Page 1

PULSAR®

Bulletin #: PS-IOM-HYPO2-0111-B

Installation, Operation &

Maintenance Instruction

ADDENDUM

HYPOPUMP2®

AUTO DE-GAS METERING PUMP

Page 2

ii

FACTORY SERVICE POLICY

If you are experiencing a problem with your Pulsafeeder pump, first review the IOM, and consult

the troubleshooting guide. If the problem is not covered or cannot be solved, please contact your

local PULSA Series Sales Representative or our Technical Service Department at (585) 292-8000

for further assistance.

Trained individuals are available to diagnose your problem and arrange a solution. Solutions may

include purchasing a replacement unit or returning the pump or components to the factory for

inspection and repair. All returns require a Return Material Authorization (R.M.A.) number to be

issued by Pulsafeeder.

Certain components may be purchased for replacement. Parts purchased to correct a warranty

issue may be credited after examination of the original parts by Pulsafeeder personnel. Parts

returned for warranty consideration that test satisfactorily, will be sent back to the originator

freight collect.

Any field modifications will void the Pulsafeeder warranty. Out-of-warranty repairs will be

subject to Pulsafeeder's stand ard bench fees and tes ting cos ts assoc iat ed wi th repla ce ment

components.

Notice

Information and specifications in this document are subject to change without notice.

Revision Histor y:

Rev A (01-01-11)

- Original Release Date

Rev B (04-7-14)

- Updated label graphics

- Updated electrical drawings

- Updated maintenance and retrofit information (section 9)

Copyright

Copyright © 2014 Pulsafeeder, I nc. All rights re serv ed.

Information in this document is subject to change without notice. No part of this publication may

be reproduced, stored in a retrieval system or transmitted in any form or any means electronic or

mechanical, including photocopying and recording for any purpose other than the purchaser’s

personal use without the written permission of Pulsafeeder, Inc.

Trademarks

PULSAR® is a registered trademark of Pulsafeeder, Inc.

PULSAR HypoPump

PULSAR Shadow

®

is a registered trademark of Pulsafeeder, Inc.

®

is a registered trademark of Pulsafeeder, Inc.

Page 3

iii

Table of Contents

1. Conventions ...................................................................................................................................... iv

2. General Safety................................................................................................................................... 1

2.1 Explosive Atmosphere Safety ................................................................................................ 1

2.2 Electrical Safety ....................................................................................................................... 1

2.3 Hydraulic Safety ...................................................................................................................... 1

3. Equipment Inspection ...................................................................................................................... 2

4. Storage………………………………………………………………………………………………..………2

4.1 Short Term (0 - 12 months) ..................................................................................................... 2

4.2 Long Term (12 months or more) ............................................................................................ 2

5. Retrofit………………………………………………………………………………………,………………2

6. Overall System Diagram .................................................................................................................. 3

7. Installation ......................................................................................................................................... 4

7.1 Location .................................................................................................................................... 4

7.2 Installation Notes ..................................................................................................................... 4

7.3 Electrical Wiring ...................................................................................................................... 4

8. Description and Operation .............................................................................................................. 6

8.1 Principle of Operation ............................................................................................................. 6

8.2 General Description ................................................................................................................ 6

8.3 Operation of Manual Override Button .................................................................................. 6

9. Maintenance ...................................................................................................................................... 7

9.1 Maintenance Notes .................................................................................................................. 7

9.2 Auto De-gas Valve Seal Kit Replacement ............................................................................. 7

9.3 Auto De-gas Valve Body and Discharge Valve Assembly Removal………………………11

10. Troubleshooting Guide………………………………………………………………………………..…11

11. Hypo Valve Replacement Instruc tions .......................................................................................... 12

USER NOTE: This addendum serves as additional information for Pulsafeeder PULSAR® and PULSAR

Shadow® metering pumps equipped with the Auto De-gas Valve for purging trapped gasses from the

reagent head. You must also reference the latest revision of the complete PULSAR® or PULSAR

Shadow® pump IOM for critical safety and operational information.

Page 4

iv

1. Conventions

A

Tips have been included within this bulletin to help the operator run the equipment

For the remainder of this bulletin, the following Conventions are in effect.

WARNING DEFINES A CONDITION THAT COULD CAUSE DAMAGE TO BOTH

THE EQUIPMENT AND THE PERSONNEL OPERATING IT

ATTENTION TO ANY WARNING

Notes are general information meant to make operating the equipment easier.

in the most efficient manner possible. These “Tips” are drawn from the knowledge

and experience of our staff engineers, and input from the field.

. PAY CLOSE

.

The HYPOPUMP2

®

Auto De-gas Pump, designed for purging entrained gas from the pump reagent

head, is referred to in this manual as the “ADV”.

Page 5

2. General Safety

The Auto De-gas Valve (ADV) was designed as a gas handling/priming aid for operation solely with

Pulsafeeder PULSAR

considered un-safe and voids all certification markings and warranties.

®

and PULSAR Shadow® metering pumps. Use for any other application is

2.1 Explosive Atmosphere Safety

Explosion Hazard -- Do not perform installation or maintenance of any kind on this device while

circuit is live and/or the area is known to be hazardous. This unit is not intended for use in

explosive or hazardous locations.

2.2 Electrical Safety

Improper application and use of the ADV can be hazardous. You are solely responsible for its use.

The ADV electrical installation must conform to all relevant electrical codes. Installation and electrical

maintenance must be performed by a qualified electrician. Before installing or servicing this device, all

power must be disconnected from the source at the main distribution panel.

The ADV emits electro-magnetic energy. Its use is restricted to industrial applications. You are

responsible for shielding this device if necessary.

It is recommended that the ADV be powered from a Ground Fault Circuit Interrupter (GFCI) protected

electrical ci rcuit.

2.3 Hydraulic Safety

Thoroughly review and adhere to the contents of the latest version of the PULSAR® or PULSAR

Shadow

metering pump.

®

Installation, Operation, Maintenance (IOM) manual for hydraulic installation of your

1

Page 6

3. Equipment Inspection

When you receive your order, check all equipment for:

• Completeness against the shipping document / purchase order

• Evidence of shipping damage.

Shortages or damage should be reported immediately to the carrier and your PULSAFEEDER

representative.

4. Storage

The ADV can be successfully stored for extended periods. The key to this success is temperature and

humidity control.

Be certain to follow the additional storage instructions provided in the IOM for the PULSAR

Shadow

attached to the pump.

4.1 Short Term (0 - 12 months)

®

pumps, and also those included in the IOM for any controllers (DLC, DLCM, ECA) that are

®

or PULSAR

The ADV should be stored in a temperature and humidity controlled environment. It is preferable to

keep the temperature constant in the range of -18 to 60° Celsius (0 to 140° Fahrenheit). The relative

humidity should be 0 to 90% non-condensing.

If the ADV is installed on the pump, it should not be removed during this period – provided the above

conditions can be applied to the pump as well. If the ADV was shipped in its own carton, it should be

stored in that carton.

4.2 Long Term (12 months or more)

Storage of the ADV for periods of longer than twelve months is not recommended. If extended storage

is unavoidable the ADV should be stored in accordance with those conditions stipulated for Short Term

Storage. In addition, a porous bag of 85g (3 oz) silica gel or similar desiccant should be placed inside

the ADV enclosure. The cover should be re-installed to seal the desiccant within the enclosure. The

conduit connection must be tightly capped.

5. Retrofit

Retrofit kits including the HypoPump2® reagent head assembly, the ADV, and other necessary parts

and hardware, are available. These allow the conversion of an existing Pulsafeeder PULSAR

PULSAR Shadow

Converting from the HypoPump

the Hypo Valve Replacement Instructions within this IOM.

®

metering pumps to a HypoPump2®. This conversion can be performed in the field.

®

to the HypoPu mp®2 does not have any port-to-port changes. See

®

and

2

Page 7

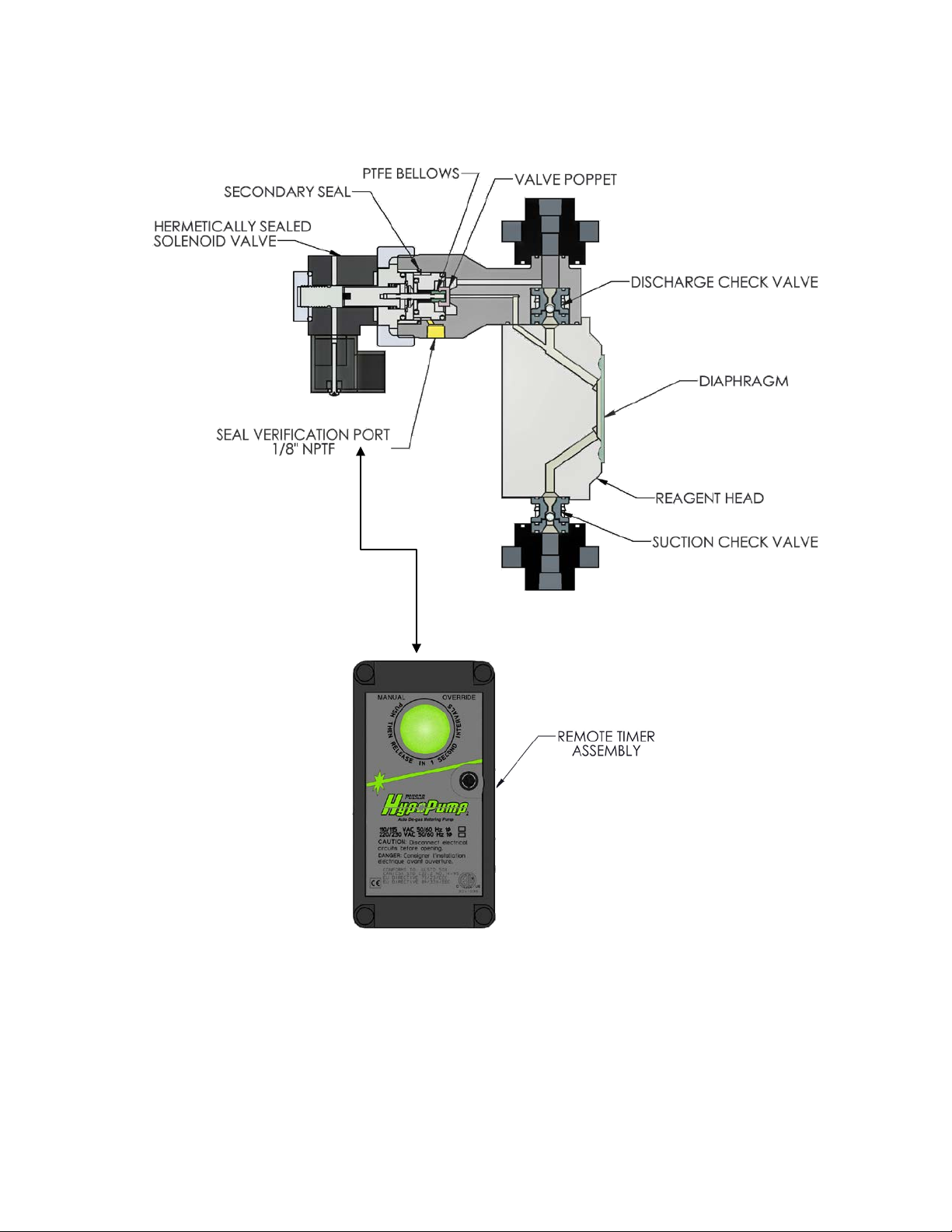

6. Overall System Diagram

\

Figure 1

The ADV consists of a pressure balanced valve which opens periodically to allow fluid from the discharge

line to bypass the discharge check valve and flow back into the pump head. The valve is actuated by a solenoid

controlled by a solid-state tim er. The ADV Valve Assembly incorporates a dual sealing design to insure the valve

function even if the Primary Bellows seal fails. The Leak Detection Port (1/8” NPTF) allows visual indication of a

Bellows failure while allowing the ADV to keep functioning. At the discretion of the user, this port may be used to

pipe any leakage to a safe vessel or a leak detection device.

3

Page 8

°

°

°

7. Installation

7.1 Location

Review the Safety section prior to installing the pump with ADV. It contains information required to

properly install and operate the ADV in an industrial environment.

Review the PULSAR

your metering pump. It details system related issues that are important to proper operation of the pump

and also the ADV. The ADV should be mounted in an area where the operator has access to the front of

the unit. Avoid locations where the ADV would be subjected to extreme cold or heat. Note the warning

statement on the next page. The installation of this device must comply with national, s ta te an d lo ca l

codes.

Allow 6 inches minimum clearance from the front of the ADV enclosu re to allow for removal and

re-installation of the ADV as a unit.

AVOID LOCATIONS WHERE THE ADV WOULD BE SUBJECTED TO EXTREME COLD OR HEAT OR

DIRECT SUNLIGHT

ITS WARRANTY

MINIMUM OPERATING TEMPERATURE 0

MAXIMUM (PVC CONSTRUCTION) 49

MAXIMUM (PVDF CONSTRUCTION) 65

®

. FAILURE TO OBSERVE THIS WARNING COULD DAMAGE THE ADV AND VOID

or PULSAR Shadow® Installation Operation Maintenance manual provided with

CELSIUS / 32° FAHRENHEIT

CELSIUS / 120° FAHRENHEIT

CELSIUS / 150° FAHRENHEIT

7.2 Installation Notes

1. Do not make any electrical connections without adequate grounding.

2. Conduit connections can carry fluids and vapors into the ADV causing damage and voiding the

warranty. Care should be taken when installing conduit to protect against fluid/vapor entry. If

necessary, provide sealed entries or conduit drains near the point of entry.

3. It is recommended that the ADV be powered from a Ground Fault Circuit Interrupter (GFCI) protected

electrical ci rcuit.

7.3 Electrical Wiring

The ADV is available in two

voltages, and is rated as follows:

115 VAC, 50/60 Hz, 0.2 A

OR

230 VAC, 50/60 Hz, 0.1 A

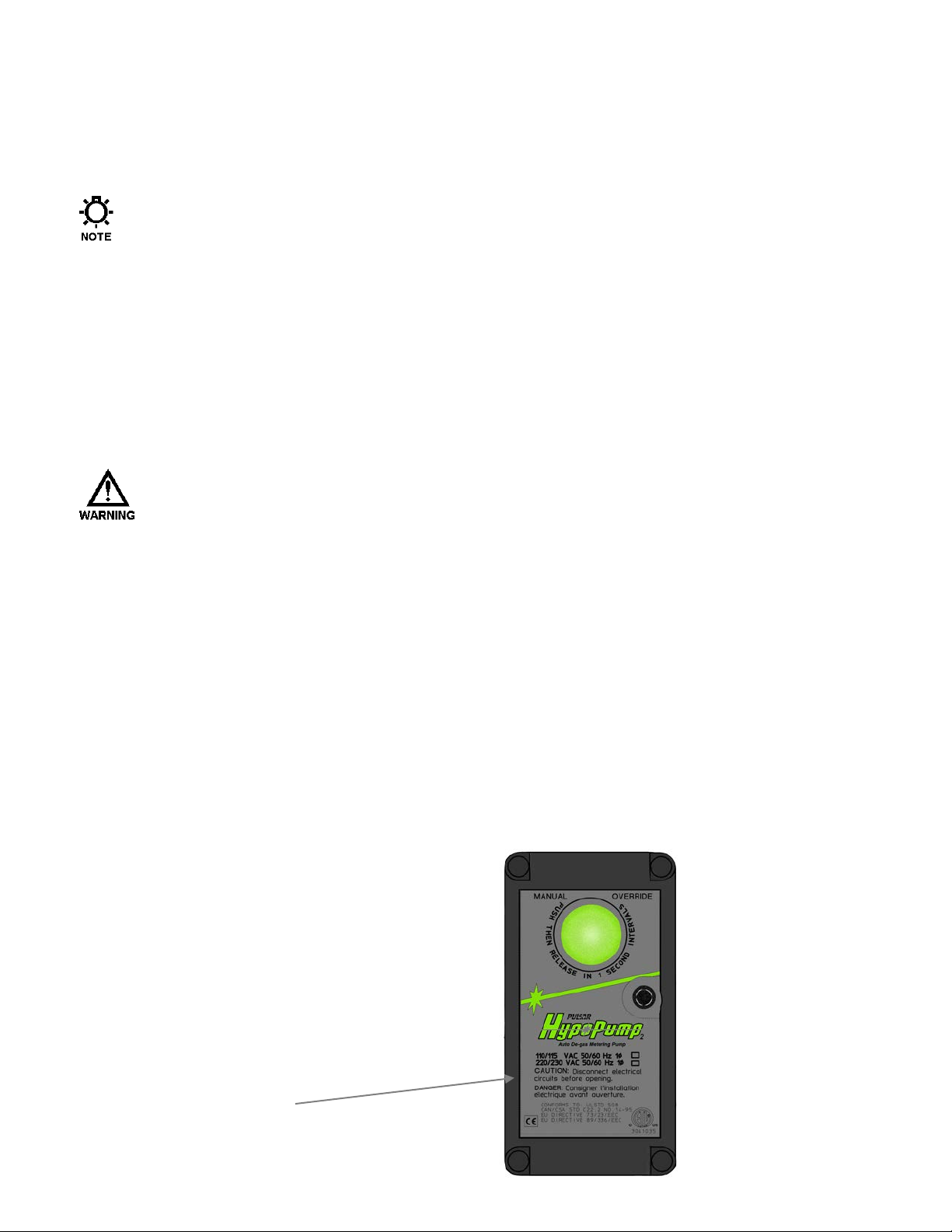

The ADV voltage is indicated on

the enclosure label.

4

Page 9

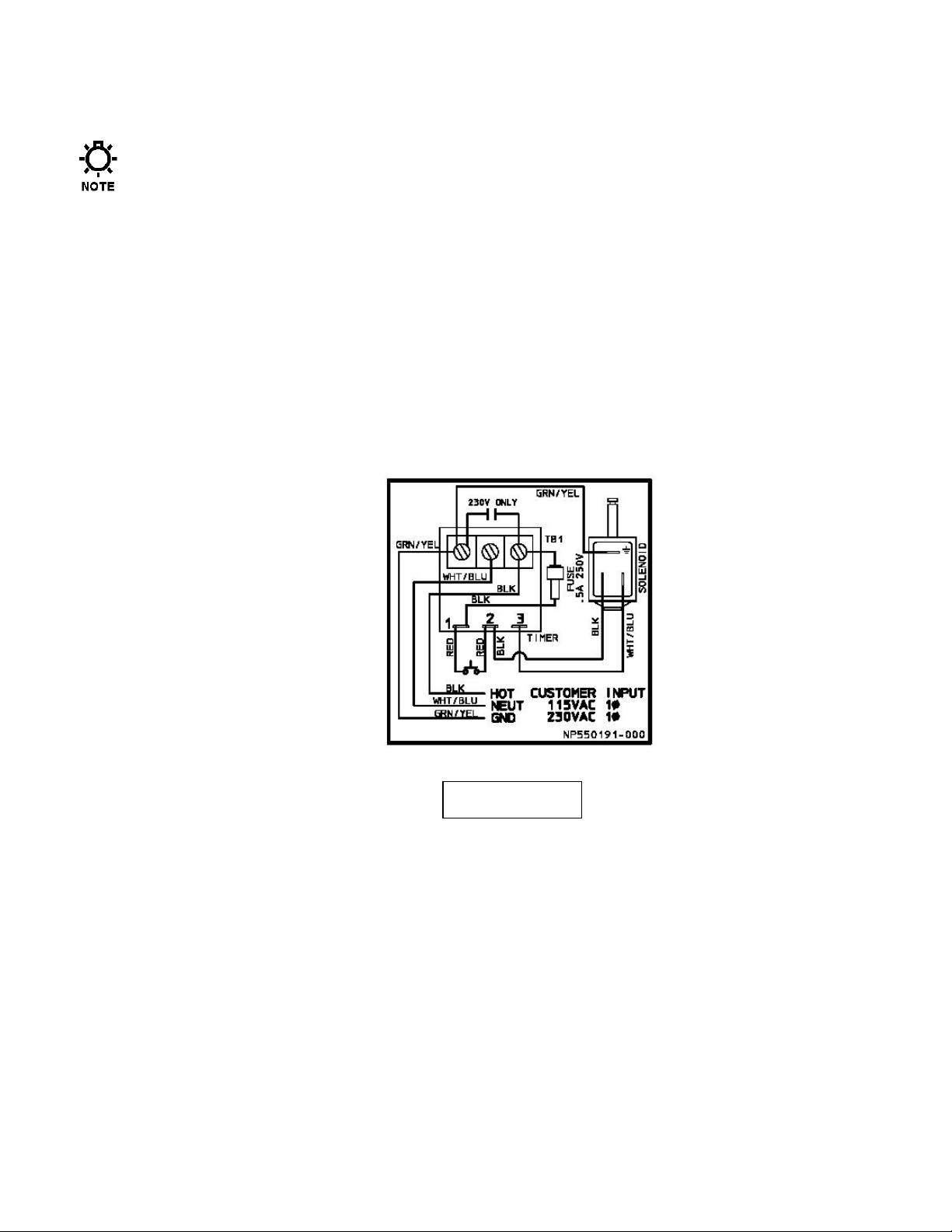

Wiring Diagram

Install wiring to the unit using a minimum of 18 inches of flexible conduit or cable attached to the

auto valve assembly in order to facilitate removal of the valve assembly from the reagent head for

cleaning or maintenance.

Wiring must conform to all applicable codes. Prior to pump startup; always check to ensure that the ADV

voltage and frequency matches that of the power supply. It is recommended that the ADV be powered

from a Ground Fault Circuit Interrupter (GFCI) protected electrical circuit.

1. Remove the enclosure front cover. Note: The plastic screw hole plugs can be pried out using a flat

bladed tool.

2. Bring AC power and ground wires into valve assembly enclosure through the 7/8” diameter hole in the

side of the enclosure. Use #20 AWG 105 degree C insulation wire size minimum. Connect per the

wiring diagram. The wiring diagram is also reproduced on a label affixed to the back of the enclosure

cover.

3. Apply power to the valve assembly with or without the pump running. Verify that the solenoid

mounted on the pump reagent head clicks every 30 seconds.

4. Reattach cover and replace plastic hole plugs over screws.

5

Page 10

8. Description and Operation

8.1 Principle of Oper ation

Reciprocating metering pumps are used with a wide variety of chemicals, such as sodium hypochlorite, that

produce gas within the piping and pump systems. This gas can accumulate in the pump reagent head,

causing the pump to “air bind” and lose prime.

The Auto De-gas Valve (ADV) prevents this by allowing a small amount of pressurized fluid from the

discharge line to bleed back into the pump head, thereby helping to keep the pump head primed and also

displacing gas through the discharge check valve. The system also has a Manual Override Button to enable

faster pump priming at pump startup or other situations.

8.2 General Description

The PULSAR

discharge valves, and Auto De-gas Valve (ADV). The ADV consists of a pressure balanced valve which

opens periodically to allow fluid from the discharge line to bypass the discharge check valve and flow back

into the pump head. The valve is actuated by a solenoid controlled by a solid-state timer. This pre-set

timer will operate properly in the majority of HypoPump applications.

Power supply required is 115 or 230 VAC, 50 or 60 Hz. All electrical components are enclosed in a NEMA

4X (IP 65) enclosure, which is isolated from the pumped fluid. The timer is preset at the factory to open for

0.25 seconds every 30 seconds in order to achieve optimum gas handling time with minimal pump capacity

loss. The valve assembly is easily removed from the pump head in order to access the discharge check

valve for cleaning or replacement. The automatic valve assembly can be run independently of the pump

motor and/or controls.

®

and PULSAR Shadow® HypoPump® system consists of the pump reagent head, suction and

8.3 Operation of Manual Override Button

The Manual Override Button functions as a fast priming aid. For best results depress the button 1 second

every few seconds. Do not hold the button down continuously.

Depress the button 1 second every few seconds

Figure 4

6

Page 11

9. Maintenance

9.1 Maintenance Notes

The O-ring seals used in the check valve and ADV are critical to product containment and pump

operation. All o-rings should be inspected carefully and any that show signs of damage or wear should

be replaced. The owner may wi sh to rep lace the se seal s any time the ADV assemb ly is remo ved fro m

the pump.

A complete cartridge seal assembly is available to the owner as a separate repair part. If necessary, the

complete ADV assembly is available as a repair item.

9.2 Auto De-gas Valve Seal Kit Replacement (NP999130-000)

CAUTION: Take all precautions to prevent environmental and personnel exposure to hazardous materials.

Any product being pumped will be released during this procedure.

1. Disconnect the power source to the pump drive motor and ADV.

2. Relieve all pressure from the piping system and follow safety requirements for contact / exposure to the

fluid being pumped.

3. Remove Cap Nut from front of solenoid and slide off solenoid.

4. Loosen and remove the Union Nut. At this point fluid being pumped may be released from the

assembly.

5. Remove Core Tube Assembly.

7

Page 12

Locate and remove

Inspect Seal Kit parts and

CAUTION: Do not unscrew any part

will affect valve performance.

6. Remove outer spring from Core Assembly (Seal Kit Assembly) and pull Core Assembly out.

7. Inspect Valve Body for O-rings that may have been left in and remove.

both O-rings

8. Remove the sleeve from the Core Tube and remove the O-ring.

9. Locate parts from the Seal Kit.

insure the small spring is

in the core.

of the seal kit during inspection or

reassembly. Any change in length

8

Page 13

10. Install NEW O-ring onto core tube, lubricate with lubricant that is compatible with product being

Check that small spring is inserted in Core

pumped, and reinstall sleeve over Core Tube.

11. Install NEW O-ring on Seal Kit and with lubricant that is compatible with product being pumped.

12. Apply a lubricant that is compatible with product being pumped to the Body O-ring and install into

Valve Body.

13. Install NEW Seal Kit into Valve Body. Use care to ONLY push straight into bore.

14. Install new spring over Core and check that Small Spring is still in the Core.

9

Page 14

15. Slide Core Tube over core and align to the tabs on the Valve Body.

16. Slide Union Nut over Core Tube and tighten onto Body. Do not over tighten, hand tight is sufficient.

17. Slide the solenoid over the Core Tube and secure with Cap Nut. Hand Tight.

18. Reapply power to the pump and ADV and follow standard startup instructions from IOM supplied

with pump.

9.3 Valve Body and Discharge Valve Assembly Removal

CAUTION: Take all precautions to prevent environmental and personnel exposure to hazardous materials.

Any product being pumped will be released during this procedure.

The O-ring seals used in the check valve and ADV are critical to product containment and pump

operation. All o-rings should be inspected carefully and any that show signs of damage or wear should

be replaced. The owner may wish to replace these seals any time the ADV as semb ly is remov ed fro m

the pump.

1. Disconnect the power source to the pump drive motor. If you plan to maintain the ADV itself, remove

power from the ADV unit. For maintenance to the check valves only, the ADV need not be

disconnected.

2. Relieve all pressure from the piping system.

3. Close the inlet and outlet shutoff valves.

4. Take all precautions to prevent environmental and personnel exposure to hazardous materials.

10

Page 15

5. Loosen the suction valve tiebar bolts and shift the suction piping slightly to drain any liquid from the

Symptom

Probable Cause

Possible Solution

Purge relay not operational

Verify power is present at timing relay.

check valves as per pump IOM.

Power interruption

Check that power is connected to the ADV

Valve stuc k open

Clean or replace Seal Kit.

delivery

check valves as per pump IOM.

Calibration or testing error

Evaluate cause and correct

ADV Valve fouled

Clean or replace Seal Kit

leakage

actuate

there is a clicking noise every 30 seconds.

Crystallized product in valve assembly

Clean or replace Seal Kit.

reagent head cavity. If the piping is closely connected it may be necessary to disconnect a union or

flange.

6. Loosen the tiebar bolts on the discharge valve and shift the piping slightly to drain any liquid.

7. Slide the valve assembly away from the front of the reagent head. Take care to not let the check valve

parts fall out of the bottom of the valve assembly as it is removed from the reagent head.

8. Once the ADV is separated, the discharge check valve components can be removed from the assembly

and cleaned or replaced.

9. Installation is the reverse of the above procedure. Be sure that the oval shaped o-ring on the bottom of

the valve assembly is in the proper position when reinstalling the valve assembly.

10. Troubleshooting Guide

Pump does not

prime (product

side)

Valve not actuating Verify power is present at Valve Solenoid and

Check valves fouled o r damaged Clean or replace suction and/or discharge

there is a clicking noise every 30 seconds.

Low pump

Leak detection

port shows

Valve fails to

Check valves fouled o r damaged . Clean or replace suction and/or discharge

Failed Bellows Seal Install New Seal Kit

Power interruption Verify power is present at Valve Solenoid and

11

Page 16

11. Hypo Valve Replacement Instructions

Remove the front cover from the old Hypo valve enclosure.

12

Page 17

Disconnect the incoming power to the old valve.

Loosen or remove the tie bar nuts and lift the valve cap to remove the hypo valve assembly.

As you remove the assembly, remember to support the check valve so it does not fall out.

13

Page 18

Remove the check valve assembly.

14

Page 19

The new Hypo valve comes in three pieces, the valve body assembly with the solenoid, the electrical enclosure and

the O-ring package. The solenoid and the elect rical enclosure are prewired.

Remove the front cover to expose the wiring and the mounting screws.

15

Page 20

Remove the two nuts, lock washers and flat washers.

Remove the plastic cover from the end of the gearbox.

16

Page 21

The existing top two holes in the rib of the gear box will line up with the holes in the electrical enclosure.

Use a 3.0 mm Allen wrench to tighten the mounting screws, and a 9 mm open end wrench for the nuts.

17

Page 22

Wire the Hypo Valve AC power per the wiring diagram. Replace the front cover.

Install the top O-ring to the valve body.

18

Page 23

Install the lower O-ring to the valve.

(Note- a small amount of light grease applied to the O-rings will help keep them in place during installation.)

Insert the check valve assembly into the valve body.

19

Page 24

Insert the new hypo valve.

Replace the valve cap and tie bar.

20

Page 25

Replace the tie bar hardware.

Apply even pressure to the Tie Bar to align the parts and next tighten the tie bar nuts. Tie bar bolts are tightened to

10 in. lb. of torque and additional tightening may be required to stop any leakage.

21

Page 26

Install the 4 screw dust caps to the front cover of the electrical enclosure.

Complete!

22

Page 27

PULSAR®

A unit of IDEX Corporation

HYPOPUMP2®

AUTO DE-GAS METERING PUMP

Bulletin #: PS-IOM-HYPO2-0111-B

2883 Brighton Henrietta Town Line Road

Rochester NY 14623

+1 (585) 292-8000

www.pulsa.com

pulsa@idexcorp.com

23

Loading...

Loading...