Page 1

INSTALLATION

OPERATION

MAINTENANCE

INSTRUCTION

BULLETIN No. 680C

ENGINEERED PUMP OPERATIONS

2883 Brighton Henrietta TL Road

P.O. Box 22909

Rochester, New York, 14692-22909 USA

Manufacturers of Quality Pumps, Fax (716) 424-5619

Controls and Systems http://www.pulsa.com

Telephone (716) 292-8000

Page 2

Table of Contents

How it Works ........................................... 2

Installation Tips ......................................... 4

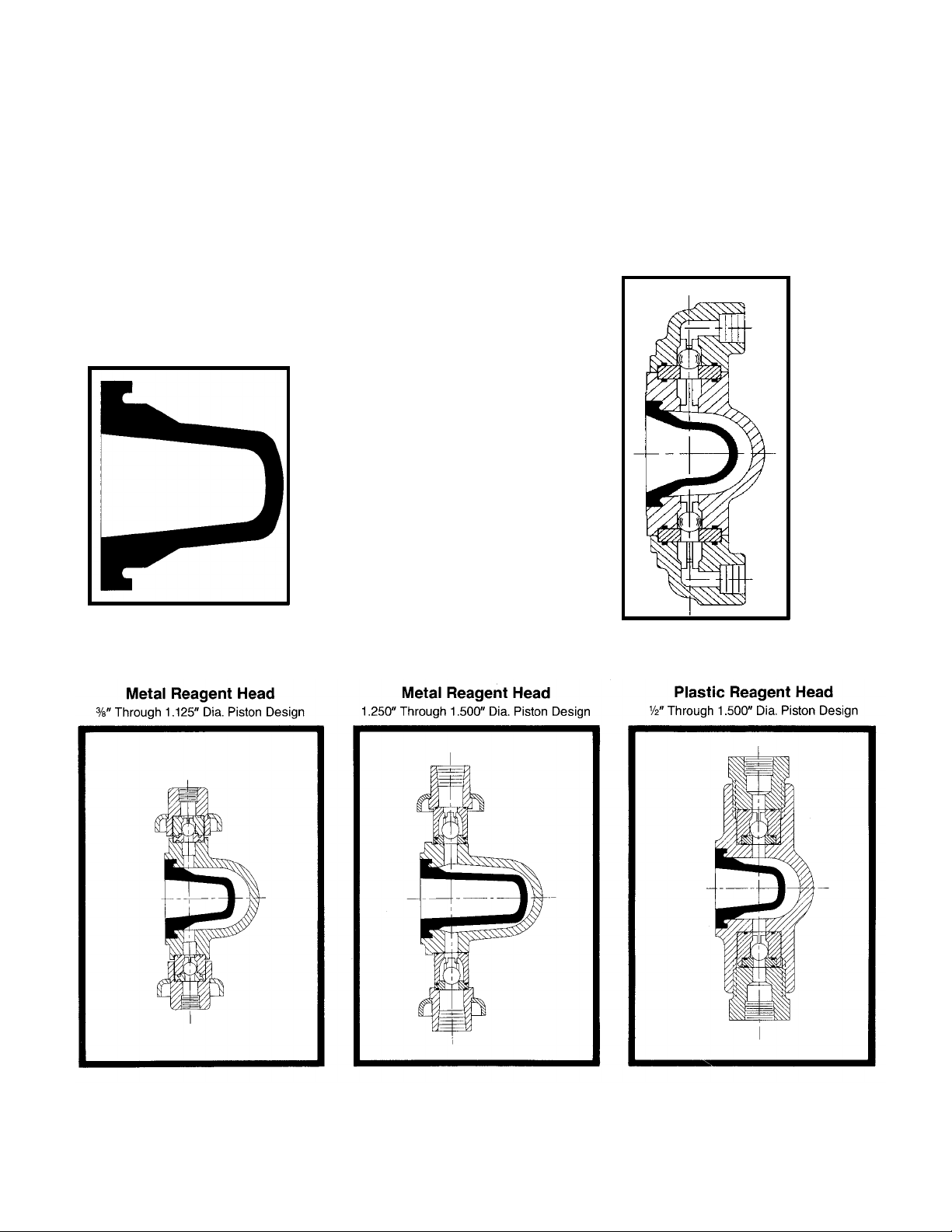

Hydracone Diaphragm

Figure 2

The HYDRACONE elastomer

diaphragm Figure No. 2

isolates product pumped from

the plunger and pump

mechanism.

Start-Up Inspection ...................................... 6

Operation and Maintenance ............................... 9

Storage Instructions ..................................... 12

Trouble Shooting ....................................... 13

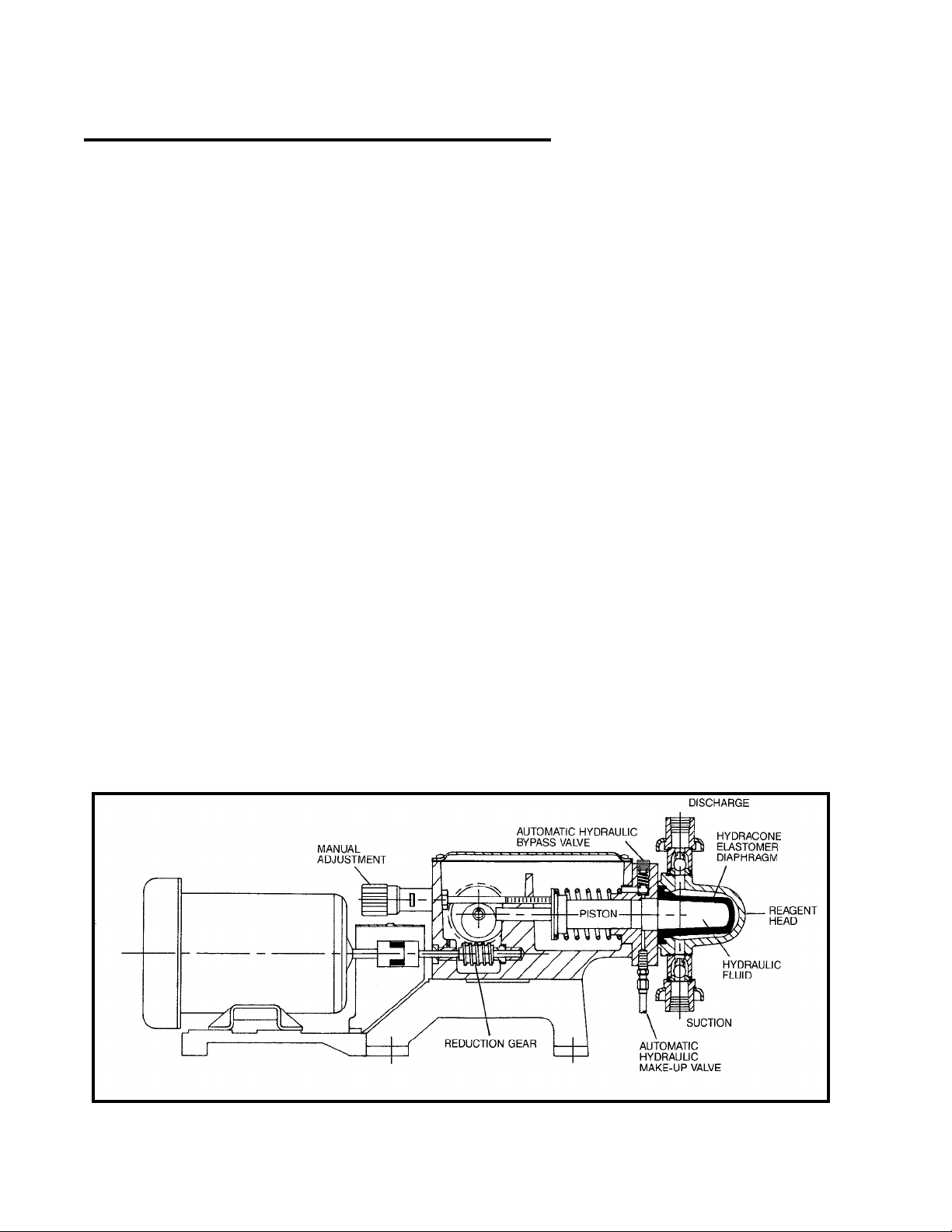

How it Works:

Figure 1

A standard foot mounted

motor drives a wormshaft at

constant speed. Through

wormgear reduction and

eccentric, a reciprocating

power stroke is transferred to

a plunger. The length of

stroke determines pump The forward movement of the

capacity and can be adjusted plunger pressurizes the

manually to provide pumping hydraulic fluid which expands

range from 0-100% of rating. the elastomer HYDRACONE

However, this plunger does diaphragm in direct relation to

not pump chemicals, but an plunger travel. As diaphragm

exceptionally stable oil having expands, chemical is forced

*

excellent lubricating qualities. from reagent head and out

This makes a perfect discharge check valve. When

pumping medium. plunger starts to return, the

plunger

A special property petroleum oil

tradenamed "PULSAlube" is generally

used as hydraulic fluid. Continual

reference to "oil" as hydraulic medium

implies its

general use rather than its use of

necessity. Check with your

representative or the factory if

substitute oils must be used.

Several elastomers are

offered including Viton and

Hypalon which provide a

*

*

satisfactory chemical

resistance for a wide variety of

corrosive fluids.

hydraulic pressure is released

and HYDRACONE returns to

normal shape. This

diaphragm return, which is not

affected by inlet pressure

conditions, draws in new

chemical under high suction

lift.

*Products of E.I. DuPont

Figure 1.

2

Page 3

Any leakage past the plunger, Any excess pressure buildup Pressure Relief Valve

however slight, is replaced by within the hydraulic chamber

the make-up valve which or reagent head due to A separate process relief

permits flow of replacement accidental valve closure or valve should be installed in

oil from the oil reservoir. line stoppage is relieved the process piping to protect

Replacement is automatic through the automatic piping and sensitive process

because the oil loss allows hydraulic bypass valve. It equipment.

the diaphragm to get out of blows off oil under excess

phase with the plunger thus pressure ahead of the plunger Plastic Reagent Head

creating a vacuum ahead of back into the oil reservoir thus 3/8" Dia. Piston Design

the plunger during the suction terminating the pumping

stroke of the pump. The action and protecting the

make-up valves are factory pump mechanism. Hydraulic

set. bypass valves are factory set

at full design pressure unless

specified differently by

purchaser.

Figure 2.

Figure 5.

Figure 3. Figure 4. Figure 6.

3

Page 4

Installation Tips

Check The Shipment

A standard PULSA Series

shipment includes the pump,

PULSAlube oil, wrenches,

instruction and parts list

packet and replacement parts

if ordered. Unpack carefully,

check packing list and make

sure all parts are received.

Check voltage of electric

motor against the service to

be used.

NOTE: Most 680 models will

Discharge Pressure:

operate without bolting down.

However, it is important to

have a solid and level

foundation so that a minimum

of vibration is evident.

Continual vibration can

loosen gaskets and pipe

connections.

All 680 models are designed

for continuous service at the

rated discharge pressure. To

prevent liquid flow through, it

is necessary that discharge

pressure be at least 5 psi

above suction pressure.

When pumping downhill a

3. Check motor alignment back pressure valve should

and reagent head and be placed in the discharge

valve bolt tightness before line.

operation. Follow bolt

torque readings carefully.

Locating the 680C Pumps:

PULSA 680C pumps are

designed to operated under

indoor atmospheric

conditions. It is desirable to

provide a hood or covering for

outdoor service. Alternate oil

or external heating must be

arranged if ambient

temperatures will be below

o o

40 F (4.4 C). Fluid

temperatures entering the

pump must be 40 F (4.4 C) or

o o

greater. Check with factory if

concerned with the suitability

of the operating environment.

1. Check level of pump. Shim

where necessary.

2. Securely bolt to foundation.

Do not distort base.

Flooded Suction Desirable:

Installation will be simpler to

operate if the liquid will flow to

the pump by gravity.

Wherever possible the pump

should be located below the

level of storage vessel.

4

Page 5

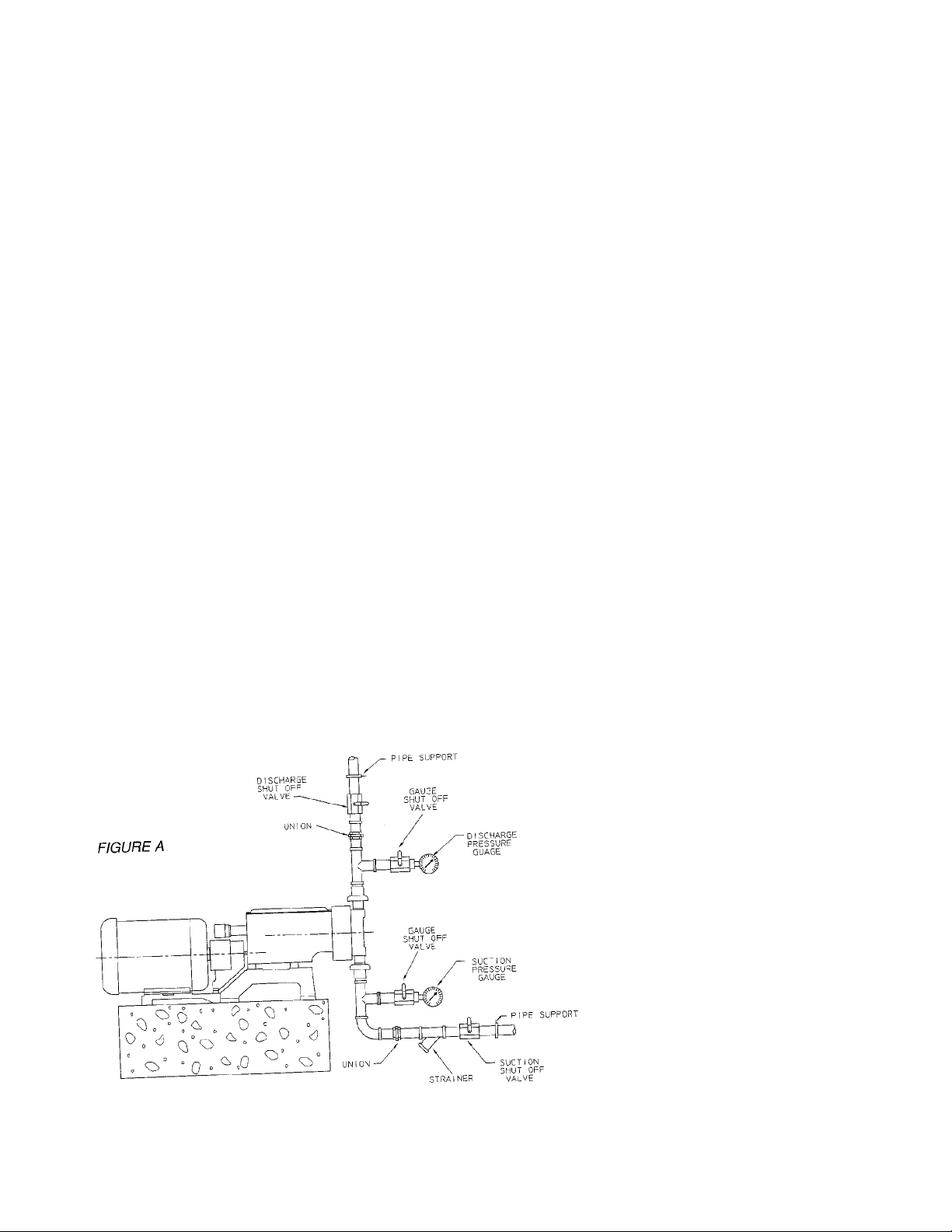

Piping: shut off valves. This permits susceptible to dirt and other

easy installation of a contaminants and any

Pipe size and length are calibration tube for calibration accumulation can cause

critical to proper operation of of the pump at start up or any malfunction. Be sure to use a

any metering pump. A future date. A tee in the pipeline strainer in the suction

restricted discharge or starved discharge piping is a must on line between the suction shut

suction condition spells a good installation because it off valve and the pump

immediate failure to any permits ease of mounting a suction valve, 100 mesh

metering pump installation. A pressure gauge to check screen is preferred.

separate brochure entitled discharge pressure at the

"Designing a Successful pump and setting the Flush Piping System:

Metering Pump Installation" is hydraulic bypass valve during Whether new or old piping is

provided to assist Engineers start up and future used, all lines should be

responsible for piping system maintenance functions. To flushed with a clean liquid or

design. Copies are available prevent strain on the pump air before connecting the

upon request (Technical fittings use pipe straps and pump to carry out pipe scale

Sheet 304). Inlet piping must braces. Do not allow the or other foreign material.

be at least equal in size to weight of the piping to be Make sure flushing liquid is

pump inlet connection. supported by a pipe union, the compatible with the chemical

valve fitting or other portion of to be pumped.

Figure A shows the preferred the pump head or leaks will

piping configuration for a occur. An air leak at a union Metal Reagent Head

good metering pump or other fitting in the suction Models:

installation. A good piping piping can severely affect

installation metering accuracy and is The metal reagent head

addresses present and future extremely difficult to detect. In assembly is provided in

requirements of the metering assembly of piping, use pipe several alloys. Piping of

system. Plan for shut off thread tape or a compound similar alloy should be

valves and unions or flanges compatible with the product selected. Dissimilar materials

installed on both suction and handled. If rigid piping is used can cause galvanic corrosion.

discharge lines. This allows we suggest bolting the pump

inspection of the check valves to its foundation. Do not backweld piping to the

without draining long runs of valve housings without first

pipe. Install a tee in the Use Strainers: removing the valve housings

suction and discharge piping from the pump as excessive

between the pump and the Pump check valves are heat can damage the reagent

head and other parts. Tie

bars must be positioned on

the valve housing before

welding.

Plastic Reagent Head

Models:

Care must be exercised when

making connections on plastic

reagent head models.

Excessive tightening can

distort or break the plastic

materials. Tubing should be

rated for the highest discharge

pressure expected. DO NOT USE

METAL PIPING.

5

Page 6

Start-Up

Final Inspection: Priming Process Head:

Inspection

Every 680C metering pump is

tested for correct capacity at

maximum pressure capability

of the hydraulic bypass valve

before shipment. The

diaphragm cavity is fully

primed and remains so for

shipment. For shipping

purposes the gear and

hydraulic reservoir oil have

been removed. Sufficient

fresh PULSAlube oil is

included with the shipment for

refilling the gear and hydraulic

reservoirs.

Warning

1. Do not run pump without

oil.

2. Do not remove main gear

box cover while pump is

running.

3. Do not run pump with

coupling guard removed.

4. Do not put hands or fingers

in gear box or reservoir

when pump is running.

Filling Gear and Oil

Reservoirs:

Remove the pump cover and

fill both reservoirs with

PULSAlube oil to the top of

the gear box partition. Do not

overfill. PULSAlube oil is

compounded to serve as both

gear lubricant and hydraulic

transfer fluid. Check with

factory if substitute oils must

be used.

The cover assembly

incorporates a free acting

diaphragm to allow breathing

of the reservoir and at the

same time seal the reservoir

from the atmosphere. Be

sure the diaphragm is

properly positioned when

replacing the cover so that it

will seal on the gear box.

Because of the pump's small 1. Open the suction line and

size and light weight it discharge line shut off

sometimes receives severe valves.

handling during shipment. 2. If the piping system design

Though physical damage may and the storage tank are

not occur, it is always possible such that the product flows

for parts to move slightly in by gravity to the pump, no

adjustment. This situation priming is required. If

might occur with motor or however, the discharge line

pneumatic control alignment. is under pressure, air will

A quick visual check should be trapped in the process

be made to assure that motor head and it will be

and control shafts have not necessary to remove the

shifted severely out of discharge pressure to

alignment or damage could enable the pump to prime

occur from starting the motor. itself.

If unusual vibration should 3. If the pump must handle a

occur after start up realign the suction lift, it may be

motor and coupling. necessary to manually

prime the reagent head.

Start-up: Remove the discharge

valve by unscrewing the

Since the hydraulic oil system two tie bar bolts and then

is primed at the factory, lifting the valve out. Fill the

priming the process system is head with process fluid, or

all that should be necessary a compatible liquid then

to produce flow. If the replace the valve in the

hydraulic system has same position and retighten

inadvertently been dumped the tie bar bolts.

due to starting up with 4. The pump is now ready for

restricted suction or discharge start-up.

conditions, repriming 5. Start the pump and

procedures under the increase the control setting

maintenance section may to full stroke.

have to be followed before 6. Make a brief check to

pump calibration can begin. assure that the pump is

producing the approximate

flow desired at the full

stroke setting. Calibration

should not be attempted on

any model until it has run at

least one hour to assure

the pump hydraulic and

reagent head systems have

stabilized.

If the pump does not produce

the approximate flow desired

at the full stroke setting refer

to the Trouble Shooting

Section for possible causes

and refer to Priming

Procedure under the

Operation and

Maintenance Section.

6

Page 7

To Adjust Flow Rate; Calibration: This is caused by

Figure B.

All pumps are tested on water and valve inefficiencies.

The 680C PULSA pumps are at room temperature with 7 Capacity at atmospheric

provided with a micrometer foot flooded head at full rated pressure will be nearly that of

knob adjustment for changing pressure. Any curves calculated displacement. As

length of stroke while in supplied by Pulsafeeder the discharge pressure

operation or idle. NOTE: The would be representative of increases there will be a

external auto locking knob this test and can only be used corresponding decrease in

must be fully disengaged prior as a guideline. capacity at a rate of

to adjustment. When approximately 1% per 100 psi

adjustment is complete the All pumps must be calibrated increase.

lock will automatically engage under actual operating

to prevent drifting of the conditions for the operator to

stroke setting. Turn know the proper adjustment

adjustment knob clockwise to for particular outputs. A

increase flow and typical displacement chart is

counterclockwise to decrease shown in Figure C. Note that

flow. The adjustment knob is output is linear with respect to

read directly in percent of micrometer settings but that

stroke length. These increase in discharge

indications can be converted pressure decreases output

to volumetric or weight units slightly and describes the line

by calibration conversion parallel to that at atmospheric

charts. pressure.

compression of hydraulic oil

Figure B

7

Page 8

Figures D and E show two PULSA pumps supplied with

typical piping arrangements automatic controls, either

for performing pump pneumatic or electronic, are

calibration. It is desirable to accompanied by separate

calibrate from the suction side instructions on output

of the pump so the pump will adjustment and calibration.

be operating under actual or

comparable discharge

conditions.

Check the capacity several

times at three different stroke

length settings and record

them on linear graph paper.

For all stable conditions,

these points should describe

a straight line.

8

Page 9

Operation and

Maintenance

The preceding instructions

have assisted you in proper

installation and start-up of

your 680C pump. The

following sections are

arranged to assist in

maintaining proper pump

operation and trouble

shooting any problems that

might develop during start-up

or thereafter.

Accurate records in the early

stages of pump operation will

reveal the type and amount of

maintenance that will be

required. A preventative

maintenance program based

on these records will insure

trouble free operation. It is

not possible in these

instructions to forecast the life

of such parts as the

diaphragm, check valves and

other parts in contact with the

product you are handling.

Corrosion rates and

conditions of operation affect

the useful life of these

materials so an individual

metering pump must be

gauged according to

particular service conditions.

HYDRACONE Diaphragm 5. Adjust the stroke length

Inspection (capacity) to maximum.

6. Remove the reservoir

The HYDRACONE cover assembly.

diaphragm is an elastomeric 7. Remove the coupling

material which stretches on guard.

each displacement of the 8. Rotate the motor

plunger. It can be damaged coupling until the pump

by the following: piston is withdrawn to full

suction stroke (toward

1. Chemical attack. drive motor end).

2. Mechanical damage 9. Loosen the hydraulic

from trash or abrasives. bypass valve screw

3. High temperature located on top of the

(Maximum 180 F, 2.2 C). hydraulic pumphead to

4. Low temperature (below be sure all hydraulic

5. Suction pressure in relieved from behind the

Service conditions will properly dispose of oil

determine life of the and product leakage that

HYDRACONE and dictate the will occur when

replacement schedule. disassembling head and

To Inspect HYDRACONE 11. Remove the inlet check

Diaphragm valve to drain reagent

1. Remove all pressure extreme caution if

2. Lock out motor. and wear proper

3. Close the inlet and outlet protective clothing.

4. Break the union or bolts and rinse the head

o o

40 F, 4.4 C). pressure has been

excess of 20 psig. diaphragm.

from the piping system. product is hazardous

shut-off valves. 12. Remove reagent head

flanges on the piping. in water or a compatible

o o

10. Arrange to catch and

valving.

head and cavity. Use

liquid.

Figure 7. Figure 8. Figure 9.

9

Page 10

13. Diaphragm can be 3. Connect inlet piping.

removed from the 4. With discharge line 8. Add PULSAlube oil to

reagent head by applying bypassed around front and rear oil

air pressure to one of the process or to drain, start reservoirs to bring oil

valve ports while motor and prime reagent level up to top of

blocking the other. Be head. partition.

sure diaphragm is 5. Set stroke length 9. After pump has run for

directed away from adjustment to maximum several hours, again

personnel so that it does stroke. check for any last traces

not strike the body when 6. If not already lose, of air at the bypass valve.

being expelled from the counting turns, loosen

head. the hydraulic bypass Check Valve

14. Diaphragms which are valve located at the top

Figure 7, 8, 9 and 10

punctured or show of the hydraulic system

evidence of tearing or to atmosphere and any Operating experience on

abrasion at the sealing air present will vent back thousands of installations has

edge should be into the gearbox oil indicated that many pump

replaced. If diaphragm reservoir as the troubles have to do with check

shows evidence of automatic make-up valve valves. Problems usually

hardening so as to be fills the piston/diaphragm stem from (a) an

non-flexible it should be chamber. Air bubbles accumulation of trash

replaced. will be evident at the vent between the valve and seat,

hole, top center of pump (b) corrosion which damages

Repriming Hydraulic head in back of return seating surfaces, (c) erosion

Systems on HYDRACONE spring. from high velocity flow, or (d)

Models 7. When last traces of air normal physical damage after

have been expelled extended service.

1. Reassemble diaphragm retighten the bypass

and reagent head, valve the same number When inspecting the valves,

tightening all bolts of turns or to a desired separate the assembly and

securely and evenly. setting using a pressure examine the components for

2. Reassemble valve gauge in the process wear, damage or

housing, valves, seats line. Approximately a 1/2 accumulation of solids. A ball

and seat gaskets and turn more after process valve seat should have a

take care in inserting pressure setting has sharp 90 edge, free of any

o

gaskets that they are been reached will seat nicks or dents. Hold the ball

properly placed. Tighten valve. The valve can be firmly on the seat and

securely. set higher if desired but examine against a light. If

do not exceed MAX. light is visible between the two

OPERATING then replace the seat and/or

PRESSURE indicated on ball.

the nameplate.

When reassembling after

cleaning or replacement be

sure to use new seals.

10

Page 11

Hydraulic Make-up Valves To adjust the valve to a lower 3. Restricted flow to the

Figure 12

set pressure, turn counter- pump causing the make-

clockwise. up valve to operate. If an

Hydraulic make-up valves are inlet strainer is plugged,

designed to maintain the To check pressure setting it is or someone closes an

correct volume of oil in the necessary to install a gauge in inlet valve thereby

hydraulic system between the the discharge line between restricting flow of fluid to

piston and the diaphragm. the pump and a shut off valve. the pump, the diaphragm

No adjustment or attention is With the pump operating at is then unable to follow

required, provided the oil is maximum stroke a gradual movement of the

clean and free of moisture closing of the shut off valve plunger. The vacuums

and chemical contamination. will cause the bypass valve to created between the

Since the valve operates only reach its cracking pressure diaphragm and the

occasionally and with very which will be observed on the plunger upset the makelittle movement it is not gauge. When the bypass up valve allowing oil to

considered a normal valve is set for maximum replace the vacuum

replacement item in a service pump operating pressure condition. This excess

schedule. If the valve is (shown on nameplate), oil will be displaced

replaced because of cracking pressure is slightly through the hydraulic

corrosion or fouling be sure above maximum operating bypass valve on the

tape or sealant is used on the pressure so that it does not discharge stroke of the

pipe threads to assure an air weep during normal pump plunger. Undersized

tight seal. operation. Dead head (restrictive) piping must

dumping pressure can be be avoided (see "Piping"

Hydraulic Bypass Valve considerably higher than page 5).

cracking pressure on some

The bypass valve is an large piston, fast stroke rate Any unusual condition in the

adjustable spring loaded models, so the internal system which prevents free

valve. It is designed to protect bypass valve should not be movement of the diaphragm

the pump against excessive considered a safety valve for will cause a recirculating

hydraulic pressure. The valve protection of the process condition between the makeis factory set to the setting piping and instrumentation. A up valve and the hydraulic

specified on the specification separate process relief valve bypass valve. Continuous oil

data sheet or set to allow should be used for this recirculation against the

operation at the maximum purpose. bypass valve will eventually

pump pressure, indicated on cavitate the hydraulic prime

the pump nameplate, without It is unusual for a hydraulic plus introduce unnecessary

weeping. bypass valve to operate load conditions within the

during normal pump pump mechanism.

operation. The following

conditions will cause valve

operation:

1. Excessive pressure

buildup in the process

which the pump is

injecting into.

2. A plugged discharge line

or someone shutting off

a valve in the discharge

line while the pump is

operating.

11

Page 12

Lubricating Instructions month interval check the and then start up in

condition of the inlet and accordance with

PULSAlube is a custom blend outlet check valves. These instructions in this

oil with additives for lubrication items along with oil seal manual.

and hydraulic transfer service. inspection should be part of a

(For emergency routine service procedure. Long Term

requirements, a list of

acceptable commercial oils is Oil Capacity For storage longer than 12

available). The diaphragm on months in addition to the

the cover of the gear box The standard 680C metering above, the following

assembly generally protects pump requires approximately procedures should be

the oil from contamination for one quart of PULSAlube oil to followed.

extended periods of time. A fill both chambers and prime

periodic six month check hydraulic pump head. 1. Every 12 months

should be made for oil level PULSAlube oil is available in PULSAlube oil should be

and possible contamination. one gallon cans, cartons of six drained from the gearbox

(6) one gallon cans, five and hydraulic reservoir.

Under sustained conditions of gallon cans or 55 gallon The gearbox and

high humidity or if water is drums. hydraulic reservoir

present, the oil can become should be flushed with

emulsified and take on a STORAGE INSTRUCTIONS kerosene or petroleum

yellowish color. Change the Short Term base solvent, thoroughly

oil immediately if this occurs dried out with a rag, and

and examine the make-up Storage of PULSA Series then refilled with fresh

valve and other parts for pump for up to 12 months PULSAlube oil.

corrosion. A suction pump after shipment is considered 2. Every 12 months the

similar to a grease gun is short term. Under this motor should be

useful for removing oil from condition the recommended connected to a power

chambers, or it may be storage procedures are as source and the pump

drained from the ports at the follows: operated for a minimum

side of each chamber. of one hour. It is not

1. The pump should be necessary to have liquid

stored indoors at room in the reagent head

temperature in a dry during this operation but

environment. the suction and

2. The pump gearbox and discharge ports must be

hydraulic reservoir is to open to atmosphere.

be completely filled with

PULSAlube oil within two After 12 months storage

months after date of Pulsafeeder's warranty

shipment. cannot cover such items as oil

3. The gearbox and seals, gaskets, piston cups

hydraulic reservoir and other items which are

should be inspected subject to deterioration with

every 3-6 months. age. If the pump has been in

Maintain the oil level and storage for longer than 12

assure that no water or months it is recommended

condensation is present, that these items be replaced

follow Procedure II, Step prior to going into service.

A below. Material and labor to

4. It is recommended that recondition or replace this

the stroke length of the class of item is the

pump be adjusted to its purchaser's responsibility.

midpoint and that the For a one year service

To establish a maintenance piston be manually warranty after extended

record and routine procedure, cycled through 3-6 storage the refurbishment and

check lubricant and drive cycles every 6 months. equipment inspection must be

mechanism at three and six 5. Prior to start-up, perform done by a Pulsafeeder

month intervals. At the first six a complete inspection serviceman.

12

Page 13

Maintenance Parts Stock Ordering Parts Trouble Shooting

Pulsafeeder offers a KOPkit When ordering parts always Experience drawn from

which uses a group of specify: thousands of installations has

recommended spares carried shown that there are three

in stock for replacement due 1. Pump model and serial outstanding areas which

to normal wear. The Kit number (stamped on contribute to the bulk of

covers such items as nameplate). operating problems. First and

diaphragm, diaphragm 2. Part number (from parts foremost is installation

gaskets if used, inlet and list), or KOPkit number. conditions - improper location

discharge valve parts, a 3. Material of reagent head and supply, inadequate or

complete set of valve gaskets construction (liquid end restrictive piping to and from

and hydraulic pump head parts). pump; unsupported piping;

gasket. The KOPkit part lack of strainer in suction

number for your pump is Additional Pulsafeeder piping.

indicated on the nameplate. Services

A sufficient quantity of The second major area is

PULSAlube oil should be on FIELD SERVICE - Including check valves. The check

hand for periodic oil changes. pump repair or conversion to valve is the heart of any pump

different services is available and sees more severe service

at nominal cost. than any other part of the

pump. Opening and closing

FACTORY REPAIR - 40 to 140 times per minute,

Complete pump the valve not only receives a

reconditioning. mechanical hammering but

receives it under high velocity

OPERATOR TRAINING corrosive, erosive and

SEMINARS - Conducted by sometimes extreme

experienced factory trained temperature conditions.

service personnel at the Foreign particles, unlevel

factory in Rochester, NY or in mounting, defective seals and

the field. Field trips are improper torquing all too often

available at nominal cost. aggravate even the simplest

application.

The third area is a simple lack

of a routine service policy.

Routine service will catch or

avoid simple operating

problems which can develop

into a crisis if left unattended.

The following is a brief trouble

shooting guide to help identify

and cure any operating

problems you might

experience.

13

Page 14

Trouble Shooting Chart

Difficulty Probable Cause Remedy

Pump Does Not Start 1. Coupling disconnected Connect and align

2. Faulty power source Check power source

3. Blown fuse, circuit breaker Replace -- Locate overload

4. Broken wire Locate and repair

5. Wired improperly Check diagram

No Delivery 1. Motor not running Check power source. Check wiring diagram

2. Supply tank empty Fill with liquid

3. Lines clogged Clean and flush

4. Closed line valves Open pipeline valves

5. Ball check valves held open with solids Clean -- inspect

6. Vapor lock, cavitation Increase suction pressure

7. Prime lost Reprime, check for leak

8. Strainer clogged Remove and clean. Replace screen if

necessary

9. Hydraulic system under-primed Refer to "Repriming Hydraulic System"

10. Check valves installed upside down See check valve illustrations

Low Delivery 1. Motor speed too low Check voltages, hertz, wiring, and terminal

connections. Check nameplate vs.

specifications

2. Check valves worn or dirty Clean, replace if damaged

3. Bypass valve opening each stroke Refer to "Hydraulic Bypass Valve"

4. Calibration system error Evaluate and correct

5. Product viscosity too high Lower viscosity by increasing product

temperature.

Increase pump size.

6. Product cavitating Increase suction pressure. Cool product

as necessary

Delivery Gradually

Drops 1. Stroke adjustment creeping Consult factory. Replace worn parts.

2. Check valve leakage Clean, replace if damaged

3. Leak in suction line Locate and correct

4. Fouled bypass or make-up valve Refer to "Operation and Maintenance"

5. Strainer fouled Clean or replace screen

6. Product change Check viscosity

7. Bypass leakage Correct for bypass valve leakage

Delivery Erratic 1. Leak in suction line Locate and correct

2. Product cavitating Increase suction pressure

3. Entrained air or gas in product Consult factory for suggested venting

4. Motor speed erratic Check voltage, hertz

5. Fouled check valves Clean, replace if necessary

14

Page 15

Difficulty Probable Cause Remedy

Delivery Higher

Than Rated 1. Suction pressure higher than Install back pressure valve or consult factory

discharge pressure for piping recommendations

2. Suction piping too small Increase pipe size -- Install PULSAtrol pulsation

dampener at pump in suction line

3. Back pressure valvae set too low Increase setting

4. Back pressure valve leaks Repair, clean, or replace

Pump Loses Oil 1. Diaphragm ruptured Replace

2. Leaky oil seal Replace

3. Cover gasket leaks Replace or tighten

4. Pump head gasket leaks Replace -- tighten pump head bolts. Seal with

permatex.

5. Gear box overfilled Remove excess oil

Air Continuously 1. Oil in reservoir low Refill to correct level

Bleeds From 2. Hydraulic Bypass valve opening Refer to "Hydraulic Bypass Valve"

Automated Air Bleed continuously

Valve 3. Suction pressure too low Increase pressure

4. Breakdown of oil, temperature high Change oil type, consult factory

Noisy Gearing,

Knocking 1. Discharge pressure too high Reduce pressure or discharge pipe size

2. Water hammer Install PULSAtrol

3. Worn bearings Replace

4. Worn gears Replace gears & check for improper hydraulic

bypass valve setting

5. End play in worm shaft Consult factory

6. Eccentric or worm gear Tighten or replace assembly

7. Bypass valve set too high Readjust (see "Hydraulic Bypass Valve")

Piping Noisy

1. Pipe size too small Increase size of piping, install PULSAtrol

2. Pipe runs too long Install PULSAtrol in line

3. Surge chambers full of liquid Recharge with air or inert gas, replace diaphragm

and recharge

4. No surge chambers used Install PULSAtrols -- pulsation dampeners

Motor Overheats

1. Pump overloaded Check operating conditions against pump design

2. Oil too viscous Consult factory

3. Low voltage Check power supply

4. Loose wire Trace and correct. Check no load amps

15

Page 16

APPENDIX PULSAFEEDER ACCESSORIES

I. PULSATROL INSTALLATION, OPERATION AND REMOVAL INSTRUCTIONS

The PULSAtrol is a pneumatically charged diaphragm type chamber that continuously stores energy. Used on

the inlet it will improve NPSH (Net Positive Suction Head available) characteristics of the suction piping

a

system. On the discharge line it will reduce dangerous peak pressures, eliminate shock waves and if of

sufficient volume will reduce pulsating flow to almost linear.

INSTALLATION

Figures 13 a and b

On both discharge and suction lines it is desirable to mount the PULSAtrol as close to the pump connection as

possible. It can be mounted in any position, but vertical is preferred for ease of charging, draining and

servicing. The air chamber is sealed and will not require replenishing regardless of position. A shut off valve

should always be used between the piping system and PULSAtrol, also a drain valve should always be

installed directly below the PULSAtrol. If the discharge line is open to atmospheric pressure then a back

pressure valve should also be incorporated in the system near the PULSAtrol to assure proper operation.

16

Page 17

OPERATION (Charging the PULSAtrol)

A. Discharge Installation

The air side of the PULSAtrol must be precharged to approximately 50 percent of anticipated mean line

pressure before placing on stream. This will permit the diaphragm to move to a neutral position between the

chambers when operating.

PROCEDURE

Pre Charge Procedure for Discharge Installation

1. Calculate the precharge pressure

Mean Line Pressure (PSIG)

+ Atmospheric Pressure

Absolute Pressure (PSIA)

x Precharge Percentage (80% Max.)

Pressure Absolute

- Atmospheric Pressure

Precharge Pressure (PSIG)

= Precharge Pressure

2. Isolate PULSAtrol from line.

3. Carefully drain off process fluid by opening a drain valve (see recommend piping arrangement).

4. Apply precharge pressure (additional liquid may drain as diaphragm moves).

5. Close drain valve.

6. Place PULSAtrol in stream.

B. Suction Installation (Flooded Suction)

Charge the PULSAtrol with adequate pressure to overcome the static suction head. Start up the pump.

Depress the stem on the charge valve, but only during discharge strokes of the pump, until the gauge indicates

pressure pulses. The diaphragm has not centered allowing the PULSAtrol to accumulate liquid while the

pump is discharging. If too much air becomes released and the gauge will not indicate pressure pulses then

recharge the PULSAtrol and repeat the procedure.

PROCEDURE

Pre Charge Procedure for Suction Installation

1. Isolate accumulator from line.

2. Carefully drain off process fluid by opening a drain valve (see recommended piping arrangement,

attached).

3. Apply 5-10 psi precharge pressure (additional liquid may drain as diaphragm moves).

4. Close drain valve.

5. Bleed off all pressure on the PULSAtrol.

6. Open the valve to put PULSAtrol in stream.

7. Push in on the stem of the charging valve during the discharge stroke of the pump and release

during the suction stroke.

8. Continue this for about 10 times and observe the compound gauge. As accumulator functions, the

needle will go from pressure to vacuum.

C. Suction Installation (Suction Lift)

Consult your PULSA Series representative or the factory for details.

17

Page 18

II. DIAPHRAGM BACK PRESSURE VALVES

Figure 14

Pulsafeeder diaphragm back pressure valves create a constant back pressure without chatter or cycling. A

TFE diaphragm, offering maximum chemical protection and service life, seals spring and bonnet from product.

This diaphragm seals directly on a replaceable seat.

Be sure to install with fluid flow in direction of arrow on valve body. If arrow is missing from plastic valve body,

install with flow exiting out center hole of valve body.

Figure 14

18

Page 19

MAINTENANCE LOG

Pump Model Serial #

Gear Ratio Maximum Flow

Piston Diameter Maximum Pressure

KOPKit

All the above information can be obtained from the pump nameplate. Refer to the Pump Specification Data Sheet

for additional information.

Date Serviced By Maintenance Performed

19

Page 20

CP 9/97 PRINTED IN USA

20

Loading...

Loading...