Page 1

PULSAlarm

Leak Detection

Vacuum and Pressure Options

For PULSA Series Metering Pumps

Models 680, 880, 7120, 7440, 7660, and 8480

Installation, Operation & Maintenance Instruction

Bulletin #: IOM–PSVLD-03 Rv B

ENGINEERED PUMP OPERATIONS

2883 Brighton Henrietta Townline Road

Rochester, New York, 14623

Telephone (585) 292-8000

Fax (585) 424-5619

www.pulsa.com E-mail:pulsa@idexcorp.com

Manufacturers of Quality Pumps,

Controls and Systems

Page 2

Pulsafeeder Factory Service Policy

Should you experience a problem with your Pulsafeeder pump, first consult the troubleshooting

guide in your operation and maintenance manual. If the problem is not covered or cannot be

solved, please contact your local Pulsafeeder Sales Representative, or Technical Services

Department for further assistance.

Trained technicians are available to diagnose your problem and arrange a solution. Solutions

may include purchase of replacement parts or returning the unit to the factory for inspection and

repair. All returns require a Return Authorization number to be issued by Pulsafeeder. Parts

purchased to correct a warranty issue may be credited after an examination of original parts by

Pulsafeeder. Warranty parts returned as defective that test good will be sent back freight collect.

No credit will be issued on any replacement electronic parts.

Any modifications or out-of-warranty repairs will be subject to bench fees and costs associated

with replacement parts.

Safety Considerations:

1. Read and understand all related instructions and documentation before attempting to

install or maintain this equipment

2. Observe all special instructions, notes, and cautions.

3. Act with care and exercise good common sense and judgment during all installation,

adjustment, and maintenance procedures.

4. Ensure that all safety and work procedures and standards that are applicable to your

company and facility are followed during the installation, maintenance, and operation of

this equipment.

4-27-2007 Rev B – change material references to “PTFE”

Notice

Information and specifications in this document are subject to change without notice.

Copyright

Copyright © 2004, 2006 Pulsafeeder, Inc. All rights reserved.

Information in this document is subject to change without notice. No part of this publication may be

reproduced, stored in a retrieval system or transmitted in any form or any means electronic or mechanical,

including photocopying and recording for any purpose other than the purchaser’s personal use without the

written permission of Pulsafeeder, Inc.

Trademarks

Pulsa Series® and PULSAlarm® are registered trademarks of Pulsafeeder, Inc.

2

Page 3

Table of Contents

1. S

YSTEM INFORMATION

1.1 Description and Theory of Operation...............................................................5

1.2 PULSAlarm Reagent Head..............................................................................6

1.3 PULSAlarm Leak Detection Diaphragm ..........................................................6

1.4 Diaphragm Construction..................................................................................7

2. E

LECTRICAL

3. S

ETUP FOR VACUUM SYSTEM

4. S

ETUP FOR PRESSURE

.............................................................................................................. 8

...............................................................................................5

..................................................................................... 9

..............................................................................................10

4.1 Pressure fill chamber.......................................................................................14

5. M

AINTENANCE

........................................................................................................... 16

5.1 Switch Setpoint Adjustment.............................................................................16

5.2 PULSAlarm Diaphragm Maintenance..............................................................17

5.2.1 PULSAlarm Diaphragm Removal.............................................................. 17

5.2.2 Inspection.................................................................................................. 18

5.2.3 PULSAlarm Diaphragm Reinstallation ...................................................... 18

5.3 Leak Detection system conversion ..................................................................19

6. S

ILICONE FLUID

MSDS.............................................................................................. 19

3

Page 4

Conventions:

.

A

WARNING DEFINES A CONDITION THAT COULD CAUSE DAMAGE TO BOTH THE

EQUIPMENT AND THE PERSONNEL OPERATING IT. PAY CLOSE ATTENTION TO ANY

WARNING

Notes are general information meant to make operating the equipment easier.

.

4

Page 5

For information on overall pump operation and maintenance, refer to the

Installation, Operation, and Maintenance manual specific to the model of pump in

question. The information in this bulletin pertains only to the PULSAlarm leak

detection system supplied as an option on Pulsafeeder PULSA Series pumps.

1. System Information

1.1 Description and Theory of Operation

The PULSAlarm leak detection system utilizes a two-layer PTFE diaphragm, coupled to a pressure

or vacuum switch.

For the vacuum-based option, a vacuum is drawn between the two layers of the diaphragm

assembly. During normal operation, vacuum is maintained. If there is a failure of either layer of

the diaphragm, the vacuum is lost. When the vacuum reaches a set value, the sensing switch is

trigger to signal an alarm. This system allows for simple setup, however the vacuum will leak

down over time under normal conditions. The system will need to have this vacuum occasionally

renewed during operation.

For the pressure-based option, the system is initially primed by filling the void within the detection

assembly and between the diaphragm layers with a barrier fluid. The setup process then bleeds

excess fluid from between the diaphragm layers until they are in close contact. The system operates

as follows:

During normal pump operation, the two layers of the PTFE diaphragm bear directly against one

another, and there is no pressure generated between the two layers. The sensing system monitors

the space between the layers, which will remain at zero pressure as long as the diaphragm layers

remain undamaged.

In the event of a failure of either layer of the diaphragm, liquid will enter the space between the two

layers. This liquid will be either the hydraulic oil (if the rear layer fails) or the pumped fluid (if the

front layer fails). As the pump operates, this liquid will generate pressure between the layers of the

diaphragm that will then be transferred outwards by the barrier fluid. This fluid will create pressure

against the pressure switch. This switch has a trip point of 5 psi (0.34 bar). When this pressure is

reached the switch will operate. The pressure system requires a more complex setup procedure,

however once operational it should require no further maintenance or operator interaction.

The output of the switch on either system (both normally closed and normally open connections are

available) can then signal the failure of the diaphragm. It is recommended that the pump be

stopped in the event a leak is detected. Immediate attention to the problem, followed by cleanup

and appropriate maintenance, will avoid further damage to the pump.

The barrier fluid used with the pressure-based system should be chosen for compatibility with the

process and environmental conditions. The fluid chosen should have as low a viscosity as possible

to aid in priming the system. Water can be used, and ethylene or propylene glycol can be added for

corrosion and temperature protection. Thin oils such as silicone oil or mineral oil can also be used.

Liquids of higher viscosity will extend the time required to properly prime the system. Thinner

liquids will allow for faster setup. Pulsafeeder supplies as standard a low viscosity silicone oil.

System identification (vacuum or pressure based) is noted on the switch cover nameplate, and also

on your Pulsa Series pump Specification Data Sheet.

5

Page 6

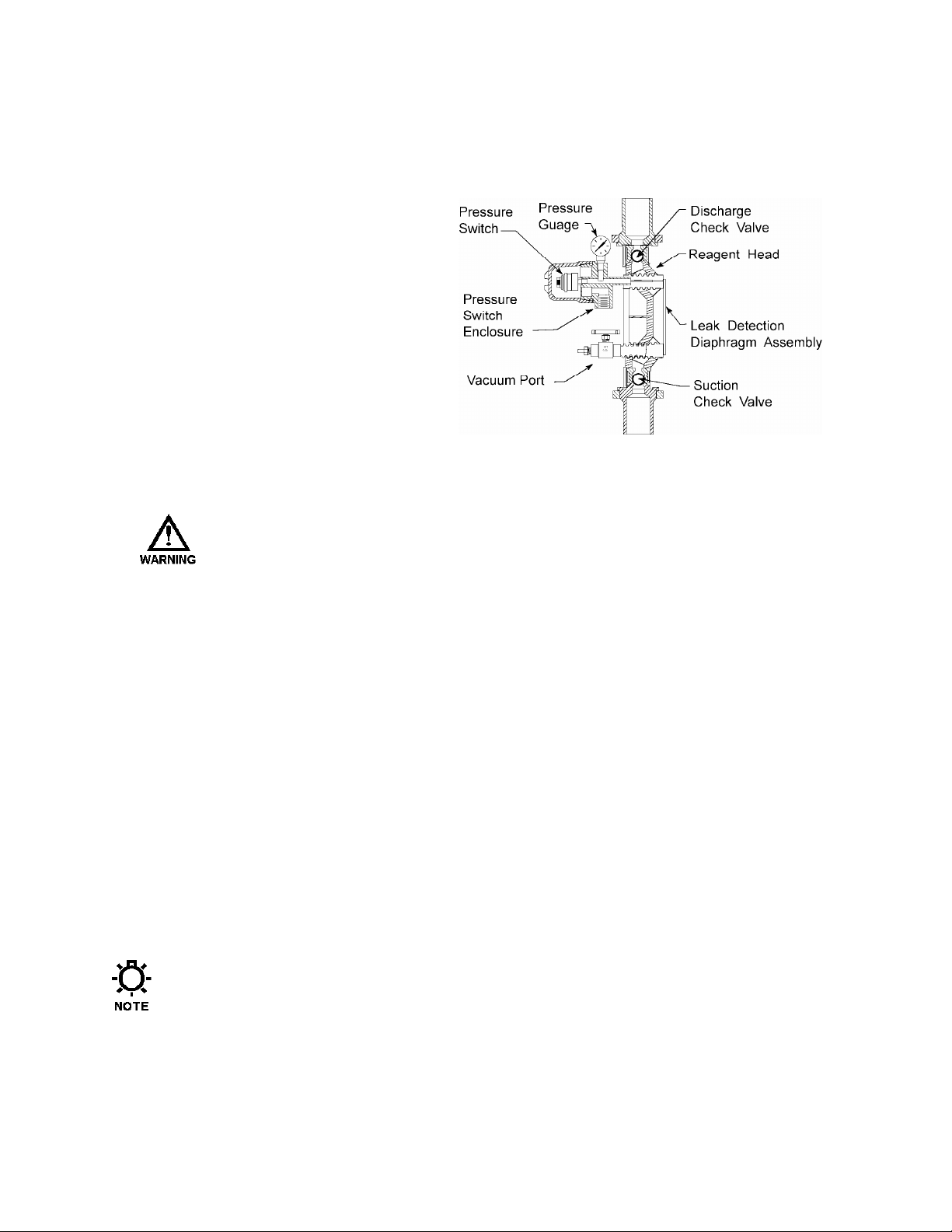

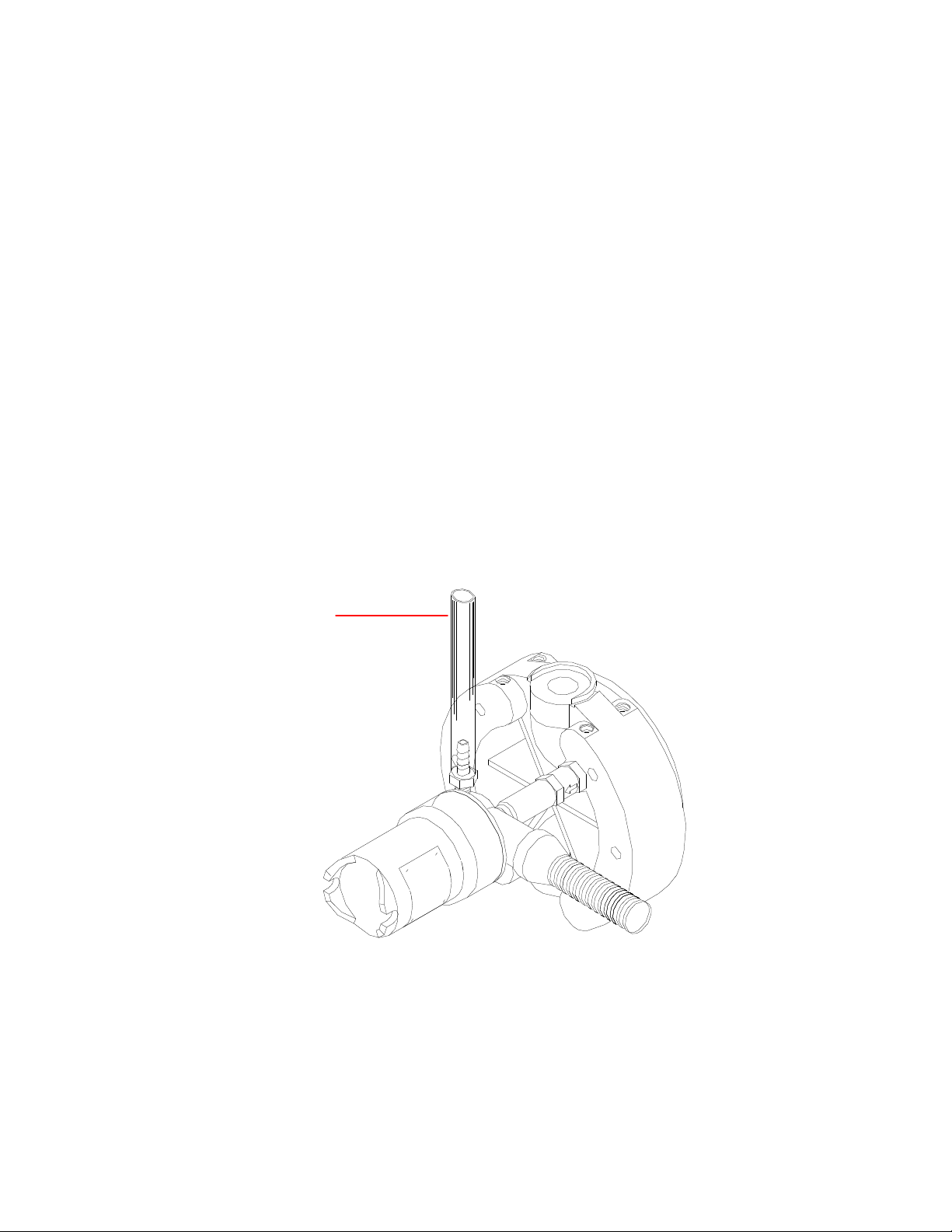

1.2 PULSAlarm Reagent Head

The PULSAlarm leak detection

reagent head assembly consists of

reagent head, leak detection

diaphragm, suction and discharge

check valves, bleed port, and optional

switch and gauge. The reagent head,

diaphragm, suction and discharge

check valves are the only parts of the

pump to contact the process liquid;

consequently, maintenance is critical

to pump performance

A

SEALED SYSTEM MUST BE MAINTAINED AT ALL TIMES DURING PUMP OPERATION,

WHETHER LEAK DETECTION IS REQUIRED OR NOT. IF THE PROPER LEVEL OF

VACUUM, BETWEEN 10 IN AND 26 IN.

PRESSURE SYSTEM IS NOT PRESENT, DECREASED FLOW AND/OR DIAPHRAGM

DAMAGE WILL OCCUR. PLEASE NOTE THAT THE FACTORY SETPOINT FOR

ACTUATION OF THE VACUUM SWITCH IS 6 IN

(

PRESSURE

).

(250

Figure 1 – reagent head

MM TO

650MM) HG,

(152MM) HG (

VACUUM) OR 5 PSIG

OR A SEALED

1.3 PULSAlarm Leak Detection Diaphragm

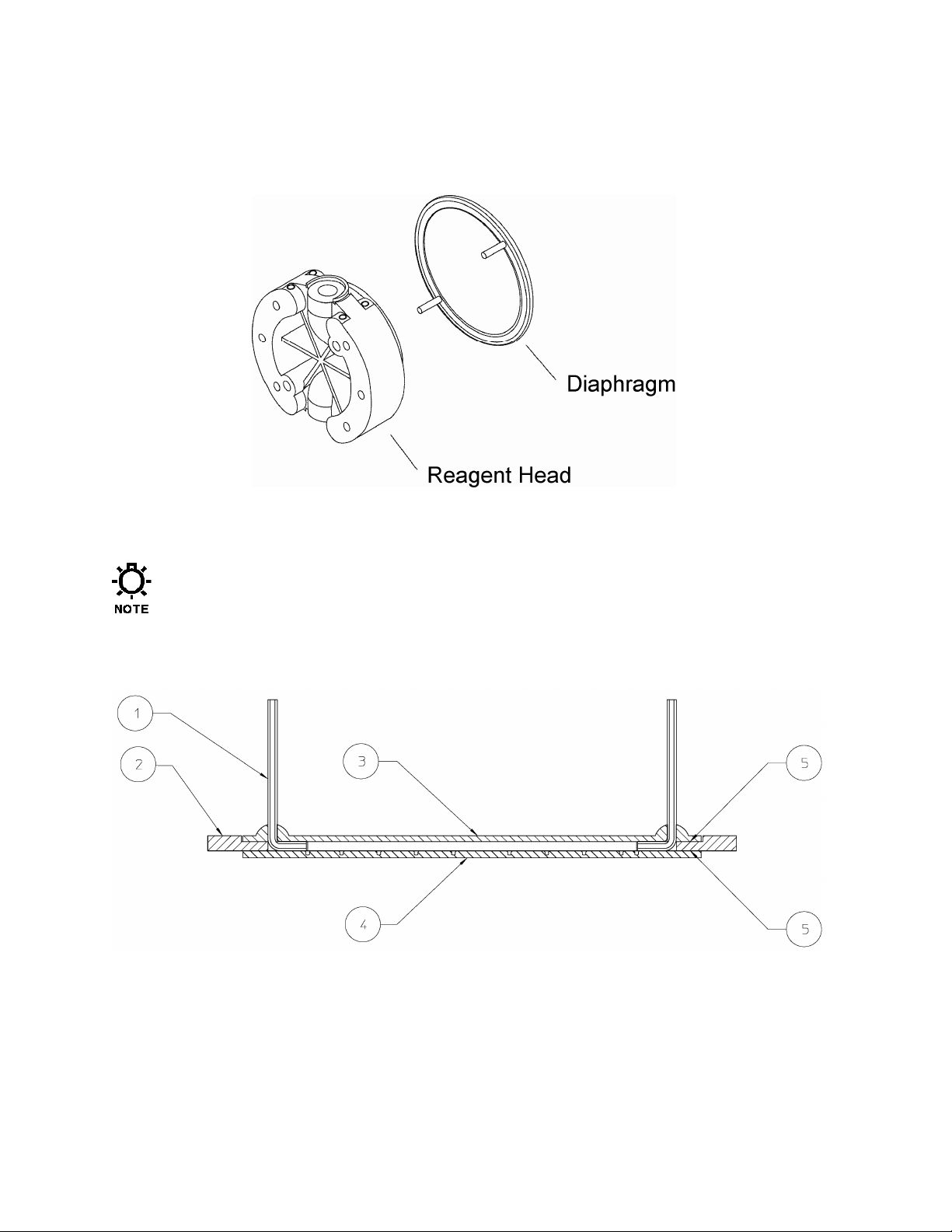

Double, or sandwiched, PTFE diaphragms are sealed at their peripheries to an intermediate metal spacer

ring. The space between the diaphragms is sealed so that the diaphragm functions as does a standard

single diaphragm. For the vacuum system, the space between the diaphragms is evacuated of air to

produce a vacuum. For the pressure system, the space between the diaphragms is filled with a small

amount of fluid. This space is connected to an adjustable electrical switch (optional) that actuates in

response to loss of vacuum or buildup of pressure resulting from rupture of either or both diaphragms.

Switch operation can be used to perform any external function, typically to signal an alarm or turn off the

pump. Refer to Figures 1 and 2.

During installation, ensure that adequate space is available at the front of the reagent head

assembly to allow for service of both the pressure switch and the diaphragm assembly.

6

Page 7

1.4 Diaphragm Construction

The adhesive rings aid in assembly and are not present for sealing purposes.

Capillary tube

Support ring

Process side PTFE layer

Hydraulic side PTFE layer

Figure 2 – diaphragm construction

Adhesive ring

Adhesive ring

7

Page 8

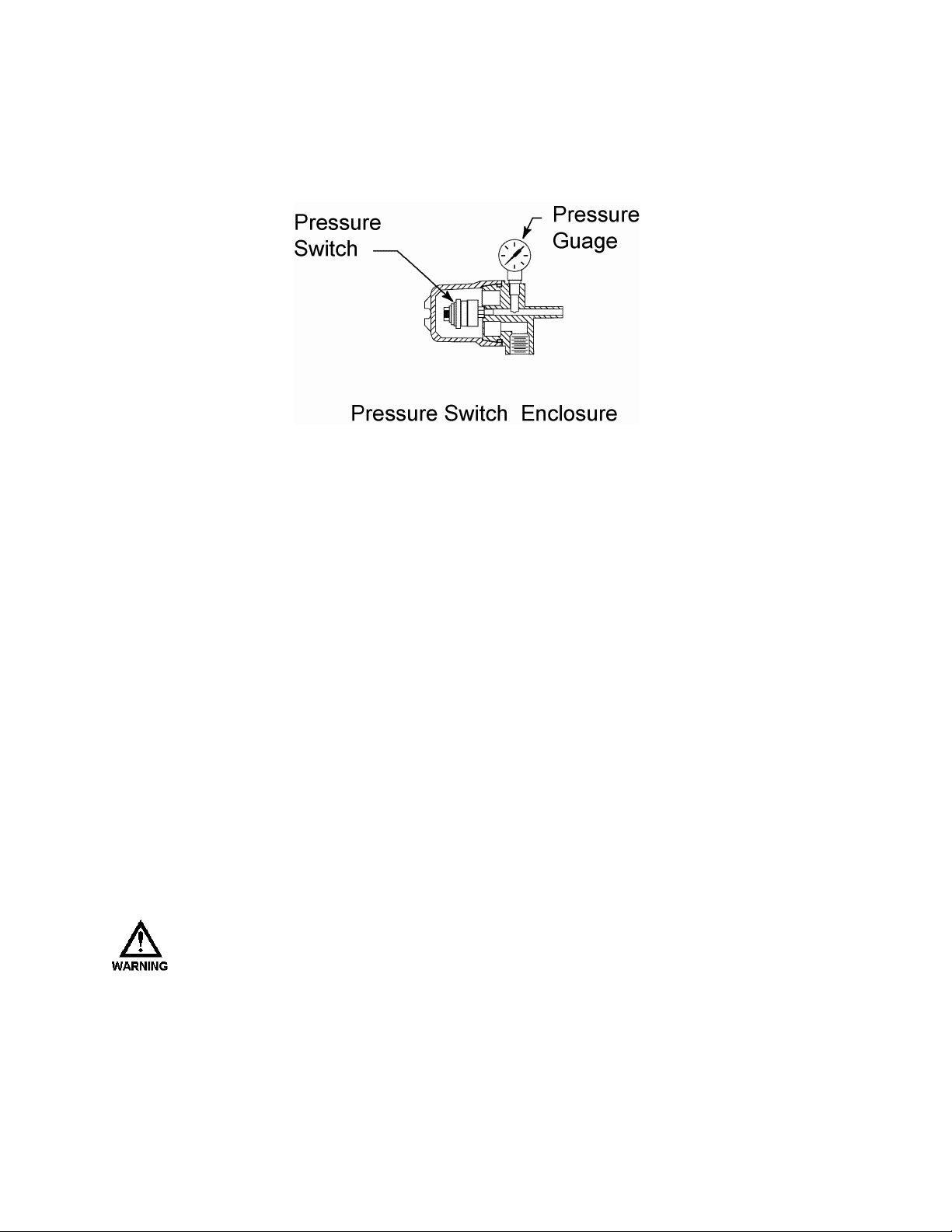

2. Electrical

If equipped with an optional pressure switch, install electrical wiring and conduit in accordance

with local electrical codes.

The switch is rated as follows:

Figure 3 – switch and housing

30 VDC or 125 VAC 1 Ampere Resistive.

The switch is the SPDT (single pole, double throw) type and can therefore be connected to

either open or to close upon detection of diaphragm leak condition. Contacts or wires are

identified as follows:

Normally Open (NO) wire color WHITE

Normally Closed (NC) wire color RED

Common (Com) wire color BLACK

T

HE ENCLOSURE IS LABELED WITH APPLICABLE SAFETY AGENCY RATINGS FOR

HAZARDOUS AREA INSTALLATION. SINCE THE SWITCH IS OF THE MECHANICAL

CONTACT TYPE, IT CAN NEVER QUALIFY AS NON-SPARKING (NON-INCENDIVE, OR

FOR OCCASIONAL AND SHORT-TERM HAZARDOUS AREA USE. PROTECTION MUST BE

PROVIDED BY THE ENCLOSURE.

“M”)

Page 9

3.

Setup for Vacuum system

A vacuum must be maintained at all times during

pump operation, otherwise, the diaphragm halves

may separate during the suction stroke of the

pump, reducing flow capacity and potentially

damaging the diaphragm.

Pumps incorporating the leak detection option are

shipped from the factory with the system

evacuated to the operating vacuum of 650 mm Hg

(26 in. Hg). Due to flexure of the PTFE

diaphragms during transit and storage, the initial

vacuum may not be present at startup. When this

occurs, re-evacuate the system to the operating

vacuum of 650 mm Hg (26 in. Hg).

In all cases, it is advisable to assume vacuum

needs to be renewed if the pump has been out of

service.

Figure 4 – vacuum system

To Apply Vacuum:

1. Connect a vacuum pump capable of generating 26 inches of vacuum to the vacuum port and

evacuate the system. A hand-operated vacuum pump is generally appropriate for this

procedure.

2. Open the needle valve on the vacuum port assembly.

3. Operate the vacuum pump to evacuate the system

4. Close the needle valve

5. Remove the vacuum pump.

6. If required, verify system operation and electrical connections.

9

Page 10

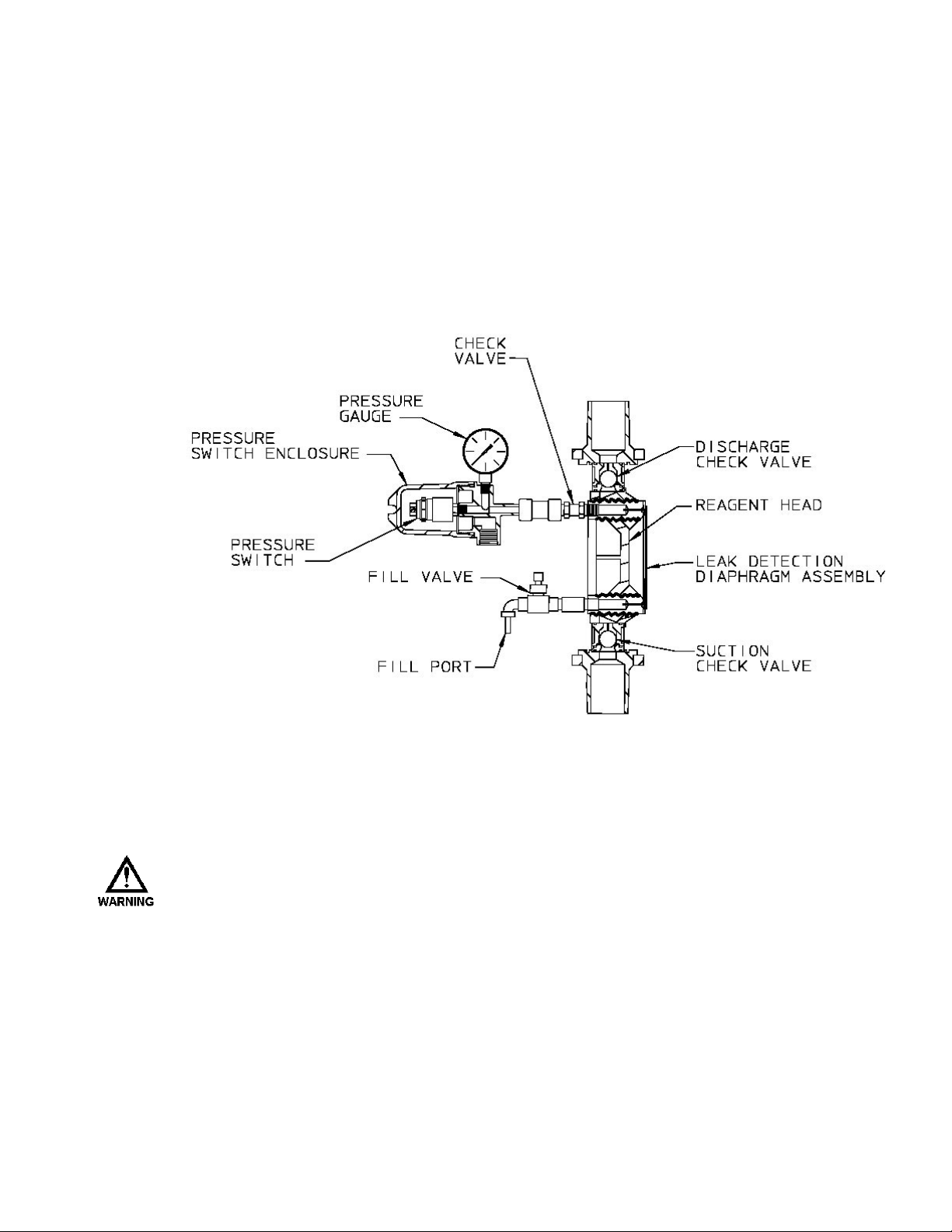

4. Setup for Pressure

Pumps incorporating pressure leak detection are shipped from the factory with the system fully

set up to work at full pump pressure. No further setup is required. The standard factory barrier

fluid is silicone oil, if any other customer-specified media is used it must be compatible with

construction materials. The system will require proper setup after maintenance or repairs, see

the following page for the proper procedure.

Figure 5 – pressure system

T

HE BARRIER FLUID USED TO PRIME THE SYSTEM WILL VARY WITH THE APPLICATION.

T

HE FLUID SELECTED MUST BE COMPATIBLE WITH THE MATERIALS OF CONSTRUCTION

USED IN THE DIAPHRAGM AND DETECTION ASSEMBLY. IT SHOULD ALSO BE COMPATIBLE

WITH THE PROCESS FLUID AND THE PROCESS CONDITIONS.

10

Page 11

To set up Pressure:

1. Complete re-assembly of the diaphragm, reagent head, and external components if they were

taken apart. Ensure that reagent head and tie-bar bolts are tightened according to the

appropriate torque specifications

2. Remove the pressure gauge from the housing body and replace it with a straight tubing

adaptor fitting. This will be referred to in this document as the “outlet side”

fitting

Figure 6 – fitting for priming “outlet side”

3. Remove the plug from the inlet side needle valve on the front of the reagent head, and install

a hose adaptor fitting. This will be referred to in this document as the “inlet side”.

Figure 7 – “inlet side”

11

Page 12

4. The method used to prime the system will vary with the chosen barrier fluid. The fluid must

be introduced under pressure on the inlet side. This pressure can be normal water pressure if

water is being used. It can be provided by a pressurized tank and/or a hand pump. Refer to

Section 4.1 for instructions on how to utilize a pressure chamber to achieve the fill. The fill

pressure should not exceed 30 psi (2 bar)

5. Connect a hand pump to the fitting on the outlet side of the system, and apply vacuum, which

serves to pull the barrier fluid through the system.

6. Attach the incoming barrier fluid supply under pressure to the inlet side and verify that the

needle valve is open.

7. WAIT…. The process will take time. Higher pressure will not help and may cause

damage to the diaphragm. Maintain pressure on the inlet side and vacuum on the outlet

side to move the fluid through the system.

8. Observe the fluid at the outlet (vacuum pump) side. When clear, air free fluid is observed,

close the inlet side needle valve and remove the pressure source.

9. Replace the plug into the needle valve to seal the system inlet.

10. Allow vacuum to remain on the outlet side of the system for approx. 2-3 minutes, this will aid

in the evacuation of excess fluid. Once complete, release the vacuum and remove the hand

pump.

11. Attach a short section of tubing to the fitting on the outlet side to catch excess fluid as the

system setup is completed in the next steps.

Open to

atmosphere

Figure 8 – bleed tubing

12. Ensure that the eccentric box of the pump has been filled to the appropriate level with the

correct hydraulic fluid.

13. If the pump is not already hydraulically primed, re-prime it now using the appropriate

procedure for a standard Pulsa Series flat diaphragm pump. If the diaphragm was never

removed, this step should not be necessary. If a new diaphragm is being installed, the pump

will need to be re-primed.

12

Page 13

14. In order to fully balance and evacuate the leak detection system, the pump must now run at

normal discharge pressure for a period of about 30 minutes to one hour. This ensures that

excess barrier fluid is fully evacuated from the system.

15. Supply either process fluid, or test fluid (i.e. water) to the suction fitting and ensure that the

discharge system is configured for safe operation. The pump can be started with minimal

discharge pressure and then slowly brought up to full pressure, if the system allows for this.

16. Apply power and start the pump.

17. Slowly increase the discharge pressure to full operating pressure, and continue to run the

pump.

18. During this time, excess barrier fluid will be displaced from the system into the length of

tubing attached to the outlet side, balancing the system for proper operation. A small pen

mark on the tube can assist in observing this process visually. Once the liquid in the tube no

longer rises, the evacuation should be complete.

19. After the startup period, remove the tubing and connection from the housing body and

reinstall the pressure gauge. Use thread sealing tape as required.

20. Verify the connections to the alarm switch if they were disturbed during maintenance.

21. The pump and pressure leak-detection system are now properly prepared and ready for

normal service. During normal operation, the gauge should indicate 0 (zero) pressure.

Under certain circumstances, the system may not completely evacuate excess

barrier fluid during the procedure as outlined above. In these cases, after several

days run time, a small amount of pressure may build in the system. If this occurs,

simply loosen the pressure gauge from the switch housing and relieve a small

amount of barrier fluid, returning the system to a zero-pressure state.

Once this startup procedure is completed, the pressure leak detection system

should require no further maintenance.

13

Page 14

4.1 Pressure fill chamber

Under certain conditions, when barrier fluids other than water are used, a pressure chamber can

be fabricated from readily available fittings that allows the barrier fluid to be fed under pressure

to the inlet of the system. Users may wish to fabricate a device based upon this sketch which will

aid in the setup of the pressure-based system.

Pressure inlet

Upper valve

Fluid chamber

Lower valve

Fluid outlet, to

reagent head

Figure 9 – optional fill chamber

14

Page 15

1. Connect a vacuum pump to the top fitting of the fluid fill device. Open BOTH valves

on the device.

2. Place the lower fill tube into the container of the barrier fluid

3. Using the vacuum function, use the hand pump to draw several ounces of fluid up into

the fill device.

4. Close both valves on the fill device

5. Remove the hose and fitting from the container, and connect the fluid fill device to the

inlet fitting on the pump head (the fitting with the needle valve).

6. Open the fill valve (needle valve) on the pump, and then open the two plastic valves on

the fluid fill device.

7. Switch the hand pump to the pressure function, and apply approximately 10-20 psi of

pressure to the fluid in the chamber. Once pressure is achieved, close the TOP valve

and disconnect the hand pump. There is now pressure pushing the barrier fluid into the

leak detection system.

8. Move the hand pump to the outlet side of the system, switch it to the vacuum function,

and continue with the filling process as outlined in the main document.

15

Page 16

5. Maintenance

Although the PULSAlarm leak detection system requires minimal maintenance,

vacuum must be maintained to prevent false alarms and diaphragm damage.

5.1 Switch Setpoint Adjustment

If the optional switch is purchased, it is factory preset at the specified vacuum setpoint, 150 mm

Hg (6 in. Hg), at which loss of vacuum causes the vacuum switch to actuate. The standard

pressure switch is set to actuate at 5 psig.

Use the following procedure to perform a Vacuum setpoint adjustment:

1. Disconnect the alarm circuit from the vacuum switch.

2. Remove the switch enclosure cover and loosen the knurled locking ring on the switch.

3. Rotate the hex adjusting ring counterclockwise to increase or clockwise to decrease the

setpoint.

4. Verify the new setpoint (refer to the next section).

5. Repeat steps (3) and (4) above until the required setpoint as attained.

6. Tighten the switch locking ring and replace the switch enclosure cover.

7. Reconnect the alarm circuit to the vacuum switch.

Use the following procedure to perform a setpoint adjustment test

8. Evacuate the system to approximately 650 mm Hg (26 in. Hg) OR properly prime and

prepare the pressure system.

9. Remove the switch cover and connect ohmmeter leads across the common terminal and the

other terminal used in operation (NO or NC).

10. Record the status of the switch (open or closed).

11. a. Vacuum: Break the vacuum system at any point external to the pump to permit gradual loss

of vacuum.

b. Pressure: remove the pressure gauge, and install a hand pump or other means of producing

a small amount of pressure in the system.

12. Observe the ohmmeter to detect actuation.

The setpoint can be observed by reading the vacuum/pressure

gauge upon actuation.

16

Page 17

5.2 PULSAlarm Diaphragm Maintenance

After diaphragm failure, pressurized process fluid can be present

in any part of the PULSAlarm leak detection vacuum system. Take

appropriate precautions and handle with care.

Figure 10 – diaphragm and head orientation

5.2.1 PULSAlarm Diaphragm Removal

Use the following procedure to remove the Leak Detection Diaphragm:

1. Disconnect the power source to the drive motor.

2. Relieve all pressure from the piping system, and close the inlet and outlet shutoff valves

3. Take all precautions to prevent environmental and personnel exposure to hazardous materials.

4. Place a suitable container underneath the pump head to catch any liquid leakage.

5. Disconnect process piping and drain any process liquid, following material safety

precautions.

6. Remove all but one top reagent head bolt. Oil will leak out between the pump head and

reagent head as the bolts are loosened.

7. Tilt the head and pour out any liquids retained by the check valves into a suitable container,

continuing to follow safety precautions as appropriate.

8. Remove the alarm switch assembly or pressure gauge from the reagent head.

9. Remove the bleed valve assembly and flat gasket from the reagent head.

10. Rinse or clean the reagent head with an appropriate material.

11. Remove the diaphragm by running a blunt blade along the periphery and prying it out.

17

Page 18

5.2.2 Inspection

Remove and inspect the diaphragm assembly. It may have taken a permanent convex/concave set

as a result of normal flexure and conformance to the dish-plate. This condition is normal and is

not cause for replacement. The diaphragm must be replaced if it is deformed, dimpled, or

obviously damaged.

If the diaphragms have been removed from the spacer ring, the entire assembly

should be replaced to ensure proper sealing of its components.

5.2.3 PULSAlarm Diaphragm Reinstallation

1. Ensure that the critical sealing areas of diaphragm assembly, reagent head, and pump head

are clean and free from debris. Align the diaphragm assembly capillary tubes with mating

holes in the seal groove in the reagent head and position it in place against the reagent head.

Ensure seating of the diaphragm sealing ring into the mating groove in the reagent head.

2. Install the reagent head bolts and tighten in an alternating pattern to ensure an even seating

force. Torque to the values recommended in the Installation, Operation, and Maintenance

manual appropriate to the pump.

3. Apply sealing compound to the gauge/pressure switch assembly and reinstall to the upper

port on the reagent head.

4. Apply sealing compound to the fill valve assembly and reinstall to the lower port on the

reagent head.

5. Open the needle valve

6. Connect a hand-held vacuum pump or other vacuum source to the vacuum port, which fits 6

mm (1/4 in.) I.D. tubing.

7. For a vacuum system, evacuate to approximately 650 mm Hg (26 in. Hg) and securely

tighten the needle valve after evacuation. Diaphragm damage or decreased flow will occur

if a vacuum is not drawn before the pump is returned to service. Refer to Section 3 “Setup

for Vacuum”.

8. For a pressure system, see Section 4, “Setup for Pressure”

9. Re-prime the pump head hydraulic system

10. If required, test vacuum or pressure system operation.

11. After diaphragm set-up and priming, the pump is ready to be returned to service.

18

Page 19

5.3 Leak Detection system conversion

Leak detection system conversion information can be found in Bulletin CV-LD-0203 (vacuum to

pressure system). For further conversion information and kits, please contact your local

Pulsafeeder sales representative.

6. Silicone Fluid MSDS

The following safety information is provided for the silicone fluid used as standard in the

PULSAlarm pressure-based leak detection system. Your system may or may not use this fluid,

consult your pump Specification Sheet or facility management for guidance.

DOW CORNING CORPORATION Material Safety Data Sheet

DOW CORNING 200(R) FLUID, 5 CST.

1. IDENTIFICATION OF THE SUBSTANCE AND OF THE COMPANY

Dow Corning Corporation South Saginaw Road Midland, Michigan 48686

24 Hour Emergency Telephone: (517) 496-5900

Customer Service: (517) 496-6000

Product Disposal Information: (517) 496-6315

CHEMTREC: (800) 424-9300

MSDS No.: 01013131 Revision Date: 2000/10/02

Generic Description: Silicone

Physical Form: Liquid

Color: Colorless

Odor: Odorless

NFPA Profile: Health 0 Flammability 1 Instability/Reactivity 0

Note: NFPA = National Fire Protection Association

2. OSHA HAZARDOUS COMPONENTS

None present. This is not a hazardous material as defined in the OSHA Hazard Communication

Standard.

3. EFFECTS OF OVEREXPOSURE

Acute Effects

Eye: Direct contact may cause temporary redness and discomfort.

Skin: No significant irritation expected from a single short-term exposure.

Inhalation: No significant effects expected from a single short-term exposure.

Oral: Low ingestion hazard in normal use.

Prolonged/Repeated Exposure Effects

Skin: No known applicable information.

Inhalation: No known applicable information.

Oral: No known applicable information.

Signs and Symptoms of Overexposure

No known applicable information.

19

Page 20

Medical Conditions Aggravated by Exposure

No known applicable information.

The above listed potential effects of overexposure are based on actual data, results of studies performed upon similar

compositions, component data and/or expert review of the product. Please refer to Section 11 for the detailed

toxicology

information.

4. FIRST AID MEASURES

Eye: Immediately flush with water.

Skin: No first aid should be needed.

Inhalation: No first aid should be needed.

Oral: No first aid should be needed.

Comments: Treat symptomatically.

5. FIRE FIGHTING MEASURES

Flash Point: > 214 °F / > 101.1 °C (Closed Cup)

Autoignition Temperature: Not determined.

Flammability Limits in Air: Not determined.

Extinguishing Media: On large fires use dry chemical, foam or water spray. On small fires use carbon

dioxide (CO2), dry chemical or water spray. Water can be used to cool fire exposed containers.

Fire Fighting Measures: Self-contained breathing apparatus and protective clothing should be worn in

fighting large fires involving chemicals. Determine the need to evacuate or isolate the area according to

your local emergency plan. Use water spray to keep fire exposed

containers cool.

Unusual Fire Hazards: None.

Hazardous Decomposition Products Thermal breakdown of this product during fire or very high heat

conditions may evolve the following hazardous

decomposition products: Carbon oxides and traces of incompletely burned carbon compounds. Silicon

dioxide. Formaldehyde.

6. ACCIDENTAL RELEASE MEASURES

Containment/Clean up: Determine whether to evacuate or isolate the area according to your local

emergency plan. Observe all personal protection equipment recommendations described in

Sections 5 and 8. For large spills, provide diking or other appropriate containment to

keep material from spreading. If diked material can be pumped, store recovered

material in appropriate container. Clean up remaining materials from spill with suitable

absorbant. Clean area as appropriate since some silicone materials, even in small

quantities, may present a slip hazard. Final cleaning may require use of steam,

solvents or detergents. Dispose of saturated absorbant or cleaning materials

appropriately, since spontaneous heating may occur. Local, state and federal laws and

regulations may apply to releases and disposal of this material, as well as those

materials and items employed in the cleanup of releases. You will need to determine

which federal, state and local laws and regulations are applicable. Sections 13 and 15

of this MSDS provide information regarding certain federal and state requirements.

Note: See section 8 for Personal Protective Equipment for Spills. Call Dow Corning Corporation, (517)

496-5900, if additional information is required.

7. HANDLING AND STORAGE

Use with adequate ventilation. Avoid eye contact.

Use reasonable care and store away from oxidizing materials.

8. EXPOSURE CONTROLS / PERSONAL PROTECTION

20

Page 21

Component Exposure Limits

There are no components with workplace exposure limits.

Engineering Controls

Local Ventilation: None should be needed.

General Ventilation: Recommended.

Personal Protective Equipment for Routine Handling

Eyes: Use proper protection - safety glasses as a minimum.

Skin: Washing at mealtime and end of shift is adequate.

Suitable Gloves: No special protection needed.

Inhalation: No respiratory protection should be needed.

Suitable Respirator: None should be needed.

Personal Protective Equipment for Spills

Eyes: Use proper protection - safety glasses as a minimum.

Skin: Washing at mealtime and end of shift is adequate.

Inhalation/Suitable Respirator: No respiratory protection should be needed.

Precautionary Measures: Avoid eye contact. Use reasonable care.

Comments: When heated to temperatures above 150 degrees C in the presence of air, product can form

formaldehyde vapors. Formaldehyde is a potential cancer hazard, a known skin

and respiratory sensitizer, and an irritant to the eyes, nose, throat, skin, and digestive

system. Safe handling conditions may be maintained by keeping vapor concentrations

within the OSHA Permissible Exposure Limit for formaldehyde.

Note: These precautions are for room temperature handling. Use at elevated temperature or aerosol/spray

applications may require added precautions.

9. PHYSICAL AND CHEMICAL PROPERTIES

Physical Form: Liquid

Color: Colorless

Odor: Odorless

Specific Gravity @ 25°C: 0.915

Viscosity: 5 cSt

Freezing/Melting Point: Not determined.

Boiling Point: > 35C/95F

Vapor Pressure @ 25°C: Not determined.

Vapor Density: Not determined.

Solubility in Water: Not determined.

pH: Not determined.

Volatile Content: Not determined.

Note: The above information is not intended for use in preparing product specifications. Contact Dow Corning before

writing specifications.

10. STABILITY AND REACTIVITY

Chemical Stability: Stable.

Hazardous Polymerization: Hazardous polymerization will not occur.

Conditions to Avoid: None.

Materials to Avoid: Oxidizing material can cause a reaction.

11. TOXICOLOGICAL INFORMATION

Acute Toxicology Data for Product Complete information is not yet available.

Component Toxicology Information

Special Hazard Information on Components

12. ECOLOGICAL INFORMATION

Environmental Fate and Distribution

Air: This product is a high molecular weight liquid polymer which has a very low vapour

pressure (<1 mm Hg). As a result it is unlikely to become an atmospheric contaminant

21

Page 22

unless generated as an aerosol.

Water: This product has a very low water solubility (< 100 ppb). As it has a specific gravity of

< 1, if discharged to water, it will initially form a surface film. As the product is non

volatile and has a high binding affinity for particulate matter, it will adsorb to

particulates and sediment out.

Soil: If discharged to surface water, this product will bind to sediment. If discharged in

effluent to a waste water treatment plant, the product is removed from the aqueous

phase by binding to sewage sludge. If the sewage sludge is subsequently spread on

soil, the silicone product is expected to degrade.

Degradation: This product, polydimethylsiloxane, degrades in soil abiotically to form smaller

molecules. These in turn are either biodegraded in soil or volatilized into the air where

they are broken down in the presence of sunlight. Under appropriate conditions, the

ultimate degradation products are inorganic silica, carbon dioxide and water vapour.

Due to the very low water solubility of this product, standard OECD protocols for ready

and inherent biodegradability are not suitable for measuring the biodegradability of this

product. The product is removed >80% during the sewage treatment process.

Environmental Effects

Toxicity to Water Organisms: Based on analogy to similar materials this product is expected to exhibit

low toxicity to aquatic organisms.

Toxicity to Soil Organisms: Experiments show that when sewage sludge containing polydimethylsiloxane

is added to soil, it has no effect on soil micro-organisms, earthworms or subsequent crops grown in the

soil.

Bioaccumulation: This product is a liquid and is a high molecular weight polymer. Due to its physical size

it is unable to pass through, or be absorbed by biological membranes. This has been confirmed by testing

or analogy with similar products.

Fate and Effects in Waste Water Treatment Plants

This product or similar products has been shown to be non-toxic to sewage sludge bacteria.

Ecotoxicity Classification Criteria

Hazard Parameters (LC50 or EC50) High Medium Low

Acute Aquatic Toxicity (mg/L) <=1 >1 and <=100 >100

Acute Terrestrial Toxicity <=100 >100 and <= 2000 >2000

This table is adapted from "Environmental Toxicology and Risk Assessment", ASTM STP 1179, p.34, 1993.

This table can be used to classify the ecotoxicity of this product when ecotoxicity data is listed above. Please read the other

information presented in the section concerning the overall ecological safety of this material.

13. DISPOSAL CONSIDERATIONS

RCRA Hazard Class (40 CFR 261)

When a decision is made to discard this material, as received, is it classified as a hazardous waste? No

State or local laws may impose additional regulatory requirements regarding disposal.

Call Dow Corning Corporate Environmental Management, (517) 496-6315, if additional information is

required.

14. TRANSPORT INFORMATION

DOT Road Shipment Information (49 CFR 172.101) Not subject to DOT.

Ocean Shipment (IMDG) Not subject to IMDG code.

Air Shipment (ICAO) Not subject to ICAO regulations.

Call Dow Corning Transporation, (517) 496-8577, if additional information is required.

15. REGULATORY INFORMATION

Contents of this MSDS comply with the OSHA Hazard Communication Standard 29 CFR 1910.1200.

TSCA Status: All chemical substances in this material are included on or exempted from listing on the

TSCA Inventory of Chemical Substances.

EPA SARA Title III Chemical Listings

Section 302 Extremely Hazardous Substances: None.

22

Page 23

Section 304 CERCLA Hazardous Substances: None.

Section 312 Hazard Class:

Acute: No

Chronic: No

Fire: No

Pressure: No

Reactive: No

Section 313 Toxic Chemicals: None present or none present in regulated quantities.

Supplemental State Compliance Information California

Warning: This product contains the following chemical(s) listed by the State of California under the Safe

Drinking Water and Toxic Enforcement Act of 1986 (Proposition 65) as being known to cause cancer,

birth defects or other reproductive harm.

Massachusetts No ingredient regulated by MA Right-to-Know Law present.

New Jersey CAS Number Wt % Component Name 63148-62-9 > 60.0 Polydimethylsiloxane

Pennsylvania CAS Number Wt % Component Name 63148-62-9 > 60.0 Polydimethylsiloxane

16. OTHER INFORMATION

Prepared by: Dow Corning Corporation

These data are offered in good faith as typical values and not as product specifications. No warranty,

either expressed or implied, is hereby made. The recommended industrial hygiene and safe handling

procedures are believed to be generally applicable. However, each user should review these

recommendations in the specific context of the intended use and determine whether they are appropriate.

(R) indicates Registered Trademark

23

Page 24

IOM–PSVLD-03

Rev B

En g i n e e r e d P u m p O p e ra ti o n s PUL S A l a r m f o r Pu ls a Se ri es

28 8 3 B r i g ht on -H e n ri e t t a T o w n li ne R oa d

Ro c h e s t e r , N Y 1 4 6 2 3

Te l e p h o ne ( 58 5) 2 9 2 - 8 0 0 0 F a x ( 5 8 5 ) 4 2 4 - 5 6 19

ht t p : / / w w w. pu ls a. c o m p u ls a@ i d e x c o r p . c o m

24

Loading...

Loading...