Page 1

PULSA® GLM

Bulletin: IOM-GLM-5000-Rev.A

Installation, Operation &

Maintenance Manual

Models: GLM1 – 6

MECHANICAL DI APHRAGM

METERING PUMP

Page 2

Pulsafeeder Fact ory Service Pol icy

Pulsafeeder’s Factory Service Policy is maintained on its website. Please source this document at

this URL:

http://www.pulsa.com/downloads/pdf/Pulsafeeder%20EPO%20Limited%20Warranty%20Statement.pdf

Safety Considerations:

1. Read and understand all related instructions and documentation before attempting to install or

maintain this equipment.

2. Observe all special instructions, notes, and cautions.

3. Act with care and exercise good common sense and judgment during all installation,

adjustment, and maintenance procedures.

4. Ensure that all safety, work procedures, and standards that are applicable to your company and

facility are followed during the installation, maintenance, and operation of this equipment.

Copyright ©2015 Pulsafeeder, Inc. All rights reserved.

Information in this document is subject to change without notice. No part of this publication may be

reproduced, stored in a retrieval system or transmitted in any form or any means electronic or

mechanical, including photocopying and recording for any purpose other than the purchaser’s

personal use without the written permission of Pulsafeeder, Inc.

ii

Page 3

Table of Contents

1. EQUIPMENT INSPECTION ....................................................................................................................... 1

2. INSTALLATION ...................................................................................................................................... 1

2.1 Location ....................................................................................................................................... 1

2.2 Motor ............................................................................................................................................ 1

2.3 Piping System ............................................................................................................................. 2

2.4 Suction Pressure Requirements ............................................................................................... 3

2.5 Discharge Pressure Requirements ........................................................................................... 4

3. EQUIPMENT STARTUP .......................................................................................................................... 5

3.1 Fastener Inspection .................................................................................................................... 5

3.2 Output Adjustment ..................................................................................................................... 5

3.3 Priming the Reagent Head ......................................................................................................... 5

3.4 Calibration ................................................................................................................................... 7

4. MAINTENANCE ..................................................................................................................................... 7

4.1 Lubrication................................................................................................................................... 8

4.2 Wet End Removal, Inspection, & Reinstallation ...................................................................... 9

4.3 Check Valv es ............................................................................................................................... 11

4.4 Motor Removal & Reinstallation ................................................................................................ 13

4.5 Pump Head Removal .................................................................................................................. 14

5. REPLACEMENT PARTS ......................................................................................................................... 15

5.1 KOPkit® Program......................................................................................................................... 15

5.2 Ordering KOPkits or Parts ......................................................................................................... 15

5.3 KOPkit numbers by model ......................................................................................................... 15

6. TROUBLESHOOTING ............................................................................................................................. 16

7. PIPING ACCESSORIES .......................................................................................................................... 17

8. DIMENSIONAL DRAWING ....................................................................................................................... 19

9. Policies & Procedures .................................................................................................................... 21

iii

Page 4

Page 5

1. Equipment Inspection

Figure 1: Foot Valve Kit

Check all equipment for completeness against the order and for any evidence of shipping damage.

Shortages or damage must be reported immediately to the carrier and your authorized representative or

distributor of PULSA GLM pumps.

Included Items:

• PULSA GLM Metering Pump with Motor Adaptor

Optional Items:

• Motor

• Foot Valve Kit (provided on PULSA GLM models 1 and 2 only).

2. Installation

2.1 Location

When s electing an installation site or designing a chemical feed system, plan for operation and routine

maintenance. Provide 3.25 ft ( 1 m) of space around the pump for this purpose.

PULSA GLM pumps are designed to operate in an environment where the pump is protected from direct

sunlight, and precipitation (i.e., under shelter). The ambient temperature must be between 32°F (0°C) and

104°F (40°C). If necessary add environmental controls.

The pump must be rigidly bolted to a solid and flat foundation to minimize vibration and prevent loosening

of the connections. The pump must be level within 5° to assure proper check valve operation.

2.2 Motor

The PULSA GLM is not typically shipped with the motor pre-installed. It must be mounted and wired in

accordance with local and national requirements by a qualified electrician. Please refer to the motor

nameplate for further manufact ure specific information.

If the PULSA GLM was purchased less motor, please refer to section 5.4 Motor Installation for further

instructions.

1

Page 6

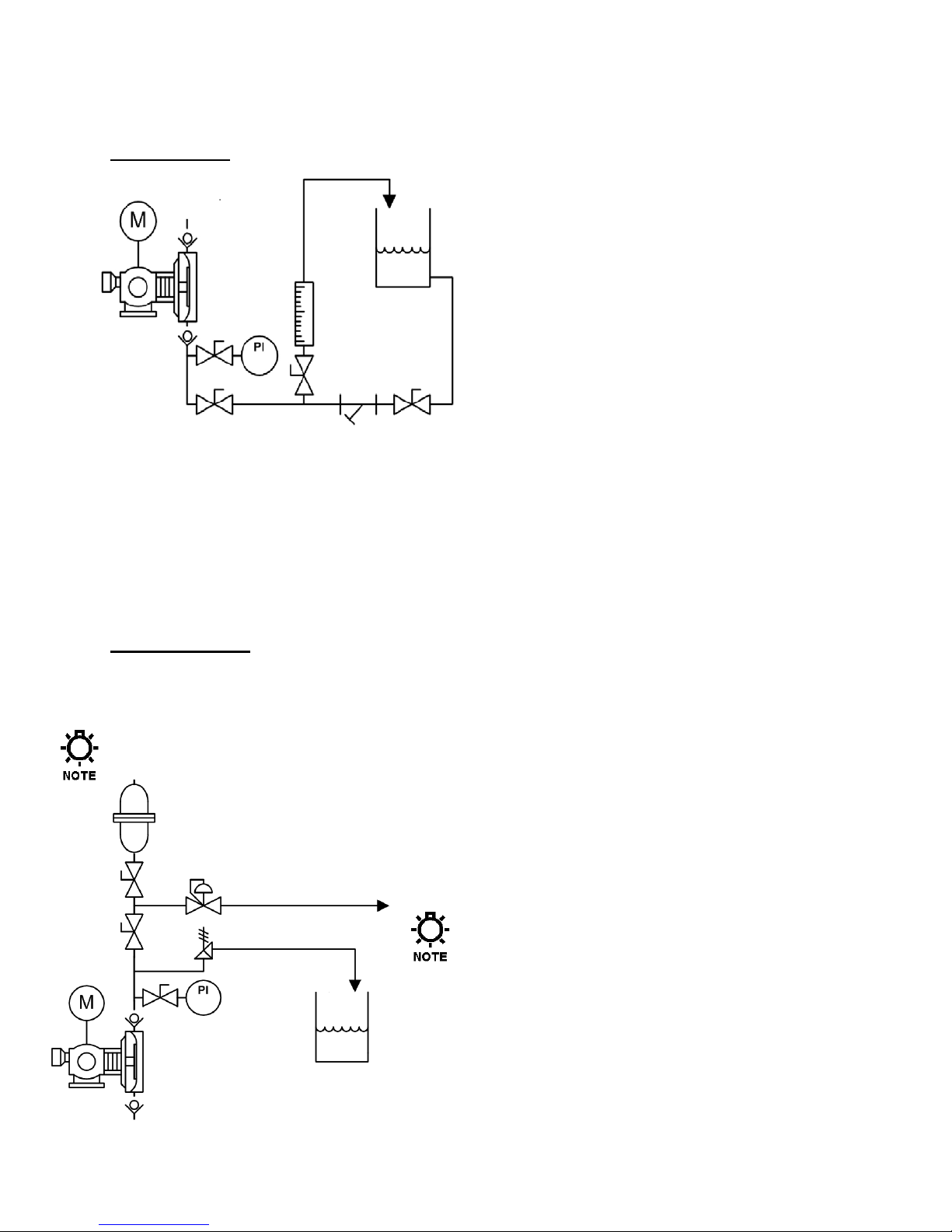

2.3 Piping System

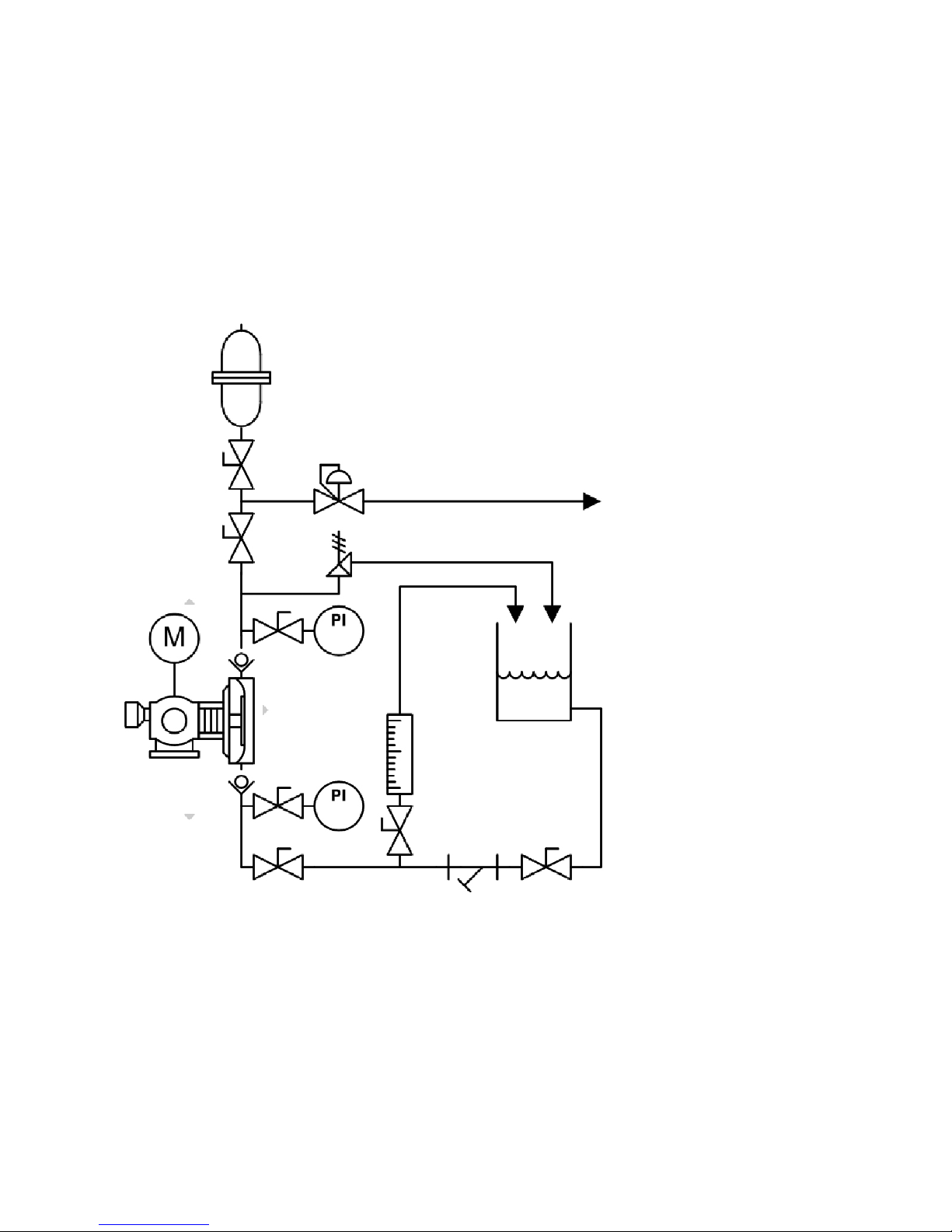

Figure 3: Discharge P&ID

Figure 2: Suction P&ID

Attention to piping detail will assure an easy startup and long life of your GLM. Please follow these guidelines:

Suction Piping

Isolation Valve and Unions: Isolation valves allow

the system to be isolated from the process fluid to

facilitate safe servicing. They also aid in the operation

of Calibration columns. Valves should include good

visible indications of open/closed condition. Unions

assist with installation and maintenance. Valves that

integrate union fittings are ideal.

Strainer: Successful installations always include a

strainer on the suction side of the pump to exclude

material that can cause the check valves to

malfunction or the diaphragm to rupture. Select the

material, size and mesh to be compatible with the fluid

type, intended flow rate and service interval. A 100

mesh screen is generally recommended.

Calibration Column (Optional): Used to calibrate pump performance. Include an isolation valve and

vent line back to the supply tank to facilitate safe operation.

Pressure Gage (Optional): A pressure gage should be included on the suction side of the pump when

the suction pressure of the system is unknown or variable. The gage is also a good indicator of Strainer

maintenance status.

Discharge Piping

Discharge Pressure Gage: Install a pressure gage no less than 2 pipe diameters from the threaded

fitting on the discharge valve. A discharge pressure gage is critical to confirming proper operation of the

pump and setting the pressure relief and back pressure valves.

IMPORTANT: DO NOT Install an elbow directly into the discharge valve threaded fitting as it will

create excessive back pressure that can lead to premature diaphragm failure.

Pressure Relief Valve: Install a Pressure Relief Valve as close

to the pump as possible. Using the leg of a T fitting for this

purpose is acceptable (with the normal discharge taking the

straight path and the relief flow taking the leg). The relief

pressure must be set at or below the rated pressure indicated

on the pumps nameplate.

NOTE: Failure to install and properly set a

Pressure Relief Valve can lead to damage of the

Pumps drive mechanism that will not be covered

under warranty.

Back Pressure Valve: Install a Back Pressure Valve to

generate a consistent Back Pressure to the pump for accurate

operation and to prevent siphoning.

Pulsation Dampener: Reciprocating diaphragm metering

pumps only discharge fluid for ½ of a pump cycle. A Pulsation

Dampener will smooth the associated flow/pressure variation to

the downstream process.

2

Page 7

Piping System Recommendations

1. When making the threaded joint to the valve cap assembly, use a sealing compound chemically

compatible with the process material (for example Loctite

®

8551 [Loctite® is a registered trade mark of

Henkel Corporation] for water service). Do not use sealing tape. The valve cap should be tightened by

hand and then tightened one additional turn (i.e., 360°) with the aid of an adjustable wrench.

2. Both new and existing piping should be cleaned, preferably by flushing with a clean liquid

(compatible with process material) and blown out with air, prior to connection to the pump.

Note - Debris from manufacturing the pip ing system (e.g., PVC shavings, TFE Tape, dirt, etc.)

can be unknowingly assembled inside the pipe. When fluid is introduced this material c an be

transferred to the pump and prevent proper check valve operation. This is a common startup

issue.

3. Piping weight must not be supported by valve housings or other portions of the reagent head, as the

resulting stresses can cause leaks. Valve loads must not exceed 10 ft-lbf (13.5 n-m) moment or 5

lbf (22 n) in any direction. When temperature variations are expected provide for thermal expansion

and contraction of piping components so that force and/or moments are controlled within the

allowable range.

4. When making process connections, ensure that pipe joint cement and thread sealants do not run

into the check valve assemblies as this will inhibit valve operation. This is a common startup issue.

2.4 Suction Pressure Requirements

Although PULSA GLM metering pumps have some suction lift capability, a flooded suction (i.e., suction

pressure higher than atmospheric pressure) is preferable whenever possible. The pump should be

located as close as possible to the suction side reservoir or fluid supply source.

For fluid with a vapor pressure of 5 psia (0.35 bar) or less (at operating temperature) the wet suction lift

capability is approximately 10 ft (3 m). If this requirement is not met, the pump will not provide reliable,

accurate flow. In suction lift conditions, the use of a foot valve is recommended at the lowest point of

the pickup tube or pipe. Pumps operating under suction lift conditions may require some liquid priming

before they will operate reliably.

3

Page 8

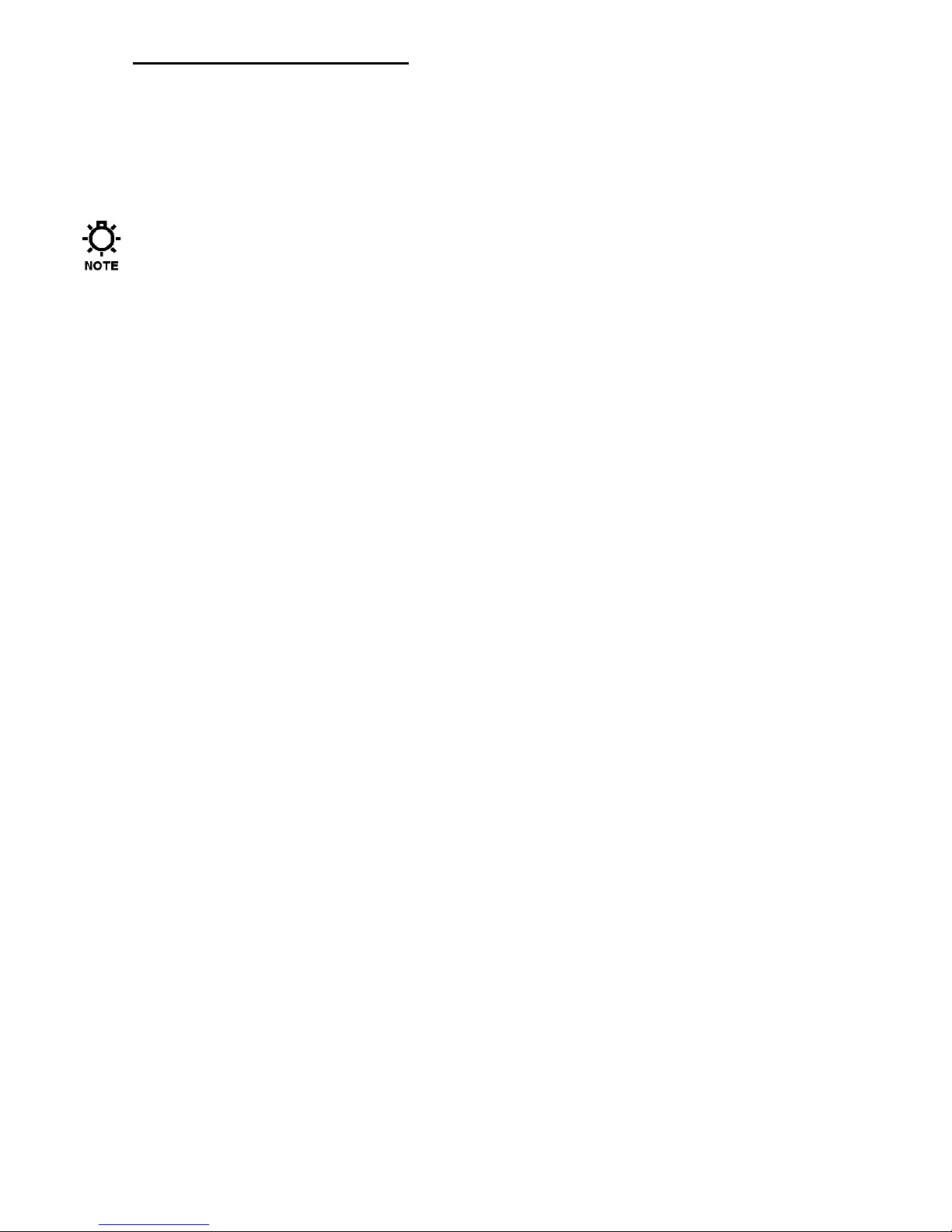

2.5 Discharge Pressure Requirements

All PULSA GLM metering pumps are designed for continuous service at the rated discharge

pressure. If the s ystem suction pressure exceeds the discharge pressure (a condition sometimes

described as “pumping downhill”), flow will be generated in addition to that generated by t he pump.

This results in a reduction in accuracy and loss of control over the metering process. To prevent this

flow-through condition, the discharge pressure must exceed the suction pressure by at least 5 psi

(0.35 bar). This can be achieved, where necessary, by the installation of a backpressure valve in the

discharge line.

Conditions where the actual discharge pressure exceeds the pumps rating are to be avoided as they

will cause damage to the pump components.

Figure 4: PULSA GLM P&ID

4

Page 9

3. Equipment Startup

Figure 5: Reagent Head Bolt

Figure 6: Stroke Adjustment Knob

3.1 Fastener Inspection

All pump fasteners should be checked prior to pump operation, and occasionally during use. This

would include reagent head mounting bolts, motor mounting bolts, and the hardware that secures the

pump to its foundation.

Reagent head mounting bolts should be torqued to 70 in-lb. and motor bolts to 40 in-lb. Bolts should be

tightened in a star pattern across the head to assure uniform clamping of the diaphragm (see

recommended tightening sequence in above diagram).

tightening sequence

3.2 Output Adjustment

All PULSA GLM pumps have a knob for manual stroke length adjustment.

The knob can be adjusted to any value between 0 to 100%. The stroke

length setting is directly proportional the flow rate of the pump.

1. Push the knob in towards the gearbox to release the locking mechanism.

Note - Making adjustments without releasing the lock

may damage the locking mechanism.

2. Adjust the knob to the desired output.

a. Read the setting directly from the knob marking where it aligns

with the stroke barrel.

b. The knob is labeled in 10% increments with 1% graduation

marks. The knob will lock in 0.5% increments.

Note – Do not adjust the knob beyond the indicated range.

For example, to set the pump to 75% stroke length (starting from the

factory default setting of 0%) push the knob in (to unlock) and turn it approximately ¾ turn clockwise

until he 75% indicator is aligned with the line on the stroke adjustment barrel.

3. Release the knob to re-engage the locking mechanism.

Note – Stroke adjustments should be made while pump is operating.

3.3 Priming the Reagent Head

1. When handling process liquids, follow all applicable personal and facility safety guidelines.

2. Ensure that the pump is ready for operation and that all process connections are secure.

5

Page 10

3. Open the suction and discharge line shutoff valves.

Figure 7: System Configured for Self-Priming

CLOSED

OPEN

4. If the piping system design and the storage tank are such that the product flows due to gravity through

the pump, reduce the discharge pressure and the system will self prime when the pump is started. In

the event the discharge line contains a significant amount of pressurized air or other gas, it may be

necessary to lower the discharge pressure to enable the pump to self-prime.

5. If the installation involves a suction lift, it may be necessary to prime the reagent head and suction line.

Operate the pump as in step 4 above - many times the pump will be capable of self priming. If it does

not begin to pump fluid, remove the discharge valve assembly. Carefully fill the reagent head through

the discharge valve port with process (or compatible) liquid, and then reinstall the check valve.

6. Start the pump at the 0% stroke length setting and slowly increase the setting to 100% to prime the

pump. If this does not work, it will be necessary to fill the suction line.

7. Filling of the suction line will necessitate the use of a foot valve or similar device at the end of the

suction line so that liquid can be maintained above the reservoir level. Remove the suction valve

assembly, fill the line with fluid, replace the suction valve, then remove the discharge valve assembly

and fill the reagent head as described in Step 5 above. The pump will now self-prime when started up

per step 6 above.

Use appropriate precautions if handling process fluid. Ensure that any other fluid used for

priming is compatible with the product that will be pumped.

6

Page 11

3.4 Calibration

Figure 8: Sample Flow Calibration Curve

All metering pumps must be calibrated to accurately correlate stroke length settings to measured

flow rates.

A typical calibration chart is shown above. Although output is linear with respect to the stroke length

setting, an increase in discharge pressure decreases output uniformly, describing a series of parallel

lines, one for each pressure (only two are shown).

The theoretical output flow rate at atmospheric discharge pressure is based on the displacement of

the diaphragm, stroke length and the stroking rate of the pump. With increasing discharge pressure

there is a corresponding decrease in output flow. Pumps are rated for a certain flow at a rated

pressure (check nameplate). Whenever possible, calibration should be performed under actual

process conditions (i.e., the same or a similar process liquid at system operating pressure).

To construct a calibration chart, measure the flow rate several times at three or more stroke settings

(e.g., 25, 50, 75, and 100), plot these values on linear graph paper, and draw a best-fit line through

the points. For stable conditions, this line should predict settings to attain required outputs.

Note - All users are encouraged to test the flow rate of their pump once installed in their

system, to ensure best accuracy and reliable operation.

4. Maintenance

Before performing any maintenance requiring reagent head or valve (wet end)

disassembly, be sure to relieve pressure from the piping system and, where hazardous

process materials are involved, render the pump safe to personnel and the environment

by cleaning and chemically neutralizing as appropriate. Wear protective clothing and

equipment as appropriate.

Accurate records from the early stages of pump operation will indicate the type and levels of required

maintenance. A preventative maintenance program based on such records will minimize operational

problems. It is not possible to forecast the lives of wetted parts such as diaphragms and check

valves. Since corrosion rates and operational conditions affect functional material life, each metering

pump must be considered according to its particular service conditions.

The PULSA GLM KOPkit

maintenance program. It is recommended that KOPkits and PULSAlube

times.

®

will contain all replacement parts normally used in a preventative

®

9M be kept available at all

7

Page 12

4.1 Lubrication

PULSA GLM pumps have an oil bath reservoir that is pre-filled with 350 mL of PULSAlube 9M at

the factory. For optimum pump performance under normal conditions, the PULSAlube 9M should

be replaced every 3,000 hours. For severe service in non-temperature controlled and/or dirty

environments the PULSAlube 9M should be replaced every 1,500 hours.

1. Disconnect the power source to the drive motor, and relieve all pressure from the piping system.

2. Remove the Vent/Fill cap on top of the Gear Box under the motor adaptor lip.

3. Locate the Gear Box drain plug at the bottom of the Gear Box under the Stroke Adjustment

Knob (see Figure below).

4. While holding the Gear Box over a catch reservoir, remove the drain plug (be sure to retain the

sealing o-ring on the plug).

5. Replace the Drain Plug and sealing o-ring.

6. Fill the Gear Box with 350 mL of PULS A lube 9M so that the level indicates in the center of the

sight glass on the side.

7. Replace the Vent/Fill cap and sealing o-ring.

Figure 9: Gear Box Fill/Drain Points

Figure 10: Gear Box PULSAlube 9M Normal Level

8

Page 13

4.2 Wet End Removal, Inspection, & Reinstallation

Qty.

GLM1 and

GLM2

GLM3 and

GLM4

GLM5 and

GLM6

1

Discharge Connection

Assembly

1 1 1 2 Discharge Valve Assembly

1 1 1 3 O-ring

2 2 2 4 Reagent Head

1 1 1

5

Diaphragm

1 1 1 6 Front Cover Plate

1 1 1

7

Hex Head Bolt

8

10

12 8 Flat Washer

8

10

12

9

Suction Check Valve

Assembly

1 1 1

10

Suction Connection Assembly

1 1 1

11

Hex Nuts

8

10

n/a

If the diaphragm has failed, process fluid may have contaminated other parts of

the pump including the drive components (although normally, any process fluid behind a

failed diaphragm would pass through the bottom drain hole). Handle with appropriate

care.

Figure 11: Wet End Components

Item Description

PULSA GLM diaphragms do not have a specific cycle life; however, the accumulation of foreign

material or debris sufficient to deform the diaphragm can eventually cause failure. Failure can also

occur as a result of system over pressure or chemical attack. Periodic diaphragm inspection and

replacement are recommended. Each user should perform regular inspections to determine the

replacement interval that is appropriate to their system conditions.

9

Page 14

4.2.1 Diaphragm Removal & Rei ns t al la t ion

1. Adjust the stroke setting to 50% and disconnect the power source to the drive motor.

2. Relieve all pressure from the piping system.

3. Close the inlet and outlet shutoff valves.

4. Place a pan underneath the pump head adaptor to catch any liquid leakage.

5. Disconnect piping to the reagent head and drain any process liquid, following all recommended

material safety precautions.

6. Remove all but one top reagent head bolt. Product will leak out between the pump head adaptor

and reagent head as the bolts are loosened. Use prescribed engineering controls to prevent

exposure and accidental discharge to environment.

7. Tilt the head and pour out any liquids retained by the check valves into a suitable container,

continuing to follow safety precautions as appropriate.

8. Remove the final bolt and rinse or clean the reagent head with an appropriate material.

9. Remove the diaphragm by turning it counter-clockwise.

10. Inspect the diaphragm. The diaphragm must be replaced if it is cracked, separated, or obviously

damaged.

11. Install the diaphragm.

12. Ensure that the critical sealing areas of diaphragm, reagent

head, and pump head are clean and free of debris.

13. Thread the diaphragm (clockwise) fully onto the shaft.

14. Install the reagent head bolts and tighten in an alternating

pattern to ensure an even seating force. Torque bolts to

70 in-lb

15. Re-prime the pump following the procedure outlined in

Section 3.3

Figure 12: Reagent Head Assembly Cross Section

10

Page 15

4.3 Check Valves

Direction of

Flow (UP)

4.3.1 General Description

The valve incorporates a ball, guide, and seat. Flow in the unchecked direction lifts the ball off the

seat, allowing liquid to pass through the guide. Reverse flow forces the ball down, sealing it against

the bevel edge of the seat and o-ring. The guide permits the ball to rotate but restricts vertical and

lateral movement in order to minimize “slip” or reverse flow. Ball rotation prolongs life by distributing

wear over the entire surface of the ball. Since ball return is by gravity, the valve must be in the

vertical position in order to function properly. Parts are sealed by o-rings.

Figure 13: Cartridge Check Valve

4.3.2 Check Valve Removal & Reinstallation, Cartridge type

Valving that is of the cartridge design is intended to be replaced as an assembly.

1. Disconnect and Lockout the power supply to the drive motor.

2. Relieve all pressure from the piping system.

3. Take all precautions necessary to prevent contamination to the environment and personnel

exposure to hazardous materials.

4. Close the inlet and outlet shutoff valves.

5. Disconnect the suction piping at the suction shut-off valve union by releasing the union retaining nut.

Caution – Process fluid may drain from the Piping. Take necessary precautions.

6. Disconnect the discharge piping at the discharge shut-off valve union by releasing the union

retaining nut.

Caution – Process fluid may drain from the piping. Take necessary precautions.

7. Loosen and remove the suction valve cartridge retaining nut and drain any liquid from

the reagent head.

8. Disconnect the discharge piping at the installed union near the discharge port.

9. Loosen and remove the discharge valve cartridge slowly to drain any trapped liquid.

10. Reinstall both new valve assemblies. For both the suction and discharge the valve orientation

should be as shown in Figure 13.

Take care to assure o-rings are fully seated in groves and are not displaced during assembly.

A pinched o-ring can cause the assembly to leak. If necessary use a compatible o-ring

retaining compound.

4.3.3 Check Valve Removal & Reins t al lation, Tie-bar type

1. Disconnect and Lockout the power supply to the drive motor.

11

Page 16

2. Relieve all pressure from the piping system.

Figure 14: Tie Bar Style

Figure 15: Metal

3. Take all precautions necessary to prevent contamination

to the environment and personnel exposure to hazardous

materials.

4. Close the inlet and outlet shutoff valves.

5. Loosen the suction valve tie-bar bolts (4) and spring the

suction piping slightly away from the head, allowing liquid

to drain. It may be necessary to loosen a union or flange.

Caution – Process fluid may drain from the Piping. Take

necessary precautions.

6. Remove the suction check valve assembly by sliding it

towards you, holding it together as a unit. Note carefully

the position of the component parts, to assist in reassembly.

7. Loosen the discharge valve tie-bar bolts (4) and spring the discharge

piping slightly away from the head, allowing liquid to drain.

It may be necessary to loosen a union or flange.

Metal Valves

Caution – Process fluid may drain from the Piping. Take necessary precautions.

8. Remove the discharge check valve assembly by sliding it towards you, holding it together as a

unit. Note carefully the position of the component parts, to assist in re-assembly.

9. Disassemble both valves and check components for wear or damage. The seats should have a

sharp edge and be free from dents or nicks. Hold a ball firmly against the seat in front of a bright

light and inspect for fit. Observation of light between the ball and seat is cause for replacement.

10. Reassemble both valves using new parts as required. Sealing o-rings should

always be replaced.

11. Replace both valve assemblies onto the pump, taking care to ensure they are

oriented correctly, with the balls above the seats, and the seats oriented with the

sharp edge up and the chamfered edge down.

Inserting the check valve assmbly into the pump in the wrong directiom, or

having the check seat upside down, will prevent proper seals at the orings, decrease pump performance, and can cause damage to the

diaphragm.

12. Carefully make sure that the check assemblies are in proper position,

and tighten the four tie-bar bolts, using a star pattern, to a torque of

6 ft-lbs (8 n-m).

13. Retighten any unions, flanges, or other process connections that may

have been loosened previously.

Valve Assembly

12

Page 17

4.4 Motor Removal & Reinstallation

Removal

1. Disconnect and Lockout the power supply to the drive motor.

2. Disconnect the motor wiring from the motor.

3. Remove the four bolts retaining the motor to the motor adaptor.

4. The motor shaft is keyed to a plastic coupling that slides into a splined bore in the pump input

shaft. Lift the motor straight up to slide the motor shaft coupling out of the pump input shaft.

Installation

1. Install the plastic coupling over the motor key onto the motor

shaft. For the 56C frame motor the coupling should be even

with the end of the shaft. For the 71 frame motor the coupling

should be installed over the shaft up to the collar (the end of

the shaft will be slightly recessed into the coupling).

Note: Assure the motor key is fully covered by the

motor coupling.

2. Reinstall the motor by sliding the motor vertically into the pump

input shaft.

3. Align the motor bolts holes to the motor adaptor plate.

4. Install the 4 motor retaining bolts. Torque to 40 in-lbf (4.5 n-m).

5. Connect the motor wiring to the motor in accordance with

Local, National and Motor Manufacturer requirements.

6. Restore power.

Figure

16: Motor M ounting

The PULSA GLM is designed to operate with any Motor rotation direction (clockwise or

counter clockwise).

13

Page 18

4.5 Pump Head Removal

Warning – Stored energy

The PULSA GLM includes a Pump Head that clamps the diaphragm to the Reagent Head. In the

event of diaphragm failure process fluid can come into contact with this part (it includes a drain hole

to prevent fluid accumulation). Over time, it is possible for this part to suffer some level of

deterioration and need replacement.

1. Disconnect and Lockout the power supply to the drive motor.

2. Relieve all pressure from the piping system.

3. Take all precautions necessary to prevent contamination to the environment and personnel

exposure to hazardous materials.

4. Close the inlet and outlet shutoff valves.

5. Remove the valving, Reagent Head and Diaphragm as described in section 4.2.1.

6. Drain the oil from the pump.

7. Set the pump stroke setting to 100%.

8. Rotate the pump motor until the Cross Head (the part that the Diaphragm threads onto) is fully

retracted into the Gear Box.

9. Evenly loosen all (4) bolts that retain the Pump Head to the Gear Box.

release possible - use caution!

The pump head compresses a

large spring that is used to

return the diaphragm to its

retracted position. Special tools

may be required to reattach the

Figure 17: Pump Head Retaining Bolt Removal

10. Remove old pump head from front of Gear Box.

a.

b. Figure 18, Pump Head Cross Section and Bellows Seal

11. Orient replacement Pump Head with drain hole pointed down. Assure o-ring is in place on

Gearbox side.

12. Ensure the bellows oil seal is seated on the end of the cross head as shown above.

13. Insert Spring Guide of Pump Head over Cross Head and into spring. Take care to a ssure s pring

does not catch on tapered guide during installation.

14. Install the four retaining bolts. Tighten evenly. Torque to 80 in-lbf.

15. Install Diaphragm, Reagent Head and Valving as defined in Section 4.2.1.

14

Page 19

5. Replacement Parts

5.1 KOPkit® Program

PULSA GLM KOPkits contain all replacement parts normally used in a preventative maintenance

program. (PULSAlube is also available separately for preventative maintenance programs. Refer to

Section 3 – Equipment Startup). There is a specific KOPkit for every PULSA GLM pump model.

Each KOPkit is vacuum-packed for extended storage. All PULSA GLM pumps have the KOPkit

number identified on the pump nameplate and Pulsafeeder order documents. KOPkits can also be

selected from the technical data sheet shipped with the pump or by a Pulsafeeder representative. A

list of the PULSA GLM KOPki t numbers can also be found on the next page. The kit is identified by

the model number of the pump, the wetted end material, and the process connection thread type.

For models with tie-bar type check valves, the appropriate components (check valve balls, seats,

and o-rings) are supplied instead of the cartridges pictured.

5.2 Ordering KOPkits or Parts

When ordering replacement parts always specify:

• Pump model and serial number (from pump nameplate), e.g., Model No. (2) with

Serial No. F406365-3.

Figure 19: PULSA GLM Nameplate

• Part number and description from the PULSA GLM parts list. Include the three-character suffix.

(Note: PULSA GLM part numbers begin either with the letters GL, NP, or W, e.g., NP170001THY or W210221-001.)

5.3 KOPkit numbers by model:

15

Page 20

Pump Model

GLM1

KM1PX-LTE (Viton®)

KM1PX (Viton®)

GLM2

KM2PX-LTE (Viton®)

KM2PX (Viton®)

GLM3

KM3PX-LTE (Viton®)

GLM4

KM4PX-LTE (Viton®)

KM4PX (Viton®)

GLM5

KM5PX-LTE (Viton®)

GLM6

KM6PX-LTE (Viton®)

KM6PX (Viton®)

GLM7 & GLM7 Duplex

KM7PX-LTE (Viton®)

KM7PX (Viton®)

GLM1

KM1FX-LTE (Viton®)

KM1FX (Viton®)

GLM2

KM2FX-LTE (Viton®)

GLM3

KM3FX-LTE (Viton®)

KM3FX (Viton®)

GLM4

KM4FX-LTE (Viton®)

GLM5

KM5FX-LTE (Viton®)

KM5FX (Viton®)

GLM6

KM6FX-LTE (Viton®)

KM6FX (Viton®)

GLM7 & GLM7 Duplex

KM7FX-LTE (Viton®)

KM7FX (Viton®)

GLM1

KM1AX-LTE (PTFE)

GLM2

KM2AX-LTE (PTFE)

KM2AX (PTFE)

GLM3

KM3AX-LTE (PTFE)

GLM4

KM4AX-LTE (PTFE)

KM4AX (PTFE)

GLM5

KM5AX-LTE (PTFE)

GLM6

KM6AX-LTE (PTFE)

KM6AX (PTFE)

GLM7 & GLM7 Duplex

KM7AX-LTE (PTFE)

Difficulty

Probable Cause

Remedy

Pump motor does

Faulty power source.

Check power source.

Blown fuse, circuit breaker.

Replace - eliminate overload.

Broken wire.

Locate and repair.

Wired improperly.

Check diagram.

Process piping blockage.

Open valves, clear other obstructions.

Test by setting stroke to 0%.

No fluid delivery

Motor not running.

Check power source. Check wiring

diagram (see above).

Supply tank empty.

Fill tank.

Line clogged.

Clean and flush.

Closed in-line valve(s).

Open valve(s).

Ball check valves held open with

solids.

Clean – inspect, flush with clear fluid.

Vapor lock, cavitation.

Increase suction pressure.

Prime lost.

Re-prime, check for leak.

Strainer clogged.

Remove and clean. Replace screen if

necessary.

Stroke adjustment set at zero.

Increase stroke length setting.

Low fluid delivery

Motor speed too low.

Check voltages, frequency, wiring,

nameplate vs. Specifications.

Check valves worn or dirty.

Clean, replace if damaged.

Calibration system error.

Evaluate and correct.

Wetted

Material

PP

Lite KOPkit

(O-ring material)

Standard KOPkit

(O-ring material)

KM3PX (Viton®)

KM5PX (Viton®)

KM2FX (Viton®)

6. Troubleshooting

not start

PVDF

316SS

KM4FX (Viton®)

KM1AX (PTFE)

KM3AX (PTFE)

KM5AX (PTFE)

KM7AX (PTFE)

and terminal connections. Check

16

Page 21

Difficulty

Probable Cause

Remedy

Product viscosity too high.

Lower viscosity by increasing product

pump and/or piping size.

Product cavitating.

Increase suction pressure.

Delivery gradually

drops.

Check valve leakage.

Clean, replace if damaged.

Leak in suction line.

Locate and correct.

Strainer fouled.

Clean or replace screen.

Product change.

Check viscosity and other variables.

Supply tank vent plugged.

Unplug vent.

Delivery erratic.

Leak in suction line.

Locate and correct.

Product cavitating.

Increase suction pressure.

Entrained air or gas in product.

Consult factory for suggested venting.

Motor speed erratic.

Check voltage and frequency.

Fouled check valves.

Clean, replace if necessary.

Inadequate backpressure

Increase discharge pressure to obtain

psi from suction to discharge.

Delivery higher than

Suction pressure higher than

discharge pressure.

Install backpressure valve or consult

factory for piping recommendations.

Back pressure valve set too low.

Increase set ting.

Back pressure valve leaks.

Repair, clean, or replace.

Noisy gearing,

Discharge pressure too high.

Reduce pressure.

Water hammer.

Install pulsation dampener.

Stroke length at partial setting.

Some operating noise is characteristic

of lost motion pumps.

Low grease level.

Add or replace grease.

Piping noisy.

Pipe size too small.

Increase size of piping - install

pulsation dampener.

Pipe runs too long.

Install pulsation dampener in line.

Pulsation dampener inoperative

or flooded.

Refill with air or inert gas. Inspect and

replace diaphragm and recharge.

No surge chamber or dampener

used.

Install pulsation dampeners.

Motor overheats.

Pump overloaded.

Check operating conditions against

pressure.

High or low voltage.

Check power source.

Loose wire.

Trace and correct.

Incorrect motor wiring.

Verify and correct.

rated.

knocking

temperature or dilution. Increase

a minimum pressure difference of 5

7. Piping Accessories

Pressure Relief Valves

Pressure relief valves are designed to protect chemical feed systems from damage that

may be caused by defective equipment or a blockage in the discharge line. These valves

function to limit the pressure downstream of the pump. Field adjust the pressure relief

valve to operate when the discharge pressure exceeds operating pressure by 10-15%.

Pressure relief valve should always be adjusted to a setting below the maximum rated

pressure of the pump. No potentially restrictive components, such as a valve, should be

installed between the pump discharge and the PRV.

Diaphragm Backpressure Valve

pump design. Verify discharge

17

Page 22

A diaphragm style backpressure valve creates constant back pressure. A PTFE or PTFEfaced diaphragm offers maximum chemical protection and service life, and seals spring

and bonnet from product.

Be sure to install with fluid flow in direction of arrow on valve body.

Pulsation Dampener

A pulsation dampener is a pneumatically charged diaphragm-type chamber that

intermittently stores hydraulic energy. Used on the inlet, it can improve NPSHA (Net

Positive Suction Head Available) characteristics of the suction piping system. On the

discharge line it will reduce discharge pressure peaks and pulsating flow variations.

18

Page 23

8. Dimensional Drawing

Dimension table in mm / inches

19

Page 24

G H J K L

M

Model

GLM1 &

GLM2

GLM3 &

GLM4

GLM5 &

GLM6

Dimension

A B C D E F

71 160.0 / 6.3

95.5 / 3.8 300.0 / 11.8 94.5 / 3.7

37.0 / 1.5

56C 196.0 / 7.7

71 160.0 / 6.3

95.5 / 3.8 315.0 / 12.4 94.5 / 3.7 37.0 / 1.5

Consult

Factory

56C 196.0 / 7.7

71 160.0 / 6.3

95.5 / 3.8 325 / 12.8 94.5 / 3.7 37.0 / 1.5

56C 196.0 / 7.7

Model

GLM1 &

GLM2

GLM3 &

GLM4

GLM5 &

GLM6

Dimension

71

56C

71

Consult

Factory

56C

71

56C

170.0 /

6.7

175.0 /

6.9

170.0 /

6.7

175.0 /

6.9

170.0 /

6.7

175.0 /

6.9

79.0 /

3.1

79.0 /

3.1

79.0 /

3.1

91.5 /

3.6

91.5 /

3.6

91.5 /

3.6

NPT /

BSPT

103.0 /

4.1

150.0 /

5.9

172.0 /

6.8

TUBING

131.0 /

5.2

N/A

N/A

NPT /

BSPT

206.0 / 8.1

300.0 /

11.8

344.0 /

13.5

TUBING

262.0 /

10.3

N/A

N/A

20

Page 25

9. Policies & Procedures

Reference our Policy Manual at http://www.pulsa.com/resources/downloads/forms

.

21

Page 26

PULSA® GLM

Pulsafeeder, Inc.

MECHANICAL DI APHRAGM METERING PUMP

Bulletin: IOM-GLM-5000-Rev.A

A unit of IDEX Corporation

2883 Brighton Henrietta Town Line Road

Rochester NY 14623

+1 (585) 292-8000

www.pulsa.com

pulsa@idexcorp.com

22

Loading...

Loading...