Page 1

Installation,

MPC®

IOM-CTL-2000-Rev.I

Operation &

Maintenance

Manual

SPEED CONTROLLER

Page 2

ii

MPC™ FACTORY SERVICE POLICY

Your MPC is a state of the art microprocessor base d mot or spe ed c ontrol for use

with Pulsafeeder Diaphragm Metering Pumps. It includes extensive on-board

diagnostics. If you are experiencing a problem with your MPC, first review the

on-screen information, then consult the troubleshooting guide. If the problem is

not covered or cannot be solved, please contact your local authorized Sales

Representative or our Technical Service Department at (585) 292-8000 for

further assistance.

Trained individuals are available to diagnose your problem and arrange a

solution. Solutions may include purchasing a replacement unit or returning the

MPC to the factory for inspection and repair. All returns require a Return Material

Authorization (R.M.A.) number to be issued by Pulsafeeder. Replacements

purchased under a possible warranty situation may be credited after an

examination of the original MPC by Pulsafeeder personnel.

Certain components may be purchased for replacement. Refer to Section 19 –

Maintenance & Spare Parts for more information and part numbers. Parts

purchased to correct a warranty issue may be credited after examination of the

original parts by Pulsafeeder personnel. Parts returned for warranty

consideration that test satisfactorily, will be sent back to the originator via freight

collect.

Any field modific ations will void the Pulsafeeder MPC warranty. Out-ofwarranty repairs will be subject to Pulsafeeder's standard bench fees and

testing costs associated with replacement components.

FCC Warning

This equipment genera tes and us es radio frequency energy. If not installed and

used properly, in strict accordance with the manufacturer’s instructions, it may

cause interference to radio communications. Operation of this equipment in a

residential area is likely to cause interference. In such cases, the user at their

own expense will be required to take whatever measures necessary to correct

the interference.

Copyright

Copyright © 2007-2014 Pulsafee der , Inc . Al l rig ht s reser ved.

Information in this document is subject to change without notice. No part of this

publication may be reproduced, stored in a retrieval system or transmitted in any

form or any means electronic or mechanical, including photocopying and

recording for any purpose other than the purchaser’s personal use without the

written permission of Pulsafeeder.

Page 3

iii

Table of Cont e nts

INSTALLATION, OPERATION & MAINTENANCE MANUAL ................................................................................. I

MPC™ FACTORY SERVICE POLICY ..................................................................................................... I

TABLE OF CONTENTS .................................................................................................................................. III

FOR THE REMAINDER OF THIS BULLETIN, THE FOLLOWING CONVENTIONS ARE IN EFFECT. ...............................V

1. INTRODUCTION ...................................................................................................................................... 1

2. FORWARD ............................................................................................................................................. 1

3. DESCRIPTION ........................................................................................................................................ 1

3.1 MPC Standard Features ........................................................................................................ 2

3.2 Options ................................................................................................................................... 3

4. SAFETY CONSIDERATIONS ..................................................................................................................... 3

4.1 General Safety ....................................................................................................................... 3

4.2 Electrical Safety ..................................................................................................................... 3

4.3 Fire Safety .............................................................................................................................. 3

4.4 Mechanical Safety ................................................................................................................. 4

4.5 Hydraulic Safety .................................................................................................................... 4

4.6 Liability Exclusion ................................................................................................................. 4

5. PUMP SUITABILITY TO SITE OF INSTALLATION ......................................................................................... 5

6. TRANSPORT AND STORAGE .................................................................................................................... 6

6.1 Consignment receipt and unpackaging .............................................................................. 6

6.2 Handling ................................................................................................................................. 6

6.3 Lifting ...................................................................................................................................... 6

6.4 Recycling and end of product life ........................................................................................ 6

7. STORAGE INSTRUCTIONS ....................................................................................................................... 8

7.1 Short Term (0 - 12 months) ................................................................................................... 8

7.2 Long Term (12 months or more) .......................................................................................... 8

8. INSTALLATION AND WIRING .................................................................................................................... 9

8.1 Location .................................................................................................................................. 9

8.2 Installation Notes ................................................................................................................... 10

8.3 Installation guidelines fo r EMC compliance ....................................................................... 10

8.3.1 The cover must be installed properly. ......................................................................... 10

8.3.2 Shielded cables used for analog inputs and outputs ................................................ 10

8.3.3 Proper Earth grounding ................................................................................................ 10

8.3.4 Ensure Power mains are properly filtered for isolation from line transients, ......... 10

8.3.5 Lightning strikes or other electrical noise sources. .................................................. 10

8.4 Electrical Wiring .................................................................................................................... 11

8.4.5 Analog input signals, so the MPC can accept a process input signal. .................... 11

8.4.6 Power Wiring Information ............................................................................................. 14

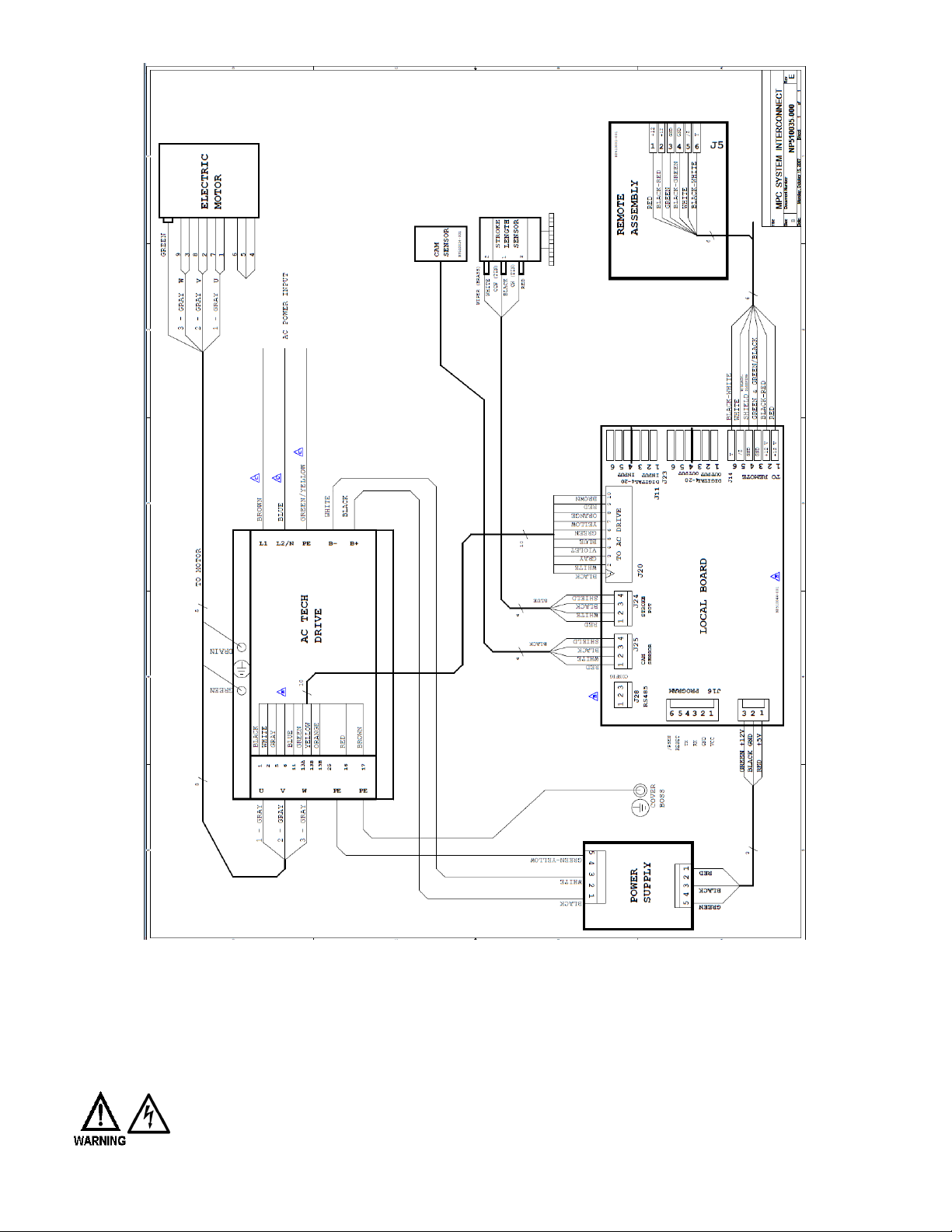

8.4.7 Power Wiring Diagram .................................................................................................. 15

8.4.8 Control Input/Output Signal Wiring ............................................................................. 18

8.5 Check Wiring and Close Access Cover .............................................................................. 20

8.6 Confirm Correct Incoming Power ........................................................................................ 20

9. START UP AND OPERATION .................................................................................................................... 22

9.1 Overview ................................................................................................................................. 22

9.2 Keypad/Lamp Operation ....................................................................................................... 23

9.3 Confirm Display and Keypad Functionality ........................................................................ 23

9.4 Flow Display ........................................................................................................................... 24

9.5 Wrapping up ........................................................................................................................... 24

10. INPUT/OUTPUT SETUP .................................................................................................................. 26

10.1 Analog Input Setup ................................................................................................................ 26

Page 4

iv

10.2 Digital Input Setup ................................................................................................................. 26

10.3 Analog Output Setup ............................................................................................................. 26

10.4 Digital Output Setup .............................................................................................................. 26

10.5 Pump Flow Calibration.......................................................................................................... 27

10.6 Analog Input Calibration ....................................................................................................... 31

10.7. Analog Output Calibration .................................................................................................... 34

10.8 Display Contrast Adjustment ............................................................................................... 35

10.9 Changing the Motor Base Frequency .................................................................................. 35

11. ALARM AND ERROR MESSAGES ................................................................................................... 36

12. EXTENDING YOUR HAND-HELD CONTROLLER ................................................................................ 38

12.1 Obtain New Cable: ................................................................................................................. 38

12.2 Removal and Connection of the Cable from the Handheld: ............................................. 38

13. SPECIFICATIONS .......................................................................................................................... 42

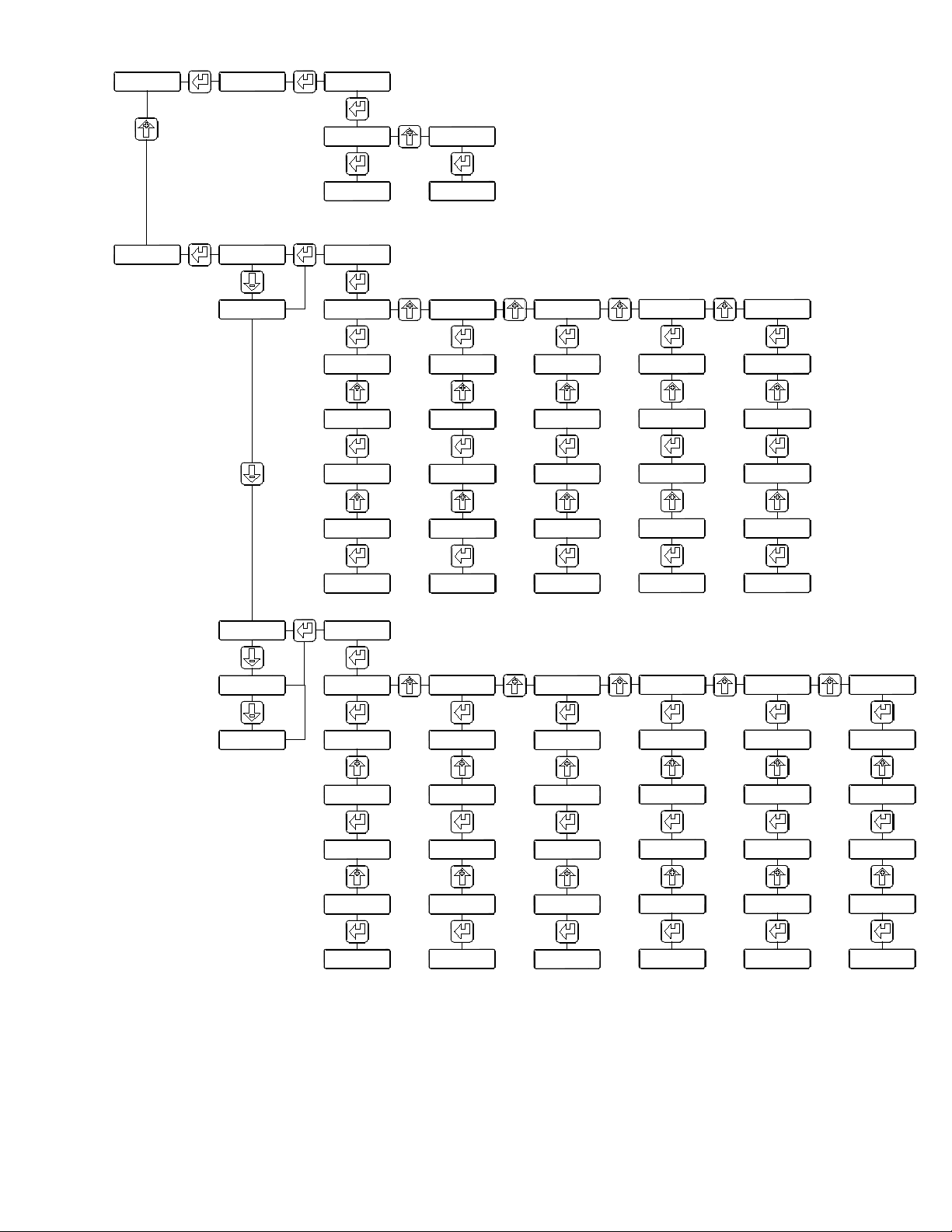

14. MENU MAPS ................................................................................................................................ 45

15. FACTORY DEFAULT VALUES ......................................................................................................... 47

16. RETRIEVAL OF SETUP INFORMATION ............................................................................................. 47

17. SPECIAL KEYPRESS ACCESS ....................................................................................................... 47

18. TROUBLESHOOTING GUIDE........................................................................................................... 48

19. MAINTENANCE & SPARE PARTS ................................................................................................... 49

19.1 Operating Precautions .......................................................................................................... 49

19.2 Cleaning and Decontamination ............................................................................................ 49

19.3 User Replaceable Parts for the MPC ................................................................................... 50

Page 5

v

Conventions

A

Notes are general information meant to make operating the

Tips have been included within this bulletin to help the operator

For the remainder of this bulletin, the following Conventions are in effect.

WARNING DEFINES A CONDITION THAT COULD CAUSE DAMAGE TO BOTH

THE EQUIPMENT AND THE PERSONNEL OPERATING IT

BE CONSULTED IN ALL CASES WHERE THE

IN ORDER TO FIND OUT THE NATURE OF THE P OTENTIAL

ANY ACTIONS WHICH HAVE TO BE TAKEN TO AVOID THEM

WARNING SYMBOL IS MARKED

. THIS MANUAL MUST

HAZARDS AND

.

CAUTION, POSSIBILITY OF ELECTRIC SHOCK AND/OR

ELECTROCUTION HAZARD!

equipment easier.

run the equipment in the most efficient manner possible. These

“Tips” are drawn from the knowledge and experience of our

staff engineers, and input from the field.

Revision History:

Rev E (3-25-05)

- Section 3.1 Description, added 3-phase vs. single-phase info

- Change description of digital output specification

- New figure 2 (pump mounting)

- Updated analog in, analog out, and flow calibration instructions

- Update error handling text, Section 11

- Add s pecifications for v olt ag e range and ELCB’s

- Add safety warnings about inrush current and capacitor discharge

throughout

Rev F (7-25-06)

- Added nametag diagram and note on proper input voltage selection

on page 9

- Added section 8.5 on adjusting motor base frequency

- Added sample digital output diagram in section 5.3.4

Rev H (9-26-07)

- Added clarification on digital output capability, sect ions 1.2, 5.3.4,

and 7.4

- Motor information added, sections 1.2, 1.3, and 11

- Added missing step in calibration instructions, section 8.1.1

Rev I (05-22-2014)

− Updated to reflect requirements of UL 61010-1 3

rd

Edition

Page 6

1. Introduction

The Metering Pump Controller (MPC) is a microprocessor base d m ot or sp eed

control device, for use with Pulsafeeder mechanical and hy dr aulic diaphragm

metering pumps. It has been designed for simplicity, yet still has many advanced

features that allow the MPC to operate in a wide variety of environments and

applications.

This instruction manual covers the MPC only. All stan dar d fea tur es ar e cov ered

in this manual and most options hav e instructions where applicable. For

information specific to the metering pump or any other accessories, please refer

to the appropriate IOM.

2. Forward

The pumps to which these “instructions” refer to are designed for use in industrial

areas and therefore cannot be treated as retail products. The present

documentation gives instructions to be used by qualified personnel only. It must

be used in compliance with the regulations, laws and technical standards in force

and cannot, under any circumstances, take the place of plant standard or

additional regulations, including any which are not legally enforceable, which

have been issued with the scope of ensuring safety.

Equipment with special manufacturing or constructive variances may differ in

details with respect to this description.

In case of any difficulty, please contact PULSAFEEDER, INC. Technical Service.

The MPC is rated for NEMA 4x locations as identified on the controller

nameplate.

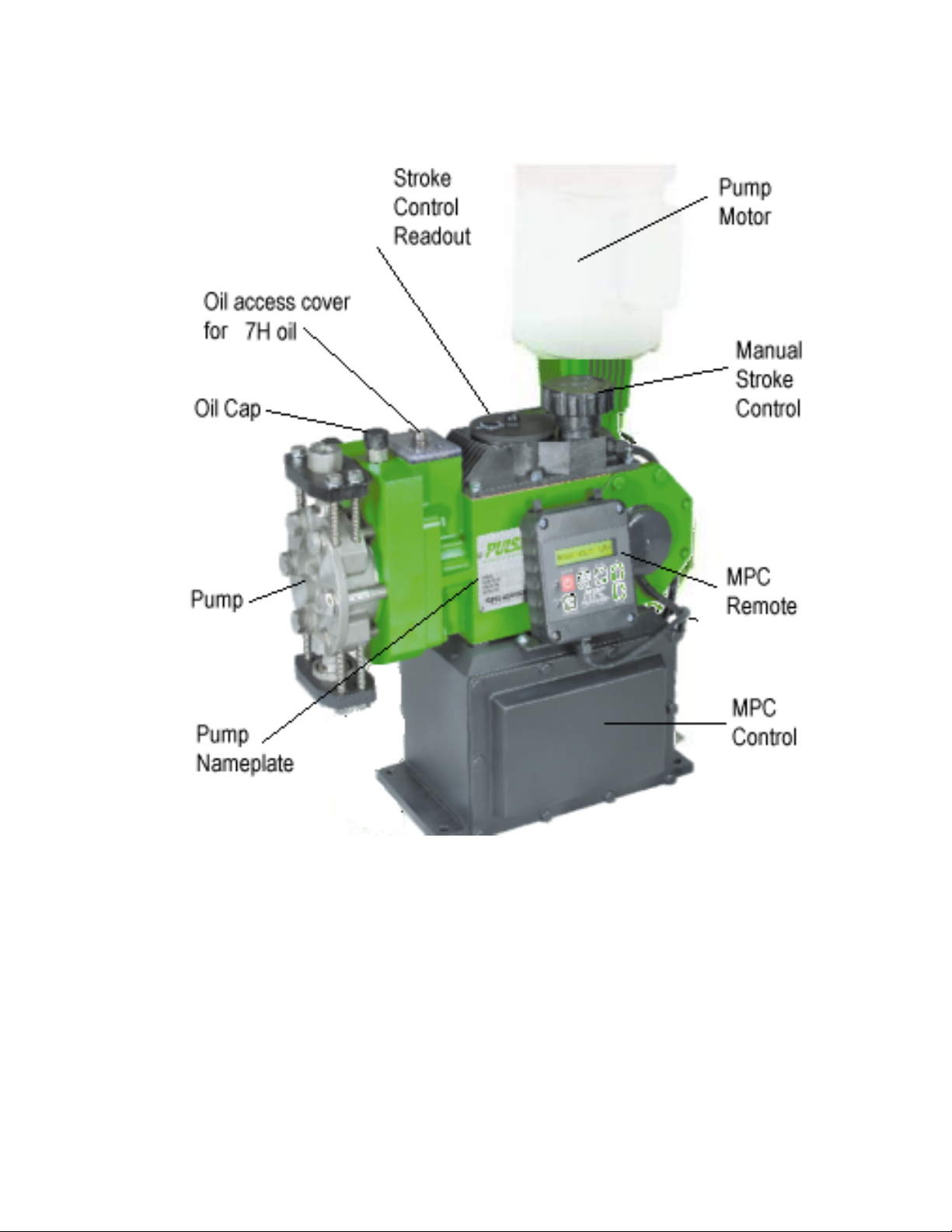

3. Description

The MPC is an advanced pump controller that is physically attached to the

pump. Its purpose is to precisely adjust output flow of a process media by

means of pump motor speed control.

The MPC is designed for a wide variety of control appl ic ati o ns . The device is

factory configured and cal i br ated for the at tached pump. The human/mach ine

interface is user friendly. Local setup and control is achieved through the

keypad and a backlit two-line liquid crystal display. Basic operation is simple

with dedicated function keys eliminating the need for a sophisticated menu

system. The MPC responds immediately to user commands. Pump output is

displayed as Gallons per Hour (GPH), Liters per Hour (LPH), Strokes per

Minute (SPM), Percent Speed, or Percent Flow (% of total pump capacity).

Digital and analog inputs will support a variety of industry standard signals to

offer flexible remote control.

The MPC is designed to simplify and automate the calibration of pump flow and

analog signals. Flow calibration uses on-screen prompting and automated

pump operation to eliminate stopwatches, calculators and human inaccuracies.

Analog signal calibration is also accomplished by simple keypad entry. It

Page 7

includes a real-time display of signal level. This eliminates the need for external

meters.

The MPC readily accepts PULSAlarm® leak detection and tank lev el inputs.

These may be configured to stop the pump and/or activate an alarm relay.

The MPC is factory configured to operate at either 60 Hz or 50 Hz input. No

special modifications , s etti ng s , or adjustments are required. All MPC controllers

are supplied with a motor rated at 60 Hz, regardless of the supply frequency.

The controller/motor combination allows for full pump speed and flow even

when operating from a 50 Hz input. Users in locations with 50 Hz AC supply do

not have to de-rate pump flow with this controller.

The motor used with the MPC is a three-phase motor; however the three-phase

power is generated internally by the MPC itself. Do not be confused by the

motor nameplate. Input power to the MPC is single-phas e AC only; either 115

or 230 volts (see Section 13, Specifications for acceptable input voltage

range). The nameplate on the rear of the MPC controller lists the appropriate

supply requirements.

At lower stroke frequencies (below 3:1 turndown), the MPC employs intermittent

motor actuation technology. This allows the user to achieve reliable low-end

performance not usually associated with variable speed controllers. By

completing a full pump stroke at constant speed, and varying the interval

between strokes, hydraulic stability and process consistency is maintained.

The AC drive used in the MPC maintains tight control over voltage and current

supplied to the pump motor. This results in lower motor operating temperatures

and less stress on motor windings, resulting in longer motor life and more

reliable overall operation. This holds true even when metering in the lower flow

ranges where the MPC uses intermittent operation.

3.1 MPC Standard Features

• Remote keypad and display for ease of operation

• Display pump flow in GPH, LPH, Strokes per Minute, or % of full pump

flow

• One 4-20 mA analog input signal for flow control

• One 4-20 mA analog output signal for flow feedback

• Two configurable digital inputs

• Three configurable digital outputs

• Advanced turndown capability

• NEMA 4X and IP56 ratings

• Available for 115 or 230 Volts, 50 or 60 Hz, single phase AC power

• Security code lockout of menus

• Commercial duty motor as standard for indoor, dry locations only

Page 8

3.2 Options

• Variable hand-held controller cable length, up to 1,000 feet from pump

• Alternate motor selections available for outdoor, washdown, chemical

duty, and other special applications

4. Safety Considerations

• Read and understand all related instructions and doc u m ent at ion before

attempting to install or maintain this equipment

• Observe all special instructions, notes, and cautions.

• Act with care and exercise good common sense and judgment during

all installation, adjustment, and maint ena nc e pr oced ur es .

• Ensure that all safety rules, work procedures, and standards that are

applicable to your company and facility are followed during the

installation, maint ena n c e, and oper a t ion of this equipment.

4.1 General Safety

The MPC was designed as a controller for operation solely with

Pulsafeeder metering pum ps . Use for any other application is considered

un-safe and voids all certification markings and warranties.

4.2 Electrical Safety

The MPC can be considered an industrial process controller. Improper

application and use can be hazardous. You are solely responsible for its

use.

The MPC's electrical installation must conform to all relevant electrical

codes. Installation and electrical maintenance must be performed by a

qualified electrician. Before installing or servicing this device, all power

must be disconnected from the sour c e at the mai n dis tr i buti o n pan el .

The MPC emits electro-magnetic energy and may generate radio

frequency interference. Its use is restricted to industrial applications. You

are responsible for shielding this energy/interference.

Certain wiring procedures may require that the user wear a wrist strap to

dissipate static charges.

4.3 Fire Safety

In case of electrical fire, use a Class C fire ex ti ng ui s her . Never use water

to extinguish a Class C fire.

Class C fires involve electrical equipment, such as appliances, wiring,

circuit breakers and outlets. Never use water to extinguish class C fires the risk of electrical shock is far too great! Class C extinguishers do not

Page 9

have a numerical rating. The C classification means the extinguishing

agent is non-conductive. Geometric symbol (blue circle)

Wait a minimum of 3 minutes after disconnecting power before

servicing the MPC or pump motor. Capacitors retain a charg e e ven

after power is removed from the controller.

4.4 Mechanical Safety

Users should note that the pump motor is always under the control of the

MPC, and as such may actuate without warning. Care should be taken to

keep loose clothing and other objects away from the pump motor.

The MPC was designed to be service free. It contains no usermaintainable components. Disassemble the MPC enclos ur e only for

initial field wiring, or as instru c ted to do so within this manual. Evidence

of unauthorized disassembly shall void the warranty.

4.5 Hydraulic Safety

Thoroughly review and adhere to the contents of the pump Installation,

Operation, Maintenance and Instruction manual for installation of the

Pulsafeeder metering pum p. As a microprocessor con tr ol led device, the

MPC may activate the pump motor without warning – generating

hydraulic pressure and fluid flow. Care should be taken to protect both

users and systems should the pump activate.

4.6 Liability Exclusion

Pulsafeeder, Inc. is unable to monitor the observance of the

instructions given in this manual, nor verify the actual working

conditions and installation of the equipment, the correct operation,

the using and maintenance of the equipment and accessories. An

incorrect installation, or misuse of the equipment, may cause

serious damage and may pose a danger to persons or property.

Any anomalies must be reported to the maintenance supervisor.

The user is not authorized to tamper with the machine for any

reason.

Attempts to disassemble, modify or tamper in general by

unauthorized personnel will void the guarantee and will release

Pulsafeeder, Inc. from any liability for damage caused to persons or

property resulting from such actions.

Page 10

Pulsafeeder, Inc. is considered released from any liability in the following

cases:

- improper installation;

- improper use of the equipment by non-professional or

inadequately trained operators;

- use not in compliance with regulations in the Country of use;

- lack of maintenance or improperly performed;

- use of non-or iginal spare parts or incorrect parts for the model in

question;

-

total or partial failure to observe the instructions;

- exceptional environmental events.

DO NOT PERFORM ANY WORK ON THE PUMP, MOTOR OR MPC

CONTROL UNIT WITH ELECTRICAL POWE R CONNECTED TO THE

MPC CONTROL UNIT. DO NOT OPERATE MPC UNIT WITH THE

COVER REMOVED. DANGER OF ELECTRONIC SHOCK AND

MECHANIC AL PINCH HAZARD!

INSTALLATION AND REPAIRS SHOULD ONLY BE PERFORME D BY

AUTHORIZED PERSONNEL!

FOLLOW ALL SAFETY/ LOCAL LOCK-OUT, T AG-OUT

PROCEEDURES!

5. Pump Suitability to Site of Installation

Upon equipment receipt, verify that pumps have not received any damage due to

transportation and are complete with every eventual accessory. In case anomalies or

damages are discovered prior to installation, please contact PULSAFEEDER, INC.

Technical Service.

Page 11

6. Transport and Storage

6.1 Consignment receipt and unpackaging

Immediately after receipt of the equipment it must be checked against

the delivery/shipping documents for its completeness and that there has

been no damage in transportation.

Check any crate, boxes or wrappings for any accessories or spare parts

that may be packed separately with the equipment or attached to side

walls of the box or equipment.

Each product has a unique serial number. Check that this number

corresponds with that advised and always quotes this number in

correspondence as well as when ordering spare parts or further

accessories.

Shortages or damage should be reported immediately to the carrier and

your Pulsafeeder Representative.

6.2 Handling

Boxes, crates, pallets or cartons may be unloaded using fork lift vehicles

or slings dependent on their size and construction.

6.3 Lifting

A crane must be used for all controller/pump sets in excess of 25 kg (55

lb). Fully trained personnel must carry out lifting, in accordance with local

regulations.

Slings, ropes and other lifting gear should be positioned where they

cannot slip and where a balanced lift is obtained.

6.4 Recycling and end of product life

At the end of the service life of the product or its parts, the relevant

materials and parts should be recycled or disposed of using an

environmentally acceptable method and local requirements. If the

product contains substances that are harmful to the environment, these

should be removed and disposed of in accordance with current

regulations. This also i ncludes the liquids and/or gases that may be used

in the "seal system" or other utilities.

Page 12

Make sure that hazardous substances are disposed of safely and that

the correct personal protective equipment is used. The safety

specifications must be i n accordance with the current regulations at all

times.

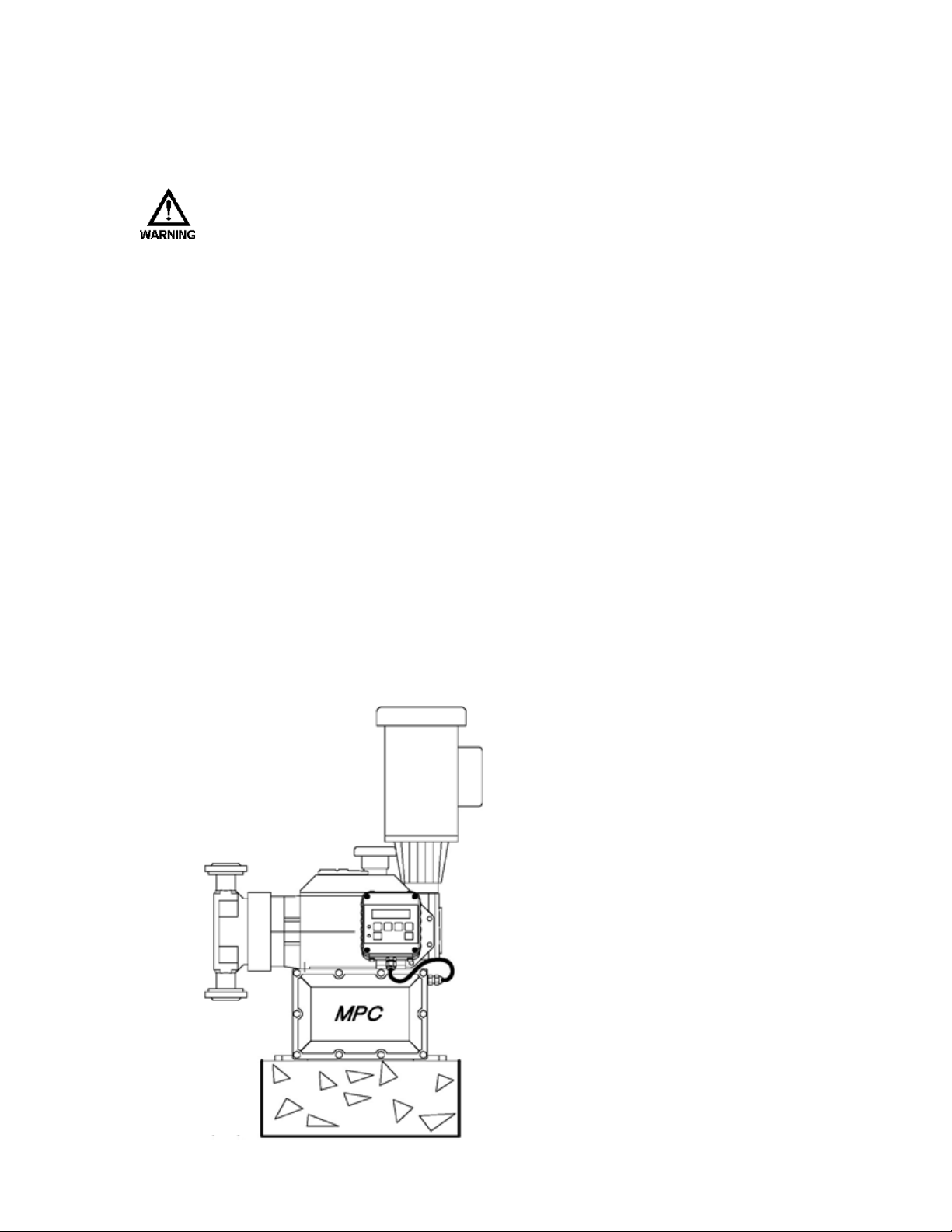

(Pulsar Pump arrangement shown)

Page 13

7. Storage Instructions

The MPC can be successfully stored for extended periods. The key to this

success is temperature and humidity control.

7.1 Short Term (0 - 12 months)

The MPC should be stored in a temperature and humidity controlled

environment. It is preferable to keep the temperature constant in the

range of -18° to 60° Celsius (0° to 140° Fahrenheit). The relative

humidity should be 0 to 90% non-condensing.

If the MPC is installed on the pump, it should not be removed during this

period provided the above conditions can be applied to the pump as

well.

7.2 Long Term (12 months or more)

Storage of the MPC for periods of longer than twelve months is not

recommended. If extended storage is unavoidable the MPC should be

stored in accordance with those conditions stipulated for Short Term

Storage. In addition, a porous bag of 85g (3 oz) silica gel or similar

dessicant should be placed inside the enclosur e. The cover should be reinstalled to seal the desiccant within the enclosure. The conduit

connections must be tightly capped. . Inspect the unit carefully for any

signs of damage and remove the desiccant before placing it into

operation

Special note for long-term storage:

If AC input power has not been applied to the MPC for a period

greater than 12 months, the controller must be prepared for

operation. The MPC should have AC power applied at the input for a

period of 8 hours before placing pump into normal operation. Refer

to Installation and Wiring section for AC power connection

instructions.

Page 14

8. Installation and Wiring

8.1 Location

Review the Safety section prior to installing the MPC. It contains

information required to properly install and operate the MPC i n an

industrial environment.

The site selected for the installation of your MPC is largely dependent on

that of the metering pump. Review the Installation, Operation, and

Maintenance manual provided with your metering pump. It details system

related issues that are important to proper operation of the pump.

Consider the following MPC related issues when selecting a site. Avoid

locations where the MPC would be subjected to extreme cold or heat.

The installation of this device must comply with national, state and local

codes.

Approximately 6 in (150 mm) of clearance should be maintained around

all 4 sides of the MPC.

No special services (e.g. air, liquid cooling) are required. Negligible

sound is emitted by the MPC - therefore, no special precautions are

necessary.

The MPC controller must be secured to an appropriate support before

use. Use four 3/8” (M8) bolts or anchors to secure the MPC controller

and pump to a fixed base. No asse mbly is required for the MPC

controller itself.

Figure 1 – Typical Installation.

Page 15

°

°

AVOID LOCATIONS WHERE THE MPC WOULD BE SUBJECTED TO EXTREME

COLD OR HEAT

40

CELSIUS (104 ° FAHRENHEIT)] OR DIRECT SUNLIGHT. FAILURE TO

OBSERVE THIS WARNING COULD DAMAGE THE

[LESS THAN 0

CELSIUS (32° FAHRENHEIT) OR GREATER THAN

MPC AND VOID ITS WARRANTY.

8.2 Installation Notes

The MPC is a microprocessor-based controll e r that uses el ectr o-static

sensitive CMOS components. Do not make any (low or extra-low

voltage) electrical connections without adequately grounding the MPC

and the worker to eliminate an electro-static charge between the two. A

conductive wrist strap worn by the worker and attached to the MPC

enclosure is adequate to satisfy this requirement.

Conduit connections can carry fluids and vapors into the MPC causing

damage and void the warranty. Care should be taken when installing

conduit to protect against fluid/vapor entry. If necessary, provide sealed

entries or conduit drains near the point of entry. The controller comes

equipped with liquid-tight connectors for signal cable entry points. The

user must supply the correct connection for the power entry, as per the

local codes and requirements. Any cable entrances that are not used

should be appropriately sealed against moisture and vapors.

The safety of any system incorporating the MPC is the responsibility of the

assembler of the system.

8.3 Installation guidelines for EMC compliance

8.3.1 The cover must be installed properly.

8.3.2 Shielded cables used for analog inputs and outputs

8.3.3 Proper Earth grounding

8.3.4 Ensure Power mains are properly filtered for isolation from line

transients,

8.3.5 Lightning strikes or other electrical noise sources.

Failure to observe the guidelines above may lead to erratic and possibly

unsafe operating conditions.

Page 16

8.4 Electrical Wiring

The MPC has many advanced features that may make wiring the unit

appear complicated. Wiring is actually very simple – one hi g h v olt ag e

connection is all that is required to take advantage of the majority of the

MPC's features.

If you will be mounting your handheld controller in a remote location,

refer to the Section Extending your Hand-Held Controller at this time.

WHILE THE MPC WIRING REQUIREMENTS ARE VERY SIMPLE, ALWAYS KEEP IN MIND

THAT ACCESS TO THESE CONNECTORS REQUIRES THE REMOVAL OF THE COVER

AS SUCH THIS PROCEDURE SHOULD ONLY BE PERFORMED BY A TRAINED

PROFESSIONAL

.

WAIT A MINIMUM OF 3 MINUTES AFTER DISCONNECTING POWER BEFORE SERVICING

MPC OR PUMP MOTOR. CAPACITORS RETAIN A CHARGE EVEN AFTER POWER IS

THE

REMOVED FROM THE CONTROLLER

.

It is highly recommended that you take a step-by-step approach to wiring and

confirming proper MPC operation:

, AND

8.4.1 Make the high voltage connections (ref. Section 8.4.7). These

will allow you to operate the MPC a nd attached Pulsafeeder

pump.

8.4.2 Decide which low voltage Inputs and Outputs (e.g., 4-20mA in)

will be used and make those connections (ref. Section 8.4.8).

8.4.3 Power-up and test the MPC to confirm the connections and

check for proper operation.

8.4.4 Configure the software via the menu system for the desired

operational conditions. Depending on the anticipated function,

users may need to enter settings for t he following:

8.4.5 Analog input signals, so the MPC can accept a proc ess input

signal.

i. Analog output settings, so the MPC can provide a process

feedback signal.

ii. Digital input s ettings, for example start/stop and/or leak

detection inputs.

iii. Digital output settings, for example status and/or alarm

outputs.

iv. Conduct a final power-up and test the MPC to confirm the

connections and check for proper operation.

v. Go to the Section 9 – Startup & Operation for details on

how to perform the power-up tests. Controller Layout

Page 17

The design of the MPC incorporates all control circuitry onto one easily

accessed circuit board. This board is located on the inside of the main

controller cover. Gain access to this board by removing the 10 bolts and gently

allowing the cover to hinge downwards.

USE CARE NOT TO PULL ON OR ATTEMPT TO COMPLETELY SEPARATE THE COVER

FROM THE

/OR DAMAGED. THIS CAN RESULT IN IMPROPER OPERATION.

AND

MPC UNIT, AS THE ELECTRICAL CONNECTIONS MAY BECOME UNPLUGGED

Page 18

FIGURE 2 – CONDUIT CONNECTION LAYOUT

Page 19

8.4.6 Power Wiring Information

• Verify the correct supply voltage (115VAC or 230VAC) with the

nameplate affixed to your MPC. Ensure that your supply voltage

matches the MPC configuration.

• Wi r es should be routed within the enclosure in a manner that

maintains separatio n between low voltage and extra-low voltage

conductors.

• Applicable national and local electrical codes take precedence over

recommendations in the table below.

• A circuit breaker or fuse must be provided as noted below.

• Upon initial application of AC power, a current inrush will occur to

charge the DC bus capacitors. This is normal operation, and

breakers and other circuit protection devices should be sized

accordingly.

Recommended Minimum Wiring and Circuit Breaker

Power

Requirements

MPC and 0.25

Hp motor

MPC and 0.33

Hp motor

MPC and 0.5 Hp

motor

MPC and 0.75

Hp motor

MPC and 1.0 Hp

motor

MPC and 1.5 Hp

motor

Note 1: Applicable standards are Cenelec EN61326-1, UL61010-1, and CSA

C22.2#61010-1 and EN61010-1 3

115 VAC Operation 230 VAC Operation

Actual

Draw

7.0 A 10 A 14

7.0 A 10 A 14

9.4 A 15 A 14

16.8 A 25 A 12

16.8 A 25 A 12

24.2 A 35 A 10

Circuit

Breaker

Wire

Size

AWG

AWG

AWG

AWG

AWG

AWG

Wire

Size

2.5

mm

2.5

mm

2.5

mm

4.0

mm

4.0

mm

6.0

mm

Safety

Approvals1

UL, CUL,

2

2

2

2

2

2

CE

UL, CUL,

CE

UL, CUL,

CE

UL, CUL 9.4 A 15 A 14

UL, CUL 9.4 A 15 A 14

UL, CUL 12.2 A 20 A 14

Actual

Draw

3.5 A 10 A 14

3.5 A 10 A 14

5.2 A 10 A 14

Circuit

Breaker

Wire

Size

AWG

AWG

AWG

AWG

AWG

AWG

Wire

Size

2.5

mm2

2.5

mm2

2.5

mm2

2.5

mm2

2.5

mm2

2.5

mm2

Table 1 – Sizing Branch Circuits

rd

edition.

The MPC requires one connection to an external power source. It uses

this same connection to power its own supply, as well as the AC pump

motor. You must take all of these loads into consideration when sizing

Safety

Approvals1

UL, CUL,

CE

UL, CUL,

CE

UL, CUL,

CE

UL, CUL

UL, CUL

UL, CUL

Page 20

the branch circuit (see Tabl e 1). A circuit breaker or disconnect switch

MPC Drive

L1

Line

Line

Earth

Ground

Ground

with fuses must be wired in series with terminals L1 and L2/N in

accordance with all applicable local and national electrical codes and

regulations. The circuit breaker or disconnect switch shall be located in

close proximity to the MPC controller. It must be positioned such that it is

not difficult to operate and must be marked or labeled to identify it as the

power disconnect for the MPC.

The MPC controller is provided with a ¾ inch NPT inlet for incoming AC

power wiring at the rear (pump gearbox end) of the enclosure. Utilize the

appropriate conduit fittings to route and seal the supply wires into the

MPC enclosure.

These wires are secured to the terminal strip at the right-hand end of the

AC drive as per Table 2 and Figure 3. Remove approximately 0.20 –

0.25 inches, (6mm) of insulation from the end of each conductor. Loosen

the terminal strip screw, and insert the stripped wire end fully into the

terminal. Tighten the screw to 4.5 in-lbs. (0.5 Nm) to secure the

conductor. Make certain that the terminal grips the wire, not the

insulation. Ensure that all wiring meets applicable local and national

codes and requirements.

8.4.7 Power Wiring Diagram

Terminal

L2 / N Neutral Line/Neutral

Table 2 – AC Drive Terminals

Note: Power wiring should have a rating of at least 300 volts AC (rms) and a

temperature rating of at least 105 Degrees C.

A circuit breaker or disconnect switch with fuses, must be provided in accordance

with all applicable local and national elec tr i cal codes and reg ul ati ons. Size

external fusing/breaker for ratings for the wiring used for the unit.

115 V Operation 230 V Operation

Applicable national and local electrical codes take precedence over

recommendations made here.

Page 21

To ensure proper operation, the MPC should remain powered at all times.

A dry contact input provides the MPC with motor status (on vs. off). See

Section 13 (Digital In #1 & Digital In #2)

Input Power must be run in separate conduit. Do not combine Power and

Control wires in a common conduit!

Field Wiring conductors shall be copper conductors only!

Figure 3 – AC Drive Power Connections

Wait a minimum of 3 minutes after disconnecting power before servicing the

MPC or pump motor. Capacitors retain a charge even after power is removed

from the controller.

Page 22

Find the proper AC input

voltage for your MPC

controller on the

nameplate at the rear of

the unit. MPC input is

always single phase, and

can be either 115 VAC or

230 VAC, determined at

time of order.

Page 23

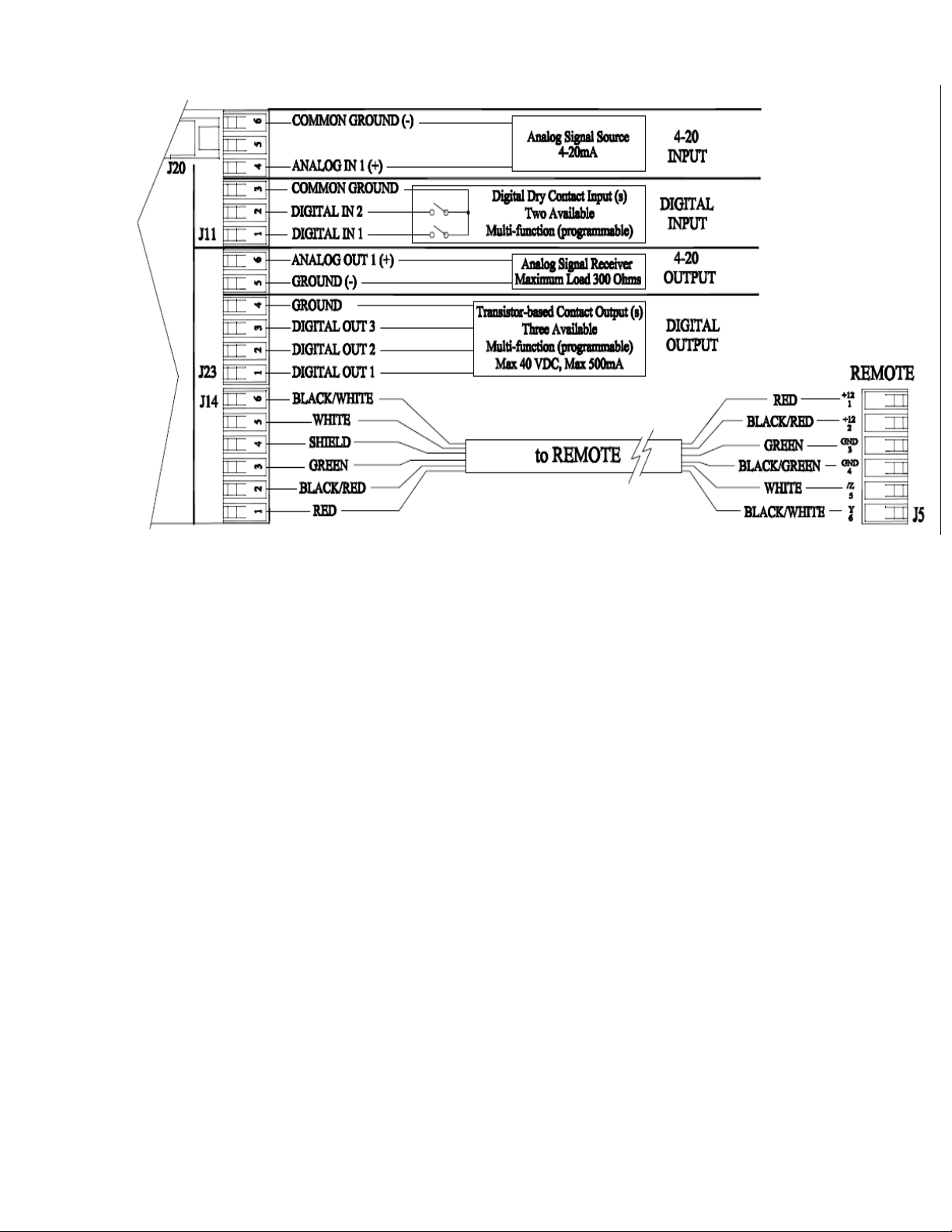

8.4.8 Control Input/Output Si gna l Wiring

Signal wiring is routed through the two unused conduit openings at the

side of the MPC. All input/output signals are connected to the terminal

strips at the edge of the MPC circuit board. Use caution to observe

proper wire location and signal polarity. Always cap or plug unused

openings. Wires should be routed within the enclosure in a manner that

maintains separation between low voltage and extra-low voltage

conductors. Ensure all low voltage wiring is installed as per any

applicable local and national electrical codes and regulations.

Utilize 20 or 22 AWG, 250 V, shielded cable, with a 105o C insulation

rating (or better) for all signal input and output wiring. Recommended

strip length is 0.39 inches or 10 mm. Re fer to Figure 4 below for signal

connection locations.

UNUSED CONDUIT OPENINGS SHOULD BE PLUGGED AS REQUIRED TO AVOID

INGRESS OF MOISTURE AND CONTAMINANTS INTO THE

NOT REMOVE THE FACTORY PROVIDED PLUG FROM OPENINGS THAT ARE NOT

REQUIRED FOR FIELD WIRING

.

IT IS RECOMMENDED THAT A WRIST STRAP BE WORN WHEN MAKING

CONNECTIONS TO ANY PRINTED CIRCUIT BOARD

.

MPC ENCLOSURE. DO

Page 24

Figure 4 – Signal Connections

Page 25

Digital output signals can drive devices such as relays or indicator lamps. 24 VDC

power must be supplied from an external source. Each output has a maximum current

capability of 500 mA. Maximum voltage capability of these circuits is 40 VDC (see the

Specifications Section, for more information).

Figure 5 – Sample Digital Output Connections

8.5 Check Wiring and Close Access Cover

Double-check all of your electrical connections. Pay attention to polarity

of all inputs and outputs – both low and extra-low voltage. Additionally,

insure that all terminals are clamping onto the bare conductor, not on its

insulation. Ensure that wires will not be trapped or pinched when front

cover is replaced and secur ed. Ensure that excess insulation is not

removed from the wires, as this can lead to poor connections or faulty

operation.

Replace the main access cover and secure the 10 bolts.

Use a nut driver to tighten the retaining bolts evenly to 35 in-lbs

(4.0 Nm). Failure to do so may cause the cover to leak and void the

warranty.

8.6 Confirm Correct Incoming Power

WITHOUT PRIOR OPERATING KNOWLEDGE, IT IS IMPOSSIBLE TO TELL IF THE

PUMP MOTOR WILL RUN WHEN POWER IS APPLIED TO THE

RESPONSIBLE FOR TAKING THE NECESSARY STEPS TO ENSURE THAT ALL

ASPECTS OF SAFETY HAVE BEEN CONSIDERED

.).

ETC

(E.G., ELECTRICAL, HYDRAULIC,

Clear all lockout tag out controls. Turn on power at the mains or

distribution panel. If the MPC's incoming power is connected correctly,

the backlighting on the MPC's display will illuminate (depending on

lighting conditions, it may be necessary to shade the display to confirm

illumination). If the display is not illuminated, first check the line voltage

MPC. YOU ARE

Page 26

with a voltmeter. If the voltage is not correct, return to 5.3.2 - Power

Wiring Information. Otherwise, proceed with the next step.

Page 27

9. Start Up and Operation

9.1 Overview

Once all electrical connections have been made, your MPC is ready for

Start-up. The following sections detail the procedures required to

complete the MPC start up.

WARNING: DO NOT attempt to remove the cover of the MPC and

set up the MPC in a very wet or rainy environment. While care has

been taken to insulate power connections, DANGEROUS voltages

are present and can cause electric shock, and possible

electrocution if safety procedures are not fo llowed

WHEN POWER IS SUPPLIED TO THE UNIT, LINE VOLTAGE IS PRESENT WITHIN

MPC ENCLOSURE EVEN WHEN THE MOTOR IS OFF.

THE

DURING START-UP, IT IS NECESSARY TO RUN THE PUMP MOTOR. THIS WILL

CAUSE FLUID TO DISCHARGE FROM THE PUMP

SAFELY DIVERTING FLOW FROM THE PUMP DURING START

CALIBRATION

THE MPC IS DESIGNED TO RUN THE PUMP CONTINUOUSLY WITHIN ITS RATED

PRESSURE AND FLOW

INTERMITTENTLY

F THIS EQUIPMENT IS USED IN ANY MANNER NOT SPECIFIED BY PULSAFEEDER,

I

PROTECTION PROVIDED BY THE EQUIPMENT MAY BE IMPAIRED

.

. OPERATION BEYOND RATED SPECIFICATIONS, EVEN

, MAY DAMAGE EQUIPMENT AND VOID THE WARRANTY.

. YOU ARE RESPONSIBLE FOR

-UP AND

.

Page 28

9.2 Keypad/Lamp Opera ti on

MANUAL

ON

Key Function Description

Motor On/Off

Auto/Manual

Menu

Press to start pump motor, press again to stop

pump motor

Press to toggle between aut o matic oper a ti on and

manual control of the pump

Press to adjust controller settings, to exit the menu

system, to move cursor back when entering

values, or to step back to higher level menus

Enter

Press to accept changes in menus, to move

cursor forward when entering values, and to

access lower level menus. Also used to toggle

between pump output display options while in

operating mode (% flow, spm, gph, etc.)

Arrow Up

Arrow Down

Press to adjust values upwards, and to scroll

through menu options

Press to adjust values downwards, and to scroll

through menu options

Lamp Color Description

Green, Amber,

Red, Off

Green, Off

Table 3 – Keypad and Lamp Operation

Off = Motor off Green = Motor on

Amber = Remote standby Red (blinking) =

Error

Green = Manual Control Off = Automatic

Control

9.3 Confirm Display and Keypad Functionality

The example display messages are shown in English for

demonstration purposes. If an alternate language has been set, the

text is displayed as a translation of the English version.

Page 29

Now that you have confirmed that the MPC is receiving power, it is

necessary to confirm that the display and keypad are f uncti o ni ng

properly. On normal po wer-up, the display appears for approximately 2

seconds.

PULSAFEEDER INC.

FW: 00.00/00.00

The first four digits displayed are the software revision for the MPC base

unit, and the second four indicate the software revision for the handheld

display/keypad module.

The keypad can be tested by depressing each key separately. Most, but

not all keys will cause the text on the display to change. Do not be

alarmed if a single key does not invoke a change to the display. This is

normal. Different key s become active/inactiv e depending on the current

operating mode.

Please note that it may be necessary to adjust the display contrast;

please refer to Section 10.8 if this is required.

9.4 Flow Display

The MPC will display calibrated pump flow in GPH or LPH on the dig i tal

display. The MPC is capable of very high turndown ratios, limited only by

pump configuration and system design. In some cases, the MPC display

will be unable to display very low flow rates, in these situations the

display may indicate 0.0 for flow, even though the pump is producing

measurable flow. If the pump is being operated under these conditions,

users may wish to perform extra flow calibrations to verify actual flow

rates at certain set points. Note that even after the additional calibrations

are done, the MPC will still not display the low flow that the pump is

producing.

In situations where the pump stroke length is set to 0 (zero) %, the pump

will also display 0 (zero) GPH or 0 (zero) LPH, regar dl ess of motor

speed setting. If the display registers no flow in this manner, check the

setting of the stroke length mechanism on your pump.

9.5 Wrapping up

Your MPC is now commissioned for use. Note that you cannot configure

the software in a way that would damage the MPC. Typically, whenever

you are about to set a critical value (e.g., Calibrate Flow), you are always

prompted to confirm your change before it takes effect. If you are ever

dissatisfied with the configuration of your MPC, you can always return to

the Factory Defaults by referring the next section.

Page 30

Factory Re-initialization is typically not required. When re-

initializing your MPC, all of the system settings and calibration

information will be overwritten by the original factory default

settings. The controller must be re-configured and re-calibrated to

your specifications.

A Factory Re-initialization should be performed only if there is reason to

believe that the internal MPC memory has become corrupted. The

condition usually manifests itself with inconsistent or erratic operation –

often associated with meaningless characters on the display, or

exaggerated numerical values.

Factory Re-Initialization:

1. Press the MENU key to access the System Setup Menu

-MENU-

CALIBRATION

2. Press the UP arrow key to display

-MENU-

SYSTEM SETUP

3. Press the ENTER key

SYSTEM SETUP

SECURITY

4. Press the UP arrow key twice to display

SYSTEM SETUP

FACTORY INIT

5. Press the ENTER key

PRESS ENTER

TO FACTORY INIT

6. Press the ENTER key

ARE YOU SURE?

YES=ENTER NO=MENU

7. Press the ENTER key

RESETTING PUMP

TO FACTORY INIT

Page 31

10. Input/Output Setup

Use the “DIGITAL I/O” menu to activate the functions required for the intended

application.

Users may also reference Section 14 – Menu Maps for additional configuration

assistance

10.1 Analog Input Setup

Use the “ANALOG I/O” menu to activate the analog input signal function.

The menu can be used to set the analog input to either ACTIVE or

INACTIVE.

10.2 Digital Input Setup

Each of the 2 Digital INPUTS can be selected as:

Inactive

Leak Detection

Tank Level Input

Remote ON/OFF Input

Flow Detection (delay time must be set)

Each can be set as normally OPEN or normally CLOSED. For example,

if an input is set to ON/OFF and NORMALLY CLOSED, this means a

CLOSED switch will activate the pump. A NORMALLY OPEN setup will

give the opposite response.

10.3 Analog Output Setup

Use the “ANALOG I/O” menu to activate the analog output signal

function.

The menu can be used to set the analog output to either ACTIVE or

INACTIVE.

10.4 Digital Output Setup

Each of the 3 Digital OUTPUTS can be selected as:

Inactive

ON/OFF Status

AUTO/MAN Status

Stroke Indicator (Pulse Output)

Alarm Indicator

Leak Detection Status

Tank Level Status

Page 32

Each can be set as normally OPEN or normally CLOSED. For example,

if an output is set to ON/OFF INDICATION and NORMALLY CLOSED,

this means that when the motor is running (indicator lamp is ON) the

output will be CLOSED. A NORMALLY OPEN setup will give the

opposite response.

Digital output circuits are transistor based and limited to 40 VD C

maximum, see Section 8.4.8 - Control Input/Output Signal Wiring,

and Specifications Section, for more information.

10.5 Pump Flow Calibration

Your MPC is factory calibrated at rated flow and pressure. Nevertheless,

you should always perform a calibration with the MPC installed in your

system. This will provide the most accurate flow display.

The only item required to calibrate your MPC is a means to measure the

flow of the pump (i.e., calibration column, graduated cylinder, etc.). The

most accurate calibration will be obtained by using a measurement device

installed on the suction side of the pump. Note that calibration values for

liquid volume will be in the user’s chosen units, either gallons or liters.

There are two methods for completing the flow calibration routine, either

“Volume” or “Flow”.

Volume Method Calibration

The volume calibration is accomplished by running the pump at two

different stroke length setti ng s, 50% and 100 % . During each run a volume

of liquid will be pumped from the calibration column. This volume is then

entered into the MPC for calibration. Note that for this calibration, the

actual volume of liquid pumped is entered in gallons or liters. Do not enter

a flow rate in gallons or liters per hour, as this will not result in a valid

calibration. The MPC display will guide the user through the steps for

calibration.

Please note that it must be safe to run the pump and dispense liquid into

the system in order to complete this calibra ti o n. The pump should be fully

primed with the product in order to complete an accurate calibration.

Hydraulic diaphragm pumps must have a proper hydraulic prime as well.

10.5.1 Flow Method Calibration

The flow calibration is accomplished by entering values for flow that are

already known to the user. The MPC will request flow values in gallons or

liters per hour for each of the two calibration points, 50% and 100% stroke

length. This calibration is useful if operational circumstances do not permit

Page 33

the pump to run for calibration. This calibration is also faster to complete if

the flow values are already known. The MPC display will guide the user

through the steps for calibration.

The nameplate flow rating of the pump can be used to complete the flow

calibration routine; however there will always be some variance in the

actual flow rate of a pump due to system conditions and pr oduct

characteristics. Using the pump’s nameplate rating will establish a

baseline flow rate on the MPC display; however it will not guarantee

absolute accuracy.

To Start Calibration

1. The starting display will be:

2. Press the MENU key

3. Press the ENTER key

SETPT XX.XXX

FLOW XX.XXX

-MENU-

CALIBRATION

CALIBRATION

PUMP FLOW

4. Press the ENTER key

CALIBRATION

“VOLUME”

5. To perform the Volume Method, press the ENTER key and go to the

next Section –Voume Method

6. To perform the Flow Method, press the UP arrow key

CALIBRATION

“FLOW”

7. Press the ENTER key and go to the Flow Method Section 10.5.2

If you receive the following message during the Volume calibration:

STROKE LENGTH OUT

OF RANGE

Verify that the manually set stroke length is at the correct position, either 50% or 100%.

Page 34

Volume Method

SET STROKE TO 50%

ENTER TO START

1. Manually adjust the stroke length of the pump to 50%

2. ** Fill your calibration column to the zero or starting point

3. Press the ENTER key

TIMER XX SEC

ENTER TO STOP

4. Allow the pump to run for any length of time you choose, dependent on flow

rate, calibration column size, process conditions, etc. The system will time out

at a maximum of 300 seconds.

5. Press the ENTER key to stop the pump

ENTER VOLUME

VOL = XX.XXX

6. Use the UP and DOWN arrow keys and the ENTER key to input the volume

pumped from the calibration column (in gallons or liters, dependent on MPC

setup).

7. Press ENTER to proceed

SET STROKE TO 100%

ENTER TO START

8. Manually adjust the stroke length of the pump to 100%

9. ** Fill your calibration column to the zero or starting point

10. Press the ENTER key

TIMER XX SEC

ENTER TO STOP

11. Allow the pump to run for any length of time you choose, dependent on flow

rate, calibration column size, process conditions, etc. The system will time out

at a maximum of 300 seconds.

12. Press the ENTER key to stop the pu mp

Page 35

ENTER VOLUME

VOL = XX.XXX

13. Use the UP and DOWN arrow keys and the ENTER key to input the volume

pumped from the calibration column (in gallons or liters, dependent on MPC

setup).

14. Press ENTER to proceed

PUMP FLOW

CALIBRATED

15. Pump flow calibration is complete

16. Pre ss t he MENU key three times to exit back to the main operating screen.

10.5.2 Flow Method

SET STROKE 50%

FLOW = 0.0000 GPH

1. You do not have to adjust the actual stroke setting of the pump

2. Use the UP and DOWN arrow keys and the ENTER key to input the

desired flow rate (in gallons or liters per hour, depend ent on MPC

setup). This should be the flow rate expected when the pump is set to

50% stroke length setting.

3. Press ENTER to proceed

SET STROKE 100%

FLOW = 000.00 GPH

4. You do not have to adjust the actual stroke setting of the pump

5. Use the UP and DOWN arrow keys and the ENTER key to input the

desired flow rate (in gallons or liters per hour, depend ent on MPC

setup). This should be the flow rate expected when the pump is set to

100% stroke length setting.

6. Press ENTER to proceed

PUMP FLOW

CALIBRATED

7. Pump flow calibration is complete

8. Press the MENU key three times to exit back to the main operating

screen.

Page 36

10.6 Analog Input Calibration

If you are not using the 4-20mA input to the MPC for control, skip this

section. To calibrate the Input Current you must first correctly wire an

external signal source. Refer to the Control Input/Output Signal

Wiring Section (8.4.8). To perform a calibration, the signal-generating

device must be active and capable of generating the full range (low to

high) of potential input signals.

1. The starting display will be:

SETPT XX.XXX

FLOW XX.XXX

2. Press the MENU key

-MENU-

CALIBRATION

3. Press the ENTER key

CALIBRATION

PUMP FLOW

4. Press the UP arrow key twice, to access the analog input calibration

CALIBRATION

ANALOG INPUT

5. Press the ENTER key

APPLY MIN MA

ENTER TO START

6. Apply your desired minimum mA control signal to the MPC (usually 4

mA)

7. Press the ENTER key

MIN SETPT X.XX MA

SPEED 000.0%

Page 37

(The mA value will be equal to your input signal level)

(The speed value is the setting the MPC will use for this signal value)

8. Press the ENTER key three times to step through the speed setting

value, most users will leave this at 000.0 %, however you an change it if

you wish using the UP and DOWN arrows.

9. Press the ENTER key once more to accept the calibration value

APPLY MAX MA

ENTER TO START

10. Apply your desired maximum mA control signal to the MPC (usually 20

mA)

11. Pre ss t he ENTER ke y

MAX SETPT X.XX MA

SPEED 100.0%

(The mA value will be equal to your input signal level)

(The speed value is the setting the MPC will use for this signal value)

12. Press the ENTER key three times to step through the speed setting

value, most users will leave this at 100.0 %, however you an change it if

you wish using the UP and DOWN arrows.

13. Press the ENTER key once more to accept the calibration value

ANALOG INPUT

CALIBRATED

14. Analog input signal calibration is complete

15. Press the MENU key three times to exit back to the main operating

screen.

If you receive the following message:

CURRENT DELTA

OUT OF RANGE

This indicates that there is not a wide enough range between your maximum

and minimum analog signals. The minimum signal range is 3 mA. The most

likely source of this error is the user did not change the value of the incoming

analog signal when moving from the MIN calibration to the MAX calibration.

Page 38

The analog input signal calibration procedure should be performed again,

ensuring that a minimum of 3 mA difference exists between the MIN and MAX

signal levels.

Page 39

10.7. Analog Output Calibration

1. The starting display will be:

SETPT XX.XXX

FLOW XX.XXX

2. Press the MENU key

-MENU-

CALIBRATION

3. Press the ENTER key

CALIBRATION

PUMP FLOW

4. Press the UP ARROW key to access the analog output calibration

CALIBRATED

ANALOG OUTPUT

5. Press the ENTER key

SET 0% FLOW TO

04.0 MA

6. Use the UP and DOWN arrow keys to adjust the output signal as

required. The actual output signal will vary and can be monitored with a

meter or your facility control system. The value displayed on the screen

may not match the actual output signal and is for visual reference only.

7. Press the ENTER key once more to accept the calibration

SET 100% FLOW TO

20.0 MA

8. Use the UP and DOWN arrow keys to adjust as in step 6 above

9. Press the ENTER key once more to accept the calibration value

CALBRATION

ANALOG OUTPUT

10. Analog output signal calibration is complete

11. Press the MENU key three times to exit back to the main operating

screen

Page 40

If you receive the following message:

CURRENT DELTA

OUT OF RANGE

This indicates that the output current for 0% flow has been set greater

than or equal to the output current sett ing for 100% flow. Repeat the

process and ensure that the 0% calibrated signal is set to a value lower

than the 100% calibrated signal.

10.8 Displa y Contrast Adjustment

Should adjustment of the contrast level of the display become

necessary, use the following procedure while in the normal operating

mode.

To increase contrast, press and hold at the same

time.

To decrease contrast, press and hold at the same

time.

10.9 Changing the Motor Base Frequency

This procedure will not be necessary during normal oper a ti on o f the

MPC controller. In the event that you need to install a different drive

motor, and that motor has a different base frequency (50 Hz vs. 60 Hz)

than the original unit, please refer to this procedure. These changes are

made at the AC drive within the MPC enclosure and not at the hand-held

unit.

This procedure is performed with power applied to the MPC. Take

ALL NECESSARY precautions, keep fingers and tools clear of

energized circuits, and perform this procedure only if you are

certain it is required.

1. Open the front cover of the MPC control

2. There are three buttons on the face of the drive, MODE, UP and DOWN.

3. Press the MODE button

Page 41

4. Scroll UP to display the default password “001”

FATAL ERRORS: The pump and controller will not run while one of these error

conditions exists. The Red LED will blink and the error message will flash on the

corrected.

5. Press MODE to enter the password

6. Scroll UP to the base frequency parameter which is “27” display will

show “P 27”

7. Press MODE to display the current setting (will be either 50 or 60)

8. Use the UP or DOWN keys to change the setting to the new value (either

50 or 60)

9. Press MODE to store the new value

10. Drive will exit the program mode after it stores the new value

This procedure should be us ed only if the base frequency of the pump

drive motor is changed.

11. Alarm and Error Messages

If a fatal error has occurred while in Operational Mode, the error will flash on the

screen and the Red LED lamp will also flash. The menus can still be accessed by

holding down the menu key. This allows the user to try and fix the source of the

error if possible.

The following table gives an example of these messages and when you can

expect them to be display ed.

Message Displayed When:

screen. Users can access the menu system by pressing the MENU key. The

red LED and the message will cease when the error condition has been

Analog Input #X

Out of Range

ALARM

LEAK DETECT

ALARM

LOW LEVEL

ALARM

AC DRIVE FAULT

ALARM

Motor error

The analog input is less than 2.4 mA or greater

than 24 mA

The leak detection input has triggered

The level monitoring input has triggered

Internal fault

The MPC has detected that the motor shaft is not

rotating at the expected speed

ALARM

CAM SENSOR

MPC controller is not receiving correct signals from

the cam sensor in the pump eccentric box

Page 42

COMMUNICATION

Stroke length

User is trying to activate the AUTO mode, but there

the controller

ERROR

NON-FATAL ERRORS: The pump and controller can still be run while these

conditions exist. The Red LED will flash, however no message will flash on the

screen. The Red LED will stop flashing once the error condition has bee n

Communication error exists between the MPC

controller and the handheld keypad/display module

corrected.

ALARM

STROKE SENSOR

SOFTWARE Fault

Error = ####

Hardware fault

Error = ####

CONSULT fa ctory

Error = ####

USER NOTIFICATIONS: These are errors in setup or calibration. They will

display on the screen for several seconds. They can be corrected by properly

completing the procedure involved.

Cannot access

With motor on

Out of range

Current delta

Out of range

MPC does not receive valid indication from the

stroke position sensor, the flow display will not be

accurate

Software related problem, record error number and

consult factory

Hardware related problem, record error number

and consult factory

Unidentified error, record error number and consult

factory

User is trying to change a setting that cannot be

changed while the pump is running

Stroke length position is not set correctly for

current operation

Not enough difference between high and low

signals during an analog input signal calibration

(min 3 mA)

Stroke delta

Out of range

No remote

Control

For unlisted or numbered error codes, consult the factory for assistance.

Pressing MENU will clear all non-fatal errors, provided the error condition

is no longer present.

Stroke length position is not set correctly for

current operation

is no remote input (mA signal or remote on/off) to

Page 43

12. Extending your Hand-Hel d Controll er

Cable Length

Part Number

Notes

The hand-held controller for your MPC can be placed as far as 1000 feet from

the pump with optional cable. It is recommended that all calibrations be

completed before the cable is lengthened, as these tasks are easier when the

pump and hand-held controller are close to each other.

To replace the cable for the hand-held unit:

POWER TO THE UNIT MUST BE OFF! A GROUNDING WRIST STRAP

SHOULD BE WORN WHEN MAKING CONNECTIONS TO ANY PCB

12.1 Obtain New Cable:

The following standard length cables are available from Pulsafeeder for use with

the MPC:

6 feet NP530130-000 Standard, supplied with all MPC controllers

Others per foot NP530147-000 (1

ft)

NOTE: do not exceed 1,000 feet total length

12.2 Removal and Connection of the Cable from the Handheld:

1. Open the handheld unit by removing the 4 screws on the face of the unit.

2. Open the unit by separating the cover from the base.

3. Disconnect the keypad from the Remote PCB by gently removing the

connector at the end of the keypad’s tail from the header on the PCB.

4. Make a note of what color lead is in each position of the terminal block

“J5”. Cut the tie-wrap that secures the cable. Loosen e ach o f the 6

positions on the terminal block “J5” and remove each lead.

5. Loosen the outer domed nut on the liquid tight, releasing the tension on

the cable. Pull the cable through the liquid tight. Thread the new cable

through the liquid tight with enough length to reconnect to the terminal

block.

6. Cut the shield wire as close as possible to the outer insulation at the

remote end only.

Page 44

7. Wrap the end of the cable with electrical tape to insulate any remaining

shield so that it will not contact the circuit board, equipment case, or any

other parts.

8. Referring to the notes taken earlier, connect each lead of the new cable to

the proper position of the terminal block; tighten the screw terminal to hold

lead. NOTE: It is recommended that you insert and secure one lead at a

time.

9. Tighten the dome nut of the liquid tight to secure/seal cable.

10. Replace cover and tighten screws. Be sure the o-ring is in its groove,

paying special attention to the corners. NOTE: Do not over tighten.

Wait a minimum of 3 minutes after disconnecting power before

servicing the MPC or pump motor. Capacitors retain a charge even after

power is removed from the controller.

1. Remove the 10 screws that are securing the cover to the side of the main

unit.

2. CAUTION: The cover is wired and should be folded down gently being

sure not to pull any of the wires that are connected to it.

3. Make a note of what color lead is in each position of the terminal block

“J14”. Loosen each position of terminal block “J14” and remove each lead.

4. Loosen the outer domed nut on the liquid tight, releasing the tension on

the cable. Pull the cable through the liquid tight. Thread the new cable

through the liquid tight with enough length to reconnect to the terminal

block.

5. Prepare the end of the cable as per figure 5b on the following page.

Ensure that the shield is fully insulated until the point where it enters the

terminal. No part of the shield should be allowed to come in contact with

the circuit board, equipment case, or any other surface.

6. Note that the black-green lead is not utilized at this end of the cable.

7. Referring to the notes taken earlier, connect each lead of the new cable to

the proper position of the ter min al block , an d tighten the screw terminal to

hold the lead. NOTE: It is recommended that you insert and secure one

lead at a time.

8. Tighten the dome nut of the liquid tight to secure/seal cable.

9. Replace cover carefully being sure not to crimp any of the cables/leads

between cover and enclosure and tighten screws.

Power the unit on, if all connections were properly made the unit will power as

normal and the display will show the start up screen.

Page 45

BLACK/WHITE

WHITE

BLACK/GREEN

GREEN

BLACK/RED

RED

TAPE SHIELD

CUT

BLK/GRN

TAPE END

AN00446-006

Figure 5a – Handheld Remote Wiring

Figure 5b – Wire Preparation Detail , Base Unit End

Page 46

Figure 6 – Handheld Remote

Page 47

13. Specifications

Control Inputs

Wiring

Specification / Description

Analog In #1

J11 pins 4-6

4-20mA control signal

Analog In #2

J11 pins 5-6

Not presently available – future release

Digital In #1

J11 pins 1-3

User to provide dry-contact input *

Turndown: Up to 1000:1 with a steady state accuracy of +/- 2 % (added

to pump accuracy rating)

3:1 with a steady state accuracy of +/- 1 % (added to pump accuracy

rating)

Operation mode: AC motor speed control with speed and stroke length

feedback

Manual stroke length control

Recommended Minimum Wiring and Circuit Breaker

Power

Requirements

MPC and 0.25

Hp motor

MPC and 0.33

Hp motor

MPC and 0.5 Hp

motor

MPC and 0.75

Hp motor

MPC and 1.0 Hp

motor

MPC and 1.5 Hp

motor

NOTE: AC drive capacitors will cause in-rush current demand when power is first

applied to the unit. Applicable national and local electrical codes take precedence

115 VAC Operation 230 VAC Operation

Actual

Draw

Circuit

Breaker

Wire

Size

7.0 A 10 A 14

AWG

7.0 A 10 A 14

AWG

9.4 A 15 A 14

AWG

16.8 A 25 A 12

AWG

16.8 A 25 A 12

AWG

24.2 A 35 A 10

AWG

over recommendations in these tables.

Wire

Size

2.5

mm

2.5

mm

2.5

mm

4.0

mm

4.0

mm

6.0

mm

Safety

Approvals1

UL, CUL,

2

2

2

2

2

2

CE

UL, CUL,

CE

UL, CUL,

CE

UL, CUL 9.4 A 15 A 14

UL, CUL 9.4 A 15 A 14

UL, CUL 12.2 A 20 A 14

Actual

Draw

Circuit

Breaker

3.5 A 10 A 14

3.5 A 10 A 14

5.2 A 10 A 14

Wire

Size

AWG

AWG

AWG

AWG

AWG

AWG

Wire

Size

2.5

mm2

2.5

mm2

2.5

mm2

2.5

mm2

2.5

mm2

2.5

mm2

Safety

Approvals

UL, CUL,

CE

UL, CUL,

CE

UL, CUL,

CE

UL, CUL

UL, CUL

UL, CUL

1

Max current 30mA; Input resistance 200 Ohm

Internally protected with resetable fuse

Minimum signal accepted = 2.4 mA

Maximum signal accepted = 24 mA

Page 48

Digital In #2

J11 pins 2-3

User to provide dry-contact input *

*All digital inputs require a dry contact input

(maximum of 2K Ohm contact resistance to regist er as

Control Outputs

Wiring

Specification / Description

Analog Out #1

J23 pins 5-

4-20mA output for pump flow indication

Internally protected with resetable fuse

Digital Out #1

J23 pins 1-

4

Transistor-based output, various functions *

Digital Out #2

J23 pins 2-

4

Transistor-based output, various functions *

Digital Out #3

J23 pins 3-

4

Transistor-based output, various functions *

All digital outputs maximum 40 VDC, maximum 500

NOTE: requires external power source

“active”). Do not apply power to these terminals.

* Digital input functions:

1. Remote on/off control of metering pump

2. Level input from supply tank

3. Leak detection of the metering pump

4. Flow detection, with use of external flow switch

accessory

6

Max voltage out 12 Volts; Max current out 30mA;

Max load resistance 300 Ohm

mA

* Digital output functions:

1. Triggering an external relay due to a fault condition

2. Auto/Manual status

3. On/Off status

4. Pulse output – Indication each time the pump strokes

5. Leak detection status indication

6. Tank level status indication

Calibration: Controller includes an on board program for signal and flow

calibration.

Input Voltage: 115 (105-125 acceptable range) or 230 (208 – 240 acceptable

range) VAC

Note: factory configured only for correct input voltage range

(specified at time of purc hase) Single phase input only 50 or 60

Hz.

Input frequency range 48 Hz to 62 Hz

Motor Req: Commercially available motor supplied by the manufacturer of

the pump controller.

Page 49

Standard selection is rated for indoor, dry environment, other

options available

Keypad: Can be mounted on the pump or up to 1000’ away from the

pump

Standard cable length 6 feet

Display: Backlit 2 line extended temperature 16 character LCD

Enclosure: NEMA 4X and IP56 ratings

Altitude: 3300 Ft (1000 M) above sea level (de-rate 5% per additional

3300 Ft).

Humidity: 0-90% (non-condensing)

Temperature: 0o C (32o F) Minimum operating temperature

40o C (104o F) Maximum operating temperature

Earth Leakage

Current: Size Earth Leakage Circuit Breakers (ELCB) to a detection level

of 30 mA or greater

Transient Voltage Max Impulse withstand 1500V (115VAC Models), 2500V

(230VAC Models) at 50uS

Voltage Overload 150% for 60 seconds or 180% for 30 seconds

Pollution Degree Suitable for Pollution Degree 1 environment only (conduit

entries must be sealed against ingress of fluids and vapors)

Page 50

ENTER TO RESET

TOTAL: 0

SYSTEM SETUP

TOTAL STROKES

LANGUAGE

FRANCAIS

LANGUAGE

<FRANCAIS>

SPEED:

SETPT:

SYSTEM SETUP

ENTER VOLUME

VOL = 00.000 GAL

TIMER: XXX SEC