Page 1

EX

MicroVision

MICROPROCESSOR – BASED

WATER TREATMENT

CONTROLLER

Installation Operation Manual

72-900-06 Rev. F

Page 1 of 38

Page 2

Table of Contents

1. GENERAL WARNINGS ............................................................................................................................... 4

2. MicroVision

3. INSTALLATION ............................................................................................................................................ 6

3.1 Location ...................................................................................................................................................... 6

3.2 Mounting Hardware ............................................................................................................................... 6

3.3 Opening the Enclosure ......................................................................................................................... 6

3.4 Sensor Installation ................................................................................................................................. 7

3.5 TYPICAL INSTALLATION ...................................................................................................................... 7

3.6 IMPORTANT SYMBOL INFORMATION .............................................................................................. 8

3.7 ELECTRICAL WIRING ............................................................................................................................ 8

3.8 Flow Switch Input ................................................................................................................................ 12

3.9 Sensor (probe) Connection Input .................................................................................................. 12

3.10 Water Meter Input ........................................................................................................................... 12

3.11 Drum Level Input ............................................................................................................................. 12

3.12 4-20mA Output ................................................................................................................................. 12

3.13 4-20mA Input .................................................................................................................................... 12

3.13.1 Fluorometer – Trace Chemical ............................................................................................ 13

3.13.2 Calibrating PTSA Probe .......................................................................................................... 14

3.14 Alarm Dry Contact Relay ............................................................................................................... 14

3.15 Keypad Operation ............................................................................................................................ 15

3.16 Communications (Optional) ......................................................................................................... 15

4. CONTROLLER PROGRAMMING ............................................................................................................. 16

4.1 Menu Map ................................................................................................................................................ 16

4.2 Menu Navigation ................................................................................................................................... 16

4.3 Home screen .......................................................................................................................................... 16

4.4 Main Menu ............................................................................................................................................... 17

4.5 Relay HOA ............................................................................................................................................... 17

4.6 Configure ................................................................................................................................................. 17

4.6.1 Date/Time ....................................................................................................................................... 17

4.6.2 Digital Inputs ................................................................................................................................. 18

4.6.3 4-20mA Out and 4-20mA In .................................................................................................... 18

4.6.4 Gal/Lit ............................................................................................................................................... 18

4.6.5 Meter Totals .................................................................................................................................... 18

4.6.6 Languages Menu ........................................................................................................................... 18

4.6.7 Display Settings ............................................................................................................................ 19

4.6.8 Password Setting .......................................................................................................................... 19

4.6.9 Software Version .......................................................................................................................... 20

4.6.10 Factory Reset Function ........................................................................................................... 20

4.7 Settings .................................................................................................................................................... 20

4.7.1 Conductivity ................................................................................................................................... 20

4.7.2 pH and ORP .................................................................................................................................... 22

4.7.3 4-20mA Outputs (Optional Accessory) ................................................................................ 24

4.7.4 4-20mA Inputs (Optional Accessory) ................................................................................... 24

4.8 Timers - Modes ..................................................................................................................................... 24

4.8.1 Timers – Pulse Timer .................................................................................................................. 25

4.8.2 Timers – Percent Timer ............................................................................................................. 25

4.8.3 Timers - 28 day (Biocide Timer) ............................................................................................ 25

4.8.4 Timers – % Post Bleed ............................................................................................................... 26

4.8.5 Timers – Limit Timer (Bleed and Feed) ............................................................................... 26

4.8.6 Timers – Alarm .............................................................................................................................. 26

72-900-06 Rev. F

Page 2 of 38

EX

FEATURES .......................................................................................................................... 4

Page 3

4.8.7 Timers – Set Point Control Mode ........................................................................................... 26

4.8.8 Timers – Disabled (Default) ..................................................................................................... 27

4.8.9 Timers – Bio Tracking (In All Timer Modes) ...................................................................... 27

4.9 Communications ................................................................................................................................... 27

4.10 USB ........................................................................................................................................................ 27

4.10.1 USB Graphing Tool .................................................................................................................. 28

4.10.2 USB Data log Timer and Tamper Codes: ........................................................................ 28

4.11 Ethernet (Optional) ......................................................................................................................... 29

4.11.1 Programming your controller PulsaLink........................................................................... 29

4.11.2 Setting Up Your Controller on PulsaLink ......................................................................... 29

5. FACTORY DEFAULTS ............................................................................................................................... 30

6. TROUBLESHOOTING GUIDE ................................................................................................................. 32

7. MAINTENANCE ........................................................................................................................................... 33

7.1 Conductivity Sensor removal and cleaning ................................................................................ 33

To remove the conductivity sensor from its tee for cleaning: .................................................... 33

To clean conductivity sensor: .................................................................................................................. 33

7.2 pH sensor Information ....................................................................................................................... 33

7.2.1 Preparation ..................................................................................................................................... 33

7.2.2 Sensor Storage ............................................................................................................................. 34

7.2.3 Sensor Cleaning ............................................................................................................................ 34

7.3 ORP Sensor Information .................................................................................................................... 34

7.3.1 ORP Maintenance and Troubleshooting ............................................................................... 34

7.3.2 Testing ORP Sensor ..................................................................................................................... 34

7.3.3 Flow Sensor .................................................................................................................................... 35

8. SPECIFICATIONS ...................................................................................................................................... 35

9. FORSEABLE MISUSE ............................................................................................................................... 36

10. MOUNTING HOLE PATTERN (Footprint) ........................................................................................... 37

72-900-06 Rev. F

Page 3 of 38

Page 4

Introduction

RELAY STATUS

LED COLOR

ON (FORCED ON FOR 5 MIN.)

AMBER

OFF

RED

AUTOMATIC ‘ON’

GREEN

AUTOMATIC ‘OFF’

OFF

The MicroVisionEX microprocessor based cooling tower controller has been designed to

monitor and control Total Dissolved Solids (TDS) in terms of electrical conductivity

measured in micro Siemens per centimeter (uS/cm). Some models also include pH, and

ORP control. A set point of the desired value to control is entered into the controller

through the front panel. As this limit is exceeded, a valve, pump or other control device

is activated via an onboard control relay to adjust the reading being measured.

1. GENERAL WARNINGS

Symbol hereinafter and upon the unit means WARNING!

If the equipment is used in a manner not specified by the manufacture, the overall

safety may be impaired.

The plug is considered mains power. Disconnection means should be readily

identifiable and easily accessible to the operator after install

Adequately rated and APPROVED/CERTIFIED power supply cord and plug (supplied

by Pulsafeeder), or cable gland suitable for the applicable country is to be attached

and replaced by manufacturer’s authorized qualified person or as per applicable local

and national regulations

Controller is for indoor use only and not suitable for wet location. Controller housing

is IP65 compliant and may be configured as such.

Verify the mains supply ratings (e.g. Volts, Amps, and Hz) where the controller is to

be powered from and ratings of the accessories as well as ratings of the controller’s

receptacles/outlets before powering up.

2. MicroVisionEX FEATURES

Toroidal Probe

MicroVisionEX uses a toroidal probe for conductivity measurement. The

measurement is made by passing an AC current through a toroidal drive coil,

which induces a current in the electrolyte solution. This induced current in turn,

induces a current in a second toroidal coil, called the pick-up toroid. The amount

of current induced in the pick-up toroid is proportional to the solution conductivity.

Output Relays

The control of the HANDS – OFF – AUTO (HOA) output relays can be controlled using the

HOA menu.

72-900-06 Rev. F

Page 4 of 38

Page 5

Drum Levels

Three (3) onboard dry contact inputs serve as Drum Level inputs. When a low level is

detected the unit will go into an alarm state and the low drum’s identity will be displayed

on the screen. The user can program the alarm to deactivate a timer if desired. Drum

level #1 is assigned to timer #1, drum level #2 is assigned to timer #2 and drum level

#3 is assigned to timer #3.

Flow Switch

MicroVisionEX has a dry contact flow switch input that will de-activate all of the control

output relays upon a no-flow indication. An alarm condition will be indicated and “Flow

Switch Alarm” will be displayed. This input is active closed:

Open = no flow; closed = flow.

If a flow switch input or other alarm condition exists, the LED’s on the front

panel will flash until the alarm condition is cleared.

4-20mA Outputs and Inputs

Optional 4-20mA inputs or outputs can be installed to increase the capabilities of the

MicroVisionEX. Connect 4-20mA equipment to the + and – terminals as shown on page 9.

Water Meter

MicroVisionEX has a dedicated water meter input that is capable of reading a dry contact

or Hall effect type water meter. Through programming this input can be used to signal a

pulse timer as well as totalizing water consumption. Some models offer up to six (6)

water meter inputs.

Alarm Relay

MicroVisionEX has a dedicated dry contact relay that can be used to interface with process

control equipment or visual indicators. This relay is un-powered.

72-900-06 Rev. F

Page 5 of 38

Page 6

3. INSTALLATION

3.1 Location

Select a mounting location convenient to grounded (True Earth) electrical and

plumbing connections. It is recommended that the controller is mounted on a wall or

other vertical surface with adequate lighting at a comfortable level. Installation

should comply with all national, state, and local codes.

Avoid locations where the controller would be subjected to direct

sunlight, extreme cold, heat, or humidity {less than 36°F (2.2°C) or

greater than 122°F (50°C), or greater than 95% RH non-condensing,

direct sunlight, vibration, vapors, liquid spills, or EMI (electromagnetic

interference; e.g., strong radio transmission and electric motors.)

Install at less than 2000m above sea level.

SAFETY PROTECTION PROVIDED BY THE EQUIPMENT MAY BE IMPAIRED IF THE

EQUIPMENT IS USED IN A MANNER NOT SPECIFIED BY THE MANUFACTURER.

THIS CONTROLLER IS INTENDED FOR INDOOR USE ONLY AND NOT SUITABLE

FOR WET LOCATION.

3.2 Mounting Hardware

Mount the controller using the four (4) holes provided.

Typically, use a #8 screw or equivalent. The mounting screw should be appropriate

for the location mounting on, i.e., sheet metal screws for mounting onto sheet metal,

wood screws for mounting onto wood or wall studs, and hollow wall drywall anchors

for mounting to drywall. Mount should be designed for 7.5 Kg, 17 lbs.

Mount the unit ergonomically, such that the unit is visible without excessive

bending or lowering of the body, and not too high such that the internals are

not visible with opening the enclosure.

3.3 Opening the Enclosure

Loosen the knob that secures the clear front cover. Then loosen four (4) screws in

the four corners of the front of the controller and carefully swing the top of the case

forward.

72-900-06 Rev. F

Page 6 of 38

Page 7

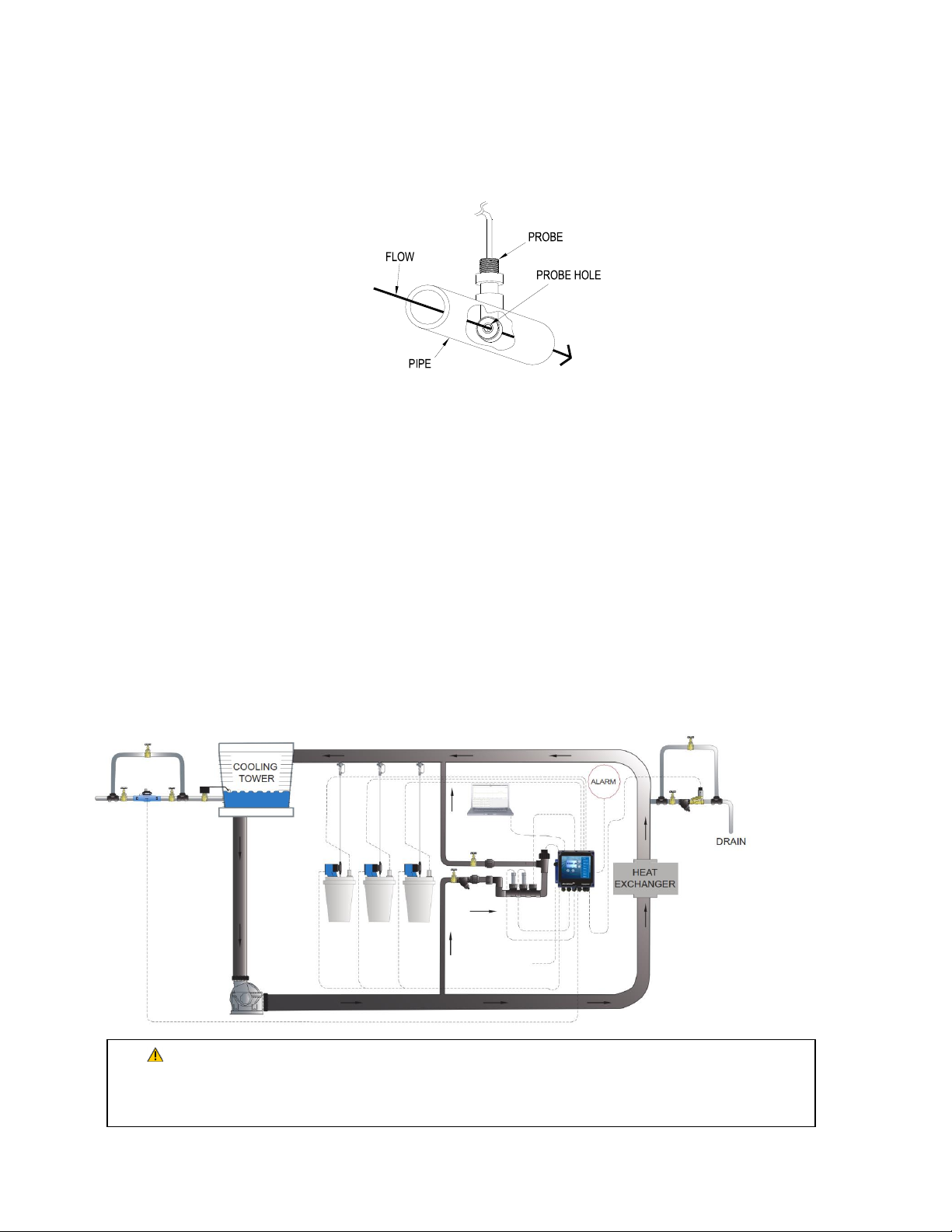

3.4 Sensor Installation

Over pressurization of the plumbing can occur when cooling tower is higher than the

piping and controller system. Ensure all pressures have been accounted for. Verify piping

and sensor allowable temperatures are above maximum temperatures of the system.

Conductivity

The controller is supplied with a temperature compensated toroidal conductivity probe

installed in a tee. The probe should only be installed where adequate flow is going around

and through the hole in the center of the probe in the tee provided.

pH and ORP

When ordered as a pH or ORP model the controller will be supplied with standard pH and

ORP probes. The probes are supplied installed in a tee. The probes should only be installed

where flow between 1 and 5 GPM is going around the probe.

Flow Switch

If the controller is provided with a flow switch, install the flow switch so that flow enters

into the bottom of the flow switch tee, and out the side of the tee. The flow switch must

always be installed in a vertical position so that the sensor wire is coming out of the top,

and the internal (red) flow shuttle is able to rise when there is flow and drop when there is

no flow. The flow switch is activated when 1 GPM (3,8 LPM) is going through it, and is

deactivated when the flow drops below 1 GPM (3,8 LPM).

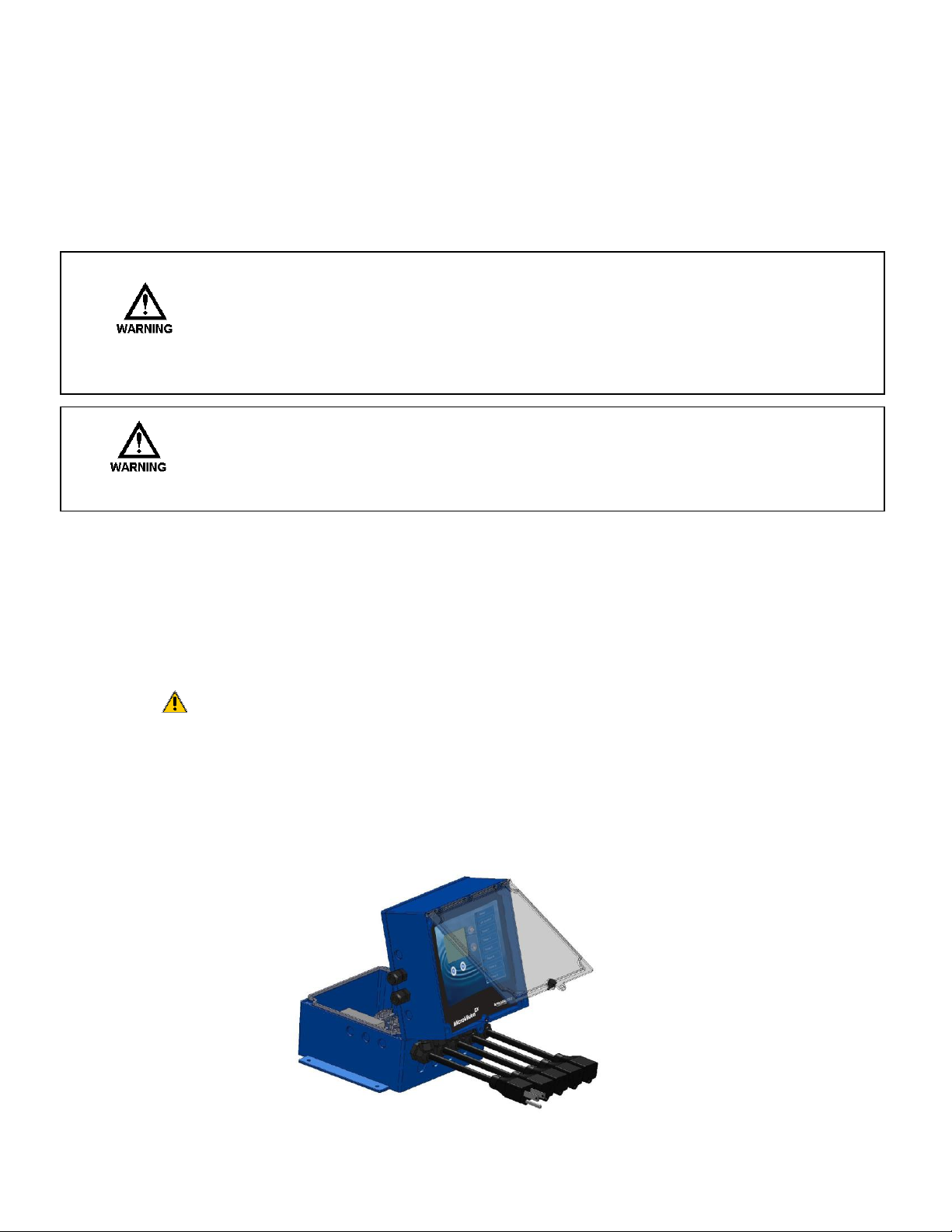

3.5 TYPICAL INSTALLATION

72-900-06 Rev. F

Page 7 of 38

Page 8

3.6 IMPORTANT SYMBOL INFORMATION

Warning indicates a condition that could cause damage to both the

equipment and the personnel operating it. Pay close attention to any

warning.

Primary Supply Ground must be connected to earth ground for safe

operation of the controller.

Chassis Ground – Connect the equipment’s ground wire here for safe

operation of external devices.

Notes to provide tips and hints

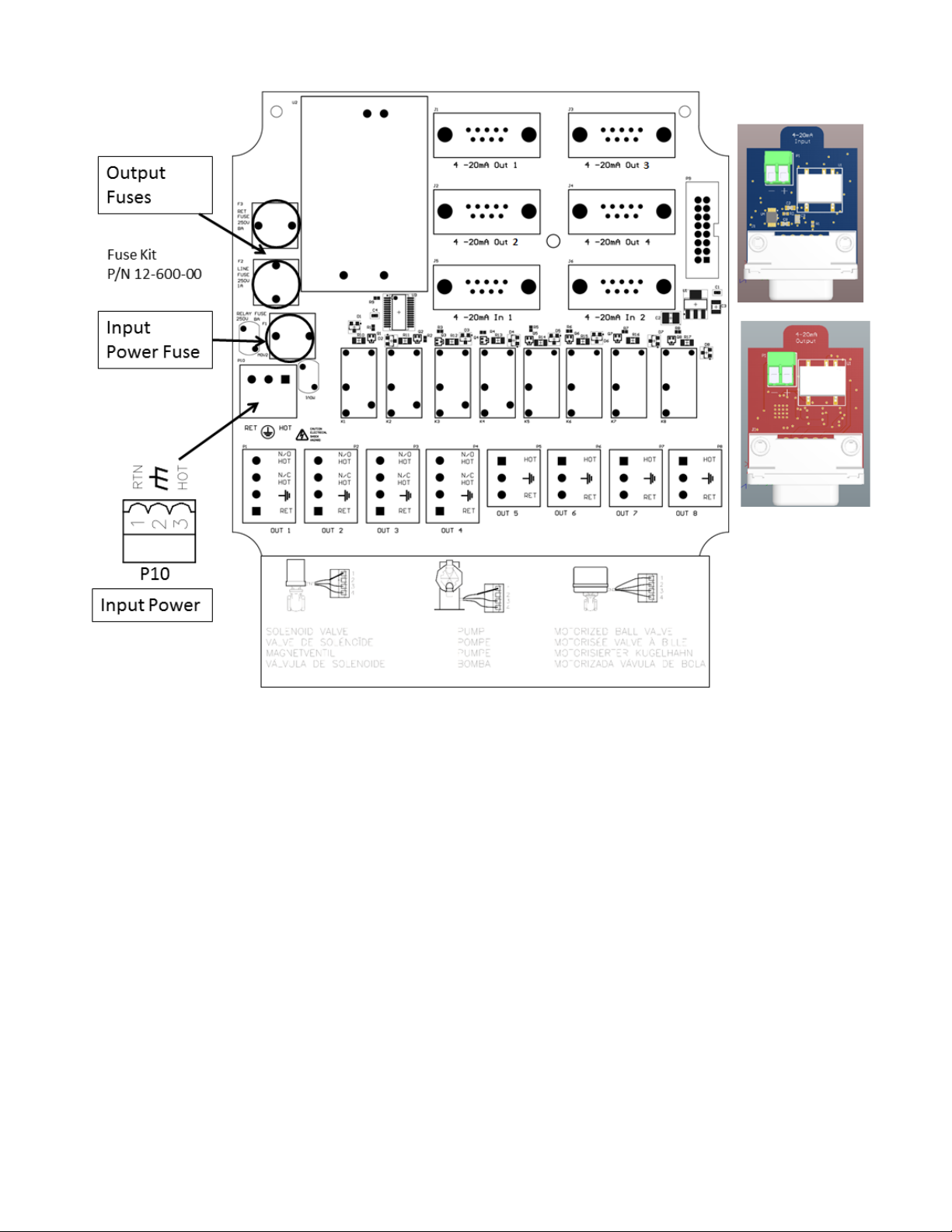

3.7 ELECTRICAL WIRING

CONTROLLER MUST BE WIRED IN ACCORDANCE WITH ALL APPLICABLE

ELECTRICAL CODES, NEC, CSA, EN, OR LOCAL AUTHORITY HAVING

JURISDICTION.

The MicroVisionEX electronic input circuitry is fuse protected on both the hot and

neutral inputs using a replaceable eight amp fuse (see page 9). For additional

protection of this instrument, use of a surge protector is recommended.

The controller should be connected to a dedicated power branch (i.e., its

own wiring, GFCI circuit breaker, etc.). For best results, the ground

should be independent (true earth) not shared.

A switch or circuit-breaker, marked as the unit’s disconnecting device

should be included in the installation. It should be in close proximity to

the unit and be easily reached by the operator.

Pre-wired controllers are supplied with a 3-wire grounded power cord and 3-wire

grounded receptacle cords for all controlled line voltage outputs.

Plug is considered as mains power disconnecting device which shall be readily

identifiable and easily accessible.

72-900-06 Rev. F

Page 8 of 38

Page 9

RELAY BOARD CONNECTIONS

Energy Usage and Duty

The unit utilizes a variety of probes and input signals to control valves, pumps,

and numerous other devices. These items are not all used in a continuous

fashion. The typical unit has a complicated duty cycle dependent on application.

For 120V and a max of 8A, a typical duty cycle of 15 minutes on and 45 minutes

off can be used. This results in an energy calculation of

120V * 8A *Power Factor* 25%

The Power Factor is the cosine of the phase angle between the Current and

Voltage of an AC circuit. Typically, 0.8 is a good estimate for US power.

The 25% is the estimate of a typical duty cycle of 15 on and 45 off.

For 240V, the amperage remains constant.

72-900-06 Rev. F

Page 9 of 38

Page 10

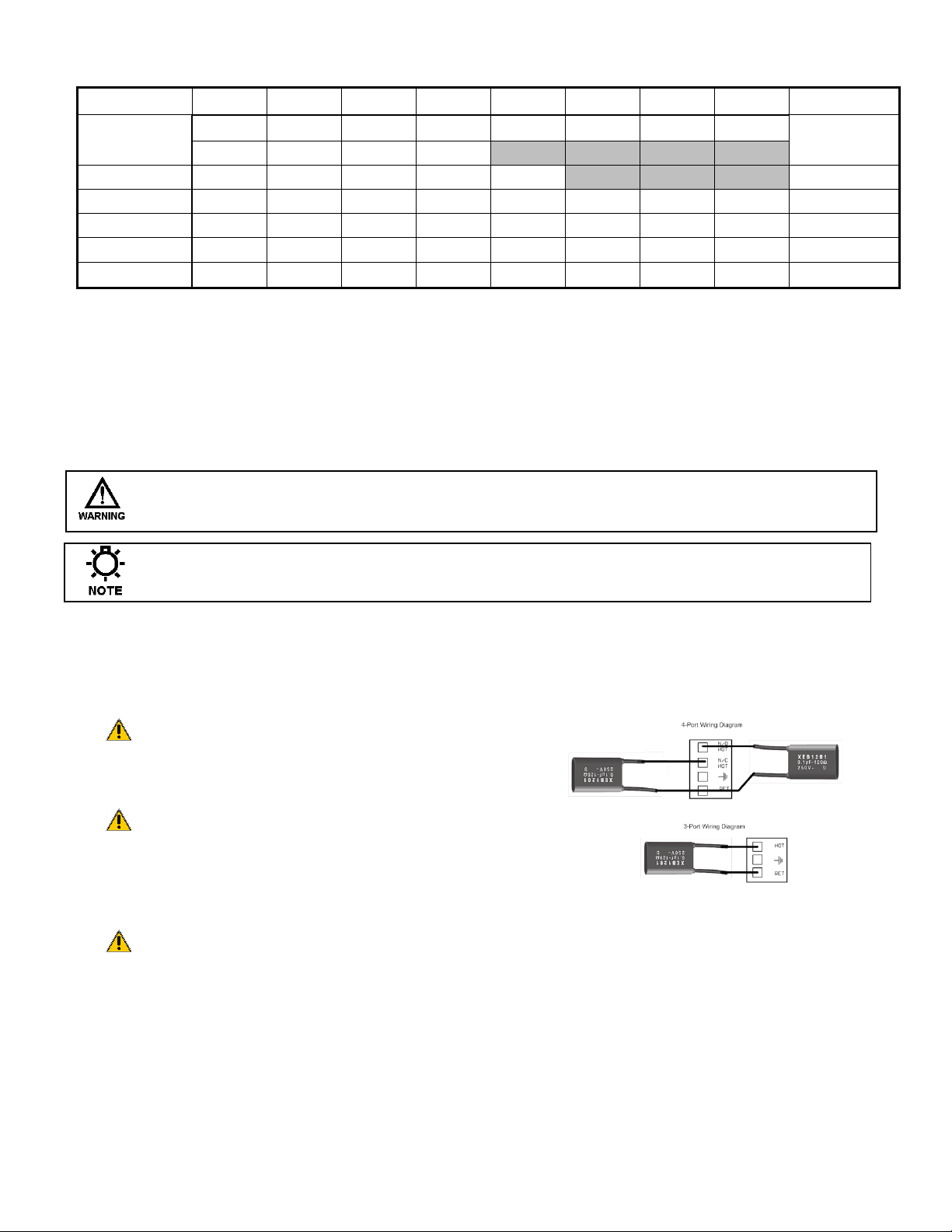

Relay Assignments

Relay 1

Relay 2

Relay 3

Relay 4

Relay 5

Relay 6

Relay 7

Relay 8

Dry contact

Model

OUT 1

OUT 2

OUT 3

OUT 4

OUT 5

OUT 6

OUT 7

OUT 8

P4

MVECXXX

Bleed

Timer 1

Timer 2

Timer 3

Alarm

MVEC5XX

Bleed

Timer 1

Timer 2

Timer 3

Timer 4

Alarm

MVECPXX

Bleed

pH

Timer 1

Timer 2

Timer 3

Timer 4

Timer 5

Timer 6

Alarm

MVECOXX

Bleed

ORP

Timer 1

Timer 2

Timer 3

Timer 4

Timer 5

Timer 6

Alarm

MVECPOX

Bleed

pH

ORP

Timer 1

Timer 2

Timer 3

Timer 4

Timer 5

Alarm

MVECPOM

Bleed

pH

ORP

Timer 1

Timer 2

Timer 3

Timer 4

Timer 5

Alarm

Conduit Models (Wiring High Voltage)

Conduit controllers have openings for conduit connections for hard wiring. Use only 18

AWG (1,2 mm²) stranded wire for conduit power and load connections. Supply (input)

power is connected via P10 located on the relay board. The top part of this terminal block

is removable to allow for easy access to the connector’s three (3) screws. For CE rated

models ensure all ferrites are installed in their specified configuration.

MAKE SURE THAT THE CONTROLLER VOLTAGE MATCHES THE INPUT VOLTAGE

AND OUTPUT VOLTAGES. DO NOT APPLY POWER UNTIL THIS CONDITION IS VERIFIED.

Make sure that all conduit connections are water tight.

The output relay terminal blocks are identified as: OUT 1 through OUT 8 these terminal

blocks can be removed in the same manner as P10. The first four relay outputs have a

N.O. and a N.C. connection, the others are N.O.

Ensure the snubber’s remain on

each of the relay outputs in the

specified wiring configuration.

Unit is to be connected to supply

mains by a qualified personnel in

accordance with local and

national codes e.g. NEC in the U.S. and CEC in Canada.

A suitable power disconnection means is to be provided

e.g. circuit breaker or switch which is identifiable and

easily accessible to the end user.

72-900-06 Rev. F

Page 10 of 38

Page 11

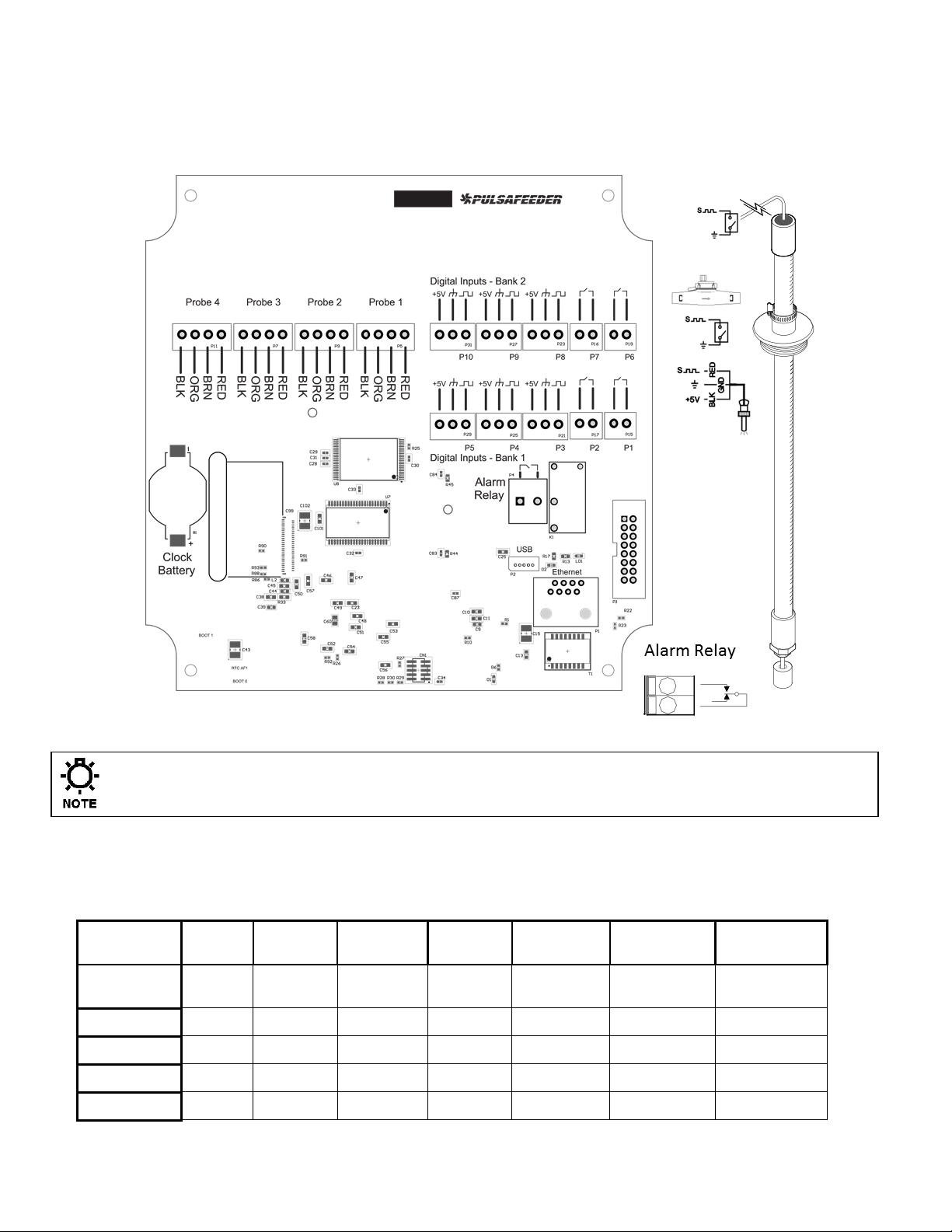

DIGITAL BOARD CONNECTIONS

Digital

Inputs

Input 1

Input 2

Input 3

Input 4

Input 5

Inputs 6 & 7

Inputs 8,9

and 10

Function

Flow

Switch

Drum

Level #1

Drum

Level #2

Drum

Level #3

Water

Meter

Water

Meter

Water Meter

Assignment

N/A

Timer #1

Timer #2

Timer #3

WM #1

WM #2 & 3

WM #4 to #6

Location

P1

P2

P3

P4

P5

P6 and P7

P8, P9, P10

Dry Contact

√ √ √ √ √ √ √

Hall Effect

√ √

The low voltage connections are found on the top board.

Use 22-24 AWG (,76 mm²) wire for: flow switch, drum levels, dry alarm, and water meter

connections. A recommended wire is OMNI cable DS92203. These signal wires must be

run separate from AC power lines.

Clock Battery # 09-710-04

Low voltage signal wires, e.g., water meter, must be run separate from AC power lines.

Digital Input assignments

There are 5 digital inputs on base conductivity models and up to 10 on featured models.

72-900-06 Rev. F

Page 11 of 38

Page 12

3.8 Flow Switch Input

It is recommended that a flow switch or auxiliary dry contact be used to make outputs

inoperative when the cooling tower is shut down. Connect detection wires to P1 to use

this interlock feature. This is active – closed: open = no flow; closed = flow.

If the controller does not have a flow switch, a jumper wire must be

connected across P1.

3.9 Sensor (probe) Connection Input

The controller is supplied with sensors prewired. Depending on the model, the

conductivity probe wires are connected to Probe 1, pH sensor on Probe 2, ORP sensor on

Probe 3, and Make up conductivity on Probe 4.

Always depressurize the unit prior to removing a sensor.

3.10 Water Meter Input

Connect the water meter to P5 on the top board. Some models have additional water

meters on P6 through P10. In order to wire a dry contact type water meter or contact

closure to a 3-port digital input, connect the two leads to the signal and ground ports.

3.11 Drum Level Input

The drum level connections are labeled as, P2 for Level 1, P3 for Level 2, and P4 for level

3. These are active closed: closed = low level; open = level is OK. The input can also be

reversed (NO or NC) in the programming.

3.12 4-20mA Output

The 4-20mA outputs, ordered separately, can be used to remotely measure any of the

controllers probe inputs and any of the 4-20mA inputs. Connect the 4-20mA receiving

equipment to the 4-20mA boards pins are marked + (positive) and – (negative). The

polarity must be observed for proper operation. The 4-20mA output current range is

approximately 0 mA to 24mA. Resistive load range should typically be 300 Ohms with a

max rating of 1200 Ohm.

3.13 4-20mA Input

Model dependent, MicroVision EX can support up to two 4-20mA analog inputs. The 420mA inputs, ordered separately, can be used to receive and data log signals from

sensors that transmit a 4-20mA output. Connect the 4-20mA equipment to the 4-20mA

boards pins are marked + (positive) and – (negative). The polarity must be observed for

proper operation.

Each 4-20mA analog input supports 2 wire loop or transmitter powered configurations.

Input resistance load is approximately 265 Ohms. Input voltage range is commonly 12V

or 24V. Up to 60V is permissible.

72-900-06 Rev. F

Page 12 of 38

Page 13

Tx

Pwr

Tx

Pwr

3.13.1 Fluorometer – Trace Chemical

The MicroVision EX can be optionally purchased panel mounted with a fluorometer, turner

LD2 or Pyxis ST-500 probe. From the factory, the probe comes prewired and calibrated.

Alternatively, the probe can be ordered separately, wired and programmed. Be sure to

observe the manufacturers wiring directions.

3.13.1.1 Turner Little Dipper™ 2

The turner is an inline fluorometer with a linear 4-20mA output which responds to trace

chemical. Typically is set to 4mA = 0 PPB and 20mA = 200 PPB probe has 4 wires; Red,

Black, Orange, and Brown. The red is the power supply voltage. Black is the Supply

ground. Orange is the positive current loop connection. Brown is the negative current loop

connection. The turner little dipper 2 requires an external power supply of 8-32 VDC (1W

Max)

72-900-06 Rev. F

Page 13 of 38

Page 14

3.13.1.2 Pyxis ST-500

The Pyxis ST-500 is also an inline fluorometer which outputs both a 4-20mA signal and a

RS-485 interface which responds to PTSA trace chemical. The ST-500 also has a 4-20mA

where 4mA = 0 PPB and 20mA = 200 PPB. Wiring the ST-500 is similar to the Little Dipper

2. The RS-485 bus is not used by the MicroVision EX (The blue and yellow wires). The

only wires necessary to terminate are power to the Pyxis and the 4-20mA loop (Brown or

white (4-20mA+) and Green (4-20mA-)). The clear wire should be connected to the

solution ground.

3.13.2 Calibrating PTSA Probe

4-20mA input probes require a 2 point calibration. In order to calibrate a Pyxis or Turner

inline fluorometer, navigate to the 4-20mA input in question. I.E. Menu -> Settings -> 420mA In 1. For a PTSA probe the units are PPB. Select Type->PPB. Select Back. Scroll

down to Calibrate. For a 2 point calibration you will need a low point and a high point. The

best way to calibrate a low point is to put the probe in deionized water, uncontaminated

with any PTSA. You should see ~4mA as the actual signal. Enter “0000” on the top line.

Before exiting this page the high point will need to be calibrated. This is ideally done in the

actual flow assembly. Place the probe in the flow allow solution to flow across the sensor

to purge any air bubbles out of the sensor. Take a sample with a handheld meter be sure

the mA signal on the controller is stable and enter the high point, the value measured by

the handheld. Alternatively, to calibrate the high point of the sensor, buffer solutions can

be used. Fully submerge the sensor in the known buffer ensure to expel air bubbles which

may have formed on the optics. The known buffer needs to be within the range of the

probes sensing capabilities. Ensure the mA output from the probe has stabilized on the

MicroVision EX under the actual reading. Enter the known value as the high point, upon

hitting enter on the last digit the value will be saved and your probe successfully calibrated.

3.14 Alarm Dry Contact Relay

The alarm dry contact activates for all system alarms and is a volt free signal. Use P4 to

connect the alarm reporting equipment. This relay will close when an alarm condition

exists and will open when no alarm conditions are present. This connection is intended to

be used to signal external process control equipment or indicators (low voltage DC

operated buzzers or lamps) when an alarm condition is present. This relay is not

protected by a fuse and should not be used to voltages above 48VDC.

72-900-06 Rev. F

Page 14 of 38

Page 15

FRONT PANEL DESCRIPTION

3.15 Keypad Operation

UP/DOWN - Dual function keys are used to move the select

(highlighted) box and to increase and decrease values.

O O - Soft keys used for various functions depending on the

currently displayed screen. The key’s function appears

above the key on the display.

3.16 Communications (Optional)

The MicroVision EX has a variety of cloud capable controllers. These controllers will ship

with a CAT5 cables with an RJ45 connection. To connect the MicroVision EX to PulsaLink,

Pulsafeeders cloud controller management software solution. The controller will need

internet access. Please terminate the provided RJ45 connection to an open internet port.

72-900-06 Rev. F

Page 15 of 38

Page 16

4. CONTROLLER PROGRAMMING

4.1 Menu Map

4.2 Menu Navigation

MicroVisionEX uses four front panel buttons to navigate through the different menus. Use

these buttons to move up and down within a list of options or move right and left to enter

or change parameter values. In some cases the MicroVisionEX display will prompt the user

to press the different buttons to assist you in selecting or changing data.

Some menus may display highlighted menu options or a checkmark () next to a menu

option. The highlighted menu option is used to indicate that another menu will be displayed

if this option is chosen. The checkmark indicates that a particular control mode has been

selected.

4.3 Home screen

The Home Screen displays the system readings and operating information. This screen is

displayed during normal operation when there are no alarm conditions on the MicroVisionEX.

If an alarm condition occurs an alarm message will flash on the screen. The LED’s to the

right of the display will also flash indicating an alarm has occurred.

The MicroVisionEX will return to this screen if no buttons are pressed for five minutes after

entering a menu.

72-900-06 Rev. F

Page 16 of 38

Page 17

4.4 Main Menu

The Main menu is the starting point for all subsequent programming menus.

Relay HOA – This menu allows for the control of the relay output states, either

manual off, or auto.

Configure – This menu allows for setting the time and date, display contrast, water

meter, etc.

Settings – This menu allows for setting the conductivity, pH and ORP configurations

Timers– This menu allows for setting the timers for the different feed modes.

Communications– This menu allows for exporting data, exporting settings,

importing settings and upgrading the O/S.

4.5 Relay HOA

From the HOA Outputs menu manually set the relay control outputs. This is useful for

servicing chemical pumps or troubleshooting electrical problems. First select the relay

output to be controlled then select the relay state.

Forcing the output to Auto may cause the control output to energize without warning.

4.6 Configure

From the Configure menu select from many different system configuration options.

Date/Time – Set the current date, date format, time, and time format.

Digital Inputs – Set the drum level settings, and water meter type and volume.

4-20mA Out- Activate or deactivate 4-20mA output options.

4-20mA In- Activate or deactivate 4-20mA input options.

Gal/Lit- Set the units that the controller displays.

Meter Totals- Display and/or reset the water meter totals.

Language – Change the controller displayed language.

Display Settings – Set the display, brightness, home screen display text, home

screen scroll rate, home screen alarm message size, and the display dampener.

Password – Set the user password.

Software Version – Displays the current software version.

Factory Restore – Restore the parameters to factory default

4.6.1 Date/Time

From the Date/Time menu set the date and time as well as the date and time display

formats.

Set Date – Set the current date.

Set Time – Set the current time.

Date Format – Pick the day/month/year format.

Time Format – Pick the 12-hour or 24-hour time of day format.

72-900-06 Rev. F

Page 17 of 38

Page 18

4.6.2 Digital Inputs

4.6.2.1 Drum Level

From the Drum Level menu select how the timer output will respond to a low drum level

indication. The available choices are to allow the pump to continue to run, or have the

pump stop when its drum level goes low. Drum level #1 is always assigned to timer #1,

Drum level #2 is always assigned to timer #2, and drum level #3 is always assigned to

timer #3.

Alarm Trigger – Program the drum level to go into alarm when the drum level

switch contact is either open or closed.

Action on Alarm – Program the drum level input to either turn off the timer relay

on alarm or allow it to keep the relay on in automatic mode.

When a drum level goes low the controller will go into alarm regardless of this

setting. Re-filling a low drum may cause the pump control output to energize without

warning.

4.6.2.2 Water Meter

From the Water Meter menu select what type of water meter the controller is attached to.

Once the meter type has been entered the next setting will be for the gallons/liters per

pulse or K-factor, depending on the meter type.

Dry contact or Hall-effect water meter- Once the type is selected enter the

resolution or volume per pulse or pulses per gal/lit for hall effect.

Gal/pulse or K factor – enter the setting for the water meter connected.

4.6.3 4-20mA Out and 4-20mA In

Activate or deactivate the 4-20mA output or input options in this screen. Analog inputs and

outputs are upgrade options for all models. To install analog signal options, first activate

them in this screen, then power the unit down and then install the signal modules as

described in the upgrade kit instructions. When the 4-20mA inputs or outputs are activated

they will have their own program settings in the “Settings” menu.

4.6.4 Gal/Lit

Select the unit of measure for the controller to display for the water meter settings.

4.6.5 Meter Totals

In the meter totals screen view the water meter total values and the date they were last

reset and reset the total values to zero in this screen.

4.6.6 Languages Menu

Select the language the controller programming displays.

English

Spanish

Portuguese

72-900-06 Rev. F

Page 18 of 38

Page 19

4.6.7 Display Settings

This menu is for setting how the controller display appears.

4.6.7.1 Brightness

Select this menu to set how bright the background is, Low, Medium, or High.

4.6.7.2 Display Line text

Select this menu to change what text is displayed on the two lines of the main home screen

display. (Pulsafeeder and MicroVision EX are the default)

4.6.7.3 Home Screen Display Scroll

Select this menu to set the speed that the home screen scrolls from displaying various

values, Low (30 seconds), Medium (10 seconds), or High (5 seconds), or OFF for no

scrolling of the main menu.

4.6.7.4 Display Alarm

Select this menu to set the size of the alarm messages that are displayed in the home

screen when they occur.

4.6.7.5 Display Dampener

The Display Dampener setting sets how often the actual conductivity reading is updated on

the Home Screen. This results in dampening of the controller response to sudden changes

in conductivity.

The controller takes a conductivity reading once every second. Increasing this value

above one second causes the controller to average the readings, hence, slowing down

the control functions.

4.6.8 Password Setting

The Controller has two Security Access Codes, each with different system privileges - an

Administrator and a User. An Administrator can access all functions of the controller. A

User level can only access those items selected by the administrator. A password level is

not required for access to the home menu.

Both passwords are active when Administrator level password is set. Conversely, both

passwords are inactive when the Administrator level password is set to 000000. Each

password consists of a six (6) digit numerical code.

The Administrator configures the following parameters to restrict User access to the

controller systems

The following is an example of the Security menu options:

Exit Home Screen = Limits access to only the Home Screen.

Relay HOA = Allows access to the Relay HOA menu.

Configure Menu = Allows access to the Configure menu.

Settings Menu = Allows access to the Settings menu.

Timer Menu = Allows access to the Timers menu.

72-900-06 Rev. F

Page 19 of 38

Page 20

Calibration = Allows access to "probe Cal".

Download = Allows the user to export the data files.

Upload = Allows the user to import program settings.

USB Settings = Allows the user to change the USB settings.

Factory Reset = Restricts access to the factory reset feature.

Once the password is set the controller will require a password to access any of the

menus. If the password is lost or unknown it will be necessary to call technical

service to gain access to the controller menus.

4.6.9 Software Version

From the Software Version screen view the current software that is running in the

MicroVision

EX

controller.

4.6.10 Factory Reset Function

The Factory Reset Function will reset all of its internal parameters to the factory default

values.

Be absolutely certain you want to reset all the parameters back to the factory

defaults. Once the reset takes place there is no way to retrieve the previous

parameters.

4.7 Settings

The Settings menu is for setting the control parameters for conductivity, pH and ORP.

4.7.1 Conductivity

Set point Type - A Set point is a setting at which the controller activates an output,

such as a solenoid valve or a metering pump on the relay outputs or dry contact

outputs. The type – Rising or Falling defines which side of the set-point the relay

activates. A Rising type means that the output activates when the input goes above

the set point. A Rising set point is commonly used in conductivity control where you

want to keep conductivity below a certain value. A Falling type activates the output

when the value goes below the set point.

Set point –This is the conductivity point where a bleed function will begin.

Differential – The differential setting controls when the bleed function stops. This

value subtracted from the conductivity set point causes the bleed function to stop.

Example: Rising Set point=1200, Differential=100, the bleed function begins when

the conductivity reaches 1200 and ends when the conductivity reaches 1100.

72-900-06 Rev. F

Page 20 of 38

Page 21

Limit Timer – Set this value to the maximum amount of time the bleed output can

Menu

Settings

Conductivity

Conductivity

1234 uS/cm

Back | Next

Probe Cal

stay energized before a Bleed Limit alarm is reported. If the next bleed cycle

completes without an alarm the alarm will clear itself on the next cycle. Setting the

limit timer value to 00:00 will turn off limiting function of the relay.

Limit Alarm- Use this option to turn the control relay off on a limit alarm, or to keep

it on in automatic mode during a limit alarm. (default is “keep relay on” for the bleed

relay)

Probe Calibration – Use this function to calibrate the probe.

Alarm Setp’t – Use this menu to specify the upper and lower values for alarm

reporting.

Settings Menu- When the settings menu is being displayed, probe control

operations stop until all settings changes are completed and

The conductivity probe is very sensitive to temperature changes. Allow the probe

roughly 10 minutes to adjust to the temperature of the test solution or sample.

Calibrating the probe without allowing the probe to equilibrate to the sample

temperature could result in erroneous controller conductivity readings.

Only use a calibration meter that incorporates temperature compensation when

performing a probe calibration.

4.7.1.1 Probe Calibration Conductivity

Because there are no metal electrodes to foul re-calibration is not required for the toroidal

probe on a regular basis. However, you may want to calibrate the probe initially to get a

base-line reading for future reference or to have the reading match a hand held tester.

There are two methods of probe calibration that can be used to calibrate this probe.

In-stream Calibration – In this method the probe is already installed in the

process flow and is currently reading conductivity. Be certain adequate flow (1

gallon/minute minimum) has been circulating around the probe for at least 15

minutes. This will ensure the probe temperature has stabilized and a more accurate

conductivity reading will be made.

Step 1 – Move to the Probe Calibration screen.

72-900-06 Rev. F

Page 21 of 38

Page 22

Step 2 – Draw a sample of the process flow water and measure the conductivity

using a calibrated meter. Be certain the meter being used to measure

conductivity is temperature compensated.

Do not allow the sample to sit for any length of time after being drawn as this may

cause the reading of the sample to be different from the probe.

Step 3 – Enter the calibrated conductivity value into the Probe Calibration screen.

If the conductivity reading varies more than 25 counts from the reading of the

calibration meter verify the sample temperature is within 1 C of the probe

temperature.

Step 4 – Return to the Home Screen and verify the proper conductivity reading is

displayed.

4.7.2 pH and ORP

From these menus configure the parameters that trigger the pH and ORP control output.

Additionally, the probe calibration, alarm set points, and the limit timer functions are also

configured in this section.

Set point Type - A Set point is a setting at which the controller activates an output,

such as a solenoid valve or a metering pump on the relay outputs or dry contact

outputs. The type – Rising or Falling defines which side of the set-point the relay

activates. A Rising type means that the output activates when the input goes above

the set point. A Rising set point is commonly used in pH control where it is desirable

to keep pH below a certain value. A Falling type activates the output when the

value goes below the set point. A common example of this is ORP control, where

maintaining a certain minimum level of an oxidizer in the system is required.

Set point –This is the point where a control relay will activate. Once the ph or ORP

has reached this value the control relay output will turn on.

Differential – The differential setting controls when the control relay deactivates.

This value subtracted from the set point causes the relay to stop.

Example: Set point=7.00, Differential=1.00, the pH begins when the pH reaches 7.0

and ends when the pH reaches 6.0.

Limit Timer – Set this value to the maximum amount of time the output can stay

energized before a pH or ORP Limit Alarm is reported. If the next control cycle

completes without an alarm the limit alarm will clear itself on the next cycle. Setting

this value to 00:00 turns off this function.

Limit Alarm- Use this option to turn the control relay off on a limit alarm or to keep

it on in automatic mode during a limit alarm. (default is “Turn relay off” for the pH

and ORP relay)

Probe Calibration – Use this function to calibrate the probe.

Alarm Setp’t – Use this menu to specify the upper and lower values for alarm

reporting.

72-900-06 Rev. F

Page 22 of 38

Page 23

Menu

Settings

pH

Probe Cal

pH Calibration

Actual 07.20 pH

Pt. 1 07.00 pH

The probe is very sensitive to temperature changes. Allow the probe roughly 5

minutes to adjust to the temperature of the test solution or sample. Calibrating the

probe without allowing the probe to equilibrate to the sample temperature could

result in erroneous controller readings.

4.7.2.1 pH and ORP Probe Calibration (1 point)

Probe Calibration – Use this function to calibrate the probe. Enter the calibrated

value based on the calibration method used. For both methods shown below the

actual reading from the probe is shown on the screen. This is the un-calibrated value

the controller is receiving from the sensor. If the actual value displayed in the

calibration screen is not close to the sample that the probe is actually in, or the

reading is changing significantly, the probe either needs to be cleaned or replaced, or

the solution the probe is in is no longer accurate. Typically ORP does not require a

calibration for most applications for that reason only pH is illustrated below.

In-Stream (Best Practice)

Begin with a clean sensor. With the pH or ORP sensor installed in the

system under normal operating conditions ensure flow is going across the

probe for at least five (5) minutes for temperature equilibrium.

Step 1 – Move to the Probe Calibration screen.

72-900-06 Rev. F

Page 23 of 38

Step 2 – Take a reading with a hand held tester from the sample valve on the

controllers flow assembly.

Step 3 – Observe that the actual reading displayed has stabilized then enter the

reading from the hand held tester as point 1. For the best results, this method

should be done with the system operating at, or within 1 pH unit, of the pH set

point.

Step 4 – Return to the Home Screen and verify the proper pH reading is

displayed.

Standard solution

Begin with a clean sensor, rinse the sensor with the standard solution to be

used for calibration purposes three (3) times, place the sensor in a

standard solution that represents the side of the pH scale for intended

control. For example, if the set point is above 7pH the standard should also

be above 7pH. With the sensor in the solution for at least five (5) minutes

for temperature equilibrium, observe that the actual value displayed has

stabilized and then enter the standard solution value as point 1.

Page 24

4.7.3 4-20mA Outputs (Optional Accessory)

4-20mA Out 1 = Cond.

9999 uS = 20.0 mA

0000 uS = 4.0 mA

Min. diff. = 1000 uS

Next

To enable 4-20mA output, see sec 4.6.3. The output will then be configurable from the

settings page. First set the type setting to the sensor input that the 4-20mA output will

track, any probe types can be configured. Then enter the sensor reading ranges to scale

the 4-20mA output to. Any sensor value can be entered for the 20.0 and 4.0mA ranges.

The actual output can then be adjusted from 20mA to 24mA and from 0mA to 5mA for

calibration to the receiving device.

4.7.4 4-20mA Inputs (Optional Accessory)

To enable a 4-20mA input, see sec 4.6.3. Once the board is enabled device will appear in

the settings page. Here you can setup the peripheral. To setup you must configure the type

and calibrate the input. To configure the type select the mode which resembles your

application. Then you must calibrate the input, depending on the input type, you may need

buffer solutions to do this. Hold the input device in a low state, enter the correlating value

in the controller on the top line, do not exit the setup until the next point has been

calibrated, otherwise you will get an error. Place the input in a high state and enter the

correlating value in the controller. Your input should now be set-up. If you still get an error

exit out and start over. If you wanted to have any timers trigger based on the 4-20mA

input you can configure a set point control timer.

4.8 Timers - Modes

From this menu pick the mode that the timer will follow.

Pulse Timer – Runs the timer based in inputs from a water meter.

Percent Timer – Sets the Timer to run on a repeating cycle. Set the Cycle time

period and percentage of the cycle time period to run for. Example: Cycle

Time=60minutes, % Minutes to run=10, the timer will run for 10% of 60 minutes, or

6 minutes every 60 minutes.

28-day timer- Runs the timer based on a calendar schedule of specific times, days,

and weeks. Typically used to add biocides

72-900-06 Rev. F

Page 24 of 38

% Post Bleed – Runs the timer for a percentage of the bleed time when the bleed

control stops.

Page 25

Limit Timer – Set this value to the maximum amount of time for the timer to run

while the bleed function is running. If this time is exceeded the controller will go into

alarm and the timer control output will de-energize.

Alarm – The timer activates based on system alarms for powering sirens, lights or

sending remote signals.

Set-point Control – This timer behaves like a conductivity, pH and ORP relay. The

relay will turn on and off based on a probe input set-point.

Disabled – The timer does not activate.

4.8.1 Timers – Pulse Timer

From this menu configure how the timer will run while in pulse timer mode. This mode uses

the water meter input to cause a counter to accumulate a certain volume of water before

the timer is activated. Once the accumulated volume is reached, the timer is activated for

the programmed Feed Time.

Feed Time – Set this value to the amount of time for the timer to run when the

water meter accumulator count reaches the accumulator set.

Accumulator Set – Set this value to the amount of water that needs to accumulate

prior to a timer feed time. The units will be in gallons or liters depending on what

units are set in the configure menu.

Accumulator Count – This is the current running count of the water meter

accumulator.

4.8.2 Timers – Percent Timer

From this menu configure the timer to operate on a percentage of a fixed cycle time

repeatedly.

Example:

Cycle Time=60minutes.

% Minutes to run=10%

In this example the timer will feed for 10% of 60 minutes, or 6 minutes every 60

minutes.

4.8.3 Timers - 28 day (Biocide Timer)

From this menu configure how often and the duration for the biocide 28-day timer to run.

This controller can also perform a pre-bleed, using a conductivity minimum with a fixed

time, and a bleed-lockout function for each biocide feed program. Each 28 day timer has

four (4) programs (Program A to D) with individually programmable settings as follows:

Days/Weeks – Set the days and weeks for the timer to run.

Start Time – Set the time of day for the timer to begin. If a pre-bleed is

programmed, this is the time that the pre-bleed starts. Setting the value to 00:00

means the start time is ignored.

Feed Time – Set this value to the amount of time for the timer to activate the timer

control relay for each start time.

72-900-06 Rev. F

Page 25 of 38

Page 26

Pre-Bleed – Set the pre-bleed time to the maximum amount of time for the pre-

bleed function to force a bleed cycle without reaching the conductivity minimum. Set

the conductivity minimum to the value for the conductivity to reach before the bleed

cycle finishes and the biocide feed time.

Bleed Lockout – Set this value to the amount of time to lock-out a bleed function

during (and after if set longer then the feed time) a biocide feed cycle.

28 day timer programs (A to D) cannot be set to run at the same time, week and

day. If two timers have the same run times only the first program, in alphabetical

order, set will run (example if A and B are the same, only A will run.)

4.8.4 Timers – % Post Bleed

From this menu configure how the timer will run while in percent post bleed mode. This

mode uses the bleed time to calculate the run time based on a user defined percentage

setting.

Percentage – Set this value to the amount of time (as a percentage) for the timer

to run after a bleed function has completed.

Example: % of Bleed=25%, the most recent bleed cycle took 20 minutes, the timer

will now feed for 25% of 20 minutes, or 5 minutes.

Limit Time – Set this value to the maximum amount of time to allow the timer to

run after a bleed cycle has completed. Setting the timer to 00:00 turns off this

function.

4.8.5 Timers – Limit Timer (Bleed and Feed)

From this menu configure how the timer will run with the bleed relay. This mode activates

the timer at the same time as the bleed time up to a user defined maximum time. Set this

value to the maximum amount of time to allow the timer to run for during bleed cycle.

Setting the limit timer value to 00:00 will turn off limiting function of the relay.

4.8.6 Timers – Alarm

In this mode the timer activates with any system alarm condition.

4.8.7 Timers – Set Point Control Mode

A set point control mode time can be pointed to any of the probe inputs. Programming the

timer mode is identical to setting up a probe. This timer mode is only an option on timer 1,

2, and 3. One of the core functions of this timer mode is to feed chemical in response to a

4-20mA probe time, a PPB or PPM type input.

Set point Type - A Set point is a setting at which the controller activates an output,

such as a solenoid valve or a metering pump on the relay outputs or dry contact

outputs. The type – Rising or Falling defines which side of the set-point the relay

activates. A Rising type means that the output activates when the input goes above

the set point. A Rising set point is commonly used in conductivity control where you

want to keep conductivity below a certain value. A Falling type activates the output

when the value goes below the set point.

Set point –This is the defined point where a relay will energize.

Differential – The differential setting controls the offset which the relay will remain

energized, once the offset is exceeded the correlating relay will de-energize.

72-900-06 Rev. F

Page 26 of 38

Page 27

Limit Timer – Set this value to the maximum amount of time relay will remain on

until an alarm is triggered. Setting the value to 00:00 disables the timer.

Limit Alarm- Use this option to turn the control relay off on a limit alarm, or to keep

it on in automatic mode during a limit alarm. (default is “keep relay on”)

Alarm Setp’t – Use this menu to specify the upper and lower values for alarm

reporting.

4.8.8 Timers – Disabled (Default)

In this mode the timer does not activate other than by the use of the HOA function.

4.8.9 Timers – Bio Tracking (In All Timer Modes)

From this menu configure how the timer will respond when a 28-day timers Feed Time

setting is running.

Skip – Choose this option for the timer to skip a feed cycle if a 28 day biocide timer

happens to be feeding.

None – Choose this option for the timer to run regardless of what the biocide feed

cycles are doing.

Any timer feed time that was skipped due to a 28 day biocide feed cycle will not

be added to the next timer feed cycle.

4.9 Communications

The controller has two primary methods of communications, a direct USB collection port

and an Ethernet port.

4.10 USB

When a USB flash drive is inserted into the USB cable the user can take certain

actions. If a password has been entered into the controller, the user must first enter

the required code to access the USB options screen.

Export Data Log

The controllers data log history file can be downloaded to the USB flash drive

in CSV format.

Export Config File

The controllers programming and set points can be down loaded for

duplication of the program on other MicroVisionEX controllers or as a record of

the current settings.

Import Config file

The controllers programming and set points can be uploaded for duplication of

the program from other MicroVisionEX controllers.

Erase Data Log

Use this function to reset the controllers data log records. The current data log

will be erased and cannot be recovered

Data Log Name

Use this setting to give the exported data files a unique file name for each

controller. The file name length is fixed at 16 characters. However, it is

72-900-06 Rev. F

Page 27 of 38

Page 28

possible to use “*” symbols in the name to create spaces. The default name

is: DataLogFile***** this produces CSV file named DataLogFile0.csv

Data Log Interval: Use this setting to define how much data the controller

will store. Options are “Custom”, 30 days, 60 days, 90 days, 120 days, 1 year

or 2 years. All Data Log Interval ranges still record controller data every 1

minute; however the “custom” setting allows for a range from 2 to 120

minutes to make exporting the data file to a USB drive or downloading faster.

Because the custom range always uses the same size memory block it stores

various ranges of data.

Example:

Custom range @ 2 Minutes = 60 Days

Custom range @ 120 minutes = 9.8 Years

Normal data log interval settings create a file that could be as large as 350MB

in size. The custom range settings create a file that could be as large as

40MB.

In order to access the data stored on the controller remotely the data

log interval must be set in either 30 days @ 1 minute or any setting in

the custom menu.

Changing the Data log interval erases the existing data log file in the controller

to create a new one. To avoid losing data, download the current log file before

changing this setting.

Operating System Upgrade

The controllers operating software can be updated in the field to the most

current version available. To upgrade the OS install the OS file on a USB drive

and plug the drive into the controller. Make a note of all controller program

settings, and then power the controller down. Press the Arrow up key and the

lower left navigation key (upper right and lower left keys diagonal from each

other) on the front panel and hold them down. Next power the controller up.

Wait approximately 30 to 60 seconds, the controllers display will come on and

the new OS will be installed. Before programming erase the data log and

perform a factory reset. Reprogram the controller settings.

4.10.1 USB Graphing Tool

The MircoVision EX data log file is output as a CSV file. This file can be opened for

easy viewing and digestion of data using our provided graphic tool. Visit:

www.pulsatron.com/support/pulsaworks to download.

4.10.2 USB Data log Timer and Tamper Codes:

Timer Modes

1792 = Disabled

1536 = Alarm

1280 = Set Point control

1024 = Limit Timer

72-900-06 Rev. F

Page 28 of 38

Page 29

768 = % Post Bleed Timer

512 = 28 day Biocide Timer

256 = Percent Timer

0 = Water Meter Pulse Timer

TMPR Column:

The tamper column will nominally appear as 0. If the unit is tampered

with you will see a 1 in the tamper column. Any other value indicates a

power cycle of the unit.

4.11 Ethernet (Optional)

On a model equipped with Ethernet communications, the MicroVisionEX controller when

networked via the Ethernet cable and an application appropriate network adapter the user

will able access the controller, download data from the unit and upload programming

changes via our online PulsaLink portal.

4.11.1 Programming your controller PulsaLink

Once the controller’s RJ45 connector has been wired to a reliable Ethernet connection. The

controller has a token which needs to be programmed. After setting the controller token to

a non-zero value (Menu->Communications->Networking->Token) power cycle the

controller to start communicating on PulsaLink. The default token is 000-000-001. See the

PulsaLink user manual for more information.

4.11.2 Setting Up Your Controller on PulsaLink

In order to access your controller online you will need to go to

“https://www.pulsalink.net/login”. Contact your company administrator if you need to be

setup with an account. An administrator needs to grant access to users to each controller.

72-900-06 Rev. F

Page 29 of 38

Page 30

5. FACTORY DEFAULTS

DEFAULTS

SYSTEM CONDUCTIVITY SCALE

0-9,999 S/CM

Set point Type

RISING

Set point

1500 µS/CM

Set point Differential

50 µS/CM

High Alarm

1700 µS/CM

Low Alarm

1300 µS/CM

Limit Timer

00:00 (disabled)

MAKE-UP CONDUCTIVITY SCALE

0-10,000 S/CM

Set point Format

CYCLES

Set point Scale

0-2000 S/CM

Set point Ranges

0-400 / 401-800 / 801-1200 / 1201-1600 / 1601

Set point Range Set points

6.0 / 5.0 / 4.0 / 3.0 / 2.0 Cycles

Set point Differential

40 µS/CM

High Alarm

840 µS/CM

Low Alarm

360 µS/CM

SYSTEM pH SCALE

0-14 pH

Set point Type

Rising

Rising Set point

7.8 pH

Set point Differential

0.2 pH

High Alarm

8.3 pH

Low Alarm

6.3 pH

Limit Timer

01:30

SYSTEM ORP SCALE

-2000-+2000 mV

Set point Type

FALLING/LOW

Set point

400 mV

Set point Differential

50 mV

High Alarm

500 mV

Low Alarm

300 mV

Limit Timer

01:30

4-20mA INPUT

NONE

Units

NONE

4-20mA OUTPUT

0-20 mA

Type

None

LEVEL INPUT

Type

Level

Keep Relay on

FLOW INPUT

Type

Flow

TIMER

Type

DISABLED

TIMER: LIMIT

Run Time

01:30 HH:MM

72-900-06 Rev. F

Page 30 of 38

Page 31

TIMER: PERCENT

Percent

0%

Percent Minutes

10

TIMER: PERCENT POST BLEED

Bleed Percent

0%

Maximum Time

01:30 HH:MM

TIMER: PULSE

Run Time

00:30 MM:SS

Pulse Set

10

Water Meter

One

TIMER: 28-DAY

Run Time

01:30 HH:MM

Lock Out

00:00 HH:MM

Pre Bleed

00:00 HH:MM

Conductivity Minimum

0 S/CM

Program: Start Time

00:00 HH:MM

Program: Week

EVERY WEEK

Program: Day

NO DAY

WATER METER

Gallons per Pulse

100

Scroll rate

High (3 seconds)

SECURITY

Passwords

(NONE)

72-900-06 Rev. F

Page 31 of 38

Page 32

6. TROUBLESHOOTING GUIDE

Symptom

Probable Cause

Possible Solution

Controller does not

power up.

No power supplied to

controller.

Insure that correct voltage is supplied to

controller.

Check circuit breaker supplying power to

the controller.

Fuse is blown.

check/replace fuses (see page 9)

Ribbon cable.

Check ribbon cable connecting upper and

lower pc boards inside controller.

Controller displays

“Flow Switch Alarm”

alarm message.

No flow thru flow

assembly.

Insure there is enough water flow through

the assembly. At least 1 GPM (3.8 LPM) of

flow.

Flow switch wiring or

connector loose.

Check flow switch connections

Flow switch stuck.

Clean flow switch sensor mechanicals.

Flow assembly clogged.

Clean inside flow assembly.

Flow switch input jumper

missing.

Install jumper if flow switch is not used.

Controller displays "

Limit" alarm message.

Programmed limit timer

set too short.

Adjust limit timer value to longer duration

Clogged bleed valve or

drain.

Clean valve or drain.

Faulty bleed valve.

Replace bleed valve.

Controller displays

"Probe Comm" alarm

message.

probe wiring or connector

loose.

Check probe connections

Bad Conductivity probe

Replace probe.

Controller displays

"Bleed Limit" alarm

message.

Conductivity Limit timer

set too short.

Adjust limit timer.

Bleed valve/drain failure.

Clear obstruction around drain.

Conductivity, pH or

ORP reading on

controller does not

match portable handheld reading.

reading is within

specification.

Due to variations in hand-held meters,

standard solutions, temperature

compensation, and the controller’s accuracy

of +/- 2%, the reading on the controller

may not match that of your hand-held

72-900-06 Rev. F

Page 32 of 38

Page 33

7. MAINTENANCE

FUSE

TYPE

F1 & F3

5 X 20mm, 8A, 250V (Output power)

F2

5 x 20mm, 1A 250 V (Input power)

The only recommended maintenance required on the controller is periodic inspection of

the conductivity sensor every 6 months. It is recommended to establish a regular

maintenance schedule designed to meet the needs of each particular application. All

other service should be performed by factory authorized personnel only. Modifications

to or tampering with the circuit level components makes all warranties, written or

implied, and/or manufacturer’s responsibility for this controller, null and void.

DISCONNECT POWER BEFORE OPENING THE UNIT TO ACCESS FUSES. MAKE SURE

THAT REPLACEMENT FUSES ARE OF SAME TYPE TO MAINTAIN SAFETY APPROVALS.

ALWAYS DEPRESSURIZE UNIT BEFORE REMOVING PROBES

7.1 Conductivity Sensor removal and cleaning

To remove the conductivity sensor from its tee for cleaning:

1. Remove power to the system.

2. Remove pressure from the system prior to unscrewing the sensor by closing the hand

valves located before and after flow assembly.

3. Open the sample port; this will facilitate removal of sensor.

4. Unscrew the coupling nut.

5. Remove the sensor.

To clean conductivity sensor:

1. Wipe the sensor with a clean cloth.

7.2 pH sensor Information

The combination pH sensor supplied with your controller is designed for maximum

reliability, accuracy, and ease of use. The reference half-cell is sealed and non-refillable.

The sensor is shipped with a protective boot or bottle filled with a junction wetting agent.

7.2.1 Preparation

Remove the lower portion of the protective boot and rinse the sensor tip with tap water. It

is possible that air bubbles may have migrated into the pH sensitive bulb during shipment.

The sensor is unable to function with air in the bulb. To remove air, gently shake the sensor

downward in the same manner as a clinical thermometer. Prior to first usage or after longterm storage, immerse the lower end of the sensor in tap water for thirty minutes. This

hydrates the pH bulb and prepares the liquid junction for contact with the test solution.

Occasionally during long-term storage or shipment, the sensor may develop a film on the

pH bulb. The film may be removed by following sensor cleaning instructions.

72-900-06 Rev. F

Page 33 of 38

Page 34

7.2.2 Sensor Storage

To maintain response, sensors should always remain wet. The preferred storage solution is

pH 4.0 buffer with saturated KCl added. Tap water will suffice for short term storage.

Do not soak in distilled water. The supplied storage boot or bottle will provide an ideal

chamber for lengthy storage

7.2.3 Sensor Cleaning

Sensors which are mechanically intact can often be restored to full response by the

following procedures:

1. Inorganic Scale Deposits. Dissolve the deposit by immersing the sensor first in 0.1M HCl

(hydrochloric acid), then in 0.1M NaOH (sodium hydroxide), and again in 0.1M HCl. Each

immersion should be for a 5-minute period.

2. Organic Oil or Grease Films. Wash sensor tip in a liquid detergent and water. If film is

known to be soluble in a particular organic solvent, wash with this solvent. Rinse sensor tip

in tap water.

If these procedures fail to rejuvenate the sensor, the problem is most likely a clogged liquid

junction. Cleaning the liquid junction involves heating a diluted KCl (Potassium Chloride)

solution to 60-80°C (139-176°F). Place sensor tip in the heated KCl solution for

approximately ten minutes. Allow the sensor to cool while immersed in the solution before

re-testing. If these steps fail to improve the sensor response, replace the sensor.

7.3 ORP Sensor Information

The ORP option provides monitoring and control with a control setpoint in millivolts (mV).

7.3.1 ORP Maintenance and Troubleshooting

ORP standard buffers of 100mV and 465mV are readily available, making it easy to

standardize ORP systems against buffers. Like pH sensors, ORP sensors are subjected to

coating and abrasion by the measured liquid and, in certain instances, are “poisoned” by

chemicals which may be present if the system goes out of control. To improve the reliability

of ORP measurement and control, the following is a means of testing sensors in solutions of

standard potential, which will determine if sensors are responding correctly or need

maintenance attention.

7.3.2 Testing ORP Sensor

Solution A: Use sufficient 100mV buffer to immerse sensors. Potential should be within +/-

10.

Solution B: Remove sensors and rinse thoroughly with water. Immerse sensors in 465mV

solution. There should be a rapid response.

The millivolt difference between the two solutions is theoretically 365mV. The absolute

values may shift upward or downward a few millivolts due to slight variations from

theoretical potential by the reference sensor.

If system potentials are correct, flush sensors with deionized water and measure the liquid

in question. If incorrect by more than 10 mV, sensors should be cleaned with aqua regia

(three volumes hydrochloric acid, one volume concentrated nitric acid.) Repeat above tests.

Once satisfactory readings are obtained, install sensors and make measurements of liquid

in question.

72-900-06 Rev. F

Page 34 of 38

Page 35

Controller

Enclosure

IP65

Power supply

120 or 220 VAC; 50/60Hz.

Reading Accuracy

+/- 2% at point of measure

Maximum relay output

current

120 VAC: 8 A Resistive/General

use.4LRA/4FLA,1/10HP (motors)

220 VAC: 8 A Resistive/General

use. Not rated for motors

Probe

Maximum temperature

122° F (50°C)

Temperature compensation

range

32°F – 122°F (0° – 50°C)

Maximum pressure

125 PSI (8,6 BAR)

Probe type

Toroidal Conductivity, standard

pH and ORP

Maximum cable length

100 Feet (30,5 Meters)

Materials of construction

Polypropylene

Conductivity reading

0-9999 uS/cm; 1 uS/cm

increments

pH reading

0.00 to 14.00

ORP

-2000mV to +2000mV

Flow Switch

Maximum temperature

127°F (52°C)

Maximum pressure

125 PSI (8,6 BAR)

Activate flow rate

Approximately 1 GPM (3,785

LPM)

Materials of construction

PVC and Glass filled

Polypropylene

Use proper handling procedures including rubber gloves, eye protection and

protective clothing, when handling any acid solution.

7.3.3 Flow Sensor

The Flow Sensor uses differential pressure to cause a shuttle to rise and magnetically

activate a reed switch. Occasionally this assembly may become fouled, preventing the

shuttle from rising and/or falling.

To clean the assembly:

1. Close isolation valves and relieve system pressure from the flow assembly.

2. Remove flow cap by loosening retaining nut. Remove flow cap from flow body by pulling

straight out.

3. Remove red shuttle by pulling straight out. Note post shuttle rides on.

4. Clean all internal surfaces of flow body with soft bristle bottle brush. Be careful of the

post that the shuttle rides on, its surfaces must be clean, but do not break it while

cleaning.

5. Clean shuttle exterior surfaces and shuttle bore with a soft brush. You may use a mild

dish soap if desired. Flush well before re-installing.

6. Re-install shuttle and attach flow cap. Open isolation valves. Check for leaks.

8. SPECIFICATIONS

72-900-06 Rev. F

Page 35 of 38

Page 36

9. FORSEABLE MISUSE

The unit has many relays which can be programmed to operate on a variety of inputs and

timers. It is important to verify the system is set up properly through testing, and that

relays are actuated by the correct timer or input. It is important to verify all unit readings

match a known value. Operating outside design intent may cause hazard. Connecting

receptacles to unapproved hardware, i.e. drills, power tools, motor driven pumps, may

cause a hazard. Use only as directed. Unit has been designed for cooling tower

applications and any other application should be discussed with the factory prior to install.

Do not operate off of another controller. Do not use with extension cords.

72-900-06 Rev. F

Page 36 of 38

Page 37

10. MOUNTING HOLE PATTERN (Footprint)

72-900-06 Rev. F

Page 37 of 38

Page 38

Factory Service Policy

USA

Pulsafeeder, Inc.

27101 Airport Rd.

Punta Gorda, FL 33982

USA

(941) 575-3800

www.pulsatron.com

European Union (EU)

Pulsafeeder-Europe

Via Kennedy, 12-20090