Page 1

Q.

YR20.246

Y-Series

GENERAL DESCRIPTION

The YR20.246 is a redundancy module for building

redundant power supply systems. It is equipped with

two input channels and one output. The two inputs are

decoupled by MOSFET technology.

The device is equipped with an automated load sharing

feature, which can compensate a small voltage

imbalance between the power supplies connected to

the inputs in order to achieve an even current share. It

also monitors the function of the redundancy circuitry

and provides a signal in case of a failure or a high

output current, which could prevent redundancy if one

power supply fails. If this feature is not required the

YR20.242 is available.

The redundancy utilizes MOSFETs instead of diodes for

the decoupling of the two input channels. This reduces

the heat generation and the voltage drop between

input and output. The redundancy module does not

require an additional auxiliary voltage.

Due to the low power losses, the unit is very slender and

only requires 32mm width on the DIN-rail. Large

connection terminals allow for a safe and fast

installation. The large international approval package

makes this unit suitable for nearly every application.

ORDER NUMBERS

Redundancy YR20.246

Module

Accessory ZM11.SIDE Side mount bracket

24-28V, 20A, DUAL REDUNDANCY MODULE

MOSFET REDUNDANCY MODULE

For 1+1 Redundancy with Automated Load Sharing

Dual Input with Single Output

Redundancy OK Signal Included which Reports the Loss

of Redundancy

160% (32.5A) Peak Load Capability

Reverse Input Polarity Protection

Full Power Between -40°C and +70°C

Width only 32mm

Rugged Metal Housing

Easy Wiring:

Distribution Terminal for Negative Pole Included

SHORT-FORM DATA

Input voltage DC 24-28V ±25%

Input voltage range 18-35Vdc

Input current 2x 0-12A ambient <+45°C

2x 0-10A ambient <+70°C

Output current 0-24A ambient <+45°C

0-20A ambient <+70°C

Input to output

voltage drop

max. 26A

0.1-0.5V

0.2-0.5V

**)

**)

in overload

short circuit mode

input: 2x5A

input: 2x10A

*)

or

Power losses 1.7W at no load

2.6-4.7W

5.6-8.7W

**)

input: 2x5A

**)

input: 2x10A

Temperature range -40°C to +70°C operational

Dimensions 32x124x117mm WxHxD

Weight 310g, 0.69lb

*) Currents at voltages below 6V

**) Depending on load share function

MARKINGS

IND. CONT. E

UL 508

UL 60950-1

Class I Div 2

planned

IECEx ATEX

Jul. 2017 / Rev. 1.4 DS-YR20.246-EN All parameters are typical values specified at 24V, 20A output current, 25°C ambient and

after a 5 minutes run-in time unless otherwise noted.

Marine

planned

1/19

Page 2

YR20.246

Y-Series

24-28V, 20A, DUAL REDUNDANCY MODULE

INDEX

Page Page

1.

Intended Use .......................................................3

2. Installation Requirements...................................3

3. Input and Output Characteristics .......................4

4. Power Losses........................................................5

5. Lifetime Expectancy and MTBF...........................5

6. Terminals and Wiring..........................................6

7. Functional Diagram.............................................6

8. Front Side and User Elements.............................7

9. “Redundancy OK” Relay Contact.......................8

10. “Load Share OK” Relay Contact .........................8

11. Automated Load Sharing....................................9

12. EMC....................................................................10

13. Environment ......................................................11

14. Protection Features ...........................................12

15. Safety Features ..................................................12

The information given in this document is correct to the best of our knowledge and experience at the time of publication. If not

expressly agreed otherwise, this information does not represent a warranty in the legal sense of the word. As the state of our

knowledge and experience is constantly changing, the information in this data sheet is subject to revision. We therefore kindly ask

you to always use the latest issue of this document (available under www.pulspower.com). No part of this document may be

reproduced or utilized in any form without our prior permission in writing.

16. Dielectric Strength............................................ 12

17. Approvals.......................................................... 13

18. RoHS, REACH and Other Fulfilled Standards .. 13

19. Physical Dimensions and Weight ..................... 14

20. Accessories ........................................................ 15

20.1. ZM11.SIDE - Side Mounting Bracket........15

21. Application Notes............................................. 16

21.1. Using Only One Input Instead of Both

Channels...............................................................16

21.2. Recommendations for Redundancy.........17

21.3. Inductive and Capacitive Loads................17

21.4. Sidewards Installation Clearances............17

21.5. 1+1 Redundancy up to 10A...................... 18

21.6. Mounting Orientations ............................19

TERMINOLOGY AND ABREVIATIONS

DC 24V A figure displayed with the AC or DC before the value represents a nominal voltage with

standard tolerances (usually ±15%) included.

E.g.: DC 12V describes a 12V battery disregarding whether it is full (13.7V) or flat (10V)

24Vdc A figure with the unit (Vdc) at the end is a momentary figure without any additional

tolerances included.

may A key word indicating flexibility of choice with no implied preference

shall A key word indicating a mandatory requirement

should A key word indicating flexibility of choice with a strongly preferred implementation

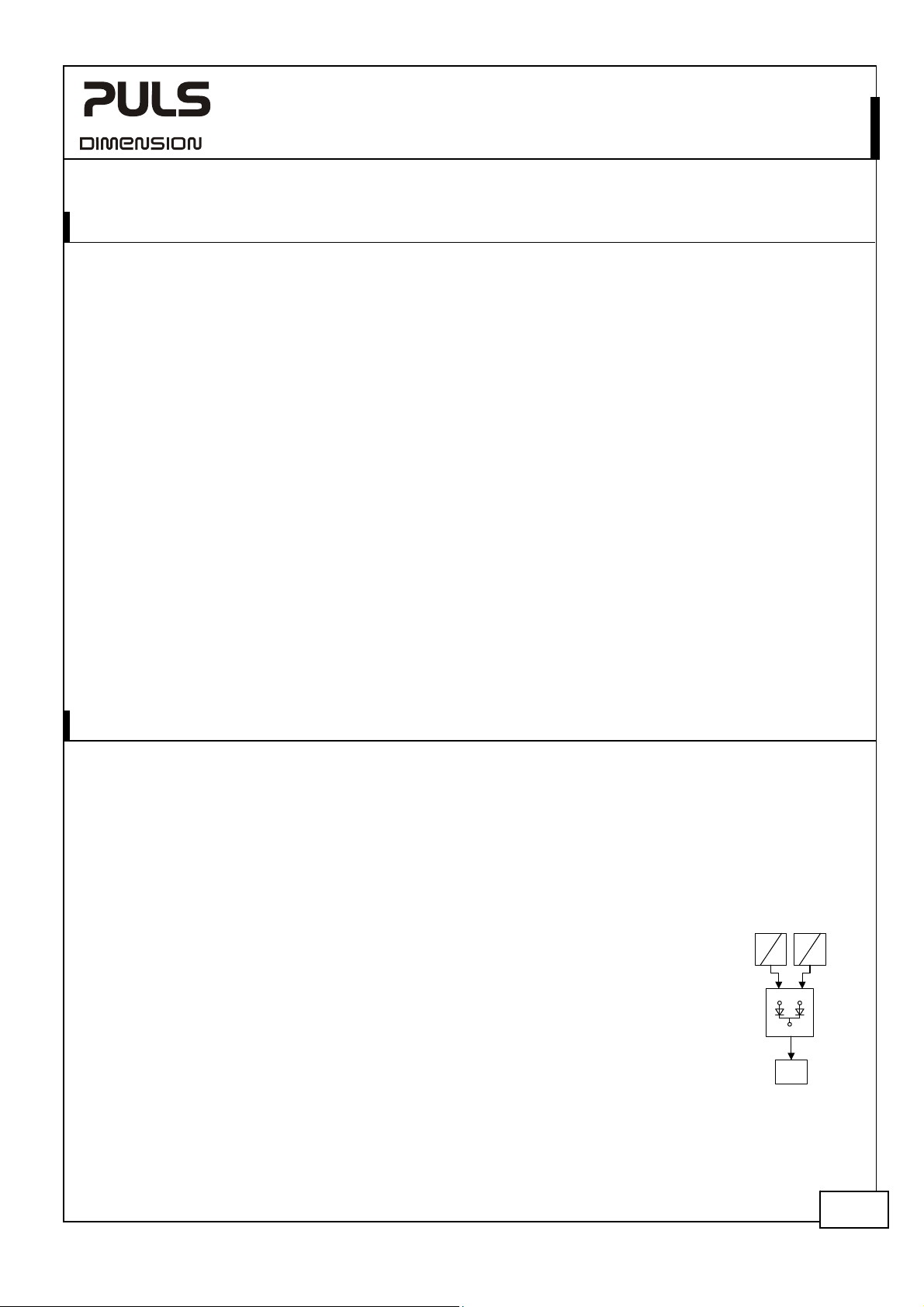

1+1 Redundancy Use of two identical power supplies in parallel to provide continued

operation following most failures in a single power supply. The two power

supply outputs should be isolated from each other by utilizing diodes or

other switching arrangements. E.g. two 10A power supplies are needed to

achieve a 10A redundant system.

ACDCAC

IN 1

IN 2

OUT

+

Load

-

DC

Jul. 2017 / Rev. 1.4 DS-YR20.246-EN All parameters are typical values specified at 24V, 20A output current, 25°C ambient and

after a 5 minutes run-in time unless otherwise noted.

2/19

Page 3

YR20.246

Y-Series

24-28V, 20A, DUAL REDUNDANCY MODULE

1. INTENDED USE

This redundancy module is designed for installation in an enclosure and is intended for the general use such as in

industrial control, office, communication, and instrumentation equipment.

This redundancy module can be used with any type of power supply as long as the maximum output current ratings

are not exceeded. It is suitable for power supplies with constant current overload behavior as well as any kind of

“Hiccup” overload behavior.

Do not use this redundancy module in equipment, where malfunction may cause severe personal injury or threaten

human life.

2. INSTALLATION REQUIREMENTS

This device may only be installed and put into operation by qualified personnel.

This device does not contain serviceable parts.

If damage or malfunction should occur during installation or operation, immediately turn power off and send unit to

the factory for inspection.

To ensure a proper load share function ensure that the wiring between the two power supplies and the redundancy

module is identical.

Mount the unit on a DIN-rail so that the input terminals are located on the bottom and the output terminals on the

top of the unit. For other mounting orientations see de-rating requirements of chapter 21.6 in this document.

This device is designed for convection cooling and does not require an external fan. Do not obstruct airflow and do

not cover the ventilation grid (e.g. cable conduits) by more than 30%!

Keep the following installation clearances:

40mm on top,

20mm on the bottom,

5mm on the left and right sides are recommended when the device is loaded permanently with more than 50% of the

rated output current. Increase the side clearance to 15mm in case the adjacent device is a heat source (e.g. another

power supply). See chapter 21.4 for other allowed clearances when used with the PULS DIMENSION series in a 1+1

redundant configuration.

Use only power supplies with a negligible output ripple voltage in the low frequency range between 50Hz and 10kHz

when used in marine applications according to the GL regulations.

The input must be powered from a SELV source (according to IEC 60950-1), a PELV source (according to IEC 62477-1) or

an Isolated Secondary Circuit (according to UL 508).

Do not ground or earth the positive output pole which could prevent redundancy in case of a ground failure. Ground

the negative output pole when needed.

WARNING

- Turn power off before working on the device. Protect against inadvertent re-powering.

- Make sure that the wiring is correct by following all local and national codes.

- Do not open, modify or repair the unit.

- Use caution to prevent any foreign objects from entering the housing.

- Do not use in wet locations or in areas where moisture or condensation can be expected.

- Do not touch during power-on, and immediately after power-off. Hot surfaces may cause burns.

Risk of electrical shock, fire, personal injury or death.

Jul. 2017 / Rev. 1.4 DS-YR20.246-EN All parameters are typical values specified at 24V, 20A output current, 25°C ambient and

after a 5 minutes run-in time unless otherwise noted.

3/19

Page 4

YR20.246

Y-Series

24-28V, 20A, DUAL REDUNDANCY MODULE

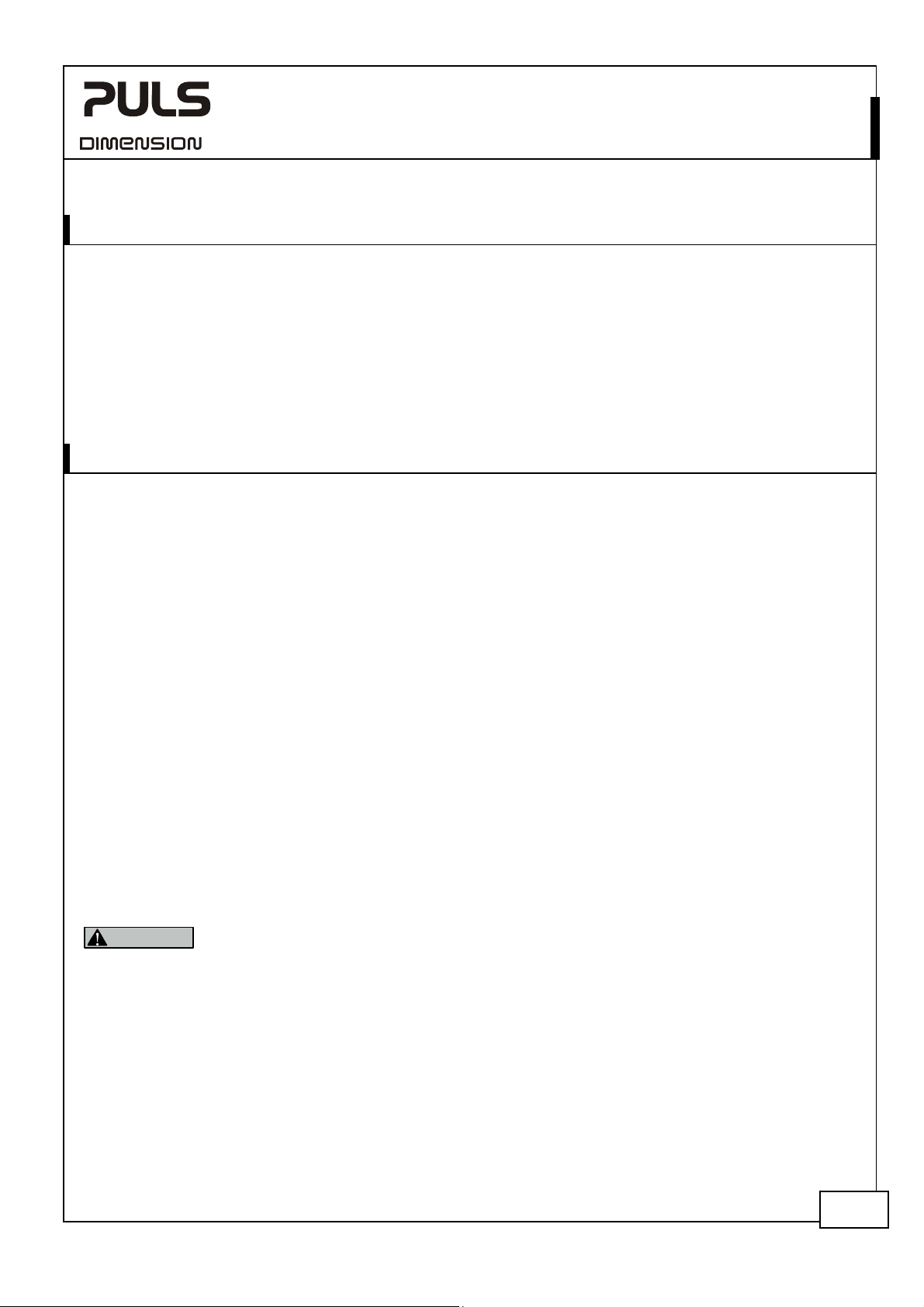

3. INPUT AND OUTPUT CHARACTERISTICS

Number of inputs - 2

Number of outputs - 1

Input voltage nom. DC 24-28V ±25%

Input voltage range - 18-35Vdc

Voltage drop, input to output typ. 0.1-0.5V at 2x5A, load share function dependent, see Fig. 3-1

typ. 0.2-0.5V at 2x10A, load share function dependent, see Fig. 3-1

typ. 0.24-0.5V at 2x12A, load share function dependent, see Fig. 3-1

Input current nom. 2x 0-12A continuous, ambient temperature < +45°C

nom. 2x 0-10A continuous, ambient temperature < +70°C

nom. 2x 17A

max. 2x 700A for max. 1ms

Output current nom. 24A continuous, ambient temperature < +45°C

nom. 20A continuous, ambient temperature < +70°C

nom. 32.5A for max. 5 seconds

max. 26A in overload /short-circuit (voltage < 6V). Ensure that the

Reverse current max. 1mA at 24V, per input, -40°C to +70°C

Reverse voltage max. 40Vdc voltage applied to the output, continuously allowed

Output capacitance typ. 320μF

1) The average value (R.M.S. value) of the output current must not exceed the values of the continuous output current.

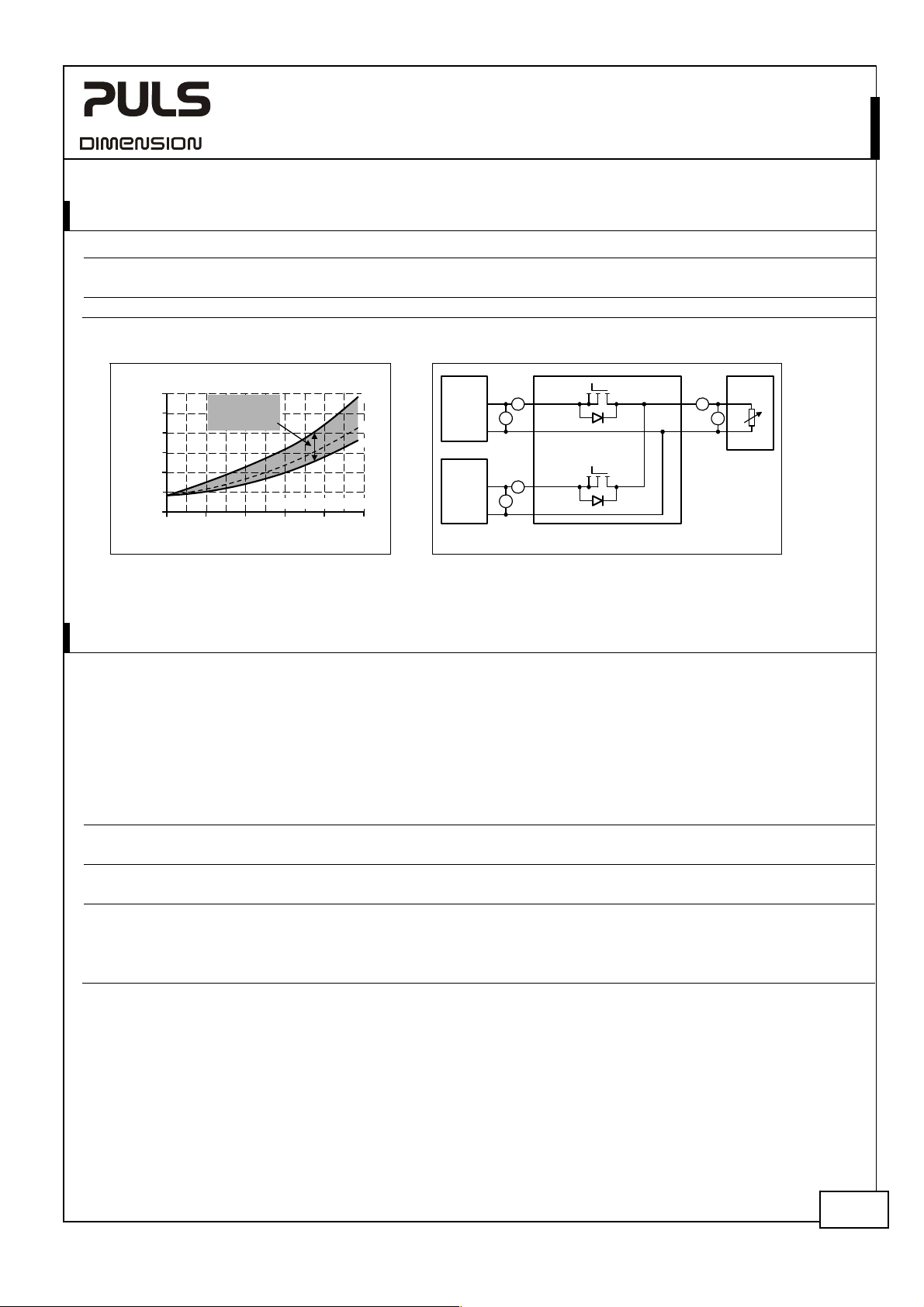

Fig. 3-1 Input to output voltage drop Fig. 3-2 Test setup for voltage drop measurements

Voltage Drop, typ

600mV

500mV

400mV

300mV

200mV

100mV

0mV

Output:

Input:

0

0

Depending on

Load Share

Regulation

Input / Output Current

5A 15A

2x5A2x2.5A

60°C

25°C

25A

20A10A

2x10A2x7.5A

2x12.5A

1)

for max. 5 seconds

sum of input currents does not exceed this value.

Power

Supply

+

24V, 12A

-

Power

Supply

+

24V, 12A

-

I1I2=

YR20.246

I

1

A

Input 1

V

U

1

I

2

A

Input 2

V

U

2

U2U1= Voltage Drop

Output

Output

I

OUT

A

U

OUT

V

Variable

Load,

0-24A

U1=

U

-

OUT

Jul. 2017 / Rev. 1.4 DS-YR20.246-EN All parameters are typical values specified at 24V, 20A output current, 25°C ambient and

after a 5 minutes run-in time unless otherwise noted.

4/19

Page 5

YR20.246

Y-Series

24-28V, 20A, DUAL REDUNDANCY MODULE

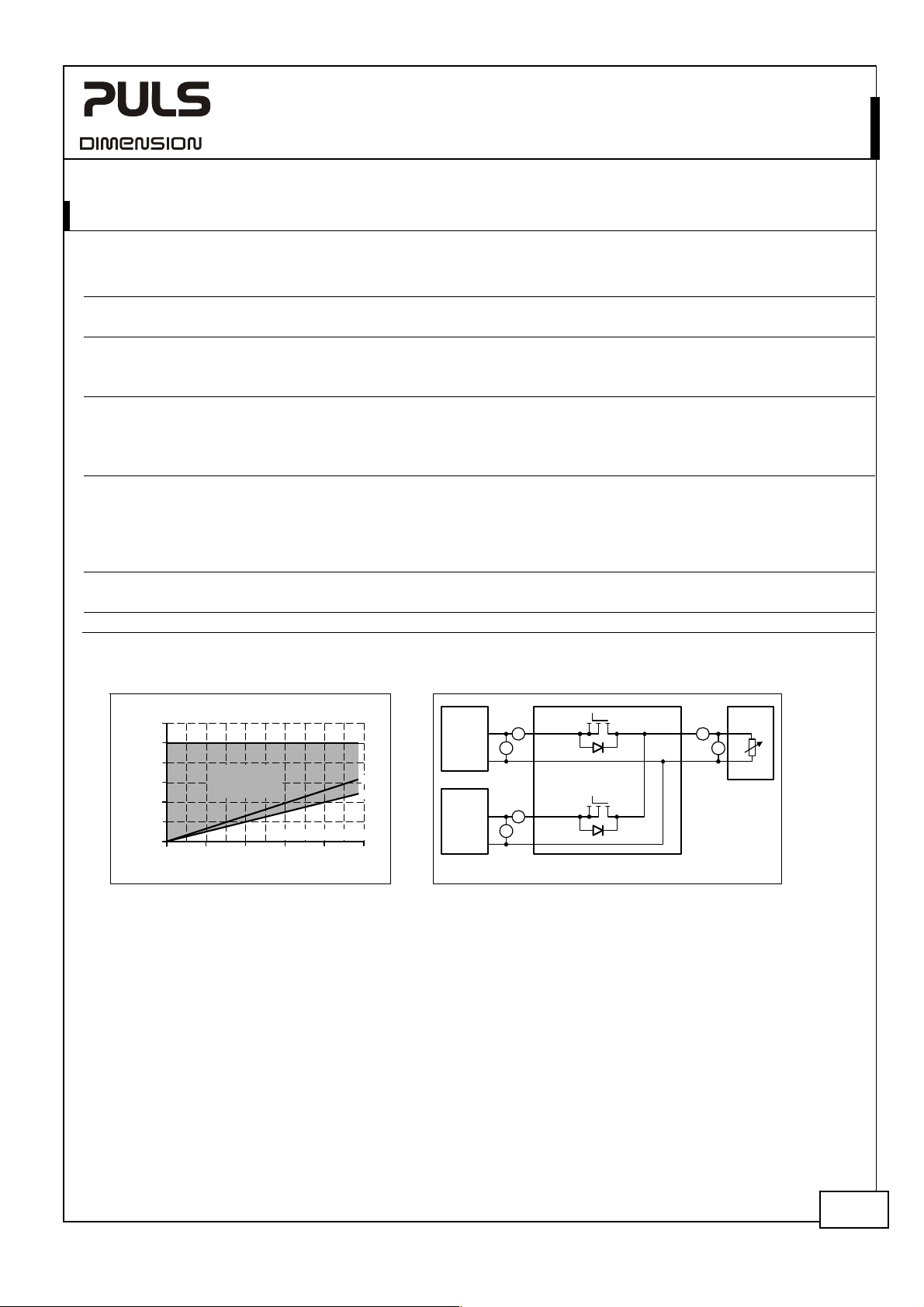

4. POWER LOSSES

Power losses typ.

typ.

2.6-4.7W

5.6-8.7W

Standby power losses typ. 1.7W at no output current

Fig. 4-1 Power losses Fig. 4-2 Test setup for power loss measurements

Power Losses, typ

12W

10W

8W

6W

4W

2W

Output:

Input:

25/

20A10A

60°C

60°C

25°C

25A

2x12.5A

Depending on

Load Share

Regulation

2x5A2x2.5A

Input / Output Current

2x10A2x7.5A

0

5A 15A

0

0

Power

Supply

+

24V, 12A

Power

Supply

24V, 12A

I1I2=

V

-

+

V

-

at 2x5A, 25°C ambient temperature

at 2x10A, 25°C ambient temperature

YR20.246

I

1

A

Input 1

U

1

I

2

A

Input 2

U

2

U2U1=Losses

U1=

Output

I1+)(

*

U

2

Output

I

OUT

A

U

OUT

I

2

*

Variable

Load,

0-24A

V

U

OUT

-

I

OUT

*

5. LIFETIME EXPECTANCY AND MTBF

The redundancy module has two input channels which are completely independent from each other. Each control

circuit, auxiliary voltage source, or other circuitry in the module are designed separately for each input. The dual input

redundancy module can be considered as two single redundancy modules combined together in one housing. The only

common point is the circuit trace that ties the two separate circuits together at the output.

The MTBF figures below are for the entire dual input module. If the MTBF number of only one path is needed, simply

double the value from the table.

Input / output current

conditions

*)

Lifetime expectancy

372 000h

1 053 000h

**)

MTBF

SN 29500, IEC 61709 2 306 000h 1 954 000h at 24V and 40°C

Input: 2x5A

Output: 10A

*)

182 000h

*)

Input: 2x10A

Output: 20A

516 000h

*)

at 24V and 40°C

*)

at 24V and 25°C

3 913 000h 3 359 000h at 24V and 25°C

**)

MTBF

MIL HDBK 217F 964 000h 858 000h Ground Fixed GF40 (24V and 40°C)

1 379 000h 1 226 000h Ground Fixed GF25 (24V and 25°C)

278 000h 243 000h Ground Benign GB40 (24V and 40°C)

381 000h 330 000h Ground Benign GB25 (24V and 25°C)

*) The Lifetime expectancy shown in the table indicates the minimum operating hours (service life) and is determined by the lifetime

expectancy of the built-in electrolytic capacitors. Lifetime expectancy is specified in operational hours and is calculated according to the

capacitor’s manufacturer specification. The manufacturer of the electrolytic capacitors only guarantees a maximum life of up to 15 years

(131 400h). Any number exceeding this value is a calculated theoretical lifetime which can be used to compare devices.

**) MTBF stands for Mean Time Between Failure, which is calculated according to statistical device failures, and indicates reliability of a

device. It is the statistical representation of the likelihood of a unit to fail and does not necessarily represent the life of a product.

The MTBF figure is a statistical representation of the likelihood of a device to fail. A MTBF figure of e.g. 1 000 000h means that

statistically one unit will fail every 100 hours if 10 000 units are installed in the field. However, it can not be determined if the failed unit

has been running for 50 000h or only for 100h.

Jul. 2017 / Rev. 1.4 DS-YR20.246-EN All parameters are typical values specified at 24V, 20A output current, 25°C ambient and

after a 5 minutes run-in time unless otherwise noted.

5/19

Page 6

YR20.246

Y-Series

24-28V, 20A, DUAL REDUNDANCY MODULE

6. TERMINALS AND WIRING

Type Screw termination

Solid wire max. 6mm2 max. 1.5mm2

Stranded wire max. 4mm

American Wire Gauge 20-10 AWG AWG 24-16

Max. wire diameter 2.8mm (including ferrule) max. 1.6mm (including ferrules)

Wire stripping length 7mm / 0.28inch 7mm / 0.28inch

Screwdriver 3.5mm slotted or Pozidrive No 2 not required

Recommended tightening torque 0.8Nm, 7lb.in not applicable

Instructions:

a) Use appropriate copper cables that are designed for minimum operating temperatures of:

60°C for ambient up to 45°C and

75°C for ambient up to 60°C and

90°C for ambient up to 70°C minimum.

b) Follow national installation codes and installation regulations!

c) Ensure that all strands of a stranded wire enter the terminal connection!

d) Screws of unused terminal compartments should be securely tightened.

e) Ferrules are allowed.

Input and Output Signals

Push-in terminals

IP20 Finger safe construction.

Suitable for field installation.

2

max. 1.5mm2

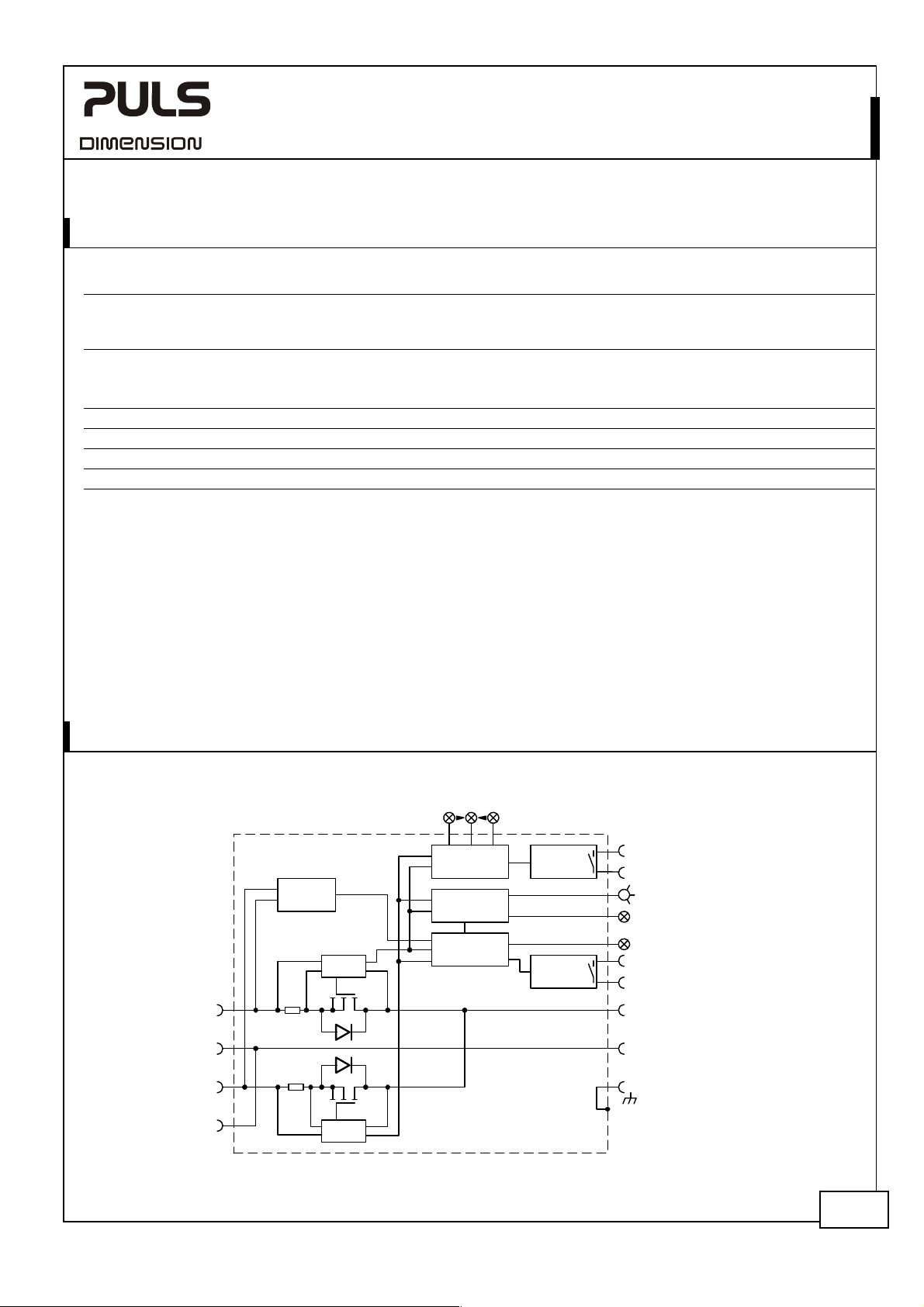

7. FUNCTIONAL DIAGRAM

Input

Voltages

Monitor

+

Input 1

-

+

Input 2

-

Control

Control

Fig. 7-1 Functional diagram

OK

Input 2Input 1

Load Share

Controller

Output Current

Monitor

Redundancy OK

Controller

Load Share

OK

Redundancy

OK

13

Load Share OK

Contact

14

5A

Output current

10A

alarm threshold

20A

Output current < IN

Redundancy OK

23

Redundancy OK

Contact

24

+

Output

-

Chassis

Ground

Jul. 2017 / Rev. 1.4 DS-YR20.246-EN All parameters are typical values specified at 24V, 20A output current, 25°C ambient and

after a 5 minutes run-in time unless otherwise noted.

6/19

Page 7

YR20.246

Y-Series

8. FRONT SIDE AND USER ELEMENTS

Fig. 8-1 Front side

Output terminals (screw terminals)

A

Chassis-Ground terminal

B

Connection of the chassis is optional and not required since the unit fulfils the

requirements according to protection class III.

Input terminals for input 1 (screw terminals)

C

D Input terminals for input 2 (screw terminals)

E Selector for output current warning threshold

If the output current increases, e. g. due to additionally loads, and exceeds the

nominal current of one power supply unit, redundancy is no longer guaranteed.

To avoid the loss in redundancy, the output current is monitored and is

reported through LEDs and relay contacts when exceeding the predefined

value.

- Set the selector to 5A in combination with two 5A power supplies (1+1 red.)

- Set the selector to 10A in combination with two 10A power supplies (1+1 red.)

- Set the selector to 20A for n+1 redundant systems. With this setting,

redundancy cannot be checked by the redundancy module any more.

Exceeding the current by less than 2 seconds will be ignored.

Green LED “Output current < IN”

F

The LED is on solid when the output current is smaller than the adjusted value

of the output current alarm selector (E).

Load share LEDs

G

The three LEDs indicate the status of the load sharing between the two power

supplies.

See chapter 11 for detailed description.

Green LED “Redundancy OK”

H

The LED is on solid when no errors are detected.

Errors:

- One or both input voltages are out of range (below 22V or above 30V).

- Output current is higher than the adjusted value of the output current

threshold setting.

- Internal defect is detected

Relay contact “Redundancy OK” (push-in terminals)

I

The relay contact is closed when no redundancy errors are detected. The relay

contact is also synchronized with the “Redundancy OK” LED.

See chapter 9 for contact ratings.

Relay contact “Load share OK” (push-in terminals)

J

The relay contact is closed when the output voltage of the two power supplies

are sufficiently adjusted.

Deviations less than 2s will be ignored.

See chapter 11 for detailed description.

See chapter 10 for contact ratings.

24-28V, 20A, DUAL REDUNDANCY MODULE

Jul. 2017 / Rev. 1.4 DS-YR20.246-EN All parameters are typical values specified at 24V, 20A output current, 25°C ambient and

after a 5 minutes run-in time unless otherwise noted.

7/19

Page 8

YR20.246

Y-Series

24-28V, 20A, DUAL REDUNDANCY MODULE

9. “REDUNDANCY OK” RELAY CONTACT

This feature reports the loss of redundancy by opening the relay contact (pin 23 and 24).

Contact is closed When no errors are detected

Contact is open When:

- one or both input voltages are below 22Vdc or above 30Vdc.

- the output current is higher than the adjusted value of the output current threshold setting.

- an internal defect of the redundancy module is detected (decoupling measures and several

internal test routines).

Input voltage errors less than 2s will be ignored.

Overcurrent errors (less than 150% of the adjusted value) less than 4s will be ignored.

Overcurrent errors (above 150% of the adjusted value) less than 30ms will be ignored.

Internal errors less than 10s will be ignored

Contact ratings max. 60Vdc 0.3A, 30Vdc 1A, 30Vac 0.5A resistive load

min. 1mA at 5Vdc minimum permissible load

Isolation voltage See dielectric strength table in section 16.

10. “LOAD SHARE OK” RELAY CONTACT

This feature monitors if the output voltages of the two power supplies connected to the input are sufficiently adjusted

for an even current distribution. The relay contact (pin 13 and 14) is closed, when load sharing occurs.

Contact is closed When the adjustment of the output voltages are sufficient

Contact is open When an even load share does not occur and readjustment of the output voltages is

recommended.

Details see chapter 11.

Contact ratings max. 60Vdc 0.3A, 30Vdc 1A, 30Vac 0.5A resistive load

min. 1mA at 5Vdc minimum permissible load

Isolation voltage See dielectric strength table in section 16.

Jul. 2017 / Rev. 1.4 DS-YR20.246-EN All parameters are typical values specified at 24V, 20A output current, 25°C ambient and

after a 5 minutes run-in time unless otherwise noted.

8/19

Page 9

YR20.246

Y-Series

24-28V, 20A, DUAL REDUNDANCY MODULE

11. AUTOMATED LOAD SHARING

Drawing even current from both power supplies in a redundancy application can provide a longer service life of the

redundant power supply system. An evenly shared current can avoid that one of the two units is getting much hotter

than the other, which reduces the lifetime of the power supply system. The YR20.246 redundancy module is equipped

with an automated load share feature, which can compensate a certain voltage unbalance between the two power

supplies connected to the inputs.

However, to reduce the losses of the active circuit in the redundancy module, the individual output voltages shall be

set as close as possible. The three LEDs on the front of the unit help to indicate if adjustment is necessary.

Optimal load sharing and

minimal power losses

Input 1

+

OK

+

Input 2

Input 1

+

OK

+

Input 2

To optimize power losses, reduce the output voltage

of the power supply, where the yellow LED is on.

Input 1

Input 2

typ. 90mV

typ. 90mV

Input 1

Input 2

Fig. 11-1 Load sharing

+

OK

+

+

OK

+

typ. 370mV

typ. 370mV

Input 1

+

OK

+

Input 2

Input 1

+

OK

+

Input 2

Reduce output voltage

of power supply 1

V

> V

OUT1

V

= V

OUT1

V

< V

OUT1

Reduce output voltage

of power supply 2

OUT2

OUT2

OUT2

Automated load sharing possible

"Load Share OK" contact is closed

Automated load sharing not possible

"Load Share OK" contact is open

The active load share feature of the YR20.246 has a similar effect and benefit as the feature “Parallel Mode” (soft

output characteristic), which is available on larger PULS power supplies.

Jul. 2017 / Rev. 1.4 DS-YR20.246-EN All parameters are typical values specified at 24V, 20A output current, 25°C ambient and

after a 5 minutes run-in time unless otherwise noted.

9/19

Page 10

YR20.246

Y-Series

24-28V, 20A, DUAL REDUNDANCY MODULE

12. EMC

The redundancy module is suitable for applications in industrial environment as well as in residential, commercial and

light industry environment without any restrictions.

EMC Immunity

Electrostatic discharge EN 61000-4-2 Contact discharge

Electromagnetic RF field EN 61000-4-3 80MHz-2.7GHz 10V/m Criterion A

Fast transients (Burst) EN 61000-4-4 Input lines

Surge voltage on input

lines

Surge voltage on output

lines

Surge voltage on signal

lines

Conducted disturbance EN 61000-4-6 0.15-80MHz 20V Criterion A

Power-frequency magnetic

field 1)

Criterions:

A: Redundancy module shows normal operation behavior within the defined limits.

Notes:

1) A test is not applicable according to EN 61000-6-2, since the device does not contain components susceptible to magnetic fields, e.g. hall

elements, electrodynamic microphones, etc.

2) Tested with capacitive coupling clamp.

EMC Emission

Conducted emission

input lines

Conducted emission

output lines

Radiated emission EN 55011, EN 55022 Class B

This device complies with FCC Part 15 rules.

Operation is subjected to following two conditions: (1) this device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that may cause undesired operation.

Notes:

3) For information only, not mandatory for EN 61000-6-3.

4) Provided, that power sources connected on the inputs fulfill the requirements too.

Switching frequency

According to generic standards: EN 61000-6-1 and EN 61000-6-2

Air discharge

Output lines

Redundancy OK signal

Load share OK signal

2)

2)

EN 61000-4-5 + Æ -

+/- Æ Chassis ground

EN 61000-4-5 + Æ -

+/- Æ Chassis ground

EN 61000-4-5 Load Share OK signalÆ PE

Redundancy OK signal

8kV

15kV

2kV

2kV

2kV

2kV

500V

1kV

500V

1kV

1kV

1kV

Criterion A

Criterion A

Criterion A

Criterion A

Criterion A

Criterion A

Criterion A

Criterion A

Criterion A

Criterion A

Criterion A

Criterion A

EN 61000-4-8 50Hz 30A/m Criterion A

According to generic standards: EN 61000-6-3 and EN 61000-6-4

IEC/CISPR 16-1-2, IEC/CISPR 16-2-1 limits for DC power ports according

EN 61000-6-3 fulfilled

IEC/CISPR 16-1-2, IEC/CISPR 16-2-1 limits for DC power ports according

EN 61000-6-3 fulfilled

4)

3) 4)

3) 4)

The internal auxiliary supply is generated with a boost converter.

The switching frequency varies from 140kHz to 500kHz depending on the input voltage.

Jul. 2017 / Rev. 1.4 DS-YR20.246-EN All parameters are typical values specified at 24V, 20A output current, 25°C ambient and

after a 5 minutes run-in time unless otherwise noted.

10/19

Page 11

YR20.246

Y-Series

24-28V, 20A, DUAL REDUNDANCY MODULE

13. ENVIRONMENT

Operational temperature

Storage temperature -40 to +85°C (-40°F to 185°F) for storage and transportation

Humidity

**)

5 to 95% r.H. IEC 60068-2-30

Vibration sinusoidal

***)

Shock

30g 6ms, 20g 11ms

Altitude 0 to 2000m (0 to 6 560ft) without any restrictions

2000 to 6000m (6 560 to 20 000ft) reduce output power or ambient temperature,

Altitude de-rating 1.25A/1000m or 5°C/1000m > 2000m (6500ft), see Fig. 13-2

Over-voltage category not applicable The concept of the overvoltage category is

Degree of pollution 2 EN 62477-1, not conductive

LABS compatibility The unit does not release any silicone or other LABS-critical substances and is suitable for

*) Operational temperature is the same as the ambient temperature and is defined as the air temperature 2cm below the unit.

**) Do not energize while condensation is present

***) Tested in combination with DIN-Rails according to EN 60715 with a height of 15mm and a thickness of 1.3mm and standard mounting

orientation.

Fig. 13-1 Output current vs. ambient temp. Fig. 13-2 Output current vs. altitude

Allowed Output Current

32.5A

s

h

o

r

t

t

e

24

n

o

r

m

l

20

15

10

5

0

a

Ambient Temperature

-25

-40 0 20 45

*)

-40°C to +70°C (-40°F to 158°F)

***)

2-17.8Hz: ±1.6mm; 17.8-500Hz: 2g

2 hours / axis

3 bumps / direction, 18 bumps in total

use in paint shops.

r

m

(

s

<

5

)

o

m

d

e

70°C

IEC 60068-2-6

IEC 60068-2-27

see Fig. 13-2

used for equipment energized directly from

the low voltage mains (IEC 60664-1 §4.3.3.2.1).

Allowed Output Current

32.5A

s

h

o

r

t

t

e

r

m

(

s

<

5

)

n

o

r

m

l

a

m

o

d

24

20

15

10

A... Tamb < 45°C

5

B... Tamb < 70°C

0

0 2000 4000

e

A

B

Altitude

6000m

Jul. 2017 / Rev. 1.4 DS-YR20.246-EN All parameters are typical values specified at 24V, 20A output current, 25°C ambient and

after a 5 minutes run-in time unless otherwise noted.

11/19

Page 12

YR20.246

Y-Series

24-28V, 20A, DUAL REDUNDANCY MODULE

14. PROTECTION FEATURES

Output over-current protection not included

Reverse input polarity

protection

Degree of protection IP 20 EN/IEC 60529

Penetration protection > 3.6mm e.g. screws, small parts

Over-temperature protection not included

Input transient protection included see EMC section

Output transient protection included see EMC section

Internal input fuse not included

included unit does not start when input voltage is reversed

15. SAFETY FEATURES

Input / output separation no galvanic separation Mosfet between input and output

Safety level of output voltage The output voltage is regarded to be SELV (EN 60950-1) or PELV (EN 60204-1, EN

62477-1, IEC 60364-4-41) if the input voltage fulfills the requirements for a SELV

source or PELV source.

Class of protection III PE (Protective Earth) or chassis connection not required

PE resistance < 0.1Ohm between housing and chassis-ground terminal

16. DIELECTRIC STRENGTH

The input and output voltages have the same reference, are floating and have no ohmic connection to ground.

Type and factory tests are conducted by the manufacturer. Field tests may be conducted in the field using the

appropriate test equipment which applies the voltage with a slow ramp (2s up and 2s down). Connect input/output

and signal terminals together before conducting the test.

When testing, set the cut-off current settings to the value in the table below.

Fig. 16-1 Dielectric strength

+

-

Jul. 2017 / Rev. 1.4 DS-YR20.246-EN All parameters are typical values specified at 24V, 20A output current, 25°C ambient and

after a 5 minutes run-in time unless otherwise noted.

Load Share OK,

Redundancy OK

A

B

ChassisIn- / Output

B

Type test 60s 500Vac 500Vac

Factory test 5s 500Vac 500Vac

Field test 5s 500Vac 500Vac

Cut-off current setting > 2mA > 2mA

A B

12/19

Page 13

YR20.246

17. APPROVALS

EC Declaration of Conformity

IEC 60950-1

UL 508

UL 60950-1

ANSI / ISA 12.12.01-2007

Class I Div 2,

planned

ATEX

EN 60079-0, EN 60079-7

IECEx

IEC 60079-0, IEC 60079-7

Marine,

planned

EAC TR Registration

Y-Series

IND. CONT. EQ.

II 3G Ex ec nC IIC T4 Gc

IECEx

Ex ec nC IIC T4 Gc

24-28V, 20A, DUAL REDUNDANCY MODULE

The CE mark indicates conformance with the

- EMC directive and the

- ATEX directive.

CB Scheme,

Information Technology Equipment

Listed for use as Industrial Control Equipment;

U.S.A. (UL 508) and Canada (C22.2 No. 107-1-01);

E-File: E198865

Recognized for use as Information Technology Equipment,

Level 5; U.S.A. (UL 60950-1) and Canada (C22.2 No. 60950);

E-File: E137006

LISTED for use in Hazardous Location Class I Div 2 T4 Groups

A,B,C,D systems; U.S.A. (ANSI / ISA 12.12.01-2007) and Canada

(C22.2 No. 213-M1987)

Suitable for use in Category 3 Zone 2 locations.

Number of ATEX certificate: EPS 11 ATEX 1 312 X

The redundancy module must be built-in in an IP54 enclosure.

Suitable for use in Category 3 Zone 2 locations.

Number of IECEx certificate: IECEx EPS 12.0032X

GL (Germanischer Lloyd) classified

Environmental category: C, EMC1

Marine and offshore applications

Registration for the Eurasian Customs Union market

(Russia, Kazakhstan, Belarus)

18. ROHS, REACH AND OTHER FULFILLED STANDARDS

RoHS Directive

REACH Directive

Jul. 2017 / Rev. 1.4 DS-YR20.246-EN All parameters are typical values specified at 24V, 20A output current, 25°C ambient and

after a 5 minutes run-in time unless otherwise noted.

Directive 2011/65/EU of the European Parliament and the

Council of June 8

certain hazardous substances in electrical and electronic

equipment.

Directive 1907/2006/EU of the European Parliament and the

Council of June 1

Evaluation, Authorisation and Restriction of Chemicals

(REACH)

th

, 2011 on the restriction of the use of

st

, 2007 regarding the Registration,

13/19

Page 14

YR20.246

Y-Series

24-28V, 20A, DUAL REDUNDANCY MODULE

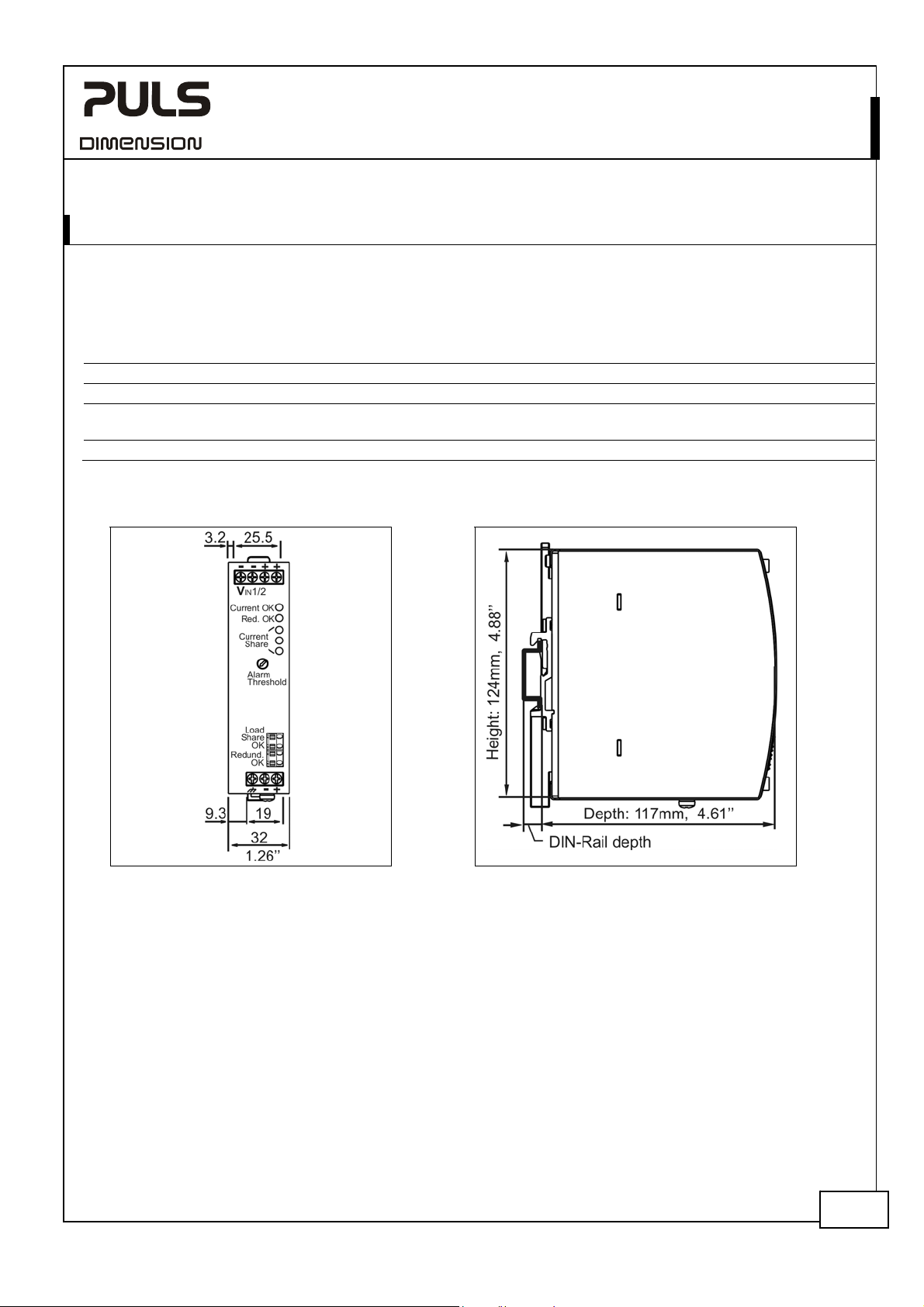

19. PHYSICAL DIMENSIONS AND WEIGHT

Width 32mm 1.26’’

Height 124mm 4.88’’

Depth 117mm 4.61’’

The DIN-rail height must be added to the unit depth to calculate the total required

installation depth.

Weight 310g / 0.69lb

DIN-Rail Use 35mm DIN-rails according to EN 60715 or EN 50022 with a height of 7.5 or 15mm.

Housing material Body: Aluminium alloy

Cover: zinc-plated steel

Installation clearances See chapter 2

Fig. 19-1 Front view Fig. 19-2 Side view

Jul. 2017 / Rev. 1.4 DS-YR20.246-EN All parameters are typical values specified at 24V, 20A output current, 25°C ambient and

after a 5 minutes run-in time unless otherwise noted.

14/19

Page 15

YR20.246

Y-Series

24-28V, 20A, DUAL REDUNDANCY MODULE

20. ACCESSORIES

20.1. ZM11.SIDE - SIDE MOUNTING BRACKET

This bracket is used to mount the YR20.246 redundancy module sideways with or without utilizing a DIN-Rail.

The two aluminum brackets and the black plastic slider of the unit have to be detached, so that the steel brackets can

be mounted.

For sideway DIN-rail mounting, the removed aluminum brackets and the black plastic slider need to be mounted on

the steel bracket.

Side mounting without DIN-

Fig. 20-1

rail brackets

Side mounting with DIN-rail

Fig. 20-2

brackets

Fig. 20-3

Mounting Dimensions

Side mounting bracket

Jul. 2017 / Rev. 1.4 DS-YR20.246-EN All parameters are typical values specified at 24V, 20A output current, 25°C ambient and

after a 5 minutes run-in time unless otherwise noted.

15/19

Page 16

YR20.246

Y-Series

24-28V, 20A, DUAL REDUNDANCY MODULE

21. APPLICATION NOTES

21.1. USING ONLY ONE INPUT INSTEAD OF BOTH CHANNELS

Using only one input instead of both is allowed up to a nominal input current of 12A (at max. +45°C ambient

temperature) or 10A (at max. +70°C ambient temperature).

The load share feature is disabled in cases one input voltage is not present or the level of the input voltage is below a

certain value. The MOSFET will be on in such cases.

However, it is always recommended to connect both input path in parallel for reduced power losses and voltage drop.

When this is not possible, the following values can be expected:

Voltage drop, input to output typ. 0.15V

Power losses typ.

2.6W

Standby power losses typ. 1.1W

Fig. 21-1 Input to output voltage drop when only one

Voltage Drop, typ.

200mV

input is used

60°C

25°C

150mV

at 1x10A, 25°C, see Fig. 21-1

at 1x10A, 25°C, see Fig. 21-3

Fig. 21-2 Test setup for voltage drop measurements

Power

Supply

24V, 12A

+

-

YR20.246

1

I

A

Input 1

V

U

1

Output

Variable

Load,

I

OUT

0-12A

Output

A

V

U

OUT

100mV

50mV

0mV

2.5A 7.5A

Input/ Output Current

10A5A0

12.5A

Input 2

Voltage Drop

Fig. 21-3 Power losses when only one input is used Fig. 21-4 Test setup for power loss measurements

Power Losses, typ

4W

3W

2W

1W

60°C

25°C

Power

Supply

24V, 12A

+

-

YR20.246

I

1

A

Input 1

V

U

1

0

2.5A 7.5A

Output Current

10A5A0

12.5A

Input 2

Losses

U1=

U

OUT

-*I

1

I

OUT

*

Output

Output

I

OUT

A

U

OUT

V

U1=

Variable

Load,

0-12A

U

OUT

-

Jul. 2017 / Rev. 1.4 DS-YR20.246-EN All parameters are typical values specified at 24V, 20A output current, 25°C ambient and

after a 5 minutes run-in time unless otherwise noted.

16/19

Page 17

YR20.246

Y-Series

24-28V, 20A, DUAL REDUNDANCY MODULE

21.2. RECOMMENDATIONS FOR REDUNDANCY

Recommendations for the configuration of redundant power systems:

- Use separate input fuses for each power supply.

- Use three-phase power supplies to gain functional safety if one phase fails.

- When single-phase power supplies are utilized connect them to different phases or mains circuits if possible.

- Set the power supply in “Parallel-Use” mode if this feature is available

- It is desirable to set the output voltages of all power supplies to the same value.

21.3. INDUCTIVE AND CAPACITIVE LOADS

The unit is designed to supply any kind of loads, including unlimited capacitive and inductive loads.

21.4. SIDEWARDS INSTALLATION CLEARANCES

The minimum clearance recommendations are defined in chapter 2.

Normally, the following installation clearance are recommended: 40mm on top, 20mm on the bottom, 5mm on the

left and right sides when the device is loaded permanently with more than 50% of the rated power. Increase this

clearance to 15mm in case the adjacent device is a heat source (e.g. another

power supply).

The clearance between the power supplies and the redundancy module can be

reduced to zero under the following conditions:

- 1+1 redundancy application with maximum 12A output current.

- The power supplies are from the PULS DIMENSION series.

- The redundancy module is placed between the two power supplies.

- The output voltage is set to the same level on both power supplies.

+

-

Output

Power

Supply

Input

-

+

+

IN 2

IN 1

YR20.246

Redundancy

Module

Output

+

-

Load

-

+

Output

Power

Supply

Input

0mm0mm

-

Jul. 2017 / Rev. 1.4 DS-YR20.246-EN All parameters are typical values specified at 24V, 20A output current, 25°C ambient and

after a 5 minutes run-in time unless otherwise noted.

17/19

Page 18

YR20.246

Y-Series

24-28V, 20A, DUAL REDUNDANCY MODULE

21.5. 1+1 REDUNDANCY UP TO 10A

1+1 Redundancy up to 10A requires two 10A power supplies and one YR20.246 redundancy module.

Note: Use separate mains systems for each power supply whenever it is possible

Fig. 21-5 Wiring diagram, 1+1 Redundancy, 10A output current

++

--

Output

24V,10A

Power

Supply

Input

LNPE

I

L

N

PE

++

Output

24V,10A

Power

Supply

Input

LNPE

I

--

--

1

Input

Load Share

OK

Redudnadcy

OK

YR20.246

Redundancy

Module

Output

optional

Input

-

++

2

o

o

o

o

+

Load

Share

Warning

Failure

Monitor

10A

Load

Jul. 2017 / Rev. 1.4 DS-YR20.246-EN All parameters are typical values specified at 24V, 20A output current, 25°C ambient and

after a 5 minutes run-in time unless otherwise noted.

18/19

Page 19

YR20.246

Y-Series

24-28V, 20A, DUAL REDUNDANCY MODULE

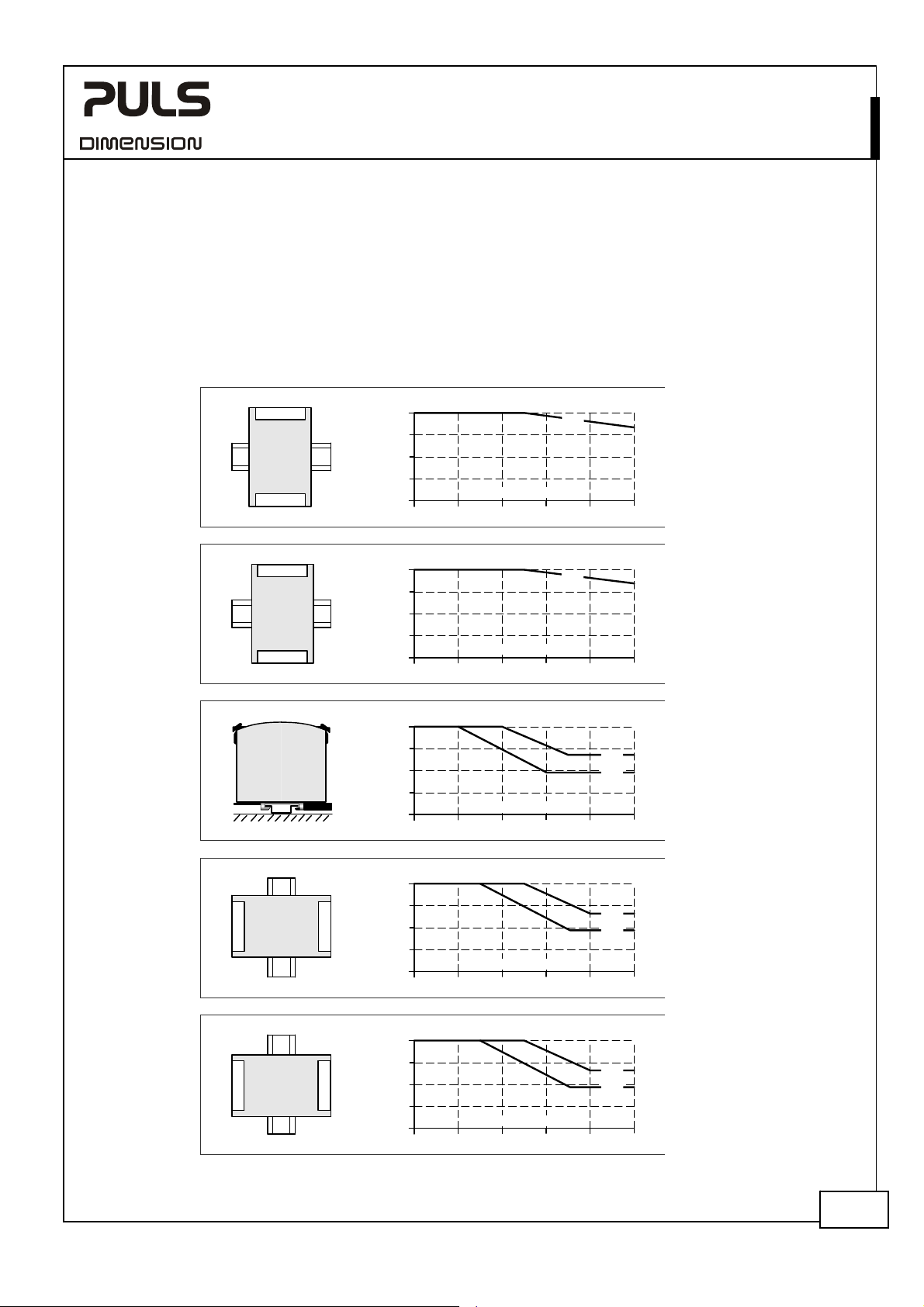

21.6. MOUNTING ORIENTATIONS

Mounting orientations other than input terminals on the bottom and output on the top require a reduction in

continuous output power or a limitation in the maximum allowed ambient temperature. The amount of reduction

influences the lifetime expectancy of the power supply. Therefore, two different derating curves for continuous

operation can be found below:

Curve A1 Recommended output current.

Curve A2 Max allowed output current (results in approximately half the lifetime expectancy of A1).

Fig. 21-6

Mounting

Orientation A

(Standard

orientation)

Fig. 21-7

Mounting

Orientation B

(Upside down)

INPUT

Redundancy

Module

OUTPUT

INPUT

OUTPUT

Module

Redundancy

Fig. 21-8

Mounting

Orientation C

(Table-top

mounting)

Fig. 21-9

Mounting

Orientation D

(Horizontal cw)

OUTPUT

Redundancy

Module

INPUT

Fig. 21-10

Mounting

Orientation E

(Horizontal ccw)

INPUT

Module

Redundancy

OUTPUT

Output Current

24A

18

12

6

0

Ambient Temperature

20 30 40 50

Output Current

24A

18

12

6

0

Ambient Temperature

20 30 40 50

Output Current

24A

18

12

6

0

Ambient Temperature

20 30 40 50

Output Current

24A

18

12

6

0

Ambient Temperature

20 30 40 50

Output Current

24A

18

12

6

0

Ambient Temperature

20 30 40 50

A

1

70°C

60

A

1

60

60

60

60

70°C

A

2

A

1

70°C

A

2

A

1

70°C

A

2

A

1

70°C

Jul. 2017 / Rev. 1.4 DS-YR20.246-EN All parameters are typical values specified at 24V, 20A output current, 25°C ambient and

after a 5 minutes run-in time unless otherwise noted.

19/19

Loading...

Loading...