Page 1

Automatic Flow Control for Chemical Feed Pumps

Installation, Operation &

Maintenance Manual

BULLETIN No. IOM-MPCV-0206 Rv. J

Manufacturers of Quality Pumps,

Controls and Systems

Engineered Pump Operations

2883 Brighton-Henrietta Townline Road

Rochester, New York 14623

Telephone: (585) 292-8000 Fax: (585) 424-5619

http://www.pulsa.com pulsa@idexcorp.com

Page 2

MPC VECTOR™ FACTORY SERVICE POLICY

Your MPC VECTOR is a state of the art microprocessor based motor speed control for use with Pulsafeeder

Eclipse Non-Metallic Gear Pumps. It includes extensive on-board diagnostics. If you are experiencing a

problem with your MPC VECTOR, first review the on-screen information, then consult the troubleshooting

guide. If the problem is not covered or cannot be solved, please contact your local authorized Sales

Representative or our Technical Service Department at (585) 292-8000 for further assistance.

Trained individuals are available to diagnose your problem and arrange a solution. Solutions may include

purchasing a replacement unit or returning the unit to the factory for inspection and repair. All returns require

a Return Material Authorization (R.M.A.) number to be issued by Pulsafeeder. Replacements purchased under

a possible warranty situation may be credited after an examination of the original parts by Pulsafeeder

personnel.

Certain components may be purchased for replacement. Refer to Section 19 – Spare Parts for more

information and part numbers. Parts purchased to correct a warranty issue may be credited after examination

of the original parts by Pulsafeeder personnel. Parts returned for warranty consideration that test satisfactorily,

will be sent back to the originator via freight collect.

Any field modifications will void the Pulsafeeder warranty. Out-of-warranty repairs will be subject to

Pulsafeeder’s standard bench fees and testing costs associated with replacement components.

FCC Warning

This equipment generates and uses radio frequency energy. If not installed and used properly, in strict

accordance with the manufacturer’s instructions, it may cause interference to radio communications.

Operation of this equipment in a residential area is likely to cause interference, in which case the user, at his

own expense, will be required to take whatever measures are necessary to correct the interference.

Copyright

Copyright © 2006, 2007, 2008 Pulsafeeder, Inc. All rights reserved.

Information in this document is subject to change without notice. No part of this publication may be

reproduced, stored in a retrieval system or transmitted in any form or any means electronic or mechanical,

including photocopying and recording for any purpose other than the purchaser’s personal use without the

written permission of Pulsafeeder.

ii

Page 3

Table of Contents

1. I

NTRODUCTION

1.1 Description .............................................................................................................................. 1

1.2 MPC VECTOR Standard Features ......................................................................................... 2

2. S

AFETY CONSIDERATIONS

2.1 General Safety......................................................................................................................... 3

2.2 Electrical Safety ...................................................................................................................... 3

2.3 Mechanical Safety................................................................................................................... 3

2.4 Hydraulic Safety...................................................................................................................... 3

3. E

QUIPMENT INSPECTION

4. S

TORAGE INSTRUCTIONS

4.1 Short Term (0 - 12 months).................................................................................................... 4

4.2 Long Term (12 months or more) ........................................................................................... 4

5. I

NSTALLATION AND WIRING

5.1 Location ................................................................................................................................... 5

5.2 Installation Notes .................................................................................................................... 6

5.3 Electrical Wiring...................................................................................................................... 6

5.3.1 Controller Layout ................................................................................................................ 6

5.3.2 Power Wiring Information .................................................................................................. 8

5.3.3 Power Wiring Diagram ....................................................................................................... 9

5.3.4 Input/Output Signal Wiring ................................................................................................ 10

5.4 Check Wiring and Close Access Cover................................................................................ 11

5.5 Confirm Correct Incoming Power ......................................................................................... 11

6. S

TART UP AND OPERATION

6.1 Overview .................................................................................................................................. 12

6.2 Critical Parameters ................................................................................................................. 12

6.3 Keypad/Lamp Operation ........................................................................................................ 13

6.4 Confirm Display and Keypad Functionality ......................................................................... 13

6.5 Motor Parameter Setup .......................................................................................................... 14

6.6 Setting Max Flow and Max Speed ......................................................................................... 14

6.7 Flow Display ............................................................................................................................ 16

6.8 Wrapping up ............................................................................................................................ 16

6.9 Factory Re-Initialization ......................................................................................................... 17

7. I

NPUT/OUTPUT SETUP

7.1 Analog Input Setup ................................................................................................................. 18

7.1.1 Analog Input 1 – Setpoint .................................................................................................. 18

7.1.2 Analog Input 2 – Flowmeter Feedback ............................................................................. 18

7.2 Digital Input Setup .................................................................................................................. 18

7.2.1 Multi-purpose Digital Inputs .............................................................................................. 18

7.3 Analog Output Setup .............................................................................................................. 19

7.4 Digital Output Setup ............................................................................................................... 19

8. C

ALIBRATIONS

8.1 Pump Flow Calibration ........................................................................................................... 20

8.1.1 WET Flow Calibration ......................................................................................................... 20

8.1.2 DRY Flow Calibration ......................................................................................................... 22

8.2 Analog Input Calibration ........................................................................................................ 24

..................................................................................................................................... 1

.................................................................................................................... 3

....................................................................................................................... 4

...................................................................................................................... 4

.................................................................................................................. 5

.................................................................................................................. 12

.......................................................................................................................... 18

..................................................................................................................................... 20

iii

Page 4

8.2.1 “WET” Analog Input Calibration (with a field signal) ......................................................24

8.2.2 “DRY” Analog Input Calibration (keypad only, no signal present)................................ 26

8.3 Analog Output Calibration .....................................................................................................28

8.4 PulsaGuard Pump Protection ................................................................................................ 30

8.4.1 PulsaGuard Calibrations, using Flow Meter Feedback................................................... 30

8.4.2 PulsaGuard Calibrations, no Flow Meter Feedback ........................................................31

8.5 Display Contrast Adjustment................................................................................................. 32

8.6 Tuning the Control Algorithm................................................................................................ 33

9. F

LOW METER INPUT

9.1 Flow Meter Installation ...........................................................................................................36

10. M

OTOR PARAMETER SETUP AND TUNING

11. A

LARM AND ERROR MESSAGES

11.1 Error Log ..................................................................................................................................41

11.1.1 Viewing the Error Log .........................................................................................................41

11.1.2 Clearing Error Log Entries .................................................................................................42

11.2 Error Messages ....................................................................................................................... 42

12. S

PECIFICATIONS

13. M

ODEL IDENTIFICATION

14. M

ENU MAPS

15. F

ACTORY DEFAULT VALUES

16. R

ETRIEVAL OF SETUP INFORMATION

17. S

PECIAL KEY PRESS ACCESS

18. T

ROUBLESHOOTING GUIDE

19. S

PARE PARTS

20. A

PPENDIX 1, HANDHELD WIRING

20.1 Removal and Connection of the Cable from the Handheld: ............................................... 54

20.2 Removal and Connection of the Cable from the Base Unit:............................................... 55

21. A

PPENDIX 2,

21.1 PID Controller Theory: ............................................................................................................ 58

21.2 Three Control Components: ..................................................................................................60

21.3 PID Basic Summary, what happens when I… ......................................................................61

21.4 Putting it all together to run the MPC Vector ....................................................................... 62

21.5 Troubleshooting ...................................................................................................................... 63

.........................................................................................................................................48

PID T

.............................................................................................................................36

..............................................................................................38

............................................................................................................41

...................................................................................................................................44

........................................................................................................................47

.................................................................................................................51

.....................................................................................................51

...............................................................................................................51

...................................................................................................................52

......................................................................................................................................53

...........................................................................................................54

HEORY AND ADJUSTMENT

........................................................................................58

iv

Page 5

Conventions

For the remainder of this bulletin, the following Conventions are in effect.

Revision History:

2-2006 Rev A First Release

3-2006 Rev B New menu maps

Digital I/O features added

4-2006 Rev C Add “Speed Mode Flow Cal” instructions

Misc. minor updates and changes for spelling, grammar, etc

7-2006 Rev D, E New illustrations, new dimensional diagram, change to MPC Vector name, added

5-2007 Rev F Updated signal connections diagram

9-2007 Rev G Added notes and diagram for digital outputs, section 5.3.4 and 7.4

1-2008 Rev H Update to match new software revision, multiple changes (3.01)

3-2008 Rev J Further updates and corrections for new software version (3.01)

A

WARNING DEFINES A CONDITION THAT COULD CAUSE DAMAGE TO BOTH

THE EQUIPMENT AND THE PERSONNEL OPERATING IT. PAY CLOSE

ATTENTION TO ANY WARNING

.

Notes are general information meant to make operating the equipment easier.

model string, minor text revision, added 3 phase information for low Hp motors.

Added hand-held wiring diagram

Added PID tutorial information in appendix

Added startup and parameter setup information section 6

Corrected steps in Dry Flow Cal for Speed Control section

Other minor text changes and additions

Safety Considerations:

1. Read and understand all related instructions and documentation before attempting to install or

maintain this equipment

2. Observe all special instructions, notes, and cautions.

3. Act with care and exercise good common sense and judgment during all installation, adjustment, and

maintenance procedures.

4. Ensure that all safety and work procedures and standards that are applicable to your company and

facility are followed during the installation, maintenance, and operation of this equipment.

v

Page 6

vi

Page 7

1. Introduction

The MPC VECTOR is a microprocessor based motor speed control device, for use with Pulsafeeder pumps. It has

been designed for simplicity, yet still has many advanced features that allow the MPC VECTOR to operate in a wide

variety of environments and applications. This product is not just a variable speed drive. It is a state of the art

multifunctional controller, which provides functionally no one stand-alone variable speed drive does. What makes this

product unique is that it combines functionality of three devices in one:

• Vector type variable speed drive.

• Input output processor (4-20 mA in and out, digital input/output), including PID loop for closed loop flow

control.

• Power monitor for detection of run-dry conditions

This instruction manual covers the MPC VECTOR control only. For information and safety precautions specific to the

pump or any other accessories, please refer to the appropriate IOM.

1.1 Description

The MPC VECTOR is an advanced pump controller that is physically separated from the pump's enclosure. Its

purpose is to precisely adjust output flow of a process media by means of pump motor speed control.

The MPC VECTOR is designed for a wide variety of control applications. If delivered with a pump and motor,

the device is factory configured. Field configuration may be required in certain installations. Local setup and

control is achieved through the keypad and a backlit two-line liquid crystal display. Basic operation is simple with

dedicated function keys eliminating the need for a sophisticated menu system. Pump output is displayed as

Gallons or Liters per Hour (GPH/LPH), Gallons or Liters per Minute (GPM/LPM), or Revolutions per Minute

(RPM).

Digital and analog inputs will support a variety of industry standard signals to offer flexible remote control.

The MPC VECTOR is designed to simplify and automate the calibration of pump flow and analog signals. Flow

calibration uses on-screen prompting and automated pump operation to eliminate stopwatches, calculators and

human inaccuracies. Analog signal calibration is also accomplished by simple keypad entry. It includes a realtime display of signal level. This eliminates the need for external meters.

The MPC VECTOR will accept, and automatically adjust to, either 60 Hz or 50 Hz input power. No special

modifications, settings, or adjustments are required. MPC VECTOR controller can be supplied with a 60 Hz, 50

Hz, or dual rated 50/60 Hz motor. The controller/motor combination allows for 60 Hz rated pump flow (1800 rpm

motor speed) even when operating from a 50 Hz input. Users in locations with 50 Hz AC supply do not have to

de-rate pump flow with this controller.

Minimum motor speed is limited under all circumstances to 31 rpm. Please note that in certain applications, the

practical minimum speed (to achieve flow and pressure) may be higher than 31 rpm. This can be dependent

on product viscosity and other application-specific variables.

Input Frequency MPC VECTOR Motor Max MPC VECTOR Output

60 Hz (USA and similar) 60 Hz (or dual rated) 60 Hz / 1800 rpm

50 Hz (Europe, Asia, etc) 50 Hz or 60 Hz or dual rated 60 Hz / 1800 rpm

1

Page 8

The motor used with the MPC VECTOR is a three-phase motor; however the three-phase power is generated

internally by the MPC VECTOR itself. Do not be confused by the motor nameplate. Input power to the

MPC VECTOR is single-phase or three-phase AC 230 volts (see Section 12, Specifications for acceptable

voltage range). The nameplate on the side of your MPC VECTOR controller will list the appropriate supply

requirements for your controller.

Motor Hp Rating MPC VECTOR Input Power* Output to Motor**

1 208/230 VAC 1 or 3 phase 230 VAC 3 phase

2 208/230 VAC 1 or 3 phase 230 VAC 3 phase

3 208/230 VAC 1 or 3 phase 230 VAC 3 phase

5 208/230 VAC 3 phase only 230 VAC 3 phase

* all input ratings are 50 or 60 Hz

** output to pump motor is always 60 Hz maximum frequency

The AC drive used in the MPC VECTOR maintains tight control over voltage and current supplied to the

pump motor. This results in lower motor operating temperatures and less stress on motor windings, resulting

in longer motor life and more reliable overall operation. Further motor selection information can be found in

Section 12, Specifications at the end of this manual.

1.2 MPC VECTOR Standard Features

• User keypad and display for ease of operation

• Display pump operation in GPH, LPH, GPM, LPM, or RPM

• One 4-20 mA analog input signal for flow control

• One analog (mA) input for flow feedback control (with an external, user supplied flow metering device

which provides an analog signal)

• Sensorless vector motor speed control

• Two configurable digital inputs

• Three configurable digital outputs (transistor type, 40 VDC maximum)

• Analog 4-20 mA feedback output

• NEMA 4X and IP56 ratings (for controller housing)

• 230 Volts, 50 or 60 Hz, single or three phase AC power for 1 through 3 Hp systems

• 230 Volts, 50 or 60 Hz, three phase (only) AC power for 5 Hp systems

• Security code lockout of menus

• Standard configurable pump protection utilizing proprietary PulsaGuard technology

2

Page 9

2. Safety Considerations

• Read and understand all related instructions and documentation before attempting to install or maintain this

equipment

• Observe all special instructions, notes, and cautions.

• Act with care and exercise good common sense and judgment during all installation, adjustment, and

maintenance procedures.

• Ensure that all safety rules, work procedures, and standards that are applicable to your company and facility

are followed during the installation, maintenance, and operation of this equipment.

2.1 General Safety

The MPC VECTOR was designed as a controller for operation solely with the Pulsafeeder Eclipse series of

non-metallic gear pumps. Use for any other application is considered unsafe and voids all certification

markings and warranties.

2.2 Electrical Safety

The MPC VECTOR is an industrial process controller. Improper application and use can be hazardous.

You are solely responsible for its use.

The MPC VECTOR electrical installation must conform to all relevant electrical codes. Installation and

electrical maintenance must be performed by a qualified electrician. Before installing or servicing this

device, all power must be disconnected from the source at the main distribution panel.

The MPC VECTOR emits electro-magnetic energy and may generate radio frequency interference. Its use is

restricted to industrial applications. You are responsible for shielding this energy/interference.

Certain wiring procedures may require that the user wear a wrist strap to dissipate static charges.

Wait a minimum of 5 minutes after disconnecting power before servicing the MPC VECTOR or pump

motor. Capacitors retain a charge even after power is removed from the controller.

2.3 Mechanical Safety

Users should note that the pump motor is always under the control of the MPC VECTOR, and as such may

actuate without warning. Care should be taken to keep loose clothing and other objects away from the pump

motor.

The MPC VECTOR was designed to be service free. It contains no user-maintainable components.

Disassemble the MPC VECTOR enclosure only for initial field wiring, or as instructed to do so within this

manual. Evidence of unauthorized disassembly shall void the warranty.

2.4 Hydraulic Safety

Thoroughly review and adhere to the contents of the pump Installation, Operation, Maintenance and

Instruction manual for any pump used with the MPC Vector control. As a microprocessor controlled device,

the MPC VECTOR may activate the pump motor without warning – generating hydraulic pressure and fluid

flow. Care should be taken to protect both users and systems should the pump activate.

3

Page 10

3. Equipment Inspection

When you receive your order, check all equipment for:

• Completeness against the shipping document / purchase order

• For any evidence of shipping damage.

Shortages or damage should be reported immediately to the carrier and your Pulsafeeder Representative.

4. Storage Instructions

The MPC VECTOR can be successfully stored for extended periods. The key to this success is temperature and

humidity control.

4.1 Short Term (0 - 12 months)

The MPC VECTOR should be stored in a temperature and humidity controlled environment. It is preferable

to keep the temperature constant in the range of -18° to 60° Celsius (0° to 140° Fahrenheit). The relative

humidity should be 0 to 90% non-condensing.

4.2 Long Term (12 months or more)

Storage of the MPC VECTOR for periods of longer than twelve months is not recommended. If extended

storage is unavoidable the MPC VECTOR should be stored in accordance with those conditions stipulated

for Short Term Storage. In addition, a porous bag of 85g (3 oz) silica gel or similar desiccant should be

placed inside the enclosure. The cover should be re-installed to seal the desiccant within the enclosure. The

conduit connections must be tightly capped.

Special note for long-term storage:

If AC input power has not been applied to the MPC VECTOR for a period greater than 12 months, the

controller must be prepared for operation. The MPC VECTOR should have AC power applied at the input

for a period of 8 hours before placing pump into normal operation. Refer to Installation and Wiring section

for AC power connection instructions.

4

Page 11

5. Installation and Wiring

5.1 Location

Review the Safety section (Section 2) prior to installing the MPC VECTOR. It contains information

required to properly install and operate the MPC VECTOR in an industrial environment.

The site selected for the installation of your MPC VECTOR is largely dependent on that of the gear pump.

Review the Installation, Operation, and Maintenance manual provided with your gear pump. It details

system related issues that are important to proper operation of the pump. Consider the following MPC

VECTOR related issues when selecting a site. Avoid locations where the MPC VECTOR would be

subjected to extreme cold or heat. Note the warning statement on the next page. The installation of this

device must comply with national, state and local codes.

The MPC VECTOR controller must be secured to an appropriate support before use. Use appropriate

hardware to secure the MPC VECTOR controller and pump to a smooth vertical surface. No assembly is

required for the MPC VECTOR controller itself.

AC TO MOTOR

AC POWER IN

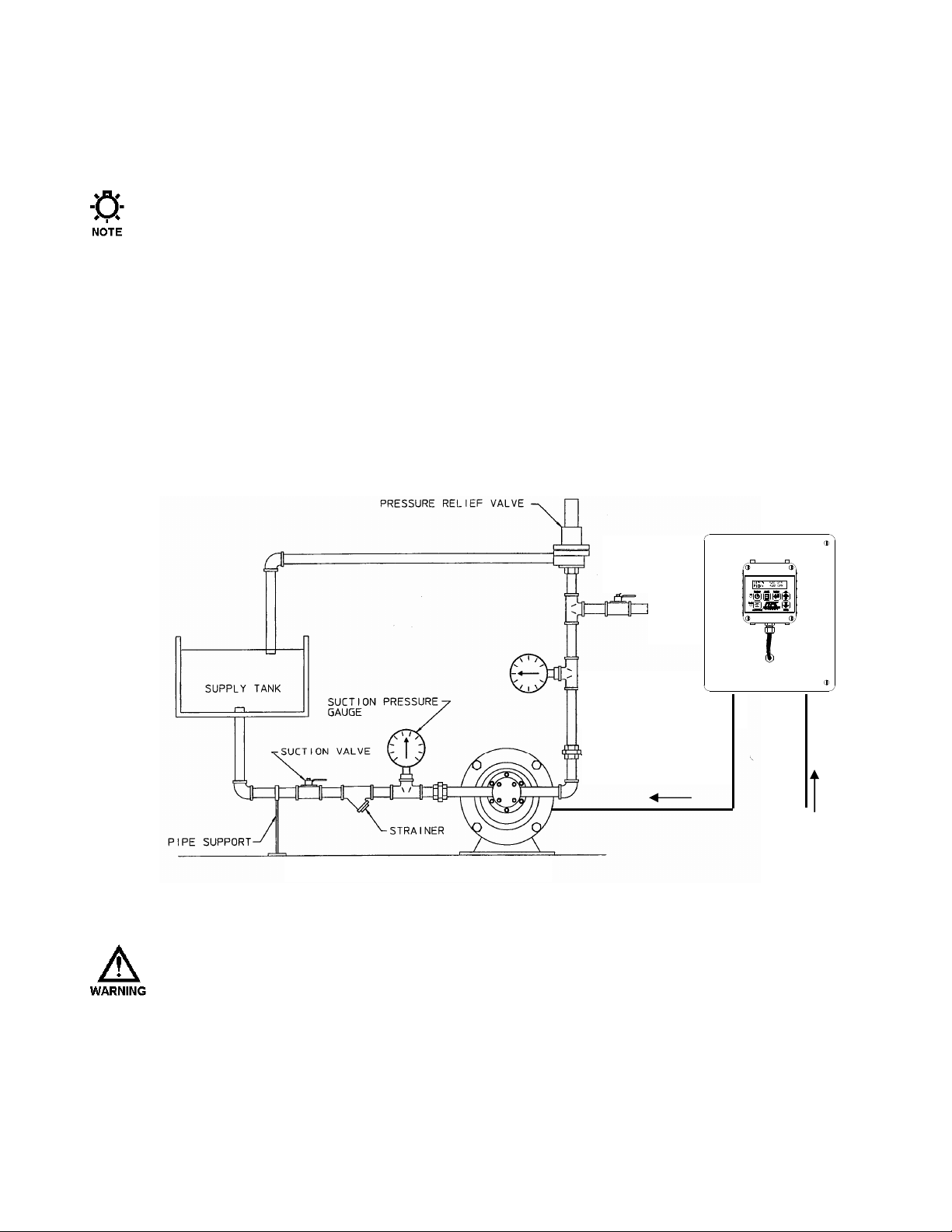

Figure 1 – Typical Installation.

A

VOID LOCATIONS WHERE THE

HEAT [LESS THAN

F

AHRENHEIT)] OR DIRECT SUNLIGHT. FAILURE TO OBSERVE THIS WARNING COULD DAMAGE THE

MPC VECTOR

0°°°° C

ELSIUS

AND VOID ITS WARRANTY

MPC VECTOR

(32°°°° F

AHRENHEIT) OR GREATER THAN 40

.

WOULD BE SUBJECTED TO EXTREME COLD OR

°°°° C

ELSIUS

(104 °°°°

5

Page 12

5.2 Installation Notes

The MPC VECTOR is a microprocessor-based controller that uses electro-static sensitive CMOS

components. Do not make any (high or low voltage) electrical connections without adequately grounding

the MPC VECTOR and the worker to eliminate an electro-static charge between the two. A conductive

wrist strap worn by the worker and attached to the MPC VECTOR’s internal ground plate is

adequate to satisfy this requirement.

Calibration is an important element of successful MPC VECTOR operation. If a flow meter is being used for

process feedback the flow meter must be calibrated prior to MPC VECTOR calibration according to

manufacturer recommendations.

Conduit connections can carry fluids and vapors into the MPC VECTOR causing damage and void the

warranty. Care should be taken when installing conduit to protect against fluid/vapor entry. If necessary,

provide sealed entries or conduit drains near the point of entry. The user must supply the correct connection

for the power entry, as per the local codes and requirements. Any cable entrances that are not used should

be appropriately sealed against moisture and vapors.

5.3 Electrical Wiring

Wait a minimum of 5 minutes after disconnecting power before servicing the MPC VECTOR or

pump motor. Capacitors retain a charge even after power is removed from the controller.

1. Make the motor connections between the control unit and the pump motor (ref. Figure 3).

2. Make the incoming AC power connections and the outgoing power connections to the pump motor (ref.

Section 5.3.2). These will allow you to operate the MPC VECTOR and attached Eclipse pump.

3. Decide which signal (control) Inputs and Outputs (e.g., 4-20mA in) will be used and make those

connections (ref. Section 5.3.4).

4. Power-up and test the MPC VECTOR to confirm the connections and check for proper operation.

5. Configure the software via the menu system for the desired operational conditions. Depending on the

anticipated function, users may need to enter settings for the following:

a. Analog input signal, so the MPC VECTOR can accept a process input signal

b. Digital input settings, for example start/stop and/or tank level inputs

c. Digital output settings, for example auto/manual status and/or alarm outputs

6. Conduct a final power-up and test the MPC VECTOR to confirm the connections and check for proper

operation.

7. Go to the Section 6 – Start Up and Operation for details on how to perform the power-up tests.

5.3.1 Controller Layout

The design of the MPC VECTOR incorporates all control circuitry onto one easily accessed circuit board.

This board is located on the inside of the main controller. Gain access to this board by removing the 2

cover screws allowing the cover to hinge open.

6

Page 13

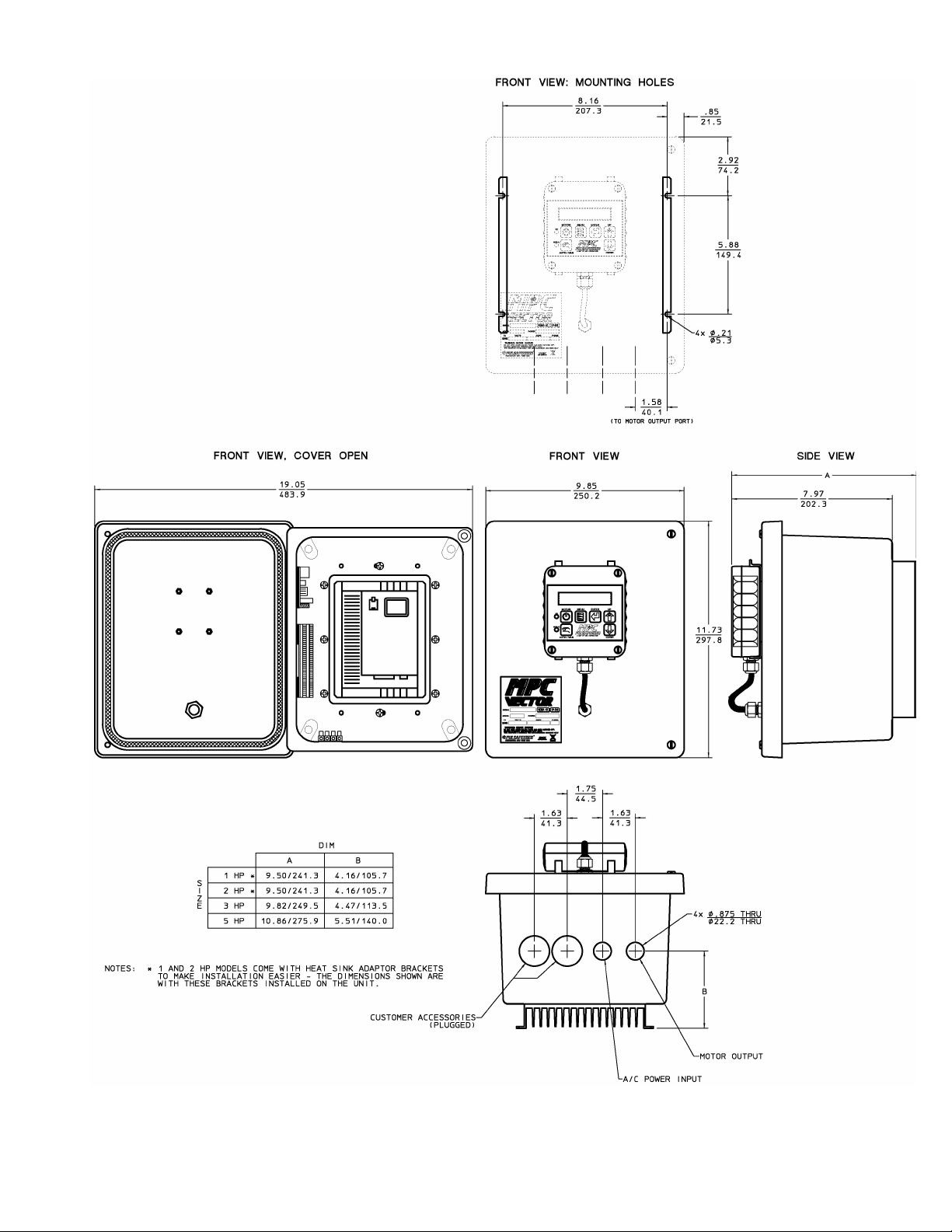

Figure 2 – Controller Layout and Dimensions

7

Page 14

5.3.2 Power Wiring Information

• Verify the correct supply voltage (230VAC single-phase or three-phase) with the nameplate

affixed to your MPC VECTOR. Ensure that your supply voltage matches the MPC VECTOR

configuration.

• The 1 hp, 2 hp, and 3 hp AC drives use single phase or three phase 230VAC input. The 5 hp

AC drive must be powered by three phase 230VAC input only.

• Wires should be routed within the enclosure in a manner that maintains separation between

high voltage and low voltage conductors. High voltage conductors should be routed to the side

opposite the control circuitry.

• Incoming power wiring should adhere to all applicable local and national electrical codes and

regulations. A circuit breaker or fuse must be provided as noted below.

• Upon initial application of AC power, a current inrush will occur to charge the DC bus

capacitors. This is normal operation, and breakers and other circuit protection devices should

be sized accordingly.

The MPC VECTOR requires one connection to an external power source. It uses this same

connection to power its own supply as well as the AC pump motor. You must take all of these loads

into consideration when sizing the branch circuit (see Table 1). A circuit breaker or disconnect

switch with fuses must be wired in series with terminals L1 and L2/N in accordance with all

applicable local and national electrical codes and regulations. The circuit breaker or disconnect

switch shall be located in close proximity to the MPC VECTOR controller installation, and must be

marked or labeled to identify it as the power disconnect for the MPC VECTOR.

Recommended Minimum Wiring and Circuit Breaker

Power

Requirements

MPC VECTOR

and 1.0 Hp motor

MPC VECTOR

and 2.0 Hp motor

MPC VECTOR

and 3.0 Hp motor

MPC VECTOR

and 5.0 Hp motor

Actual

10.6 A 15 A 14 AWG 2.0 mm2 5.8 A 10 A 14 AWG 2.0 mm

14.8 A 20 A 14 AWG 2.0 mm2 9.1 A 15 A 14 AWG 2.0 mm

19.7 A 25 A 12 AWG 3.5 mm2 12.4 A 20 A 14 AWG 2.0 mm

Single Phase 208/230 VAC Three Phase 208/230 VAC

Circuit

Draw

--- --- --- --- 19.6 A 25 A 12 AWG 3.5 mm2

Breaker

Wire

Size

Wire

Size

Actual

Draw

Circuit

Breaker

Wire

Size

Wire

Size

2

2

2

Table 1 – Sizing Branch Circuits

The MPC VECTOR controller is provided with a 7/8” thru hole for incoming AC power wiring and

a 7/8” thru hole for motor wiring at the bottom of the enclosure. Utilize the appropriate conduit

fittings to route and seal the supply wires into the MPC VECTOR enclosure.

The power wires are secured to the terminal strip at the bottom end of the AC drive as per Table 2.

Remove approximately 0.20 – 0.25” of insulation from the end of each conductor. Loosen the

terminal strip screw, and insert the stripped wire end fully into the terminal. Tighten the screw to

8

Page 15

secure the conductor, making certain that the terminal grips the wire, not the insulation. Ensure that

all wiring meets applicable local and national codes and requirements.

5.3.3 Power Wiring Diagram

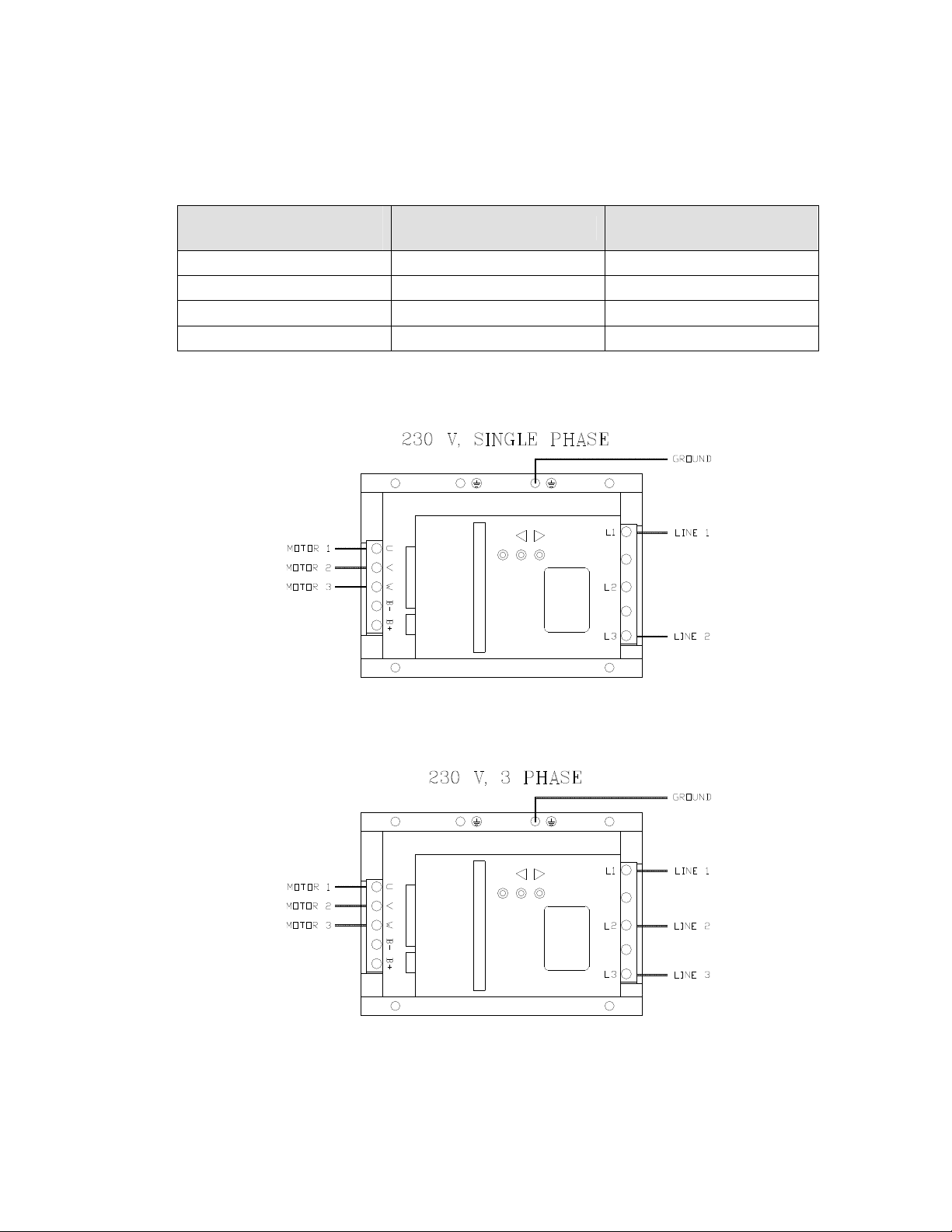

MPC VECTOR Drive

Terminal

L1 Line 1 Line 1

L2 N/C Line 2

L3 Line 2 Line 3

Ground Plate Ground Ground

Single Phase 208/230 VAC Three Phase 208/230 VAC

Table 2 – AC Drive Terminals

Figure 3 – AC Power Connections

Wait a minimum of 5 minutes after disconnecting power before servicing the MPC VECTOR or pump motor.

Capacitors retain a charge even after power is removed from the controller.

9

Page 16

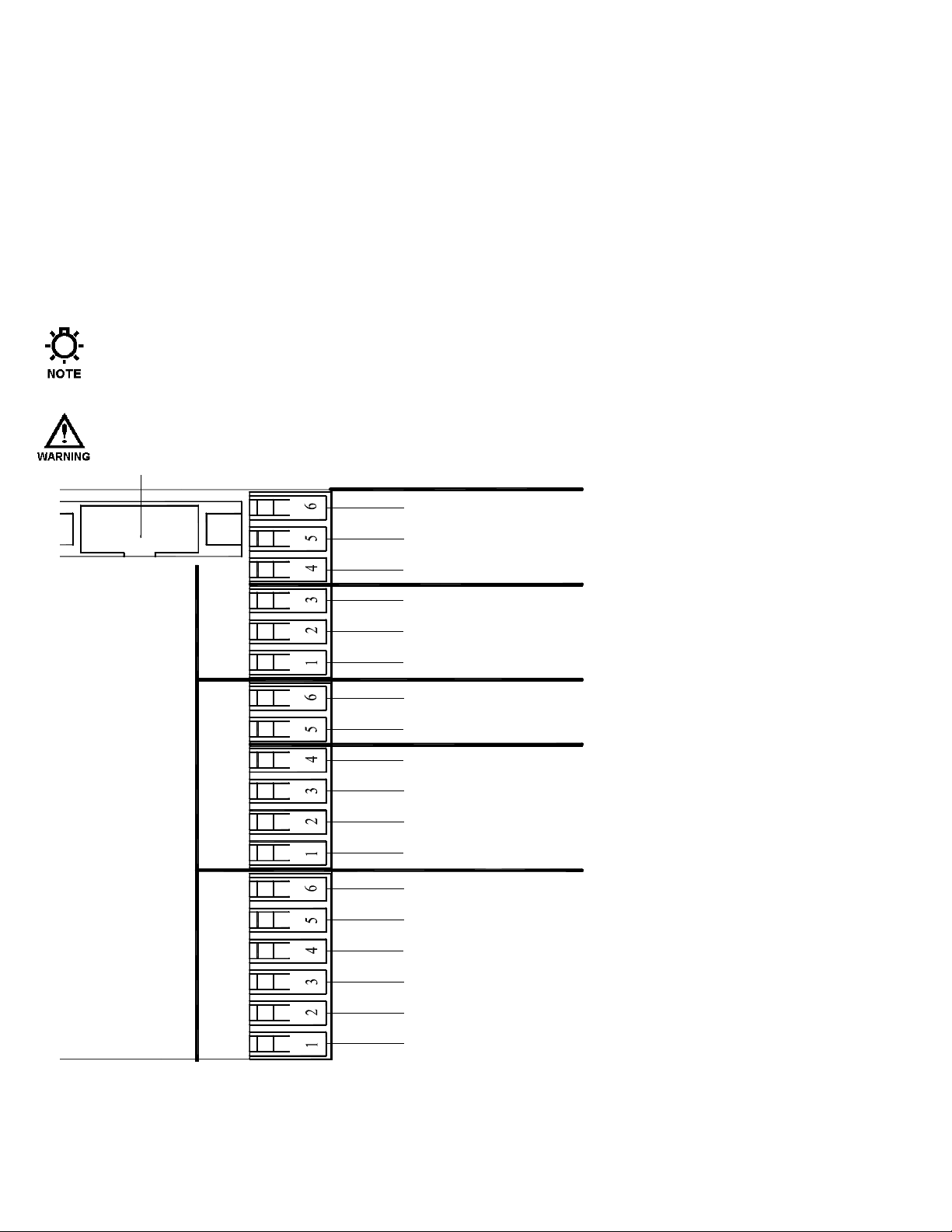

5.3.4 Input/Output Signal Wiring

4-20 INPUT

(

)

(

)

Signal wiring is routed through the two unused conduit openings at the base of the MPC VECTOR.

All input/output signals are connected to the terminal strips at the edge of the MPC VECTOR circuit

board except for flow meter feedback which is connected to a separate terminal block. Use caution

to observe proper wire location and signal polarity. Always cap or plug unused openings. Wires

should be routed with in the enclosure in a manner that maintains separation between high voltage

and low voltage conductors. Ensure all low voltage wiring is installed as per any applicable local

and national electrical codes and regulations.

Utilize 16 to 22 AWG, 250 V shielded cable with a 75o C insulation rating (or better) for all signal

input and output wiring. Recommended strip length is 0.39” or 10 mm. Refer to Figure 4 below for

signal connection locations.

Unused conduit openings should be plugged as required to avoid ingress of moisture and contaminants

into the MPC VECTOR enclosure. Do not remove the factory provided plug from openings that are not

required for field wiring.

I

T IS RECOMMENDED THAT A WRIST STRAP BE WORN WHEN MAKING CONNECTIONS TO ANY PRINTED

CIRCUIT BOARD

.

GROUND

J20

J11

J23

J14

ANALOG IN 2

ANALOG IN 1

F L O W M E T E R S I G N A L

P R O C E S S S I G N A L

DIGITAL INPUT

GROUND

DIGITAL IN 2

DIGITAL IN 1

4-20 OUTPUT

ANALOG OUT 1

GROUND

DIGITAL OUTPUT

GROUND

DIGITAL OUT 3

DIGITAL OUT 2

DIGITAL OUT 1

REMOTE

BLACK/WHITE

WHITE

SHIELD

BLACK/GREEN -GREEN

Figure 4a – Signal Connections

10

BLACK/RED

RED

Page 17

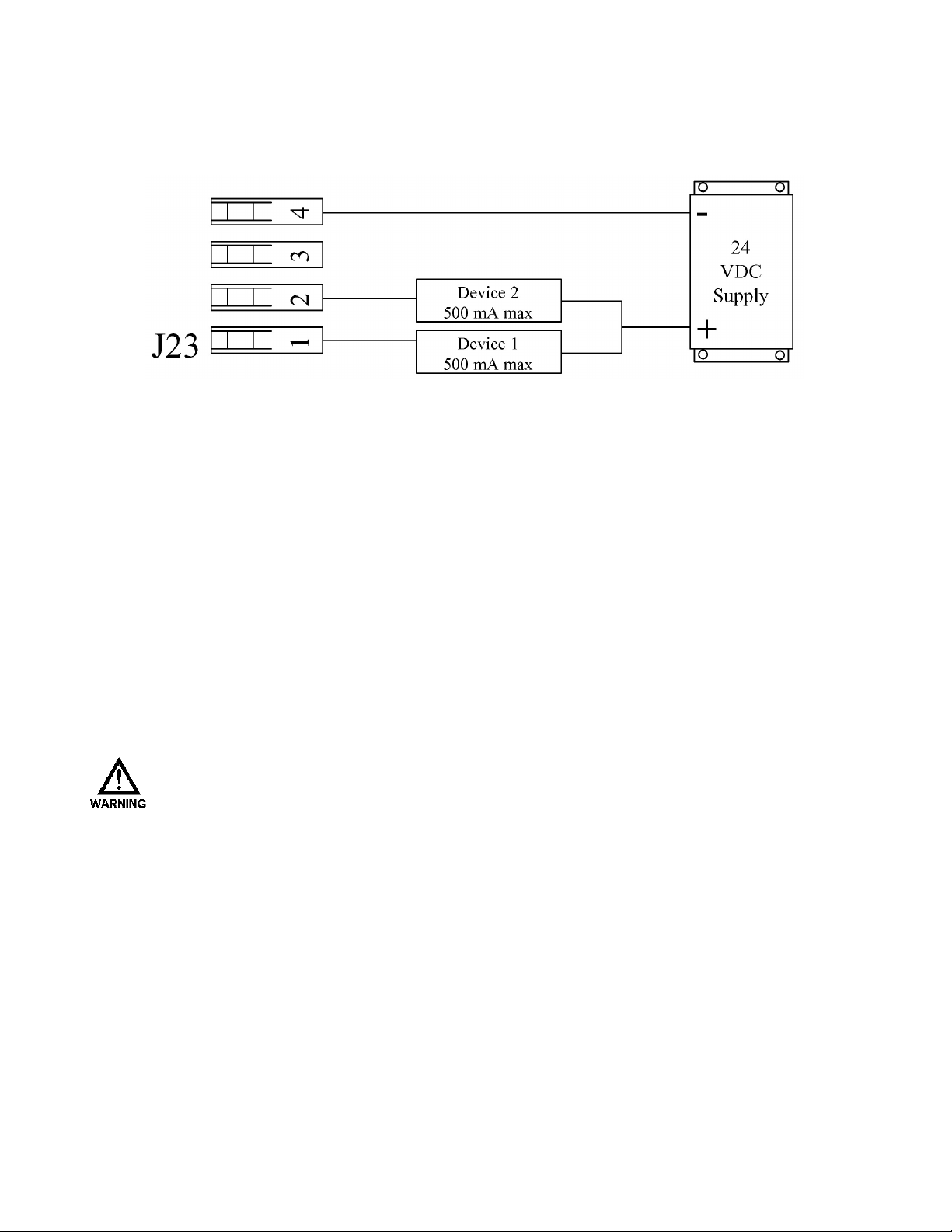

Digital output signals can drive devices such as relays or indicator lamps. 5 to 24 VDC power must be

supplied from an external source. Each output has a maximum current capability of 500 mA. Maximum

voltage capability of these circuits is 40 VDC (see Section 12, Specifications, for more information).

Figure 4b – Sample Digital Output Connections, (power can be in the range of 5 – 24 VDC)

5.4 Check Wiring and Close Access Cover

Double-check all of your electrical connections. Pay attention to polarity of all inputs and outputs – both

low and high voltage. Additionally, insure that all terminals are clamping onto the bare conductor, not on

its insulation. Ensure that wires will not be trapped or pinched when front cover is replaced and secured.

Ensure that excess insulation is not removed from the wires, as this can lead to poor connections or faulty

operation.

Replace the main access cover and secure the 2 screws.

5.5 Confirm Correct Incoming Power

W

ITHOUT PRIOR OPERATING KNOWLEDGE, IT IS IMPOSSIBLE TO TELL IF THE PUMP MOTOR WILL

RUN WHEN POWER IS APPLIED TO THE

NECESSARY STEPS TO ENSURE THAT ALL ASPECTS OF SAFETY HAVE BEEN CONSIDERED (E.G.,

ELECTRICAL, HYDRAULIC, ETC

.).

Turn on power at the mains or distribution panel. If the MPC VECTOR's incoming power is connected

correctly, the backlighting on the MPC VECTOR’s display will illuminate (depending on lighting

conditions, it may be necessary to shade the display to confirm illumination). If the display is not

illuminated, first check the line voltage with a voltmeter. If the voltage is not correct, return to Section

5.3.2 – Power Wiring Information. Otherwise, proceed with the next step.

MPC VECTOR. Y

OU ARE RESPONSIBLE FOR TAKING THE

11

Page 18

6. Start Up and Operation

6.1 Overview

Once all electrical connections have been made, your MPC VECTOR is ready for setup and operation. The

following sections detail the procedures required to complete the MPC VECTOR start up.

W

HEN POWER IS SUPPLIED TO THE UNIT, LINE VOLTAGE IS PRESENT WITHIN THE

ENCLOSURE EVEN WHEN THE MOTOR IS

DURING START-UP, IT IS NECESSARY TO RUN THE PUMP MOTOR. THIS WILL CAUSE FLUID TO

DISCHARGE FROM THE PUMP. YOU ARE RESPONSIBLE FOR SAFELY DIVERTING FLOW FROM THE

PUMP DURING START-UP AND CALIBRATION

6.2 Critical Parameters

For proper operation of the MPC VECTOR control, at startup the following parameters and calibrations must

be entered and/or verified:

Parameter(s) Reference IOM Section

OFF.

MPC VECTOR

.

Pump maximum flow Section 6.6

Flow meter calibration (if using this feature) Ref flowmeter IOM as required

Flow calibration in speed mode Section 8.2

Motor calibration for Vector mode Section 10

4-20 mA analog signal calibration Section 8.3

Flow meter type setup Section 9

12

Page 19

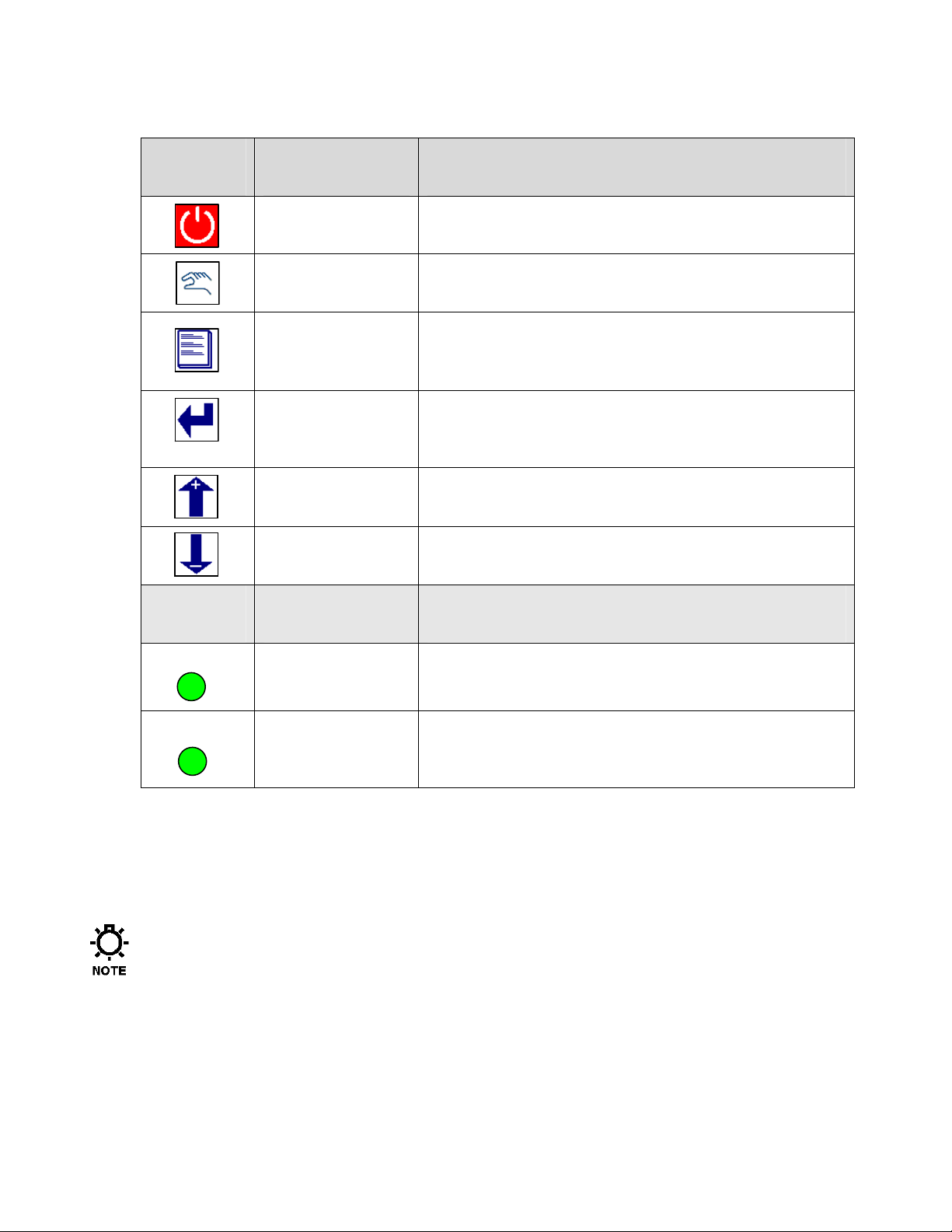

6.3 Keypad/Lamp Operation

Green = Manual Control Off = Automatic Control

MANUAL

ON

Key Function Description

Motor On/Off Press to start pump, press again to stop pump

Lamp Color Description

Auto/Manual

Menu

Enter

Arrow Up

Arrow Down

Green, Amber,

Red, Off

Press to toggle between automatic operation and manual

control of the pump

Press to adjust controller settings, to exit the menu system,

to move cursor back when entering values, or to step back to

higher level menus

Press to accept changes in menus, to move cursor forwards

when entering values, and to access lower level menus.

Press to adjust values upwards, and to scroll through menu

options

Press to adjust values downwards, and to scroll through

menu options

Off = Motor off Green = Motor on

Amber = Remote standby Red (blinking) = Error

Green, Off

Table 3 – Keypad and Lamp Operation

6.4 Confirm Display and Keypad Functionality

The example display messages are shown in English for demonstration purposes. If an alternate

language has been set, the text is displayed as a translation of the English version.

Now that you have confirmed that the MPC VECTOR is receiving power, it is necessary to confirm that the

display and keypad are functioning properly. On normal power-up, the display appears for approximately 2

seconds.

P U L S A F E E D E R INC.

F W : 0 0 . 0 0 / 0 0.00

The first four digits displayed are the software revision for the MPC VECTOR control board, and the second

four indicate the software revision for the remote board.

13

Page 20

The revision numbers should be identical for both units. Unpredictable or unstable operation may result

from mismatched software revisions.

Please note that it may be necessary to adjust the display contrast. Please refer to Section 8.6 if this is

required.

6.5 Motor Parameter Setup

The MPC VECTOR controller interfaces closely with the Eclipse pump motor. The MPC VECTOR needs to

know certain details about the motor in order to function properly. End users may have to input or adjust

motor parameters before operation. Use the following as a guide:

If you: Have received your MPC VECTOR and Eclipse pump and motor as a unit from the factory,

and Your MPC VECTOR to motor wiring distance is less than 25 feet

Then you should not have to perform any parameter setup or calibration. All parameters and setup have been

completed for you at the factory.

If you: Are using the MPC VECTOR with a motor that did not come from the factory, or

Your MPC VECTOR to motor wiring distance is greater than 25 feet, or

You are replacing the motor on an existing setup

Then you may have to enter the motor parameters, and you will have to perform a motor auto-setup

procedure. Please reference Section 10, Motor Parameter Setup and Tuning, before proceeding with

operation of your MPC VECTOR controller.

6.6 Setting Max Flow and Max Speed

What is Max Flow?

The value entered into the Max Flow is largely used for display purposes. It limits the flow rates that can be

entered during normal operations, as well as during analog calibration routines and PulsaGuard calibration.

Internally it is also used in PID calculations.

What should my Max Flow be set to?

Max Flow can vary for a gear pump based on the viscosity of the fluid being pumped and the system

pressure. It is recommended that the Max Flow be set 10% higher than your pump is rated for at 0PSI. This

will allow for a full range of data entry.

What if I try to set my pump to a flow higher than it can actually achieve for my current pressure and

viscosity?

The pump has internal software protections and validations which prevent the motor from exceeding 1800

RPM (approximate). If the pump can only achieve 2.5GPM at 1800 RPM for your system configuration and

the flow rate is set to 10GPM, the motor will spin at 1800 RPM and produce 2.5GPM.

What is Max Speed?

Max Speed is the maximum speed that the motor can spin, according to the manufacturer. This is largely

unused by the MPC Vector at the moment and will not affect operations. It is recommended that this value is

kept at 1800 RPM.

14

Page 21

Setting Max Flow

1) Begin at the main screen displaying the current flow/speed setpoint

S E T P T 0 . 0 0 G P M

F L O W 0 . 0 0 G P M

2) Press the MENU key to access the menus.

- M E N U -

C A L I B R A T I O N

3) Press the UP or DOWN arrow keys until you get to System Setup.

- M E N U -

S Y S T E M S E T U P

4) Press the ENTER key to access System Setup Menus.

S Y S T E M S E T U P

S T A T U S

5) Press the UP key until you see the Information setup option.

S Y S T E M S E T U P

I N F O R M A T I O N

6) Press the ENTER key to access the Information screens.

P U L S A F E E D E R , INC

F W : 1 . 0 4 / 1 .04

7) Press the UP or DOWN arrow keys until you see Max flow and Speed displayed.

M A X : 6 . 0 0 G P M

M A X : 1 8 0 0 R P M

8) Press the Enter key to allow Max Flow to be edited. A blinking cursor will appear

M A X : 6 . 0 0 G P M

M A X : 1 8 0 0 R P M

9) Press the UP or DOWN arrow keys to manipulate the flow rate until you reach your max flow.

M A X : 8 . 5 0 G P M

M A X : 1 8 0 0 R P M

10) Press the ENTER key to accept the new Max Flow rate. Note that the blinking cursor has moved to the

Max Speed location.

M A X : 8 . 5 0 G P M

M A X : 1 8 0 0 R P M

11) Press the ENTER key again to save the Max Flow and Max Speed. Note that the blinking cursor

should disappear at this point.

M A X : 8 . 5 0 G P M

M A X : 1 8 0 0 R P M

15

Page 22

6.7 Flow Display

The MPC VECTOR will display calibrated pump flow in GPH, LPH, GPM, or LPM on the digital display

when configured for flow control. The motor speed (in RPM) may also be viewed while in flow control.

Changes to the flow units are made in the System Setup Menu.

6.8 Wrapping up

Your MPC VECTOR is now commissioned for use. Note that you cannot configure the software in a way

that would damage the MPC VECTOR. Typically, whenever you are about to set a critical value (e.g.,

Calibrate Flow), you are always prompted to confirm your change before it takes effect. If you are ever

dissatisfied with the configuration of your MPC VECTOR, you can always return to the Factory Defaults by

referring to Section 6.7.

16

Page 23

6.9 Factory Re-Initialization

Factory Re-initialization is typically not required. When re-initializing your MPC VECTOR, all of the

system settings and calibration information will be overwritten by the original factory default settings.

The controller must be re-configured and re-calibrated to your specifications.

A Factory Re-initialization should be performed only if there is reason to believe that the MPC VECTOR is

operating abnormally. The condition usually manifests itself with inconsistent or erratic operation – often

associated with meaningless characters on the display, or exaggerated numerical values. Commonly, a user

has entered incorrect parameters, or made changes to the setup of the control.

Once a re-initialization has been performed, all operating parameters should be checked and adjusted or reentered as necessary, including maximum flow and rpm, motor parameters, flow and analog signal

calibrations, etc.

Factory Re-Initialization:

1. Press the MENU key to access the System Setup Menu

- M E N U -

C A L I B R A T I O N

2. Press the UP arrow key to display

- M E N U -

S Y S T E M S E T U P

3. Press the ENTER key

S Y S T E M S E T U P

S T A T U S

4. Press the UP arrow key twice

S Y S T E M S E T U P

F A C T O R Y I N I T

5. Press the ENTER key

P R E S S E N T E R

T O F A C T O R Y INIT

6. Press the ENTER key

A R E Y O U S U R E?

Y E S = E N T E R NO=ME N U

7. Pres the ENTER key

R E S E T T I N G P UMP

T O F A C T O R Y INIT

17

Page 24

7. Input/Output Setup

Use the “DIGITAL I/O” and “ANALOG I/O” menus to activate the functions required for the intended

application.

Users may also reference Section 14 – Menu Maps for additional configuration assistance

7.1 Analog Input Setup

Two Analog Inputs are provided for the User. Analog Input 1 is used for Setpoint input. Analog Input 2 is

used for systems configured for analog process feedback from a flow meter.

7.1.1 Analog Input 1 – Setpoint

See Figure 4 – Signal Connections to insure that you have your Analog Input signal connected to the proper

location before activating. Use the “ANALOG I/O” menu to activate the analog input signal function. The

menu can be used to set the analog input to either ACTIVE or INACTIVE. The setpoint input should be

calibrated prior to activation (ref. Section 8.2 – Analog Input Calibration).

7.1.2 Analog Input 2 – Flowmeter Feedback

See Section 9 Flow Meter Input for installation instructions. The flow meter input signal must be configured

properly prior to use. Use the “FLOW SENSOR” sub-menu under “SYSTEM SETUP” to enable the process

feedback analog input. The flow sensor type must be set to “ANALOG” to enable this input. The process

feedback input should be calibrated prior to activation (ref. Section 8.1 – Pump Flow Calibration).

7.2 Digital Input Setup

7.2.1 Multi-purpose Digital Inputs

Each of the 2 Digital INPUTS can be selected as: Inactive

Each can be set as normally OPEN or normally CLOSED. For example, if an input is set to ON/OFF and

NORMALLY CLOSED, this means a CLOSED switch will activate the pump. A NORMALLY OPEN

setup will give the opposite response. These inputs are to be attached to a dry contact circuit only, apply no

voltage to these inputs.

Tank Level Input

Leak Detection (using external device)

Remote ON/OFF Input

Flow verification Input

18

Page 25

7.3 Analog Output Setup

No setup is required for the analog output. Analog output is always available at the corresponding terminals

(see wiring diagram Figure 4a, Section 5.3.4). The analog output follows and is proportional to motor speed.

7.4 Digital Output Setup

Each of the 3 Digital OUTPUTS can be selected as: ON/OFF Status

AUTO/MAN Status

Leak Detected

Alarm Indicator

Tank Level Status

Each can be set as normally OPEN or normally CLOSED. For example, if an output is set to ON/OFF

INDICATION and NORMALLY CLOSED, this means that when the motor is running (indicator lamp is

ON) the output will be CLOSED. A NORMALLY OPEN setup will give the opposite response.

Digital output circuits are transistor based and limited to 40 VDC maximum, see Section 5.3.4, Input/Output

Signal Wiring, and Section 11, Specifications, for more information).

19

Page 26

8. Calibrations

As a convention in this manual:

“WET” calibrations

pump running with fluid, or an electrical signal input provided at the appropriate terminals.

will refer to those that require normal operating conditions, for example the

“DRY” calibration

or that a specific input signal be present.

Some of the calibration routines may be performed either way. Note any system requirements listed

for each routine.

routines are run under other conditions, and often do not require the pump to run

8.1 Pump Flow Calibration

Pump flow calibration is not necessary for the standard speed controller. It is only necessary for models

configured for flow meter feedback. The selected flow meter should meet or exceed requirements listed in

the Flow Meters section (ref. Section12 - Specifications). The flow meter should also be calibrated prior to

MPC VECTOR calibration according to manufacturer specifications.

Y

OUR

MPC VECTOR

DEPENDENT AND FLOW METER DEPENDENT. YOU MUST ALWAYS PERFORM A CALIBRATION WITH

THE

MPC VECTOR

CALIBRATE THE UNIT MAY RESULT IN DAMAGE TO SYSTEM COMPONENTS

The pump may be calibrated in WET (under normal operating conditions) or DRY (performed with pump

off) conditions.

8.1.1 WET Flow Calibration

The Wet Flow Calibration routine will require that the user turns on the pump. The flow meter should be

configured and calibrated prior to MPC VECTOR calibration (refer to flow meter IOM for calibration

instructions). Please note that it must be safe to run the pump and dispense liquid into the system in order to

complete this calibration. The pump should be fully primed with the product in order to complete an

accurate calibration.

IS NOT FACTORY CALIBRATED AS THE CALIBRATIONS ARE SYSTEM

INSTALLED IN YOUR SYSTEM PRIOR TO USE. FAILURE TO PROPERLY

.

1. Press the MENU key to access the Calibration Menu.

2. Press the ENTER key to access Pump Flow Calibration screen.

3. Press the ENTER key to access Wet Pump Flow Calibration screen.

4. Press the ENTER key to begin Flow Calibration

R P M 0

20

- M E N U -

C A L I B R A T I O N

C A L I B R A T I O N

P U M P F L O W

P U M P F L O W

W E T C A L

C A L S P E E D

Page 27

5. Using the UP and/or DOWN arrow keys adjust the motor speed to approximate setpoint. This speed is just

a reference point for the MPC MPC VECTOR to measure flow meter input. If the maximum motor speed

for a given application is known, it is best to use this as a flow calibration point.

C A L S P E E D

R P M 1800

6. Press the ENTER key to accept the calibration speed.

S T A R T M O T O R

Y E S = E N T R N O =MENU

7. Press the ENTER key to start the motor and advance to the flow entry screen. You cannot start the motor

with the motor key during MENU operations.

P U M P F L O W

F L O W : 0 0 0 . 00GPM

T

HE MOTOR WILL START WHEN THE ENTER KEY IS PRESSED. MAKE SURE THAT YOUR SYSTEM IS

PREPARED FOR OPERATIONS BEFORE STARTING THE MOTOR

8. Obtain flow rate from flow meter.

.

Pay close attention to the units used for flow rates. The flow rate entered into the MPC VECTOR

calibration MUST match the units displayed on the MPC VECTOR. You may back out of this

calibration routine at this time and change the MPC VECTOR flow units, if necessary.

9. Enter the flow rate from your flow meter. If flow meter output is not visually available you may obtain

flow rate through measurements and stopwatch. The UP and DOWN arrow keys may be used to change

each digit. Press the ENTER key after each digit has been entered to advance to the next digit or the

MENU key to back up.

P U M P F L O W

F L O W : 0 0 4 . 80gpm

The calibration routine may be exited at any time prior to pressing ENTER after the last digit has been

entered by pressing the MENU key (several times) to back out. If there is a problem with flow units or

flow meter calibration back out before completing MPC VECTOR calibration and fix the problem.

10. Once all digits have been entered and the ENTER key is pressed, the WET flow calibration routine is

complete and you should see the following screen.

P U M P F L O W

C A L I B R A T E D

After the ENTER key has been pressed it will take several seconds for the calibration routine to

complete.

11. Pump flow calibration is complete.

12. Press the MENU key three times to exit back to the main operating screen.

21

Page 28

8.1.2 DRY Flow Calibration

The DRY Flow Calibration routine does not require the pump to run. Instead, the user may input known

flow meter feedback values. This process can be used for fine adjustment of flow rate display, or in

situations where it is not possible or not safe to run the pump during calibration.

The DRY Flow Calibration Routine may be used to make small adjustments to the MPC VECTOR

calibration to ensure to make the MPC VECTOR display more closely matches the Flow Meter display.

If you are not using a flow meter for feedback, the DRY flow calibration routine can be used, but will

display motor RPM instead of mA value during the procedure.

1. Press the MENU key to access the Calibration Menu.

- M E N U -

C A L I B R A T I O N

2. Press the ENTER key to access Pump Flow Calibration screen.

C A L I B R A T I O N

P U M P F L O W

3. Press the ENTER key to access Wet Pump Flow Calibration screen.

P U M P F L O W

W E T C A L

4. Press the UP or DOWN key to access DRY Pump Flow Calibration screen.

P U M P F L O W

D R Y C A L

5. Press the ENTER key to access the DRY Pump Flow Calibration routine. A blinking cursor will show you

that you are adjusting the Current (mA).

M I N S E T P T 0.0MA

F L O W : 0 . 00GPM

6. Press the UP and/or DOWN keys to adjust the Current setpoint.

M I N S E T P T 4.0MA

F L O W : 0 . 00GPM

7. Press the ENTER key to accept this setpoint. The Cursor will now blink on the second line, indicating that

the Flow is the active field. Press the UP and/or DOWN keys to adjust the Flow setpoint.

M I N S E T P T 4.0MA

F L O W : 0 . 00GPM

8. Press the ENTER key to access the MAX setpoint values. The cursor will blink on the top line indicating

that the Current setpoint may be adjusted.

M A X S E T P T 1 6.0MA

F L O W : 4 . 00GPM

22

Page 29

9. Press the UP and/or DOWN arrow keys to adjust the Max Current setpoint.

M A X S E T P T 2 0.0MA

F L O W : 4 . 00GPM

10. Press ENTER to accept the Current Setpoint. The cursor will blink on the bottom line indicating that the

Flow setpoint may be adjusted.

11. Press the UP and/or DOWN arrow keys to adjust the Max Flow setpoint. Note that you can not set this

value greater than the Maximum Flow the pump is rated for (you may see the maximum rated flow in the

Pump Information screens).

M A X S E T P T 2 0.0MA

F L O W : 5 . 92GPM

You may back out of the DRY calibration routine at any point up to now without saving any calibration

settings. Use the MENU button to back up.

12. Press the ENTER key to save the new Analog Calibration values. Upon completion of Calibration

you should see the following screen.

P U M P F L O W

C A L I B R A T E D

13. Press the MENU key several times to return to Operations Mode.

To optimize feedback, it is best to set 4mA to 0 flow and 20mA to a value slightly higher (10-20% or

so) than your max desired flow setting. This allows the user a full range of flow setpoints as well as

giving the MPC VECTOR the best possible Analog resolution.

23

Page 30

8.2 Analog Input Calibration

If you are not using the 4-20mA input to the MPC VECTOR for control, skip this section. To calibrate the

Input Current you must first correctly wire an external signal source. Refer to Section 5 – Installation: Low

Voltage Input Connections, Analog Input. As with the flow calibration routine, the Analog Input may be

calibrated WET or DRY. To perform a WET calibration, the signal-generating device must be active and

capable of generating the full range (low to high) of potential input signals. A DRY calibration requires no

input signal.

If the MPC VECTOR is configured for Speed Control instead of Flow Control the displays below reflecting

pump flow will be replaced with pump speed displays. For example the bottom line of step 8 of the WET

Calibration routine will display ‘SPEED XXXX RPM’.

8.2.1 “WET” Analog Input Calibration

1. The starting display will be:

S E T P T X X . X X X

F L O W X X . X X X

2. Press the MENU key

- M E N U -

C A L I B R A T I O N

3. Press the ENTER key

C A L I B R A T I O N

P U M P F L O W

4. Press the UP arrow key twice, to access the analog input calibration

C A L I B R A T I O N

A N A L O G I N P U T

5. Press the ENTER key

A N A L O G I N P U T

(with a field signal)

6. Press the ENTER key

A P P L Y M I N M A

E N T E R T O S T ART

7. Apply your desired minimum mA control signal to the MPC VECTOR (usually 4 mA)

8. Press the ENTER key

M I N S E T P T 4 . 2 M A

F L O W 0 .00GP M

(The mA value will be equal to your input signal level)

(The lower line shows the setting the MPC VECTOR will use for this signal value)

9. Press the UP and DOWN arrow keys to change the Speed/Flow corresponding to the Analog Input Value.

24

W E T C A L

Page 31

10. Press the ENTER key once more to accept the calibration value

A P P L Y M A X M A

E N T E R T O S T ART

11. Apply your desired maximum mA control signal to the MPC VECTOR (usually 20 mA)

12. Press the ENTER key

M A X S E T P T 2 0 . 2 M A

F L O W 7 .01GP M

(The mA value will be equal to your input signal level)

(The lower line shows the setting the MPC VECTOR will use for this signal value)

13. Press the UP and DOWN arrows to adjust the Speed/Flow corresponding to the Analog Input value.

14. Press the ENTER key once more to accept the calibration value

A N A L O G I N P U T

C A L I B R A T E D

15. Analog input signal calibration is complete

16. Press the MENU key three times to exit back to the main operating screen.

If you receive the following message:

C U R R E N T D E L TA

O U T O F R A N G E

This indicates that there is not a wide enough range between your maximum and minimum analog signals.

The minimum signal range is 3 mA. The most likely source of this error is the user did not change the value

of the incoming analog signal when moving from the MIN calibration to the MAX calibration.

The analog input signal calibration procedure should be performed again, ensuring that a minimum

of 3 mA difference exsists between the MIN and MAX signal levels.

25

Page 32

8.2.2 “DRY” Analog Input Calibration

1. The starting display will be:

(keypad only, no signal present)

S E T P T X X . X X X

F L O W X X . X X X

2. Press the MENU key

- M E N U -

C A L I B R A T I O N

3. Press the ENTER key

C A L I B R A T I O N

P U M P F L O W

4. Press the UP arrow key twice, to access the analog input calibration

C A L I B R A T I O N

A N A L O G I N P U T

5. Press the ENTER key

A N A L O G I N P U T

W E T C A L

6. Press the UP or DOWN key

A N A L O G I N P U T

D R Y C A L

7. Press the ENTER key to access the DRY Pump Flow Calibration routine for ANALOG Flow Meters. A

blinking cursor will show you that you are adjusting the Current (mA).

M I N S E T P T 0.0MA

F L O W : 0 . 00GPM

8. Press the UP and/or DOWN keys to adjust the Current setpoint.

M I N S E T P T 4.0MA

F L O W : 0 . 00GPM

9. Press the ENTER key to accept this setpoint. The Cursor will now blink on the second line, indicating that

the 4mA Flow is the active field. Press the UP and/or DOWN keys to adjust the Flow setpoint.

M I N S E T P T 4.0MA

F L O W : 0 . 00GPM

10. Press the ENTER key to access the MAX setpoint values. The cursor will blink on the top line indicating

that the Current setpoint may be adjusted.

M A X S E T P T 1 6.0MA

F L O W : 4 . 00GPM

26

Page 33

11. Press the UP and/or DOWN arrow keys to adjust the Max Current setpoint.

M A X S E T P T 2 0.0MA

F L O W : 4 . 00GPM

12. Press ENTER to accept the Current Setpoint. The cursor will blink on the bottom line indicating that the

Flow setpoint may be adjusted.

13. Press the UP and/or DOWN arrow keys to adjust the Max Flow setpoint.

M A X S E T P T 2 0.0MA

F L O W : 5 . 92GPM

You may back out of the DRY calibration routine at any point up to now without saving any calibration

settings by pressing the MENU key several times.

1. Press the ENTER key to save the new Analog Calibration values. Upon completion of

Calibration you should see the following screen.

A N A L O G I N P U T

C A L I B R A T E D

2. Press the MENU key several times to return to Operations Mode.

27

Page 34

8.3 Analog Output Calibration

The analog output calibration routine maps the motor speed of the MPC VECTOR to a 4-20mA output signal. The

output signal is NOT proportional to pump flow. If a 4-20mA signal representing flow is required it must be

obtained by splitting the flow meter output signal.

1. The starting display will be:

S E T P T X X . X X X

F L O W X X . X X X

2. Press the MENU key

- M E N U -

C A L I B R A T I O N

3. Press the ENTER key

C A L I B R A T I O N

P U M P F L O W

4. Press the UP ARROW key to access the analog output calibration

C A L I B R A T E D

A N A L O G O U T P UT

5. Press the ENTER key

S E T 0 % S P E E D TO

0 4 . 0 M A

6. Use the UP and DOWN arrow keys to adjust the output signal as required. The actual output signal

will vary and can be monitored with a meter or your facility control system. The value displayed on

the screen may not match the actual output signal and is for visual reference only.

7. Press the ENTER key once more to accept the calibration

S E T 1 0 0 % S P EED T O

2 0 . 0 M A

8. Use the UP and DOWN arrow keys to adjust as in step 6 above

28

Page 35

9. Press the ENTER key once more to accept the calibration value

A N A L O G O U T P UT

C A L I B R A T E D

10. Analog output signal calibration is complete

11. Press the MENU key three times to exit back to the main operating screen

If you receive the following message:

C U R R E N T D E L TA

O U T O F R A N G E

This indicates that the output current for 0% speed has been set greater than or equal to the output current

setting for 100% speed. Repeat the process and ensure that the 0% calibrated signal is set to a value lower

than the 100% calibrated signal.

29

Page 36

8.4 PulsaGuard Pump Protection

PulsaGuard is designed to turn your pump off when running in dangerous conditions. These conditions are

user configurable and can be easily modified to meet each application.

When flow meter feedback is being provided, PulsaGuard will turn off your motor if a low flow set point is

crossed for more than 10 seconds. This will protect the pump in under-loaded or overloaded conditions, which

would cause the flow to fall below the user’s acceptable limit. The MPC VECTOR will also trigger an alarm

condition if the flow set point cannot be reached for some reason. This alarm will be displayed on the MPC

MPC VECTOR display but will not shut the motor off. If the MPC VECTOR is operating without flow meter

feedback PulsaGuard can read the motor current and shut off the pump if the current drops below the shut off

level and stays under that level for 10 seconds, effectively protecting equipment from under-loaded conditions.

The PulsaGuard pump protection may be enabled and disabled as desired from the System Setup menus (see

section 8.4.2: PulsaGuard Enable/Disable). Note that once a calibration is performed the pump protection is

automatically enabled, you will not have to manually enable it.

8.4.1 PulsaGuard Calibrations, using Flow Meter Feedback

1. The starting display will be:

S E T P T X X . X X X

F L O W X X . X X X

2. Press the MENU key

- M E N U -

C A L I B R A T I O N

3. Press the ENTER key

C A L I B R A T I O N

P U M P F L O W

4. Press the UP key

C A L I B R A T I O N

P U L S A G U A R D

5. Press the ENTER key

M I N S E T P O I N T

S E T P T : 0 . 00GPM

6. Using the UP and DOWN arrow keys set the low flow setpoint

M I N S E T P O I N T

S E T P T : 0 . 50GPM

30

Page 37

7. Press the ENTER key to complete the PulsaGuard Calibration.

P U L S A G U A R D

C A L I B R A T E D

8.4.2 PulsaGuard Calibrations, no Flow Meter Feedback

PulsaGuard may be calibrated WET or DRY. A WET calibration requires that the user simulate

underloaded conditions.

Follow Steps 1-4 above. You should see the following screen

C A L I B R A T I O N

P U L S A G U A R D

5. Press the ENTER key.

P U L S A G U A R D

W E T C A L

WET CALIBRATION:

6. Press the ENTER key again to access the WET calibration routine.

S T A R T M O T O R

Y E S = E N T R N O =MENU

7. Run the pump to meet desired low setpoint conditions. You may adjust the speed of the motor using

the UP and DOWN arrow keys. The output current of the motor will be displayed on the screen. The

values below are not indicative of what your display will show.

M I N S E T P T 2.0A

S P E E D : 1 2 00RPM

8. Once the MPC MPC VECTOR has reached the desired low current setpoint, press the ENTER key.

P U L S A G U A R D

C A L I B R A T E D

9. PulsaGuard Pump Protection is now calibrated and enabled.

DRY CALIBRATION:

6. Press the UP key

P U L S A G U A R D

D R Y C A L

31

Page 38

7. Press the ENTER key

M I N S E T P O I N T

S E T P T : 0.0A

8. Use the UP and DOWN keys to adjust the current setpoint

M I N S E T P O I N T

S E T P T : 2.0A

9. Press the ENTER key to accept the calibration value.

P U L S A G U A R D

C A L I B R A T E D

10. PulsaGuard Pump Protection is now calibrated and enabled.

8.5 Display Contrast Adjustment

Should adjustment of the contrast level of the display become necessary, use the following procedure while

in the normal operating mode.

To increase contrast, press and hold at the same time.

To decrease contrast, press and hold at the same time.

32

Page 39

8.6 Tuning the Control Algorithm

This option should only be used by control systems engineers who are familiar with tuning PID loops.

This is not intended for the casual user. Changing these values may result in the system oscillating

without settling on the set point or never reaching the set point at all. See Section 21, Appendix 2 for

more information and theory on PID control.

The MPC VECTOR allows users to tune the motor control algorithm to speed up or slow down the MPC

VECTOR response time. This is done by adjusting the PID Controller parameter coefficients.

The user may adjust the Proportional coefficient, kp, the Integration coefficient, ki, and the Derivative

coefficient, kd, independently. The user may also view and modify the sampling period of the control loop, ts.

Modifying the PID coefficients

1. The starting display will be:

S E T P T X X . X X X

F L O W X X . X X X

2. Press the MENU key

3. Press the UP arrow key

4. Press the ENTER key

5. Press the DOWN

6. Press the ENTER key

- M E N U -

C A L I B R A T I O N

- M E N U -

S Y S T E M S E T U P

S Y S T E M S E T U P

S T A T U S

S Y S T E M S E T U P

P I D P A R A M E T ERS

P I D P A R A M E T ERS

C O E F F I C I E N T S

7. Press the ENTER key

P R O P O R T I O N A L

X . X X X

33

Page 40

8. Press the UP and/or DOWN keys to adjust the denominator, kp'

P R O P O R T I O N A L

X . 1 0 0

9. Press the ENTER key

I N T E G R A L

X . X X X

10. Press the UP and/or DOWN keys to adjust the denominator, ki'

I N T E G R A L

X . 0 5 0

11. Press the ENTER key

D E R I V A T I V E

X . X X X

12. Press the UP and/or DOWN keys to adjust the denominator, kd'

D E R I V A T I V E

X . 0 5 0

13. You may back out without saving the new PID coefficients at this point by hitting the MENU key

several times to return to the first screen. If you want to save the changes press the ENTER key

P I D P A R A M E T ERS

C O E F F I C I E N T S

14. The new PID coefficients have been set.

34

Page 41

Modifying the Sampling Interval, when Flow Meter feedback is used

1. The starting display will be:

S E T P T X X . X X X

F L O W X X . X X X

2. Press the MENU key

- M E N U -

C A L I B R A T I O N

3. Press the UP arrow key

- M E N U -

S Y S T E M S E T U P

4. Press the ENTER key

S Y S T E M S E T U P

S T A T U S

5. Press the DOWN key until you get to the PID screen

S Y S T E M S E T U P

P I D P A R A M E T ERS

6. Press the ENTER key

P I D P A R A M E T ERS

C O E F F I C I E N T S

7. Press the UP arrow key

P I D P A R A M E T ERS

S A M P L I N G P E RIOD

8. Press the ENTER key

S A M P L I N G P E RIOD

P E R I O D : XXXMS

9. Press the UP and/or DOWN arrows to adjust the sampling period, ts

S A M P L I N G P E RIOD

P E R I O D : XXXMS

10. Press the ENTER key to accept the new sampling period

P I D P A R A M E T ERS

S A M P L I N G P E RIOD

11. The new PID sampling period has been set.

35

Page 42

9. Flow Meter Input

The MPC VECTOR accepts flow meter process feedback from an analog (4-20mA) flow metering device. The

manufacturer of the flow meter is not important but the process signal must conform to a set of minimum

specifications in order to work with the MPC VECTOR.

9.1 Flow Meter Installation

Prior to installation make sure your flow meter conforms to the MPC VECTOR’s flow meter specifications

(refer to Section 13, Specifications). Your flow meter must also be calibrated independently prior to

installation.

Figure 5 – Flow Meter Connection

1. Remove MPC VECTOR power and wait 30 seconds for complete power dissipation.

2. Connect your flow meter input to the Flow Meter Input Terminal Block (ref Fig. X.XX).

3.

Plug in MPC VECTOR. After the system information is displayed the starting display will be:

S E T P T X X . X X X

F L O W X X . X X X

4. Press the MENU key

- M E N U -

C A L I B R A T I O N

5. Press the UP arrow key

- M E N U -

S Y S T E M S E T U P

36

Page 43

6. Press the ENTER key

S Y S T E M S E T U P

S T A T U S

7. Press the DOWN key five (5) times

S Y S T E M S E T U P

F L O W S E N S O R

8. Press the ENTER key to enter the Flow Sensor setup menus.

F L O W S E N S O R

S E N S O R T Y P E

9.

Press the ENTER key to see the current sensor configuration

.

S E N S O R T Y P E

I N A C T I V E

10. Press the ENTER key to change the sensor type.

S E N S O R T Y P E

< I N A C T I V E >

11. Press the UP arrow key until the analog flow meter option is displayed.

S E N S O R T Y P E

< A N A L O G >

12. Press the ENTER key to accept the new configuration.

S E N S O R T Y P E

A N A L O G

13. Press the MENU key several times to return to the Main screen.

14. Perform either a WET or DRY Flow Calibration on your MPC VECTOR (see Section 8.1: Pump Flow

Calibration).

15.

Your MPC MPC VECTOR is now ready for use with your flow meter.

37

Page 44

10. Motor Parameter Setup and Tuning

The MPC VECTOR controller must know several motor characteristics before the motor can be calibrated.

This calibration allows the controller to maintain precise control over the operation of the motor.

If the drive has not been calibrated an error will appear on the screen. In addition, at startup the User Interface

will be redirected to the Calibration/Motor Parameter sub-menu.

If your MPC VECTOR unit has been shipped from the factory as a complete unit with Eclipse pump

and motor, these parameters will have been entered at the factory. No further user input will be

required.

Note that the ranges listed in the table below reflect absolute min/max accepted by the drive and may not

match a specific application. These do not have to be set in any particular order but will be presented

sequentially by the User Interface. The parameters will need to be entered in the field if the MPC VECTOR

controller was shipped without a motor, or if the motor is changed to a different model than was originally

supplied.

S

ETTING THESE PARAMETERS IMPROPERLY AND RUNNING THE AUTO-CALIBRATION ROUTINE CAN

RESULT IN DRIVE ERRORS.

Reference motor parameter table, next page

38

Page 45

Param.

85 Motor Rated Speed Nameplate RPM Rating 300 – 65,000

86 Motor Rated Amps Nameplate FLA Rating 0.0 – 480 Amps Various 1

87 Motor Rated Volts Nameplate Voltage Rating 0 – 600 Volts 230 VAC

88 Motor Base Frequency Nameplate Frequency 25 – 500 Hz 50 or 60 Hz

91 Motor Cosine Phi Nameplate Cosine Phi 0.4 – 0.99 Approx 0.8 2

81 Invoking this parameter begins the auto-calibration routine

NOTES:

1. FLA = Full Load Amps

2. The Cosine Phi is also known as the Power Factor, this will sometimes be on the nameplate as

“PF”. If the Power Factor is given as a %, always use the decimal equivalent (for example a power

factor of 84% would be entered as 0.84) If the Cosine Phi is not provided by the motor manufacturer,

one of the following formulas may be used.

Name Description Range Typical Note

1800 RPM

RPM

COS

)2(

COS

1

−

=Φ

sincos)1(

CurrentgMagnetizin

CurrentMotor

=Φ

746

×

HPMotor

CurrentMotorVoltageMotorEfficiencyMotor

×××

732.1

After all of the Parameters have been entered, the drive needs to perform an auto-calibration routine