U–Series

UBC10.241, UBC10.241-N1

24V, 10A, DC-UPS

28. APPLICATION NOTES

28.1. BATTERY REPLACEMENT INTERVALS

Batteries have a limited life time. They degrade slowly beginning from the production and need to be replaced

periodically. The design life figures can be found in the individual datasheets of the batteries and usually is specified

according to the Eurobat guideline or according to the manufacturer’s specifications.

The design life is the estimated life based on laboratory condition, and is quoted at 20°C using the manufacturer’s

recommended float voltage condition. According to the Eurobat guideline, design lives have been structured into the

following different groups:

3 - 5 years:

6 - 9 years:

10 - 12 years:

A battery failure within the specified design life of the battery usually results in a complete loss of the battery

function (broken cell, defect connection, …) and will be detected and reported by the periodical battery tests which

are included in the UBC10.241 DC-UPS control unit.

If the operational parameters differ from those which are specified for the design life, an earlier change of the

battery might be necessary. The “real life” is called service life and is defined as the point at which the cell’s actual

capacity has reached 80% of its nominal capacity. At the end of the service life the capacity degrades much faster, so

that a further use of the battery is not recommended.

Temperature effect:

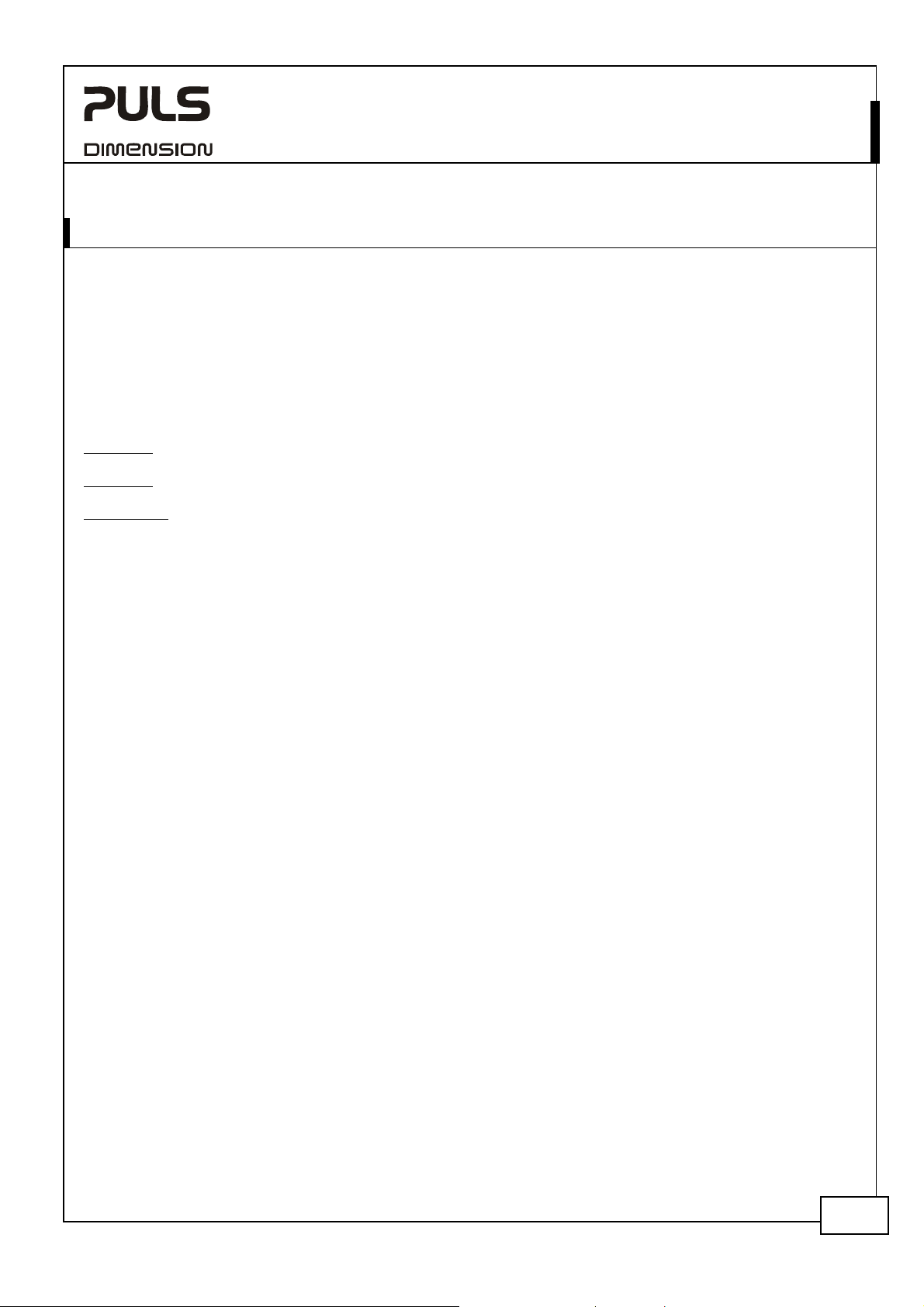

The temperature has the most impact in the service life. The hotter the temperature, the earlier the wear-out phase

of the battery begins. The wear-out results in a degradation of battery capacity. See Fig. 28-1 for details.

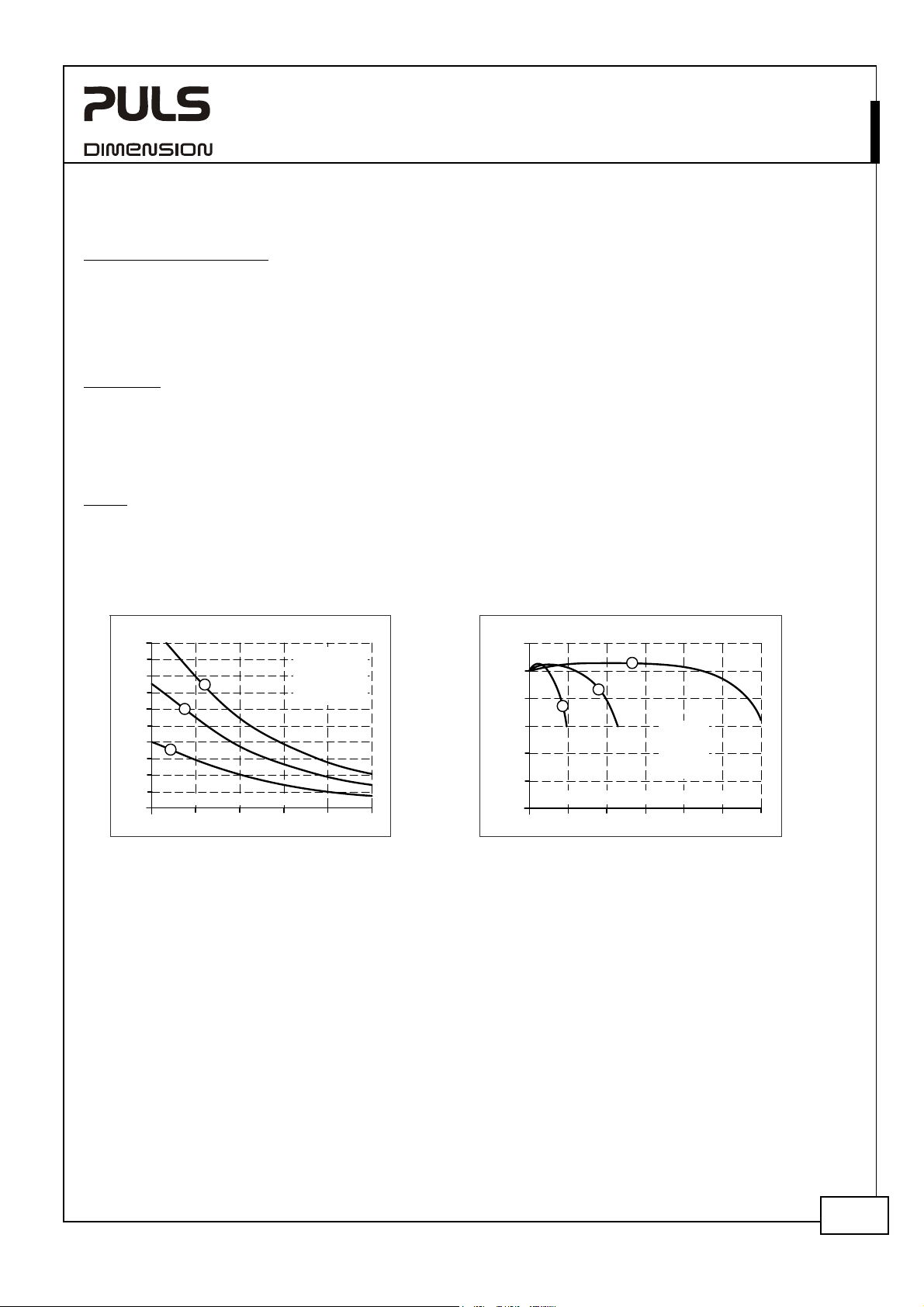

Effect of discharging cycles

The number as well as the depth of discharging cycles is limited. A replacement of the battery might be necessary

earlier than the calculated service life if the battery exceeds the numbers and values of Fig. 28-2.

Other effects which shorten the service life

Guidelines for a long battery service life:

This group of batteries is very popular in standby applications and in small emergency equipment.

This represents a 4 years design life with a production tolerance of ±1 year.

This group of batteries is usually used when an improved life is required.

This represents a 7.5 years design life with a production tolerance of ±1.5 years.

This group of batteries is used when in applications where longest life and highest safety level are

required. This represents a 11 years design life with a production tolerance of ±1 year.

Overcharging and deep discharging shortens the service life and should be avoided. Thanks to the single

battery concept of the UBC10.241, the end-of-charge voltage is precisely set automatically avoiding

unnecessary aging effects.

Charge retention is important to get the longest battery life. Stored batteries which are not fully charged

age faster then charged batteries. Batteries which are not in use should be recharged at least once a year.

Excessive float charge ripple across the battery has an effect of reducing life and performance. The

UBC10.241 does not produce such a ripple voltage. This effect can be ignored when the battery is charged

with the UBC10.241.

Place the DC-UPS in a cool location: E.g. near the bottom of the control cabinet.

Do not place the DC-UPS near heat generating devices.

Do not store discharged batteries.

Do not discharge the battery more than necessary. Set buffer time limiter to the required buffer time.

The depth of discharge reduces the service life of the battery and limits the number of cycles. See Fig. 28-2.

May. 2008 / Rev. 1.1 DS-UBC10.241-EN

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time

unless otherwise noted. It is assumed that the input power source can deliver a sufficient output current.

www.pulspower.com Phone +49 89 9278 0 Germany

21/23

U–Series

UBC10.241, UBC10.241-N1

24V, 10A, DC-UPS

Example for calculating the service life and the required replacement cycle:

Parameters for the example:

A 5Ah battery with a design life of 3-5 years is used (e.g. Yuasa battery which is used for type UZB12.051)

The average ambient temperature is 30°C

One buffer event consumes approx. 25% of the achievable buffer time.

One buffer event per day

Calculation:

Ambient temperature influence:

According to Fig. 28-1 curve A, a 2 years service life can be expected for an ambient temperature of 30°C.

Number of discharging cycles: 2 years * 365 cycles = 730cycles in 2 years.

According to Fig. 28-2, curve C has to be used (only 25% of battery capacity is required). 730 cycles have only a

negligible influence in a battery degradation and can be ignored.

Result:

The battery shall be replaced after 2 years.

Please note that the battery degrading begins from the production date (check date code on the battery) which may

shorten the replacement intervals.

Fig. 28-1 Service life versus ambient

Service Life in Years

10

9

8

7

6

5

4

3

2

1

20°C

temperatures, typ *)

C

B

A

Ambient Temperature

30°C 35°C

25°C

Design Life

of Battery

A:

3-5 Years

B:

6-9 Years

C:

10-12 Years

40°C

45°C

Fig. 28-2 Cell capacity degradation vs. discharging

Cell Capacity

120%

100%

80%

60%

40%

20%

A

0

200

cycles *)

C

B

Depth of

discharge

A:

100%

B:

50%

C:

30%

Number of Discharging Cycles

400 600 800 1000 1200

*) datasheet figures from battery manufacturer

28.2. PARALLEL AND SERIAL USE

Do not use the DC-UPS in parallel to increase the output power. However, two units of the DC-UPS can be paralleled

for 1+1 redundancy to gain a higher system reliability.

Do not use batteries in parallel, since the battery quality test might create an error message.

Do not connect two or more units in series for higher output voltages.

Do not connect two or more units in a row to get longer hold-up times.

May. 2008 / Rev. 1.1 DS-UBC10.241-EN

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time

unless otherwise noted. It is assumed that the input power source can deliver a sufficient output current.

www.pulspower.com Phone +49 89 9278 0 Germany

22/23

U–Series

UBC10.241, UBC10.241-N1

24V, 10A, DC-UPS

28.3. USING THE INHIBIT INPUT

The inhibit input disables buffering. In normal mode, a static signal is required. In buffer mode, a pulse with a

minimum length of 250ms is required to stop buffering. The inhibit is stored and can be reset by cycling the input

voltage.

For service purposes, the inhibit input can also be used to connect a service switch. Therefore, the inhibit signal can

be supplied from the output of the DC-UPS.

Fig. 28-3 Wiring example for inhibit input

-

+-+

-

Output

Power

Supply

Input

NL

PE

+

+

-

IN

OUT

24V

DC-UPS

UBC10.241

Signal Port

24V

-

+ -

Inhibit

+

Buffered

Load

Service

Switch

28.4. TROUBLESHOOTING

The LEDs on the front of the unit and relay contacts indicate the status of the DC-UPS. Please see also chapter 14.

The following guidelines provide instructions for fixing the most common failures and problems. Always start with

the most likely and easiest-to-check condition. Some of the suggestions may require special safety precautions. See

notes in section 25 first.

“Check wiring” LED is on Check correct wiring between the battery and the DC-UPS

Check battery fuse. Is the battery fuse inserted or blown?

Check battery voltage (must be typically between 7.4V and 15.1V)

Check input voltage (must be typically between 22.8V and 30V)

Check battery polarity

DC-UPS did not buffer Inhibit input was set

Battery did not have enough time to be charged and is still below the deep discharge

protection limit.

DC-UPS stopped buffering Buffer time limiter stopped buffering Æ set buffer time limiter to a higher value

Deep discharge protection stopped buffering Æ allow sufficient time for charging

the battery

Output was overloaded or short circuit Æ reduce load

Output has shut down Cycle the input power to reset the DC-UPS

Let DC-UPS cool down, over temperature protection might have triggered.

DC-UPS constantly switches between normal mode and buffer mode

The supplying source on the input is too small and can not deliver sufficient current

Æ Use a larger power supply or reduce the output load

The input voltage is same as transfer threshold. Æ Increase input voltage

May. 2008 / Rev. 1.1 DS-UBC10.241-EN

All parameters are specified at an input voltage of 24V, 10A output load, 25°C ambient and after a 5 minutes run-in time

unless otherwise noted. It is assumed that the input power source can deliver a sufficient output current.

www.pulspower.com Phone +49 89 9278 0 Germany

23/23

Loading...

Loading...