Page 1

Installation

Operation

Maintenance

Instruction

Bulletin #: IOM-680

IOM-680 Rev B.

i

Page 2

Table of Contents

1. INTRODUCTION ..................................................................................................................................... 1

1.1 How Things Work .................................................................................................................... 1

1.2

Hydraulically Balance Flat Diaphragm Design ..................................................................... 1

1.3

Pump Head Assemblies .......................................................................................................... 2

1.4

Make-up Hydraulic Bypass and Bleeder Valves within the Hydraulic System ................. 2

1.5

Hydraulic Bypass Valve .......................................................................................................... 4

1.6

Pressure Relief Valve .............................................................................................................. 4

1.7

Bleeder Valve ........................................................................................................................... 4

Reagent Head Assemblies ..................................................................................................... 4

1.8

2.

INSTALLATION ...................................................................................................................................... 5

2.1

Check the Shipment ................................................................................................................ 5

2.2

Locating the 680 Pumps ......................................................................................................... 5

2.3

Flooded Suction Desirable ..................................................................................................... 5

2.4

Discharge Pressure ................................................................................................................. 5

2.5

Piping ........................................................................................................................................ 5

2.6

Strainers ................................................................................................................................... 6

Flush Piping System ............................................................................................................... 6

2.7

2.8

Metal Reagent Head Models ................................................................................................... 7

2.9

Plastic Reagent Head .............................................................................................................. 7

3.

START-UP INSPECTION ......................................................................................................................... 7

3.1

Filling Gear and Oil Reservoirs .............................................................................................. 7

3.2

Final Inspection ....................................................................................................................... 7

Start-up ..................................................................................................................................... 8

3.3

3.4

Priming Process Head ............................................................................................................ 8

To Adjust Flow Rate ................................................................................................................ 9

3.5

ii

Page 3

4. OPERATION AND MAINTENANCE ............................................................................................................ 9

Diaphragm Inspection ............................................................................................................. 10

4.1

4.2

Repriming Hydraulic ............................................................................................................... 11

Piston and Diaphragm Alignment .......................................................................................... 11

4.3

4.4

Check Valves ........................................................................................................................... 12

4.5

Hydraulic Make-up Valve ........................................................................................................ 12

4.6

Adjustable Valves .................................................................................................................... 13

Hydrualic Bypass Valve .......................................................................................................... 13

4.7

4.8

Automatic Bleed Valve ............................................................................................................ 14

4.9

Manual Bleed Valve ................................................................................................................. 15

4.10

Lubricating Instructions ......................................................................................................... 15

4.11

Oil Capacity .............................................................................................................................. 16

5.

STORAGE INSTRUCTIONS ....................................................................................................................... 16

5.1

Short Term ............................................................................................................................... 16

5.2

Long Term ................................................................................................................................ 16

5.3

Maintenance and KOPkits ...................................................................................................... 17

5.4

Ordering Parts ......................................................................................................................... 17

5.5

Additional Services ................................................................................................................. 17

6.

TROUBLESHOOTING .............................................................................................................................. 18

7.

PULSATROL ....................................................................................................................................... 20

7.1

Installation ................................................................................................................................ 20

Operation .................................................................................................................................. 21

7.2

8.

DIAPHRAGM BACK PRESSURE VALVES .................................................................................................. 22

Revision History:

Rev A Release Date Sept 1997, first revision

Rev B Release Date January 2006

iii

Page 4

1. Introduction

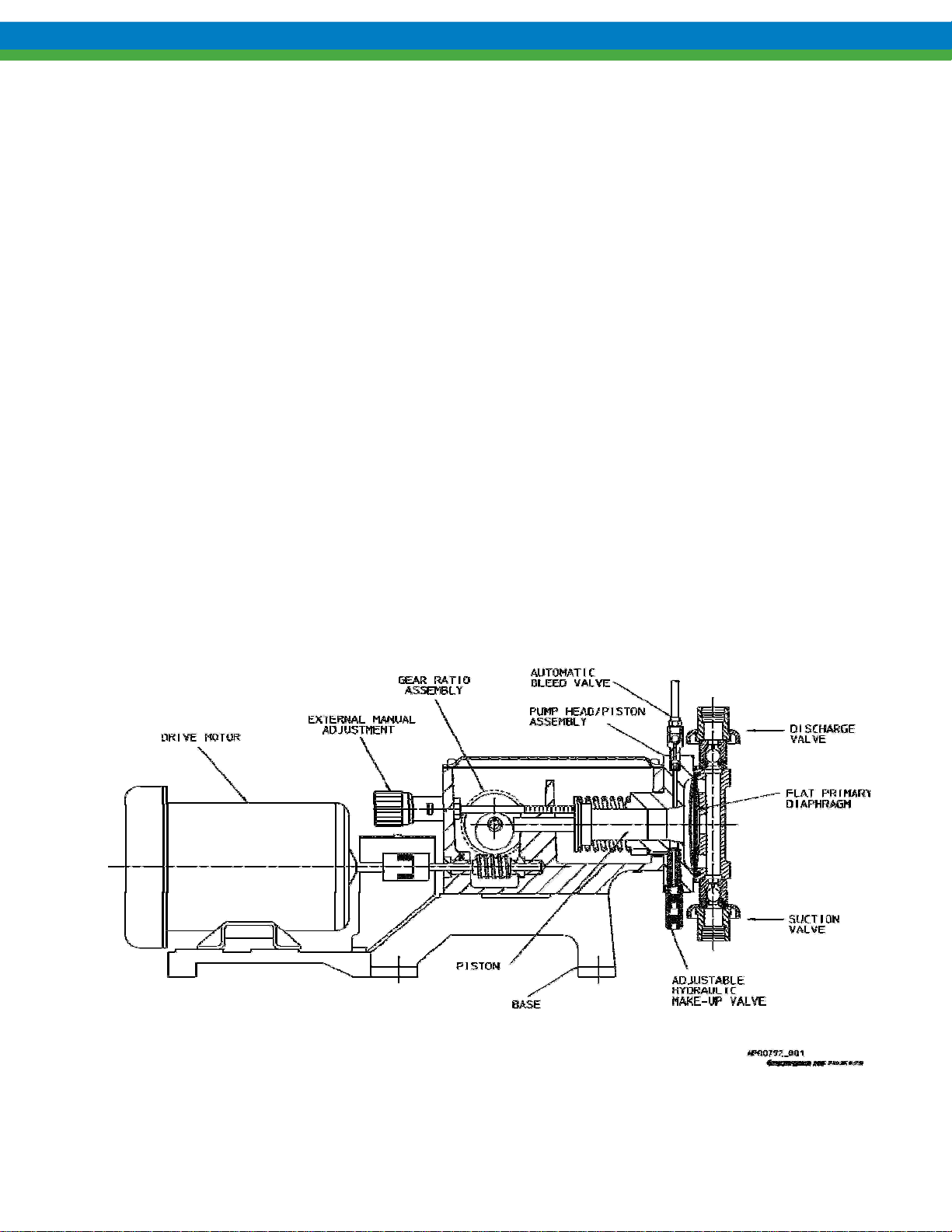

1.1 How it Works

A standard foot mounted motor drives a worm shaft at constant speed. Through worm gear reduction and

eccentric, a reciprocating power stroke is transferred to a plunger. The length of the plunger stroke

determines pump capacity and can be adjusted manually to provide pumping range from

0-100% of rating. However, this plunger does not pump chemicals, but an exceptionally stable oil*, having

excellent lubrication qualities. This makes a perfect pumping medium.

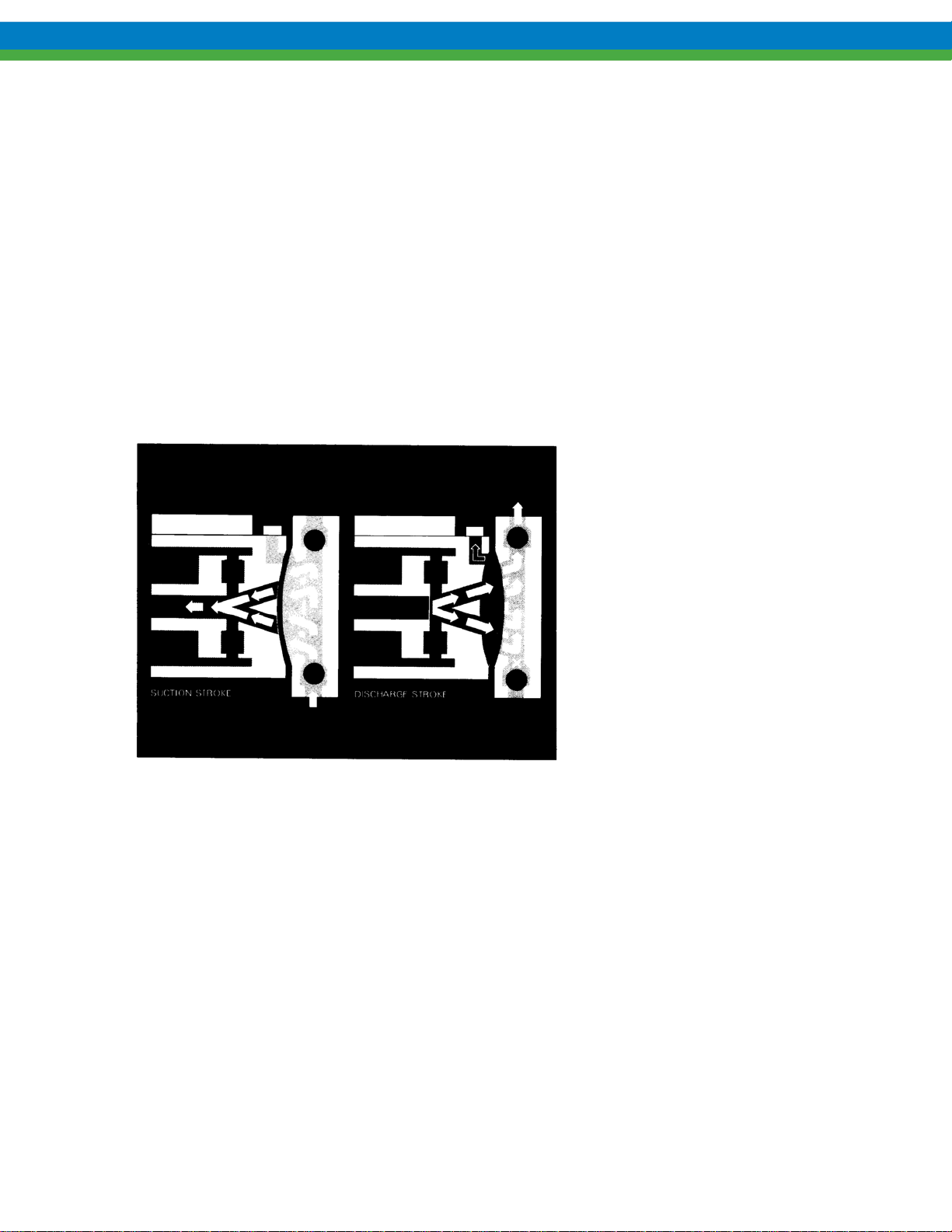

1.2 Hydraulically Balanced Flat Diaphragm Design (Figure 2)

Using this oil, the plunger hydraulically moves a diaphragm alternately forward and backward. A

displacement from this diaphragm movement in turn, takes in the liquid (chemical) being pumped through a

suction check valve on the suction stroke of the plunger and discharges a like amount of liquid (chemical)

through a discharge check valve on a forward or discharge stroke. The plunger operating in a sized cylinder

and at exact stroke length gives exact displacement and accurate pumping rate. The diaphragm isolates the

chemical being pumped within the reagent head and check valves. No other parts need to be of special

chemically stable material. This isolation of prompt eliminates the possibility of contamination. The plunger

handles only oil and no stuffing box is required.

*A special property petroleum oil tradenamed “PULSAlube” is generally used as hydraulic fluid. Continual reference to “Oil” as hydraulic medium

implies its general use rather than its use of necessity. Check with your representative or the factory if substitute oils must be used.

(Figure 2)

1

Page 5

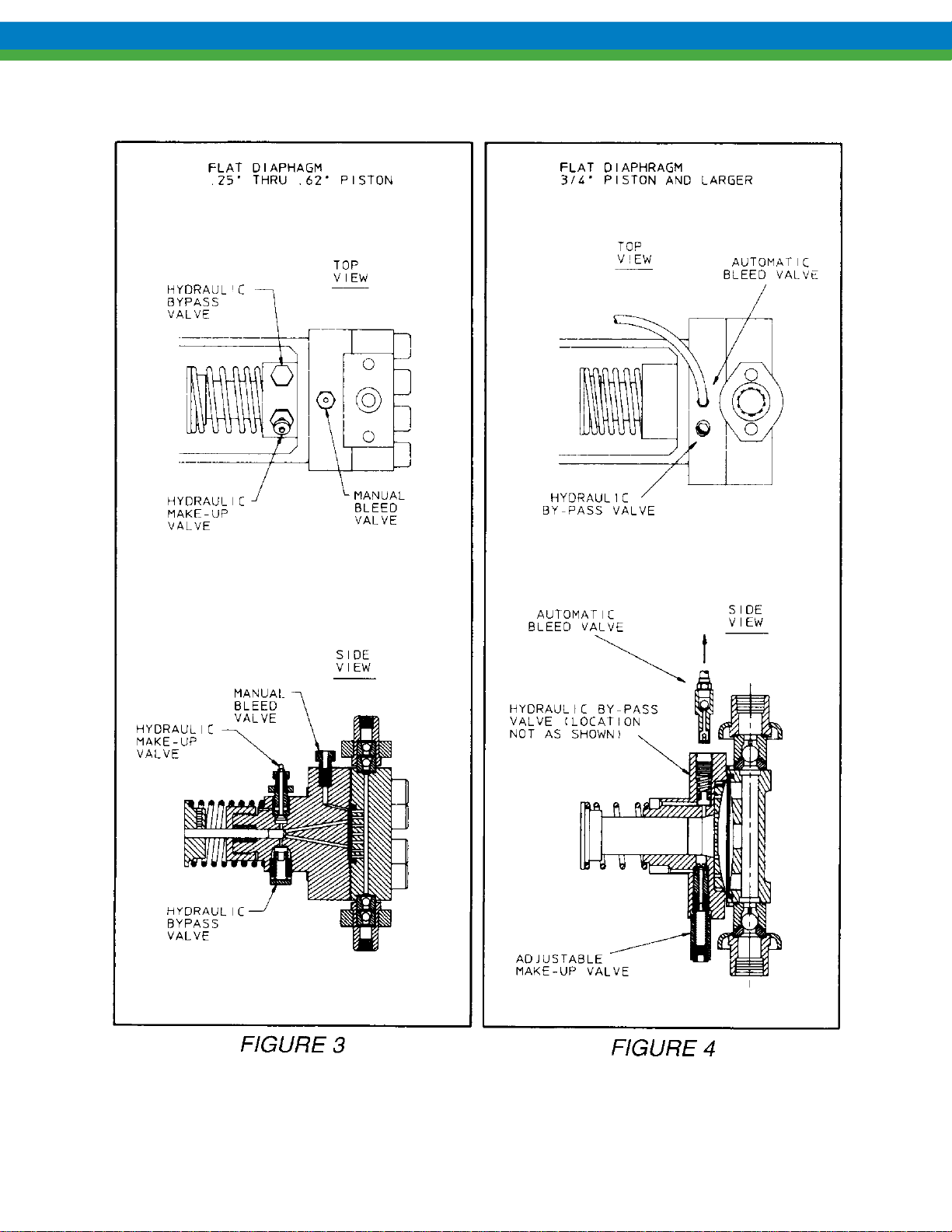

1.3 Pump Head Assemblies

The hydraulic pump head assembly contains the plunger cylinder and various hydraulic components to

protect and maintain a precise hydraulic balance between the plunger and the diaphragm. Figure No. 3 and

Figure No. 4 shows various styles of pump head assemblies.

1.4 Make-Up, Hydraulic Bypass and Bleeder Valves within the

Hydraulic System

Figures No. 3 and Figure No. 4 show the locations of valves according to piston diameter and diaphragm style

selected.

Make-Up Valve

Any leakage past the plunger or

bleeder, however slight, is replaced

by the make-up valve which

permits flow of replacement oil

from the oil reservoir. This is an

automatic function. The oil loss

allows the diaphragm to get out of

phase with plunger thus creating a

vacuum ahead of the plunger during

the suction stroke. The make-up

valves are factory set.

2

Page 6

3

Page 7

1.5 Hydraulic Bypass Valve

Any excess hydraulic pressure buildup within the pump compression chamber or chemical end due to

accidental valve closure or line stoppage is relieved through the hydraulic bypass valve. It blows off oil

under excess pressure ahead of the plunger back into the oil reservoir thus terminating the pumping action

and protecting the pump mechanism. Hydraulic bypass valves are factory set at full design pressure unless

specified differently by purchaser.

1.6 Pressure Relief Valve

A separate process relief valve should be installed in the process piping to protect piping and sensitive

process equipment.

1.7 Bleeder Valve

The function of this valve is to release any air or oil vapors from ahead of the piston and maintain a solid

hydraulic medium to transmit infinite movements of the piston to the diaphragm. In large piston models

where adequate oil movement exists, the bleed valve functions automatically weeping a minute quantity of

oil plus any air or vapor out of the hydraulic system. In small piston models where oil movement and

hydraulic instabilities are minimal a manual bleed valve is used.

Additional detail on the function of these valves will be given as applicable in the Operation, Maintenance

and Trouble Shooting Sections.

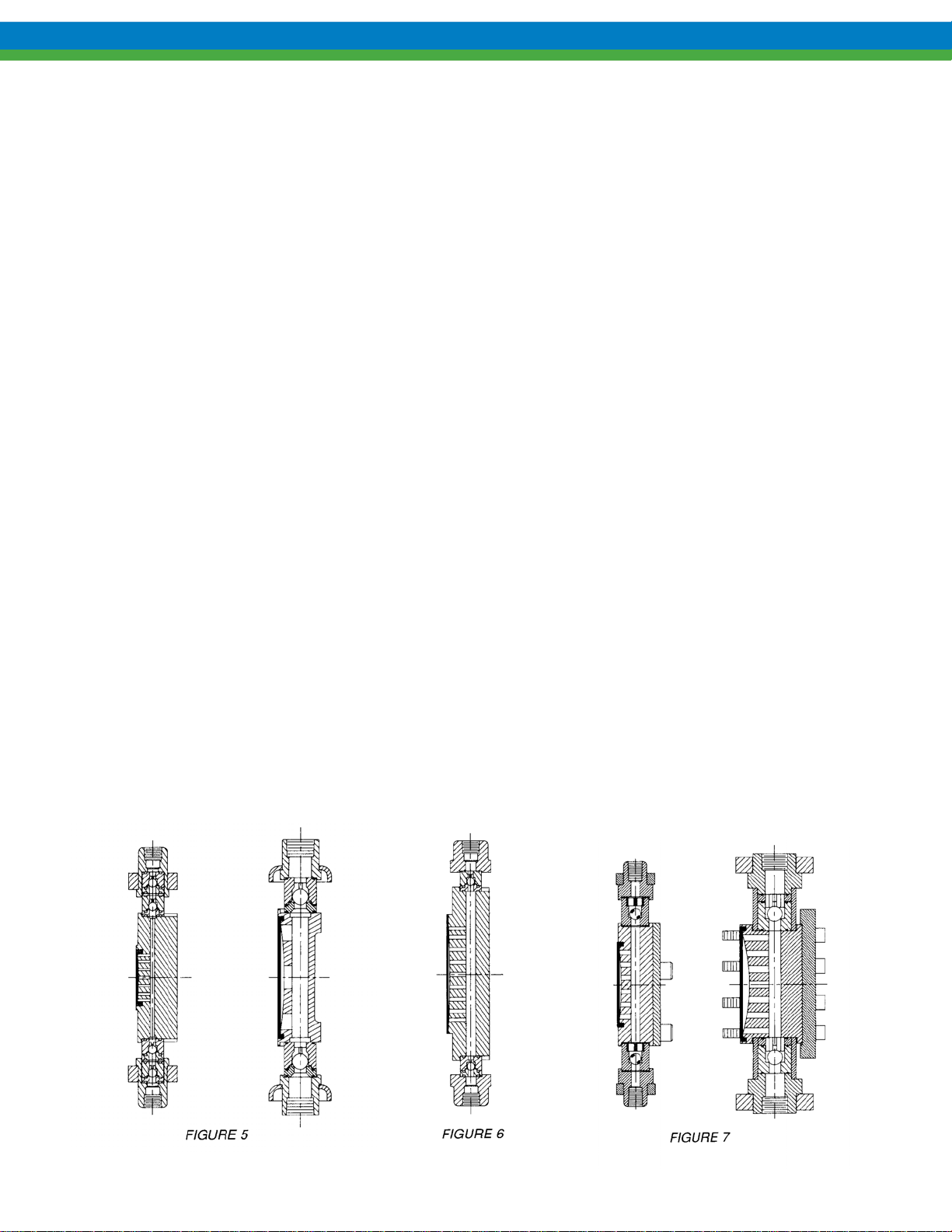

1.8 Reagent Head Assemblies

Flat diaphragm reagent head assemblies are available in several basic configurations. They are:

Figure No. 5 ¼” through 1 ½” piston metal reagent head and plastic diaphragm

Figure No. 6 ¼” through

Figure No. 7 ½” through 1 ½”, plastic reagent head and plastic diaphragm

5/8” metal reagent head and metal diaphragm

4

Page 8

2. Installation Tips

2.1 Check the Shipment

A standard Pulsafeeder shipment includes the pump, PULSAlube oil, wrenches, instruction and parts list

packet as well as replacement parts if ordered. Unpack carefully, check packing list and make sure all parts

are received. Check voltage of electric motor against the service to be used.

2.2 Locating the 680 Pumps

PULSAFEEDER pumps are designed to operate under indoor atmospheric conditions. It is desirable to

provide a hood or covering for outdoor service. Alternate oil or external heating is required if ambient

temperatures will be below 40

◦

below 40

1. Check level of pump. Shim where necessary.

2. Securely bolt to foundation. Do not

3. Check motor alignment, reagent head, and valve bolt tightness before operation. Follow bolt torque

NOTE: Most 680 models will operate without bolting down. However, it is important to have a solid

and level foundation so that a minimum of vibration is evident. Continual vibration can loosen

gaskets and pipe connections.

F (4.4 ◦C).

readings carefully.

◦

F (4.4 ◦C). Check with factory if fluid temperatures entering the pump will be

distort base.

2.3 Flooded Suction Desirable

Installation will be simpler to operate if the liquid will flow to the pump by gravity. Wherever possible, the

pump should be located below the level of storage vessel.

2.4 Discharge Pressure

All 680 models are designed for continuous service at the rated discharge pressure. To prevent liquid flow

through, it is necessary that discharge pressure be at least 5 psi above suction pressure. When pumping

downhill, a back pressure valve should be placed in the discharge line.

2.5 Piping

Pipe size and length are critical to proper operation of any metering pump. A restricted discharge or starved

suction condition spells immediate failure to any metering pump installation. A separate brochure entitled

“Designing a Successful Metering Pump Installation” is provided to assist engineers responsible for piping

system design. Copies are available upon request (Technical Sheet 304). Inlet piping must be at least equal in

size to pump inlet connection.

5

Page 9

Figure A shows the preferred piping configuration for a good metering pump installation. A god piping

installation addresses present and future requirements of the metering system. Plan for shut off valves and

unions or flanges installed on both the suction and discharge lines. This allows inspection of the check valves

without draining long runs of pipe. Install a tee in the suction and discharge

piping between the pump and shut off valves. This permits easy installation of a calibration tube for

calibration of the pump at start up or any future date. A tee in the discharge piping is a must on a good

installation because it permits ease of mounting a pressure gauge to check discharge pressure at the pump

and setting the hydraulic bypass valve during start up and future maintenance functions. To prevent strain on

the pump fittings use pipe straps and braces. Do not allow the weight of the piping to be supported by a pipe

union, the valve fitting or other portion of the pump head or leaks will occur. An air leak at a union or other

fitting in the suction piping can severely affect metering accuracy and is extremely difficult to detect. In

assembly of piping, use pipe thread tape or a compound compatible with the product handled. If rigid piping

is used, we suggest bolting the pump to its foundation.

2.6 Strainers

Pump check valves are susceptible to dirt and other contaminates and any accumulation can cause

malfunction. Be sure to use a pipeline strainer in the suction line between the suction shut off valve and the

pump suction valve. 100 mesh screen is preferred.

2.7 Flush Piping System

Whether new or old piping is used, all lines should be flushed with a clean liquid or air before starting pump

to carry out pipe scale or other foreign material. Make sure flushing liquid is compatible with the chemical to

be pumped.

6

Page 10

2.8 Metal Reagent Head Models

The metal reagent head assembly is provided in several alloys. Piping of similar alloy should be selected.

Dissimilar materials can cause galvanic corrosion.

Do not backweld piping to the valve housings without first removing the valve housings from the pump as

excessive heat can damage the reagent head and other parts. Tie bars must be positioned on the valve

housing before welding.

2.9 Plastic Reagent Head Models

Care must be exercised when making connections on plastic reagent head models. Excessive tightening can

distort or break the plastic materials. Tubing should be rated for the highest discharge pressure expected. DO

NOT USE METAL PIPING.

3. Start-Up Inspection

Every 680 metering pump is tested for correct capacity at maximum pressure capability of the pressure relief

valve before shipment. The diaphragm cavity is fully primed and remains so for shipment. For shipping

purposes, the gear and hydraulic reservoir oil have been removed. Sufficient fresh PULSAlube oil is

included with the shipment for refilling the gear and hydraulic reservoirs.

WARNING

1. DO NOT run pump without oil.

2. DO NOT remove main gear box cover while pump is running.

3. DO NOT run pump with coupling guard removed.

4. DO NOT put hands or fingers in gear box or reservoir when pump is running.

3.1 Filling Gear and Oil Reservoirs

Remove the pump cover and fill both reservoirs with PULSAlube oil to the top of the gear box partition. Do

not overfill. PULSAlube oil is compounded to serve as both gear lubricant and hydraulic transfer fluid.

Check with factory if substitute oils must be used.

The cover assembly incorporates a free acting diaphragm to allow breathing of the reservoir and at the same

time seal the reservoir from the atmosphere. Be sure the diaphragm is properly positioned when replacing the

cover so that it will seal on the gear box.

3.2 Final Inspection

Because of the pump’s small size and light weight it sometimes receives severe handling during shipment.

Though physical damage may not occur, it is always possible for parts to move slightly in adjustment. This

situation might occur with motor or pneumatic control alignment. A quick visual check should be made to

assure that motor and control shafts have not shifted severely out of alignment or damage could occur from

starting the motor. If unusual vibration should occur after start up, realign the motor and coupling.

7

Page 11

3.3 Start-up

Since the hydraulic oil system is primed at the factory, priming the process system is all that should be

necessary to produce flow. If the hydraulic system has inadvertently been dumped due to start up with

restricted suction or discharge conditions or improper adjustments to compensator or bleed valves, repriming

procedures under the maintenance section may have to be followed before pump calibration can begin.

3.4 Priming Process Head

1. Open the suction line and discharge line shut off valves.

2. If the piping system design and the storage tank are such that the product flows by gravity to the pump,

no priming is required. If however, the discharge line is under pressure, air will be trapped in the process

head and it will be necessary to remove the discharge pressure to enable the pump to prime itself.

3. If the pump must handle a suction lift, it may be necessary to manually prime the reagent head. Remove

the discharge valve by unscrewing the two tie bar bolts and then lifting the valve out. Fill the head with

process fluid, or a compatible liquid, then replace the valve in the same position and retighten the tie bar

bolts.

4. The pump is now ready for start-up.

5. Start the pump and increase the control setting to full stroke.

6. Make a brief check to assure that the pump is producing the approximate flow desired at the full stroke

setting. Calibration should not be attempted on any model until it has run at least one hour to assure the

pump hydraulic and reagent head systems have stabilized.

Due to agitation of the PULSAlube oil when filling the reservoirs, minute air bubbles will have formed.

It takes at least one hour running time to dissipate the bubbles and develop a sound hydraulic system. In

some of the very low displacement models it may take up to eight hours running time to stabilize the

system and permit accurate calibration. This is generally limited to models with ¼” and 3/8” diameter

plungers.

If the pump does not produce the approximate flow desired at the full stroke setting refer the Trouble

Shooting Section for possible causes and refer to the Priming Procedure under the Operation and

Maintenance Section.

IOM-NMG-0804 – Rev E

8

Page 12

3.5 To Adjust Flow Rate (Figure B)

The 680 Pulsafeeder pumps are provided with a lock-in place micrometer knob adjustment for changing

length of stroke while in operation or idle. Push in on locking device and turn adjustment knob clockwise to

increase flow and counterclockwise to decrease flow. These indications can be converted to volumetric or

weight units by calibration conversion charts. On earlier model micrometer knobs you may increase the

friction on the adjustment or completely lock up the adjustment knob by removing the gear box cover and

tightening the friction nut on the adjustment shaft.

4. Operation and Maintenance

The preceding instructions have assisted you in proper installation and start-up of your 680 pump. The following

sections are arranged to assist in maintaining proper pump operation and troubleshooting any problems that might

develop during start-up or thereafter.

Accurate records in the early stages of pump operation will reveal the type and amount of maintenance that will

be required. A preventative maintenance program based on these records will insure trouble free operation. It is

not possible in these instructions to forecast the life of such parts as the diaphragm, check valves and other parts

in contact with the product you are handling. Corrosion rates and conditions of operation affect the useful life of

these materials so an individual metering pump must e gauged according to particular service conditions.

9

Page 13

4.1 Diaphragm Inspection (Figure 3 & 4)

Pulsafeeder TFE plastic or metal diaphragms are not subject to stress fatigue and do not fail from repeated

flexure. However, long-time accumulation of foreign material or entrapment of hard, sharp particles between the

diaphragm and the dish cavity can eventually cause premature damage.

Periodic inspection of the diaphragm is desirable, especially if the product pumped carries large particles or trash.

To remove the diaphragm, the first four steps are the same for plastic and metal diaphragms.

1. Remove all pressure from the piping system.

2. Close the inlet and outlet shut-off valves.

3. Break the union or flanges on the piping.

4. Arrange to catch and properly dispose of the oil and product leakage that will occur when disassembling head

and valving.

5. Remove the inlet check valve to drain reagent head and cavity. Use extreme caution if product is hazardous

and wear proper protective clothing.

For plastic diaphragms, follow Steps 6 through 10. For metal, follow Steps 11 through 15.

6. Remove reagent head bolts and rinse the head in water or a compatible liquid.

7. Flat disc style diaphragms in TFE material which remain attached to the reagent head can be removed

undamaged by forcing compressed air into the inlet port while plugging the discharge port. Diaphragms

which remain attached to the hydraulic pump head can be removed undamaged by rotating the piston by hand.

8. If the diaphragm shows no evidence of damage, there is no need to replace it. A slight warped condition is

normal and will not require replacement of the diaphragm.

9. On models which have an insert dish plate, make sure the dish plate is reset in the pump head with the cavity

on the diaphragm side and one of the four holes closest to the outer edge positioned at the top to permit air to

bleed out of the cavity when priming.

10. Some Pulsafeeder plastic diaphragms incorporate an integral “O” ring design. Follow torque restriction in

table on the following page. Simply tighten to bolt strength limit. On other models, where there is no “O”

ring, the diaphragm must be compressed to form a seal. Be careful to follow the torque limits in the table

(page 10). MODELS WITH PLASTIC HEAD AND VALVES MUST BE TIGHTENED BY HAND ONLY

TO AVOID DISTORTION OF PARTS.

The following steps apply to metal diaphragms:

11. As the diaphragm is sealed by “O” rings, or gaskets, at bolt the pump head and reagent head, leakage of both

oil and product pumped can occur simultaneously when the reagent head bolts are loosened. It is, therefore,

desirable to remove the inlet check valve to drain the reagent head and cavity. Proceed with care if the

product is hazardous.

12. When removing the reagent head bolts, leave two bottom bolts in place but back them out until the diaphragm

is exposed at the top. Pick out the diaphragm with needle nose pliers.

13. If the diaphragm shows damage, replace it.

14. If the “O” rings are extruded or cut, replace them. On models with flat gaskets, replace the gaskets each time

the head is removed. Make sure gaskets are properly centered on serrations located on the pump and reagent

head. Hold the gaskets in place with an adhesive. DO NOT COMPLETELY COAT THE GASKETS AS

THIS WILL FILL SERRATIONS WITH COMPUND AND IMPAIR SEALING.

15. Before reassembly, make sure all faces of the reagent head and pump are clean.

10

Page 14

BOLT TORQUE RECOMMENDATIONS

FOR MODELS WITH METAL HEADS AND PLASTIC DIAPHRAGMS (1) (2)

Piston Dia. Reagent Head Bolts Tie Bar Bolts

.250-.500

.625-1.50

(1) Metal diaphragm models/reagent head bolts can be tightened to normal range compatible with bolt sizes. Tie bar bolt

torque same as for plastic diaphragm models.

(2) DO NOT use these torque ratings for models with plastic reagent head and valve housings. Bolts on these models

should only be hand tightened for adequate seal at their lower pressure rating.

240-300 in. lbs 276-345 kg.m

60-70 in. lbs. .69-81 kg.-m

45-65 in. lbs. .52-75kg.-m

25-45 in. lbs. .29-52 kg.-m

4.2 Repriming Hydraulic (Figure 3 & 4)

1. Reassemble diaphragm and reagent head, tightening all bolts securely and evenly. Use reliable torque wrench

to valves indicated.

2. Reassemble valve housing and take care in inserting gaskets that they are properly positioned. Replace valves,

seats and seat gaskets incorrect orientation for direction of flow (see Figure 8-11) and tighten securely.

3. Connect inlet piping.

4. With discharge line bypassed around process or to drain, start motor and prime reagent head.

5. Set stroke length adjustment to maximum stroke.

6. Stop the pump and remove the manual bleed/auto bleed valve assembly from pump head.

7. Place a plastic pipette (i.e. turkey baster) in the manual bleed/auto bleed valve hole of the pump head. Fill

pipette with oil being used in gearbox.

8. Start the pump. As the pump operates each suction stroke of the pump will draw in oil from pipette and each

discharge stroke will expel air from the pump head.

9. Add oil to pipette as necessary until no more air is expelled from the pump head and oil is moving up and

down pipette with piston movement.

10. Shut down the pump and manually retract the piston to full rearward position. (This may be done by

removing coupling cover and manually turning motor shaft.)

11. Remove the pipette and replace the manual bleed/auto bleed valve assembly.

4.3 Piston and Diaphragm Alignment

12. Manually rotate motor shaft until piston is in full forward position.

13. If piston does not set up before full forward position is obtained then pump piston and diaphragm is phased.

14. If piston set up at some point prior to achieving full forward position then loosen up bypass valve setting

(keeping track of the number of turns) until piston slips forward forcing excess oil from the pump head

through the bypass valve. Move piston to full forward position.

15. Retighten bypass valve to previous setting, but do not exceed MAX OPERATING PRESSURE indicated on

pump nameplate.

16. Hydraulics is primed and piston is phased with diaphragm.

17. Add PULSAlube oil to front and rear reservoirs to bring oil level up to top of partition.

18. After the pump has run for several hours, again bleed manual air vent for any last trace of air.

11

Page 15

4.4 Check Valves (Figure 8, 9, 10 & 11)

Operating experience on thousands of installations has indicated the many metering pump troubles have to do

with check valves. Problems usually stem from (a) an accumulation of trash between the valve and seat, (b)

corrosion which damages seating surfaces, (c) erosion from high velocity flow, or (d) normal physical damage

after extended service.

When reassembling after cleaning or replacement be sure to use new seals. Separate the valve assembly and

examine the components for wear, damage or accumulation of solids. A ball valve seat should have a sharp 90

edge, free of any nicks or dents. Hold the ball firmly on the seat and examine against a light. If light is visible

between the two then replace the seat and/or ball.

◦

4.5 Hydraulic Make-up Valve

Hydraulic make-up valves are designed to maintain the correct volume of oil in the hydraulic system between the

piston and the diaphragm. Pumps are supplied with one of two valve styles shown in figures 12 &13.

12

Page 16

4.6 Adjustable Valves (Figure 12)

This valve is factory set and operator adjustable. Under normal circumstances adjustment is not necessary.

Normal victory setting allows two threads to show from end of threaded shaft to locking nut. The valve requires

no routine maintenance and is not considered a normal replacement item. In some situations it is necessary to

adjust the valve. If sprint tension is too tight, this condition is signaled by a gradual loss in pump capacity. If

spring tension is too loose, oil will be forced from bypass valve on every stroke.

(Figure 13)

This valve is adjusted by turning the adjusting bolt (Figure 13) to vary the spring tension on the valve. The

following procedure is used at the factory for setting the valve:

1. The set screw and back-up spring are removed. Care should be used when handling the spring. DO NOT

STRETCH OR COMPRESS THE SPRING BY HAND.

2. The set screw threads are cleaned and 4-6 wraps of Teflon tape are applied.

3. The set screw is re-threaded into the valve body until it bottoms out. It is then backed out (turn counterclockwise) 4-5 turns.

If more than three tube size bubbles appear in the bleeder line during a four hour pumping period and the pump is

new or the make-up valve has been recently re-calibrated- DO NOT repeat Steps 1 through 3 above. Instead,

a fine “tune-in” procedure should be undertaken.

1. Disconnect power to idle pump.

2. Tighten Set Screw (turn clockwise) 1 turn.

3. Allow pump to sit idle for hour to permit entrained air to separate from oil. If it is not possible to shut the

pump down the air laden oil can be replaced by manually opening the pressure relief valve (see PRESSURE

RELIEF VALVE section) and rotate motor coupling by hand. After the recirculating oil is clear of air, the

pressure relief valve must be reset.

4. The pump should be restarted and check periodically for excessive air exiting from the bleeder valve. The

procedure should be repeated as necessary.

Valve removal/replacement can be accomplished by loosening the valve body (turn clockwise) with a ½” wrench.

Should the valve assembly require cleaning, remove the valve body from the pump head. Remove the set screw

from the valve body. Carefully remove and retain the spring that is captured by the set screw in the valve body.

Insert the long end of a ¼” Allen wrench into the valve body to forced open the poppet. Be careful to apply only

enough pressure to open the valve 1/8” maximum. Opening the valve more than 1/8” can damage the

poppet spring. Rinse the poppet end of the valve in solvent. Blow dry with air.

4.7 Hydraulic Bypass Valve

The hydraulic bypass valve is an adjustable spring loaded valve. It is designed to protect the pump against

excessive hydraulic pressure. The valve is factory set to the “Relief Valve Setting” if specified on the

specification data sheet or set to allow operation at the maximum pump pressure, indicated on the pump

nameplate, without relieving.

To adjust the valve to a lower relief pressure, turn counter-clockwise.

To check the pressure setting it is necessary to install a gauge in the discharge line between the pump and a shut

off valve. With the pump operating at maximum stroke, a gradual closing of the shut off valve will cause the

bypass valve to reach its cracking pressure which will be observed on the gauge. When the bypass valve is set for

maximum pump operating pressure (shown on nameplate), cracking pressure is slightly above maximum

operating pressure so that it does not weep during normal pump operation. Dead head dumping pressure can be

considerably higher than cracking pressure on some large piston, fast stroke rate models, so the internal bypass

valve should not be considered a safety valve for protection of the process piping and instrumentation. In the case

13

Page 17

of large piston fast stroke rate pumps, the dumping pressure is an instantaneous pressure generally experienced

only in the first discharge stroke of the pump since the make-up valve cannot replace the displacement of the

piston in one stroke.

It is unusual for a hydraulic bypass valve to operate during normal pump operation. The following conditions will

cause bypass pump operation.

1. Excessive pressure buildup in the process which the pump is injecting into.

2. A plugged discharge line or someone shutting off a valve in the discharge line while the pump is operating.

3. Restricted flow to the pump causing the make-up valve to operate. If an inlet strainer is plugged, or someone

closes an inlet valve thereby restricting the flow of fluid to the pump, the diaphragm is then unable to follow

movement of the plunger. The vacuum created between the diaphragm and the plunger upset the make-up

valve allowing oil to replace the vacuum condition. This excess oil will be displaced through the bypass valve

on the discharge stroke of the plunger. Undersized (restrictive) piping must be avoided (see “Piping” page 5.)

Any unusual condition in the system which prevents free movement of the diaphragm will cause a

recirculating condition between the make-up valve and the hydraulic bypass valve. Continuous oil

recirculation against the bypass valve will eventually cavitate the hydraulic prime plus introduce unnecessary

load conditions within the pump mechanism.

4.8 Automatic Bleed Valve (Figure 14)

The automatic bleed valve is a gravity operated ball check valve designed to displace a small quantity of hydraulic

oil or air on each pump stroke.

Any accumulation of solids can cause malfunction. Unscrew the valve and clean it with kerosene or solvent. If

solids cannot be removed, the valve must be replaced since there is no means of repair.

14

Page 18

4.9 Manual Bleed Valve (Figure 15)

The manual bleed valve is used in small piston models where oil movement and hydraulic instabilities are

minimal. To operate this valve, loosen the valve a slight amount until the oil is seen coming out. Leave the valve

loosened for a few strokes of the pump and then retighten.

4.10 Lubricating Instructions

PULSAlube is a custom blend of oil with additives for lubrication and hydraulic transfer service (For emergency

requirements, a list of acceptable commercial oils is available). The diaphragm on the cover of the gear box

assembly generally protects the oil from contamination for extended periods of time. A periodic six month check

should be made for oil level and possible contamination.

Under sustained conditions of high humidity or if wear is present, the oil can become emulsified and take on a

yellowish color. Change the oil immediately if this occurs and examine the make-up valve and other parts for

corrosion. A suction pump similar to a grease gun is useful for removing oil from the chambers, or it may be

drained from the ports at the side of each chamber.

To establish a maintenance record and routine procedure, check lubricant and drive mechanism at three and six

month intervals. At the first six month interval check the condition of the inlet and outlet check valves. These

items along with oil seal inspection should be part of a routine service procedure.

15

Page 19

4.11 Oil Capacity

The standard 680 metering pump requires approximately one quart of PULSAlube oil to fill both chambers and

prime hydraulic pump head. PULSAlube oil is available in one quart bottles, one gallon bottles, 5 gallon pails or

55 gallon drums.

5. Storage Instructions

5.1 Short Term

Storage of PULSA Series pumps for up to 12 months after shipment is considered short term. Under this

condition the recommended storage procedures are as follows:

1. The pump should be stored indoors at room temperature in a dry environment.

2. The pump gearbox and hydraulic reservoir is to be completely filled with PULSAlube oil within two months

after date of shipment.

3. The gearbox and hydraulic reservoir should be inspected ever 3-6 months. Maintain the oil level and assure

that no water or condensation is present, follow Procedure II, Step A below.

4. It is recommended that the stroke length of the pump be adjusted to its midpoint and that the piston be

manually cycled through 3-6 cycles every six months.

5. Prior to start-up, perform a complete inspection and then start up in accordance with instructions in this

manual.

5.2 Long Term

For storage longer than 12 months in addition to the above, the following procedures should be followed.

1. Every 12 months PULSAlube oil should be drained from the gearbox and hydraulic reservoir. The gearbox

and the hydraulic reservoir should be flushed with kerosene or petroleum base solvent, thoroughly dried out

with a rag, and then refilled with fresh PULSAlube oil.

2. Every 12 months the motor should be connected to a power source and the pump operated for a minimum of

one hour. It is not necessary to have liquid in the reagent head during this operation but the suction and

discharge ports must be open to the atmosphere.

After 12 months storage, Pulsafeeder’s warranty cannot cover such items as oil seals, gaskets, piston cups, and

other items which are subject to deterioration with age. If the pump has been in storage for longer than 12 months,

it is recommended that these items be replaced prior to going into service. Material and labor to recondition or

replace this class of item is the purchaser’s responsibility. For a one year service warranty after extended storage,

the refurbishment and equipment inspection must be done by a Pulsafeeder serviceman.

16

Page 20

5.3 Maintenance Parts Stock- KOPkits®

Pulsafeeder offers a KOPkit which is a group of recommended spares carried in stock for replacement due to

normal wear. The Kit covers such items as diaphragm, diaphragm gaskets if used, inlet and discharge valve parts,

a complete set of valve gaskets and hydraulic pump head gasket. The KOPkit part number for your pump is

indicated don the nameplate. A sufficient quantity of PULSAlube oil should be on hand for periodic oil changes.

5.4 Ordering Parts

When ordering parts, always specify:

1. Pump model and serial number (stamped on nameplate).

2. Part number (from parts list), or KOPkit number.

3. Material of reagent head construction (liquid end parts).

5.5 Additional Pulsafeeder Services

FIELD SERVICE: Including pump repair or conversion to different services is available at nominal cost.

FACTORY REPAIR: Complete pump reconditioning

OPERATOR TRAINING SEMINARS: Conducted by experienced factory trained service personnel at the

factory in Rochester, NY or in the field. Field trips are available at nominal cost.

17

Page 21

6. Troubleshooting

Difficulty Probable Cause Remedy

Pump does not start 1. Coupling disconnected.

2. Faulty power source

3. Blown fuse, circuit breaker

4. Broken wire

5. Wired improperly.

No Delivery

wiring diagram.

Low Delivery 1. Motor Speed too low.

1. Motor not running.

2. Supply tank empty.

3. Lines clogged.

4. Closed lined valves.

5. Ball check valves held open with

solids.

6. Vapor lock, cavitation.

7. Prime lost.

8. Strainer clogged.

9. Hydraulic system under-primed.

10. Check valves installed upside down.

2. Check valves worn or dirty.

3. Hydraulic Bypass valve opening

each stroke.

4. Calibration system error.

5. Product viscosity too high.

6. Product cavitating.

1. Connect and align

2. Check power source.

3. Replace-locate overload.

4. Locate and repair.

5. Check diagram.

1. Check power source.

2. Fill with liquid.

3. Clean and flush

4. Open pipeline valves.

5. Clean-inspect.

6. Increase suction pressure.

7. Reprime, check for leaks

8. Remove and clean.

9. Refer to “Repriming

Hydraulic System”.

10. See check valve illustrations.

1. Check voltages, hertz, wiring, and

terminal connections. Check

nameplate vs. specifications.

2. Clean, replace if damaged.

3. Refer to “Hydraulic Bypass Valve”

4. Evaluate and correct.

5. Lower viscosity by increasing

product temperature. Increase

pump size.

6. Increase suction pressure. Cool

product as necessary.

Delivery Gradually

Drops

1. Stroke adjustment creeping.

2. Check valve leakage.

3. Leak in suction line.

4. Fouled bypass or make-up valve.

5. Strainer fouled.

6. Product change.

7. Bypass leakage.

18

1. Consult factory. Replace worn

parts.

2. Clean, replace if damaged.

3. Locate and correct.

4. Refer to “Operation and

Maintenance”.

5. Clean or replace screen.

6. Check viscosity.

7. Correct for bypass valve leakage.

8.

Page 22

Difficulty Probable Cause Remedy

Delivery Erratic 1. Leak in suction line.

2. Product cavitating.

3. Entrained air or gas in product.

4. Motor speed erratic.

5. Fouled check valves.

Delivery Higher Than

Rated

Pump Loses Oil 1. Diaphragm ruptured.

1. Suction pressure higher than

discharge pressure.

2. Discharge piping too small.

3. Back pressure valve set too low.

4. Back pressure valve leaks.

2. Leaky oil seal.

3. Cover gasket leaks.

4. Pump head gasket leaks.

5. Gear box overfilled.

1. Locate and correct.

2. Increase suction pressure.

3. Consult factory for suggested

venting.

4. Check voltage, hertz.

5. Clean, replace if necessary.

1. Install back pressure valve or

consult factory for piping

recommendations.

2. Increase pipe size-install

PULSAtrol pulsation dampener at

pump in discharge line.

3. Increase setting.

4. Repair, clean, or replace.

1. Replace.

2. Replace.

3. Replace or tighten.

4. Replace. Tighten pump head bolts.

Seal with permatex.

5. Remove excess oil.

Air Continuously

Bleeds From

Automated Air Bleed

Valve

Noisy Gearing,

Knocking

1. Oil in reservoir low.

2. Hydraulic bypass valve opening

continuously.

3. Suction pressure too low.

4. Breakdown of oil, temperature high.

1. Discharge pressure too high.

2. Water hammer.

3. Worn bearings.

4. Worn gears.

5. End play in worm shaft.

6. Eccentric or worm gear.

7. Bypass valve set too high.

1. Refill to correct level.

2. Refer to “Hydraulic Bypass Valve”.

3. Increase pressure.

4. Change oil type, consult factory.

1. Reduce pressure or discharge piping

size.

2. Install PULSAtrol.

3. Replace.

4. Replace gears & check for improper

hydraulic bypass valve setting.

5. Consult factory.

6. Tighten or replace assembly.

7. Readjust (see “Hydraulic bypass

Valve”.

19

Page 23

Difficulty Probable Cause Remedy

Piping Noisy 1. Pipe size too small.

2. Pipe runs too long.

3. Surge chambers full of liquid.

4. No surge chambers used.

Motor Overheats

pump design

1. Pump overloaded

2. Oil too viscous

3. Low voltage

4. Loose wire

1. Increase size of piping, install

PULSAtrol.

2. Install PULSAtrol in line.

3. Recharge with air or inert gas,

replace diaphragm and recharge

4. Install PULSAtrols-pulsation

dampeners

1. Check operating conditions against

2. Consult factory

3. Check power supply

4. Trace and correct. Check no load

amps.

7. PULSAtrol Installation, Operation and

Removal Instructions

The PULSAtrol is a pneumatically charged diaphragm type chamber that continuously stores energy. Used on the

inlet it will improve NPSH

On the discharge line it will reduce dangerous peak pressures, eliminate shock waves and if of sufficient volume,

will reduce pulsation flow to almost linear.

(NET Positive Suction Head available) characteristics of the suction piping system.

a

7.1 Installation (Figure 16 a and b)

On both discharge and suction lines it is desirable to mount the PULSAtrol as close to the pump connection as

possible. It can be mounted in any position, but vertical is preferred for ease of charging, draining and servicing.

The air chamber is sealed and will not require replenishing regardless of position. A shut off valve should always

be used between the piping system and PULSAtrol; also a drain valve should always be installed directly below

the PULSAtrol. If the discharge line is open to atmospheric pressure then a back pressure valve should also be

incorporated in the system near the PULSAtrol to assure proper operation.

20

Page 24

7.2 Operation (Charging the PULSAtrol)

PROCEDURE: Pre-Charge Procedure for Discharge Installation

1. Calculate the precharge pressure:

Mean Line Pressure (PSIG)

+ Atmospheric Pressure

Absolute Pressure (PSIA)

x Precharge Percentage

Pressure Absolute

-Atmospheric Pressure

Precharge Pressure (PSIG)

=Precharge Pressure

2. Isolate PULSAtrol from line.

3. Carefully drain off process fluid by opening a drain valve (see recommended piping arrangement).

4. Apply precharge pressure (additional liquid may drain as diaphragm moves).

5. Close drain valve.

6. Place PULSAtrol in stream.

PROCEDURE: Pre-Charge Procedure for Suction Installation

1. Isolate accumulator from line.

2. Carefully drain off process fluid by opening a drain valve (see recommended piping arrangement,

attached.

3. Apply 5-10 psi precharge pressure (additional liquid may drain as diaphragm moves).

4. Close drain valve.

5. Bleed off all pressure on the PULSAtrol.

6. Open the valve to put PULSAtrol in stream.

7. Push in on the stem of the charging valve during the discharge stroke of the pump and release

during the suction stroke.

8. Continue this for about 10 times and observe the compound gauge. As accumulator functions, the

needle will go from pressure to vacuum.

(80% Max)

PROCEDURE: Suction Installation (Suction Lift)

Consult your PULSA Series representative or the factory for details.

21

Page 25

8. Diaphragm Back Pressure Valves (Figure 17)

Pulsafeeder diaphragm back pressure valves create a constant back pressure without chatter or cycling. A TFE

diaphragm, offering maximum chemical protection and service life, seals spring and bonnet from product. This

diaphragm seals directly on a replaceable seat..

Be sure to install with fluid flow in direction of arrow on valve body. If arrow is missing from plastic valve body,

install with flow exiting out center hole of valve body.

22

Page 26

23

IOM-680 0922-Rev B

Loading...

Loading...