Page 1

INSTALLATION

OPERATION

MAINTENANCE

INSTRUCTION

BULLETIN No. IOM-PS-DLCM-1101-Rev E

Manufacturer’s of Quality Pumps,

Controls and Systems

Engineered Pump Operations

2883 Brighton-Henrietta Townline Road

Rochester, New York 14623

Telephone: (585) 292-8000 Fax: (585) 424-5619

http://www.pulsa.com

E-mail: pulsa@pulsa.com

Page 2

DLCM™ FACTORY SERVICE POLICY

Your DLCM is a state of the art microprocessor based stroke length and motor speed control for use with

PULSAR Diaphragm Metering Pumps. It includes extensive on-board diagnostics. If you are experiencing

a problem with your DLCM, first review the diagnostic menu, then consult the trouble shooting guide. If

the problem is not covered or cannot be solved, please contact your local PULSA Series Sales Organization

or our Technical Service Department at (585) 292-8000 for further assistance. Do not open or tamper

with your DLCM enclosure as this will void the warranty.

Trained individuals are available to diagnose your problem and arrange a solution. Solutions may include

purchasing a replacement unit or returning the DLCM to the factory for inspection and repair. All returns

require a Return Material Authorization (R.M.A.) number to be issued by Pulsafeeder. Replacements

purchased under a possible warranty situation may be credited after an examination of the original DLCM

by Pulsafeeder personnel.

Certain components may be purchased for replacement. Refer to Section 15 – Spare Parts for more

information and part numbers. Parts purchased to correct a warranty issue may be credited after

examination of the original parts by Pulsafeeder personnel. Parts returned for warranty consideration that

test satisfactorily, will be sent back to the originator freight collect.

Any field modifications will void the Pulsafeeder DLCM warranty. Out-of-warranty repairs will be

subject to Pulsafeeder's standard bench fees and testing costs associated with replacement

components.

DLCM LIMITED WARRANTY

The manufacturer warrants the DLCM, microprocessor-based controller against defects in materials or

workmanship for a period of one year under normal use from date of shipment. The manufacturer's

liability is limited to the repair or replacement of any failed component which is proven defective in

material or workmanship upon manufacturer's examination. This warranty does not include removal or

installation costs and in no event shall the manufacturer's liability exceed the selling price of such

equipment.

This warranty does not extend to damage by corrosion, erosion, mishandling, any force of nature or any

other conditions beyond the seller's reasonable control.

The manufacturer disclaims all liability for damage to its products through improper installation,

maintenance, use or attempts to operate such products beyond their functional capacity, intentionally or

otherwise or any unauthorized repair. The manufacturer is not responsible for consequential or other

damages, injuries or expenses incurred through the use of its products.

The above warranty is in lieu of any other guarantee, either expressed or implied. The manufacturer makes

no warranty of fitness or merchantability. No agent of ours is authorized to make any warranty other than

the above.

FCC Warning

This equipment generates and uses radio frequency energy. If not installed and used properly, in strict

accordance with the manufacturer’s instructions, it may cause interference to radio communications.

Operation of this equipment in a residential area is likely to cause interference in which case the user, at his

own expense, will be required to take whatever measures necessary to correct the interference.

Copyright

Copyright © 2001 Pulsafeeder, Inc. All rights reserved.

Information in this document is subject to change without notice. No part of this publication may be

reproduced, stored in a retrieval system or transmitted in any form or any means electronic or mechanical,

including photocopying and recording for any purpose other than the purchaser’s personal use without the

written permission of Pulsafeeder.

ii

Page 3

Table of Contents

1. I

NTRODUCTION

.....................................................................................................................................1

1.1 Description...............................................................................................................................1

1.2 DLCM Standard Features .......................................................................................................2

1.3 Options.....................................................................................................................................2

1.4 Accessories .............................................................................................................................2

2. S

AFETY CONSIDERATIONS

....................................................................................................................3

2.1 General Safety .........................................................................................................................3

2.1.1 Explosive Atmosphere Safety ........................................................................................ 3

2.1.2 Electrical Safety ...............................................................................................................3

2.1.3 Mechanical Safety............................................................................................................3

2.1.4 Hydraulic Safety...............................................................................................................3

3. E

QUIPMENT INSPECTION

4. S

TORAGE INSTRUCTIONS

.......................................................................................................................4

......................................................................................................................4

4.1 Storage Length ........................................................................................................................4

4.1.1 Short Term (0 - 12 months).............................................................................................4

4.1.2 Long Term (12 months or more) ....................................................................................4

5. I

NSTALLATION

......................................................................................................................................5

5.1 Location ...................................................................................................................................5

5.2 Installation Notes ....................................................................................................................6

5.3 Electrical Wiring ......................................................................................................................6

5.3.1 Getting Started.................................................................................................................7

5.3.2 Finding your way around the Field Wiring Board ........................................................8

5.4 High Voltage Connections .....................................................................................................9

5.4.1 Supply Power ...................................................................................................................9

5.4.2 PULSAR Motor .................................................................................................................11

5.4.3 Alarm Relay ......................................................................................................................12

5.5 Low Voltage Input Connections ............................................................................................12

5.5.1 Analog Inputs...................................................................................................................13

5.5.2 Alarm Input.......................................................................................................................14

5.5.3 Level Input (Remote Start/Stop).....................................................................................14

5.6 Low Voltage Output Connections .........................................................................................15

5.6.1 Current Output ................................................................................................................. 16

5.6.2 Alarm Dry Contact Output ..............................................................................................16

5.6.3 Run Status or Stroke Counter ........................................................................................ 17

5.7 Tachometer Input ....................................................................................................................17

5.8 Motor Thermostat....................................................................................................................19

5.9 Serial Communications Input ................................................................................................19

5.10 Fuse Replacement...................................................................................................................21

6. S

TART UP INSTRUCTIONS

......................................................................................................................22

6.1 Overview ..................................................................................................................................22

6.1.1 User Interface Familiarization. .......................................................................................22

6.1.2 Check Wiring and Close Access cover .........................................................................24

6.1.3 Confirm Correct Incoming Power ..................................................................................25

6.1.4 Confirm Display and Keypad functionality ................................................................... 25

6.1.5 Performing a Factory Re-initialization...........................................................................26

6.1.6 Test Pump Motor .............................................................................................................27

6.1.7 Set Time and Date............................................................................................................28

6.1.8 Flow Calibration (1-point). ..............................................................................................29

6.1.9 Analog Input Calibration.................................................................................................30

6.2 Wrapping up. ...........................................................................................................................31

7. G

ENERAL OPERATION

..........................................................................................................................32

7.1 General Operation Instructions .............................................................................................32

7.1.1 Pump Flow Calibration....................................................................................................32

7.1.2 Analog Input Signal Calibration ..................................................................................... 36

7.1.3 Reverse Acting Analog Input Signal Calibration.......................................................... 39

7.1.4 Analog Output Signal Calibration .................................................................................. 40

iii

Page 4

7.2 Menu .........................................................................................................................................41

7.2.1 Alarm, and Error messages............................................................................................42

7.2.2 Diagnostics ......................................................................................................................43

7.2.3 Set Time and Date............................................................................................................45

7.2.4 Analog Signal Failure Set Up .........................................................................................47

7.2.5 MODBUS Signal Failure Setup ....................................................................................... 50

7.2.6 Analog Output Set Up .....................................................................................................53

7.2.7 Motor Speed Display .......................................................................................................54

7.2.8 End Point Set Up..............................................................................................................55

7.2.9 Leak Detection Failure Set Up........................................................................................58

7.2.10 Level / Remote / Start – Stop Set Up..............................................................................59

7.2.11 Digital Output Set Up.......................................................................................................62

7.2.12 Motor Thermostat Set Up................................................................................................ 64

7.2.13 Over Temperature Set Up ...............................................................................................65

7.2.14 Power Failure Set Up.......................................................................................................66

7.2.15 Alarm Relay ......................................................................................................................67

7.2.16 Analog Mode ....................................................................................................................67

7.2.17 MODBUS Mode ................................................................................................................69

7.2.18 Security............................................................................................................................. 72

7.2.19 Number Format ................................................................................................................73

7.2.20 Contrast Adjust................................................................................................................74

7.2.21 Serial Communications...................................................................................................74

7.2.22 Serial Diagnostics............................................................................................................77

7.2.23 Language..........................................................................................................................79

7.2.24 Factory Default Settings .................................................................................................79

7.3 Units..........................................................................................................................................80

7.4 Varying the Flow Rate - Manually ..........................................................................................81

7.5 Mode .........................................................................................................................................81

7.6 Batch.........................................................................................................................................81

7.6.1 One Time Only .................................................................................................................81

7.6.2 Repeating .........................................................................................................................82

7.6.3 Overlapped .......................................................................................................................82

8. D

IAGRAMS

9. S

PECIFICATIONS

: I

NSTALLATION

/ C

OMPONENT

..............................................................................................86

...................................................................................................................................88

9.1 Overview ..................................................................................................................................88

10. F

ACTORY DEFAULT VALUES

11. T

ROUBLE SHOOTING GUIDE

.................................................................................................................91

..................................................................................................................94

11.1 System Diagnostics ................................................................................................................ 94

11.1.1 Encoder Diagnostics.......................................................................................................101

11.1.2 Tachometer Troubleshooting.........................................................................................102

11.1.3 Tachometer Upgrade Adjustment Instructions ............................................................ 103

12. C

ONVERSION (MANUAL TO

13. G

ENERAL REPAIRS

...............................................................................................................................106

DLCM) .......................................................................................................104

13.1 Emergency Manual Pulsar Operation ...................................................................................106

13.2 DLCM Replacement.................................................................................................................107

14. P

ULSANET SPECIFICATION

...................................................................................................................114

14.1 Introduction .............................................................................................................................114

14.2 Operational Overview .............................................................................................................114

14.3 MODBUS Messaging...............................................................................................................115

14.4 PulsaNet DDE Server Messaging ..........................................................................................115

14.5 Coils..........................................................................................................................................116

14.6 Input Bits (1x references) ....................................................................................................... 116

14.7 Input Registers ........................................................................................................................117

14.8 Holding Registers....................................................................................................................117

15. MODBUS M

.................................................................................................................................123

ODE

15.1 Introduction .............................................................................................................................123

15.2 General Discussion.................................................................................................................123

16. S

PARE PARTS

......................................................................................................................................124

iv

Page 5

D

IAGNOSTIC FORM

......................................................................................................................................125

v

Page 6

Conventions

For the remainder of this bulletin, the following Conventions are in effect.

A

WARNING DEFINES A CONDITION THAT COULD CAUSE DAMAGE TO BOTH

. P

THE EQUIPMENT AND THE PERSONNEL OPERATING IT

ATTENTION TO ANY WARNING

Notes are general information meant to make operating the equipment easier.

Tips have been included within this bulletin to help the operator run the

equipment in the most efficient manner possible. These “Tips” are drawn

from the knowledge and experience of our staff engineers, and input from the

field.

This is a procedure heading. A Procedure Heading indicates the starting

point for a procedure within a specific section of this manual.

.

AY CLOSE

vi

Page 7

1. Introduction

The DLCM is an advanced microprocessor based controller designed for use with the PULSAR diaphragm

metering pump. It controls the output of the pump by varying its stroke rate and the amount of fluid

discharged with each stroke. It has many advanced features that allow it to operate in a wide variety of

industrial environments.

This instruction manual covers all standard features of the DLCM and where applicable, specific options.

1.1 Description

The DLCM integrates a motor speed controller and a stroke length controller into a single pump mounted

package. Its purpose is to precisely adjust the flow of a process media by adjusting the pump motor speed

and stroke length.

The DLCM is designed for the international industrial market. The device is factory configured and

calibrated for the attached pump. The man/machine interface is user friendly. Local setup and control is

achieved through the nine button keypad and a back-lit two-line liquid crystal display. Pump output is

displayed as a percentage of stroke length position and motor speed, or in units of calibrated flow: CMH,

GPH, LPH, CCH, CMM, GPM, LPM, or CCM. In addition, the DLCM display supports any one of four

languages: English, French, German or Spanish.

The DLCM supports a variety of remote control options. These inputs and outputs are fully isolated for

improved protection and reliability. A Batch feature, with up to three independent programs, supplements

the control features and allows for greater flow turn down.

The DLCM includes the PULSAnet Serial Communications system. This allows the DLCM to interface

digitally to other DLC’s, DLCM’s, PLC’s, or PC’s using the MODBUS™ communications protocol over

a 4 wire RS-485 network.

The DLCM is designed to simplify and automate the calibration of pump flow and analog signals. Flow

calibration uses on-screen prompting, automated pump operation, and automatic curve fitting to eliminate

the need for stop-watches, calculators and reduces the possibility of human error. Analog signal

calibration is also accomplished by simple key-pad entry. It includes real-time display of signal levels.

This eliminates the need for external meters.

The DLCM readily accepts PULSAlarm leak detection, Level Input detection or Remote Start/Stop

station inputs that can be configured to stop the pump and/or activate an alarm relay.

The Remote Start/Stop cannot be configured to activate the alarm relay.

Failures are time and date stamped into memory for later retrieval. Other diagnostics include analog

signal failure and line power failure monitoring. These are also time and date stamped and may be preset

to control stroke position or motor status upon detection of a failure.

Security password protection may be activated to prevent tampering. All settings and diagnostics have a

battery back-up for up to 10 years in the absence of power.

The DLCM is available in any combination of 120/240 VAC, 50/60Hz. Protection exists to prevent

damage against over or under voltage conditions in the event the wrong power line source is used.

1

Page 8

1.2 DLCM Standard Features

DC Motor Speed Control with tachometer feedback

i

Manual Stroke Length Control

i

Keypad

i

Back-lit 2 line 16 character LCD display

i

NEMA 4X Enclosure

i

Two 4-20mA inputs for independent speed and stroke length control

i

One 4-20mA output

i

MODBUS RS-485 Serial Communications

i

10-Year Battery Backed Clock

i

Solid State Alarm Relay

i

Level Input/Remote Start-Stop Inputs

i

PULSAlarm Leak Detection Interface

i

Diagnostics

i

1.3 Options

Operating Voltage/Frequency

i

1.4 Accessories

Pulsanet MODBUS DDE Server

i

2

Page 9

2. Safety Considerations

The DLCM is a sophisticated microprocessor based controller for use only with PULSAR diaphragm

metering pumps. It yields tremendous control capacity – electrical, mechanical and (in conjunction with

the PULSAR pump) hydraulic in nature. In consideration of SAFETY, you should be mindful of this

relative to your safety, that of co-workers and of the process environment. Consider the following prior to

the installation and operation of a DLCM controlled PULSAR metering pump.

2.1 General Safety

The DLCM was designed as a motor speed controller and stroke length position actuator for operation

solely with the PULSAR metering pump. Use for any other application is considered un-safe and voids

all certification markings and warranties.

2.1.1 Explosive Atmosphere Safety

Explosion Hazard -- Do not perform installation or maintenance of any kind on this device while

circuit is live and/or the area is known to be hazardous.

With the proper marking, this equipment is suitable for use in Class I, Division 2, Groups C & D; Zone

2, Groups IIA and IIB or non-hazardous locations only.

2.1.2 Electrical Safety

The DLCM can be considered an industrial stroke length controller with an integrated motor speed

controller. Improper application and use can be hazardous. You are solely responsible for its use.

The DLCM's electrical installation must conform to all relevant electrical codes. Installation and

electrical maintenance must be performed by a qualified electrician. Before installing or servicing this

device, all power must be disconnected from the source at the main distribution panel.

The DLCM emits electro-magnetic energy and generates radio frequency interference. Its use is

restricted to industrial applications. You are responsible for shielding this energy/interference.

2.1.3 Mechanical Safety

When properly installed, the device has only one externally accessible moving part – the hand

adjustment knob. This component is under computer control and as such may actuate without warning.

Care should be taken to keep loose clothing away from this component. Hands and fingers should be

kept clear while the knob is turning under DLCM control.

The DLCM was designed to be service free. It contains no user-maintainable components. Removal of

the entire DLCM as an assembly from the pump is permissible. Do not disassemble the DLCM

enclosure unless instructed to do so in Section 12 of this manual. Evidence of disassembly shall void

the warranty.

2.1.4 Hydraulic Safety

Thoroughly review and adhere to the contents of the PULSAR Installation, Operation, Maintenance

and Instruction manual (Bulletin No. PMP-IOM-96) for hydraulic installation of your PULSAR

metering pump. As a microprocessor controlled device, the DLCM may activate the pump motor

without warning – generating hydraulic pressure and fluid flow. Care should be taken to protect both

users and systems should the pump activate.

3

Page 10

3. Equipment Inspection

When you receive your order, check all equipment for:

Completeness against the shipping document / purchase order

i

For any evidence of shipping damage.

i

Shortages or damage should be reported immediately to the carrier and your PULSAFEEDER

representative.

4. Storage Instructions

The DLCM can be successfully stored for extended periods. The key to this success is temperature and

humidity control.

4.1 Storage Length

4.1.1 Short Term (0 - 12 months)

The DLCM should be stored in a temperature and humidity controlled environment. It is preferable to

keep the temperature constant in the range of -18 to 60° Celsius (0 to 140° Fahrenheit). The relative

humidity should be 0 to 90% non-condensing.

The adjustment knob should be rotated in alternate directions by hand one full revolution every six

months.

If the DLCM is installed on the pump, it should not be removed during this period – provided the above

conditions can be applied to the pump as well. If the DLCM is removed from the pump, it should be

stored in the same pump mounted orientation. After removal of the DLCM from the PULSAR

metering pump, seal the eccentric box opening with a dust and moisture proof material. If the DLCM

was shipped in its own carton, it should be stored in that carton.

4.1.2 Long Term (12 months or more)

Storage of the DLCM for periods of longer than twelve months is not recommended. If extended

storage is unavoidable the DLCM should be stored in accordance with those conditions stipulated for

Short Term Storage. In addition, a porous bag of 85g (3 oz) silica gel or similar desiccant should be

placed beneath the wiring access cover. The cover should be re-installed to seal the desiccant within

the enclosure. The three conduit connections must be tightly capped.

4

Page 11

5. Installation

5.1 Location

Review the Safety section prior to installing the DLCM. It contains information required to properly

install and operate the DLCM in an industrial environment.

The site selected for the installation of your DLCM is largely dependent on that of the PULSAR metering

pump. Review the PULSAR Installation Operation Maintenance Instruction Manual (Bulletin No. PMPIOM-96) provided with your PULSAR metering pump. It details system related issues that are important

to proper operation of the PULSAR metering pump. Consider the following DLCM related issues when

selecting a site. The DLCM should be mounted in an area where the operator has access to the front of

the unit and a clear view of the display panel and keyboard. Avoid locations where the DLCM would be

subjected to extreme cold or heat. Note the warning statement on the next page. The installation of this

device must comply with national, state and local codes.

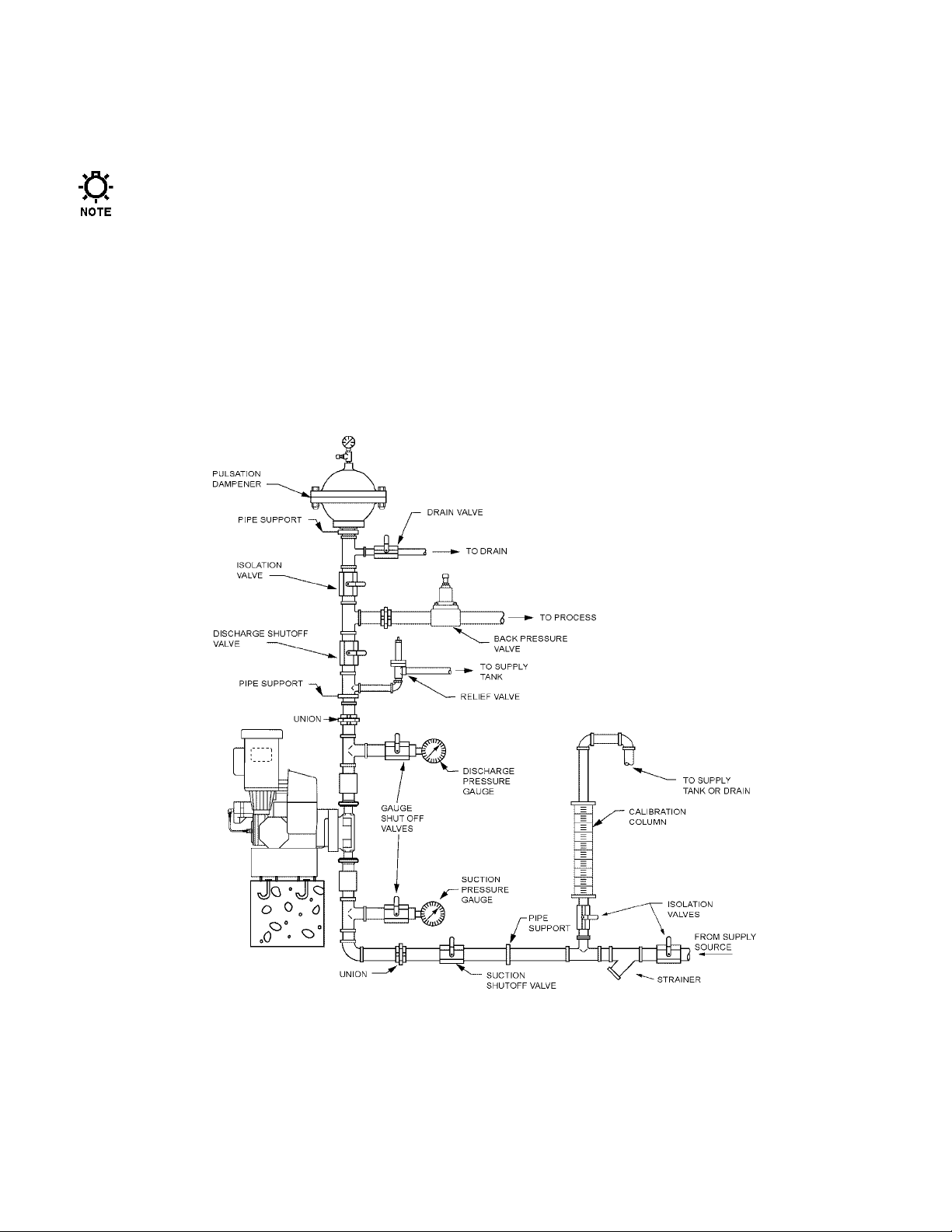

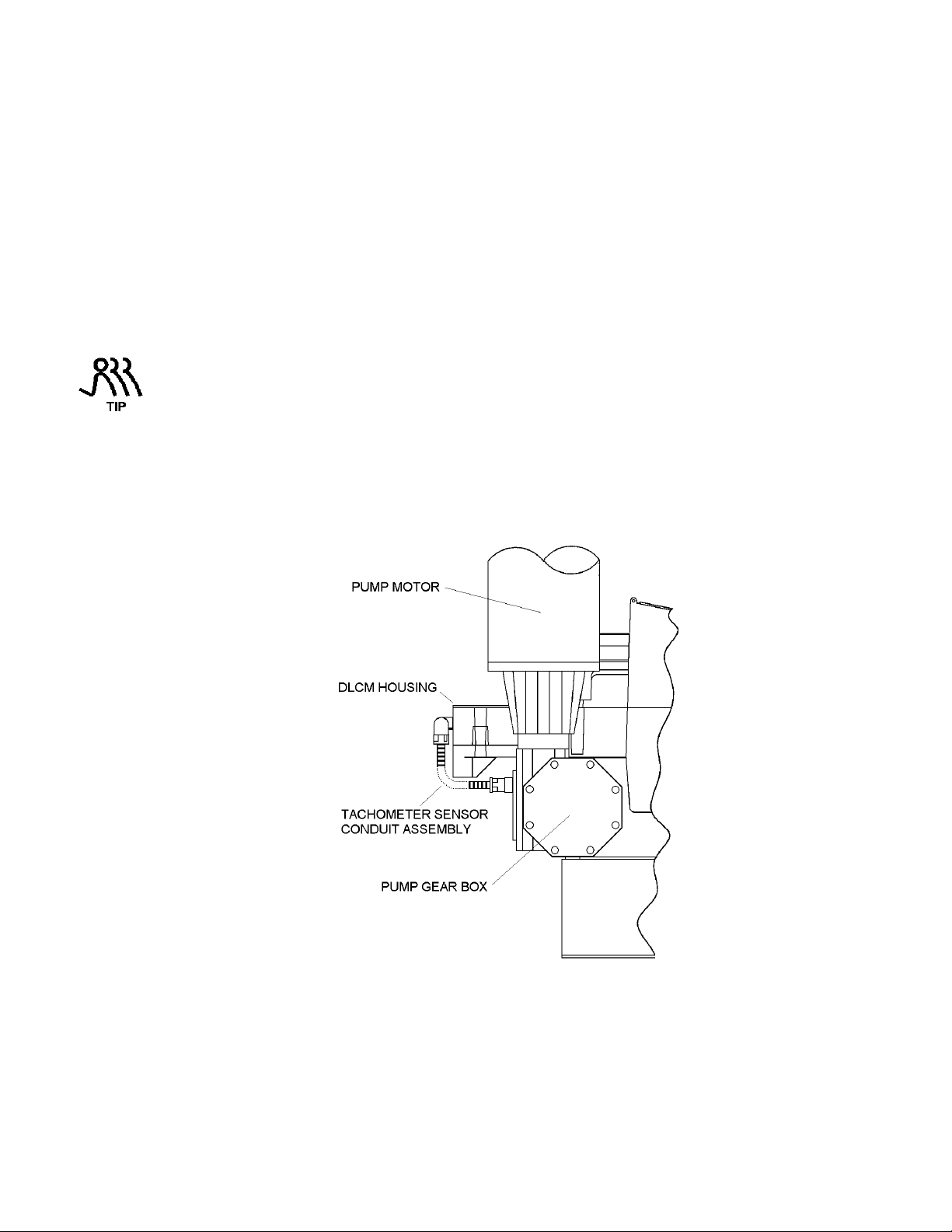

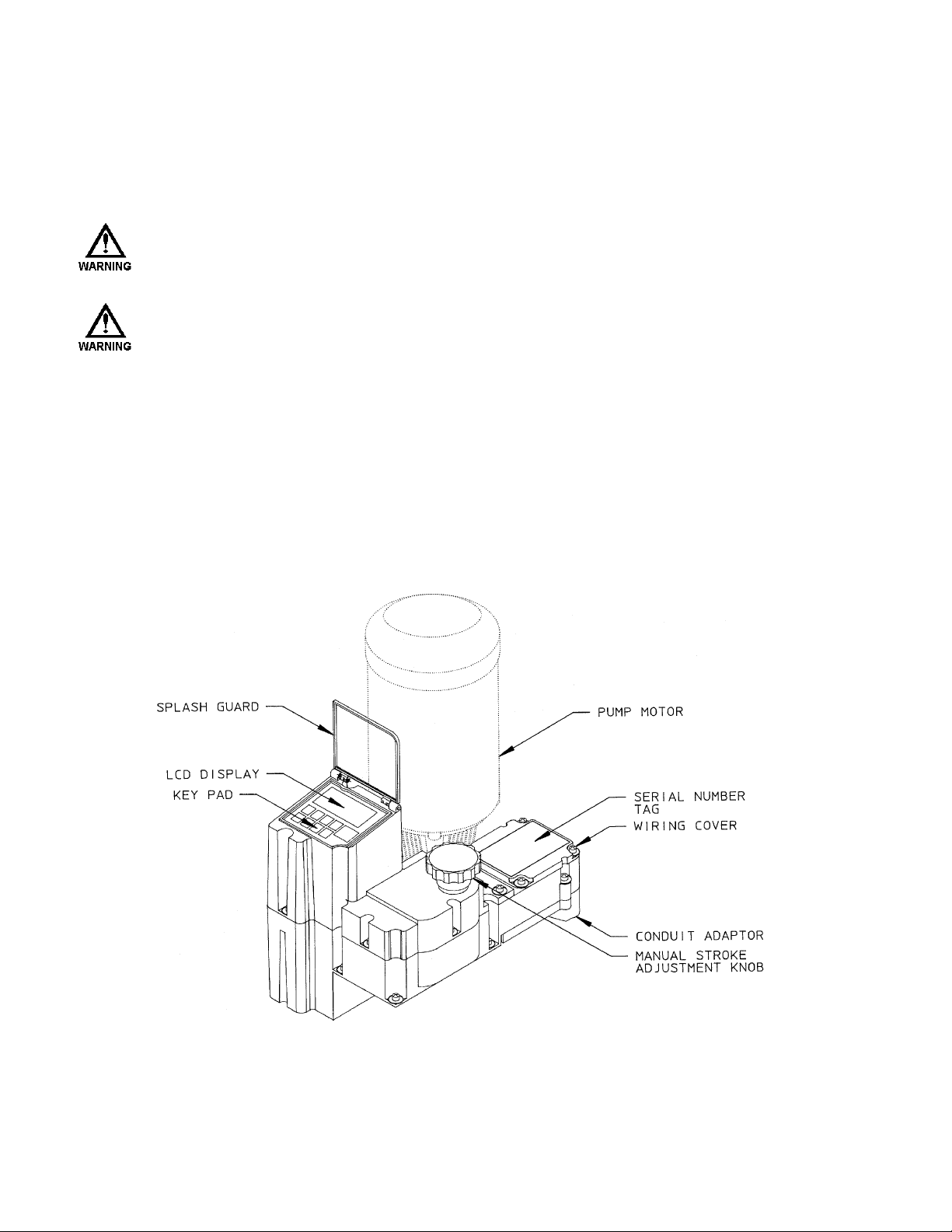

Figure 1 – Typical Installation.

5

Page 12

A

VOID LOCATIONS WHERE THE

[

LESS THAN

F

AHRENHEIT

DLCM

THE

–18

CELSIUS

°

)]

OR DIRECT SUNLIGHT

AND VOID ITS WARRANTY

5.2 Installation Notes

1. The DLCM is a microprocessor based controller that uses electro-static sensitive CMOS components.

Do not make any electrical connections (high or low voltage) without adequately grounding the DLCM

and the worker to eliminate an electro-static charge between the two. A conductive wrist strap worn by

the worker and attached to the DLCM enclosure is adequate to satisfy this requirement.

2. Calibration is an important element of successful DLCM operation. Permanent installation of a

calibration column as depicted in Figure 1 is strongly recommended.

3. Conduit connections can carry fluids and vapors into the DLCM causing damage and void the

warranty. Care should be taken when installing conduit to protect against fluid/vapor entry. If

necessary, provide sealed entries or conduit drains near the point of entry.

5.3 Electrical Wiring

The DLCM has many advanced features that may make wiring the unit appear complicated. Wiring is

actually very simple – one high voltage connection is all that is required to take advantage of a majority

of the DLCM's features. It is highly recommended that you take a step-by-step approach to wiring and

confirming proper DLCM operation:

DLCM

(0

FAHRENHEIT) OR GREATER THAN

°

WOULD BE SUBJECTED TO EXTREME COLD OR HEAT

. F

AILURE TO OBSERVE THIS WARNING COULD DAMAGE

.

40

°

CELSIUS

(104

°

1. Make the high voltage connection. These will allow you to operate the DLCM and attached PULSAR

pump.

2. Power-up and test the DLCM to confirm the connections and check for proper operation.

3. Power-down the DLCM.

4. Decide which low voltage Inputs (e.g., 4-20mA in) will be used and make those connections.

5. Power-up and test the DLCM to confirm the connections and check for proper operation.

6. Power-down the DLCM.

7. Decide which low voltage Outputs (e.g., 4-20mA out) will be used and make those connections.

8. Conduct a final power-up and test the DLCM to confirm the connections and check for proper

operation.

9. Go to the Section 6 – Start Up Instructions for details on how to perform the power-up tests.

6

Page 13

5.3.1 Getting Started

The field wiring of the DLCM is accomplished through a rear access cover at the back of the unit –

near the PULSAR gearbox and motor. The access panel is opened by removing the 4 retaining screws

(Phillips head screw driver required). Removal reveals the Field Wiring Board (refer to Figure 2).

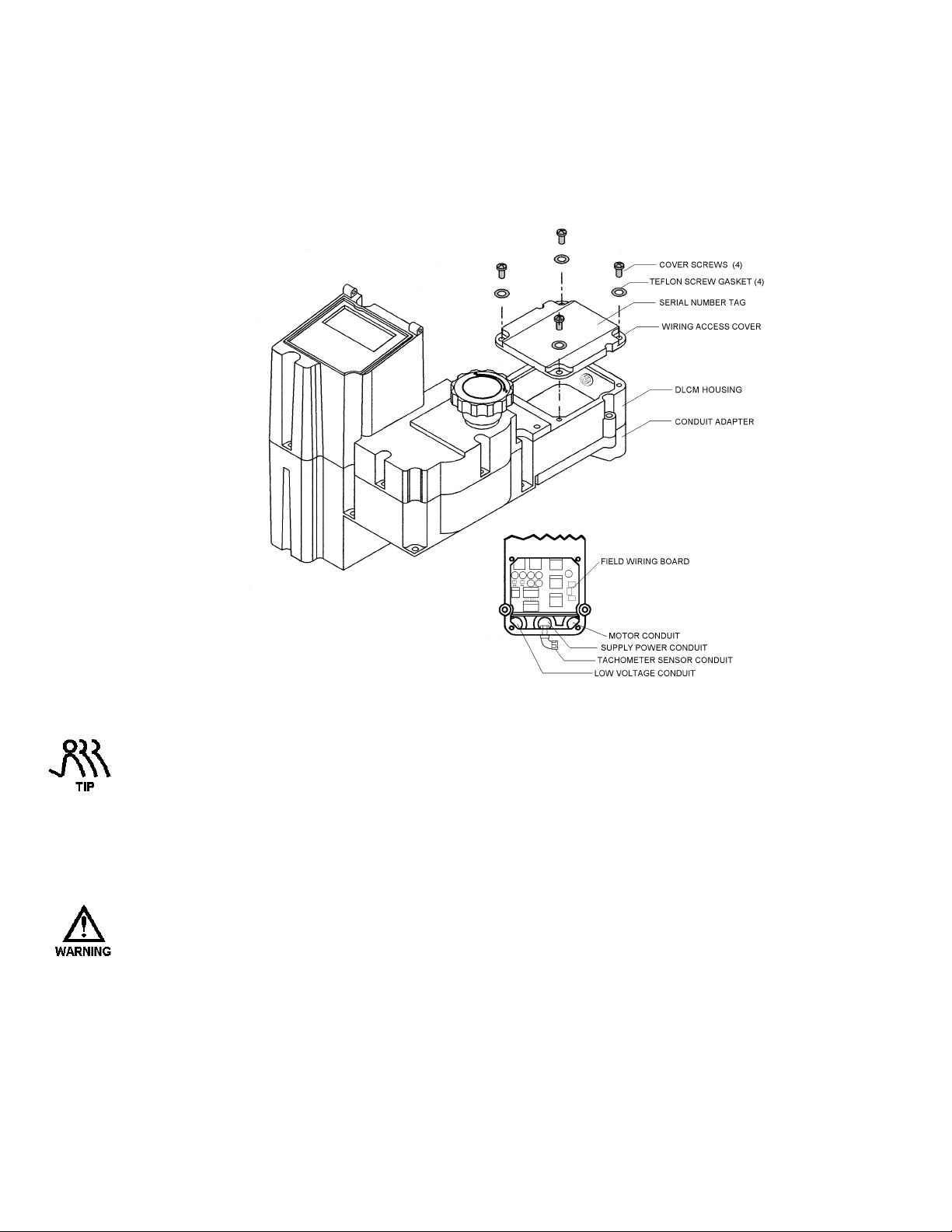

Figure 2 – Accessing the Field Wiring Board

The Field Wiring Access Cover has the Serial Number Tag on it. Keep the cover with the DLCM it

was removed from. The DLCM is marked internally with the Serial Number. The internal marking

will be used for warranty claims.

The Field Wiring Board (refer to Figure 2) contains wiring blocks for making all of the electrical

connections. It is mechanically attached to the Conduit Adapter. The adapter in conjunction with the

Field Wiring Board form a modular connector or plug. This allows the DLCM to be removed from the

PULSAR unit without disturbing the conduit connections.

R

EMOVE THE CONDUIT ADAPTER AND FIELD WIRING BOARD FOR

PURPOSES ONLY

(

REFER TO SECTION

12 – B

ASIC REPAIRS) FOR FURTHER INFORMATION

DLCM

REPAIR/REPLACEMENT

.

7

Page 14

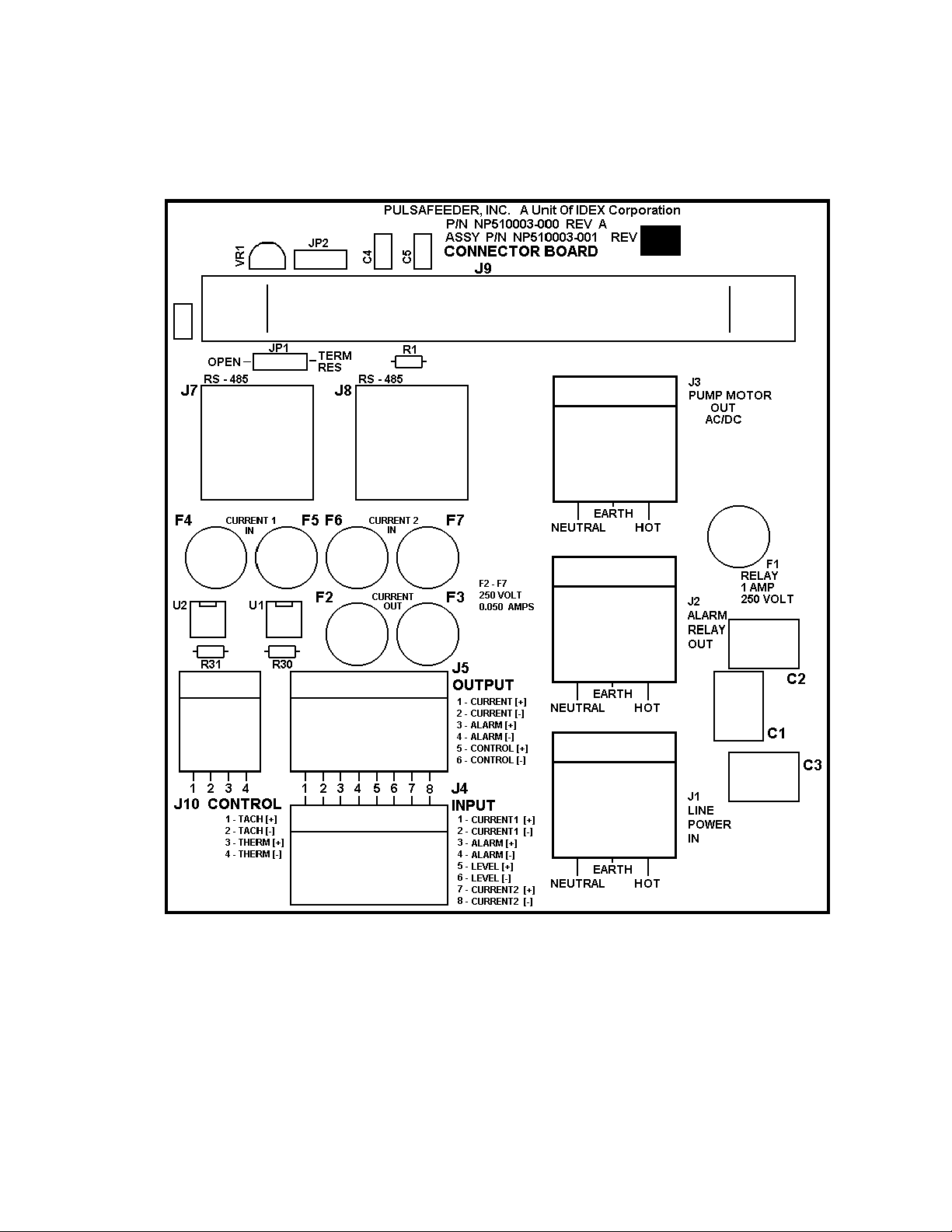

5.3.2 Finding your way around the Field Wiring Board

The electrical connections are segregated on the Field Wiring Board. The high voltage connections are

on the right-half side while the low voltage connections are on the left. Refer to Figure 3, Field

Wiring Board for specific connection and fuse locations.

Figure 3. Field Wiring Board

8

Page 15

5.4 High Voltage Connections

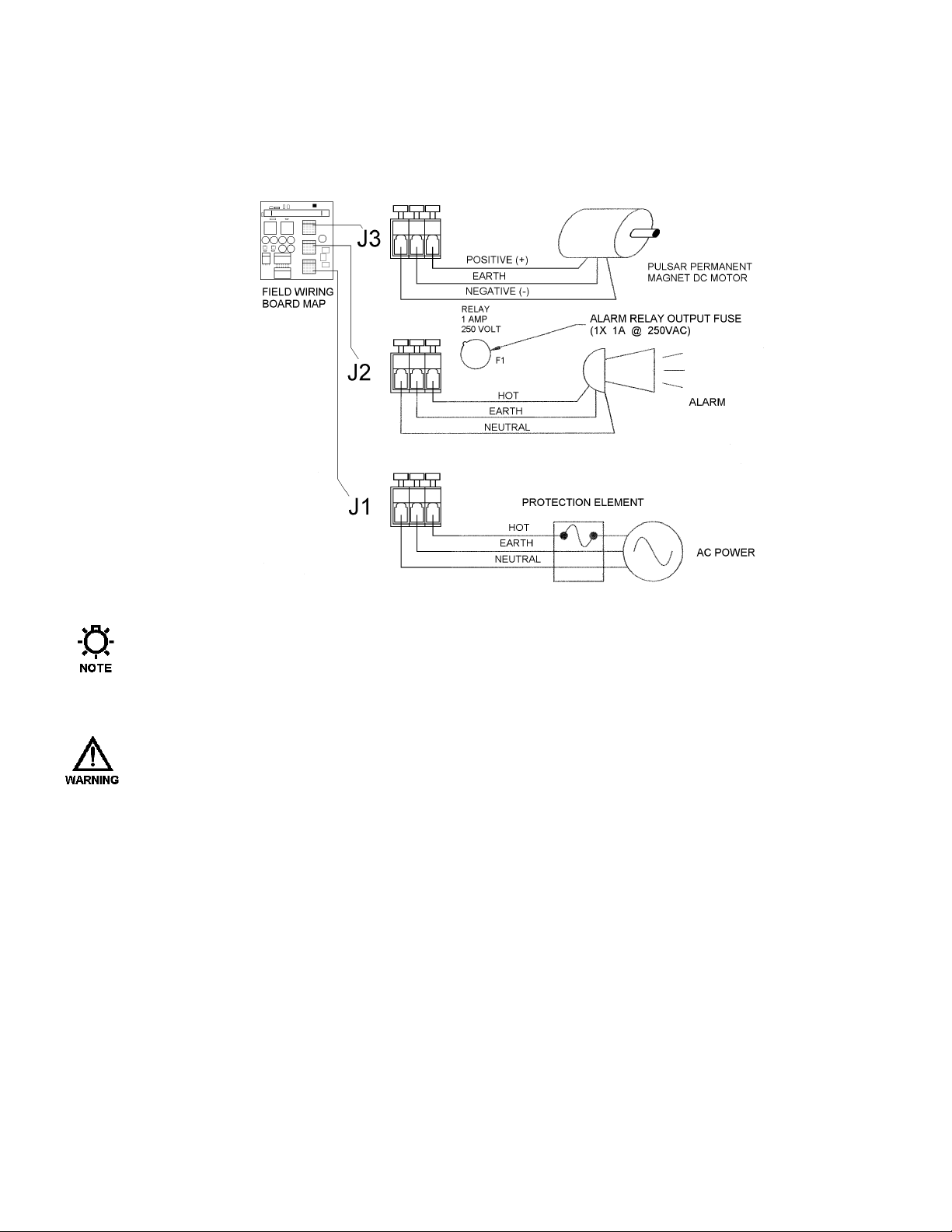

There are only three high voltage connections to be made on the DLCM: supply power (J1), PULSAR

motor load (J3), and Alarm Relay Load (J2). Only the supply power and PULSAR motor load

connections are required. Refer to Figure 4 for connection location.

The Positive (+) and Negative (-) wires may not be labeled. Do not be concerned with polarity when

hooking up the motor. It does not matter what direction the motor rotates.

5.4.1 Supply Power

T

DLCM

HE

CONNECTION TO POWER ITS OWN SUPPLY

OUTPUT

BRANCH CIRCUIT

The DLCM power supply and attached PULSAR motor are not fuse protected. You are responsible for

correctly sizing the protection element (i.e., fuse or circuit breaker at the distribution panel). Use the

work sheet on the next page for correctly sizing the branch protection element.

REQUIRES ONE CONNECTION TO AN EXTERNAL POWER SOURCE

. Y

OU MUST TAKE THESE EXTERNAL LOADS INTO CONSIDERATION WHEN SIZING THE

.

Figure 4 – High Voltage Connections

,

DC

THE

PUMP MOTOR AND THE ALARM RELAY

. I

T USES THIS SAME

9

Page 16

The DLCM with an attached pump motor and alarm load, should be connected to its own branch

circuit. Size the supply wire and protective element according to local code requirements. Use 14

AWG, 105° C insulation wire or better. Attach the supply to the J1 terminal block labeled 'LINE

POWER IN'. Make 3 connections: Neutral, Earth (ground) and Hot as labeled.

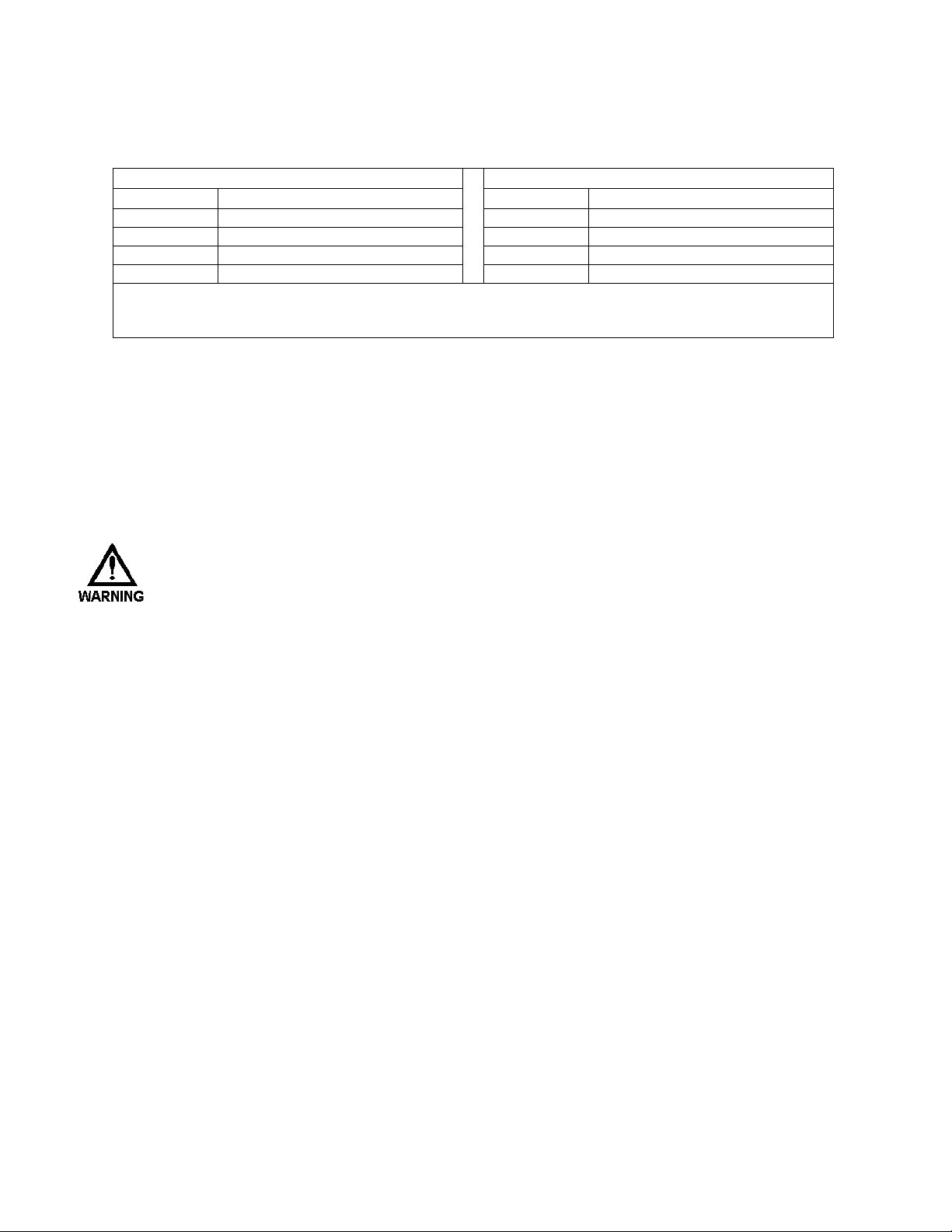

115VAC +/- 10% 50/60Hz 230VAC +/- 10% 50/60Hz

Device Current Requirement (Amp) Device Current Requirement (Amp)

DLCM 1A (1A Max.) DLCM .5A (.5A Max.)

Pump Motor* + (8A Max.) Pump Motor* + (4A Max.)

Alarm Relay* + (1A Max.) Alarm Relay* + (1A Max.)

Total ** = Total ** =

* In-rush current requirements should be considered. All values RMS.

** Calculation is for guideline purposes only. User must consult local electrical codes when sizing branch

circuits. Protection must not exceed 10Amps RMS at 115VAC or 5.5Amps RMS at 230VAC.

Branch Circuit Protective Element Sizing Worksheet.

The operating voltage and frequency of the DLCM are factory configured – an internal motor and

capacitor are sized according to voltage and frequency. If the power supplied to the unit does not

match the factory configuration, the DLCM will display either an {OVER VOLTAGE} or {UNDER

VOLTAGE} diagnostic message on power-up. This is possible because the microprocessor and

display are powered by a switching power supply. It detects the incoming power and self-regulates its

output. This power supply is protected by a 7.4 Joule surge suppression device. The microprocessor

will not operate the internal stroke adjustment motor, potentially causing damage, until the voltage

problem is corrected.

H

IGH VOLTAGE CIRCUITS (E.G

H

COMBINE

LESS THAN

ELECTRICAL INTERFERENCE THAT MAY RESULT IN IMPROPER

OPERATION

IGH VOLTAGE (I.E

32VDC)

LINES IN A COMMON CONDUIT

.

.,

BRANCH) SHOULD BE RUN IN SEPARATE CONDUIT

.,

GREATER THAN

100VAC)

! F

AILURE TO COMPLY WILL RESULT IN

LINES AND LOW VOLTAGE (I.E

(

AND POSSIBLY UNSAFE

. D

O NOT

.,

)

10

Page 17

5.4.2 PULSAR Motor

In most cases the DLCM is supplied with a factory installed DC motor. If a motor was not supplied, it

is important to select the proper type. Refer to the chart below for acceptable DLCM motors (refer to

Section 9 – Specifications for motor details):

Motors must be permanent magnet, SCR drive rated DC motors. The DLCM cannot control motors

with separate field windings.

Part Number Developed

H/P

For 115 Volt line power

NP500059-000 1/4 hp 90 Volts 2.5 amps TENV

NP500050-000 1/3 hp 90 Volts 3.2 amps TENV

CDPWD3330 1/2 hp 90 Volts 4.8 amps TENV

For 230 Volt line power

CDPWD3306 1/4 hp 180 Volts 1.25 amps TENV

NP500051-000 1/3 hp 180 Volts 1.6 amps TENV

CDPWD3326 1/2 hp 180 Volts 2.5 amps TENV

NP500053-000 1.0 hp 180 Volts 5.0 amps TEFC

Armature

Voltage

Full Load

Current

Enclosure

Type

Connect the permanent magnet DC pump motor to the J3 terminal block labeled 'PUMP MOTOR OUT

AC/DC.' Use 14 AWG, 105° C insulation wire size or larger. If the DLCM supply voltage is

115VAC, you must use a 90Volt Armature motor. If the DLCM supply voltage is 230VAC, you must

use a 180Volt Armature motor.

T

DLCM

HE

ALARM

SUPPLY VOLTAGE TO THE ATTACHED DEVICE

BE DISCONNECTED AT THE MAIN BEFORE WORKING ON ELECTRICAL CONNECTIONS OR ANY

MOVING PUMP COMPONENTS

USES SOLID-STATE RELAYS FOR IT'S HIGH VOLTAGE OUTPUTS (I.E

). I

N THE

'OFF'

STATE, THESE DEVICES TYPICALLY LEAK

(

OR TERMINAL BLOCK

(E.G.,

MOTOR, GEAR TRAIN, ETC

.).

20-30MA

)! T

HE SUPPLY POWER MUST

.,

MOTOR AND

OF CURRENT AT THE

D

OUBLE CHECK ALL CONNECTIONS TO CONFIRM GOOD ELECTRICAL CONTACT BETWEEN THE

. M

TERMINAL BLOCK CLAMP AND BARE WIRE

. I

INSULATION

DIVIDERS BETWEEN TERMINALS

NSURE THAT BARE WIRE IS NOT FRAYED AND DOES NOT RISE ABOVE THE

.

AKE SURE THE CLAMP IS ON THE WIRE, NOT THE

At high motor turndown settings the DC motor can overheat under certain conditions. Non-standard

motors must include built-in thermal protection and a dry contact thermal switch for connection to the

DLCM’s Motor Thermostat input. Refer to Section 5.8 – Motor Thermostat for additional

information.

11

Page 18

5.4.3 Alarm Relay

The Alarm Relay is an output that is configured by the operator. Refer to Section 7 – General

Operation for specific instructions on how to activate the Alarm Relay. The Alarm Relay Load must

not exceed 1 Amp at rated voltage. Connect the Alarm load to the J2 terminal block labeled 'ALARM

RELAY OUT.' Use 22 AWG wire size or larger. Make three connections: Neutral, Earth (ground) and

Hot as labeled.

5.5 Low Voltage Input Connections

There are two types of Low Voltage inputs: Current (e.g., 4-20mA) and Dry Contact. The Low Voltage

Input connection block is labeled J4 'INPUT' (refer to Figure 5). It contains four pairs of inputs:

Current 1, Alarm, Level and Current 2.

Figure 5 – Low Voltage Input

T

HE DRY CONTACT INPUTS ARE SELF-POWERED

. D

CLOSURE TO ACTIVATE

T

HE WIRE USED TO CONNECT LOW VOLTAGE INPUTS, AND SERIAL COMMUNICATIONS SHOULD

BE RUN IN A CONDUIT SEPARATE FROM THE

V

OLTAGE (I.E

LINES IN A COMMON CONDUIT

INTERFERENCE THAT MAY RESULT IN IMPROPER

.,

GREATER THAN

O NOT ATTACH EXTERNALLY POWERED CIRCUITRY

100VAC)

! F

AILURE TO COMPLY WILL RESULT IN ELECTRICAL

. S

UPPLY ONLY A MECHANICAL SWITCH

H

IGH VOLTAGE POWER

LINES AND LOW VOLTAGE (I.E

(

AND POSSIBLY UNSAFE) OPERATION

. D

.

O NOT COMBINE HIGH

.,

LESS THAN

32VDC)

.

12

Page 19

5.5.1 Analog Inputs

The DLCM can accept either one or two analog input signals. These signals ultimately control the

pump’s flow. Analog Input #1 is used to control either the pump stroke and speed (refer to the note:

below) or the pump stroke only. When Analog Input #2 is used, it controls motor speed only.

The DLCM can operate using only Analog Input #1 to control both Stroke and Motor Speed. If this is

the desired mode of operation, the installed software will determine what Stroke and Speed are required

to produce the desired flow rate (refer to Section 7 – General Operation: End Point Set Up) for further

information.

The Analog input accepts current inputs in the range of 0 to 25mA (e.g., 4-20mA) provided the 'span,'

(the difference between the High and Low value), is greater than 2mA. Voltage signals in the 0-5 volt

range are accepted but displayed as current during Analog Input calibration.

Split-ranging, reverse acting, and ratio control are accomplished in the calibration routine in Section 7

– General Operation. No hardware adjustments are required. The channels are electrically isolated,

surge protected and fused for protection. The inputs are designed to avoid damage in the event high

voltage is inadvertently applied.

To make the Stroke Length Control connection, use 0.32mm2 – 0.52mm2 (22-20 AWG) wire for

hookup. Attach the analog signal generated by an external device (e.g., PLC) to the connection points

labeled '1-CURRENT1(+)' and '2-CURRENT1(-)' on the J4 terminal block labeled 'INPUT' (refer to

Figure 5). Attach the Positive lead to position 1 and the Negative lead to position 2.

To make the Motor Speed Control connection, use 0.32mm2 – 0.52mm2 (22-20 AWG) wire for hookup.

Attach the analog signal generated by an external device (e.g.: PLC) to the connection points labeled '7CURRENT2(+)' and '8-CURRENT2(-)' on the J4 terminal block labeled 'INPUT' (refer to Figure 5).

Attach the Positive lead to position 7 and the Negative lead to position 8.

Position indicators are printed on the circuit board above the terminal. The DLCM will provide

approximately 200 ohms of resistance to a current loop. Each Analog Input is isolated from all other

inputs, outputs and earth ground. Follow the instructions in Section 7 – General Operation for Analog

Input signal calibration and set-up.

13

Page 20

5.5.2 Alarm Input

The Alarm Dry Contact Input is designed to operate with the PULSAlarm leak detection option. It is

software configurable to generate an alarm, activate the alarm relay and/or shut down the PULSAR

motor. The input is internally powered – only a mechanical switch closure is required for activation.

Use 0.32mm

2

– 0.52mm2 (22-20 AWG) wire. Attach one side of the switching device to the position

labeled '3-ALARM(+)' and the other side to the position labeled '4-ALARM(-)' of connector J4-INPUT

(refer to Figure 5). A resistance of 15K ohms or less is required across the two connections for proper

detection. Follow the instructions in Section 7 – General Operation for Alarm Input (Leak Detection)

software set-up.

5.5.3 Level Input (Remote Start/Stop)

The Level Dry Contact Input is designed to monitor a single-point Level Input sensor and generate an

alarm, activate the alarm relay and/or shut down the PULSAR motor. It can also be used with a

Remote Start/Stop station (Dry Contact switch) to start and stop the pump’s motor. The input is

internally powered, only a mechanical switch closure is required for activation. Use 0.32mm

0.52mm

LEVEL(+)' and the other side to the position labeled '6-LEVEL(-) of connector J4-INPUT (refer to

Figure 5). A resistance of 15K ohms or less across the two terminals is required for proper detection.

Follow the instructions in Section 7 – General Operation for Level / Start-Stop set-up.

2

(22-20 AWG) wire. Attach one side of the switching device to the position labeled '5-

2

–

14

Page 21

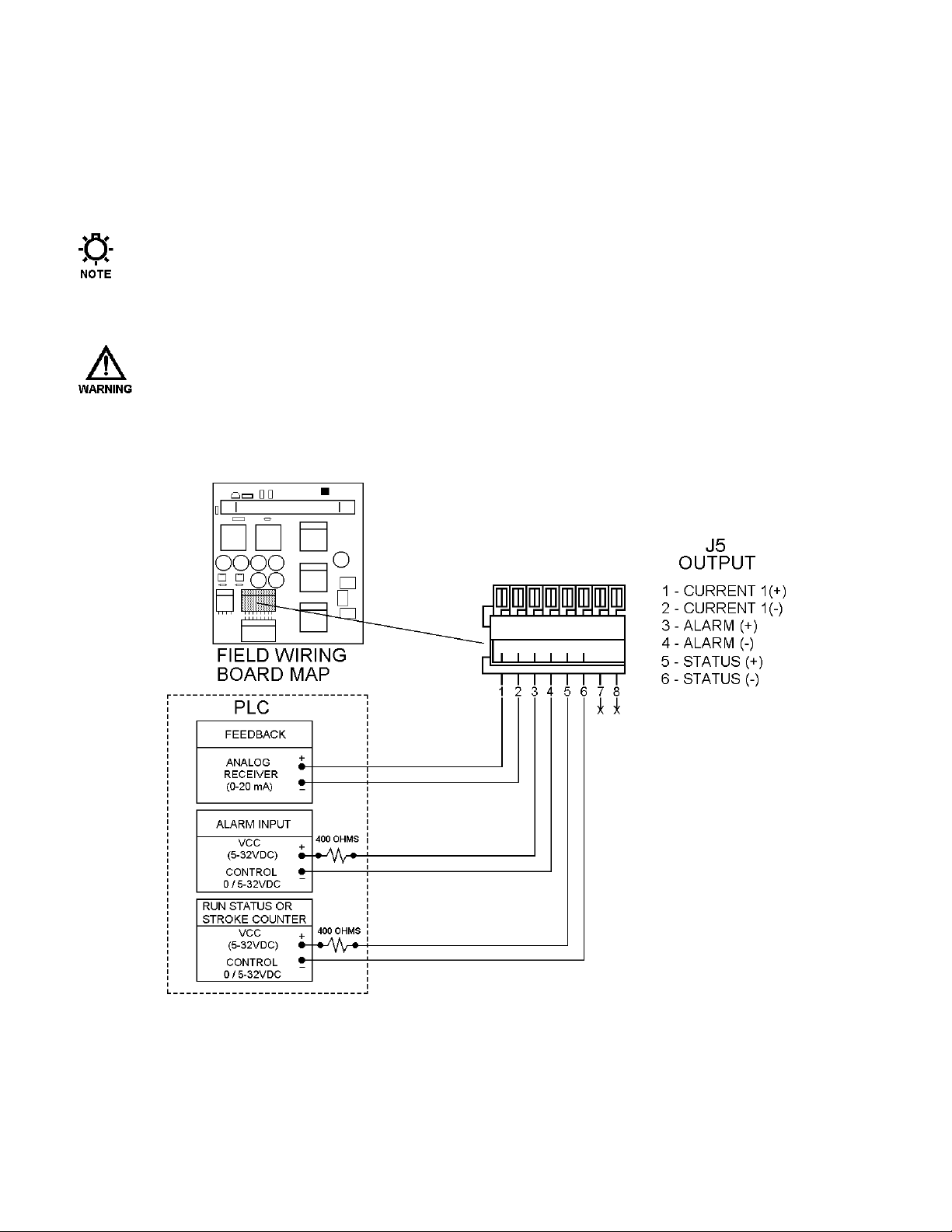

5.6 Low Voltage Output Connections

There are two types of Low Voltage outputs: Analog (e.g., 4-20mA) and Transistor based Dry Contact.

The Low Voltage Output connection block is labeled J5 'OUTPUT' (refer to Figure 6). It contains threepairs of outputs: Current, Alarm and Motor Status/Stroke.

The Transistor based Dry Contact outputs are optically isolated. To achieve total isolation, they are

not self powered. The external device must supply and detect a return voltage level (32VDC max).

T

HE WIRE USED TO CONNECT LOW VOLTAGE INPUTS, OUTPUTS AND SERIAL COMMUNICATIONS

SHOULD BE RUN IN A CONDUIT SEPARATE FROM THE

H

COMBINE

THAN

ELECTRICAL INTERFERENCE THAT MAY RESULT IN IMPROPER

OPERATION

IGH VOLTAGE (I.E

32VDC)

LINES IN A COMMON CONDUIT

.

.,

GREATER THAN

100VAC)

! F

AILURE TO COMPLY WILL RESULT IN

H

IGH VOLTAGE POWER

LINES AND LOW VOLTAGE (I.E

(

AND POSSIBLY UNSAFE

. D

O NOT

.,

LESS

)

Figure 6 – Low Voltage Output

15

Page 22

5.6.1 Current Output

The Current Output Channel can follow one of three signals:

a) Calibrated flow

b) Calibrated stroke length

c) True motor speed

It is calibrated to source current in the 0 to 20mA range (e.g., 4-20mA). The output can be calibrated

for reverse acting and split ranging and control. Refer to Section 7 – General Operation: Calibration

for further details.

Current Output is used to control slave devices (e.g., DLCM's, ELMA's, PULSAMATICs, etc.) or to

fulfill closed loop system requirements. Attach the connection points labeled '1-CURRENT(+) and '2CURRENT(-)' on connector J5-OUTPUT (refer to Figure 6) to the external device. Use 0.32mm

0.52mm

2

(22-20 AWG) wire. Attach the Positive lead to position 1 and the Negative lead to position 2.

The analog output will drive against a maximum load of approximately 700 ohms. Thus, a single

DLCM Analog Output could be used to drive two slave DLCM's. They, in turn, could each drive two

additional slaves. The Analog Output is isolated from all other inputs, outputs and earth ground.

Follow the instructions in Section 7 – General Operation: Analog Output Signal Calibration.

5.6.2 Alarm Dry Contact Output

The Alarm output is a solid state transistor closure. It indicates the present state of the alarm relay

output. If the Alarm Relay is on, the Alarm Dry Contact will be closed. If the Alarm Relay is off, the

Alarm Dry Contact will be open. It is commonly used to indicate an alarm status to external control

equipment (i.e., PLC, PC or other Manual controllers). Refer to Figure 6.

2

–

VCC (+5VDC) and Ground are provided on terminals 7 and 8 of connector J5. A 250 ohm resistor

from terminal '7-VCC' to terminal '3-ALARM(+)' will cause a +5VDC signal to appear between

terminals '4-ALARM(-)' and '8-DCGND' when the Alarm Relay is on. This technique is only

recommended if the input on the external device is isolated from all other inputs, outputs and

grounds.

An opto-coupler is used to achieve total isolation of this output. As such, the external control

equipment must generate the supply on the positive output and detect the return of that signal from the

DLCM. In a typical application, use 0.32mm

2

– 0.52mm2 (22-20 AWG) wire to attach the terminal

labeled '3-ALARM(+)' – the collector terminal – to the external equipment's logic supply. Connect the

terminal labeled '4-ALARM(-)' – the emitter terminal – to the positive input of the equipment. The

negative input of the equipment should be connected to its isolated ground. A series resistance of 400

ohms is recommended – especially when sinking current (e.g., a photo-diode of an opto-isolator). The

Alarm output cannot be separately configured in the software, it follows the Alarm Relay output.

16

Page 23

5.6.3 Run Status or Stroke Counter

The Status output can be configured through software to indicate that the pump motor is on or to

generate a pulse with every pump stroke (for use with an external stroke counter). The factory default

for this output is to indicate Pump Motor Status. The Stoke output is not in phase with the pump stroke

but has a 50% duty cycle (e.g., the output is ON for half of the stroke and OFF for the other half.).

An opto-coupler is used to achieve total isolation of this output. As such, the external control

equipment must generate the supply on the positive output and detect the return of that signal from the

DLCM. In a typical application, use 0.32mm

labeled '5-STATUS(+)' – the collector terminal – to the external equipment's logic supply. Connect the

terminal labeled '6-STATUS(-)' – the emitter terminal – to the positive input of the equipment. The

negative input of the equipment should be connected to its isolated ground. A series resistance of 400

ohms is recommended – especially when sinking current (e.g., a photo-diode of an opto-isolator).

There is also an internal stroke counter that is re-settable. Refer to Section 7.2 - Menu –

Diagnostics – Diag. Menu 11/11.

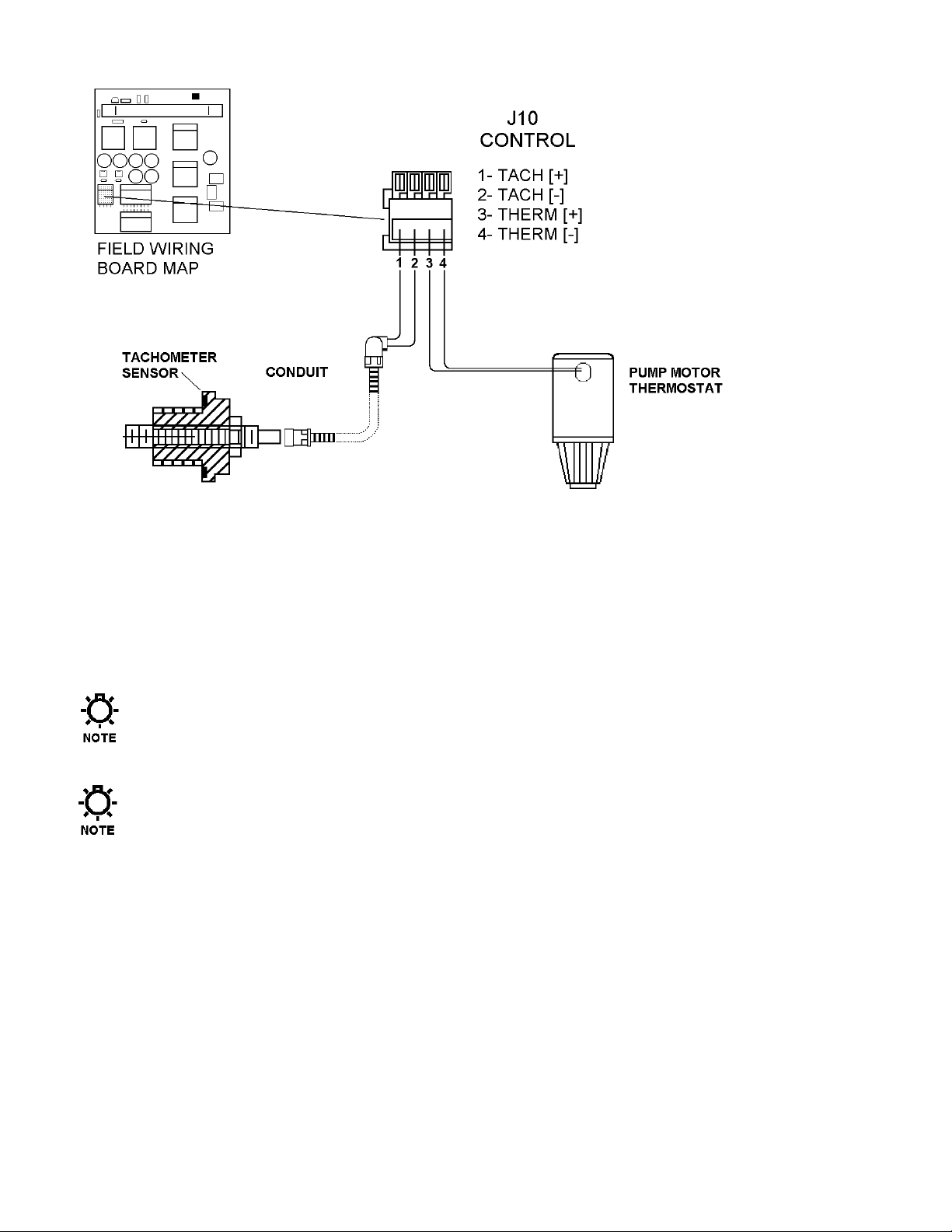

5.7 Tachometer Input

The Tachometer Sensor is connected to the Tachometer Input. It senses motor rotation. This input allows

the DLCM to control motor speed.

2

– 0.52mm2 (22-20 AWG) wire to attach the terminal

Figure 7 – Tachometer Sensor Conduit Assembly

17

Page 24

Figure 8 – Tachometer and Pump Motor Thermostat Connections

To connect the Tachometer Input, connect the wire labeled VDC (typically brown) to the connection

point labeled 1–TACH [+] on connector J-10 CONTROL. Connect the wire labeled TACH (typically

blue) to the connection point labeled 2–TACH [-] on connector J-10 CONTROL. Make these

connections using the 22 AWG wire provided with the Tachometer Sensor (refer to Figure 8).

For additional information relating to the Tachometer Sensor, refer to Section 13 – Repairs: DLCM

Replacement.

The Tach input is designed for use with the supplied sensor only. Do not attempt to use any other

device (e.g.: motor based tachometer outputs).

It is permissible to run the pump motor thermostat in the same conduit as the pump motor power.

The signal is conditioned to prevent erroneous operation due to cross-talk.

18

Page 25

5.8 Motor Thermostat

The motor thermostat has been supplied as an equipment safety measure. This allows the DLCM pump

motor to operate without the danger of overheating the motor windings.

In the event that the internal temperature of the motor exceeds the motor manufacturer’s specification,

the DLCM can be configured to:

a) Turn the motor off.

b) Sound an alarm.

c) Restart the motor when the temperature lowers to a safe level.

For more information about the Motor Thermostat settings, refer to Section 7 – General Operation:

Motor Thermostat Setup .

To connect the Motor Thermostat to the DLCM, connect the two thermostat wires (typically these

wires are a smaller gauge wire) coming from the pump motor to the connection point labeled ‘3–

THERM [+]’ and ‘4–THERM [-]’ on connector J–10 CONTROL (refer to Figure 8).

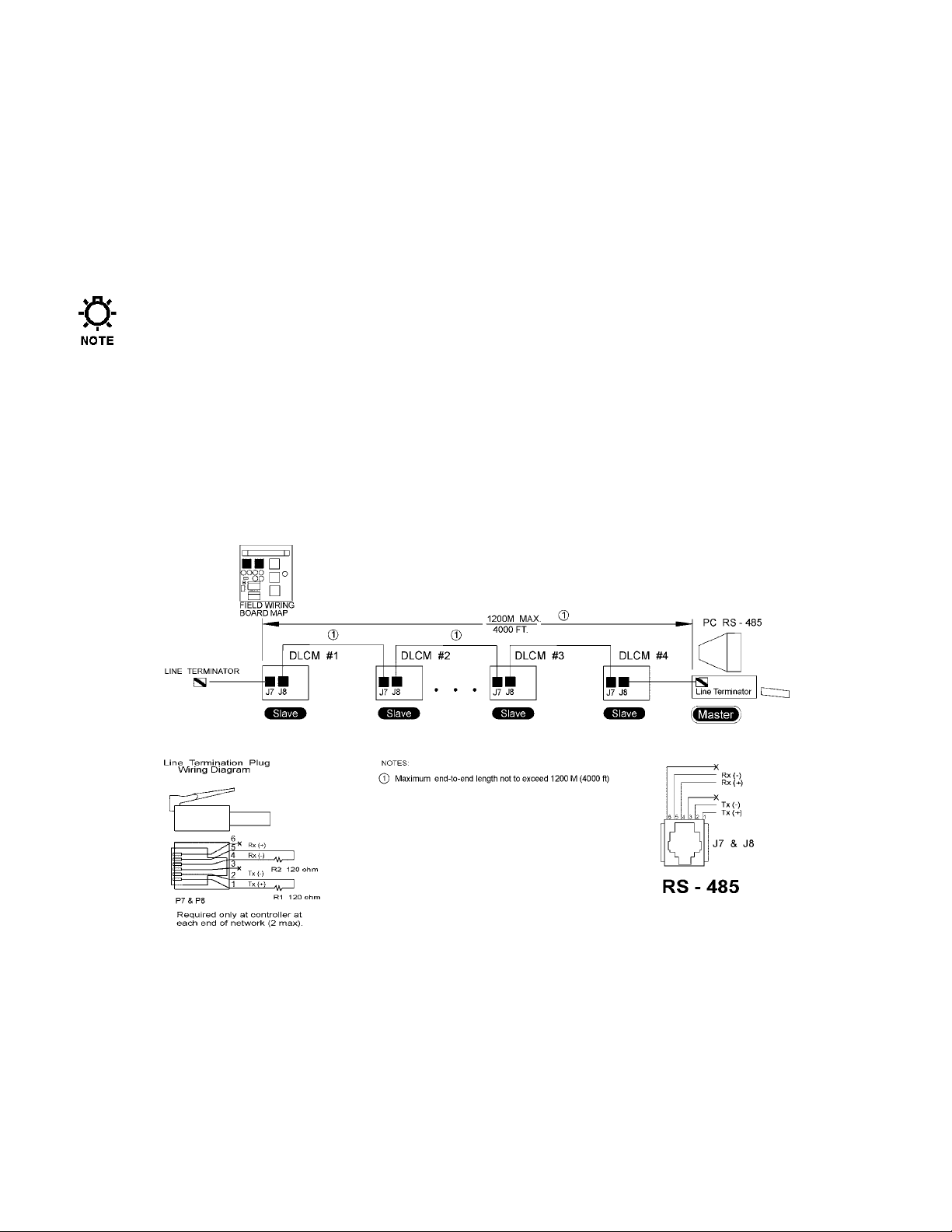

5.9 Serial Communications Input

The Serial Communications input is used to communicate digitally with the DLCM. It allows remote

control and, if so configured, can be used to replace the analog input and output to allow one or more

DLCM’s to be slaved to a single DLC, DLCM, PLC, or PC master.

Figure 9 – Typical Serial Communications Connections

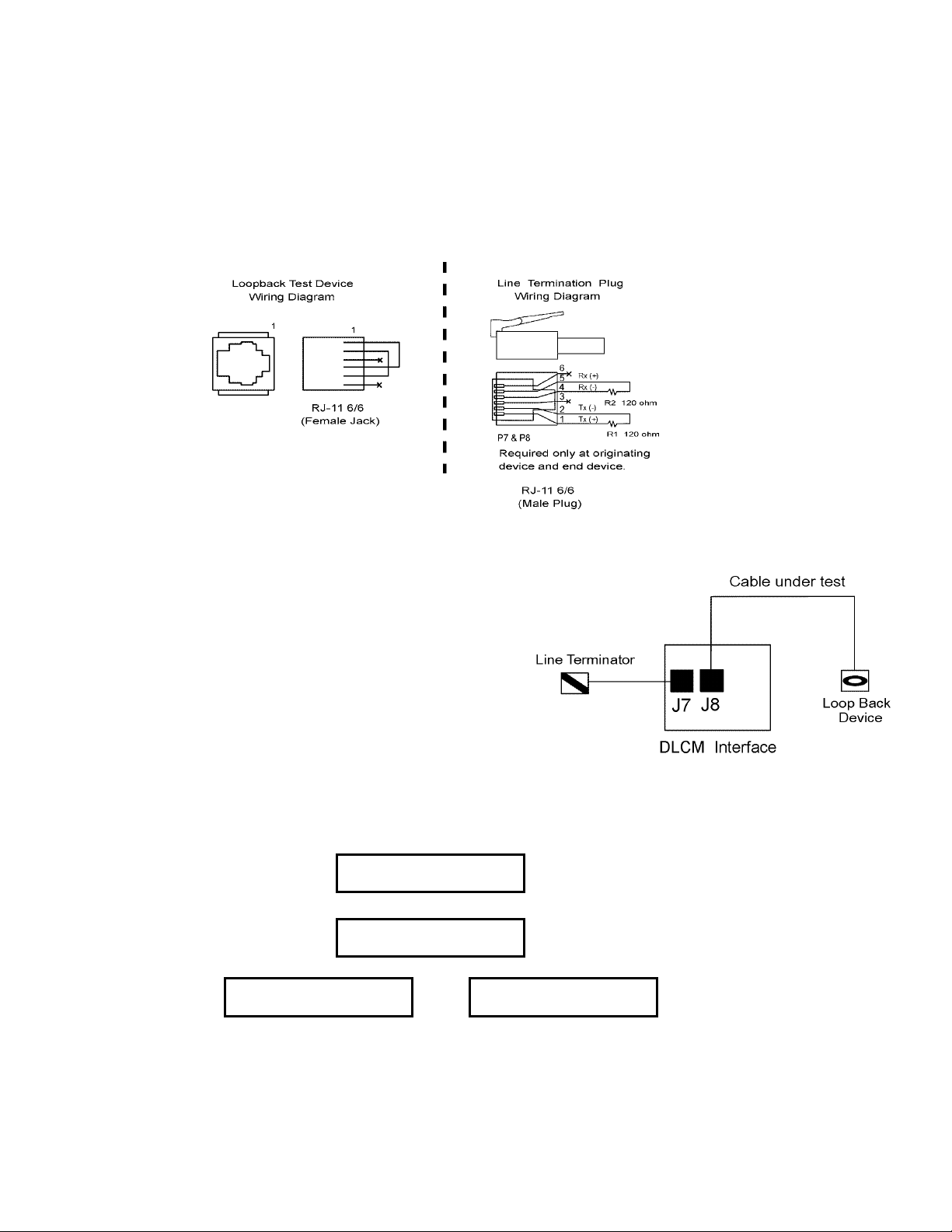

Use Belden™ Type 1590A data twist cable or equivalent. RJ-11 connectors (not supplied) are used to

plug into jacks J7 & J8 (refer to Figure 9).

The DLCM uses a 4-wire RS-485 network. This uses two wires for transmit and two wires for receive.

The RS-485 specification limits the total network length to 1200M (4000 ft). It also requires termination

resisters at both the first and last device.

Line Terminators can be constructed according to the drawing above.

19

Page 26

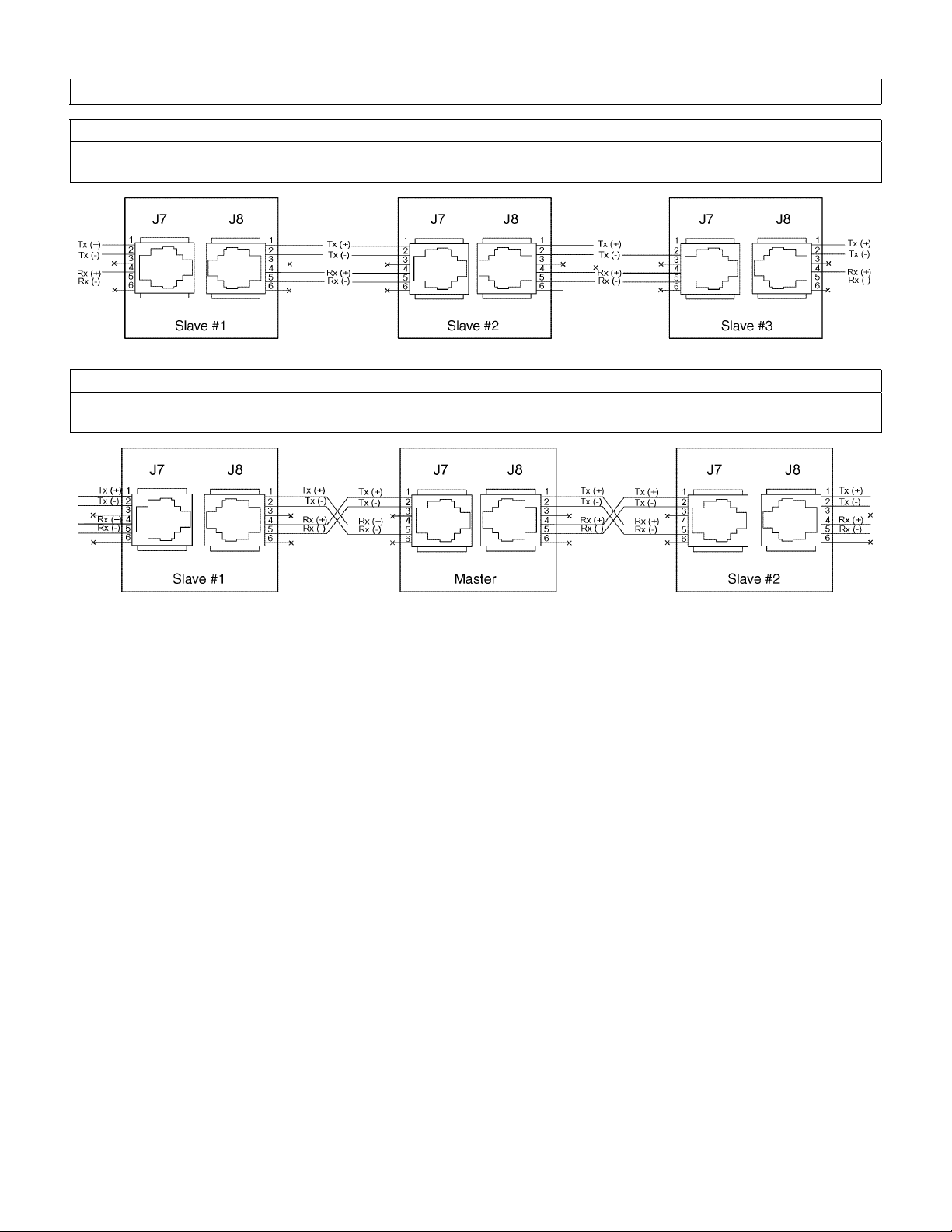

Slave to Slave

When connecting two Slaves, the wiring is straight through. For example: Connect the transmit lines

to the transmit lines and the receive lines to the receive lines (refer to the drawing below).

Master to Slave

When wiring between a Master and a Slave, the Transmit and Receive lines must be crossed. For

example: Connect the transmit lines to the receive lines (refer to the drawing below).

Important Wiring Detail

Figure 10 – Wiring Detail

20

Page 27

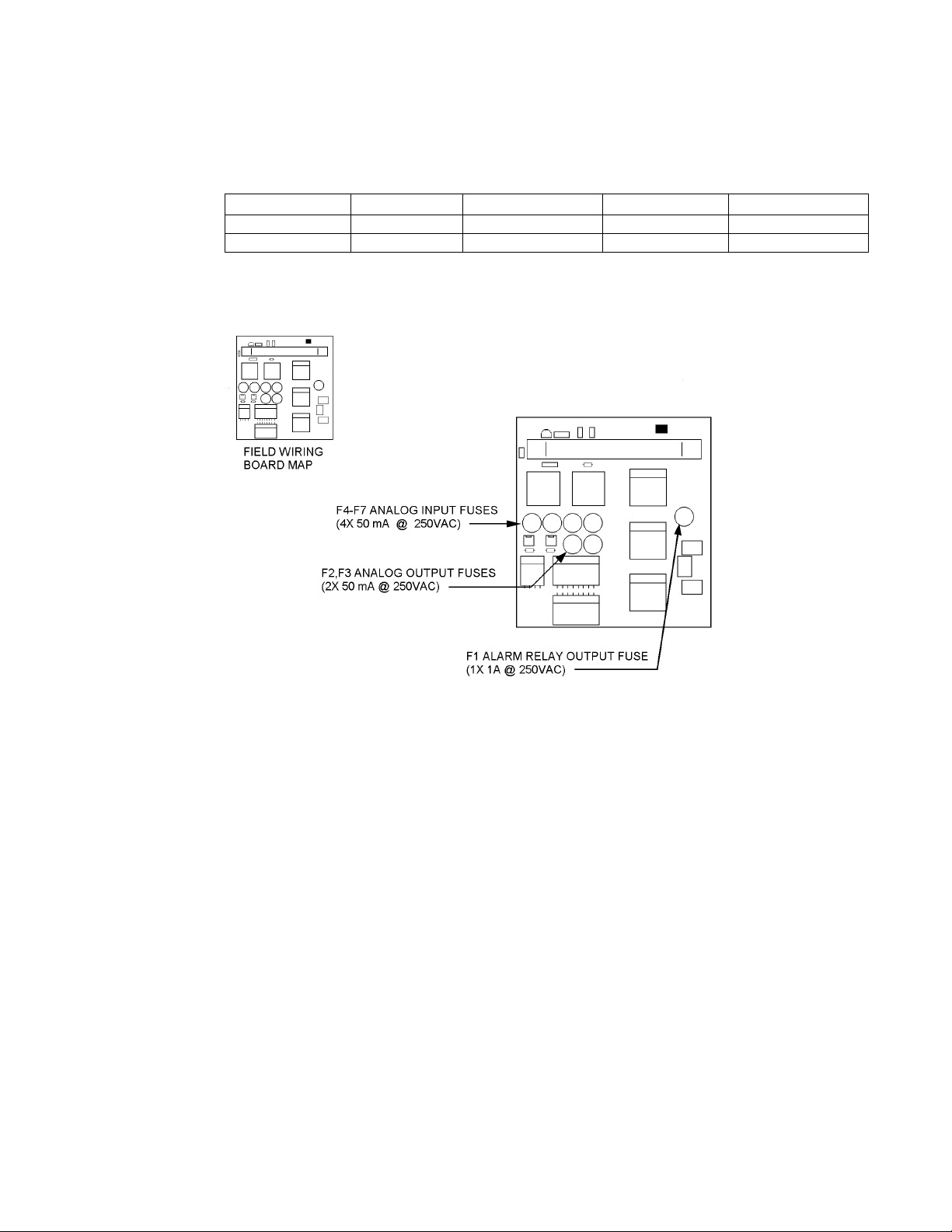

5.10 Fuse Replacement

Although Fuse replacement is not a part of normal installation, it is possible that fuse failure will result

from improper wiring. The DLCM uses a total of 7 user replaceable fuses: 1 for the alarm relay output, 2

for each of the Current Input and Output Channels. The table below details fuse replacement information:

Designator Function Rating Wickman P/N Pulsafeeder P/N

F1 Alarm Relay 1A @ 250VAC WK4048-ND NP5300026-000

F2-7 Current I/O 50mA @ 250VAC WK3022-ND NP5300027-000

Figure 11 details the location of these fuses on the Field Wiring Board.

Replacement Fuse Information

Figure 11. – Fuse Location.

The Internal DLCM power supply is fused at 2 Amps. This fuse is not user serviceable. The DLCM

Stroke Length Adjustment Synchronous Motor is inherently protected. It can operate continuously in a

locked rotor state. The DLCM also monitors this motor's duty cycle to maintain a 50% balance between

ON and OFF times. The serial ports and the Remote Run Status Output are protected by self-resetting

current limit devices. These components are not user serviceable.

21

Page 28

6. Start Up Instructions

6.1 Overview

Once all electrical connections have been made, your DLCM is ready for Start-up. The following nine

sections detail the procedures required to complete a DLCM start up.

W

HEN POWER IS SUPPLIED TO THE UNIT, LINE VOLTAGE IS PRESENT ON THE FIELD WIRING

B

OARD LOCATED AT THE BACK OF THE UNIT EVEN WHEN THE MOTOR IS

OFF.

D

URING START-UP, IT IS NECESSARY TO RUN THE PUMP MOTOR

. Y

DISCHARGE FROM THE PUMP

-

PUMP DURING START

UP AND CALIBRATION

OU ARE RESPONSIBLE FOR SAFELY DIVERTING FLOW FROM THE

6.1.1 User Interface Familiarization.

There are four key elements that will be useful in starting-up the DLCM:

a) Display

b) Keypad

c) Manual Adjustment Knob

d) Pump Motor.

Refer to Figure 12 to familiarize yourself with the location of these items before proceeding.

. T

HIS WILL CAUSE FLUID TO

.

Figure 12. – Key DLCM start-up elements.

22

Page 29

6.1.1.1 Display:

This is a 2 line by 16 character alpha-numeric Liquid Crystal Display (LCD) located above the

keypad. It is back-lit with a yellow-green light source for easy viewing in dark areas. Its contrast

can be adjusted by using the keypad.

6.1.1.2 Keypad:

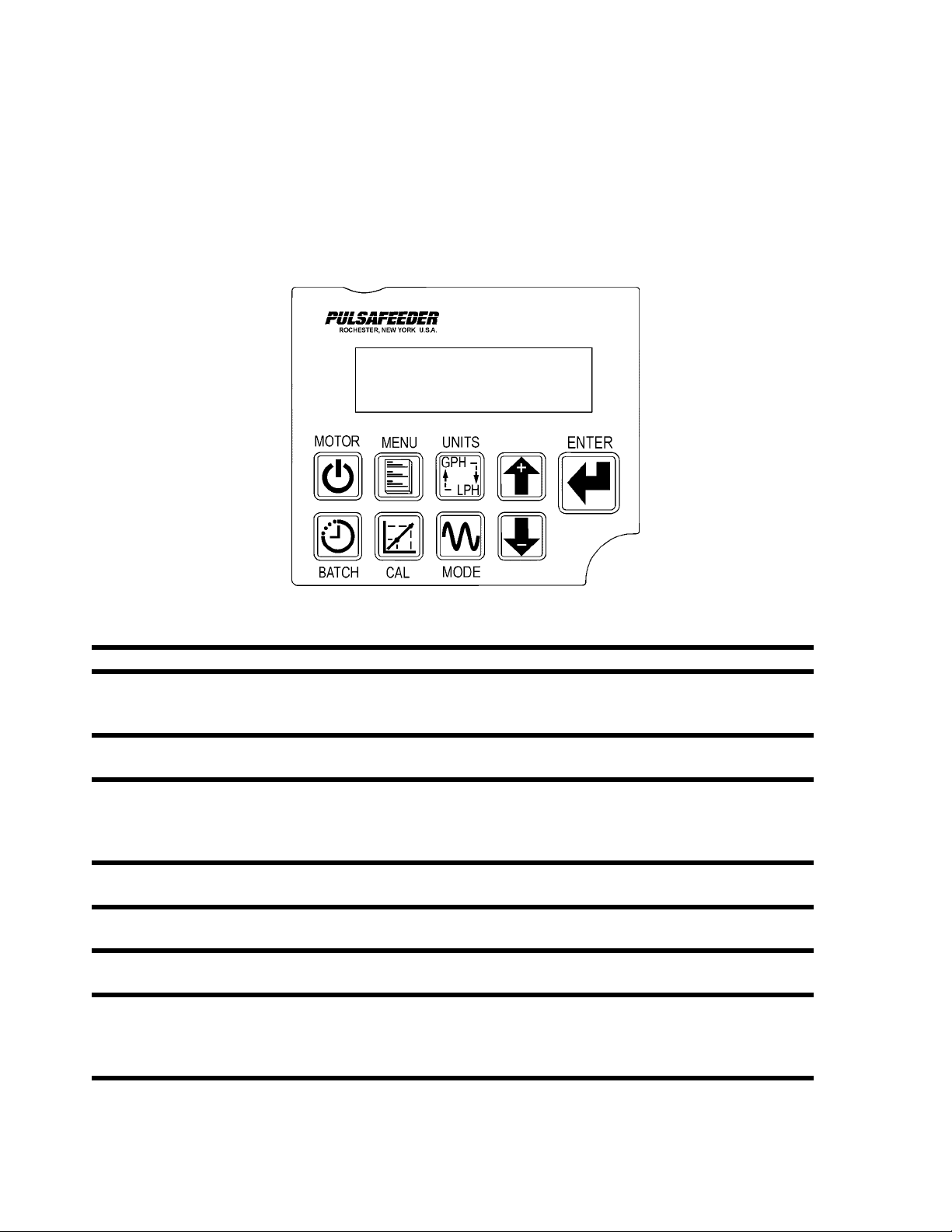

The Keypad is a sealed 9-button membrane style input device. It is easy to use and will guide you

quickly to specific functions. Refer to Figure 13 to familiarize yourself with the function of each

key before starting.

MOTOR

MENU

UNITS

ARROWS

ENTER

BATCH

CAL

MODE

Figure 13 – Key Pad

Press this key to Start the PULSAR motor or place it in stand-by.

Press this key to access the Configuration Menu. Press the ARROW keys to scroll

through the Configuration Menu Items. Press [MENU] a second time to exit the

Configuration menu to the current operating mode (e.g., MANUAL MODE).

Press this key to cycle to the next flow unit type whenever a flow unit is displayed at

the operating mode (e.g., MANUAL MODE).

These keys are used to change values currently displayed on screen. Use [DOWN]

to decrease the value and [UP] to increase it. Pressing both [UP] and [DOWN]

simultaneously performs special editing and by-pass functions. This is described

further in Section 7 – General Operation.

Use this key to accept a flashing value or parameter and proceed to the next submenu screen.

This key is used to activate the [BATCH] processing menu. Press [BATCH] a second

time to exit the Batch Setup function.

Press [CAL] to activate the Calibration menu for Flow and Analog Signals. Press

[CAL] a second time to exit the Calibration function.

The [MODE] key is used to change the operating mode of the DLCM. For example,

press once to change from MANUAL to ANALOG. Press a second time to change

from ANALOG to MODBUS. Press a third time to change from MODBUS back to

MANUAL.

23

Page 30

6.1.1.3 Manual Adjustment Knob:

The manual adjustment knob is mechanically attached to the PULSAR stroke length adjustment

mechanism. The DLCM uses the shaft attached to this knob to make its automatic adjustments.

Visually, the knob is a good indication of what the DLCM is doing. For example, if the DLCM is

increasing the pump stroke length – moving from 0 to 100% -- the knob will turn counter-clockwise

until the desired position is achieved.

If you try to force the adjustment, the DLCM will automatically react to adjust the position to the

programmed setting. If you manually adjust the knob while performing a pump calibration, the

calibration session will be terminated

While in the Analog Signal or MODBUS Mode – any attempts you make to change the stroke setting

using the Manual Control Knob to a value other than that specified by the remote signal will cause the

DLCM to make a correction.

The Manual Adjustment Knob should not be adjusted while power is removed from the DLCM. If

the knob is moved while the DLCM power is out, upon re-starting the DLCM will detect the

movement and perform a Zero Calibration .

W

HEN THE

{CALIBRATING ZERO}),

Z

ERO CALIBRATION THE

INTERVENTION COULD CAUSE THE

RESULT IN AN IMPROPER CALIBRATION

DLCM

IS PERFORMING A ZERO CALIBRATION (THE DISPLAY WILL READ

DO NOT TO TOUCH THE MANUAL ADJUSTMENT KNOB

DLCM

IS SEARCHING FOR A HARD MECHANICAL STOP

DLCM

TO INCORRECTLY DETECT THIS STOP

.

You may notice that when adjusting from a lower to a higher value (e.g., 10% to 20%) the DLCM

appears to 'over-shoot' its destination and reverse direction for approximately 1/16 of a revolution.

This behavior is normal. The DLCM always approaches a new position from the same direction to

eliminate backlash in the stroke adjustment mechanism.

6.1.2 Check Wiring and Close Access cover

Double check all of your electrical connections. Pay attention to polarity of all inputs and outputs –

both low and high voltage. Additionally, insure that all clamp style terminals are clamping onto the

bare conductor, not on its insulation.

Replace the wiring access cover and its 4 retaining screws with associated washers.

Use a screwdriver to tighten the retaining screws evenly. Failure to do so may cause the cover to leak

and void the Warranty. The supplied teflon washers are required to properly seal this cover. Failure

to replace these components will void the warranty.

. D

. A

NY MANUAL

. T

HIS WILL

URING A

24

Page 31

6.1.3 Confirm Correct Incoming Power

Double check that the wiring access cover is on and tightened down. Whenever power is supplied to

the DLCM, the display's back-lighting will 'glow' with a yellow-green light. The presence of this backlighting is an excellent indication that the DLCM's incoming power has been wired successfully and

voltage is present. Characters may or may not appear on the display. This is normal and will be

covered in the next section.

W

ITHOUT PRIOR OPERATING KNOWLEDGE, IT IS IMPOSSIBLE TO TELL IF THE

WILL RUN WHEN POWER IS APPLIED TO THE

NECESSARY STEPS TO ENSURE THAT ALL ASPECTS OF SAFETY HAVE BEEN CONSIDERED

ELECTRICAL, HYDRAULIC, ETC

APPLYING POWER

.

.). I

F IN DOUBT, DISCONNECT THE MOTOR FROM

DLCM. Y

The DLCM detects any adjustments made to manual adjustment knob while its power is off. If it

detects that the knob position has been changed, it will perform a zero calibration when the motor is

started. This action is normal.

Turn on power at the main. If the DLCM's incoming power is connected correctly, the back-lighting

on the DLCM's display will illuminate (depending on lighting conditions, it may be necessary to shade

the display to confirm illumination). If the display is not illuminated, first check the line voltage with a

volt meter. If the voltage is not correct, return to Section 5 – Installation: High Voltage Connections.

Otherwise, proceed with the next step.

6.1.4 Confirm Display and Keypad functionality

The example display messages are shown in English for demonstration purposes. If an alternate

language has been set, the text is displayed as a translation of the English version.

Now that you have confirmed that the DLCM is receiving power, it is necessary to confirm that the

display and keypad are functioning properly. On normal power-up, the {SELF-TEST} display appears

for approximately 5 seconds. After that time, the display will change the message to one of the

following:

PULSAR

OU ARE RESPONSIBLE FOR TAKING THE

MOTOR

(E.G.,

J3

PRIOR TO

SELF-TEST

1.20

10.0%

MANUAL MODE

- or -

- or -

TURN MOTOR ON

CALIBRATING ZERO

BATCH#1 RUNNING

10.0%

- or -

- or -

PLEASE WAIT

CALIBRATING ZERO

MOTOR STOPPED

- or -

At this time, the actual message is not important, the characters should be visible and form a reasonable

message.

If the display is blank (no-characters) then the display contrast must be adjusted. This is accomplished

by pressing and holding [MENU] while simultaneously pressing [UP]. This will darken the display.

Be patient! You may have to hold both keys down for as long as 30 seconds before the characters will

become visible. If the display is too dark, press [MENU] and [DOWN] simultaneously to decrease

(lighten) the contrast. Once the contrast is properly adjusted, check the message displayed. If it does

not look similar to one of those shown above, proceed directly to the next section to perform a Factory

Re-initialization on your DLCM.

25

Page 32

The keypad can be tested by depressing each key separately. Most, but not all keys will cause the text

on the display to change. Do not be alarmed if a single key does not invoke a change to the display.

This is normal. Different keys become active/inactive depending on the current operating mode .

There are a number of functions that the DLCM performs (e.g., zero calibration) where the keypad has

no effect. If the stroke adjustment knob is not moving, at least one key on the key pad should cause the

text on the display to change. Go to Section 6.1.6. If this is not the case, refer to Section 11 – Trouble

Shooting.

6.1.5 Performing a Factory Re-initialization

When Re-initializing your DLCM, all of the system settings will be overwritten by the original factory

default settings. The controller must be re-configured to your specifications (e.g., re-calibrated).

If your DLCM appears to be functioning properly – the display is similar to one of those shown on the

previous page – skip to Section 6.1.6.

A Factory Re-initialization restores all factory defaults to the DLCM's memory, and typically is not

required.

A Factory Re-initialization should be performed only if there is reason to believe that the internal

DLCM memory has become corrupted. A number of factors could cause this including: long-term

storage, disregard of electrostatic precautions (refer to Section 2 – Safety) during installation, improper

wiring, voltage surges, etc. The condition usually manifests itself with inconsistent or erratic operation

– often associated with characters on the display. Depending on the state of your DLCM, use one of

the following procedures:

Start-up Factory Re-Initialization:

Use this procedure when you cannot read the display, or if the DLCM does not seem to be responding

to your key presses:

1. Cycle power to the unit (turn it OFF then ON).

2. Within the first 5 seconds of power on, depress and hold the [UNITS], [MODE], and [ENTER]

keys simultaneously for approximately 1 second.

3. The display will continue to display the version number while the DLCM’s memory is restored.

The display will then show {TURN MOTOR ON / CALIBRATING ZERO}. Return to Section

6.1.4. Confirm the display and keypad are functioning properly.

26

Page 33

Menu Factory Re-initialization:

Use this procedure if the display and key pad appear to be functioning properly, but you suspect other

problems with data corruption, erratic operation, etc. Factory Re-initialization can be found in the

Configure Menu. Perform the following steps:

1. Apply power to the unit. Wait for the {SELF-TEST} display to disappear. The unit should display

a standard power on screen.

2. Press [MENU]. The display will show the first menu item {DIAGNOSTICS}.

3. Press [DOWN]. The {FACTORY DEFAULTS} menu item should be displayed. If not, continue

pressing [DOWN] until it does.

4. Press [ENTER]. The prompt {FACTORY RESET? / NO} is displayed.

5. Press [UP]. The prompt will read {FACTORY RESET? / YES}.

6. Press [ENTER] to accept the {YES} prompt. The prompt {ARE YOU SURE? / NO} is displayed.

7. Press [UP]. The prompt will read {ARE YOU SURE? / YES}.

8. Press [ENTER] to accept the {YES} prompt.

9. The display will read {PLEASE WAIT} for approximately 5 seconds while the DLCM’s memory

is restored. The display should then display {TURN MOTOR ON / TESTING ENCODER}.

Return to Section 6.1.4. Confirm the display and keypad are functioning properly.

6.1.6 Test Pump Motor

The Level Input, PULSAlarm and Signal Loss inputs can be configured to shut the motor down if

they are enabled. If this is the case, a message is displayed on the screen indicating the failure. You

cannot re-start the motor until these inputs have been corrected or the {Motor Off} option has been

disabled. Refer to Section 7 – General Operation for further information on configuring these

options.

To test the PULSAR motor connection, press [MOTOR]. If the motor is running it should stop and the

display should read {MOTOR STOPPED} or {TURN MOTOR ON / CALIBRATING ZERO} or

{TURN MOTOR ON / TESTING ENCODER} as shown below.

MOTOR STOPPED

If the motor is stopped, press [MOTOR] to start it and set the unit in Operating Mode. The display

should then read {MANUAL MODE} or {BATCH#X RUNNING} or {PLEASE WAIT /

CALIBRATING ZERO} as shown below.

10.0%

MANUAL MODE

If the display appears as shown above, but the PULSAR motor does not start, return to Section 5 –

Installation: High Voltage Connections and check your wiring. If the wiring is correct, refer to

Section 11 – Trouble Shooting.

The motor speed may be low enough that it is hard to tell that it is running. Check for fluid

discharge.

- or -

- or -

TURN MOTOR ON

CALIBRATING ZERO

BATCH#1 RUNNING

10.0%

- or -

- or -

TURN MOTOR ON

TESTING ENCODER

PLEASE WAIT

CALIBRATING ZERO

27

Page 34

6.1.7 Set Time and Date

The clock on your DLCM has been activated at the factory, but you should set it to the local time and

date of the installation site.

Time and Date are set in the Configuration Menu. Below is an example that accepts some software

default values:

1. From the Current Operating Mode Display, press [MENU]. The {–MENU– / DIAGNOSTICS-0}

screen is displayed (refer to illustrations below).

2. Press [UP] one time. The {–MENU– / SET TIME AND DATE} screen is displayed.

3. Press [ENTER]. The date and time screen is displayed.

4. Press [ENTER] to accept the 24 Hour time setting.

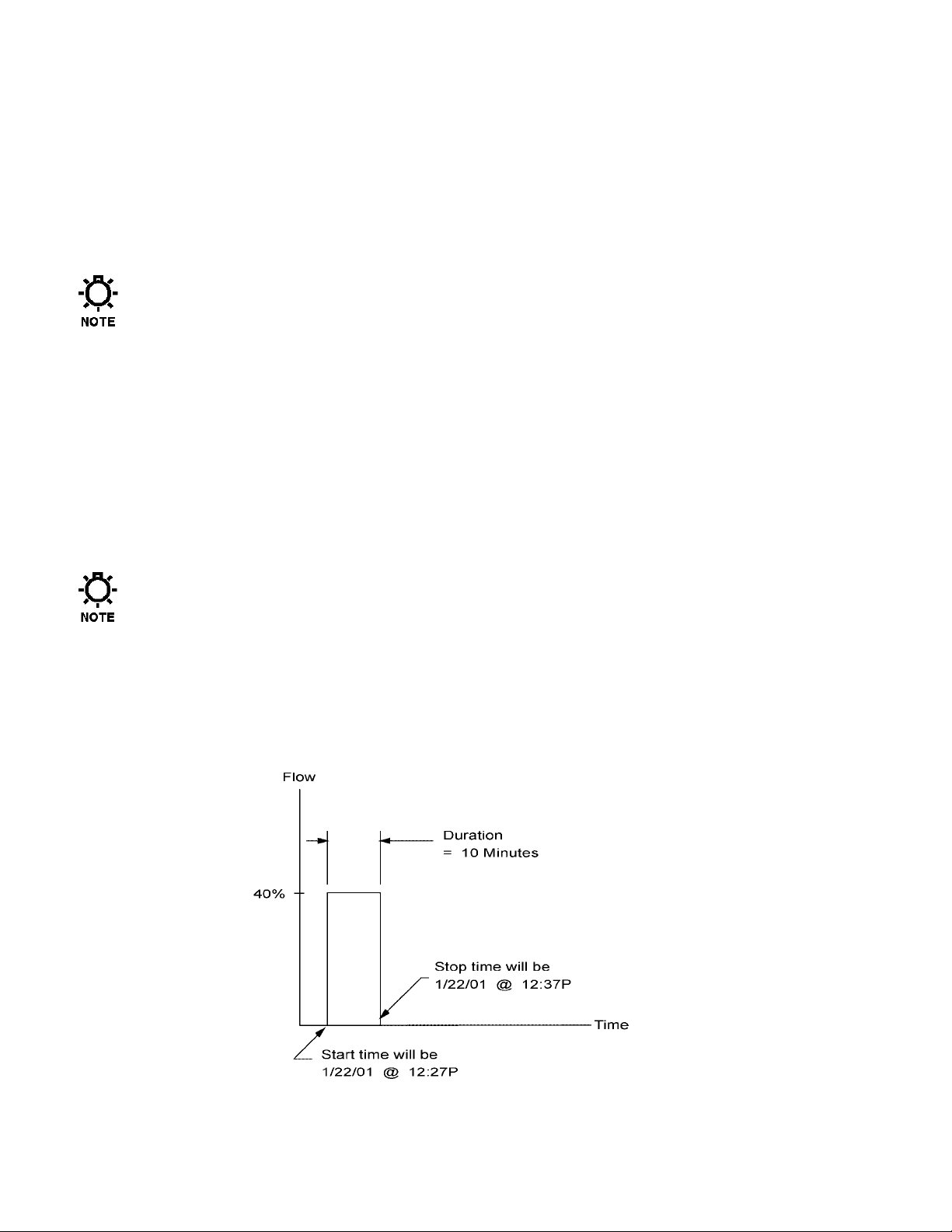

5. Press [UP] or [DOWN] to adjust the hour value displayed to the local time. Press [ENTER].

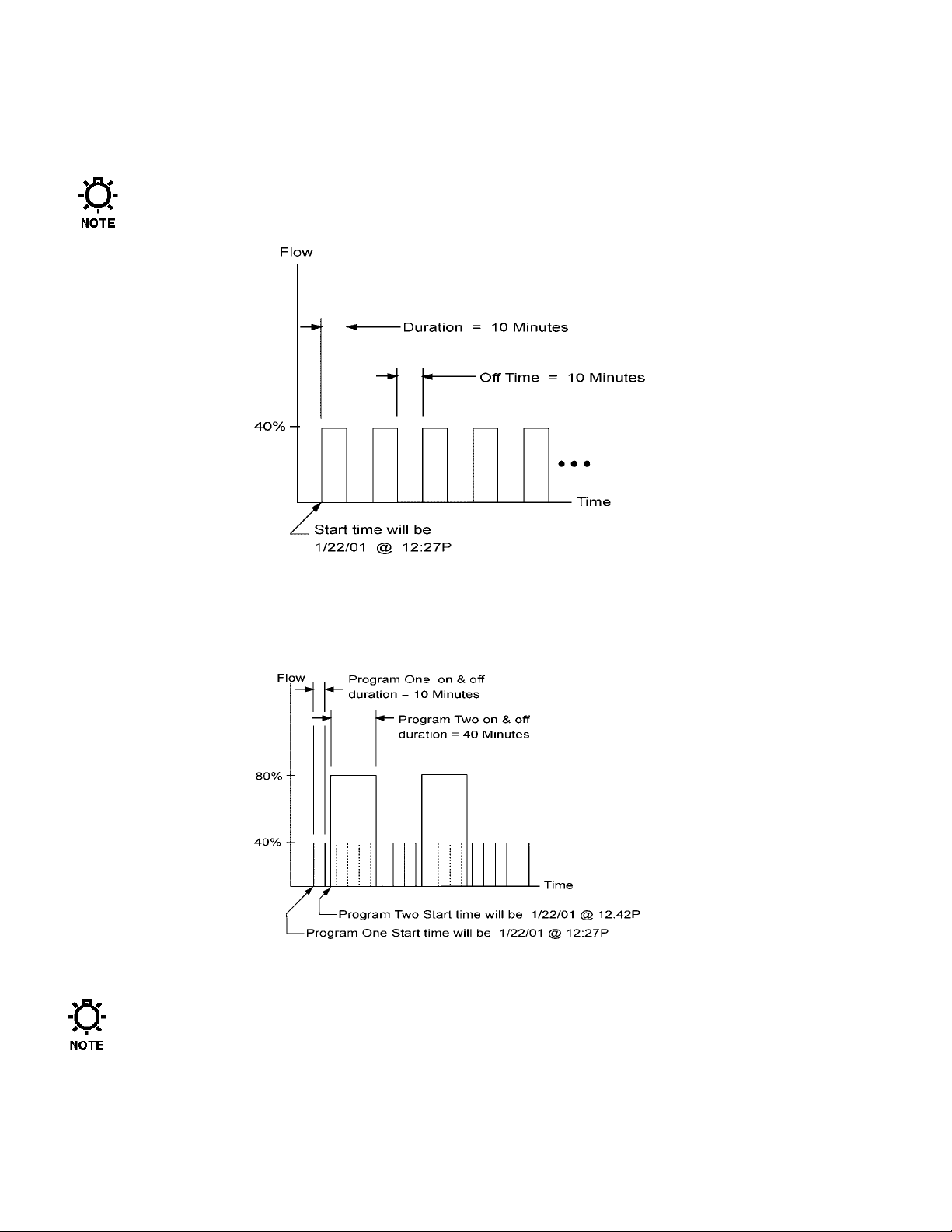

6. Press [UP] or [DOWN] to adjust the 10 minute value displayed to the local time. Press [ENTER].

7. Press [UP] or [DOWN] to adjust the minute value displayed to the local time. Press [ENTER]

twice (to accept the default MM/DD/YY format setting).

8. Press [UP] or [DOWN] to adjust the month value displayed to the current month. Press [ENTER].

9. Press [UP] or [DOWN] to adjust the day value displayed to the current day. Press [ENTER].

10. Press [UP] or [DOWN] to adjust the year value displayed to the current year. Press [ENTER]

twice (accepting the default Daylight Savings NO setting).

The time and date information has now been set.

-MENU-

DIAGNOSTICS – 0

Press

[UP]

-MENU-

SET TIME AND DATE

Press

[ENTER]

24 HR MM/DD/YY

21:07 1/22/01

Refer to Section 7 – General Operation: Set Time and Date for more detailed instructions on how to set

the Time and Date information.

28

Page 35

6.1.8 Flow Calibration (1-point).

Your DLCM is factory calibrated at rated flow and pressure (1-point). Nevertheless, you should

always perform a calibration with the PULSAR DLCM installed in your system. The only item

required to calibrate your DLCM is a means to measure the output of the pump (i.e., calibration

column, graduated cylinder, etc.). The following is a minimal procedure for performing a 1-point

calibration.

1. Press [MOTOR] to start the motor (if the motor is not currently running).

2. Press [UNITS] repeatedly until a unit that is consistent with your flow measurement device (i.e.,

calibration column) appears. For example, if your column reads in Liters then set the display to

LPM or LPH. Liters will be used in this example.

3. Press [CAL]. The {CALIBRATE / PUMP FLOW} screen is displayed.

4. Press [ENTER]. The {LAST FLOW CAL / 11:32 1/22/01} screen is displayed.

5. Press [ENTER]. The {FLOW CALIBRATION / 1-POINT} screen is displayed.

6. Press [ENTER]. The {CALIBRATE ZERO? / YES} screen is displayed.

If you are confident with the quality of your zero calibration, press [UP] and the {CALIBRATE

ZERO? / NO} screen is displayed. Press [ENTER] and continue with step 10.

7. Press [ENTER]. The {TURN MOTOR ON / TESTING ENCODER} screen is displayed, or if the

pump motor was ON when you started the calibration process, the {PLEASE WAIT / TESTING

ENCODER} screen is displayed.

8. Turn the pump motor on if necessary and the encoder performs its self test. When the self test is

completed, the{PLEASE WAIT / CALIBRATING ZERO} screen is displayed. The DLCM will

adjust the stroke to the 0% position and the motor speed to 100%.

9. When the zero calibration is complete the {PLEASE WAIT / MOTOR CAL.} screen is displayed.

PLEASE WAIT

MOTOR CAL.

With the stroke set at 0% the motor will run at 100% for a few seconds, and then decrease speed to

5%.

It will take anywhere from approximately 10 seconds to 5 minutes to complete the speed change. If

your pump continues to run after 5 minutes there is an error and you should contact Technical

Services.

10. The {PLEASE WAIT / XX% 100%} screen is displayed. The DLCM will adjust the stroke to the

100% position. The PULSAR motor will shut off.

PLEASE WAIT

XX% 100%

11. The {ENTER TO START/ 100% 2.641718 G} screen is displayed. The value '2.641718'

represents the amount of fluid discharged over 60 seconds the last time a calibration was performed

at the 100% stroke setting. Record the fluid base reading from your calibration column.

12. Press [ENTER]. The PULSAR motor will start to run. A timer is displayed counting down from

60 seconds. After 60 seconds the motor will stop automatically.

TIMER: XX SEC

2.641718 G

13. The {ENTER VALUE 100% / 2.641718 G} screen is displayed. Calculate the measured volume

displaced from the calibration column and enter the new value one position at a time using [UP]

and [DOWN] to change an individual position. Press [ENTER] to move the cursor to the next

position.

29

Page 36

14.

Pressing [ENTER] on the last position will cause the {CONFIRM CHANGE? / YES} screen to be

displayed. Press [ENTER] to accept. Your 1-point calibration is now complete.

Refer to Section7 – General Operation: Calibration, Pump Flow for more detailed instructions on

how to perform DLCM calibration.

6.1.9 Analog Input Calibration.

If you are not using the 0-20mA input to the DLCM for control, skip this section. To calibrate the

Input Current you must first correctly wire an external signal source. Refer to Section 5 – Installation:

Low Voltage Input Connections, Analog Input. To perform a calibration, the signal generating device

(e.g., PLC) must be powered up and capable of altering its output from minimum to maximum signal.

6.1.9.1 One – Signal Analog Input Calibration

The following is a minimal procedure for calibrating the Analog Input if the 1 – Signal option is to be

used.

1. Press [CAL]. The {CALIBRATE / PUMP FLOW} screen is displayed.

2. Press [UP]. The {CALIBRATE / ANALOG IN} screen is displayed.

3. Press [ENTER]. The {0% = 4.0mA / 100% = 20.0mA} screen is displayed. These values represent the

previous calibration.

4. Press [ENTER]. The {INPUT ANALOG MIN / 0% = XXmA} screen is displayed. Adjust your PLC

to output a minimum signal (i.e., 4.0mA). The DLCM display will update as the incoming signal

changes.

5. When the displayed value stabilizes, press [ENTER] to accept it. The {INPUT ANALOG MAX /

100% = XXmA} screen is displayed. Adjust your PLC to output a maximum signal (i.e., 20.0mA).

Again, the DLCM display will update with the changing signal.

6. When the displayed value stabilizes, press [ENTER] to accept it. The {INPUT RATIO / 100% =

XX.XmA} screen is displayed.