Page 1

Standard Product Operations

27101 Airport Rd., Punta Gorda, FL 33982

Tel: (941) 575-3800 Tel: (800) 333-6677

Fax: (941) 575-4085 Fax: (800) 456-4085

spotech@pulsa.com www.Pulsafeeder.com

Manufacturers of Quality Pumps,

Controls, and Systems

Installation, Operation and Maintenance

Manual

Automatic Polymer Makedown Systems

72-910-APMDS-E Rev A

Page 2

Automatic Polymer Makedown Systems

Installation, Operation and Maintenance Manual

Pulsafeeder Factory Service Policy

Should you experience a problem with your Polymer Makedown System, first consult the

troubleshooting guide in this operation and maintenance manual, as well as the information in the

manual for your Pulsatron pump. If the problem is not covered or cannot be solved, please contact

your local Pulsafeeder Sales Representative or Distributor, or our Technical Services Department for

further assistance.

Trained technicians are available to diagnose your problem and arrange a solution. Solutions may

include purchase of replacement parts or returning the unit to the factory for inspection and repair. All

returns require a Return Authorization number to be issued by Pulsafeeder. Parts purchased to correct

a warranty issue may be credited after an examination of original parts by Pulsafeeder. Warranty parts

returned as defective which test good will be sent back freight collect. No credit will be issued on any

replacement electronic parts.

Any modifications or out-of-warranty repairs will be subject to bench fees and costs associated with

replacement parts.

Copyright ©2013 Pulsafeeder, Inc. All rights reserved.

Information in this document is subject to change without notice. No part of this publication may be

reproduced, stored in a retrieval system or transmitted in any form or any means electronic or

mechanical, including photocopying and recording for any purpose other than the purchaser’s personal

use without the written permission of Pulsafeeder, Inc.

72-910-APMDS-E Rev A

ii

Page 3

Automatic Polymer Makedown Systems

Installation, Operation and Maintenance Manual

Table of Contents

Topic Page

Introduction ........................................................................................................... 4

Safety .................................................................................................................... 5

Skid Layout and Component Descriptions ........................................................... 6

Systems Overview ................................................................................................ 7

Supply Side ..................................................................................................... 7

Process Side .................................................................................................... 8

Installation ............................................................................................................ 9

Owner Installed Piping/Tubing, & Electrical ................................................. 9

Schematic ............................................................................................................ 11

Initial System Start ............................................................................................. 12

Initial Prime .................................................................................................. 12

System Operation ................................................................................................ 13

Polymer Makedown Process ............................................................................... 13

72-910-APMDS-E Rev A

iii

Page 4

Automatic Polymer Makedown Systems

Installation, Operation and Maintenance Manual

Introduction

Congratulations! With the Pulsafeeder Pre-Engineered Polymer Makedown System, you have the

finest polymer makedown equipment platform available. This system includes the essential elements

for successful installation and operation of your system(s). You are encouraged to:

READ THIS MANUAL!

Pulsafeeder Pre-Engineered Polymer Makedown Systems are designed to support multi-pump

installations for injection. The skid components (valves, gauges, interconnecting piping, etc.) are

furnished to meet your specified operational requirements. The Dosing Pump(s), per se, may be

furnished separately, so installation, operation and maintenance instructions for pump(s) are located

elsewhere.

72-910-APMDS-E Rev A

Introduction Page 4

Page 5

Automatic Polymer Makedown Systems

!

WARNING

Do NOT use Pulsafeeder Systems (or Pulsafeeder Pumps) for flammable liquids.

!

WARNING

Prior to working on any portion of the System, disconnect pump(s) from power supply,

de-pressurize the system and drain chemicals from the lines.

!

WARNING

Inspect tubing regularly and replace as necessary.

When inspecting tubing, wear protective clothing and safety glasses.

!

CAUTION

If skid is exposed to sunlight, use UV-resistant tubing.

!

CAUTION

Follow directions and warnings provided with chemicals from the chemical

manufacturer. User/owner is responsible for determining chemical compatibility with

chemical feed pump(s) and system components.

!

CAUTION

Secure chemicals, metering pump(s) and system, making them inaccessible to

children, pets and unauthorized personnel.

!

WARNING

Always wear protective clothing including gloves and safety goggles when

working on or near chemical metering pumps and systems.

Installation and start-up of chemical dosing system will require both mechanical

(plumbing) and electrical work. Only qualified and licensed plumbers and

electricians should perform this.

!

CAUTION

Installation, Operation and Maintenance Manual

Safety

Your safety is of the utmost concern to Pulsafeeder. Dosing pumps and systems can handle harsh or

toxic chemicals and exposure can lead to serious injury or death. Always wear appropriate protective

clothing (for example, safety glasses, gloves, coveralls, etc.) and follow safe handling procedures. Pay

attention to what you’re doing and note safety advisories where they are shown throughout this

manual. Some examples of safety issues and precautions for Pulsafeeder Pre-Engineered Polymer

Makedown Systems are:

72-910-APMDS-E Rev A

Safety Page 5

Page 6

Automatic Polymer Makedown Systems

!

CAUTION

Never remove the Tank Cover without removing power to the Polymer

Makedown System first. The tank mixer blades (inside the tank) can cause serious

harm or even death if allowed to come in contact with a person during operation.

Installation, Operation and Maintenance Manual

System Layout and Components

Figure 1, below, illustrates a static mixer polymer makedown system with integrated control and daytank. This system can be used for two different chemicals or for redundant pump operation with one

chemical. Your skid system may be less complex than this. Note the various components and their

descriptions as they apply to your system.

72-910-APMDS-E Rev A

Skid Layout and Components Page 6

Page 7

Automatic Polymer Makedown Systems

Mixer, Tank

Level Sensor

Control Panel

Calibration

Column

Flow Indicator,

Water

Static Mixer

Made-down

Polymer Day

Tank

Back Pressure Valve

Water Inlet, Left Side, Back or Front

Mounting Base

Made-down

Polymer Inlet

Made-down

Polymer Outlet

to Day-tank

Neat Polymer

Injection Quill

Neat Polymer Inlet

Neat Polymer Pump

Pump Power Supply

Calibration

Column Fill

Valve

Low Flow Switch

Figure 1

Made-down

Polymer outlet

tp Process

Installation, Operation and Maintenance Manual

72-910-APMDS-E Rev A

Skid Layout and Components Page 7

Page 8

Automatic Polymer Makedown Systems

Pump

Neat

Polymer

Tank

Supply

Line

Figure 3

Flooded Suction

Flooded Suction

This is the most trouble free type of installation.

Since the Supply Line tubing is filled with

chemical, priming is accomplished quickly and the

chance of losing prime is reduced.

Recommended for very low flow rate applications.

e.g. 2 ml/hr, or where pumping solutions such as

sodium hypochlorite or hydrogen peroxide which

can form air bubbles.

Supply Line should gradually slope downward

from the Solution Tank to the Skid Suction

Connection.

It is strongly recommended to add a drain

provision on the suction side to facilitate

emptying and flushing of the system for

maintenance.

Installation, Operation and Maintenance Manual

Systems Overview

The Polymer Makedown System is designed to inject neat polymer into a clean water stream and to

agitate this mixture through a static mixer causing the polymer strands to expand into a ‘made-down’

aqueous solution. The solution is stored in the polymer solution day-tank and mixed occasionally with

the rotary mixer located in the tank. The tank outlet is typically connected to the dosing pump(s) which

inject the solution into the process application. The dosing pump(s) are not provided with the Polymer

Makedown System and are not powered by the System.

Supply Side

Dosing chemicals are usually sourced from a barrel or tote container. The source must be located

above the centerline of the neat polymer pump which is referred to as a “flooded suction”. Because

Neat Polymer is a high viscosity fluid, the supply should never be located below the centerline of the

pump(s) which is referred to as “suction lift.” Connections to and from the Neat Polymer Tank are

most commonly made with flexible hose or tubing although they may be made with hard piping. The

Neat Polymer Tank should be covered to prevent contamination.

Process side

72-910-APMDS-E Rev A

Skid Layout and Components Page 8

Page 9

Automatic Polymer Makedown Systems

Installation, Operation and Maintenance Manual

The injection point in the served process or system must be higher than the top of the Solution Supply

Tank to prohibit gravity feeding unless suitable backpressure is always present at the injection point.

In applications where the injection point is below the Solution Supply Tank (example – injection

into a well) or where the injection point may be at reduced pressure (example – injection into the

suction side of a pump), installation of an anti-siphon valve in the process feed line will prevent gravity

feeding.

Note: For some applications where air or gas may form in the suction line, this may interrupt flow.

In this case, it may be desirable to add a “Proof of Flow” device on the process side to alert if chemical

injection flow is somehow interrupted. Contact your Pulsafeeder distributor.

72-910-APMDS-E Rev A

Skid Layout and Components Page 9

Page 10

Automatic Polymer Makedown Systems

!

CAUTION

Some dosing chemicals will react with water, e.g., acids, polymers, etc. Check MSDS

for the chemical to be handled. If adverse reaction with water is indicated, ensure that

all portions of the skid piping, its components (and the pump) are free from water prior

to filling skid system with chemical.

CAUTION

If skid is exposed to sunlight, use UV-resistant tubing.

!

WARNING

Ensure that for all piping, tubing, fittings and other appurtenances, their materials are

compatible with the liquid to be pumped and the design is suitable for the pressures and

temperatures of the application. System design must ensure safety for operation and

maintenance as well as for anyone who may be in proximity to the system.

Failure to do so may result in damage to equipment, personal injury or death.

Installation, Operation and Maintenance Manual

Installation

Prior to attempting installation, familiarize yourself with the layout and components furnished with

your Pulsafeeder Polymer Makedown System. These vary from system to system – review the

documentation supplied with your order. Inspect your system for damage which may have occurred

during transit. If damage is discovered, immediately file a claim with the carrier and contact your

Pulsafeeder distributor for any required replacement parts or components.

All systems (and pumps) have been tested with water at the factory.

Polymer Makedown Systems are to be floor-mounted only. Mounting holes are provided on the skid

for floor mounting. Securely attach skid and the day-tank to the floor, in a position to prevent falling

or tipping.

Securely attach the provided ¾” x ½” diameter x 10’ long tubing from the system’s Made-down

Polymer Outlet to the Day-tank’s Made-down Polymer Inlet, on the hose barbs with the hose clamps

provided; refer to Figure 1 on page 6. It is best to cut this tubing to the desired length prior to

installation, and be sure to support the tubing adequately over its length as its weight will increase

when filled with made-down polymer.

Installation area should provide ease of access to skid components (and pumps) and the area should be

kept free of clutter to enable safe operation and maintenance.

Note that pumps/motors are designed for ambient temperatures of 104OF (40OC) maximum.

It is preferable that skid systems (and pumps) be located out of direct sunlight. If skid system is

exposed to sunlight, provide protection for the pump/motor to prevent overheating and UV damage.

Owner-Installed Piping/Tubing

The next series of steps are the connection of your piping/tubing which include the neat polymer

supply line and tank outlet for made-down polymer supply to the system.

These are your responsibility.

72-910-APMDS-E Rev A

Skid Layout and Components Page 10

Page 11

Automatic Polymer Makedown Systems

Installation, Operation and Maintenance Manual

Neat Polymer Supply Line

This line connects the source of the neat polymer to the Pulsafeeder Polymer Makedown System.

Please refer to Figure 1 on page 6. The neat polymer source must be located above the centerline of

the pump (flooded suction condition); ensure that the suction line has a gradual downward slope from

the tank to the skid suction connection. The purpose of this is to prevent air pocket(s) in the suction

line which could affect proper operation of the pump. Include whatever provisions you consider

necessary to facilitate maintenance and operation such as isolation valve(s), drain and/or flush

connections, etc., making sure that this sub-system enables SAFE OPERATION.

Discharge Line

This line connects the Pulsafeeder Polymer Makedown System to your served process. Please refer to

Figure 1 on page 6. If the injection point is below the dosing chemical source or if injecting into a low

pressure area such as the suction of a pump, an anti-siphon/ back pressure valve should be located as

close as possible to the injection point to prevent unwanted chemical feeding. Include whatever

provisions you consider necessary to facilitate maintenance and operation such as isolation valve(s),

drain and/or flush connections, etc., making sure that this sub-system enables SAFE OPERATION.

Electrical Connection

The control panel is provided with a standard plug for connection to 115V (+/-10%) , 20A power to

operate.

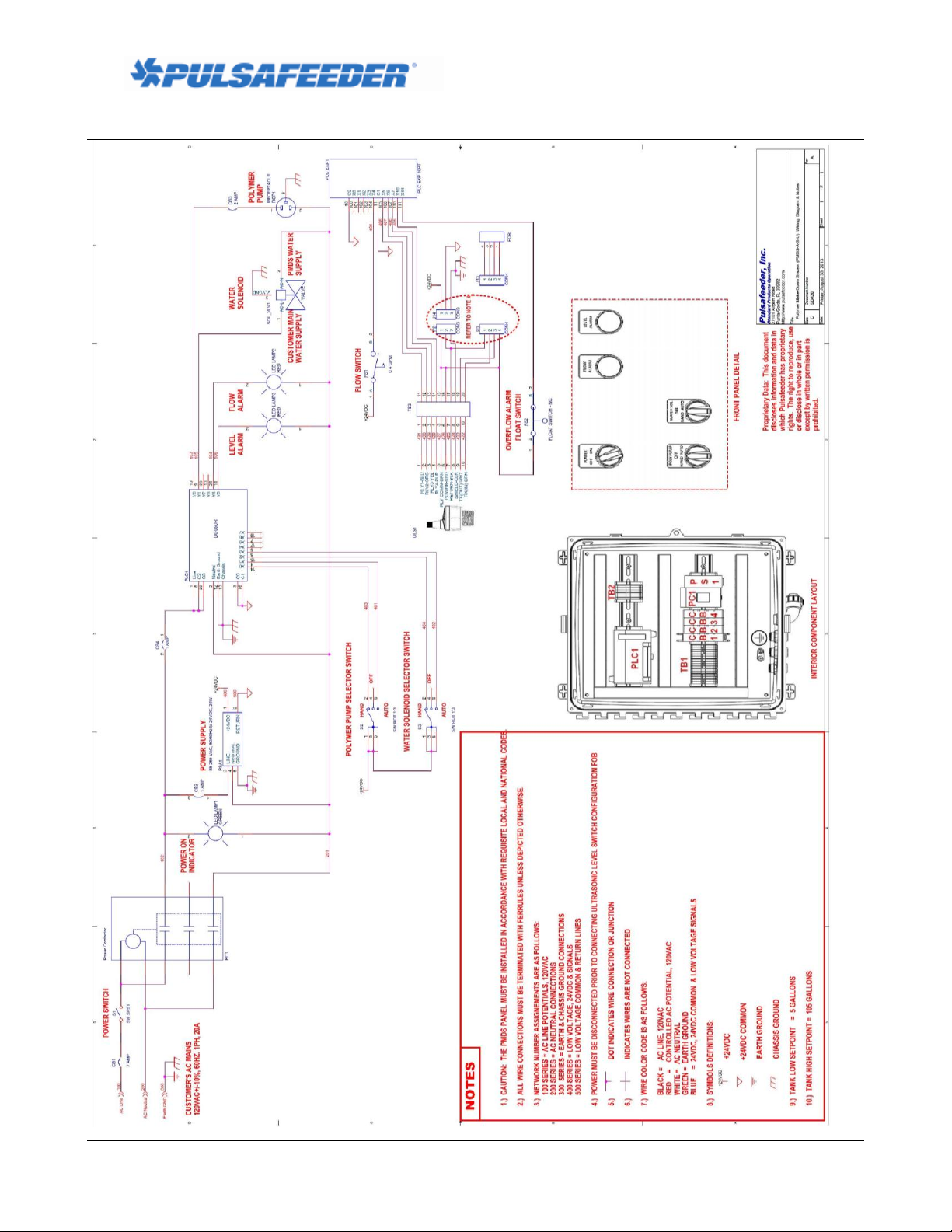

Electrical Schematic

Refer to diagram on page 11.

72-910-APMDS-E Rev A

Skid Layout and Components Page 11

Page 12

Automatic Polymer Makedown Systems

Installation, Operation and Maintenance Manual

72-910-APMDS-E Rev A

Skid Layout and Components Page 12

Page 13

Automatic Polymer Makedown Systems

Selecting the manual operation mode marked “HAND” for any of the switches

will operate that device without regard for any of the safety features or alarm

modes that may be active. All safety requirements are the responsibility of the

operator while in manual “HAND” mode.

!

CAUTION

Installation, Operation and Maintenance Manual

Initial System Start

Be sure that all selectors are in the “OFF” position before power is connected; this includes:

1. Main Power switch, marked “POWER”.

2. Neat Polymer Feed Pump switch, marked “POLY. PUMP”.

3. Water Inlet Solenoid Valve switch, marked “WATER SOL.”.

4. Polymer Tank Mixer switch, marked “MIXER”.

Initial Prime

The neat polymer pump must be primed before it can function within the system. This will require an

initial start of the pump. It is recommended that the system piping be filled with water before polymer

is introduced to the system.

1. Turn the Main Power switch to the “On” position.

2. Turn the Water Inlet Solenoid switch marked “WATER SOL.” to “HAND” position to initiate

water flow.

3. Once water starts to enter the Polymer Storage Tank, turn the Water Inlet Solenoid switch

marked “WATER SOL.” to “OFF” position to terminate water flow.

4. Open the Calibration Column Fill Valve; this aids in pump priming by providing a vent path to

the calibration column, bypassing the Back Pressure Valve.

5. Turn “POLY. PUMP” switch to “Hand” to start the Neat Polymer Pump.

6. Observe polymer flow through the clear braided tubing connecting the pump discharge to the

system piping; when present the pump is primed.

7. Turn “POLY. PUMP” switch to “OFF” to stop the Neat Polymer Pump.

8. Close the Calibration Column Fill Valve.

72-910-APMDS-E Rev A

Skid Layout and Components Page 13

Page 14

Automatic Polymer Makedown Systems

1/9 = 1 minute “ON” followed by 9 minutes “OFF”

4/6 = 4 minutes “ON” followed by 6 minutes “OFF”

7/3 = 7 minutes “ON” followed by 3 minutes “OFF”

10/0 = 10 minutes “ON” with no “OFF” time; continuous operation

Installation, Operation and Maintenance Manual

System Operation

1. After the Neat Polymer Pump is primed, turn the Main Power switch, marked “POWER” to the

“OFF” position.

2. Turn the Neat Polymer Feed Pump switch, marked “POLY. PUMP” to the “AUTO” position.

3. Turn the Water Inlet Solenoid Valve switch, marked “WATER SOL.” To the “AUTO”

position.

4. Optional: Turn the Polymer Tank Mixer switch, marked “MIXER” to the “AUTO” position.

5. Optional: Select the Mixer Cycle desired:

6. Turn the Main Power switch, marked “POWER” to the “ON” position; the unit will begin to

function automatically.

Polymer Makedown Process

o Process Start

This is a polymer makedown system utilizes a batch process sequence. The makedown

process is triggered to start when the high level switch in the storage tank is open, and the

low level switch in the tank changes from closed to open, indicating that the level in the

tank has just dropped below the low level.

o Polymer Makedown for Tank Fill

When triggered to start the controller will energize the Water Inlet Solenoid Valve to open,

allowing municipal water to flow into the system. This flow is verified by the condition of

the Flow Switch changing from Open to Closed contact. At the same time the Neat Polymer

Pump is energized to pump neat polymer into the water flow where it is ‘made-down’ into a

polymer solution and stored in the storage tank. This process continues until the High Level

switch is closed, leading to the process flush cycle.

Flow Switch Interrupt – When the Water Inlet Solenoid Valve is open, the Flow Switch

status should show Closed to verify water flow in the system, and otherwise show Open

indication that water flow has terminated. There are two alarm conditions that will be

triggered by the Flow Switch, causing the Red ‘Flow Alarm’ light to illuminate and power

supply to be removed from the Water Inlet Solenoid Valve and the Neat Polymer Pump

until reset by the Flow Switch condition returning to that expected, or by removing power

from the PLC allowing this alarm to reset to off when power resumes.

72-910-APMDS-E Rev A

Skid Layout and Components Page 14

Page 15

Installation, Operation and Maintenance Manual

1. No Flow Alarm: There is a 5 second delay from the opening of the Water Inlet

Solenoid Valve to reading the flow switch status for alarm. If the Flow Switch

contact status is Open (indicating No Flow, or loss of incoming water) the alarm

condition in will be activated.

2. Undesired Flow Alarm: There is a 5 second delay following closure of the Water

Inlet Solenoid Valve to the reading the flow switch status for alarm. If the Flow

Switch contact status is Closed (indicating flow, or a failure of the Water Inlet

Solenoid Valve to close) the alarm condition in will be activated.

o Process Flush Cycle

This process begins when the Tank Fill operation has ended, triggered by the Low Level

Switch in the closed condition, and the High Level Switch moving from to open to the

closed condition. The Neat Polymer Pump will be de-energized and the Water Inlet

Solenoid Valve will be allowed to remain open for the ‘Flush Time’ period of 10 seconds.

When the Flush Time has expired, the Water Inlet Solenoid Valve will be de-energized

allowing it to close, ending the fill process.

Automatic Polymer Makedown Systems

Mixer Operation – Optional Equipment

o The mixer is a 115V, 1/3Hp propeller or paddlewheel style unit that is flange mounted to the tank,

with either a Fixed Speed or Variable Speed motor. It is actuated via the HOA switch on the

control panel. In ‘Hand’ setting the mixer will run continuously. In ‘Auto’ mode it will follow a

timer sequence as selected by the operator from a multi position switch on the control panel. For

the VFD option, the speed adjustment for the mixer can be made on the mixer motor.

Level Sensor Operation

o The Conductivity Level Sensor has 2 level positions that are pre-programmed into the unit, which

function as a Low Level Batch Start and a High Level Batch Stop. Each reports as discrete Dry

Contact signal. If the tank liquid level is above a particular set point, that contact will show as

closed, if below a particular set point the contact will show as open. The ‘High Level Alarm’ is a

separate float switch which will deactivate the system when closed. If this float ever comes in

contact with polymer it should be thoroughly cleaned or replaced.

o The Ultrasonic Level Sensor has 3 level positions that are pre-programmed into the unit, which

function as a Low Level Batch Start, a High Level Batch Stop and a High Level Alarm. Each

reports as discrete Dry Contact signal. If the tank liquid level is above a particular set point, that

contact will show as closed, if below a particular set point the contact will show as open. The ‘High

Level Alarm’ is a separate float switch which will deactivate the system when closed. If this float

ever comes in contact with polymer it should be thoroughly cleaned or replaced.

72-910-APMDS-E Rev A

Skid Layout and Components Page 15

Loading...

Loading...