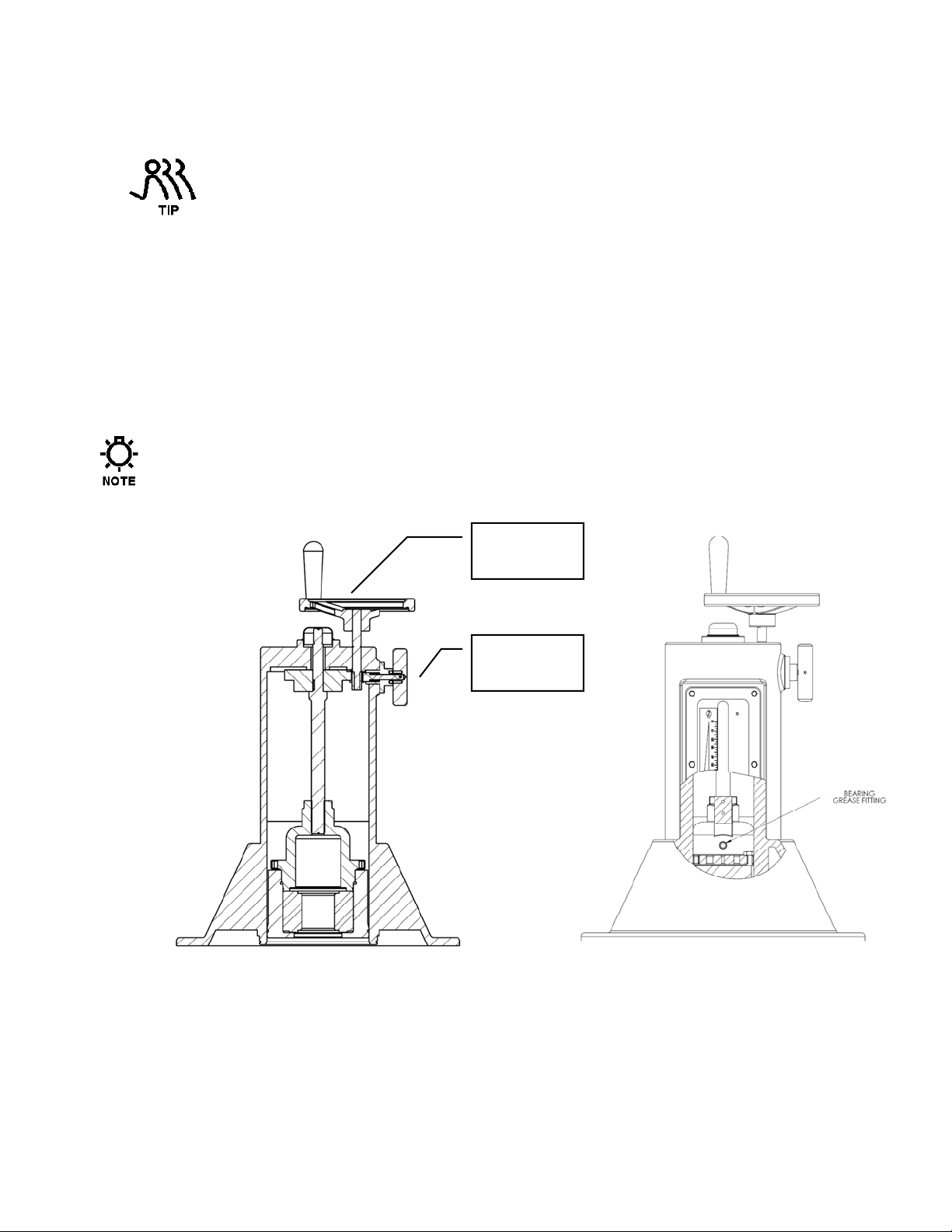

7.7 Stroke Control Assembly

7.7.1 Stroke Control Assembly Maintenance

The stroke adjust housing has grease fittings that will need to be maintained.

(Refer to Figure 27).

1. Disconnect the power source to the drive motor (e.g., lockout/tagout the motor

disconnect).

2. To access the grease fitting remove Qty 6 lens cover bolts.

3. Remove the protective lens cover.

4. Adjust the stroke setting from 100 % down to approximately 65%. The grease fitting

should be visible in the slot that the stroke setting indicator rides in.

5. Use a standard grease gun to inject Heavy Duty Grease (e.g., NLGI #2 Lithium

Complex Grease) until resistance is felt.

6. Use a standard grease gun to inject Heavy Duty Grease (e.g., NLGI #2 Lithium

Complex Grease) into grease fitting “A” until grease is seen squeezing out from gear

area. To observe the gear area in the stroke adjust housing remove the stroke lock

mechanism from the stroke adjust housing. See Figure 27 Right picture.

Grease Fitting “A” Remove stroke

lock to observe

gears being greased

Figure 27

40

Page 45

7.8 Motor Removal and Reinstallation

1. Disconnect the power source to the drive motor (e.g., lockout/tagout the motor disconnect).

2. Disconnect the motor wiring from the motor.

3. Attach required lifting device to the motor. Do not put any tension on the pump motor at this

time.

4. Remove the four Motor Attachment Bolts from the motor (refer to Figure 24). Some European

motors will have eight bolts

5. Open the access panel by removing the three access panel screws to expose the coupling.

The coupling is an interlocking jaw design and uses an elastomeric spider between the two

coupling halves. The upper half of the coupling remains on the motor shaft and the lower

half stays on the worm gear shaft.

6. Lift the motor from the mounting adaptor.

7. If the motor is to be replaced, position the “old” motor so that the upper coupling is accessible.

8. Loosen the upper coupling setscrew to allow removal of the upper coupling half, taking care to

not lose the shaft key.

9. Install the upper coupling half on the shaft of the replacement motor, ensuring that the shaft key

is in place.

10. Align the end of the shaft flush with the inner surface of the coupling and tighten the setscrew.

11. Reinstall the motor by reversing the steps above.

41

Page 46

8. Replacement Parts

8.1 PulsaPro Series KOPkit Program

PulsaPro

maintenance program.

PULSAlube Universal or Ultra is available for preventative maintenance programs.

Refer to the Equipment Startup section.

There is a specific KOPkit for every

KOPkit is vacuum-packed for extended storage.

PulsaPro

All

a) the pump nameplate,

b) the specification data sheet, and

c) the Pulsafeeder order documents.

KOPkits can also be selected from the technical data sheet shipped with the pump or by a

Pulsafeeder representative.

Series KOPkits contain all replacement parts normally used in a preventative

PulsaPro

Series pumps will have the KOPkit number identified on:

8.2 Ordering KOPkits or Parts

When ordering replacement parts always specify:

Series pump model. When practical, each

a) Pump model and serial number (stamped on pump nameplate), e.g., Model No.

PRO9000000X with Serial No. X775123.

b) Part number and description from the

character suffix.(TNR)

PulsaPro

e.g., NP170001-TNR or W210221-001.

Series part numbers begin either with the letters “NP”, “RS” or the letter “W”,

PulsaPro

Series parts list. Include the three-

42

Page 47

9. PULSAlarm Leak Detection Assembly

The PULSAlarm leak detection assembly consists of a reagent head, leak detection

diaphragm, fill port, and pressure switch and gauge. The reagent head, diaphragm, suction

and discharge check valves are the only parts of the pump to contact the process liquid consequently, maintenance is critical to pump performance.

Figure 24

A SEALED SYSTEM MUST BE MAINTAINED AT ALL TIMES DURING PUMP OPERATION,

WHETHER LEAK DETECTION IS REQUIRED OR NOT

IS NOT PRESENT

, DECREASED FLOW AND/OR DIAPHRAGM DAMAGE WILL OCCUR.

. IF A SEALED PRESSURE SYSTEM

PLEASE NOTE THAT THE FACTORY SET POINT FOR ACTUATION OF THE PRESSURE

SWITCH IS

25 PSIG.

43

Page 48

9.1 PULSAlarm Leak Detection Diaphragm

Double, or sandwiched, TFE diaphragms are sealed at their peripheries to an intermediate

metal spacer ring. The space between the diaphragms is sealed so that the diaphragm

functions in a manner similar to a standard single diaphragm. In the pressure system, the

space between the diaphragms is filled with a small amount of fluid. At startup, any excess

fluid in the system is expelled through the check valve. Once the excess is removed the

system is capped and sealed. The fluid as supplied from the factory is Silicone LD, but an

alternate fluid can be used if compatibility with the materials of construction is verified. This

space is connected to an adjustable electrical switch (optional) that actuates in response to

buildup of pressure resulting from rupture of either or both diaphragms. Switch operation can

be used to perform any external function, typically to signal an alarm or turn off the pump.

For component location refer to Figure 24.

9.2 Leak Detection – Setup for Pressure

Pumps incorporating pressure leak detection are shipped from the factory with the system fully

set up to work at full pump pressure. No further setup is required. The standard factory barrier

fluid is Silicone LD, if any other customer-specified media is used it must be compatible with

construction materials. The system will require proper setup after maintenance or repairs see

section 9.3 on the following page for the proper procedure.

Figure 25

44

Page 49

Pressure System Set-up and Priming

If the pressurized leak detection system is opened to the atmosphere during maintenance

or inspection, the system must be re-primed properly to avoid diaphragm damage and

ensure proper leak detection operation and system performance.

THE STANDARD FACTORY INTERMEDIATE FLUID IS SILICONE LD. IF ANY OTHER

CUSTOMER

OF CONSTRUCTION

APPROPRIATE SAFETY PRECAUTIONS

Use the following procedure to set-up the pressurized leak-detection system:

1. Complete re-assembly of the diaphragm, reagent head, and external components. Ensure

that reagent head and tie-bar bolts are tightened according to the appropriate torque

specifications (consult Appendix III)

2. Remove the pressure gauge from the housing body and replace with the straight tubing

connection supplied with the pump. Connect a vacuum supply (hand vacuum pump) to the

tube fitting.

-SPECIFIED MEDIA IS USED, IT MUST BE COMPATIBLE WITH THE MATERIALS

. REFER TO THE FLUID MANUFACTURER’S LITERATURE FOR

.

If the system was previously sealed, you may need to remove the plug and re-install the

hose fittings at the fill port. There should be a container in the vacuum line to trap excess

barrier fluid. An inexpensive automotive brake bleeding kit is appropriate for this

purpose.

3. Connect the fill tube to the fill valve tube connection. Any short length of the appropriate

sized tubing may be used for this purpose.

4. Open the fill valve.

5. Place the fill tube into a container of the barrier fluid being used.

6. Apply vacuum, the fluid should rise into the fill tube and enter the system.

7. Observe the fluid at the exit (vacuum pump) side. When clear, air free fluid is observed,

close the fill valve, while maintaining the vacuum on the system to begin the process of

drawing out excess fluid.

If you are re-using a previously installed diaphragm, it will take time for the Silicone LD

fluid to migrate through the system, be patient!

8. Release the vacuum, and remove both the fill tube and the vacuum pump from the fittings.

9. Empty the fill tube of fluid, and place it on the fitting near the switch, extending upwards, and

open to the atmosphere.

10. Ensure that the eccentric box of the pump has been filled to the appropriate level with the

correct hydraulic fluid.

11. Adjust the pump to the zero stroke (0%) position.

45

Page 50

12. If the pump is not already hydraulically primed, remove the PTP valve from the top of the

pump head. Using a plastic funnel or similar, slowly pour hydraulic fluid into the pump head

cavity until full. The end of the funnel should fit into the small diameter hole at the bottom of

the PTP socket – not the larger threaded diameter. The threaded diameter includes a side

drain passage that will prevent oil from entering the pump head if used. Alternatively apply a

Drain

Passage

vacuum to the bottom hole of the PTP socket to draw oil from the makeup valve.