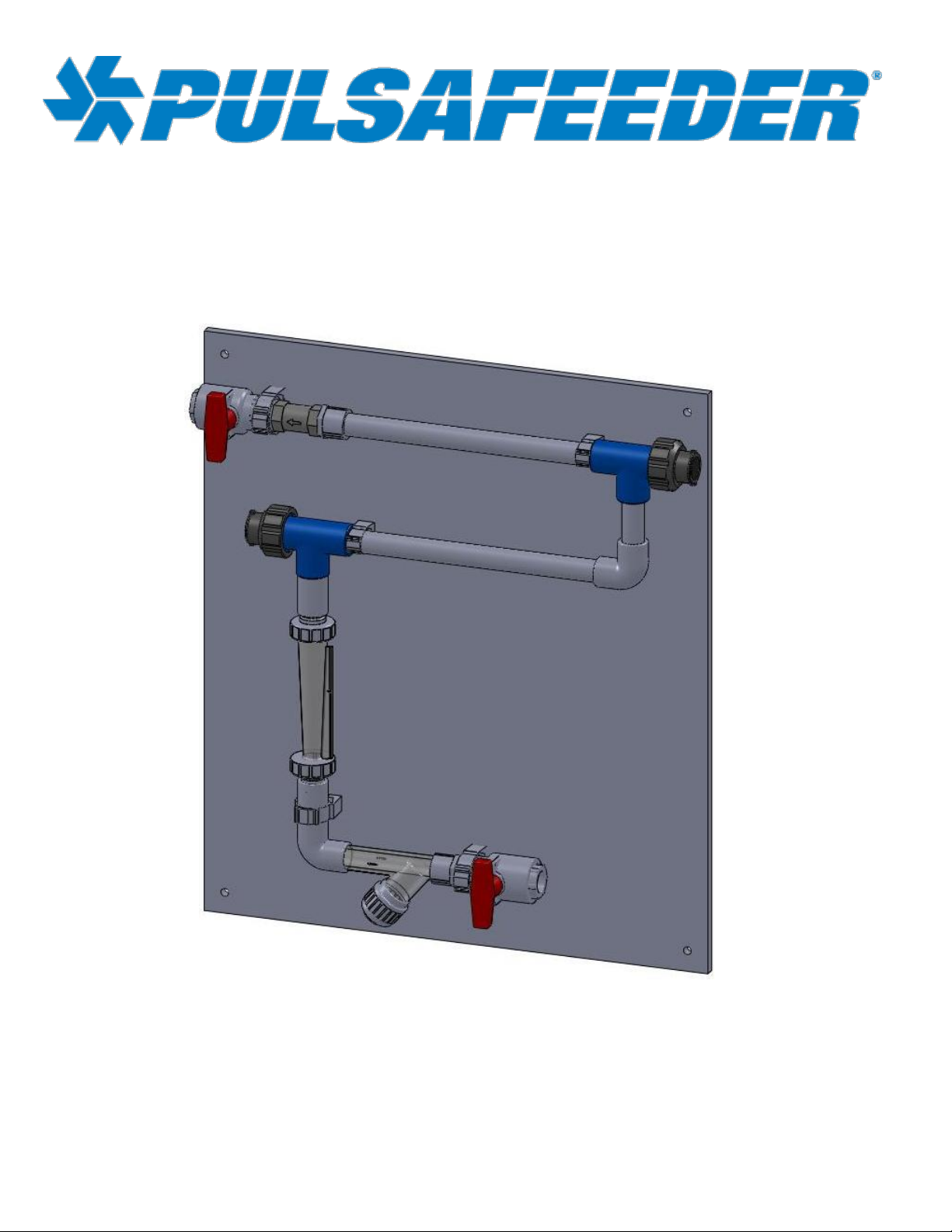

Corrosion Coupon Rack

INSTALLATION & OPERATION MANUAL

72-912-00 1 Revision C

Table of Contents

1 Cautions and Warnings .......................................................................................... 2

2 Temperature to Pressure Ratings ................................................................................. 3

3 Installation ......................................................................................................... 4

4 Operation ......................................................................................................... 5

5 Specifications .................................................................................................... 6

6 Parts ............................................................................................................... 7

7 Technical Support ............................................................................................... 7

1 Cautions and Warnings

1. It is recommended that the installer and operator utilize the appropriate personal safety equipment while

interacting with the Corrosion Coupon Rack (CCR); i.e. safety glasses, gloves, etc.

2. It is the installer’s responsibility to install the product away from sensitive equipment such as open electrical

devices to protect from potential electrical shock and or damage in the event of a leak or failure of the CCR

assembly.

3. It is the installer’s responsibility to provide for secondary containment, leak detecting equipment and or

drainage of potential water that may drip from the CCR during normal usage or in the unlikely event of a

rupture/failure.

4. This device has a rated operating pressure; however rapid pressure spikes that result from water hammer or

uncontrolled surges from external sources can cause pressures far above the rating of the product. The

purchaser/installer must make sure these spikes are prevented to assure safe operation of the CCR.

5. PVC versions of the CCR can be affected by high temperatures. The device is not designed to operate above

140O F (60O C). Pressure is also derated at higher temperatures.

6. Any modification to the CCR voids the warranty and any resulting failure is the sole responsibility of the

purchaser/installer.

7. Removal of the CCR piping from the supplied back plate is a modification not allowed and voids the warranty.

8. Prior to any service to the unit, always close the inlet isolation valve and release the pressure and completely

drain the unit.

72-912-00 2 Revision C

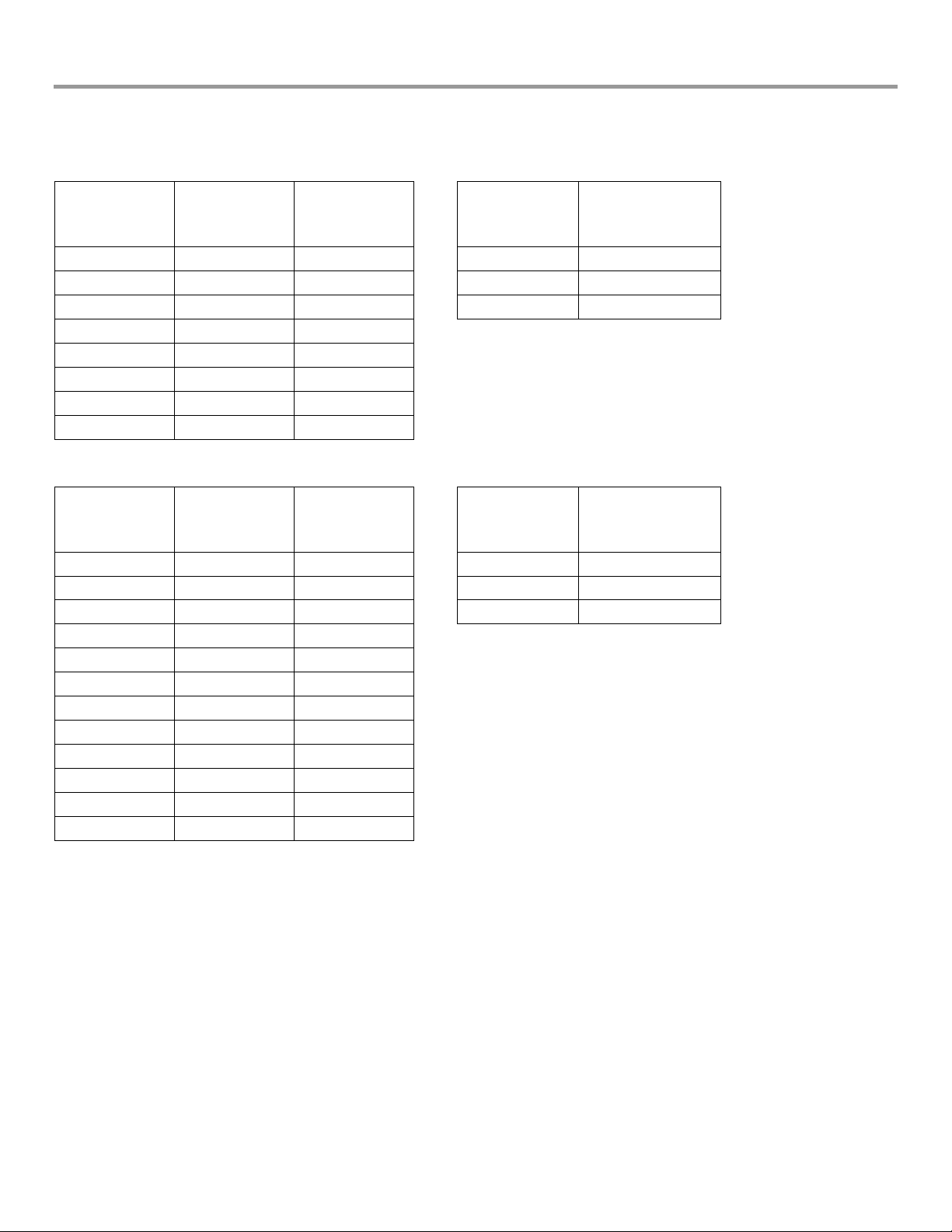

PVC Temperature to Pressure Ratings

PVC Schedule 80 Industrial Pipe

Operating

Temp (°F)

Operating

Temp (°C)

% Pressure

Derate

Nom. Size

(in)

Maximum

Working

Pressure (PSI)

73

22.8

100%

1/2"

850

80

26.7

88%

3/4"

690

90

32.2

75%

1"

630

100

37.8

62%

110

43.3

51%

120

48.9

40%

130

54.4

31%

140

60.0

22%

CPVC Temperature to Pressure Ratings

CPVC Schedule 80 Industrial Pipe

Operating

Temp (°F)

Operating

Temp (°C)

De-Rating

Factor

Nom. Pipe

Size (in)

Maximum

Working

Pressure (PSI)

80

26.7

100%

1/2"

850

90

32.2

91%

3/4"

690

100

37.8

82%

1"

630

110

43.3

72%

120

48.9

65%

130

54.4

57%

140

60.0

50%

150

65.6

42%

160

71.1

40%

170

76.7

29%

180

82.2

25%

200

93.3

20%

Example:

Material Type

Pipe Size

Temperature

Max W.P.

De-Rating Factor

De-Rated Max

W.P.

CPVC

1/2"

120 °F

850 x 65% =

552.5

2 Temperature to Pressure Ratings

72-912-00 3 Revision C

Corrosion Coupon Rack

3 Installation

Corrosion coupon racks are typically installed on the side stream of re-circulating systems to allow for

controlled testing of coupon samples. Samples are periodically removed and examined by a laboratory in

order to calculate corrosion rates and other effects such as pitting.

1) Securely fasten the coupon rack to a wall or other rigid surface.

2) Secure inlet and outlet piping using a suitable pipe clamp.

3) The coupon rack is designed with the inlet on the bottom and the outlet at the top, there must be more

pressure on the inlet side than there is on the outlet side in order for flow to occur.

4) Do not install any ancillary equipment on the inlet side of the sample stream, e.g, metering pumps,

sensors or analyzers.

5) Avoid installations that have variable flow velocities; installation of a flow control valve may be required.

6) Install inlet and outlet isolation valves (unless equipped).

The corrosion coupon rack is designed for outdoor installations, PVC and CPVC models should not be

exposed to direct sunlight and must be protected from environmental conditions. Verify that the pressure and

temperature of the installation do not exceed those in the specifications section of this manual.

72-912-00 4 Revision C

COUPON

MOUNTING

HARDWARE

SUPPLIED

WITNESS

SLOT

WITNESS

TABS

4 Operation

To remove the coupons, turn off the isolation valves and loosen the coupon holder to remove the coupon

sample. Install the coupon by hand tightening the holder into the tee, noting the witness marks on the holder

body. Restore flow by opening the isolation valves and then inspect for leaks.

Threaded Connect Style

Quick Release Style

Coupon Handling:

Do not leave finger prints on samples.

Do not clean samples.

Use the treated envelope supplied with coupon samples for storage before and after testing.

Use TFE tape on threaded type holders, quick connect type holders use O-Ring style seals.

Witness slot (or tabs) on holders must be vertical so that the coupon is also vertical.

72-912-00 5 Revision C

5 Specifications

3/4" PVC piping

1" PVC piping

3/4" CPVC piping

1" CPVC piping

3/4" black iron

piping

max 150 psi (10.4

bar), 1400 F (600C)

max 150 psi (10.4

bar), 1400 F (600C)

max 150 psi (10.4

bar), 2120 F

(1000C)

max 150 psi (10.4

bar), 2120 F (1000C)

max 250 psi (10.4

bar), 2120 F (1000C)

Model

Model

Model

Model

Model

Model

Model

Model

Model

Model

CCR1

CCR10

CCR1A

CCR10A

CCR1B

CCR10B

CCR10C

CCR10C

CCR1D

CCR10D

CCR2

CCR20

CCR2A

CCR20A

CCR2B

CCR20B

CCR20C

CCR20C

CCR2D

CCR20D

CCR3

CCR30

CCR3A

CCR30A

CCR3B

CCR30B

CCR30C

CCR30C

CCR3D

CCR30D

CCR4

CCR40

CCR4A

CCR40A

CCR4B

CCR40B

CCR40C

CCR40C

CCR4D

CCR40D

CCR5

CCR50

CCR5A

CCR50A

CCR5B

CCR50B

CCR50C

CCR50C

CCR5D

CCR50D

CCR6

CCR60

CCR6A

CCR60A

CCR6B

CCR60B

CCR60C

CCR60C

CCR6D

CCR60D

Available options:

Option

Description

X1

Quick release coupon holders (PVC only)

X4

3/4 hot/cold water flow meter 150 psi (10.4 bar) max 130ºF (54ºC). max

X6

1 cold water flow meter 150 psi (10.4 bar) max 130ºF (54ºC) max

X7

PVC outlet ball valve std, 3/4 blk iron units use 3/4" brass ball valve

X8A

Y Strainer for 3/4 PVC

X8B

Y Strainer for 1 PVC or CPVC

X8C

Y Strainer for 3/4 CPVC or black iron

X8D

3/4" Polypropylene bowl strainer 30 mesh, 150 psi max 70⁰F max

X8E

1" Polypropylene T strainer 30 mesh, 150 psi max 70⁰F max

X9

Clear PVC pipe sections

F3

Flow control valve 3 GPM (3/4" only)

F5

Flow control valve 5 GPM (3/4" only)

Z4

Sample and Drain port

1F10

1" 10 GPM Flow control Valve

1F5

1" 5 GPM Flow control Valve

72-912-00 6 Revision C

Coupon Rack Replacement Parts

Part No.

Description

16-756-51-1

Quick Release coupon holder with hardware

16-756-50

PVC and CPVC holder with hardware

16-756-42

Steel on black iron holder with hardware

16-756-43

Steel on black iron holder with hardware

High Temp / Pressure

33-022-16

3/4 hot/cold water flow meter

6 Parts

7 Technical Support

Factory Service Policy

If you are experiencing a problem with your corrosion coupon rack, first consult the troubleshooting guide in this

manual. If the problem is not covered or cannot be solved, contact Technical Services for assistance:

PULSAFEEDER INC. (SPO)

27101 AIRPORT ROAD

PUNTA GORDA, FL 33982

941-575-3800

Trained technicians are available to diagnose your problem and arrange a solution. Solutions may include purchase of

replacement parts or returning the unit to the factory for inspection and repair. All returns require a Return

Authorization number to be issued by Pulsafeeder. Parts purchased to correct a warranty issue may be credited after

an examination of original parts by Pulsafeeder. Warranty parts returned as defective which test good will be sent back

freight collect. No credit will be issued on any replacement electronic parts.

Any modifications or out-of-warranty repairs will be subject to bench fees and costs associated with replacement parts.

Warranty

Pulsafeeder, Inc. warrants control systems of its manufacture to be free of defects in material or workmanship. Liability

under this policy extends for 12 months from date of shipment. Electrodes/probes are considered maintenance items

and as such are warranted for six (6) months from the date of shipment of the controller. Electrodes/probes purchased

as spare parts are warranted for 90 days from date of shipment. The manufacturer's liability is limited to repair or

replacement of any failed equipment or part, which is proven defective in material or workmanship upon completion of

the manufacturer's examination. This warranty does not include removal or installation costs and in no event shall the

manufacturer's liability exceed the selling price of such equipment or part.

The manufacturer disclaims all liability for damage to its products through improper installation, maintenance, use, or

attempts to operate such products beyond their functional capacity, intentionally or otherwise, or any unauthorized

repair. The manufacturer is not responsible for consequential or other damages, injuries, or expense incurred through

the use of its products.

The above warranty is in lieu of any other warranty, whether expressed or implied. The manufacturer makes no

warranty of fitness or merchantability. No agent of ours is authorized to provide any warranty other than the above.

72-912-00 7 Revision C

Loading...

Loading...