Page 1

Installation

Operation

Maintenance

Instruction

Bulletin #: IOM-NMG-0804 – Rev F

i

Page 2

ii

Page 3

Pulsafeeder Factory Service Policy

Should you experience a problem with your Eclipse Standard/Eclipse Hypo Series pump, first consult the

troubleshooting guide in this installation, operation and maintenance manual. If the problem is not

covered or cannot be solved, please contact your local Pulsafeeder Distributor or our Technical Services

Department for further assistance.

Trained technicians are available to diagnose your problem and arrange a solution. Solutions may include

purchase of replacement parts or returning the unit to the factory for inspection and repair. All returns

require a Return Authorization number to be issued by Pulsafeeder. Parts purchased to correct a warranty

issue may be credited after an examination of original parts by Pulsafeeder. Warranty parts returned as

defective, which test good, will be sent back freight collect. No credit will be issued on any replacement

electronic parts.

Any modifications or out-of-warranty repairs will be subject to bench fees and costs associated with

replacement parts.

Safety Considerations:

1. Read and understand all related instructions and documentation before attempting to install or maintain

this equipment

2. Observe all special instructions, notes, and cautions.

3. Act with care and exercise good common sense and judgment during all installation, adjustment, and

maintenance procedures.

4. Ensure that all safety and work procedures and standards that are applicable to your company and facility

are followed during the installation, maintenance, and operation of this equipment.

Trademarks

Eclipse® is a registered trademark of Pulsafeeder Inc.

Copyright ©2005/2006 Pulsafeeder Inc. All rights reserved.

Information in this document is subject to change without notice. No part of this publication may be

reproduced, stored in a retrieval system or transmitted in any form or any means electronic or mechanical,

including photocopying and recording for any purpose other than the purchaser’s personal use without the

written permission of Pulsafeeder Inc.

iii

Page 4

Conventions:

The following Conventions are used in this document.

A WARNING DEFINES A CONDITION THAT COULD CAUSE DAMAGE TO BOTH THE EQUIPMENT

AND THE PERSONNEL OPERATING IT

Notes are general information meant to make operating the equipment easier.

Revision History:

. PAY CLOSE ATTENTION TO ANY WARNING.

Rev A Release Date August 2005, first revision

Rev B Release Date December 2005

Updates and corrections to various text throughout

New figure 47 showing motor adaptor

Update Specifications and add information on page 44

Update BOM, all models

Add motor rotation vs. flow direction diagram (figure 2b)

Add o-ring reference chart (Section 18)

Rev C/C2 Release Date December 2006

Added new information for model E10

Updated flow curves for all models

Minor updates to Specification pages, remove KalRez O-ri n g opti o ns

Rev D Release December 2006

Model E10 now upgraded to E12, new flow cur ves, up dat e t ext

Rev E Release May 2009

Model E125 added, new flow curves, update text

Rev F Release June 2012

Eclipse Hypo Series added, updated text and pictures

Updated KOPKits to new part number format

iv

Page 5

Table of Contents

1. INTRODUCTION ..................................................................................................................................... 1

1.1 General Description ................................................................................................................ 1

2. EQUIPMENT INSPECTION AND STORAGE ................................................................................................ 2

3. INSTALLATION ...................................................................................................................................... 3

4. EQUIPMENT SETUP AND OPERATION ..................................................................................................... 5

5. MAINTENANCE OVERVIEW .................................................................................................................... 6

5.1 Recommended Spares ........................................................................................................... 7

5.2 Maintenance precautions for magnet-driven equipment: .................................................. 7

5.3 KOPKit Maintenance, All Models ........................................................................................... 8

6. DISASSEMBLY/ASSEMBLY, ECLIPSE STANDARD/ECLIPSE HYPO 02 ........................................................ 9

6.1 Disassembly ............................................................................................................................ 9

6.2 Inspection ................................................................................................................................ 12

6.3 Assembly ................................................................................................................................. 13

7. DISASSEMBLY/ASSEMBLY, ECLIPSE STANDARD/ECLIPSE HYPO 05/12 ................................................... 19

7.1 Disassembly ............................................................................................................................ 19

7.2 Inspection ................................................................................................................................ 22

7.3 Assembly ................................................................................................................................. 23

8. DISASSEMBLY/ASSEMBLY, ECLIPSE STANDARD/ECLIPSE HYPO 25/75/125 ............................................ 29

8.1 Disassembly ............................................................................................................................ 29

8.2 Inspection ................................................................................................................................ 32

8.3 Assembly ................................................................................................................................. 33

9. INSPECTION AND WEAR LIMITS ............................................................................................................. 39

9.1.1 Bearings ........................................................................................................................... 39

9.1.2 Shafts ............................................................................................................................... 39

9.1.3 Gears ................................................................................................................................ 39

9.1.4 Housing Liner .................................................................................................................. 39

9.1.5 Special Note, Viscosity ................................................................................................... 39

9.1.6 Service and Replacement Limits ................................................................................... 40

10. TROUBLESHOOTING CHART .................................................................................................................. 41

11. SPECIFICATIONS ................................................................................................................................... 42

11.1 Eclipse Standard/Eclipse Hypo 02 General Specifications ................................................ 42

11.2 Eclipse Standard/Eclipse Hypo 05 General Specifications ................................................ 42

11.3 Eclipse Standard/Eclipse Hypo 12 General Specifications ................................................ 43

11.4 Eclipse Standard/Eclipse Hypo 25 General Specifications ................................................ 43

11.5 Eclipse Standard/Eclipse Hypo 75 General Specifications ................................................ 44

11.6 Eclipse Standard/Eclipse Hypo 125 General Specifications .............................................. 44

12. MODEL IDENTIFICATION – ECLIPSE STANDARD ...................................................................................... 47

13. MODEL IDENTIFICATION – ECLIPSE HYPO .............................................................................................. 48

14. PARTS DIAGRAM AND LIST, ECLIPSE STANDARD 02 .............................................................................. 49

15. PARTS DIAGRAM AND LIST, ECLIPSE STANDARD 05 .............................................................................. 53

16. PARTS DIAGRAM AND LIST, ECLIPSE STANDARD 12 .............................................................................. 58

17. PARTS DIAGRAM AND LIST, ECLIPSE STANDARD 25 .............................................................................. 63

18. PARTS DIAGRAM AND LIST, ECLIPSE STANDARD 75 .............................................................................. 68

19. PARTS DIAGRAM AND LIST, ECLIPSE STANDARD 125 ............................................................................ 74

20. PARTS DIAGRAM AND LIST, ECLIPSE HYPO 02 ...................................................................................... 79

21. PARTS DIAGRAM AND LIST, ECLIPSE HYPO 05 ...................................................................................... 83

22. PARTS DIAGRAM AND LIST, ECLIPSE HYPO 12 ...................................................................................... 87

v

Page 6

23. PARTS DIAGRAM AND LIST, ECLIPSE HYPO 25 ...................................................................................... 91

24. PARTS DIAGRAM AND LIST, ECLIPSE HYPO 75 ...................................................................................... 95

25. PARTS DIAGRAM AND LIST, ECLIPSE HYPO 125 .................................................................................... 100

26. DIMENSIONAL DRAWINGS ..................................................................................................................... 104

26.1 Eclipse Standard/Eclipse Hypo 02 ........................................................................................ 104

26.2 Eclipse Standard/Eclipse Hypo 05 ........................................................................................ 105

26.3 Eclipse Standard/Eclipse Hypo 12 ........................................................................................ 106

26.4 Eclipse Standard/Eclipse Hypo 25 ........................................................................................ 107

26.5 Eclipse Standard/Eclipse Hypo 75/125 ................................................................................. 108

27. PERFORMANCE CURVES (STANDARD & HYPO) ...................................................................................... 109

28. ATEX DIRECTIVE ................................................................................................................................. 127

vi

Page 7

1. Introduction

1.1 General Description

Pulsafeeder’s Eclipse Standard/Eclipse Hypo Series pumps safely handle hazardous, highly corrosive, explosive

or toxic chemicals. Eclipse Hypo Series pumps were designed specifically for installation into Sodium

Hypochlorite applications. The Eclipse Standard/Eclipse Hypo Series pumps provide safe, leak-free service

because the magnetic coupling eliminates the need for traditional sealing methods, such as mechanical seals or

packing.

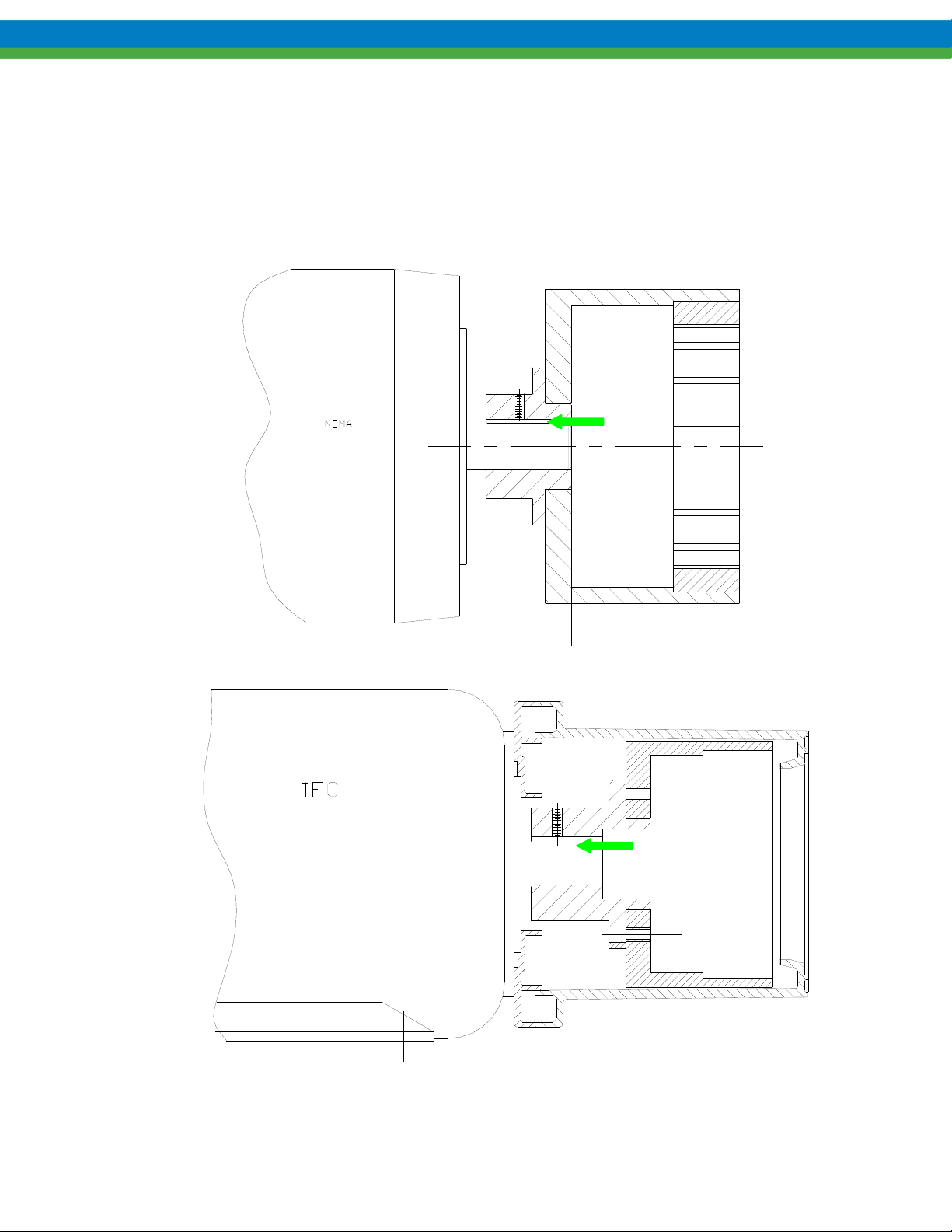

Eclipse Standard/Eclipse Hypo Series gear pumps mount to standard NEMA 56C, 143/145TC and 182/184TC

motors and IEC 63, 80, 100 and 112 B14 metric flanged (C-face) motors. This enables the pumps to be close

coupled, which provides greater assembled strength, complete isolated enclosure of all moving parts, and compact

design. This also eliminates the need for special base plate mounting, shaft couplings and guards, complicated

drives, and pump bearing lubrication and maintenance, while minimizing plant real estate for optimum pump

installation.

All Eclipse Standard/Eclipse Hypo Series pumps transmit rotational torque from the motor shaft to the pump shaft

by means of a magnetic drive coupling. The principle of operation of the magnetic drive coupling is that an

encapsulated driven magnet assembly is mounted on the end of the pump shaft. It is then contained by a closed

end containment shell or “containment can” which seals against the pump center housing with a static o-ring. A

drive magnet assembly attached to an electric motor shaft rotates around the containment can. When the drive

magnet assembly rotates, lines of magnetic flux or force cause the driven magnet assembly to rotate which in turn

causes the pump shaft to rotate.

All magnetic drive couplings are designed for satisfactory operation of the pump. The magnetic couplings have an

integral safety feature that allows them to “decouple” if the coupling torque limit is exceeded. This situation

might occur if foreign material were to jam the pump gears or if unusually high torque was developed on pump

start-up. Eclipse Standard/Eclipse Hypo Series pumps use permanent rare earth Neodymium Iron magnets that

can run decoupled without losing their magnetic strength provided magnet temperatures do not exceed 450

0

(232

C).

IF THE PUMP IS ALLOWED TO RUN FOR AN EXTENDED PERIOD OF TIME DECOUPLED, HIGH

TEMPERATURES COULD BE GENERATED THROUGH OPPOSING MAGNETIC FORCES THAT

ULTIMATELY WOULD CAUSE THE LOSS OF MAGNETIC STRENGTH

Eclipse Standard/Eclipse Hypo Series pumps feature continuous operation over wide temperature and pressure

variations, constant volume pulsation free flow, the ability to handle wide viscosity variations, and ease of

inspection and maintenance. Specific limitations are covered in this manual and summarized in Section 11,

Specifications.

To achieve successful operation and maximum life from your pump, make sure that the pump selection and

materials are compatible with the service and operating conditions of your application.

0

F

.

1

Page 8

2. Equipment Inspection and Storage

Check all equipment for completeness and accuracy against the order and for any evidence of

shipping damage. Shortages or damage should be reported immediately to the freight carrier and

to your Pulsafeeder representative.

If the pump is not going to be installed immediately, the following steps should be taken:

Leave pump in original shipping carton.

Store indoors in a dry ambient atmosphere. Avoid temperature variations.

Leave all shipping plugs in place.

Contact the motor manufacturer for specific motor storage information.

These instructions should be read carefully by the personnel responsible for installation, operation and

maintenance of the equipment and kept in a convenient place for ready reference. It is recommended that a copy

of the order documents be kept with this manual as well as a written record of the pump model and serial number,

which is on the nametag attached to the pump.

Figure 1

2

Page 9

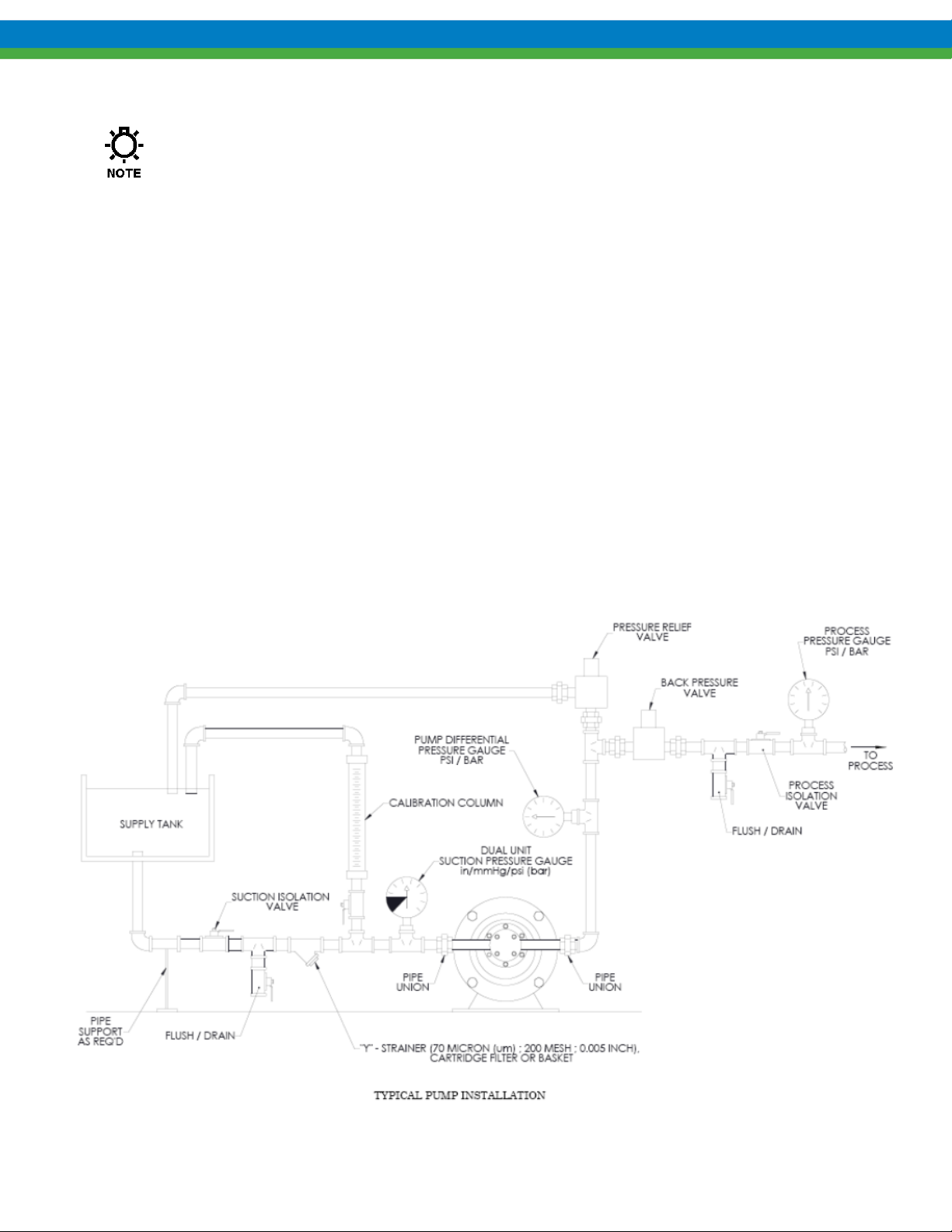

3. Installation

Pump installation site should provide easy access for routine maintenance and protect the pump

from environmental elements and from leaks or drips from nearby process equipment. See

Figure 2 for typical installation diagram.

o Bolt the pump motor down firmly to mounting surface. Provide for air movement and circulation over electric

motor to enhance proper cooling.

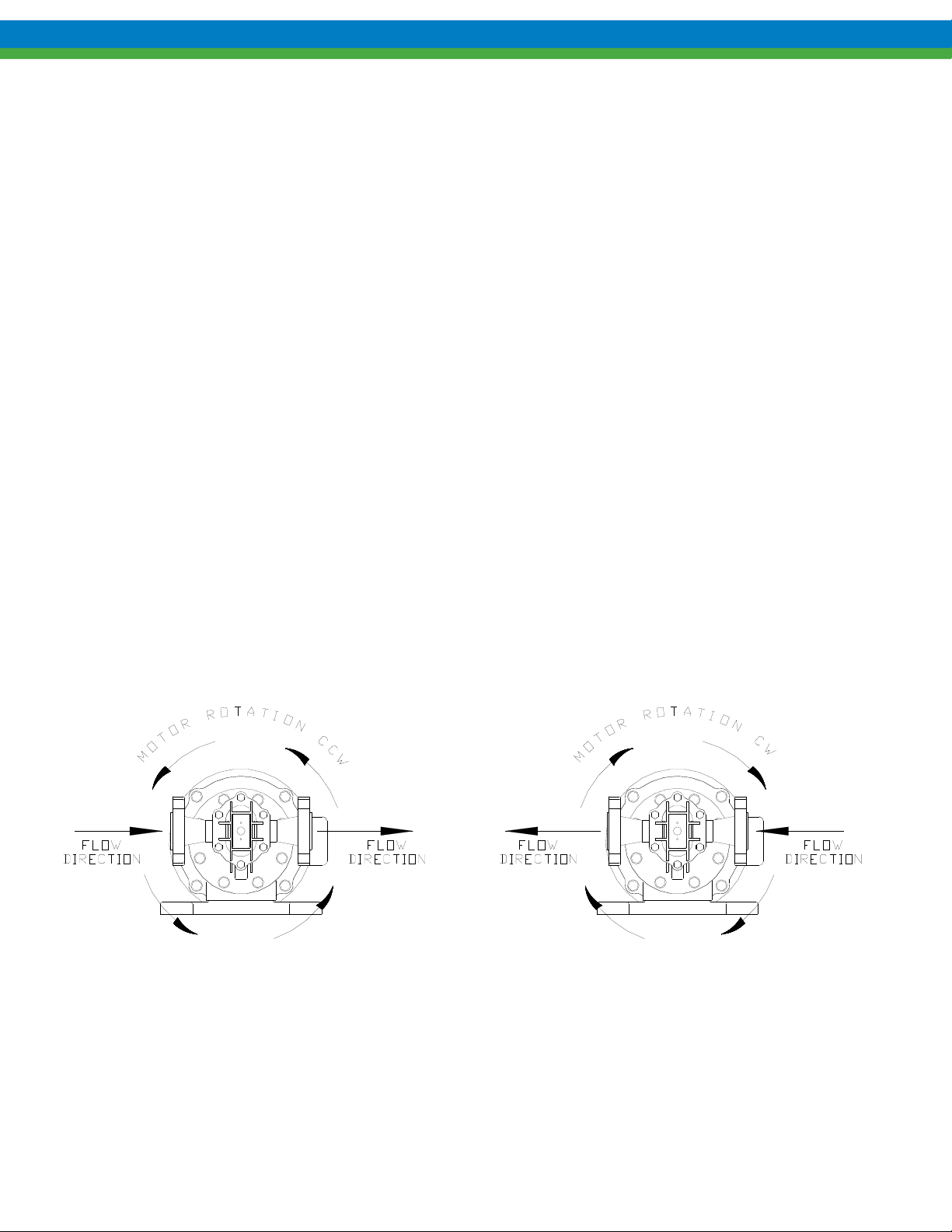

o While looking at the pump from the magnetic drive end, the suction port is to the right when the pump drive

shaft rotates clockwise and is located below the ports. Reversing drive shaft rotation reverses flow and thus

suction and discharge ports. Since the Eclipse Standard/Eclipse Hypo series pumps can be installed both

vertically and horizontally, it is very important to verify proper motor rotation before final piping is

established.

o When installed horizontally, make sure the pump housing drain is on the bottom of the pump. If the pump is

installed with the drain facing upwards, the rotation of the motor will be incorrect and either needs to be

reversed or the pump orientation corrected. Reference the pump drawings in Section 18 of this manual for

drain location.

o Installation of vacuum or pressure gauges in the suction and discharge piping is recommended to properly

monitor system operation.

o Keep suction piping system short and straight to minimize friction loss to the pump. Make sure that the pump

will not run dry. Flooded suction or gravity fed fluid to pump inlet is generally preferred.

o Use only full-bore ball valves or gate valves in the suction piping. If suction strainers are used, size them to

minimize pressure drop and select those of a type that are easily cleaned and maintained.

o Arrange all suction piping and fittings to prevent formation of air pockets. Make sure all joints are airtight.

o Flush and blow out all suction lines prior to mating to pump. Use nipples and unions, for ease of maintenance.

Figure 2a – General Installation

3

Page 10

o Do not force, bend, or spring either suction or discharge piping when mating up to the pump. Use supports or

hangers at intervals as required in an effort to compensate for piping strain due to vector forces and bending

forces. When necessary, install thermal expansion joints or accessories so minimal piping strain is placed

upon the pump.

o Check all bolts and nuts for tightness. Correct any conditions that could cause destructive vibration or

leakage.

o If start-up screens are used, be sure they do not clog and starve suction. Start up screens should be removed

prior to placing system into regular operation.

o If flexible suction lines are used, be sure their selection and installation will prevent wall collapse and thus a

starved suction condition.

o When taking suction from a tank or vessel, avoid entry of sludge or solids into suction line by placing suction

line inlet above maximum expected level of solids.

o Discharge line should be fitted with properly sized pressure relief valve to protect both pump and discharge

system. Pressure relief valve outlet should be piped back to the supply tank.

o When a by-pass system is used to control flow from the pump, the bypassed fluid should be piped back to the

suction vessel to prevent heat build-up due to recirculation cavitation. If it is absolutely necessary to pipe bypass back to the pump suction line, the point of entry should be at least one foot away from the suction inlet.

Provision for cooling should be made in the event of excessive heat buildup through fluid recirculation.

o Where pumped fluids may solidify, cry stallize, or precipitate, provisions should be made to thoroughly flush

pump and piping prior to periods of shutdown. Pay particular attention to proper flushing and draining of the

magnetic coupling area because this area may not completely self drain.

Figure 2b – Flow vs. Motor Rotation

4

Page 11

4. Equipment Setup and Operation

Prior to operation, make sure all suction piping is air tight and clean. Check that electrical service to motor agrees

with nameplate ratings. Jog the motor to check rotation and for signs of binding. To check rotation, observe the

motor fan. Rewire motor if necessary. As noted in Section 3, Installation, Eclipse Standard/Eclipse Hypo Series

pumps are bi-directional, the direction of flow is determined by the direction of motor rotation.

ALTHOUGH THE ECLIPSE STANDARD/ECLIPSE HYPO SERIES PUMPS ARE DESIGNED WITH SOME RUN-

DRY CAPABILITY, IT IS NOT RECOMMENDED THAT ANY MAGNETICALLY DRIVEN PUMP BE RUN DRY. THIS

CONDITION CAN CAUSE SIGNIFICANT TEMPERATURE INCREASES RESULTING IN PREMATURE DAMAGE TO

WEAR SURFACES FROM LACK OF LUBRICATION AND

Pumping fluids containing abrasives should be avoided, as accelerated pump wear will result. Eclipse

Standard/Eclipse Hypo Series gear pumps are designed to handle clear fluids at viscosities up to 10,000 cps.

The pump is designed to self prime if fluid is supplied at the pump inlet. If foot valves are used, the valve should

be of the flapper type and sized to minimize friction loss.

If the pump operates near the boiling point of the pumped fluid, a recirculation loop can be set up between the

discharge and suction connections with provisions for flow control in the recirculation loop.

Power Monitors are strongly recommended for optimum protection of all magnetically driven pumps. Consult

factory for selection and support.

Do not operate the pump against a closed or blocked discharge. Doing so can cause the magnetic drive to

decouple. If decoupling occurs, stop the motor and restart after the obstruction has been cleared.

Operation against closed or blocked discharge can also result in casing pressure that exceeds the pump’s

published safe limits. This can result in damage to the casing parts and/or containment can.

As a safety precaution, a pressure relief valve by-pass system is highly recommended. Ideally, the pressure relief

valve is set for a low pressure at start-up to allow the pump to flood with liquid and evacuate air quickly. It can

then be re-adjusted to a setting appropriate to the application.

Hardware and fasteners can loosen during transportation and installation. All pump hardware should be checked

and verified tight before placing the pump in operation. Consult the table in Section 12 for the recommended

torque values for all pump hardware.

Pump hardware should be checked on a regular basis, especially if the pump is subject to temperature variations

or cycling that might cause it to loosen during operation.

Start pump with discharge and suction valves open and check for proper operation. Excessive noise or vibration

is an indication of harmful cavitation, which may be due to insufficient NPSH (Net Positive Suction Head).

/OR VAPORIZATION OF LIQUID IN THE PUMP.

5

Page 12

5. Maintenance Overview

The timing for maintenance of the pump is established primarily on past performance. Each installation is

different. Therefore, regular inspections, and detailed maintenance records of past performance can be invaluable

for determining future preventative maintenance intervals. For motor maintenance instructions consult the motor

manufacturer.

BEFORE PERFORMING ANY MAINTENANCE REQUIRING PUMP DISASSEMBLY, BE SURE TO FLUSH AND

DRAIN PUMP THOROUGHLY WITH A NEUTRALIZING FLUID

EQUIPMENT WITH PROPER CARE

When changing a pump from one service to another, be sure to check that all wetted parts of the pump are

compatible with the fluid to be handled and that the motor is sufficiently sized for the application. If in doubt

contact your Pulsafeeder representative for assistance.

All magnetic drive couplings have a specific maximum torque limit. If this torque is exceeded

the drive will decouple. Operation in the decoupled mode should be avoided as high

temperatures could be generated.

.

. WEAR PROTECTIVE CLOTHING AND HANDLE

Whenever gear pumps exhibit reduced flow rates, inability to maintain pressures, noisy or otherwise abnormal

operation, first refer to the troubleshooting section at the end of this manual. If the problem cannot be resolved the

pump must be inspected for wear or damage. Eclipse Standard/Eclipse Hypo Series gear pumps can be easily

opened for cleaning and inspection without disturbing piping connections by removing the pump front housing

cover.

Where inspection shows wear, rebuilding the pump using a KOPKit is strongly recommended. Quite often,

original hydraulic performance can be restored by simply changing the KOPKit alone.

Magnets (both drive and driven) can attract small particles of debris during handling. Always visually

inspect the magnetic parts of the pump for cleanliness during re-assembly. Wipe carefully to remove

debris, particles, or other small parts without damaging the surface of the magnets.

6

Page 13

5.1 Recommended Spares

KOPKits – The basic Eclipse Standard/Eclipse Hypo Series KOPKit consists of the following parts, which are

recommended as typical spare parts. The KOPKit provides an easy means to keep the right parts for your Eclipse

Standard/Eclipse Hypo Series pump close at hand.

Drive Gear and Shaft Assembly 1 each

Idler Gear and Shaft Assembly 1 each

Housing Liner 1 each

Bearings 2 each

O-Rings 3 or 4 each

The model number stamped on the pump nameplate identifies the pump type and other details. Refer to the model

number chart if you are unsure of exactly what type of pump you have, or when ordering parts or KOPKits.

Always refer to the full model and serial number in

Drawings and consolidated bill of materials for each size pump are included in this manual. Recommended spare

parts are identified on the consolidated bill of materials.

any correspondence with your Pulsafeeder representative.

5.2 Maintenance precautions for magnet-driven equipment:

Non-magnetic tools and non-magnetic work surfaces are recommended to perform any disassembly or

maintenance of the pump.

Do not wear a wristwatch in the vicinity of the drive or driven magnets, wristwatches may be damaged

by the transmission of magnetic flux.

The strong magnetic field will damage credit cards, security badges, or other magnetic data strips.

Keep them a safe distance from the magnets.

Take precautions in handling pump magnets if you have prosthetic devices, metal or medical inserts

installed in your body. Consult your physician for guidance in handling magnets.

Completely flush and drain pump prior to pump disassembly.

The exposed magnets on the drive magnet assembly are very fragile and will chip easily. Use extreme

care in handling them.

Take care to avoid magnetic particles or objects from attaching themselves to the drive magnets. It is

difficult to remove small particles, and larger objects could be attracted with enough force to break the

magnets.

BE CAREFUL DURING DISASSEMBLY AND REASSEMBLY OF THE DRIVE AND DRIVEN MAGNET

ASSEMBLIES

CLOSE TOGETHER THERE IS A STRONG TENDENCY TO SNAP TOGETHER SUDDENLY

CAUSING INJURY TO FINGERS OR FLESH

. THE MAGNETIC ATTRACTION FORCES ARE HIGH, AND WHEN THE MAGNETS COME

D

O NOT MACHINE THE MAGNETS OR MAGNET CARRIERS IN THE DRIVE OR DRIVEN MAGNET

ASSEMBLIES

. THE MAGNETIC DUST THAT WOULD BE PRODUCED IS HIGHLY FLAMMABLE.

, POTENTIALLY

.

7

Page 14

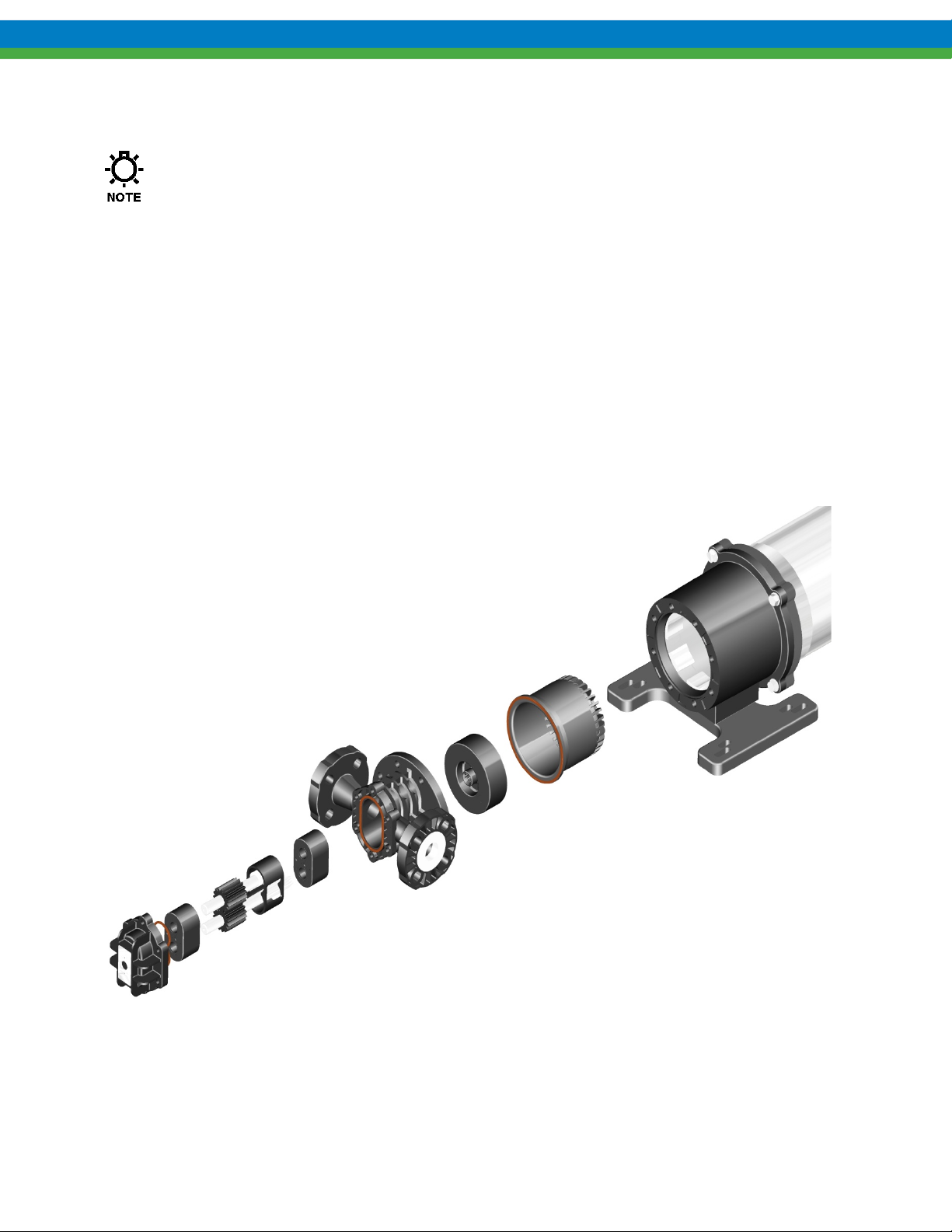

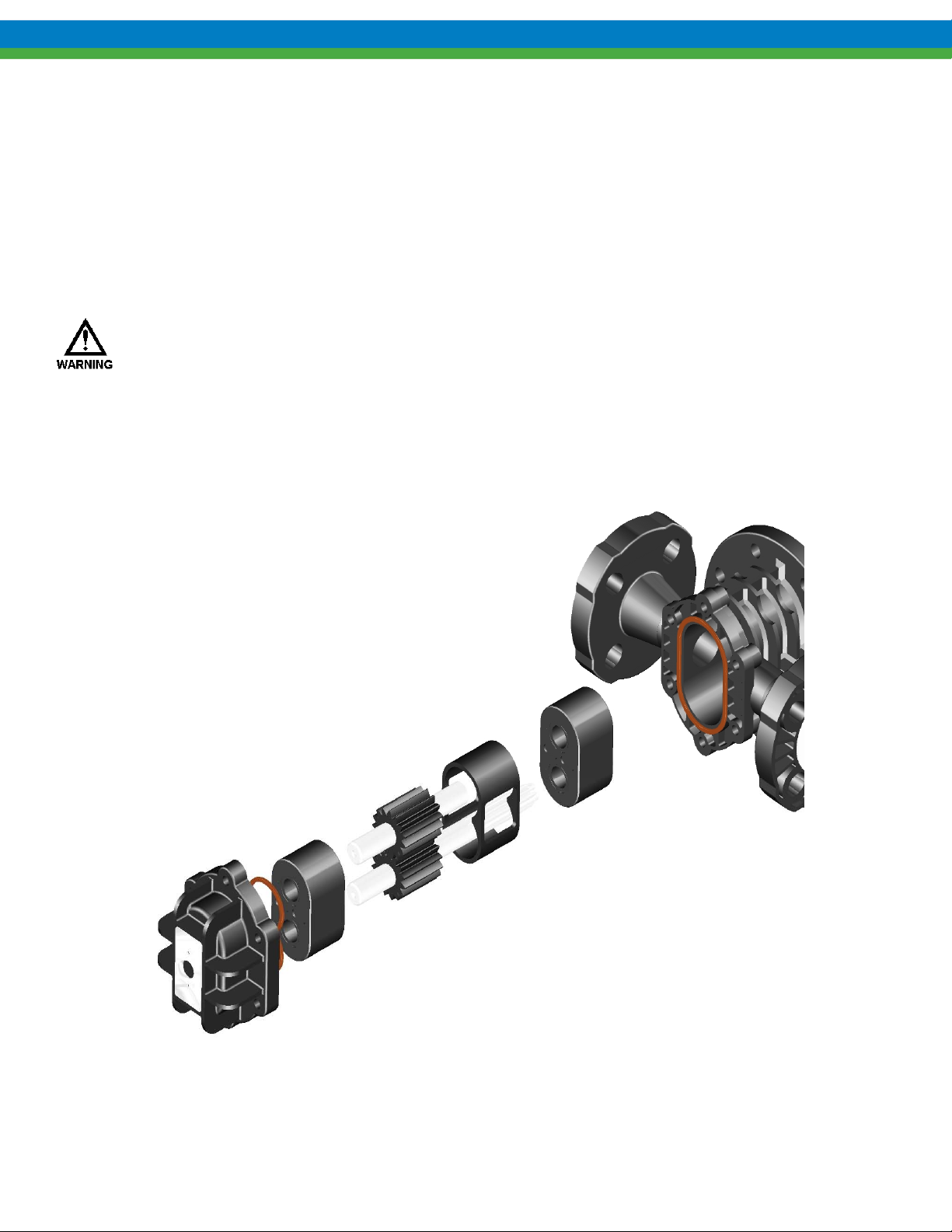

5.3 KOPKit Maintenance, All Models

All Eclipse Standard/Eclipse Hypo gear pumps are designed for easy access to the regularly serviced internal

components. These components are part of the KOPKit described in Section 5.1.

The KOPKit for an Eclipse Standard/Eclipse Hypo pump can be installed without removing the pump from

service. The pump can be disassembled in the horizontal position while still connected to the process lines.

Special precautions must be taken to ensure the pump is safe to work on.

BEFORE PERFORMING ANY MAINTENANCE REQUIRING PUMP DISASSEMBLY, BE SURE TO RELIEVE

PRESSURE FROM THE PIPING SYSTEM

SHUTOFF

RENDER THE PUMP SAFE TO PERSONNEL AND THE ENVIRONMENT BY CLEANING AND CHEMICALLY

NEUTRALIZING AS APPROPRIATE

The following sections of the IOM review disassembly and assembly of the Eclipse Standard/Eclipse Hypo pump

on the service bench. If you are working on your Eclipse Standard/Eclipse Hypo pump in the field, the same

procedures are used except that your pump will be horizontally mounted, whereas the illustrations in the IOM

sections show the pumps in a vertical position.

/BLOCKING DEVICES, AND, WHERE HAZARDOUS PROCESS MATERIALS ARE INVOLVED,

, ISOLATE THE PUMP FULLY USING THE APPROPRIATE

. WEAR PROTECTIVE CLOTHING AND EQUIPMENT AS REQUIRED.

Figure 3

8

Page 15

6. Disassembly/Assembly, Eclipse Standard/Eclipse Hypo 02

BEFORE PERFORMING ANY MAINTENANCE REQUIRING PUMP DISASSEMBLY, BE SURE TO RELIEVE

PRESSURE FROM THE PIPING SYSTEM AND

RENDER THE PUMP SAFE TO PERSONNEL AND THE ENVIRONMENT BY CLEANING AND CHEMICALLY

NEUTRALIZING AS APPROPRIATE

. WEAR PROTECTIVE CLOTHING AND EQUIPMENT AS APPROPRIATE.

, WHERE HAZARDOUS PROCESS MATERIALS ARE INVOLVED,

6.1 Disassembly

Close all suction and discharge valves.

Disconnect power source to motor.

Flush and drain pump

Remove piping (optional for KOPKit).

NOTE: The can area will not fully drain and will contain some process fluid.

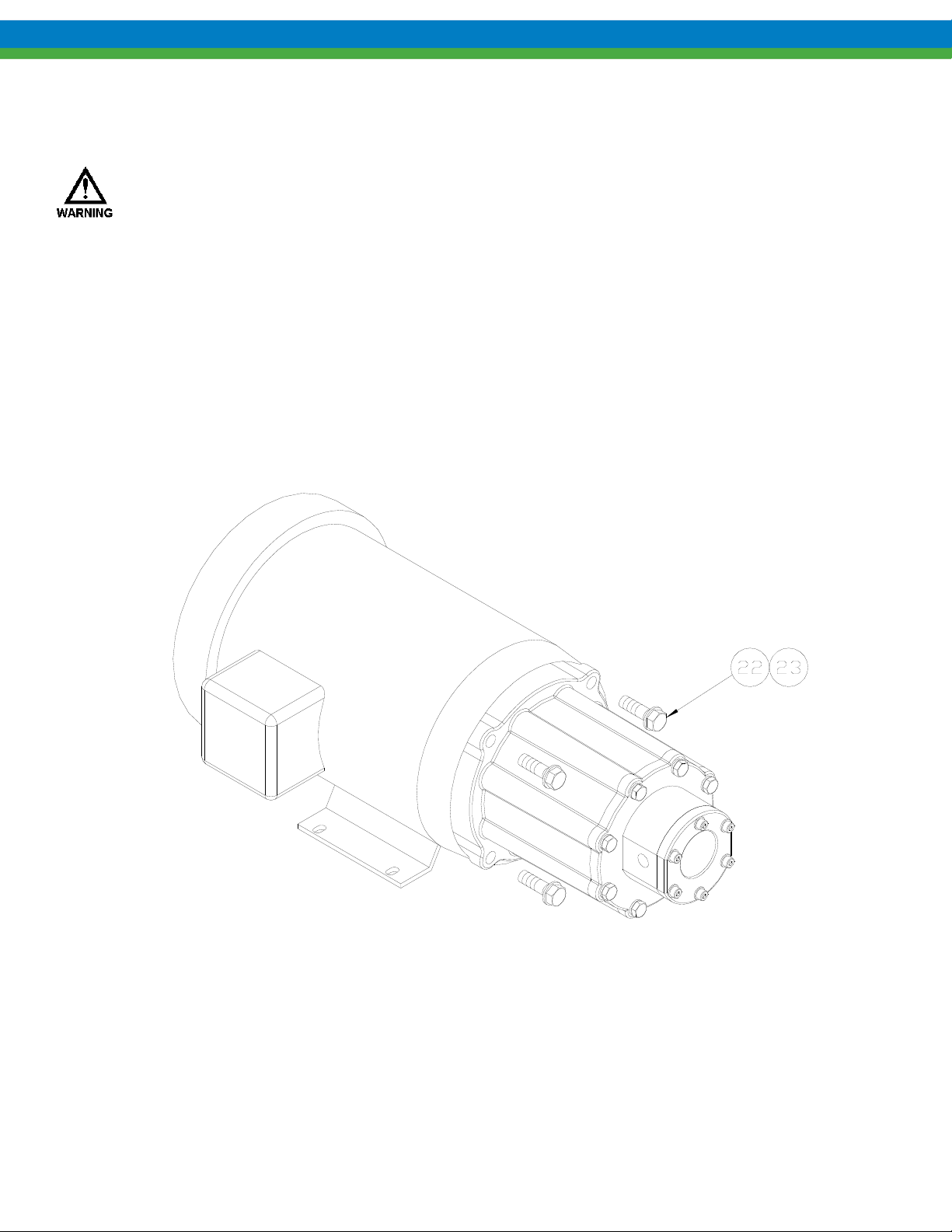

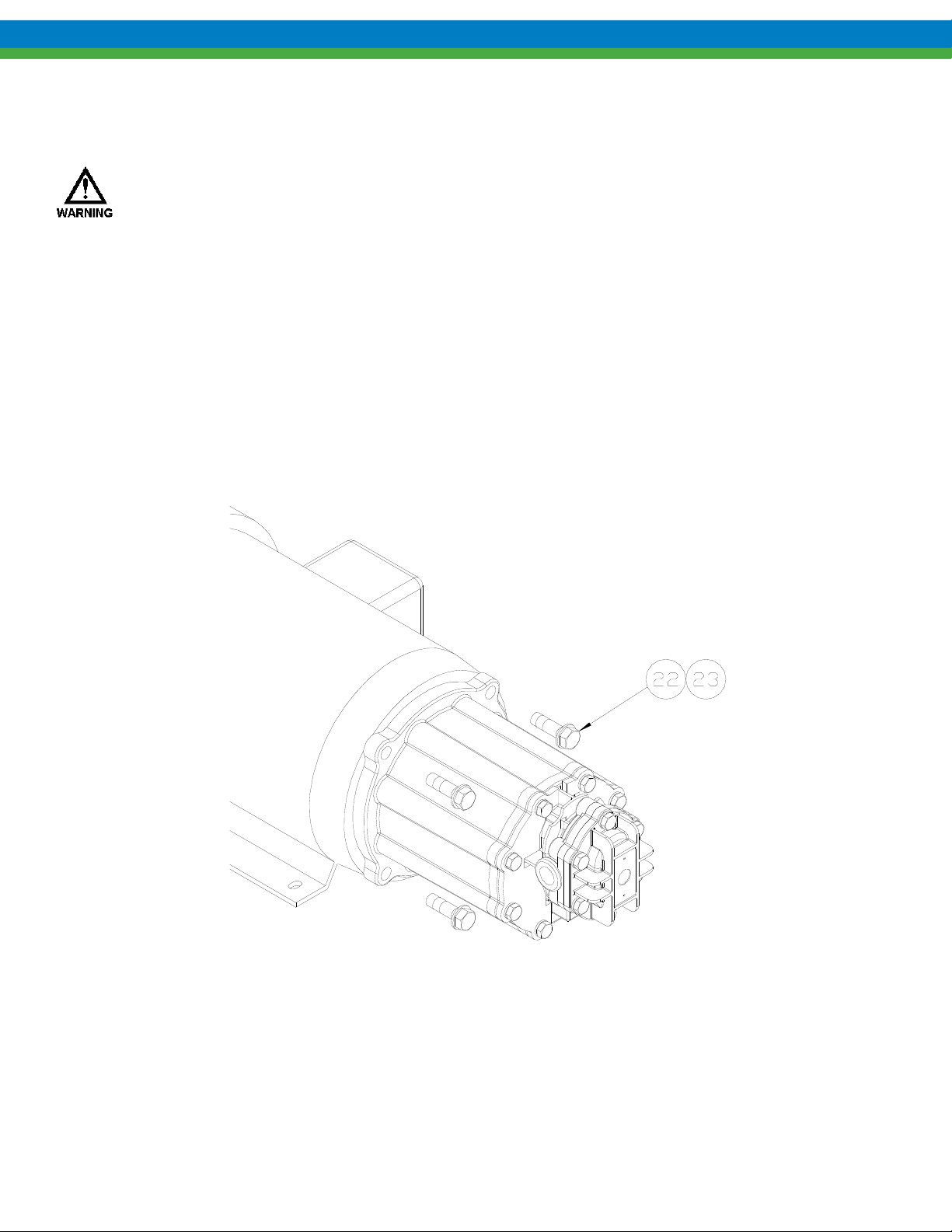

1. Remove the four motor bolts and washers (items 22, 23) and slide the entire pump straight off the motor.

Figure 4

2. Place pump assembly (motor spool down) on the work surface.

9

Page 16

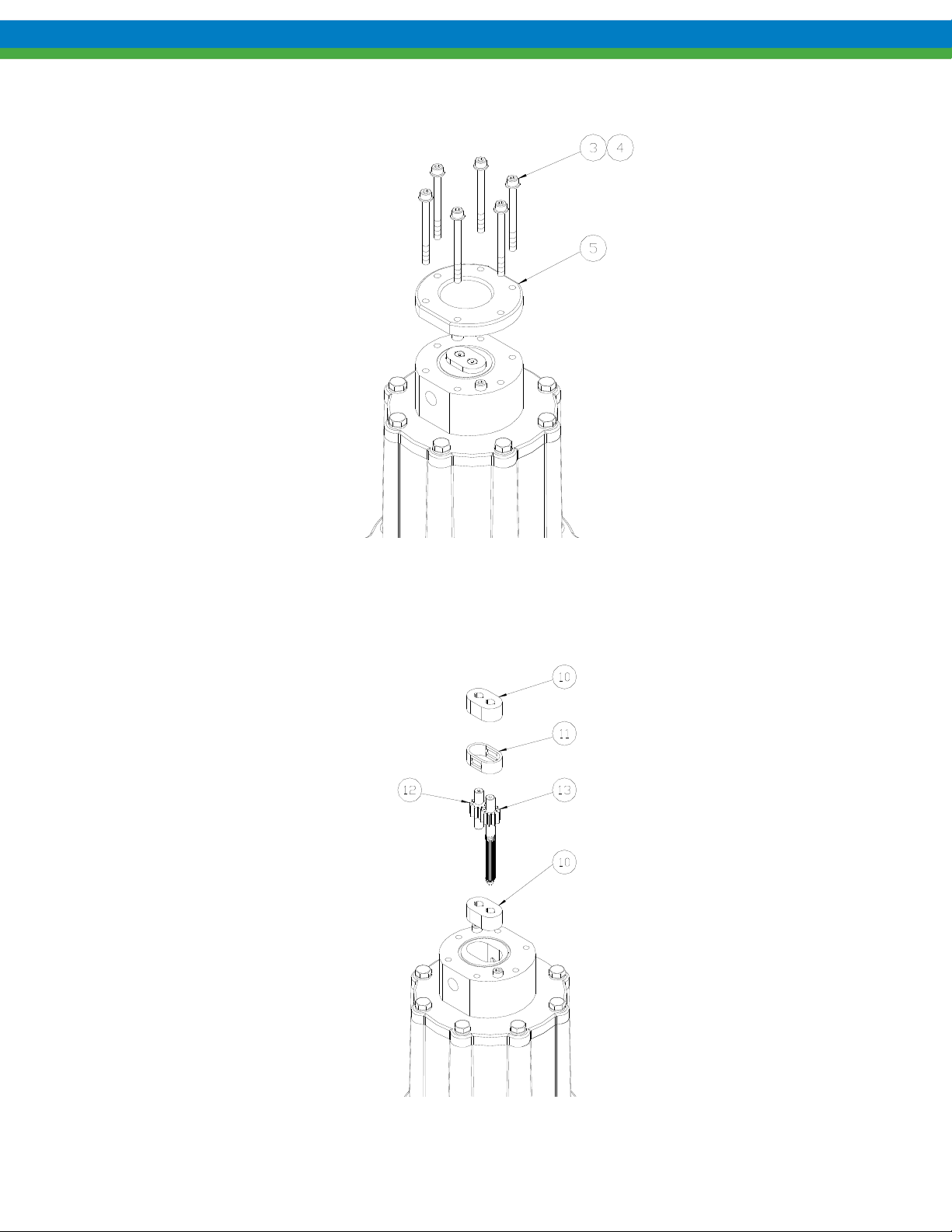

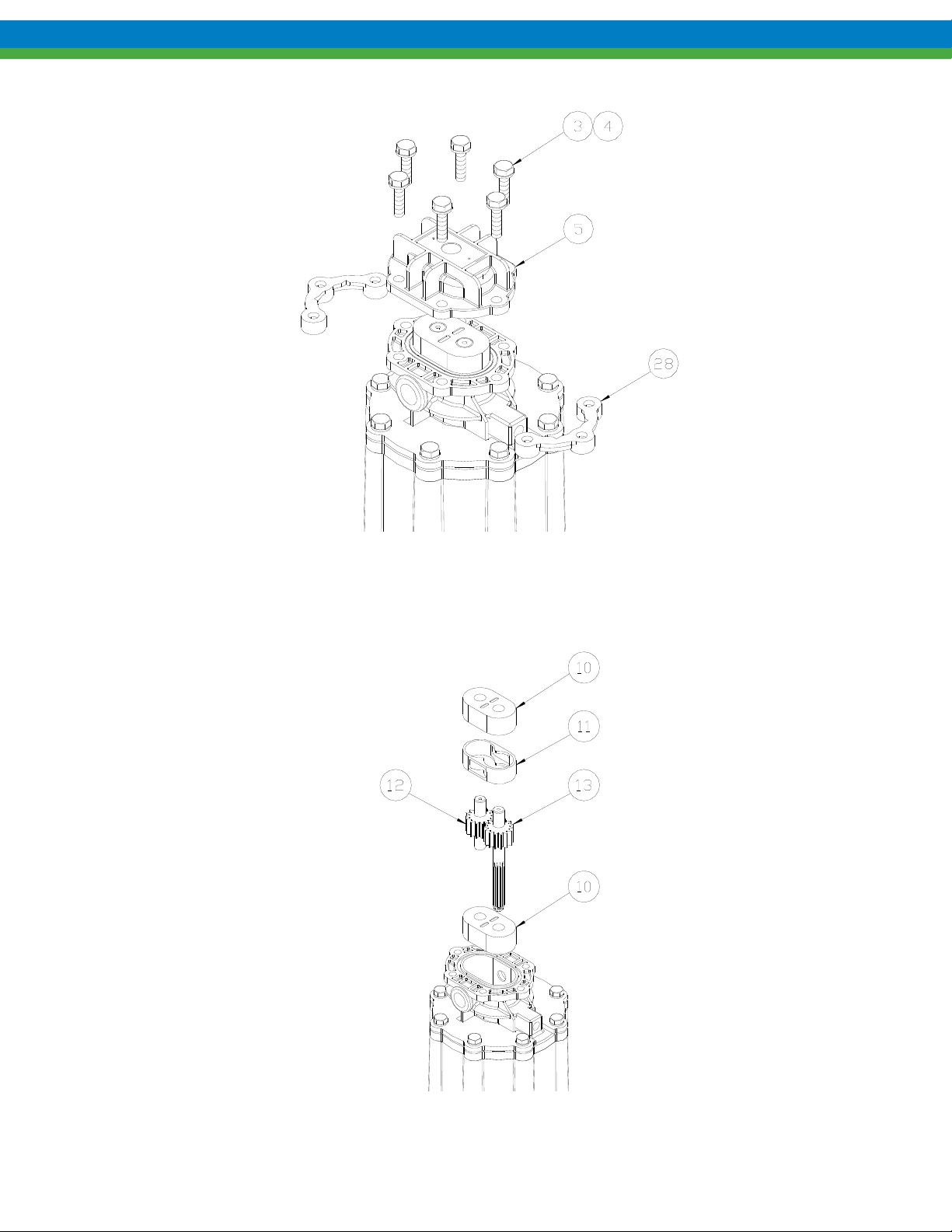

3. Remove the six bolts and flat washers (items 3, 4) and remove front cover (item 5) as shown.

Figure 5

4. Remove bearings (item 10), gear/shaft assemblies (items 12, 13) and housing liner (item11) as shown. These

parts, along with the three o-rings make up a standard Eclipse Standard/Eclipse Hypo Series KOPKit. Check

parts for wear and replace with a KOPKit as required.

Figure 6

10

Page 17

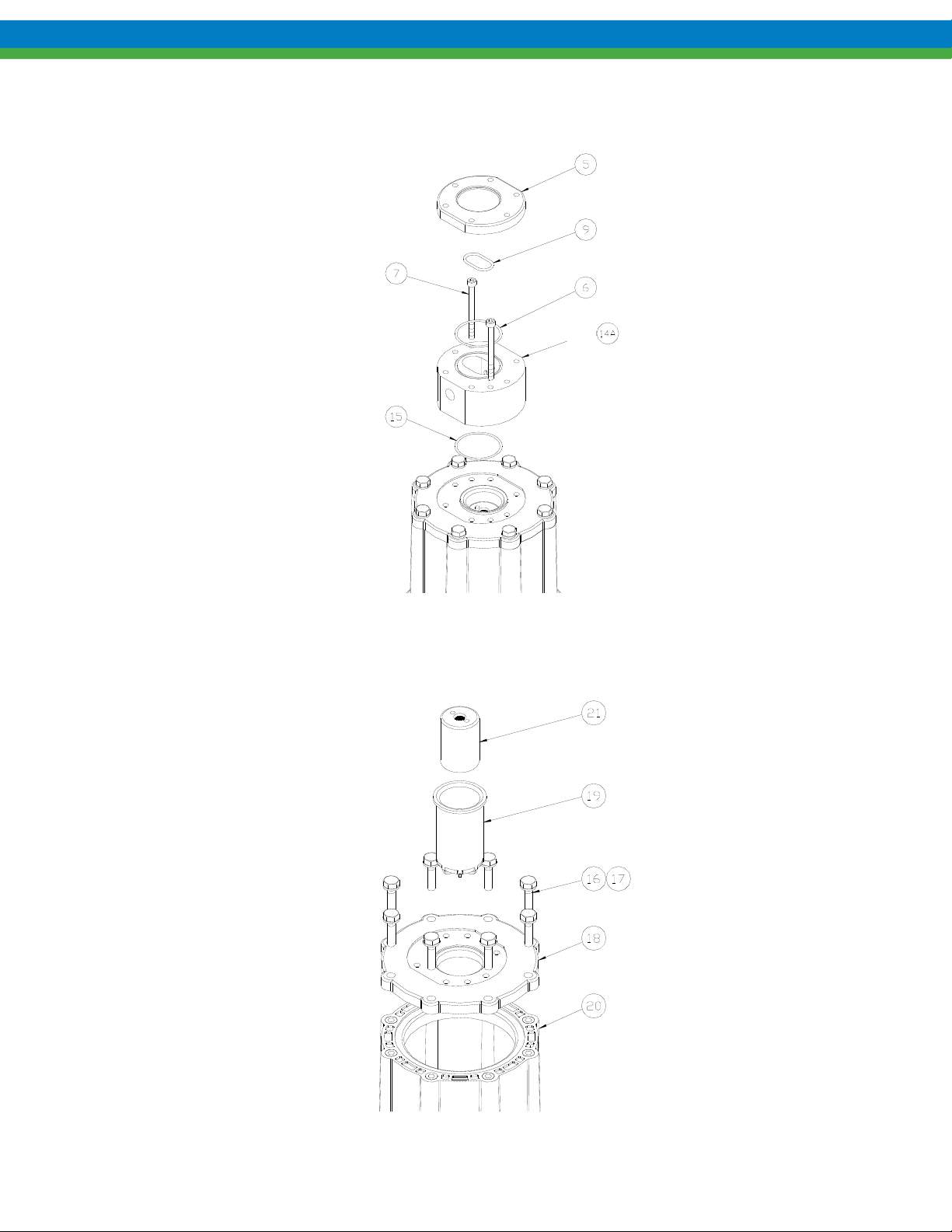

5. Remove the two remaining bolts (item 7) to detach the center housing (item 14).

6. Remove all o-rings from the center housing and front cover. There are two in the center housing (items 6 and 15)

and one in the front cover (item 9) as shown.

Figure 7

7. Remove the eight mounting bolts and washers (items 16, 17) holding the adapter plate (item 18) to the motor

spool (item 20) and detach the adapter plate.

8. Remove driven magnet assembly (item 21) and containment can (item 19) from adapter plate as shown.

Figure 8

11

Page 18

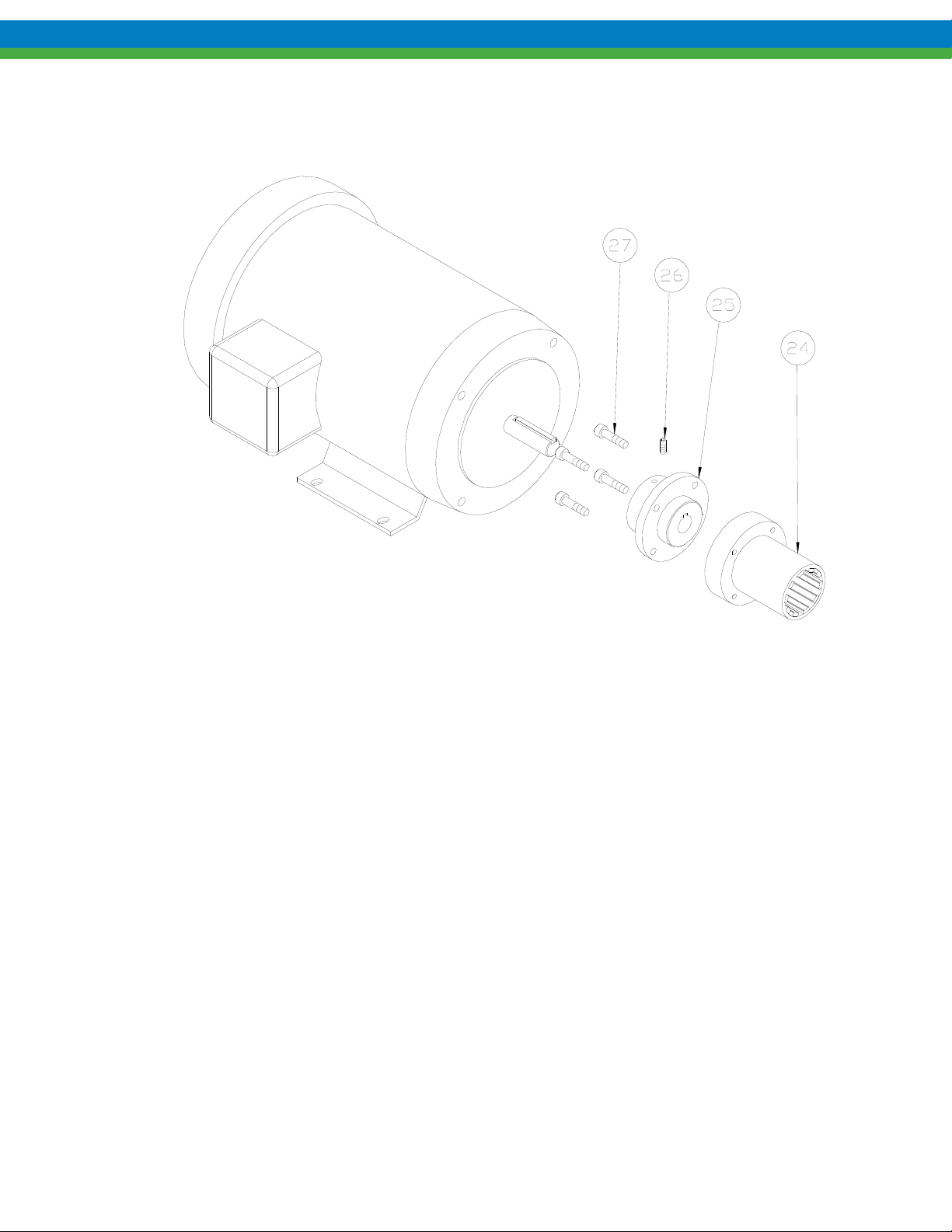

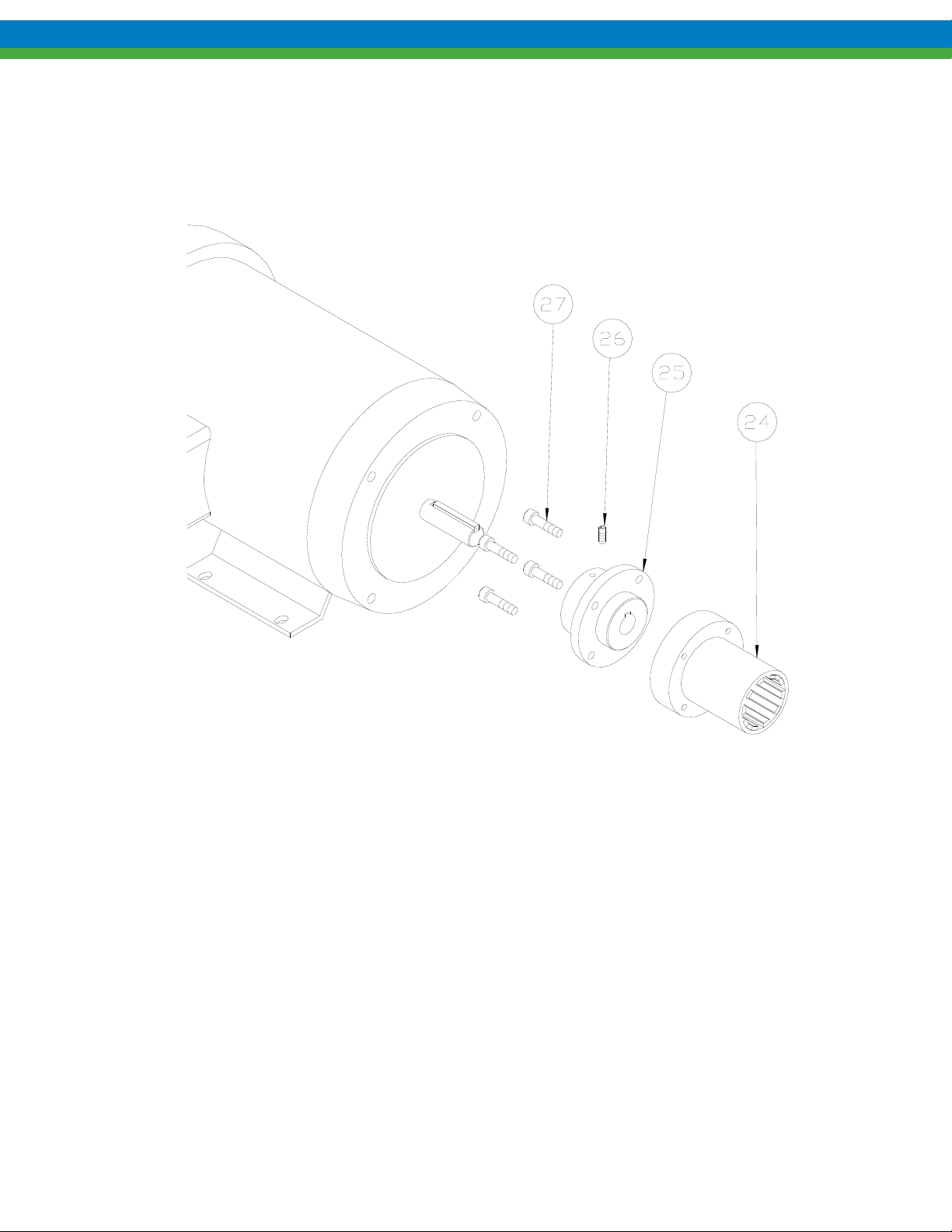

9. Remove drive magnet assembly (item 24) from the motor by loosening the setscrew (item 26) in the magnet hub

and slide off the motor shaft. Retain the key from the motor shaft.

10. If required, the magnet hub (item 25) can be separated from the drive magnet (item 24) by removing the four

screws (item 27) and detaching.

6.2 Inspection

Refer to Section 9, Inspection and Wear Limits, for details.

Figure 9

12

Page 19

6.3 Assembly

1. Place motor spool (item 20) flat on work surface. Align “molded-in” flats on the spool adapter plate (item 18)

with any two of the motor mounting bolt holes on the motor spool as shown.

2. Set in place and install eight mounting bolts and washers (items 16, 17). Tighten these bolts to the torque

specified in Section 12. Always tighten fasteners in a progressive “crisscross” pattern.

3. Install the containment can (item 19) into the spool adapter plate until it is properly seated into the assembly.

4. Install the driven magnet assembly (item 21) into the containment can. The driven magnet is symmetrical and can

be inserted with either end facing out (orientation does not matter).

Figure 10

5. Inspect all o-rings to be sure there is no damage such as pinching prior to assembly.

13

Page 20

6. Install o-rings (items 6, 15) into grooves on both sides of the center housing. Some o-ring lubricant may help

keep the o-rings in place during assembly. Be sure both o-rings are fully seated into housing grooves.

Figure 11

7. Place the center housing (item 14) with o-rings installed onto the spool adapter plate (open bore facing out),

aligning the flat sides on the center housing to the flat sides on the spool adapter plate as shown. If the center

housing does not sit flat, rotate 180º until it seats into place.

8. Secure the center housing using 2 bolts (item 7) in holes as shown. Tighten these bolts to the torque specified in

Section 12. Always tighten fasteners in a progressive “crisscross” pattern.

Figure 12

14

Page 21

9. Insert a bearing (item 10) into the center housing (item 14) and slide to the bottom of the housing. Bearings are

symmetrical and orientation does not matter.

10. Install the housing liner (item 11) and slide until it seats against the first bearing. Install the idler gear (item 12)

into the top hole in bearing until the gear seats against the first bearing.

11. Install the drive gear (item 13), splined-end first, into the assembly until it bottoms out against the bearing. The

shaft may have to be rotated slightly to properly fit the splined-end into the drive magnet and gear to the idler gear

assembly.

12. Insert the second bearing (item 10) into the housing bore until it rests against the housing liner. Bearings are

symmetrical and orientation does not matter.

Figure 13

13. Install the spacer o-ring (item 9) into front cover as shown. Some o-ring lubricant may help keep the o-rings in

place during assembly.

Figure 14

15

Page 22

14. Install front cover with spacer o-ring using the six bolts and washers. Tighten these bolts to the torque specified

in Section 12. Always tighten fasteners in a progressive “crisscross” pattern.

Figure 15

15. For IEC frame motors only, if it was removed, install the motor adaptor plate (item 31) onto the motor face using

the four bolts and washers (items 29 and 30). Always tighten fasteners in a progressive “crisscross” pattern.

Figure 16

16

Page 23

16. Secure the magnet hub (item 25) to the drive magnet (item 24) using the four screws (item 27). Always tighten

fasteners in a progressive “crisscross” pattern.

Figure 17

17

Page 24

17. Align the keyway, and slide the drive magnet onto the motor shaft until the end of the motor shaft aligns with

faces of the drive magnet motor hub as shown below. Secure with the setscrew (item 26). Application of a noseize compound on the shaft and key will make future maintenance easier.

18. Complete assembly by replacing the assembled pump onto the motor, using care not to allow fingers to get

pinched when the magnets attract. Secure the pump to the motor with the four bolts and washers (items22, 23).

Always tighten fasteners in a progressive “crisscross” pattern.

Figure 18

18

Page 25

7. Disassembly/Assembly, Eclipse Standard/Eclipse Hypo 05/12

BEFORE PERFORMING ANY MAINTENANCE REQUIRING PUMP DISASSEMBLY, BE SURE TO RELIEVE

PRESSURE FROM THE PIPING SYSTEM AND

RENDER THE PUMP SAFE TO PERSONNEL AND THE ENVIRONMENT BY CLEANING AND CHEMICALLY

NEUTRALIZING AS APPROPRIATE

. WEAR PROTECTIVE CLOTHING AND EQUIPMENT AS APPROPRIATE.

, WHERE HAZARDOUS PROCESS MATERIALS ARE INVOLVED,

7.1 Disassembly

Close all suction and discharge valves.

Disconnect power source to motor.

Flush and drain pump

Remove piping (optional for KOPKit).

NOTE: The can area will not fully drain and will contain some process fluid.

1. Remove the four motor bolts and washers (items 22, 23) and slide the entire pump straight off the motor.

Figure 19

2. Place pump assembly (motor spool down) on the work surface.

19

Page 26

3. Remove the six bolts and washers (items 3, 4), remove front cover (item 5) and nut plates (item 28) as shown.

Figure 20

4. Remove bearings (item 10), gear/shaft assemblies (items 12, 13) and housing liner (item 11) as shown. These

parts, along with the four o-rings make up a standard Eclipse Standard/Eclipse Hypo Series KOPKit. Check parts

for wear and replace with a KOPKit as required.

Figure 21

20

Page 27

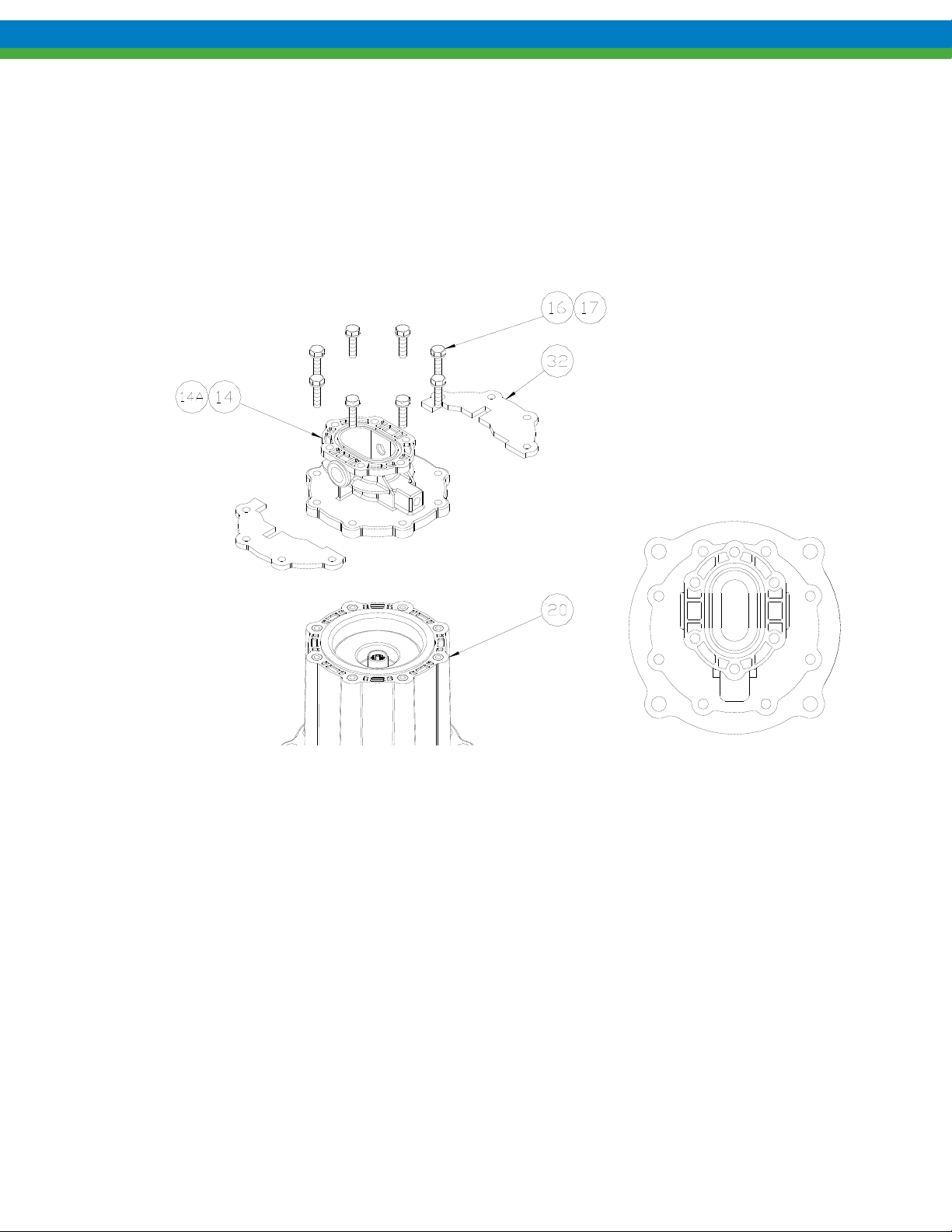

5. Remove the eight mounting bolts and washers (items 16, 17) holding the center housing (item 14) to the motor

spool (item 20). Remove the center housing and retaining plates (item 32).

6. Remove all o-rings from the center housing and front cover. There are two o-rings in the center housing (items 6,

15) and one in the front cover (item 9) as shown.

Figure 22

7. Remove driven magnet assembly (item 21) and containment can (item 19) from the motor spool (item 20) as

shown.

Figure 23

21

Page 28

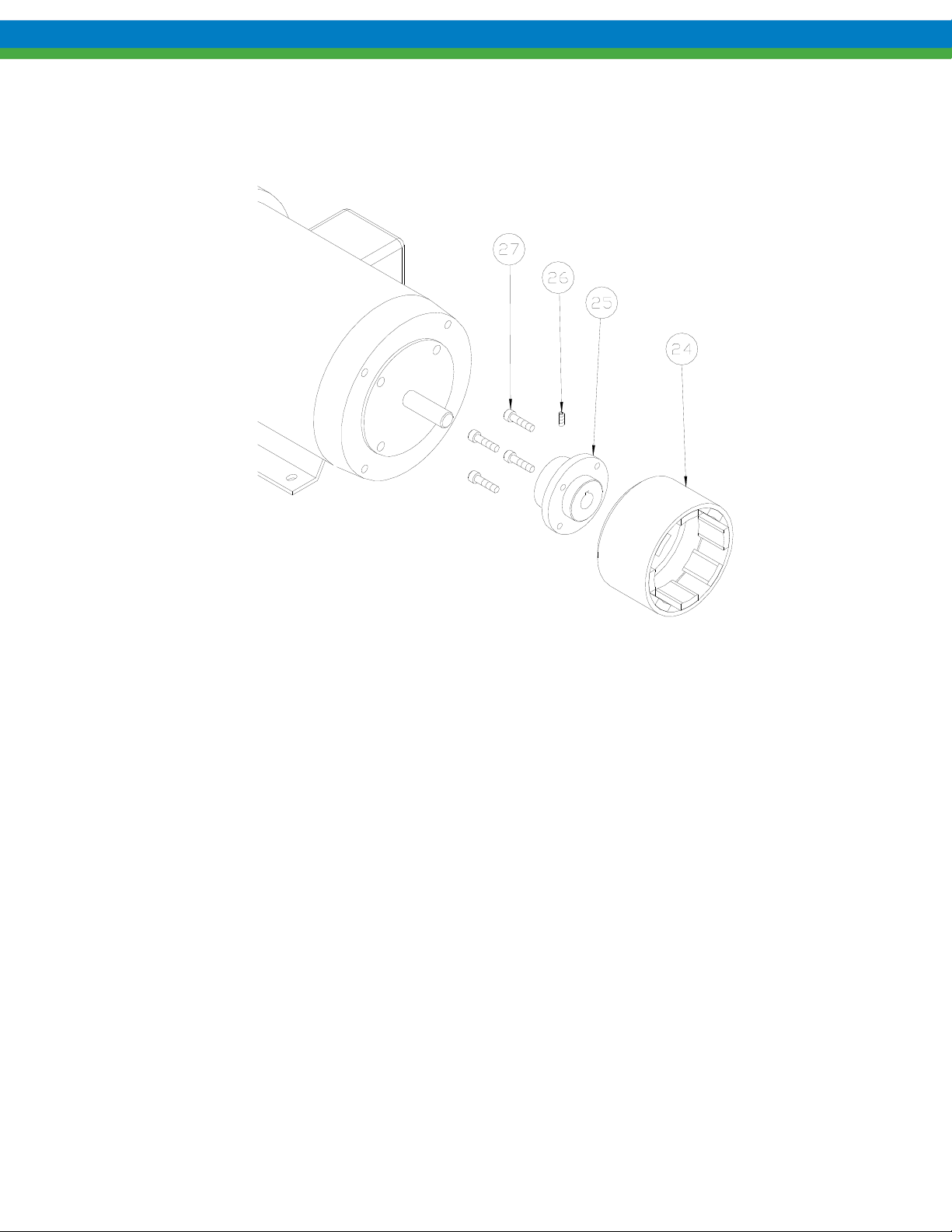

8. Remove drive magnet assembly from the motor by loosening the setscrew (item 26) in the magnet hub (item 25)

and slide off the motor shaft. Retain the key from the motor shaft.

9. If required, the magnet hub (item 25) can be separated from the drive magnet (item 24) by removing the four

screws (item 27) and detaching.

7.2 Inspection

Refer to Section 9, Inspection and Wear Limits, for details.

Figure 24

22

Page 29

7.3 Assembly

1. Place motor spool (item 20) flat on work surface.

2. Insert the containment can (item 19) and driven magnet (item 21) into the motor spool as shown. The driven

magnet is symmetrical and orientation does not matter.

Figure 25

3. Inspect all o-rings to be sure there is no damage such as pinching prior to assembly.

Figure 26

23

Page 30

4. Install o-rings (items 6, 15) into each side of the center housing (item 14) as shown. Some o-ring lubricant

may help keep the o-rings in place during assembly. Be sure both o-rings are fully seated into housing

grooves.

5. Place the center housing, with o-rings, onto the motor spool, aligning the port connections between any set of

motor spool bolt holes as shown. Add the retaining plates (item 32). Secure with eight bolts and washers

(items 16, 17). Tighten these bolts to the torque specified in Section 12. Always tighten fasteners in a

progressive “crisscross” pattern.

Figure 27

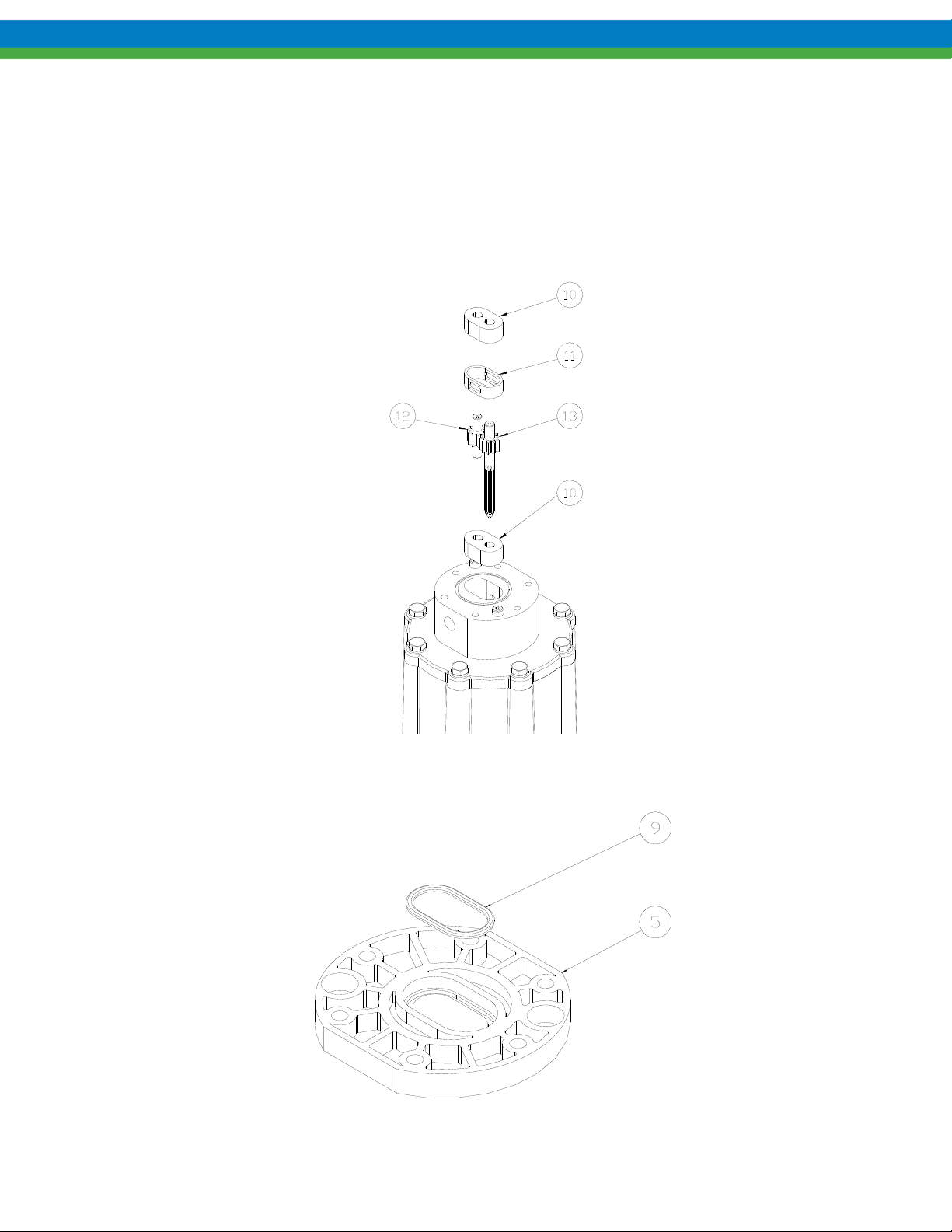

6. Insert a bearing (item 10) into center housing and slide to bottom of bore. Bearings are symmetrical and

orientation does not matter. Install the housing liner (item 11) and slide until it seats against the first bearing.

Install idler gear (item 12) into the top hole in bearing until the gear seats against the first bearing.

7. Install the drive gear (item 13), splined-end first, into the assembly until it bottoms out against the bearing.

The shaft may have to be rotated slightly to properly fit the splined-end into the drive magnet and mesh gear

teeth with the idler gear.

24

Page 31

8. Insert the second bearing (item 10) into the housing bore until it rests against the housing liner. Bearings are

symmetrical and orientation does not matter.

Figure 28

9. Install the spacer o-ring (item 9) into the front cover (item 5) as shown. Some o-ring lubricant may help keep

the o-rings in place during assembly.

Figure 29

25

Page 32

10. Place the front cover (item 5) with o-ring onto the assembled pump. Secure the front cover using the six bolts

and washers (items 3, 4) and two nut plates (item 28) as shown. The flat side of the nut plates mate against

the back of the center housing flange. Tighten these bolts to the torque specified in Section 12. Always

tighten fasteners in a progressive “crisscross” pattern.

Figure 30

11. For IEC frame motors only, if it was removed, install the motor adaptor plate (item 31) onto the motor face

using the four bolts and washers (items 29 and 30). Always tighten fasteners in a progressive “crisscross”

pattern.

Figure 31

26

Page 33

12. Secure the magnet hub (item 25) to the drive magnet (item 24) using the four screws (item 27). Always

tighten fasteners in a progressive “crisscross” pattern.

Figure 32

27

Page 34

13. Align the keyway, and slide the drive magnet onto the motor shaft until the end of the motor shaft aligns with

faces of the drive magnet motor hub as shown below. Secure with the setscrew (item 26). Application of a noseize compound on the shaft and key will make future maintenance easier.

14. Complete assembly by replacing the assembled pump onto the motor, using care not to allow fingers to get

pinched when the magnets attract. Secure the pump to the motor with the four bolts and washers (items

22,23). Always tighten fasteners in a progressive “crisscross” pattern.

Figure 33

28

Page 35

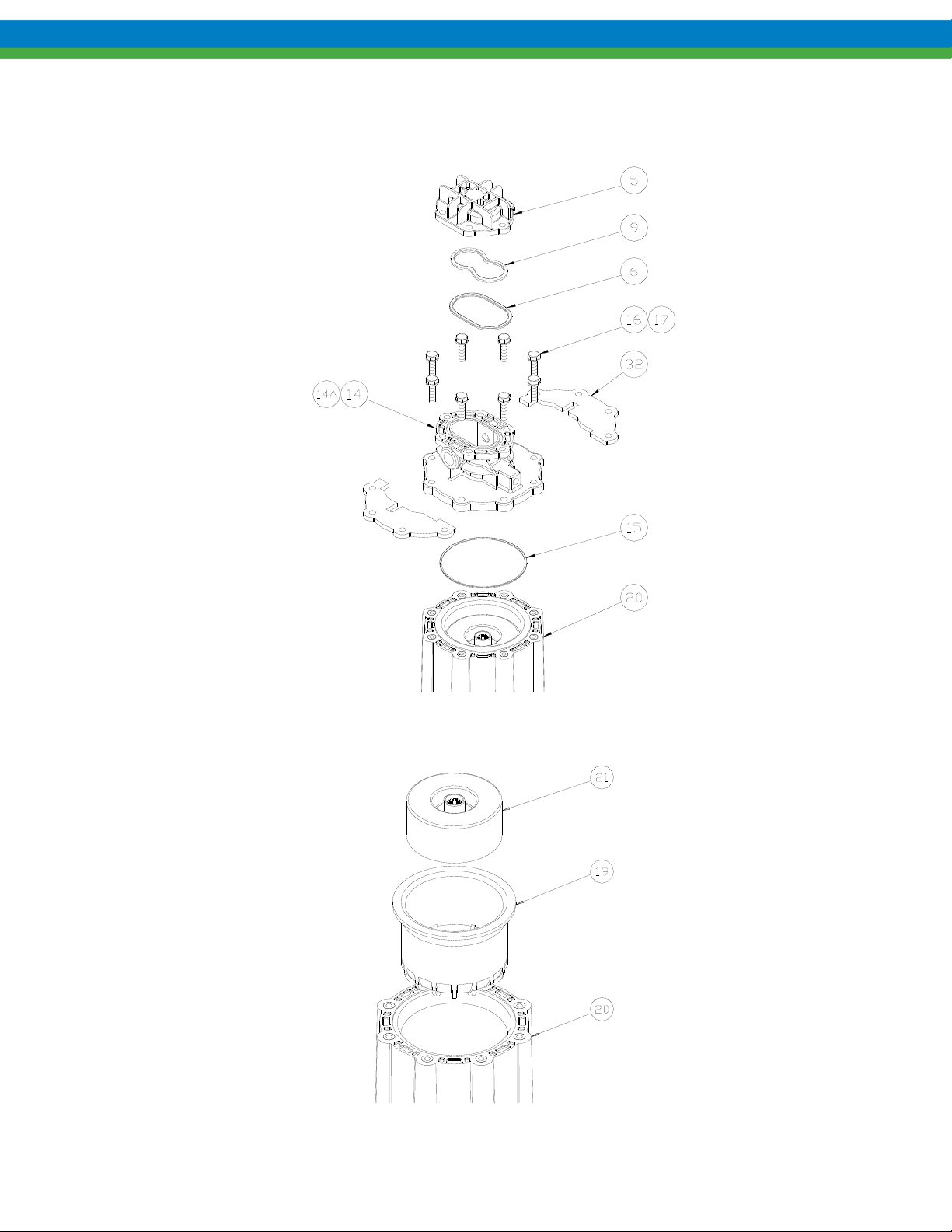

8. Disassembly/Assembly, Eclipse Standard/Eclipse Hypo 25/75/125

BEFORE PERFORMING ANY MAINTENANCE REQUIRING PUMP DISASSEMBLY, BE SURE TO RELIEVE

PRESSURE FROM THE PIPING SYSTEM AND

RENDER THE PUMP SAFE TO PERSONNEL AND THE ENVIRONMENT BY CLEANING AND CHEMICALLY

NEUTRALIZING AS APPROPRIATE

. WEAR PROTECTIVE CLOTHING AND EQUIPMENT AS APPROPRIATE.

, WHERE HAZARDOUS PROCESS MATERIALS ARE INVOLVED,

8.1 Disassembly

Close all suction and discharge valves.

Disconnect power source to motor.

Flush and drain pump

Remove piping (optional for KOPKit).

NOTE: The can area will not fully drain and will contain some process fluid

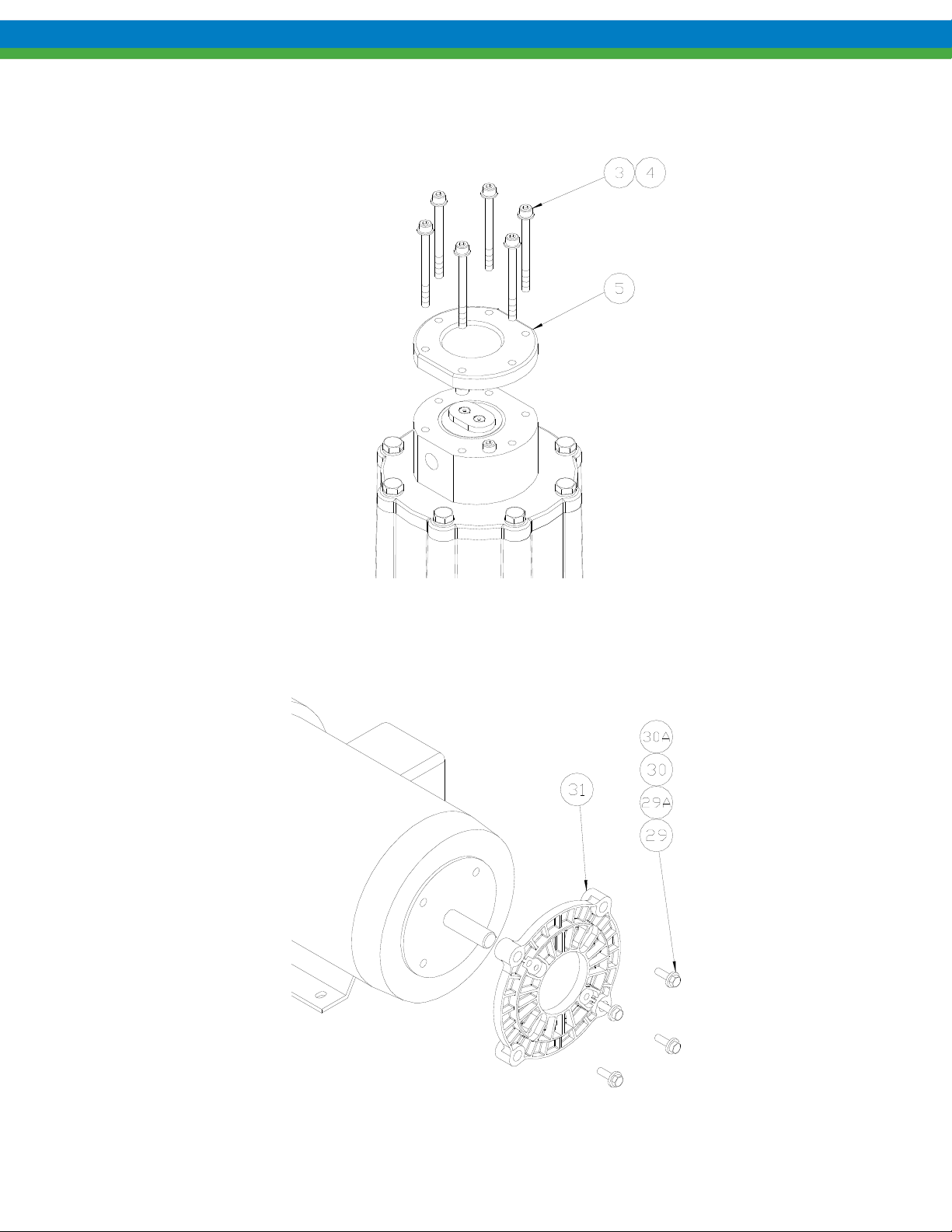

1. Remove the four motor bolts and washers (items 22, 23) and slide the entire pump straight off the motor.

Figure 34

2. Place pump assembly (motor spool down) on the work surface.

3. Remove the six bolts and washers (items 3, 4), remove front cover (item 5) and nut plates (item 28) as shown.

4. If required, the mounting base (item 32) can be detached by removing the four bolts and washers (items 33,

34) as shown.

29

Page 36

Figure 35

5. Remove bearings (item 10), gear/shaft assemblies (items 12, 13) and housing liner (item 11) as shown. These

parts, along with the four o-rings make up a standard Eclipse Standard/Eclipse Hypo Series KOPKit. Check

parts for wear and replace with a KOPKit as required.

Figure 36

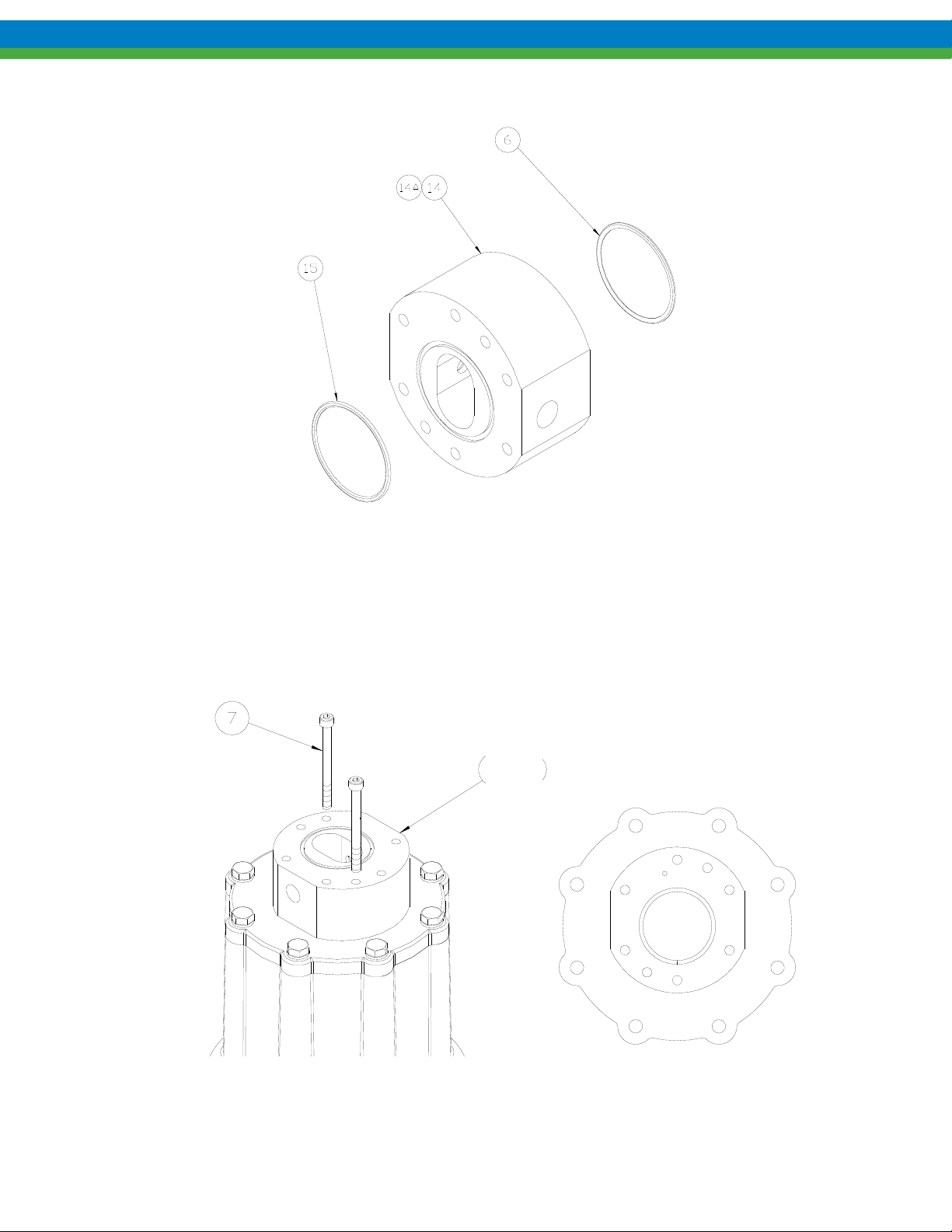

6. Remove the eight mounting bolts and washers (items 16, 17) holding the center housing (item 14) to the

motor spool (item 20). Detach the center housing and retaining plates (item 35).

7. Remove all o-rings from the center housing and front cover. There is one o-ring in the center housing (item

15) and two in the front cover (items 6, 9) as shown.

30

Page 37

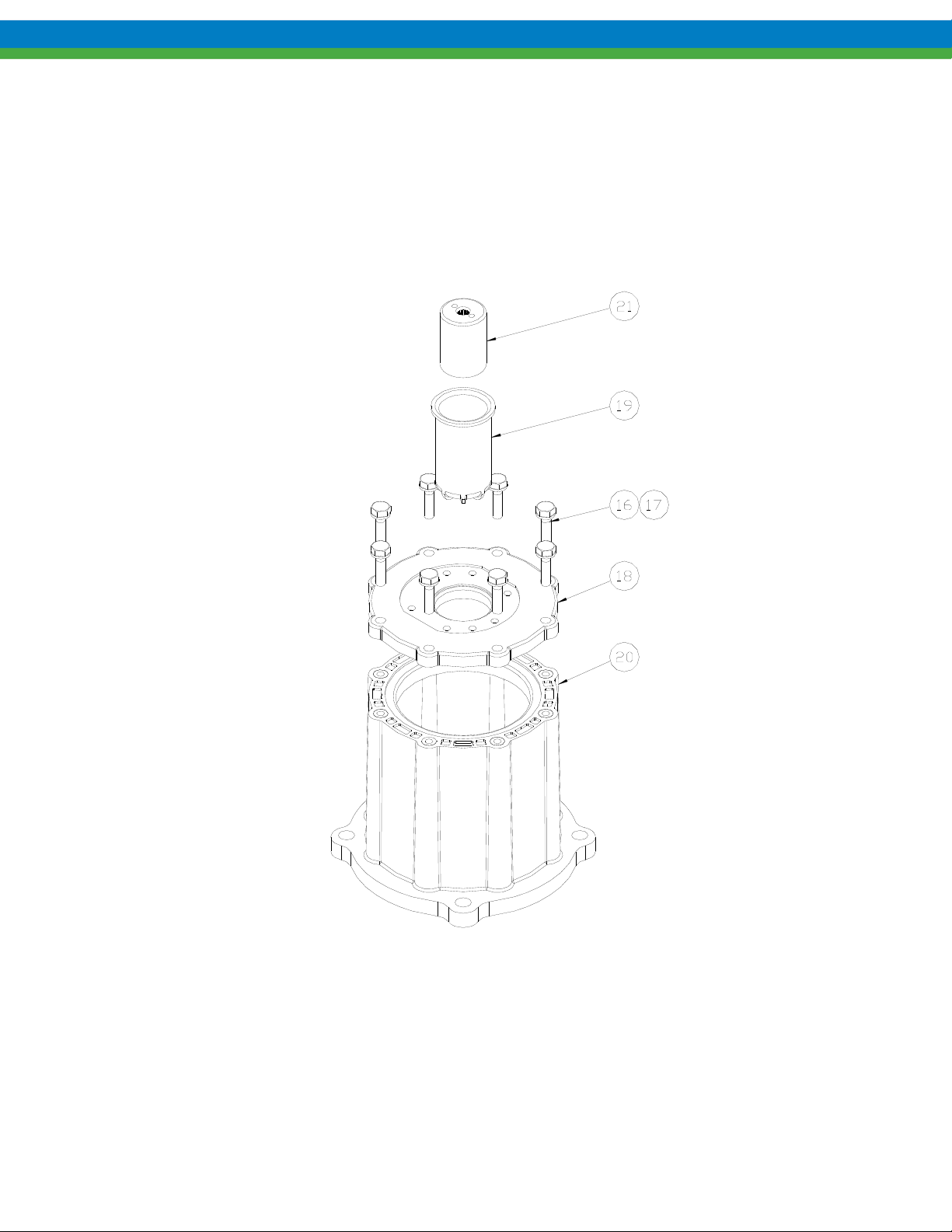

Figure 37

8. Remove driven magnet assembly (item 21) and containment can (item 19) from the motor spool (item 20) as

shown.

Figure 38

9. Remove drive magnet assembly from the motor by loosening the setscrew (item 26) in the magnet hub (item

25) and slide off the motor shaft. Retain the key from the motor shaft.

10. If required, the magnet hub (item 25) can be separated from the drive magnet (item 24) by removing the four

screws (item 27) and detaching.

31

Page 38

8.2 Inspection

Refer to Section 9, Inspection and Wear Limits, for details.

Figure 39

32

Page 39

8.3 Assembly

1. Place motor spool flat on work surface.

2. Insert containment can (item 19) and driven magnet (item 21) into motor spool (item 20) as shown. The

driven magnet is symmetrical and orientation does not matter.

Figure 40

3. Inspect all o-rings to be sure there is no damage such as pinching prior to assembly.

Figure 41

33

Page 40

4. Install o-ring (item 15) into the back side of the center housing (item 14) as shown. Some o-ring lubricant

may help keep the o-rings in place during assembly. Be sure the o-ring is fully seated into housing groove.

Figure 42

5. Place the center housing (item 14) onto the motor spool, aligning the port connections with the pump

baseplate as shown. Place the two retaining plates (item 35) onto the center housing and secure with eight

bolts and washers (items 16, 17). Tighten bolts to the torque specified in Section 12. Always tighten fasteners

in a progressive “crisscross” pattern.

6. Insert a bearing (item 10) into center housing (item 14) and slide to bottom of bore. Bearings are symmetrical

and orientation does not matter. Install the housing liner (item 11) and slide until it seats against the first

bearing. Install idler gear (item 12) into the top hole in the bearing until the gear seats against the first

bearing.

7. Install the drive gear (item 13), splined-end first, into the assembly until it bottoms out against the bearing.

The shaft may have to be rotated slightly to properly fit the splined-end into the drive magnet and mesh gear

teeth with the idler gear.

34

Page 41

8. Insert the second bearing into the housing bore until it rests against the housing liner. Bearings are

symmetrical and orientation does not matter.

Figure 43

9. Install the two o-rings (items 6, 9) into the front cover (item 5) as shown. Some o-ring lubricant may help

keep the o-rings in place during assembly.

Figure 44

35

Page 42

10. Place the front cover (item 5) with o-ring onto the assembled pump. Secure the front cover using the six bolts

and washers (items 3, 4) and two nut plates (item 28) as shown. The flat side of the nut plates mates against

the back of the center housing flange. Tighten bolts to the torque specified in Section 12. Always tighten

fasteners in a progressive “crisscross” pattern.

Figure 44

11. Secure the mounting base (item 32) to the motor spool (item 20) using the four bolts and washers (items 33,

34) as shown. Always tighten fasteners in a progressive “crisscross” pattern.

36

Page 43

12. If it was removed, install the motor adaptor plate (item 18) onto the motor face using the four bolts and

washers (items 29 and 30). Always tighten fasteners in a progressive “crisscross” pattern.

NOTE: E125 May use (2) Adaptor Plates, ref #18.

Figure 45

13. Secure the magnet hub (item 25) to the drive magnet (item 24) using the four screws (item 27). Always

tighten fasteners in a progressive “crisscross” pattern.

Figure 46

37

Page 44

14. Align the keyway, and slide the drive magnet onto the motor shaft until the end of the motor shaft aligns with

faces of the drive magnet motor hub as shown below. Secure with the setscrew (item 26). Application of a noseize compound on the shaft and key will make future maintenance easier.

15. Complete assembly by replacing the assembled pump onto the motor, using care not to allow fingers to get

pinched when the magnets attract. Secure the pump to the motor with the four bolts and washers (items 22,

23). Always tighten fasteners in a progressive “crisscross” pattern.

Figure 47

38

Page 45

9. Inspection and Wear Limits

Inspect internal pump components as follows:

9.1.1 Bearings

Inspect bearing bores (2) and end surfaces for wear and scoring. If wear or scoring is present on the end surface

of the bearing, the bearing can be flipped to expose the undamaged face to the gear side. Bearing should be

replaced when both ends show wear and/or scoring, or when the bores have reached the replacement limit (see

chart).

9.1.2 Shafts

Both the idler and the drive shaft should be inspected carefully for scoring, wear, and any signs of cracking or

chips in the surface of the ceramic material. No cracks or chips are allowed. Shafts should be replaced if they

show signs of cracks or chips anywhere on the surface, if they are deeply scored, or if they have reached their

replacement limit (see chart).

9.1.3 Gears

Gears can be measured for dimensional change to their length and outside diameter. Gear teeth should also be

visually inspected for wear and damage. Gear teeth can be damaged due to solids moving through the pump,

which will affect only some teeth, or excessive pressure, which will distort the outside tips of all teeth. Gears that

have reached their replacement limits (see chart) or show signs of physical damage or distortion should be

replaced. Backlash can be checked by temporarily inserting the two gear/shaft assemblies into known good

bearings and observing gear tooth mesh and backlash.

9.1.4 Housing Liner

The housing liner should be visually inspected for scoring, wear, and steps on the ID of the two gear bores. See

chart for specific limits.

9.1.5 Special Note, Viscosity

The viscosity of the pumped product will affect the service limits of your Eclipse Standard/Eclipse Hypo pump.

Fluids with higher viscosities will usually be more tolerant of wear and allow longer maintenance intervals.

Fluids with low viscosities will usually require more frequent maintenance, as they are less tolerant of clearances

between the pump’s internal surfaces. Each application is different, and only regular inspection and good records

will determine what the correct maintenance interval is for your application.

39

Page 46

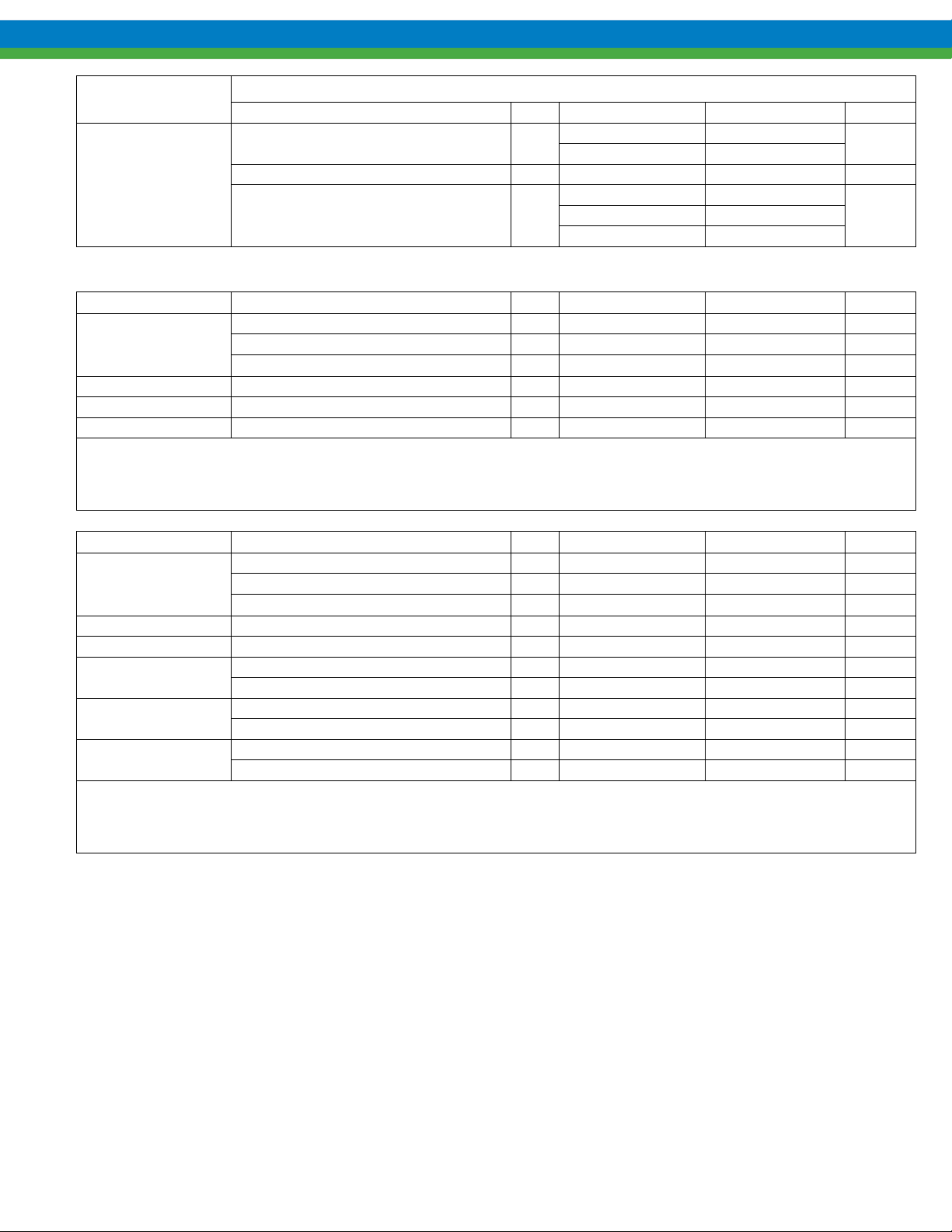

9.1.6 Service and Replacement Limits

Part Pump Model New Spec

Dimension

Bearings

Shafts E02/EH02 OD 0.2916”

Gears

E02/EH02

E05/EH05

E12/EH12

E25/EH25

E75/EH75

E125/EH125

E05/EH05

E12/EH12

E25/EH25 OD 0.625”

E75/EH75

E125/EH125

E02/EH02

ID 0.293”

Length 0.499”

ID 0.439” 0.003 bore wear

ID 0.627” 0.004 bore wear

ID 1.002” 0.005 bore wear

OD 0.437”

OD 1.000”

NOTE: Cracks or chips in shaft surface are not allowed

Length 0.4055”

OD 0.600”

Serviceable Limit Replacement Limit

0.0025 bore wear

end wear – flip over

end wear – flip over

end wear – flip over

end wear – flip over

0.001 smooth wear

0.0005 wear – length

0.003 wear – OD

0.010 Backlash

0.005 bore wear

both ends worn

0.006 bore wear

both ends worn

0.008 bore wear

both ends worn

0.010 bore wear

both ends worn

0.001 deep or rough

scoring

0.001 wear – length

0.006 wear – OD

0.020 Backlash

Housing

Liner

Length 0.624”

E05/EH05

E12/EH12

E25/EH25

E75/EH75

E125/EH125

E02/EH02 n/a 0.002 wear or step 0.004 wear or step

E05/EH05

E12/EH12

E25/EH25 n/a 0.004 wear or step 0.008 wear or step

E75/EH75

E125/EH125

OD 1.063”

Length 1.249”

OD 1.063”

Length 1.499”

OD 1.417”

Length 1.998”

OD 2.125”

Length 2.998”

OD 2.125”

n/a 0.003 wear or step 0.006 wear or step

n/a 0.005 wear or step 0.010 wear or step

0.001 wear – length

0.004 wear – OD

0.015 Backlash

Same as E05/EH05

above

0.002 wear – length

0.005 wear – OD

0.020 Backlash

0.003 wear – length

0.006 wear – OD

0.025 Backlash

0.002 wear – length

0.008 wear – OD

0.030 Backlash

Same as E05/EH05 above

0.004 wear – length

0.010 wear – OD

0.040 Backlash

0.006 wear – length

0.012 wear – OD

0.050 Backlash

40

Page 47

10. Troubleshooting Chart

Symptom Probable Cause Remedy

No Liquid Delivered

Low Liquid

Delivery

Pump not primed. Prime pump. Ensure suction piping and any strainers are

clean and clear of any obstructions.

Motor Incorrectly wired. Check wiring diagram.

Air leak in suction. Locate and repair leak.

Rotation direction

incorrect.

Suction and/or discharge

valves closed.

Suction lift too high. Do not exceed published limits.

Magnetic coupling

decoupled.

Discharge head higher than

calculated.

Air leak in suction. Locate and repair leak.

Rotational speed incorrect. Check speed and wiring. Adjust as required.

Suction pipe restrictions Ensure suction valve is fully open and strainer is clean.

Pressure relief valve open Reset PRV to proper setting based on system pressure.

Pump components worn. Inspect and repair as required.

Reverse motor wiring.

Open valves.

Stop motor, eliminate blockage or jamming and restart.

If no blockage exists verify that operating conditions do

not exceed capabilities of the pump.

Reduce discharge restrictions e.g.: Open throttle valve

or back-pressure valve.

Low Discharge

Pressure

Pump Gradually

Loses Prime

Pump Noisy

Motor Runs Hot or

Overloads

Rotational speed incorrect. Check speed and adjust as required.

Air leak in suction. Repair leak.

Air or gas in liquid. Eliminate air or gas that can be caused by obstructions

in suction piping, leak in suction pipe, or cavitation

and/or boiling of pumped fluid.

Pump components worn Inspect and repair as required.

Air pocket in suction line. Eliminate pocket.

Air entering suction line. Keep suction inlet submerged at all times.

Pump worn or damaged. Inspect and repair as required.

Air or gas in liquid. Eliminate air or gas.

It is normal for motors to

feel hot even when not

overloaded.

Motor wired incorrectly. Check wiring diagram.

Voltage or frequency low. Correct condition.

Motor not sized correctly

for the flow.

Heavy or viscous liquid

being pumped.

Check the actual temperature of the motor housing with

suitable instrumentation. Verify the figures with the

motor manufacturer.

Higher pressures may require more power than the

motor is capable of.

Pumping fluids heavier or more viscous than water

requires a properly sized, higher powered motors.

Binding internal pump

parts.

Inspect and correct condition.

41

Page 48

11. Specifications

11.1 Eclipse Standard/Eclipse Hypo 02 General Specifications

Port Size and Type ¼ inch FNPT or ISO 7-1

Direction of Rotation Bi-directional

Theoretical Displacement 0.033 US gal / 100 rev. (1.2 cc / rev.)

Maximum Differential Pressure 150 psig (10 bar, 1034 kPa)

Maximum Allowable Working Pressure 200 psig (13.8 bar, 1379 kPa)

Maximum Speed 1750 rpm

Maximum Capacity at 0 psig 0.4 US gpm (1.5 LPM)

Maximum Viscosity 5,000 cps

Maximum Process Fluid Temperature 150 F (66 C) at maximum differential pressure

Minimum Process Fluid Temperature -40 F (-40 C)

Fluid pH Range 0-14

Gear Type Compact Spur Gear Design

Bearing Type Sleeve Bearing Integral Wear Plate

Magnetic Torque Rating 22 in-lbs. (2.5 N-m)

Motor Frame Sizes - NEMA 56C and 143/145TC

Motor Frame Sizes - IEC 63 and 80 B14 Face

Pump Housing Materials of Construction Standard: Carbon Reinforced ETFE / Hypo: Kynar

Gear Materials of Construction Modified PTFE

Can Materials of Construction Standard: Carbon Reinforced ETFE / Hypo: Kynar

Magnet Materials of Construction Neodymium Iron

O-ring Seal Materials FKM “A”

Approximate Weight 3.6 lbs. (1.6 kg) less motor

11.2 Eclipse Standard/Eclipse Hypo 05 General Specifications

Port Size and Type

Direction of Rotation Bi-directional

Theoretical Displacement 0.113 US gal / 100 rev. (4.3 cc / rev.)

Maximum Differential Pressure 150 psig (10 bar, 1034 kPa)

Maximum Allowable Working Pressure 200 psi (13.8 bar, 1379 kPa)

Maximum Speed 1750 rpm

Maximum Capacity at 0 psig 1.3 US gpm (4.9 LPM)

Maximum Viscosity 10,000 cps

Maximum Process Fluid Temperature 150 F (66 C) at maximum differential pressure

Minimum Process Fluid Temperature -40 F (-40 C)

Fluid pH Range 0-14

Gear Type Compact Spur Gear Design

Bearing Type Sleeve Bearing Integral Wear Plate

Magnetic Torque Rating 228 in-lbs. (25.7 N-m)

Motor Frame Sizes - NEMA 56C and 143/145TC

Motor Frame Sizes - IEC 63 and 80 B14 Face

Pump Housing Materials of Construction Standard: Carbon Reinforced ETFE / Hypo: Kynar

Gear Materials of Construction Modified PTFE

Can Materials of Construction Standard: Carbon Reinforced ETFE / Hypo: Kynar

Magnet Materials of Construction Neodymium Iron

O-ring Seal Materials FKM “A”

Approximate Weight 8.9 lbs. (4.0 kg) less motor

3

/8 inch FNPT or ISO 7-1

42

Page 49

11.3 Eclipse Standard/Eclipse Hypo 12 General Specifications

Port Size and Type ¾” FNPT or ISO 7-1

Direction of Rotation Bi-directional

Theoretical Displacement 0.226 US gal / 100 rev. (8.6 cc / rev.)

Maximum Differential Pressure Carbon Bearing 100 psig (6.8 bar, 690 kPa)

Maximum Differential Pressure SiC Bearing 150 psig (10 bar, 1034 kPa)

Maximum Allowable Working Pressure Carbon Brg

and SiC Brg

Maximum Speed 1750 rpm

Maximum Capacity at 0 psig 3.2 US gpm (12.1 LPM)

Maximum Viscosity 10,000 cps

Maximum Process Fluid Temperature 150 F (66 C) at maximum differential pressure

Minimum Process Fluid Temperature -40 F (-40 C)

Fluid pH Range 0-14

Gear Type Compact Spur Gear Design

Bearing Type Sleeve Bearing Integral Wear Plate

Magnetic Torque Rating 228 in-lbs. (25.7 N-m)

Motor Frame Sizes - NEMA 56C and 143/145TC

Motor Frame Sizes - IEC 63 and 80 B14 Face

Pump Housing Materials of Construction Standard: Carbon Reinforced ETFE / Hypo: Kynar

Gear Materials of Construction Modified PTFE

Can Materials of Construction Standard: Carbon Reinforced ETFE / Hypo: Kynar

Magnet Materials of Construction Neodymium Iron

O-ring Seal Materials FKM “A”

Approximate Weight 10.0 lbs. (4.5 kg) less motor

200 psi (13.8 bar, 1379 kPa)

11.4 Eclipse Standard/Eclipse Hypo 25 General Specifications

Port Size and Type 1 inch ANSI 150# / DIN 20/25 Flanged

Direction of Rotation Bi-directional

Theoretical Displacement 0.479 US gal / 100 rev. (18.1 cc / rev.)

Maximum Differential Pressure 150 psig (10 bar, 1034 kPa)

Maximum Allowable Working Pressure 200 psi (13.8 bar, 1379 kPa)

Maximum Speed 1750 rpm

Maximum Capacity at 0 psig 6.5 US gpm (24.6 LPM, 1.5 m3/hr)

Maximum Viscosity 10,000 cps

Maximum Process Fluid Temperature 150 F (66 C) at maximum differential pressure

Minimum Process Fluid Temperature -40 F (-40 C)

Fluid pH Range 0-14

Gear Type Compact Spur Gear Design

Bearing Type Sleeve Bearing Integral Wear Plate

Magnetic Torque Rating 474 in-lbs. (53.5 N-m)

Motor Frame Sizes - NEMA 56C, 143/145TC and 182/184TC

Motor Frame Sizes - IEC 100/112 B14 Face

Pump Housing Materials of Construction Standard: Carbon Reinforced ETFE / Hypo: Kynar

Gear Materials of Construction Modified PTFE

Can Materials of Construction Standard: Carbon Reinforced ETFE / Hypo: Kynar

Inner Magnet Materials of Construction Neodymium Iron

O-ring Seal Materials FKM “A”

Approximate Weight 26.0 lbs. (11.8 kg) less motor

43

Page 50

11.5 Eclipse Standard/Eclipse Hypo 75 General Specifications

Port Size and Type 1.5 inch ANSI 150# / DIN 32/40 Flanged

Direction of Rotation Bi-directional

Theoretical Displacement 1.423 US gal / 100 rev. (53.9 cc / rev.)

Maximum Differential Pressure 150 psig (10 bar, 1034 kPa)

Maximum Allowable Working Pressure 200 psi (13.8 bar, 1379 kPa)

Maximum Speed 1750 rpm

Maximum Capacity at 0 psig 20 US gpm (75 LPM, 4.5 m3/hr)

Maximum Viscosity 10,000 cps

Maximum Process Fluid Temperature 150 F (66 C) at maximum 125 psi differential pressure

Minimum Process Fluid Temperature -40 F (-40 C)

Fluid pH Range 0-14

Gear Type Compact Spur Gear Design

Bearing Type Sleeve Bearing Integral Wear Plate

Magnetic Torque Rating 668 in-lbs. (75.4 N-m)

Motor Frame Sizes - NEMA 143/145TC and 182/184TC

Motor Frame Sizes - IEC 100/112 B14 Face

Pump Housing Materials of Construction Standard: Carbon Reinforced ETFE / Hypo: Kynar

Gear Materials of Construction Modified PTFE

Can Materials of Construction Standard: Carbon Reinforced ETFE / Hypo: Kynar

Inner Magnet Materials of Construction Neodymium Iron

O-ring Seal Materials FKM “A”

Approximate Weight 43.7 lbs. (19.8 kg) less motor

11.6 Eclipse Standard/Eclipse Hypo 125 General Specifications

Port Size and Type 1.5 inch ANSI 150# / DIN 32/40 Flanged

Direction of Rotation Bi-directional

Theoretical Displacement 2.135 US gal / 100 rev. (80.82 cc / rev.)

Maximum Differential Pressure Carbon Bearing 80 psig (5.5 bar, 552 kPa)

Maximum Differential Pressure SiC Bearing 100 psig (6.8 bar, 689 kPa)

Maximum Allowable Working Pressure Carbon Brg

and SiC Brg

Maximum Speed 1750 rpm

Maximum Capacity at 0 psig 33 US gpm (12.1 LPM)

Maximum Viscosity

Maximum Process Fluid Temperature 150 F (66 C) at maximum differential pressure

Minimum Process Fluid Temperature -40 F (-40 C)

Fluid pH Range 0-14

Gear Type Compact Spur Gear Design

Bearing Type Sleeve Bearing Integral Wear Plate

Magnetic Torque Rating 668 in-lbs. (75.4 N-m)

Motor Frame Sizes - NEMA 143/145TC, 182/184TC, 213/215TC, 254/256TC

Motor Frame Sizes - IEC 100/112 B14 Face, 132 B14 Face

Pump Housing Materials of Construction Standard: Carbon Reinforced ETFE / Hypo: Kynar

Gear Materials of Construction Modified PTFE

Can Materials of Construction Standard: Carbon Reinforced ETFE / Hypo: Kynar

Magnet Materials of Construction Neodymium Iron

O-ring Seal Materials FKM “A”, EPDM, FEP

Approximate Weight Approx. 44.7 lbs. (20.3 kg)

200 psi (13.8 bar, 1379 kPa)

10,000cps

44

Page 51

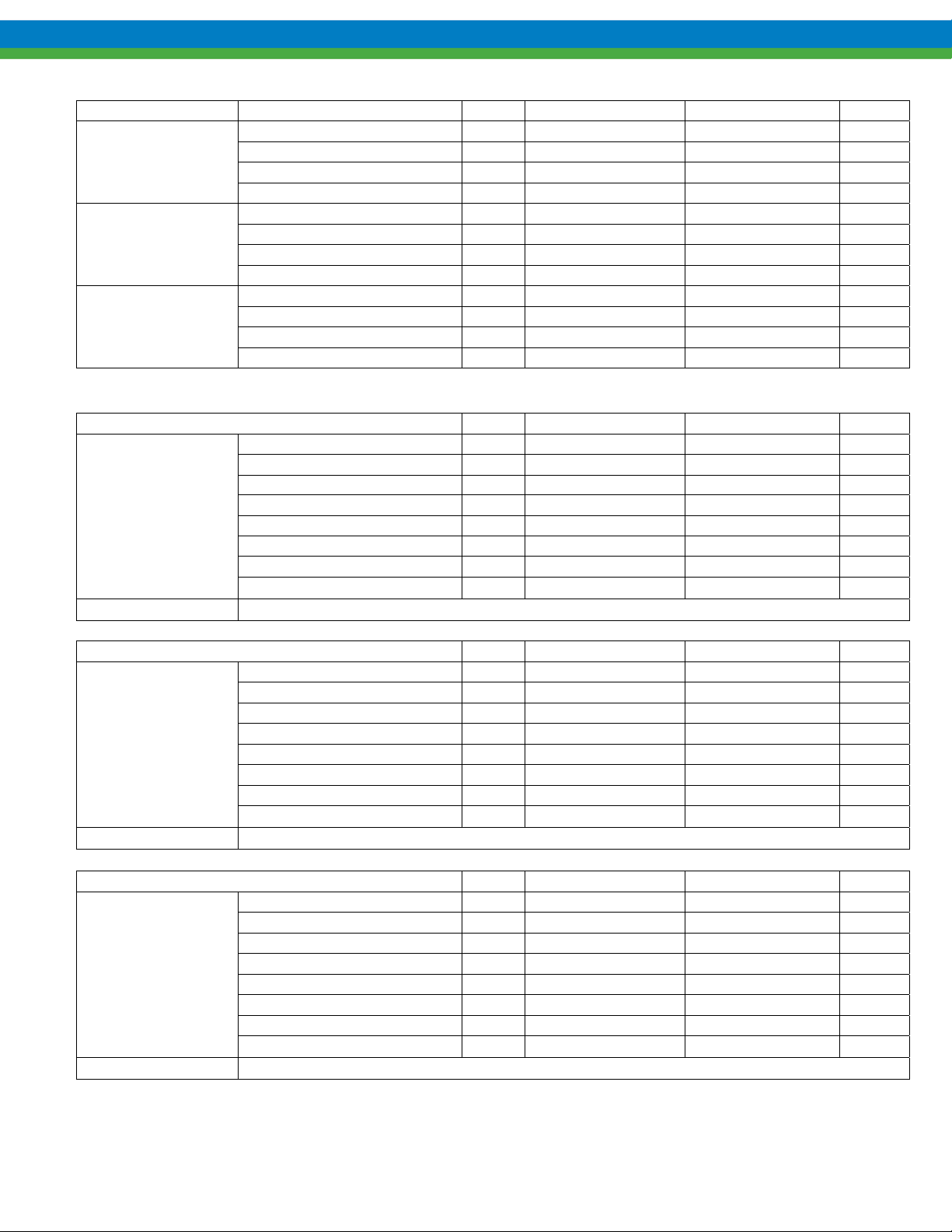

Maximum Sound Levels

Pump Size Sound Level (dB)

Eclipse Standard/Eclipse Hypo 02 80

Eclipse Standard/Eclipse Hypo 05 81

Eclipse Standard/Eclipse Hypo 12 82

Eclipse Standard/Eclipse Hypo 25 83

Eclipse Standard/Eclipse Hypo 75 85

Eclipse Standard/Eclipse Hypo 125 95

Maximum Flange Loads

Pump Size Flange Loads lb (N) Flange Loads Ft-lb (N-m)

Eclipse Standard/Eclipse Hypo 02 25 (111) 10 (13.5)

Eclipse Standard/Eclipse Hypo 05 25 (111) 20 (27)

Eclipse Standard/Eclipse Hypo 12 25 (111) 25 (33)

Eclipse Standard/Eclipse Hypo 25 30 (133) 20 (27)

Eclipse Standard/Eclipse Hypo 75, & 125 50 (222) 25 (34)

Maximum Suction Lift (Dry or Wetted Pump)

Pump Size Feet (m)

Eclipse Standard/Eclipse Hypo 02 3 (0.9)

Eclipse Standard/Eclipse Hypo 05 3 (0.9)

Eclipse Standard/Eclipse Hypo 12 3 (0.9)

Eclipse Standard/Eclipse Hypo 25 5 (1.5)

Eclipse Standard/Eclipse Hypo 75, & 125 5 (1.5)

NPSH Required

NPSHr = 2 ft (0.6m) at 1750rpm – All Sizes

Vacuum Systems – Flooded Suction

Maximum vacuum of 28 in-Hg (14 psi- gauge) or 0.1mm Hg (Absolute)

Solids Handling Capability

Size: 70 Microns / 0.003 inches / 0.07 mm

Maximum Concentrations: 10%

200 Mesh strainer recommended

45

Page 52

Recommended

Pump Size Bolt Position Bolt Size

in-lbs N-m

Front Cover / Housing 10 - 32 15 1.7

Housing Adaptor -to- Spool 1/4 - 20 48 .4

Spool -to- Motor Adaptor or

Eclipse Standard/Eclipse Hypo

02

Eclipse Standard/Eclipse Hypo

05 and 12

Eclipse Standard/Eclipse Hypo

25

Eclipse Standard/Eclipse Hypo

75 and 125

Motor 3/8 - 16 72 8.1

Motor Adaptor -to- Motor

56C 3/8 - 16 72 8.1

63 B14 M5 - 0.80 24 2.7

80 B14 M6 - 1.00 48 5.4

Front Cover 1/4 - 20 60 6.8

Housing -to- Spool 1/4 - 20 60 6.8

Spool -to- Motor Adaptor or

Motor 3/8 - 16 72 8.1

Motor Adaptor -to- Motor

56C 3/8 - 16 72 8.1

143TC - 182C 3/8 - 16 72 8.1

63 B14 M5 - 0.80 24 2.7

80 B14 M6 - 1.00 48 5.4

Front Cover 1/4 - 20 72 8.1

Housing -to- Spool 3/8 - 16 120 13.6

Spool -to- Motor Adaptor 3/8 - 16 120 13.6

Base Mount -to- Spool 3/8 - 16 120 13.6

Flange Bolts (min. to seal) Varies 120 13.6

Motor Adaptor -to- Motor

56C 72 8.1

143TC - 182C 3/8 - 16 120 13.6

100 - 112 B14 M8 - 1.25 120 13.6

Front Cover 3/8 - 16 120 13.6

Housing -to- Spool 3/8 - 16 120 13.6

Spool -to- Motor Adaptor 3/8 - 16 120 13.6

Base Mount -to- Spool 3/8 - 16 120 13.6

Flange Bolts (min. to seal) Varies 120 13.6

Motor Adaptor -to- Motor

143TC - 182C 3/8 - 16 120 13.6

1182TC - 184TC 1/2 - 13 120 13.6

2213TC - 215TC

2254TC - 256TC

1/2 - 13

1/2 - 13

Torque

120 13.6

120 13.6

1100 - 112 B14 M8 - 1.25 120 13.6

1132 B34 M8 - 1.25 120 13.6

46

Page 53

12. Model Identification – Eclipse Standard

Position Sample Specifies Options

1 E

2 and 3 02

4 E

5 L

6 V

7 F

8 -

9 X

In the above example, the Eclipse Standard pump E02ELVF-X is a Model 02 pump, ETFE base materials, FNPT process connections,

carbon bearings, FKM O-rings, and a NEMA 56 motor mounting.

and Connections

E - Eclipse Standard

Size

Base Material E - ETFE, FNPT

F - ETFE,Flange

Bearings L – Carbon Graphite

B - Silicon-Carbide

O-rings V – FKM “A”

Motor F - NEMA 56C

Mounting O - NEMA 143TC-182C

R - NEMA 182-184TC

H - IEC B3/B14 63

J - IEC B3/B14 71 (special order)

position 8 is a dash

Options X – Complete Pump (No Options)

A – Bearing Flush Ports

N – Pump Wet End Only

B – Options A and N

02

05

12

25

75

125

B - ETFE,

E – EPDM

K – Kalrez

W - NEMA 213TC – 215TC

Z – NEMA 254TC – 256TC

K - IEC B3/B14 80

L - IEC B3/B14 90 (special order

E125 only)

P - IEC B3/B14 100/112

V - IEC B3/B14 132

Y - No motor mount kit

ISO 7-1

47

Page 54

13. Model Identification – Eclipse Hypo

Position Sample Specifies Options

1 and 2 EH

3 and 4 02

5 K

6 L

7 V

8 F

P - IEC B3/B14 100/112

Y - No motor mount kit

9 -

10 X

In the above example, the Eclipse Standard pump EH02KBVF-X is a Model 02 pump, Carbon filled PVDF base materials, FNPT

process connections, Silicon-Carbide bearings, FKM O-rings, and a NEMA 56 motor mounting.

Options Description for both Eclipse Standard/Eclipse Hypo:

and Connections B – Carbon filled PVDF, BSPT, ISO 7-1

EH - Eclipse Hypo

Size

Base Material K – Carbon filled PVDF, FNPT

N – Carbon filled PVDF, Flanged

Bearings B - Silicon-Carbide

O-rings V – FKM “A”

Motor F - NEMA 56C

Mounting O - NEMA 143TC-182C

R - NEMA 182-184TC

W - NEMA 213TC – 215TC

H - IEC B3/B14 63

J - IEC B3/B14 71 (special order)

K - IEC B3/B14 80

position 9 is a dash

Options X – Complete Pump (No Options)

A – Bearing Flush Ports

N – Pump Wet End Only

B – Options A and N

02

05

12

25

75

125

L - IEC B3/B14 90 (special order

E125 only)

Complete pump model number with no magnet options (“X” or “A” in position 9 (Standard) / position 10 (Hypo)) inclu des drive

magnet and all necessary motor mounting hardware for a specified motor size.

Option “Y” in position 7 (Standard) / position 8 (Hypo) is for a bare pump with drive magnet, but no motor mounting hardware

(magnet hub, motor adapter when applicable). This will typically be used as a spare pump or as inventory until a specific motor size is

identified.

Option “N” in position 9 (Standard) / position 10 (Hypo) is for a bare pump without the drive magnet. This will typically only be used

as a “wet end” repair kit for an existing unit when the drive magnet is not required with the new pump. This option can only be used

in combination with a “Y” code in position 7 (Standard)/position 8 (Hypo).

Consult factory for availability of option combinations not covered in the above chart.

48

Page 55

14. Parts Diagram and List, Eclipse Standard 02

49

Page 56

Eclipse Standard Pump Series Size 02

Consolidated Bill of Material – Eclipse Standard

Position 4 Base Pump Material and Port

Position 1,2,3,4 - Base Pump Material/Ports

(* Denotes recommended spares) ETFE

E02 Description Item Part Number: Material Qty

Screw 3 W770274-188 Stainless Steel 6

Washer 4 W771006-188 Stainless Steel 6

Screw 7 W770274-188 Stainless Steel 2

Cover, Front 5 NG020001-FTE ETFE 1

Name Plate 1 NG550001-304 Stainless Steel 1

Can, Containment 19 NG210004-FTE ETFE 1

Common Parts

E

B

Driven Magnet Assembly 21 NG200030-TEF Neo / ETFE 1

Drive Magnet 24 NG200034-STL Neo / Steel 1

Adapter, Spool 20 NG110010-PET Polyester 1

Adapter, Can 18 NG110012-PET Polyester 1

Bolt 16 W770403-188 Stainless Steel 8

Washer 17 NG990018-188 Stainless Steel 8

Plug, Drain NG990014-FTE ETFE 1

Tape for Name Plate -- NG990016-000 3M VHB FOAM 1 sq. in.

Housing, Center FNPT

Housing, Center FBSPT NG040020-FTE Carbon-filled ETFE

Connection

(E) or (B)

NG040019-FTE Carbon-filled ETFE

14

1

Position 5 - Bearing Materials

Description Item Part Number: Material Qty

Liner, Housing * 11 NG220002-FTE ETFE 1

Common Parts

L

B

Gear Assembly, Drive * 13 NG010014-FTE ETFE / ALA 1

Gear Assembly, Idler * 12 NG010013-FTE ETFE / ALA 1

Bearing *

Bearing * NG080001-SIC Silicon Carbide

Position 6 - O-ring Material Selection

Description Item Part Number: Material Qty

O-ring Containment Can * 15 NG440029-VTA Viton A 1

V

E

K

O-ring Cover * 6 NG440029-VTA Viton A 1

O-ring Compression * 9 NG440020-VTA Viton A 1

O-ring Drain Plug * NG440012-VTA Viton A 1

O-ring Containment Can * 15 W078452-N0R EPDM 1

O-ring Cover * 6 W078452-N0R EPDM 1

O-ring Compression * 9 NG440020-N0R EPDM 1

O-ring Drain Plug * W059100-N0R EPDM 1

O-ring Containment Can * 15 NG440029-KLZ Kalrez 1

O-ring Cover * 6 NG440029-KLZ Kalrez 1

O-ring Compression * 9 NG440020-KLZ Kalrez 1

O-ring Drain Plug * NG440012-KLZ Kalrez 1

NG080001-CBN Carbon -92

10

2

50

Page 57

Position 7 - NEMA C-Face and IEC B34 Metric Frame Magnetic Coupling Arrangement

56C NEMA frame components Item Part Number: Material Qty

Coupling Hub 25 NG940002-STL Steel 1

Set Screw 26 W771004-031 Steel 1

F

Motor Mount Kit # E02XXXF

Bolt 22 W770425-188 Stainless Steel 4

Washer 23 NG990019-188 Stainless Steel 4

Screw 27 W770021-188 Stainless Steel 4

63 IEC B34 frame components

Coupling Hub 25A NG940004-STL Steel 1

Set Screw 26A NP991004-017 Steel 1

Adapter, Motor 31 NG110005-PET Polyester 1

H

Motor Mount Kit # E02XXXH

71 IEC B34 frame components

J

Motor Mount Kit # E02XXXJ

Bolt 29 NP990418-188 Stainless Steel 4

Washer 30 NP991016-188 Stainless Steel 4

Bolt 22 W770426-188 Stainless Steel 4

Washer 23 NG990019-188 Stainless Steel 4

Screw 27 W770021-188 Stainless Steel 4

Coupling Hub 25A NG940011-STL Steel 1

Set Screw 26A NG990027-1 88 Steel 1

Adapter, Motor 31 NG110019-ALU Aluminum 1

Bolt 29 W770546-188 Stainless Steel 4

Bolt 22 W770426-188 Stainless Steel 4

Washer 23 NG990019-188 Stainless Steel 4

Screw 27 W770021-188 Stainless Steel 4

Item Part Number: Material Qty

Item Part Number: Material Qty

80 IEC B34 frame components

Coupling Hub 25B NG940005-STL Steel 1

Set Screw 26B NP991004-001 Steel 1

Adapter, Motor 31 NG110005-PET Polyester 1

K

Motor Mount Kit # E02XXXK

Bolt 29A W770546-188 Stainless Steel 4

Washer 30A NP991017-188 Stainless Steel 4

Bolt 22 W770426-188 Stainless Steel 4

Washer 23 NG990019-188 Stainless Steel 4

Screw 27 W770021-188 Stainless Steel 4

Item Part Number: Material Qty

51

Page 58

KOPKits

Kit # Description Item Part Number: Material Qty

E02XLx-LTE or

E02XBx-LTE

V

E

K

LTE Kit Reference:

Bearing Not Included

E02Xx(x) – O-Ring Material Code

Example: E02XBE-LTE

Kit # Description Item Part Number: Material Qty

E02Xxx-STD

L

B

V

E

K

STD Kit Reference:

E02X(x) – Bearing Material Code

E02Xx(x) – O-Ring Material Code

Example: E02XBE-STD

Liner, Housing 11 NG220002-FTE ETFE 1

Gear Assembly, Drive 13 NG010014-FTE ETFE / ALA 1

Gear Assembly, Idler 12 NG010013-FTE ETFE / ALA 1

O-ring Cover 6 NG440029-VTA Viton A 1

O-ring Cover 6 W078452-N0R EPDM 1

O-ring Cover 6 NG440029-KLZ Kalrez 1

Liner, Housing 11 NG220002-FTE ETFE 1

Gear Assembly, Drive 13 NG010014-FTE ETFE / ALA 1

Gear Assembly, Idler 12 NG010013-FTE ETFE / ALA 1

Bearing 10 NG080001-CBN Carbon -92 2

Bearing 10 NG080001-SIC Silicon Carbide 2

O-ring Cover 6 NG440029-VTA Viton A 1

O-ring Compression 9 NG440020-VTA Viton A 1

O-ring Cover 6 W078452-N0R EPDM 1

O-ring Compression 9 NG440020-N0R EPDM 1

O-ring Cover 6 NG440029-KLZ Kalrez 1

O-ring Compression 9 NG440020-KLZ Kalrez 1

Kit # Description Item Part Number: Material Qty

Liner, Housing 11 NG220002-FTE ETFE 1

Gear Assembly, Drive 13 NG010014-FTE ETFE / ALA 1

E02Xxx-PRO

L

B

V

E

K

PRO Kit Reference:

E02X(x) – Bearing Material Code

E02Xx(x) – O-Ring Material Code

Example: E02XBE-PRO

Gear Assembly, Idler 12 NG010013-FTE ETFE / ALA 1

Screw 3 W770274-188 Stainless Steel 6

Washer 4 W771006-188 Stainless Steel 6

Bearing 10 NG080001-CBN Carbon -92 2

Bearing 10 NG080001-SIC Silicon Carbide 2

O-ring Cover 6 NG440029-VTA Viton A 1

O-ring Compression 9 NG440020-VTA Viton A 1

O-ring Cover 6 W078452-N0R EPDM 1

O-ring Compression 9 NG440020-N0R EPDM 1

O-ring Cover 6 NG440029-KLZ Kalrez 1

O-ring Compression 9 NG440020-KLZ Kalrez 1

52

Page 59

15. Parts Diagram and List, Eclipse Standard 05

53

Page 60

Eclipse Standard Pump Series Size 05

Consolidated Bill of Material – Eclipse Standard

Position 4 Base Pump Material

Position 1,2,3,4 - Base Pump Material/Ports

(* Denotes recommended spares) ETFE

E05 Description Item Part Number: Material Qty

Bolt 3 W770403-188 Stainless Steel 6

Washer 4 NG990018-188 Stainless Steel 6

Plate, Nut 28 NG990009-188 Stainless Steel 2

Cover, Front 5 NG020002-FTE ETFE 1

Plate, Reinforcement 32 NG120006-188 Stainless Steel 2

Bolt 16 W770403-188 Stainless Steel 8

Common Parts

E

B

Washer 17 NG990018-188 Stainless Steel 8

Name Plate 1 NG550003-304 Stainless Steel 1

Drive Screw 2 W771000-188 Stainless Steel 2

Can, Containment 19 NG210005-FTE ETFE 1

Driven Magnet Assembly 21 NG200031-TEF Neo / ETFE 1

Drive Magnet 24 NG200035-STL Neo / Steel 1

Adapter, Spool 20 NG110010-PET Polyester 1

Plug, Drain 34 NG990014-FTE ETFE 1

Housing, Center FNPT

Housing, Center FBSPT (B) NG040022-FTE ETFE

and Port Connection

(E) or (B)

14

NG040021-FTE ETFE

1

Position 5 - Bearing Materials

Description Item Part Number: Material Qty

Liner, Housing * 11 NG220003-FTE ETFE 1

Common Parts

L

B

Gear Assembly, Drive * 13 NG010016-FTE ETFE / ALA 1

Gear Assembly, Idler * 12 NG010015-FTE ETFE / ALA 1

Bearing * 10 NG080002-CBN Carbon -92 2

Bearing * 10 NG080002-SIC Silicon Carbide 2

Position 6 - O-ring Material Selection

Description Item Part Number: Material Qty

O-ring Containment Can * 15 NG440154-VTA Viton A 1

V

E

K

O-ring Cover * 6 NG440137-VTA Viton A 1

O-ring Drain Plug * 33 NG440012-VTA Viton A 1

O-ring Compression * 9 NG440129-VTA Viton A 1

O-ring Containment Can * 15 NG440154-N0R EPDM 1

O-ring Cover * 6 NG440137-N0R EPDM 1

O-ring Drain Plug * 33 W059100-N0R EPDM 1

O-ring Compression * 9 NG440129-N0R EPDM 1

O-ring Containment Can * 15 NG440154-KLZ Kalrez 1

O-ring Cover * 6 NG440137-KLZ Kalrez 1

O-ring Drain Plug * 33 NG440012-KLZ Kalrez 1

O-ring Compression * 9 NG440129-KLZ Kalrez 1

54

Page 61

Position 7 - NEMA C-Face and IEC B34 Metric Frame Magnetic Coupling Arrangement

56C NEMA frame components

Coupling Hub 25 NG940002-STL Steel 1

Set Screw 26 W771004-031 Steel 1

F

Motor Mount Kit # E05XXXF

Bolt 22 W770425-188 Stainless Steel 4

Washer 23 NG990019-188 Stainless Steel 4