Page 1

PULSAR® ECA

ELECTRONIC CONTROL ASSEMBLY

Installation, Operation &

IOM-CTL-2001-Rev E

Maintenance Instructio n

NEMA Type 4X

Page 2

Page 3

ECA FACTORY SERVICE POLICY

Your ECA is a state of the art microprocessor-based stroke length control device for use with

PULSAR® Diaphragm Metering Pumps. If you are experiencing a problem with your ECA, consult the

trouble-shooting guide. If the problem is not covered or cannot be solved, please contact your local

PULSA Series Sales Organization or our Technical Service Department at (585) 292-8000 for further

assistance.

Trained individuals are available to diagnose your problem and arrange a solution. Solutions may

include purchasing a replacement unit or returning the ECA to the factory for inspection and repair.

All returns require a Return Material Authorization (R.M.A.) number to be issued by Pulsafeeder. Parts

purchased to correct a warranty issue may be credited after examination of the original parts by

Pulsafeeder personnel. Parts returned for warranty considerations which are good will be sent back

freight collect.

Any field modifications will void the warranty. Out-of-warranty repairs will be subject to Pulsafeeder's

standard bench fees and testing costs associated with replacement components.

FCC Warning

This equipment generates and uses radio frequency energy. If not installed and used properly, in strict

accordance with the manufacturer’s instructions, it may cause interference to radio communications.

Operation of this equipment in a residential area is likely to cause interference in which case the user,

at his own expense, will be required to take whatever measures necessary to correct the interference.

Copyright

Copyright © 2006 - 2014 Pulsafeeder, Inc. All rights reserved.

Information in this document is subject to change without notice. No part of this publication may be

reproduced, stored in a retrieval system or transmitted in any form or any means electronic or

mechanical, including photocopying and recording for any purpose other than the purchaser’s personal

use without the written permission of Pulsafeeder.

Page 4

Table of Contents

1. INTRODUCTION ................................................................................................................................ 1

2. FOREWORD ...................................................................................................................................... 1

2.1 Description ............................................................................................................................... 1

2.2 ECA Standard Features .......................................................................................................... 1

3. SAFETY CONSIDERATIONS ............................................................................................................ 2

3.1 General Safety ......................................................................................................................... 2

3.2 Electrical Safety ....................................................................................................................... 3

3.3 Fire Safety ................................................................................................................................ 3

3.4 Hydraulic Safety ...................................................................................................................... 3

3.5 Liability Exclusion ................................................................................................................... 3

4. TRANSPORT AND STORAGE ................................................................................................................... 5

4.1 Consignment receipt and unpackagin g ................................................................................ 5

4.2 Handling ................................................................................................................................... 5

4.3 Lifting ........................................................................................................................................ 5

4.4 Recycling and end of product life .......................................................................................... 5

5. STORAGE INSTRUCTIONS ...................................................................................................................... 6

5.1 Short Term (0 - 12 months) ..................................................................................................... 6

5.2 Long Term (12 months or more) ............................................................................................ 7

6. INSTALLATION AND WIRING ................................................................................................................... 8

6.1 Location .................................................................................................................................... 8

6.2 Installation Notes ..................................................................................................................... 8

6.3 Installation guidelines for EMC compli ance ......................................................................... 8

6.4 Housing Access ....................................................................................................................... 9

6.5 Electrical Wiring ...................................................................................................................... 11

6.6 Power Wiring Information ....................................................................................................... 11

6.7 Labeling – Nameplate .............................................................................................................. 15

6.8 Control Input and Output Connections ................................................................................. 15

6.8.1 Motor Status Input ........................................................................................................... 15

6.8.2 Analog Input (current loop) ............................................................................................ 15

6.8.3 Analog Output (current loop) ......................................................................................... 16

7. START UP AND OPERATION ................................................................................................................... 17

7.1 Overview ................................................................................................................................... 17

8. INPUT/OUTPUT SETUP ........................................................................................................................... 17

8.1 System User Calibration ......................................................................................................... 17

8.1.1 Analog Input Signal Calibration ..................................................................................... 17

8.1.2 Analog Input Signal Loss................................................................................................ 18

8.1.3 Analog Output Signal Calibration .................................................................................. 18

9. MECHANICAL ZERO CALIBRATION ......................................................................................................... 19

9.1 Factory Re-initialization .......................................................................................................... 20

10. DIAGNOSTICS ................................................................................................................................... 20

10.1 Trouble Code Reporting ......................................................................................................... 20

10.2 Trouble Codes ......................................................................................................................... 22

10.3 Self-Test Mode ......................................................................................................................... 23

10.4 Error Recovery ......................................................................................................................... 24

11. SPECIFICATIONS ................................................................................................................................... 25

12. POWER-UP OPTIONS SUMMARY ............................................................................................................ 26

13. FIELD WIRING SUMMARY ....................................................................................................................... 27

14. TROUBLESHOOTING GUIDE ................................................................................................................... 1

15. MAINTENANCE & SPARE PARTS ............................................................................................................ 2

15.1 Operating Precautions ............................................................................................................ 2

15.2 Cleaning and Decontamination .............................................................................................. 2

15.3 User Replaceable Parts for the ECA ...................................................................................... 3

ii

Page 5

A WARNING DEFINES A CONDITION THAT COULD CAUSE DAMAGE TO BOTH THE

Tips have been included within this bulletin to help the operator run the

Conventions

For the remainder of this bulletin, the following conventions are in effect.

EQUIPMENT AND THE PERSONNEL OPERATING IT. THIS MANUAL MUST BE CONSULTED

IN ALL CASES WHERE THE

NATURE OF THE POTENTIAL HAZARDS AND ANY ACTIONS WHICH HAVE TO BE TAKEN

TO AVOID THEM

WARNING SYMBOL IS MARKED IN ORDER TO FIND OUT THE

.

CAUTION,

Notes are general information meant to make operating the equipment

easier.

equipment in the most efficient manner possible. These “Tips” are drawn

from the knowledge and experience of our staff engineers, and input from

the field.

Revision History:

Rev E (07-24-2014)

− Updated to reflect requirements of UL 61010-1 3

POSSIBILITY OF ELECTRIC SHOCK

rd

Edition

iii

Page 6

Page 7

1. INTRODUCTION

The ECA is a microprocessor based stroke length control device for use with the PULSAR

diaphragm-metering pump. It has been designed to operate in a variety of industrial

environments. This document describes the ECA controller only. The operation and maintenance

of the PULSAR metering pump is covered in the pump IOM. Please refer to this IOM for important

safety and operational instructions for your PULSAR pump.

2. FOREWORD

The pumps to which these “instructions” refer to are designed for use in industrial areas and

therefore cannot be treated as retail products. The present documentation gives instructions to be

used by qualified personnel only. It must be used in compliance with the regulations, laws

and technical standards in force and cannot, under any circumstances, take the place of plant

standard or additional regulations, including any which are not legally enforceable, which have

been issued with the scope of ensuring safety.

Equipment with special manufacturing or constructive variances may differ in details with respect

to this description.

In case of any difficulty, please contact PULSAFEEDER, INC. Technical Service.

The ECA is rated for NEMA 4 locations as identified on the controller nameplate.

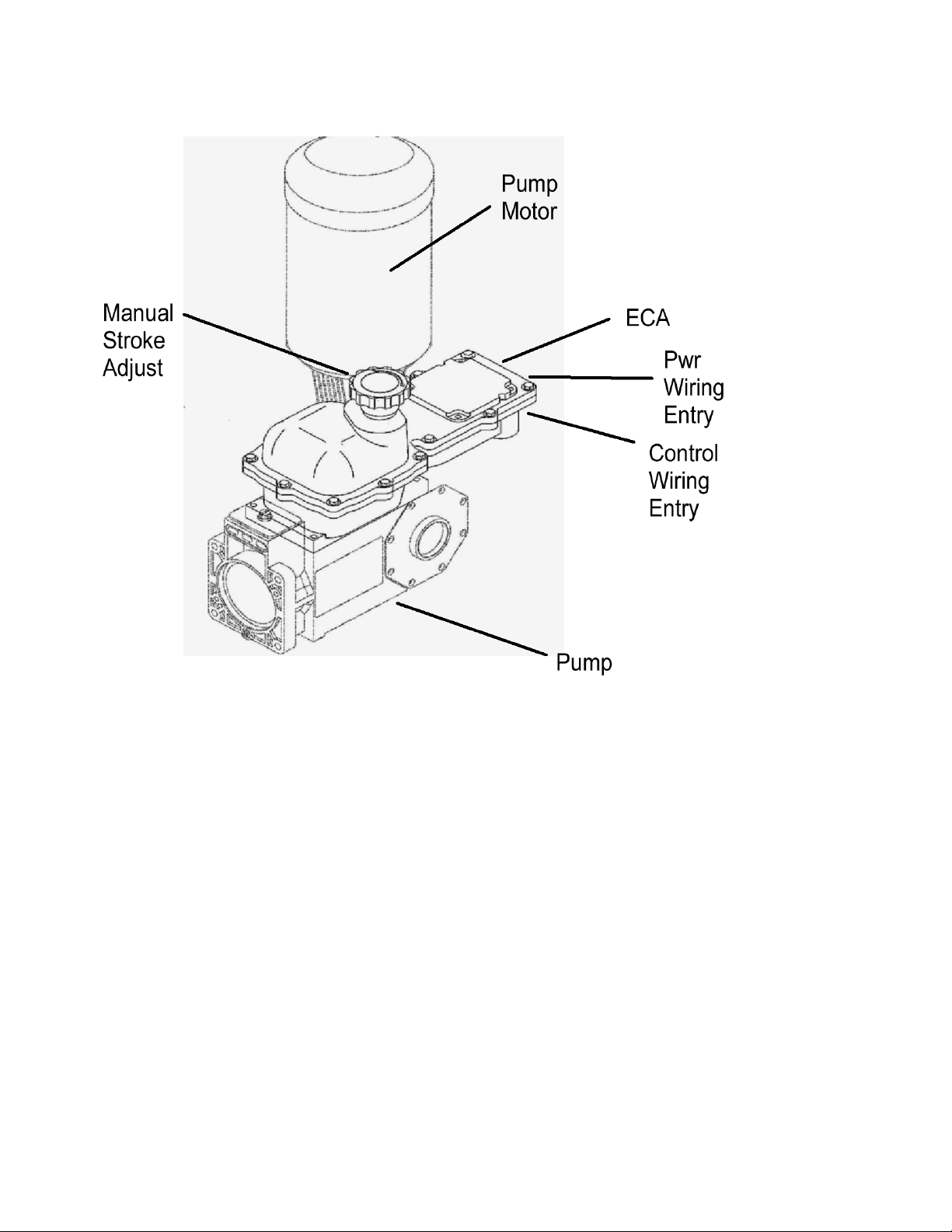

2.1 Description

The ECA is an electromechanical servo controller dedicated to the PULSAR diaphragm

metering pump series. The unit is physically attached and integrated into the pump's design.

The controller allows for precise adjustment of output flow of a process media by means of

stroke length positioning.

The ECA is designed for the international industrial market. The analog control signals offer

flexible remote control. They are fully isolated - from each other as well as earth ground - for

improved protection and reliability.

The ECA is designed to simplify and automate the calibration of the analog signals. Analog

signal calibratio n is ac c omp lis h ed by simple push button entry. Calibration functions must be

completed while the internal circuitry of the unit is accessible, and therefore at a time when the

surrounding environment is considered safe for electronic work.

2.2 ECA Standard Features

• Electronic Stroke Length Control

• NEMA Type 4x enclosure

• 4-20mA input and output

• EEPROM storage of calibration data

• Diagnostics and Self-Test mode

1

Page 8

The ECA is available for 115 or 230 VAC

operation, at either 50 or 60 Hz. Each ECA

controller must be operated on the appropriate

AC supply as per the nameplate ratings.

3.

SAFETY CONSIDERATIONS

The ECA is a sophisticated microprocessor based controller for use only with PULSAR diaphragm

metering pumps. It yields tremendous control capacity -- electrical, mechanical and (in conjunction

with the PULSAR pump) hydraulic in nature. In consideration of SAFETY, the user should be

mindful of this relative to his/her safety, that of co-workers and of the process environment. Please

consider the following prior to the installation and operation of an ECA controlled PULSAR metering

pump:

• Read and understand all related instructions and documentation before attempting to install

or maintain this equipment

• Observe all special instructions, notes, and cautions.

• Act with care and exercise good common sense and judgment during all installation,

adjustment, and maintenance procedures.

• Ensure that all safety rules, work procedures, and standards that are applicable to your

company and facility are followed during the installation, maintenance, and operation of this

equipment.

3.1 General Safety

The ECA was designed as a stroke length position actuator for operation solely with the

PULSAR metering pump. Use for any other application is considered un-safe and voids all

certification markings and warranties.

2

Page 9

3.2 Electrical Safety

The ECA can be considered an industrial process controller. Improper application and use can

be hazardous. You are solely responsible for its use.

The ECA’s electr ical installation must conform to all local, state and national relevant electrical

codes. Installation and electrical maintenance must be performed by a qualified electrician.

Before installing or servicing this device, all power must be disconnected from the source at the

main distribution panel.

The ECA emits electro-magnetic energy and may generate radio frequency interference. Its use

is restricted to industrial applications. You are responsible for shielding this energy/interference.

Certain wiring procedures may require that the user wear a wrist strap to dissipate static

charges.

.

I

NSTALLATION AND ELECTRICAL MAINTENANCE MUST BE P E RFORMED BY A QUALIFIED ELECTRICIAN.

Before installing or servicing this device, all power must be disconnected from the source at

the main distribution panel. Certain calibration functions must be completed while the electronic

section of the unit is exposed and power is applied to the unit, be certain to ensure that proper

procedures are followed and that fingers, tools, and wiring do not contact exposed circuitry and

components.

The ECA emits electromagnetic energy and generates radio frequency interference. It s use is

restricted to industrial applications. The user bears all responsibility for shielding this

energy/interference.

3.3 Fire Safety

In case of electrical fire, use a Class C fire extinguisher. Never use water to extinguish a

Class C fire.

Class C fires involve electrical equipment, such as appliances, wiring, circuit breakers and

outlets. Never use water to extinguish class C fires - the risk of electrical shock is far too great!

Class C extinguishers do not have a numerical rating. The C classification means the

extinguishing agent is non-conductive. Geometric symbol (blue circle)

3.4 Hydraulic Safety

Thoroughly review and adhere to the contents of the PULSAR Installation, Operation,

Maintenance Instruction manual (current version) for hydraulic installation of your PULSAR

metering pump.

3.5 Liability Exclusion

Pulsafeeder, Inc. is unable to monitor the observance of the instructions given in this manual,

nor verify the actual working conditions and installation of the equipment, the correct operation

and maintenance of the equipment and accessories. An incorrect installation, or misuse of the

equipment, may cause serious damage and may pose a danger to persons or property. Any

anomalies must be reported to the maintenance supervisor. The user is not authorized to

tamper with the machine for any reason.

3

Page 10

Attempts to disassemble, modify or tamper in general by unauthorized personnel will void the guarantee and will release Pulsafeeder, Inc. from any liability for damage caused to persons or property resulting from such actions.

Pulsafeeder, Inc. is considered released from any liability in the following cases:

- improper installation;

- improper use of the equipment by non-professional or inadequately trained

operators;

- use not in compliance with regulations in the Country of use;

- lack of maintenance or improperly performed;

- use of non-original spare parts or incorrect parts for the model in

question;

- total or partial failure to observe the instructions;

- exceptional environmental events.

DO NOT PERFORM ANY WORK ON THE PUMP, MOTOR OR ECA CONTROL UNIT WITH ELECTRICAL POWER CONNECTED TO THE ECA CONTROL UNIT. DO NOT OPERATE ECA UNIT WITH THE COVER REMOVED. D ANGER OF ELECTRONIC SHOCK AND MECHANICAL PINCH HAZARD!

INSTALLATION AND REPAIRS SHOULD ONLY BE PERFORMED BY AUTHORIZED PERSONNEL!

- FOLLOW ALL SAFETY/ LOCAL LOCK-OUT, TAG-OUT PROCEEDURES!

4

Page 11

4. TRANSPORT AND STORAGE

4.1 Consignment receipt and unpackaging

Immediately after receipt of the equipment it must be checked against the delivery/shipping

documents for its completeness and that there has been no damage in transportation.

Check any crate, boxes or wrappings for any accessories or spare parts that may be packed

separately with the equipment or attached to side walls of the box or equipment.

Each product has a unique serial number. Check that this number corresponds with that

advised and always quotes this number in correspondence as well as when ordering spare

parts or further accessories.

Shortages or damage should be reported immediately to the carrier and your Pulsafeeder

Representative.

4.2 Handling

Boxes, crates, pallets or cartons may be unloaded using fork lift vehicles or slings dependent

on their size and construction.

4.3 Lifting

A crane must be used for all controller/pump sets in excess of 25 kg (55 lb). Fully trained

personnel must carry out lifting, in accordance with local regulations.

Slings, ropes and other lifting gear should be positioned where they cannot slip and where a

balanced lift is obtained.

4.4 Recycling and end of product life

At the end of the service life of the product or its parts, the relevant materials and parts should

be recycled or disposed of using an environmentally acceptable method and local

requirements. If the product contains substances that are harmful to the environment, these

should be removed and disposed of in accordance with current regulations. This also includes

the liquids and/or gases that may be used in the "seal system" or other utilities.

Make sure that hazardous substances are disposed of safely and that the correct personal

protective equipment is used. The safety specifications must be in accordance with the current

regulations at all times.

5

Page 12

5.

6

STORAGE INSTRUCTIONS

The ECA can be successfully st ored for extended periods. The key to this success is control

of temperature and humidity.

5.1 Short Term (0 - 12 months)

The ECA should be stored in a temperature and humidity controlled environment. It is

preferable to keep the temperature constant in the range of -18 to 40° Celsius (0 to 104°

Fahrenheit). The relative humidity should be 0 to 90% non-condensing.

If the ECA is installed on the pump, it should not be removed during this period - provided the

above conditions can be applied to the pump as well.

Page 13

If the ECA i s removed from the pump eccentric box, it should be stored in the same pump

mounted orientation. After removing the ECA from the eccentric box, seal the opening with

a dust and moisture proof material. If the ECA was shipped in its own carton, it should be

stored in that carton.

5.2 Long Term (12 months or more)

Storage of the ECA for periods of longer than twelve months is not recommended. If extended

storage is unavoidable, the ECA should be stored in accordance with those conditions

stipulated for Short Term Storage. In addition, a porous bag of 85g (3 oz) silica gel or similar

desiccant should be placed within the enclosure. The cover should be re-installed to seal the

desiccant within the enclosure. The two conduit connections must be tightly capped. Inspect

the unit carefully for any signs of damage and remove the desiccant before placing it into

operation.

Special note for long-term storage:

If AC input power has not been applied to the ECA for a period greater than 12 months, the

controller must be prepared for operation. The ECA should have AC power applied at the

input for a period of 8 hours before placing pump into normal operation. Refer to Installation

and Wiring section for AC power connection instructions.

7

Page 14

6. IN S TAL LATION AN D WIRING

6.1 Location

The site selected for the installation of your ECA is largely dependent on that of the

PULSAR metering pump. Please review the PULSAR Installation Operation

Review the Safety section prior to installing the ECA. It contains important information

required to properly install and operate the ECA in industrial environments.

Maintenance Instruction Manual (current version) provided with your PULSAR

metering pump. It details system related issues that are important to proper operation

of the PULSAR metering pump. Be mindful of the following ECA related issues when

selecting a site. Avoid locations where the ECA would be subjected to extreme cold or

heat. Note the warning statement. The installation of this device must comply with

national, state and local codes.

A

VOID LOCATIONS WHERE THE ECA WOULD BE SUBJECTED TO EXTREME COLD OR HEAT [LESS T HAN

-18° CELSIUS (0° FAHRENHEIT) OR GREATER THAN 40° CELSIUS (104° FAHRENHEIT)] OR DIRECT

SUNLIGHT. FAILURE TO OBSERVE THIS WARNING COULD DAMAGE THE ECA AND VOID ITS WARRANTY.

6.2 Installation Notes

• The ECA is a microprocessor-based controller that uses static sensitive CMOS

components. Do not make any electrical connections (high or low voltage) without

adequately grounding the ECA and the worker to eliminate any electrostatic charge

between the two. A conductive wrist strap worn by the worker and attached to the ECA

enclosure is adequate to satisfy this requirement.

• Conduit connections can carry fluids and vapors into the ECA causing damage and

void the warranty. Care should be taken when installing conduit to protect against

fluid/vapor entry. In accordance with any applicable codes provide sealed entries and

conduit drains near the point of entry as required.

• All applicable codes and regulations should be adhered to in the installation and wiring

of the ECA.

The safety of any system incorporating the ECA is the responsibility of the assembler

of the system.

6.3 Installation guidelines for EMC compliance

• The cover must be installed properly.

• Shielded cables used for analog inputs and outputs

• Proper Earth grounding

• Insure Power mains are properly filtered for isolation from line transients, lightning

strikes, or other electrical noise sources.

Failure to observe the guidelines above may lead to erratic and possibly unsafe operating

conditions.

8

Page 15

6.4 Housing Access

All wiring and programming of the ECA must be accomplished through the removal of the

housing cover. Use this procedure for removal and replacement:

Cover Removal

• Disconnect power at the source (follow your local Lock-Out-Tag-Out procedures).

• Disconnect power at the source.

• Loosen and remove the 4 Phillips head screws which secure the rear cover.

• Grasp the cover and lift straight up.

Cover Re-installation

9

Figure 1

Page 16

1. Disconnect power at the source (follow your local Lock-out-Tag-out procedures).

2. Verify that the mating surface of the lower half of the ECA is clean.

3. Inspect the mating surface for any indication of damage or dirt.

4. Position the cover and set in place.

5. Insert and tighten the 4 phillips head screws.

6. Return the ECA to the desired operating condition.

7. Torque the 13 Socket Head Cap Screws to 100in-lb (11.3 N-m). Use a crisscross pattern

to tighten the bolts to ensure a proper seal around the entire perimeter.

Figure 2

8. Check the cover lies flat with no air gaps. Re-torque the cover bolts if needed. DO NOT

exceed a maximum of 125in-lb (14.1N-m) torque.

9. When wiring is completed and cover is properly replaced, the ECA is now ready for

operation. Remove Lock-out-Tag-out protection and restore power. See 4.4 for Electrical

Wiring.

10

Page 17

6.5 Electrical Wiring

WHILE THE ECA WIRING REQUIREMENTS ARE VERY SIMPLE, ALWAYS KEEP IN MIND THAT ACCESS

TO THESE CONNECTORS REQUIRES THE REMOVAL OF THE COVER, AND AS SUCH THIS PROCEDURE

SHOULD ONLY BE PERFORMED BY A TRAINED PROFESSIONAL

Wait a minimum of 3 minutes after disconnecting power before servicing the ECA or

pump motor. Capacitors retain a charge even after power is removed from the controller.

It is highly recommended that you take a step-by-step approach to wiring and confirming proper

ECA operation:

1. Make the Line voltage connections. These will allow you to operate the ECA and

attached Pulsafeeder pump.

2. Decide which low voltage Inputs and Outputs (e.g., 4-20mA in) will be used and make

those connections

3. Power-up and test the ECA to confirm the connections and check for proper operation.

.

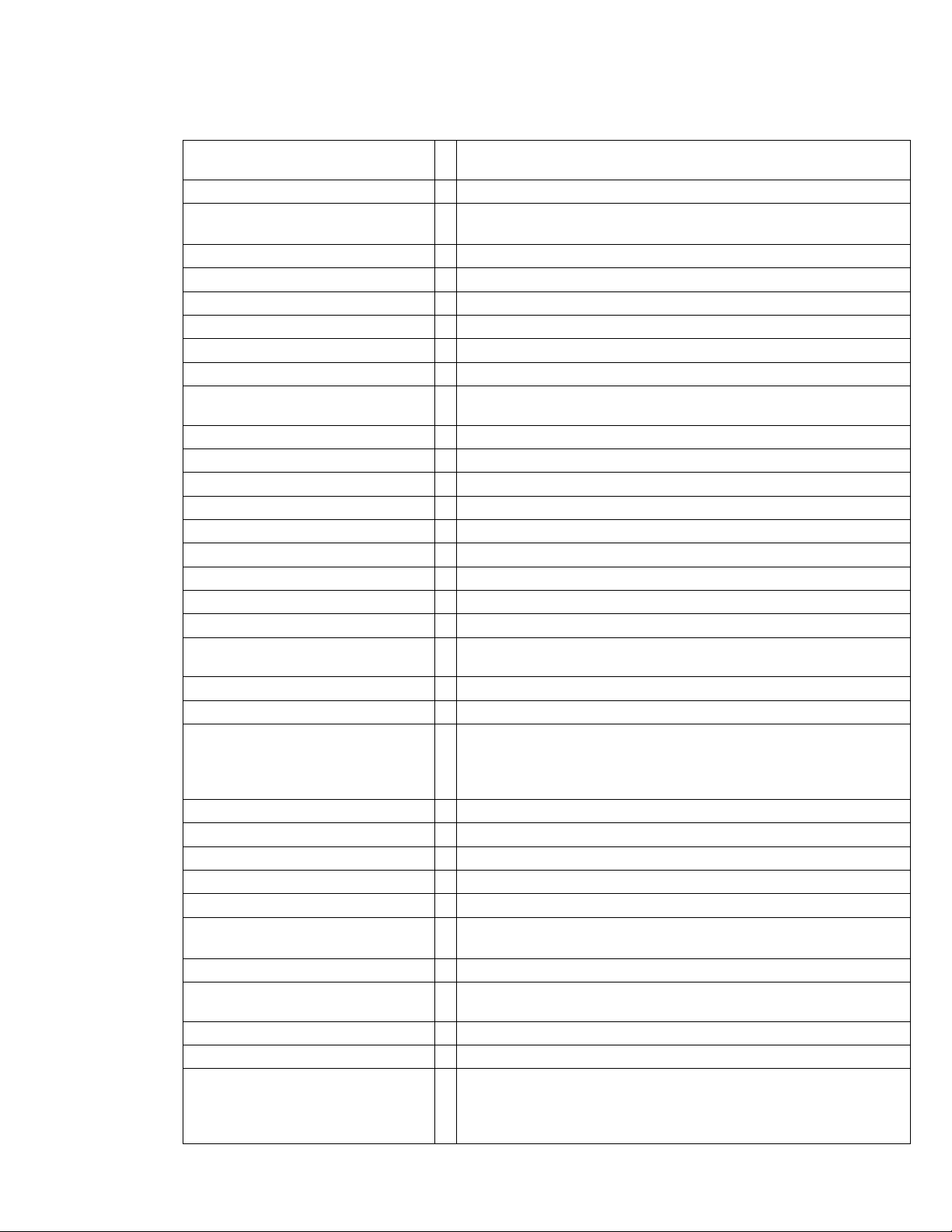

6.6 Power Wiring Information

THESE PROCEDURES REQUIRE REMOVAL OF THE ENCLOSURE COVER. THIS SHOULD BE DONE ONLY IF

THE AREA IS KNOWN TO BE SAFE FOR ELECTRONIC WORK.

• Verify the correct supply voltage (115VAC or 230VAC) with the nameplate affixed to

your ECA. Ensure that your supply voltage matches the ECA configuration.

• Wires should be routed within the enclosure in a manner that maintains separation

between line voltage and extra-low voltage conductors.

• Applicable national and local electrical codes take precedence over

recommendations in the table below.

• A circuit breaker or fuse must be provided as noted below.

11

Page 18

14

AWG

2.5

mm2

UL, CUL,

CE

14

AWG

2.5

mm2

UL, CUL,

CE

Power

Requirements

Recommended Minimum Wiring and Circuit Breaker

115 VAC Operation

Actual Circuit Wire Wire Safety Actual Circuit Wire Wire Safety

Draw Breaker Size Size Approvals1 Draw Breaker Size Size Approvals1

230 VAC Operation

ECA

200ma 10A

Note 1: UL File E217212, Applicable standards are CSA 22.2 14-23, Cenelec EN61326-1,

UL61010-1, and EN61010-1 3

rd

edition

200ma 10A

Note the ECA input current ratings from the name plate and check the applicable electrical codes

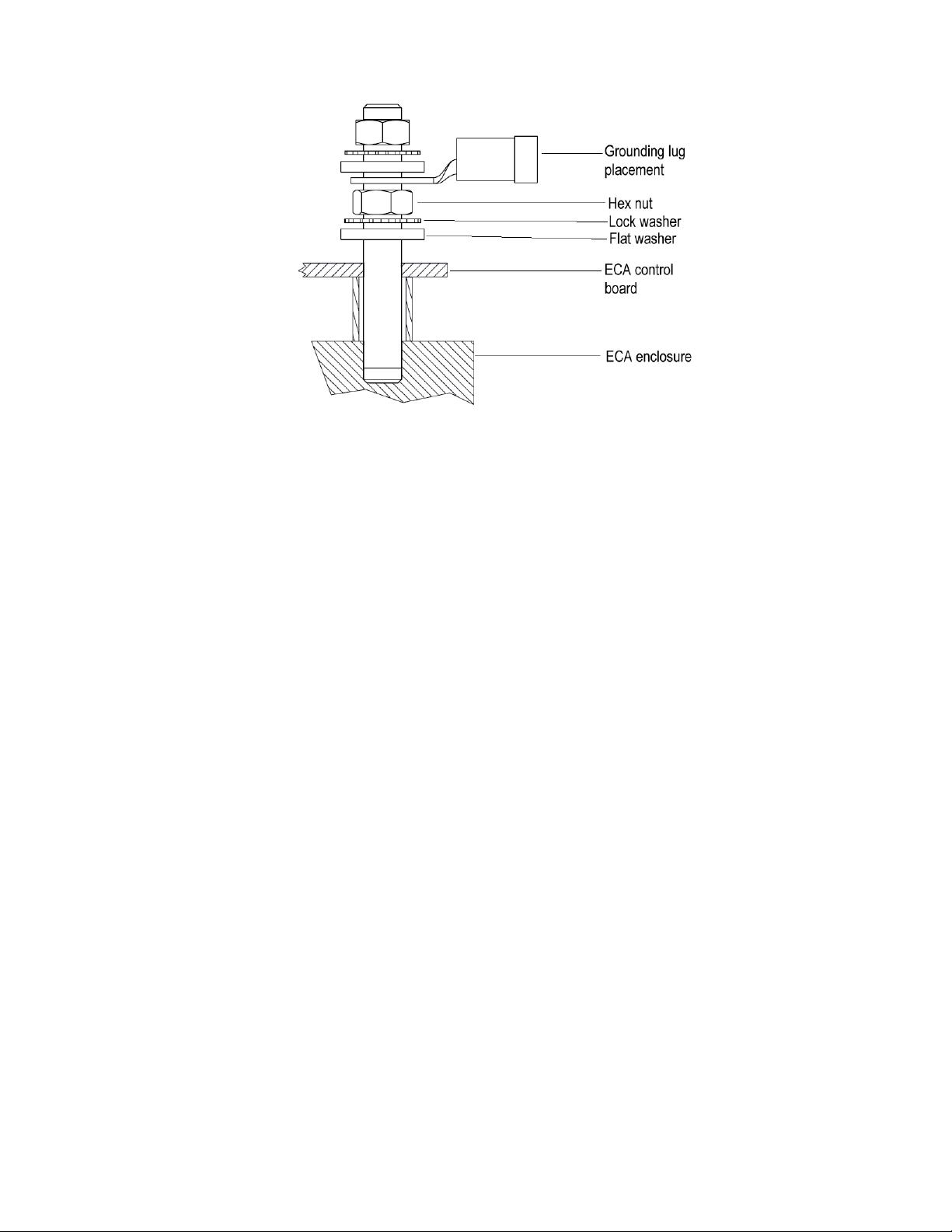

for required wire type and size, grounding requirements, over-current protection, and incoming

power disconnect before wiring the controller. Connect the proper AC voltage supply to power the

ECA at connector J7. Neutral and Line connection points are indicated on the circuit board under

the connector. The Earth connection is made to the stud on the chassis via a ring terminal

(provided). See Figure 3 for details. Remove approximately 0.3 inches, (7-8mm) of insulation from

the end of each conductor. Loosen the terminal strip screw, and insert the stripped wire end fully

into the terminal. Tight en the screw to 5 in-lbs. (0.5 Nm) to secure the conductor. Make certain

that the terminal grips the wire, not the insulation. The operating voltage and frequency of the

ECA is factory configured -- an internal motor and capacitor are sized according to voltage and

frequency. If the power supplied to the unit does not match the factory configuration (shown on

the nameplate), it will malfunction/damage and void the warranty.

Note: Power wiring should have a rating of at least 300 volts AC (rms) and a temperature

rating of at least 105 Degrees C.

A circuit breaker or disconnect switch with fuses, must be provided in accordance with all

applicable local and national electrical codes and regulations. Size external fusing/breaker for

ratings for the wiring used for the unit.

Applicable national and local electrical codes take precedence over recommendations made here.

To ensure proper operation, the ECA should remain powered at all times. A dry

contact input provides the ECA with motor status (on vs. off). See Motor Status Input

Section

Input Power must be run in separate conduit. Do not combine Power and Control wires in

a common conduit!

Field Wiring conductors shall be copper conductors only!

12

Page 19

Figure 3 – Earth grounding

13

Page 20

Ref. Section

Motor Status

Input

Figure 4

14

Page 21

6.7 Labeling – Nameplate

6.8 Control Input and Output Connections

6.8.1 Motor Status Input

The contactor or motor starter controlling the PULSAR motor should be equipped with a

normally open auxiliary contact, which closes to indicate the PULSAR motor is on. This

auxiliary contact, which must be an un-powered, dry contact only, is to be wired to inputs (J4-5

and J4-6) at the ECA, after removing the factory installed jumper wire. Remove approximately

0.3 inches, (7-8mm) of insulation from the end of each conductor. Loosen the terminal strip

screw, and insert the stripped wire end fully into the terminal. Tighten the screw to 5 in-lbs.

(0.5 Nm) to secure the conductor. Make certain that the terminal grips the wire, not the

insulation. It is critical that the ECA receive this input, as stroke length should only be adjusted

when the pump motor is running. An alternate contact that represents motor status (for

example a relay contact in a local control cabinet) can also be used for this function.

D

AMAGE TO THE ECA MAY OCCUR IF THE STATUS INPUT WIRING RECOMMENDATIONS ARE NOT

FOLLOWED.

6.8.2 Analog Input (current loop)

The Analog Input is used for remote control of the pump flow. It accepts current inputs

anywhere in the range of 0 to 25mA (e.g., 4-20mA) provided the “span” (the difference

between the high and low value) is greater than 2mA. Use shielded cable (minimum 2conductor) for connection to the Analog Input. Recommended: use shielded cable, 22AWG, 3pair, and 6-conductor for connections (e.g. Belden 5545FE). Attach the positive lead to

terminal J4-1 and the negative lead to terminal J4-2 (see Figure 5). Position indicators are

printed on the circuit board below each terminal. Remove approximately 0.3 inches, (7-8mm)

of insulation from the end of each conductor. Loosen the terminal strip screw, and insert the

stripped wire end fully into the terminal. Tighten the screw to 5 in-lbs. (0.5 Nm) to secure the

conductor. Make certain that the terminal grips the wire, not the insulation. The ECA will

provide approximately 160 ohms of resistance to a current loop. It will also accept voltage

signals in the 0-4 volt DC range. The Analog Input is electrically isolated from all other inputs,

outputs and earth ground.

15

Page 22

Ref. Section Analog

Ref. Section Analog

6.8.3 Analog Output (current loop)

The Analog Output sends a signal representing the actual stroke length position. It can

be adjusted to source current in the 0 to 25 mA range (4-20mA factory default). The

output can also be s et up for reverse-acting or split-ranging operation. The Current

Output can be used to control slave devices (e.g. ECA’s, ELMA's, PULSAMATICs,

etc.) or to fulfill closed loop system r equirem ents. Use shielded cable (minimum 2conductor) for connection to the analog output. Recommended: use shielded cable,

22AWG, 3-pair, and 6-conductor for connections (e.g. Belden 5545FE). Attach the

positive lead to terminal J4-3 and the negative lead to terminal J4-4 (see Figure 5).

Position indicators are printed on the circuit board below each terminal. Remove

approximately 0.3 inches, (7-8mm) of insulation from the end of each conductor.

Loosen the terminal strip screw, and insert the stripped wire end fully into the terminal.

Tighten the screw to 5 in-lbs. (0.5 Nm) to secure the conductor. Make certain that the

terminal grips the wire, not the insulation. The Analog Output will drive a maximum

load of approximately 700 ohms. The Analog Output is electrically isolated from all

other inputs, outputs, and earth ground.

Note: Analog Input and Analog Output wiring should have a rating of at least 300 volts AC

(rms) and a temperature rating of at least 75 Degrees C.

Note: If strip length guidelines in above sections are not followed, there is a risk of electric

shock as well as shorting of adjacent connections generating hazardous sparks.

Output

Input

16

Figure 5

Page 23

Figure 6

7. START UP AND OPERATION

7.1 Overview

Once all electrical connections have been made, your ECA is ready for Start-up. The

following sections detail the procedures required to complete the ECA start up.

WARNING: The ECA NEMA 4X Stroke controller includes a manual stroke control

wheel. DO NOT OPERATE THIS MANUAL STRO KE CONTROL WHEEL WHILE THE

POWER TO THE STROKE CONTROLLER IS OFF. This will cause the electronics to

error. The ECA will stop operation and will need to be reset to look for the motor zero

position!

- WARNING: DO NOT attempt to remove the cover of the ECA and set up the ECA

in a very wet or rainy environment. While care has been taken to insulate power

connections, DANGEROUS voltages are present and can cause electric shock, and

possible electrocution if safety procedures are not followed

W

HEN POWER IS SUPPLIED TO THE UNIT, LINE VOLTAGE MAY BE PRESENT WITHIN THE ECA

ENCLOSURE EVEN WHEN THE MOTOR IS OFF.

D

URING START-UP, IT MAY BE NECESSARY TO RUN THE PUMP MOTOR. THIS WILL CAUSE FLUID TO

DISCHARGE FROM THE PUMP

PUMP DURING START-UP AND CALIBRATION.

T

HE ECA IS DESIGNED TO CONTROL THE PUMP STROKE LENGTH

WITHIN THE PUMPS RATED PRESSURE AND FLOW

BEYOND RATED SPECIFICATIONS

DAMAGE EQUIPMENT AND VOID THE WARRANTY

I

F THIS EQUIPMENT IS USED IN ANY MANNER NOT SPECIFIED BY

PULSAFEEDER, PROTECTION PROVIDED BY THE EQUIPMENT MAY BE

IMPAIRED

.

8. INPUT/OUT SETUP

- WARNING: DANGEROUS LINE VOLTAGES ARE

PRESENT ON THE CIRCUIT BOARD DURING THIS

PROCEDURE. USE CAUTION WHILE PRESSING BUTTONS.

. YOU ARE RESPONSIBLE FOR SAFELY DIVERTING FLOW FROM THE

. OPERATION

, EVEN INTERMITTENTLY, MAY

.

8.1 System User Calibration

8.1.1 Analog Input Signal Calibration

The analog input signal should be user calibrated to each system. To perform a

calibration, the signal-generating device (e.g., PLC) must be powered up, wired to

the ECA and capable of altering its output from the minimum to the maximum

17

Page 24

signal. Note that the minimum span, or difference between low and high values, is

2.0 mA. The ECA will not actuate to change stroke length during this process.

THIS PROCEDURE REQUIRES REMOVAL OF THE ENCLOSURE COVER. THIS PROCE DURE S HOUL D BE

PERFORMED ONLY IF THE AREA IS KNOWN TO BE SAFE FOR ELECTRONIC WORK.

• With the cover removed and power supplied to the ECA, press and release the

white Input Cal pushbutton. The Cal Input LED will blink slowly, indicating the ECA

is ready to accept the low (0% stroke) analog input value.

• Send the low analog signal to the ECA (generally 4 mA) from the signal-generating

device (e.g., PLC). It is highly recommended that you use the actual signal the ECA

will be receiving during calibration.

• When the low analog input value has stabilized (allow 10-15 seconds), press the

white Input Cal pushbutton to accept it as the 0% flow analog signal value. The Cal

Input LED will now blink rapidly.

• Send the desired analog high signal (generally 20 mA).

• When the high analog input value has stabilized (allow 10-15 seconds), press the

white Input Cal pushbutton to accept it as the high (100% stroke) analog signal

value. The Cal Input LED will extinguish, unless the minimum span of 2.0 mA is

violated, then the ECA will return to step 1 above.

Reverse-acting calibration is accomplished by input of a high signal (i.e., 20 mA) as the low

(0% stroke) analog input value, and a low signal (i.e. 4 mA) as the high (100% stroke)

analog signal.

• Replace the cover (see Section Cover Re-installation) and continue with the

output calibration if that function is being utilized.

8.1.2 Analog Input Signal Los s

A failure of the analog input signal is detected if the input signal falls below the

calibrated 0% stroke signal by 0.3 mA. For example, if the ECA is calibrated with a

range of 4-20 mA and the signal falls to 3.6 mA then a Signal Loss failure will be

logged. If the calibrated 0% stroke signal is 0.3 mA or less, no Signal Loss failure

will be generated. Input signals above the calibrated 100% stroke signal are simply

ignored, the stroke position will be driven to 100% and no error condition occurs.

In the event of a loss of analog signal

or an abnormally low signal, the ECA

will drive to the zero stroke position.

The ECA will recover once a valid

analog signal is present and resume

control to the appropriate set point.

8.1.3 Analog Output Signal Calibration

18

Page 25

Figure 7

T

HIS PROCEDURE REQUIRES REMOVAL OF THE ENCLOSURE COVER. THIS SHOULD BE DONE ONLY IF THE AREA

IS KNOWN TO SAFE FOR ELECTRONIC WORK

To calibrate the analog output, attach a milli-ammeter to the output circuit of the ECA in series

with the PLC used to control the process (as shown in figure 7). I t is recommended that you

calibrate the ECA analog output values to whatever is required by the PLC. For example, the

ECA output can be adjusted at the zero point so that the screen on the PLC system reads

zero %, regardless of the actual mA value of the signal. The ECA will not actuate to change

stroke length during this process.

1. With the cover removed and power supplied to the ECA, press the black Output Cal

pushbutton. The Cal Output LED will blink slowly and current output will be set to the present

analog out low calibration value. (4 mA factory default)

2. Press and hold the white Input Cal pushbutton to increase current

output until the desired low set point is reached. Release and press

again to decrease current output. Current will change in steps of

approximately 0.02 mA, at a rate of 20 steps per second.

3. Press the black Output Cal pushbutton. The Cal Output LED will

blink rapidly and current output will be set to the present analog out

high calibration value. (20 mA factory default)

4. Press and hold the white Input Cal pushbutton to decrease current

output until desired high set point is reached. Release and press

again to increase current output. Current will change in steps of

0.125 mA at a rate of 20 steps per second.

5. Press the black Output Cal pushbutton. The Cal Output LED will

extinguish, unless the minimum span of 2.0 mA is violated, then the

ECA will return to step 1 above.

6. Remove Power to the ECA. Replace the cover (see Section Cover

Re-installation) and return power to the ECA.

.

Figure 10

9. MECHANICAL ZERO CALIBRATION

THIS PROCEDURE REQUIRES REMOVAL OF THE ENCLOSURE COVER. THIS SHOULD BE DONE ONLY IF

THE AREA IS KNOWN TO BE SAFE FOR ELECTRONIC WORK.

If the ECA was shipped with a pump attached, the mechanical zero calibration was

performed at t he factor y. If the ECA was shipped without a pump attached, performing the

mechanical zero calibration is mandatory to successful installation/operation. The ECA

controller automatically performs a mechanical zero calibration if it does not have a valid

zero calibration set point stored. If you suspect the zero calibration set point is incorrect,

follow the calibration procedure below. The pump MUST be running during this

process to ensure an accurate zero position is calibrated. Therefore you MUST

ensure it is safe to operate the pump during the procedure.

• Verify that power to the ECA is off

• Remove the enclosure cover.

19

Page 26

• Press and hold the BLACK pushbutton

• Apply power to the ECA.

• A mechanical zero calibration routine will begin. The routine begins when the motor

internal to the ECA starts motion looking for the zero position. Once the ECA

begins the routine you may release the pushbutton.

• The calibration routine is complete when the motor reaches the zero position and

the rotor locks for approximately 30 seconds. Zero calibration ends when the motor

stops running. .

• Remove Power to the ECA. Replace the cover (see Section Cover Re-

installation) and return power to the ECA.

9.1 Factory Re-initialization

THIS PROCEDURE REQUIRES REMOVAL OF THE ENCLOSURE COVER. THIS SHOULD BE DONE ONLY IF

THE AREA IS KNOWN TO BE SAFE FOR ELECTRONIC WORK

A Factory Re-initialization restores all EEPROM calibration settings and mode settings to their

factory default values and is typically not required. The user also needs to keep in mind that

once the Factory Re-Initialization is performed, all user calibrations are erased. This procedure

should be performed only if the user has reason to believe that the internal ECA memory has

become corrupted. Memory Corruption usually manifests itself with inconsistent or erratic

operation. A number of factors could cause memory value corruption including:

.

1. Disregard of electrostatic precautions during installation,

2. Improper wiring,

3. Voltage surges, spikes, etc.

The pump MUST be running during this process to ensure an accurate zero position is

obtained. Therefore you MUST ensure it is safe to operate the pump during the

procedure.

• Verify that power to the ECA is off.

• Remove the enclosure cover.

• Press and hold both black and white pushbuttons while applying power to the ECA.

• Release the CAL pushbuttons and the unit is restored to the factory default settings.

• The unit will automatically perform a new mechanical zero calibration as part of the

Factory Re-Initialization routine.

• Perform any additional calibration procedures as required.

• Remove Power to the ECA. Replace the cover and return power to the ECA.

10. DIAGNOSTICS

10.1 Trouble Code Reporting

The ECA is designed to be as fault-tolerant and self-recovering as possible. When the ECA

encounters an abnormal condition, a trouble code is indicated by blinking CAL LED’s located on

the ECA main board, internal to the enclosure, as follows:

• Both LED’s will blink once.

• The Cal Input LED will blink a number of times to indicate the first trouble code digit.

20

Page 27

• The Cal Output LED will blink a number of times to indicate the second trouble code

digit.

This sequence will repeat until the trouble condition is cleared.

21

Page 28

Code

Definition

Description

Action

10.2 Trouble Codes

11

or

12

13

14

21

Encoder

Error

Position

Error

Over

Temperature

Signal Loss

The CPU failed to read an encoder pulse, or has not

received the expected signals in a certain amount of time.

Thus, the controller has lost its zero reference. It then

attempts to recover by doing a mechanical zero

calibration. If the mechanical zero calibration is

successful, this error is cleared, and normal operation

continues. If further errors prevent successful mechanical

zero calibration, this error is a fatal error and requires

user intervention.

Failure to reach commanded position within the timeout

period (5 minutes). After 10 minutes, the error will clear

and the controller will automatically retry the position

adjustment. If the error continues to occur for ten

consecutive times, no further retries will be attempted,

and the error will become a fatal error requiring user

intervention.

The motor thermistor indicates the motor case

temperature has reached approximately 90°C (194°F).

This will stop motor operation until the motor case

temperature drops below approximately 80°C (176°F) at

which point the error clears automatically.

The Analog Input signal dropped more than 0.3 mA below

the low cal point. This error clears automatically when the

analog input signal returns to normal.

Clear error by

cycling power.

Wait 10 minutes,

or clear fatal error

by cycling power.

Correct reason for

motor OverTemperature

condition.

Correct reason for

low input signal.

22

23

24

33

Self-Test

Signal Error

Self-Test

Signal Error

Self-Test

Thermistor

Error

Self-test

passed

The Analog Output signal and Analog Input signal at 0%

stroke position do not agree (refer to Self-Test Mode

description for further details).

The Analog Output signal and Analog Input signal at

100% stroke position do not agree (refer to Self-Test

Mode description for further details).

Thermistor readings are not within specifications.

Refer to Self-Test Mode description for additional

information.

Refer to Self-Test

Mode

Refer to Self-Test

Mode

Contact factory

No action.

22

Page 29

10.3 Self-Test Mode

The ECA has a diagnostic test mode which can be used to verify performance and troubleshoot

problems. To initiate the self-test:

• Remove power from the ECA, and remove the top cover.

• Disconnect any field wires attached to J4, and connect Analog Out to Analog In.

(jumper J4-1 to J4-3 and J4-2 to J4-4).

• Press and hold the white Input Cal pushbutton.

• Apply power to the ECA and release white Input Cal pushbutton. The ECA will

enter the self-test mode and automatically perform the following tests:

Calibrates mechanical zero position

Drives to the 0% stroke position, testing the motor drive and the encoder. Both Cal

LED’s will blink if the zero calibration fails.

Pauses for 30 seconds, and then confirms that the Analog Output and the Analog Input

are correct. Sets trouble code 22 if analog ports do not agree.

Drives to the 100% stroke position, testing the motor drive and the encoder. Sets the

trouble code to 13 if the 100% position is not attainable.

Pauses for 30 seconds, and then confirms that the Analog Output and the Analog Input

are correct. Sets trouble code 23 if analog ports do not agree.

Confirms that the motor thermistor is reading in correct range. Sets trouble code 24 if

thermistor readings are outside specifications.

Sets trouble code 33 to indicate test passed.

Turn power off to the ECA, and remove the jumpers installed in step 2. Re-connect field

wires.

23

Page 30

Replace the cover and return power to the ECA.

10.4 Error Recovery

In cases of abnormal operation, the following procedure is recommended:

1. First, check all power and process connections to ensure all wiring is secure and properly

connected.

2. Check the internal connections within the ECA.

3. Ensure that the cable connections from the stroke adjustment motor and encoder are

secure and seated properly.

4. Perform a Factory Re-initialization, as previously mentioned in this IOM. This will also

force a new mechanical zero calibration to be performed. The pump motor should be

operating during this process as the ECA will adjust stroke to re-locate the zero position.

Ensure that it is safe to operate the pump during this step.

5. Perform a new Analog Input signal calibration

6. Perform a new Analog Output signal calibration

24

Page 31

Input Power

115 Volt/ 60Hz, 115 Volt/ 50Hz, 230 Volt/ 60 Hz, or 230 Volt/

50Hz

Input Current

Stroke Length Control

0 – 100% control range

Resolution – 0.0625% increments

Stroke Adjustment response

Approximately 1% per second

Analog Input

Operating Range

Input Impedance

160 ohms

Minimum Span

2.0 mA

Isolation

500V from all other inputs, outputs and ground, optically

isolated

Conditioning

Split Ranging and Reverse Acting accessible via calibration.

Analog Output

Operating Range

0 to 25.5mA (4-20 mA factory default)

Maximum Load

700 ohms

Minimum Span

Conditioning

Split Ranging and Reverse Acting accessible via calibration.

Isolation

500V from all other inputs, outputs and ground, optically

isolated.

Status Input

Motor On/Off

Optically isolated dry contact input. Open contact indicates

here.

Environmental

Rated Ambient Temperature

-20°C to 40°C (-4°F to 104°F)

Storage Ambient Temperature

-25°C to 60°C (-13°F to 140°F)

Enclosure

NEMA4, IP66, NEMA 4X

Approvals

UL/ULC - NEMA 4X

CE – IEC EN 61010-1

(230VAC Models) at 50uS

Voltage Overload

120% Continuous,

Pollution Degree

Suitable for Pollution Degree 3

(specified at time of purchase) Single phase input only 50 or 60

11. SPECIFICATIONS

200ma nominal, 2 amperes (short circuit)

0 to 25.5mA (4-20 mA factory default)

8 second running average.

Transient Voltage

2.0 mA

None. Output represents current stroke position.

motor is off. Controller will then suspend all stroke control

action. Motor starter should provide a contact for connection

Max Impulse withstand 1500V (115VAC Models), 2500V

Input Voltage

25

115 (105-125 acceptable range) or 230 (208 – 240 acceptable

range) VAC

Note: factory configured only for correct input voltage range

Page 32

Hz. Input frequency range 48 Hz to 62 Hz

Altitude:

3300 Ft (1000 M) above sea level (de-rate 5% per additional

3300 Ft)

Humidity

0-90% (non-condensing)

40° C (104° F) Maximum operating temperature

Earth Leakage Current

Size Earth Leakage Circuit Breakers (ELCB) to a detection

level of 30 mA or greater

Fuse

checked after any failure of the unit to power up properly.

Temperature

0° C (32° F) Minimum operating temperature

One Power input fuse (AC over current protection) is located on

the main control board. This fuse is a 2 amp slow-blow type

(Schurter 34.6618, Digik e y 486-1138-ND. The fuses should be

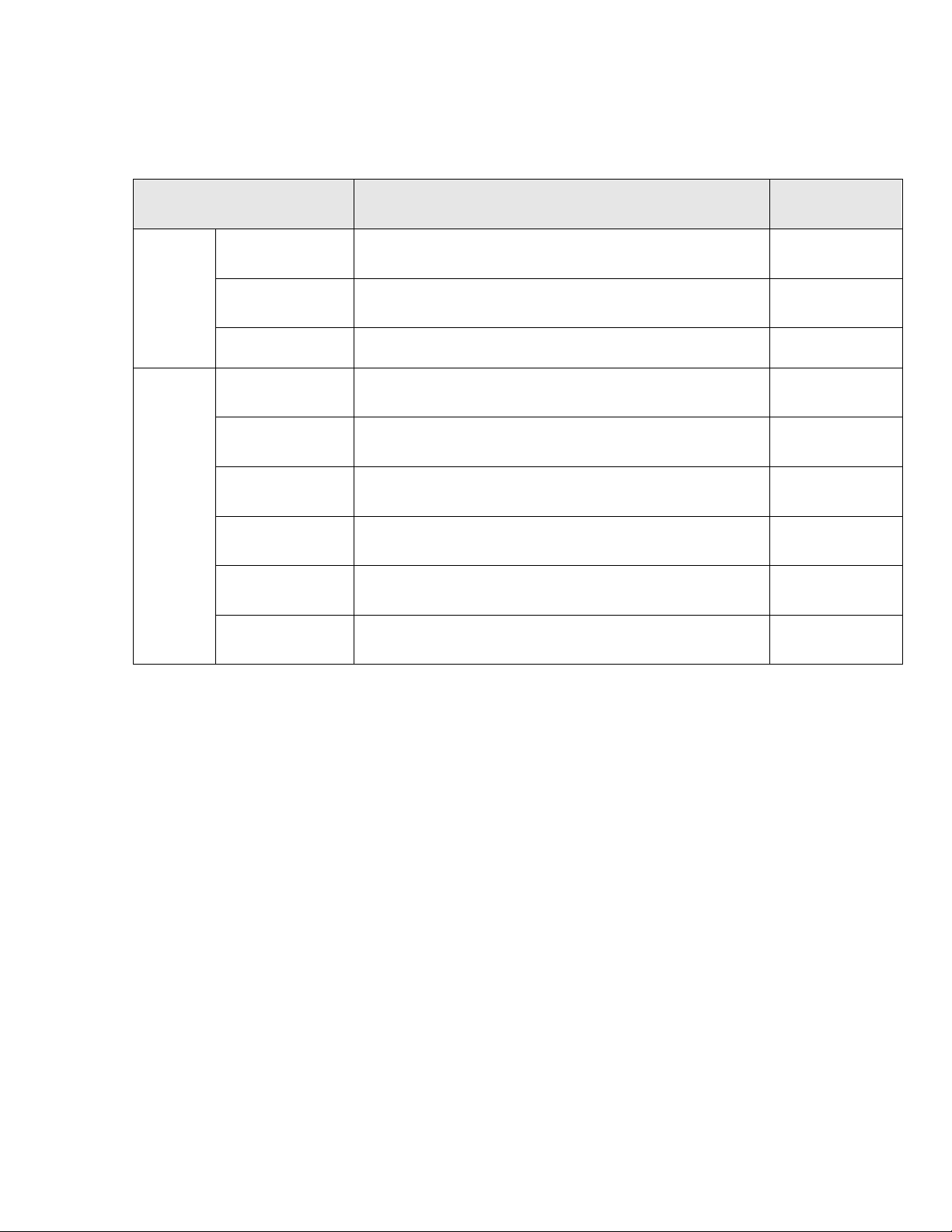

12. POWER-UP OPTIONS SUMMARY

Upon application of input power, the ECA will perform certain functions if the pushbuttons are used, as

follows:

Pushbuttons

pressed at powerup

Function

Reference

Section

NONE Normal operation, use all calibration data from memory

BLACK key Forces a mechanical zero position calibration Mechanical

Calibration

WHITE key Initiates self-test with jumpers Self-Test

BOTH keys (WHITE

and BLACK)

Resets all to factory default values, performs an

automatic mechanical zero calibration, analog signals

will require re-calibration

Zero

Mode

Error

Recovery

26

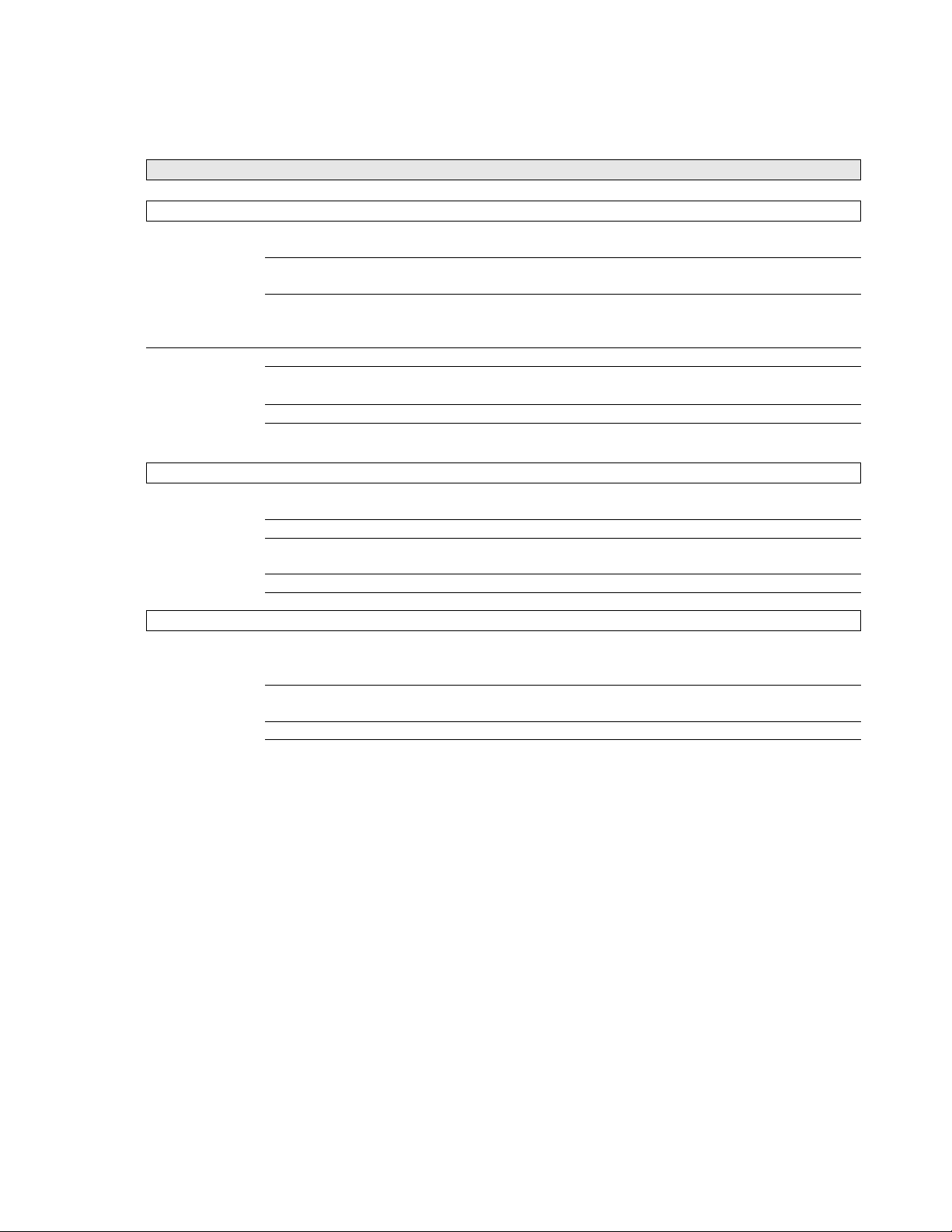

Page 33

Electrical

Electrical

Wiring

13. FIELD WIRING SUMMARY

Connector Location

Function/Connection

Reference

Section

J7

J4

Line

Neutral

Ground

Position 1

Position 2

Position 3

Position 4

Position 5

Position 6

Line connection 115VAC, Line 1 connection 230

VAC

Neutral connection 115 VAC, Line 2 connection 230

VAC

Earth ground connection 115 or 230 VAC

Analog input (control) signal positive (+) Analog Input

Analog input (control) signal common (-) Analog Input

Analog output (feedback) signal positive (+) Analog Output

Analog output (feedback) signal common (-) Analog Output

Motor enable dry contact Motor Status

Motor enable dry contact Motor Status

Electrical

Wiring

Wiring

(current loop)

(current loop)

(current loop)

(current loop)

Input

Input

27

Page 34

Page 35

Problem Potential Cause Solution

INTERNAL LED DISPLAY

No LED

Display

Normal, after setup.

No action required

No power supplied.

Check power source. plug & circuit

breaker

Supply power wired incorrec tl y.

Check wiring.

Supply power outside of specification.

Check voltage/frequency against

specification.

LED’s are

Normal at startup

Adjust as per Start-up & Operation section

Indicates operation fault

Trouble Code

section for LED blink codes

POWER

No power

No power supplied.

Check power source. Plug & Circuit

Breaker

Indicators

Supply power wired incorrec tl y.

Check wiring.

Supply power outside of specification.

Check voltage/frequency against

specification.

Motor

Motor not

stroke control

No power supplied

Check power source. Plug & Circuit

Internal fuse is blown

Replace internal fuse, Call service if

condition continues

Damaged electronics or motor

Call field service

14. TROUBLESHOOTING GUIDE

flashing

working/ No

See table in Diagnostics

Breaker

Page 36

15. MAINTENANCE & SPARE PARTS

All maintenance work must be carried out only when the ECA and connected

equipment is stopped and disconnected from mains supply (including auxiliary

circuits). Maintaining original characteristics over time must be ensured by an

efficient maintenance and inspection plan, developed and managed by qualified

technicians, taking into account the service and the actual environmental conditions

in which it operates.

15.1 Operating Precautions

All operations must be performed by qualified personnel.

Work on the unit should only be performed with safety supervisor authorization, after

having verified that:

a) Disconnect power at the source (follow your local lockout tag out procedures)

b) The power line is disconnected and no parts are energized, including any auxiliaries

c) Ensure that any risk of accidental restart has been excluded

d) Consult Manufacturers Pump Operating Manual for instructions on minimizing risk

due to pressurized or chemically dangerous conditions with in the Pump system

e) With pump switched off, that the ON-OFF valves on the suction and discharge

pipelines are closed.

f) Pump has been adequately cleaned, when operating in environments exposed to

aggressive chemicals.

g) Maintenance personnel shall refer to the Installation & Wiring Instruction section for

safe return to service after repair.

Since the machine object of supply is a product designed and intended for operation in

industrial areas, additional measures must be adopted and assured by the person

responsible for the installation, should more restrictive safety conditions be required.

15.2 Cleaning and Decontamination

The ECA enclosure may be cleaned with water and mild detergent.

Decontamination shall occur when the ECA is exposed to a release of process

chemicals. Follow the SDS for clean-up in the event of a chemical spill.

2

Page 37

15.3 User Replaceable Parts for the ECA

MFG & MFG P/N Description

Schurter 34.6618

Fuse,

2 amp slow-blow type (available via

Digikey 486-1138-ND)

3

Page 38

A unit of IDEX Corporation

2883 Brighton Henrietta Town Line Road

Rochester NY 14623

+1 (585) 292-8000

pulsa.com

pulsa@idexcorp.com

4

Loading...

Loading...