Page 1

CD10.241

P

S

Output voltage

Adjustment range

24 - 28V

Factory setting 24.1V

Output current

10 – 8.6A

At +60°C ambient

Derate linearly between +45°C and +70°C

Input voltage

DC 24V

-25%/+46%

Input current

Input inrush current

6A peak

Efficiency

Losses

14.8W

Hold

Temperature range

Size (W x H x D)

42x124x117mm

Without DIN-rail

Weight

O

M

CD-Series

RODUCT DESCRIPTION

The CD10.241 is a DIN-rail mountable DC/DC converter

of the DIMENSION series which provides a floating,

stabilized and galvanically separated SELV/PELV output

voltage.

The CD-Series is part of the DIMENSION power supply

family. The most outstanding features of CD10.241 are

the high efficiency, the small size and the wide

operational temperature range.

The CD-Series includes all the essential basic functions.

The devices have a power reserve of 20% included,

which may even be used continuously at temperatures

up to +45°C.

High immunity to transients and power surges as well as

low electromagnetic emission and a large international

approval package for a variety of applications makes

this unit suitable for nearly every situation.

DC/DC Converter 24V/24V, 10A, 240W

DC/DC CONVERTER

24V DC-Input

Isolated 24Vdc Output

Efficiency 94.2%

Width only 42mm

20% Output Power Reserves

Full Power Between -25°C and +60°C

Soft-start Function

Minimal Inrush Current Surge

Reverse Input Polarity Protection

3 Year Warranty

HORT-FORM DATA

DC 24V Nominal

12 – 10.3A Below +45°C ambient

7.5 – 6.5A At +70°C ambient

10.5A

94.2%

-up time 4ms

-25°C to +70°C

500g / 1.1lb

RDER NUMBERS

DC/DC Converter

Mechanical Accessory

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

CD10.241

ZM2.WALL Wall/panel mount bracket

ZM12.SIDE Side mount bracket

AIN APPROVALS

For details or a complete approval list see section 18.

Ind. Cont. Eq.

IECEx

ATEX

planned

1/27

Page 2

CD10.241

I

T

CD-Series

NDEX

Page Page

1. Intended Use .......................................................3

2. Installation Instructions ......................................3

3. DC-Input...............................................................5

4. Input Inrush Current ...........................................7

5. Soft-start Feature ................................................7

6. Output .................................................................8

7. Hold-up Time .......................................................9

8. Efficiency and Power Losses.............................. 10

9. Functional Diagram ........................................... 11

10. Front Side and User Elements ........................... 11

11. Connection Terminals ....................................... 12

12. Lifetime Expectancy .......................................... 13

13. MTBF .................................................................. 13

14. EMC .................................................................... 14

15. Environment ...................................................... 15

16. Safety and Protection Features ........................ 16

17. Dielectric Strength ............................................ 16

18. Approvals ........................................................... 17

DC/DC Converter 24V/24V, 10A, 240W

19. RoHS, REACH and Other Fulfilled Standards .. 17

20. Physical Dimensions and Weight ..................... 18

21. Accessories ........................................................ 19

21.1. ZM2.WALL – Wall/Panel Mount Bracket . 19

21.2. ZM12.SIDE - Side Mount Bracket ............. 19

21.3. YRM2.DIODE - Redundancy Module ....... 21

21.4. UF20.241 - Buffer Module ........................ 21

22. Application Notes ............................................. 22

22.1. Peak Current Capability ........................... 22

22.2. Output Circuit Breakers ............................ 23

22.3. Charging of Batteries ............................... 23

22.4. Series Operation ....................................... 24

22.5. Parallel Use to Increase Output Power .... 24

22.6. Parallel Use for Redundancy .................... 25

22.7. Use in a Tightly Sealed Enclosure ............ 26

22.8. Mounting Orientations ............................ 27

The information given in this document is correct to the best of our knowledge and experience at the time of

publication. If not expressly agreed otherwise, this information does not represent a warranty in the legal sense of the

word. As the state of our knowledge and experience is constantly changing, the information in this data sheet is

subject to revision. We therefore kindly ask you to always use the latest issue of this document (available under

www.pulspower.com).

No part of this document may be reproduced or utilized in any form without our prior permission in writing.

ERMINOLOGY AND ABREVIATIONS

PE and symbol PE is the abbreviation for Protective Earth and has the same meaning as the symbol .

Earth, Ground This document uses the term “earth” which is the same as the U.S. term “ground”.

T.b.d. To be defined, value or description will follow later.

DC 24V A figure displayed with the AC or DC before the value represents a nominal voltage with

standard tolerances included.

E.g.: DC 12V describes a 12V battery disregarding whether it is full (13.7V) or flat (10V)

24Vdc A figure with the unit (Vac) at the end is a momentary figure without any additional

tolerances included.

may A key word indicating flexibility of choice with no implied preference.

shall A key word indicating a mandatory requirement.

should A key word indicating flexibility of choice with a strongly preferred implementation.

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

2/27

Page 3

CD10.241

1. I

2. I

WARNING

CD-Series

DC/DC Converter 24V/24V, 10A, 240W

NTENDED USE

This device is designed for installation in an enclosure and is intended for the general use such as in industrial control,

office, communication, and instrumentation equipment.

Do not use this device in equipment where malfunction may cause severe personal injury or threaten human life.

NSTALLATION INSTRUCTIONS

Risk of electrical shock, fire, personal injury or death.

- Turn power off before working on the device. Protect against inadvertent re-powering.

- Do not modify or repair the unit.

- Do not open the unit as high voltages may present inside.

- Use caution to prevent any foreign objects from entering the housing.

- Do not use in wet locations or in areas where moisture or condensation can be expected.

- Do not touch during power-on, and immediately after power-off. Hot surface may cause burns.

Obey the following installation requirements:

This device may only be installed and put into operation by qualified personnel.

This device does not contain serviceable parts. The tripping of an internal fuse is caused by an internal defect.

If damage or malfunction should occur during installation or operation, immediately turn power off and send unit to

the factory for inspection.

Install device in an enclosure providing protection against electrical, mechanical and fire hazards.

Install the device onto a DIN-rail according to EN 60715 with the input terminals on the bottom of the device. Other

mounting orientations require a reduction in output current.

Make sure that the wiring is correct by following all local and national codes. Use appropriate copper cables that are

designed for a minimum operating temperature of 60°C for ambient temperatures up to +45°C, 75°C for ambient

temperatures up to +60°C and 90°C for ambient temperatures up to +70°C. Ensure that all strands of a stranded wire

enter the terminal connection.

Unused screw terminals should be securely tightened.

The device is designed for pollution degree 2 areas in controlled environments. No condensation or frost allowed.

The enclosure of the device provides a degree of protection of IP20.

The input can be powered from batteries or similar DC sources. The voltage between the input terminals and ground

must not exceed 60Vdc continuously. The ripple voltage in the low frequency range between 50Hz and 10kHz must be

negligible when used in marine applications.

The input must be powered from a PELV or SELV source or an "Isolated Secondary Circuit" in order to maintain a SELV

or PELV output.

Check for correct input polarity. The device will not operate when the voltage is reversed.

A disconnecting means shall be provided for the input of the device.

The device is designed as “Class of Protection III” equipment according to IEC 61140.

A PE (ground) connection is not required. However, connecting the chassis ground terminal to ground can be

beneficial to gain a high EMI immunity.

The device is designed for convection cooling and does not require an external fan. Do not obstruct airflow and do not

cover ventilation grid!

The device is designed for altitudes up to 6000m (19685ft). See additional requirements in this document for use above

2000m (6560ft).

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

3/27

Page 4

CD10.241

CD-Series

Keep the following minimum installation clearances: 40mm on top, 20mm on the bottom, 5mm left and right side.

Increase the 5mm to 15mm in case the adjacent device is a heat source. When the device is permanently loaded with

less than 50%, the 5mm can be reduced to zero.

The device is designed, tested and approved for branch circuits up to 50A without additional protection device. If an

external fuse is utilized, do not use circuit breakers smaller than 20A B- or C-Characteristic to avoid a nuisance tripping

of the circuit breaker.

The maximum surrounding air temperature is +70°C (+158°F). The operational temperature is the same as the ambient

or surrounding air temperature and is defined 2cm below the device.

The device is designed to operate in areas between 5% and 95% relative humidity.

DC/DC Converter 24V/24V, 10A, 240W

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

4/27

Page 5

CD10.241

3. DC-I

DC i

DC i

Allowed voltage

and

Allowed

Turn

Shut

Input current

Start

Rise time

Turn

Input capacitance

External input protection

See recommendations in chapter 2.

Turn-on

17.5Vdc

V

IN

P

OUT

Shut-down

32.4Vdc

15.5Vdc

18.0Vdc

Rated input range

35.0Vdc

Start-up

delay

Rise

Time

Overshoot

- 5%

Output

Voltage

Input

Voltage

12A

2

3 4 6

8

0

4

8

12

16A

10

Output Current

5

7

9

11

Input: 24Vdc

Input

Current,

typ.

Input: 18Vdc

CD-Series

DC/DC Converter 24V/24V, 10A, 240W

NPUT

The input can be powered from batteries or similar DC sources and must be a PELV or SELV source or an "Isolated

Secondary Circuit" in order to maintain a SELV or PELV output.

Check for correct input polarity. The device will not operate when the voltage is reversed.

nput Nom. DC 24V -25%/+46%

nput range Min. 18.0-35.0Vdc Continuous operation

between input

earth/ground

input ripple voltage Max. 5Vpp In the frequency range from 47 to 500Hz, the

-on voltage Typ. 17.5Vdc Steady-state value, see Fig. 3-1

-down voltage Typ. 15.5Vdc Steady-state value, see Fig. 3-1

Typ. 10.5A At 24Vdc input and 24V, 10A output load , see Fig. 3-3

-up delay Typ. 200ms See Fig. 3-1

Typ. 200ms At 24V, 10A constant current load, 0mF load

-on overshoot Max. 250mV See Fig. 3-2

Typ. 4 300µF Installed inside the device, external capacitors on the

Max. 60Vdc or

Continuous operation, according to IEC 62477-1

42.2Vac

momentary input voltage must always be within the

specified limits.

Typ. 14.3A At 18Vdc input and 24V, 10A output load, see Fig. 3-3

capacitance, see Fig. 3-2

Typ. 200ms At 24V, 10A constant current load, 10mF load

capacitance, see Fig. 3-2

input are allowed without any limitations.

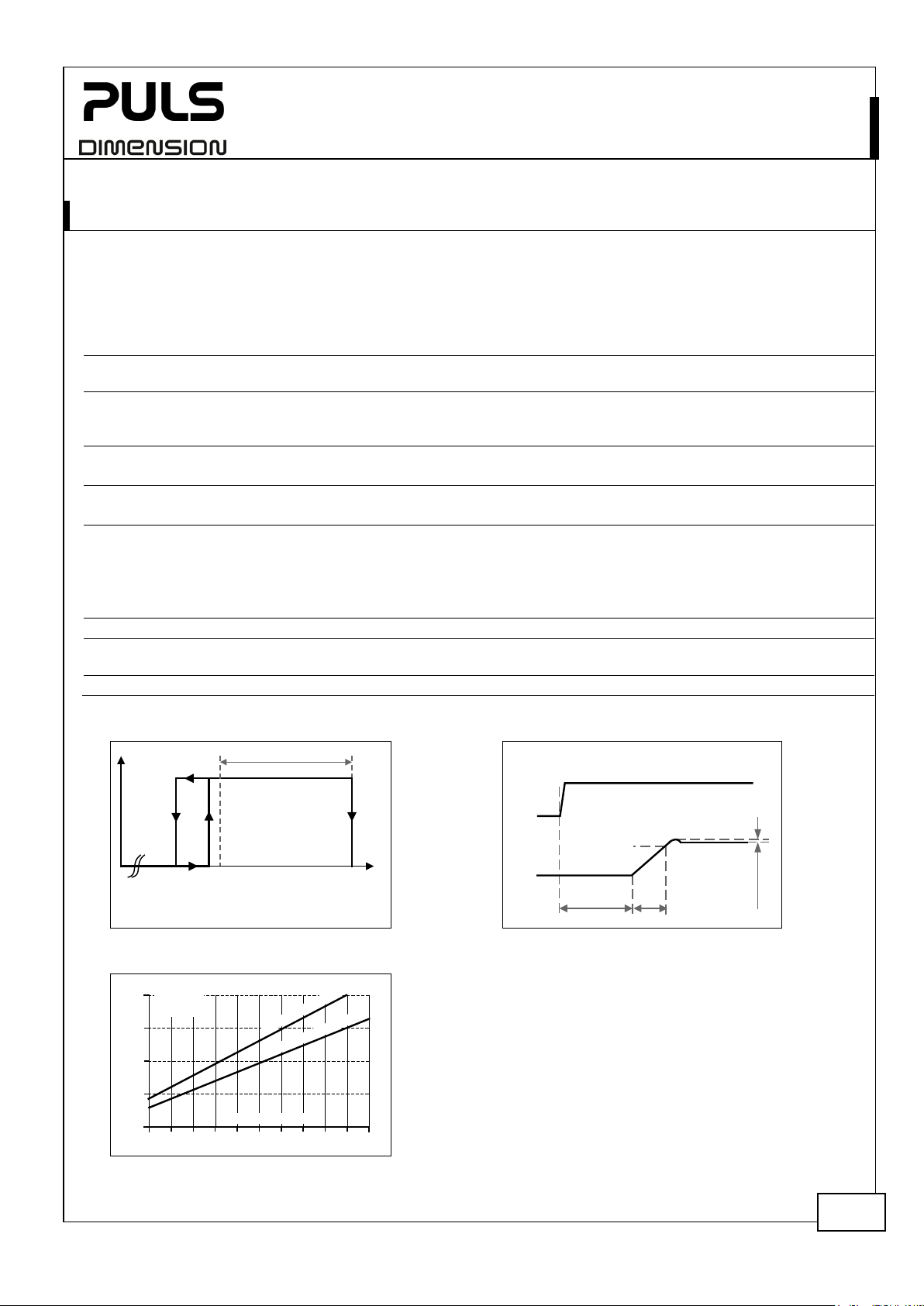

Fig. 3-1 Input voltage range Fig. 3-2 Turn-on behavior, definitions

Fig. 3-3 Input current vs. output load

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

5/27

Page 6

CD10.241

1 mOhm

10 mOhm

100 mOhm

1 Ohm

0.1mH 1mH 10mH

Inductance of the supplying network

Resistance of the

supplying network

(a) max.

(b) typ.

(a)

(b)

CD-Series

DC/DC Converter 24V/24V, 10A, 240W

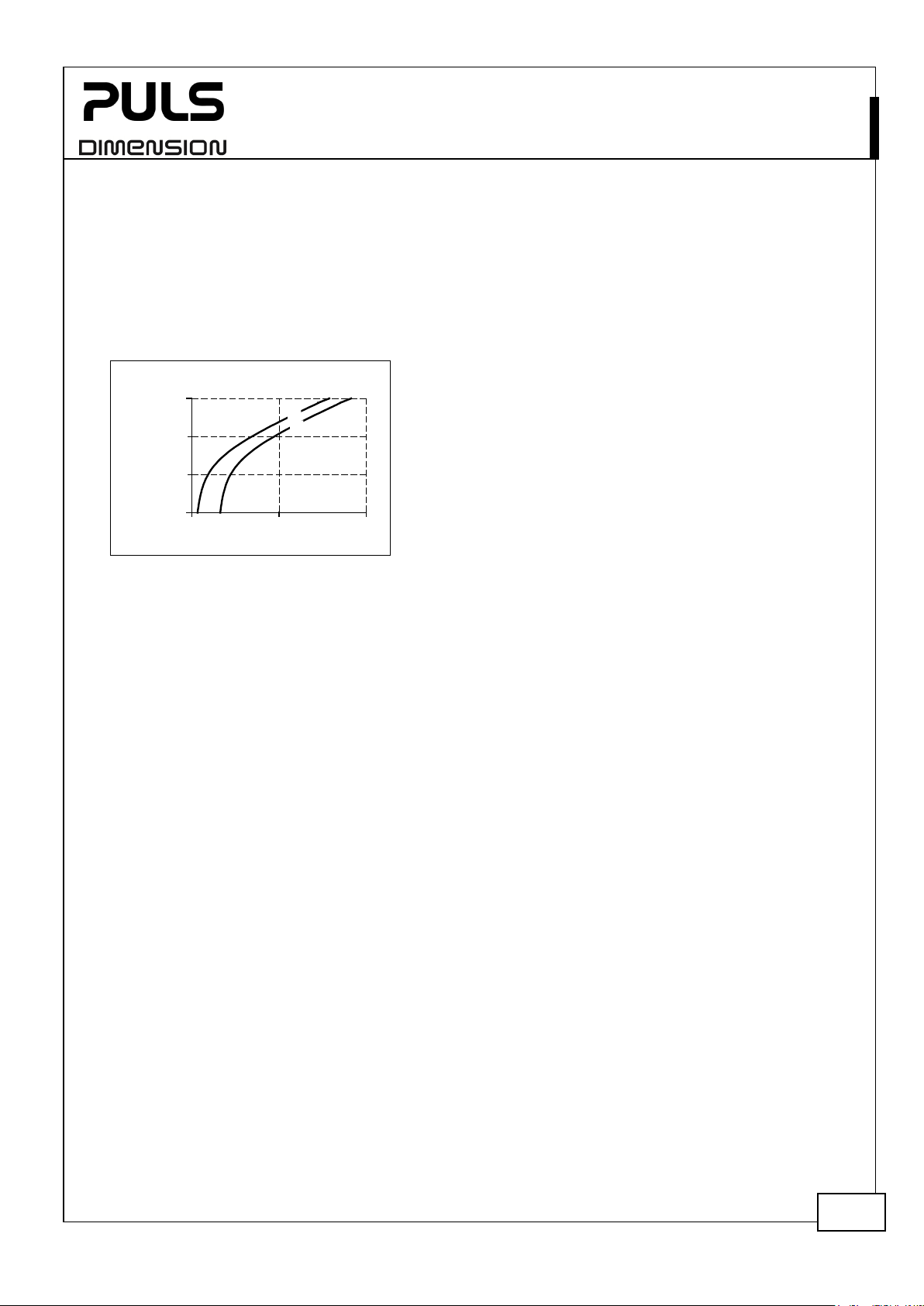

Requirements for the Supplying Source

In certain circumstances, the input filter of the DC/DC converter can show a resonant effect which is caused by the

supplying network. Especially when additional external input filters are utilized, a superimposed AC voltage can be

generated on the input terminals of the DC/DC converter which might cause a malfunction of the unit. Therefore,

additional input filters are not recommended. To avoid the resonant effects, the minimal resistance of the supplying

network which depends on the inductance of the input network, shall be above the boundary curve in Fig. 3-4.

Fig. 3-4 External input filter requirements to

avoid filter instabilities

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

6/27

Page 7

CD10.241

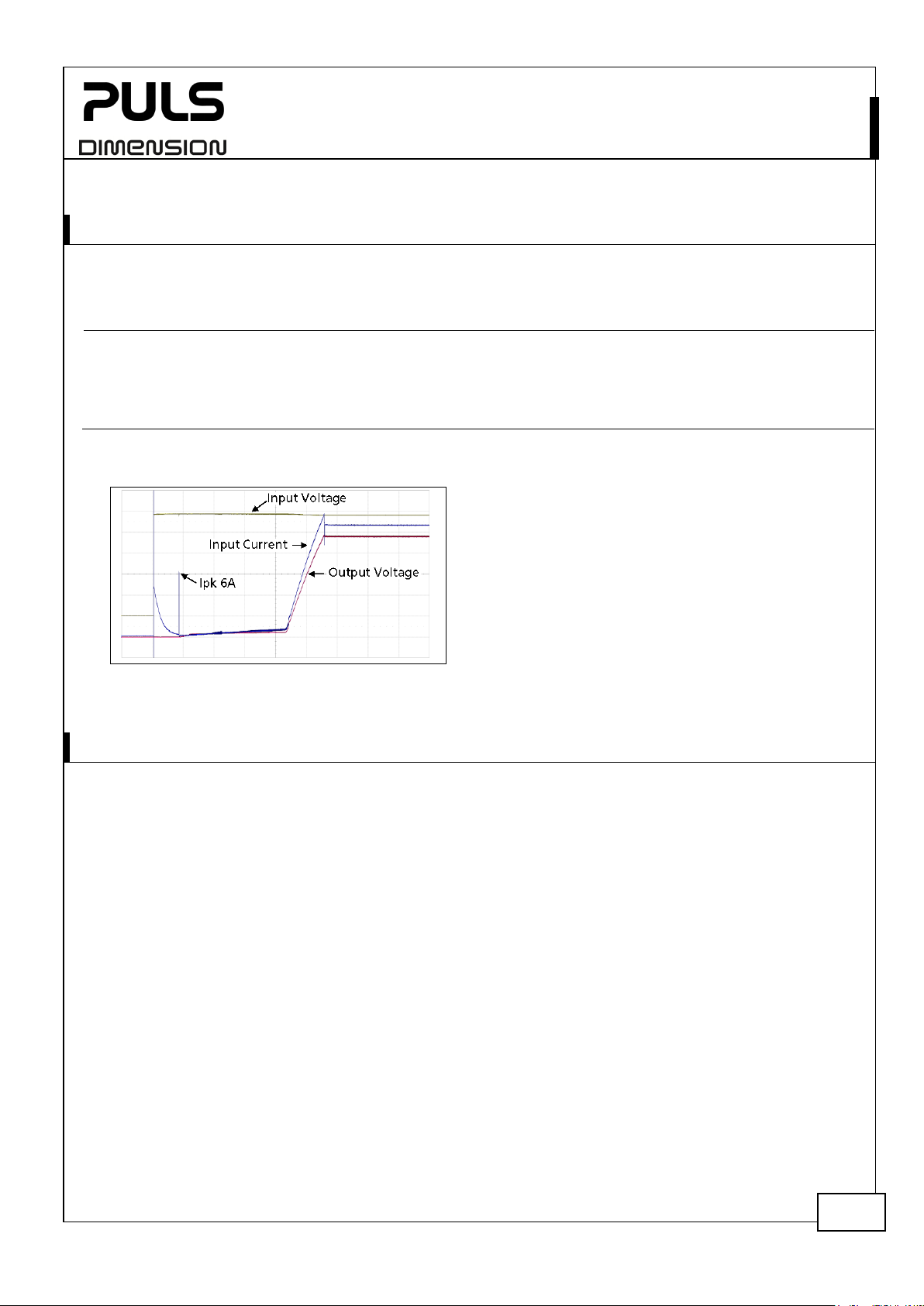

4. I

Inrush current

Inrush energy

5. S

CD-Series

DC/DC Converter 24V/24V, 10A, 240W

NPUT INRUSH CURRENT

An active inrush limitation circuit (inrush limiting NTC resistor which is bypassed by a MOSFET) limits the input inrush

current after turn-on of the input voltage.

The charging current into EMI suppression capacitors is disregarded in the first microseconds after switch-on.

Max. 8A At +25°C ambient, cold start

Max. 25A At +60°C ambient, cold start

Typ. 6A

Typ. 22A

Max. 1A2s Between -25°C to +70°C, cold start

Fig. 4-1 Typical input inrush current behavior at

nominal load and 25°C ambient

At +25°C ambient, cold start

peak

At +60°C ambient, cold start

peak

Input: 24Vdc

Output: 24V, 10A, constant current load

Ambient: 25°C

Input current 2A / DIV

Input voltage 5V / DIV

Output voltage 5V / DIV

Time basis: 100ms / DIV

OFT-START FEATURE

After the DC/DC converter is turned on, the internal output current rises slowly to its nominal value. This method

charges the output capacitors (internal and external capacitors) slowly and avoids high input currents during turn-on.

High input currents can produce a high voltage drop on the input wiring (especially with long and thin cables) which

reduces the terminal voltage on the DC/DC converter. If the terminal voltage is below the shut-down voltage, the

DC/DC converter will turn-off and will make a new start-up attempt. This effect is avoided with the integrated softstart function. Please note, that this function increases the rise time of the output voltage by a small amount.

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

7/27

Page 8

CD10.241

6. O

Output voltage

Adjustment range

Factory setting

24.1V

±0.2%, at full load, cold unit

Line regulation

Load regulation

Ripple and noise vo

Output current

Nom.

8.6A

At 28V and +60° ambient temperature

Overload behavior

Overload/

Output capacitance

Back

Output Voltage

0

0 4 8

4

8

12

28V

16

20

24

16A

62

10 12

14

Adjustment

Range

Output Current

Output Current

21 27

14A

13.0

13.5

36Vdc302418

10.0

10.5

11.0

11.5

12.5

12.0

33

Input Voltage

CD-Series

DC/DC Converter 24V/24V, 10A, 240W

UTPUT

The output provides a SELV/PELV rated voltage, which is galvanically isolated from the input voltage and is designed

to supply any kind of loads, including unlimited capacitive and inductive loads.

The output is electronically protected against overload, no-load and short-circuits. In case of a protection event,

audible noise may occur.

Nom. 24V

Min. 24-28V Guaranteed value from 23-28V

Max. 30V This is the maximum output voltage which can occur

at the clockwise end position of the potentiometer due

to tolerances. It is not a guaranteed value which can be

achieved.

Max. 25mV Between 18 and 35Vdc input voltage variation

Max. 100mV Between 0 and 10A load variation, static value

ltage Max. 50mVpp Bandwidth 20Hz to 20MHz, 50Ohm

Nom. 12A At 24V and an ambient temperature below +45°C

Nom. 10A At 24V and +60° ambient temperature

Nom. 7.5A At 24V and +70° ambient temperature

Nom. 10.3A At 28V and an ambient temperature below +45°

Nom. 6.5A At 28V and +70° ambient temperature

Continuous current

short-circuit current Max. 15A Continuous current

Typ. 4 500µF Included inside the power supply

-feeding loads Max. 35V The unit is resistant and does not show malfunctioning

when a load feeds back voltage to the power supply. It

does not matter whether the power supply is on or off.

The absorbing energy can be calculated according to the

built-in large sized output capacitor.

Fig. 6-1 Output voltage vs. output current at

24Vdc input voltage, typ.

Fig. 6-2 Current limitation vs. input voltage,

(23V constant voltage load), typ.

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

8/27

Page 9

CD10.241

7. H

Hold

0

2

4

6

8ms

18 20 22 24 28V

dc

Input Voltage

Hold-up Time

(a) 24V, 5A, typ.

(b) 24V, 5A, min.

(c) 24V, 10A, typ.

(d) 24V, 10A, min.

26

(a)

(b)

(c)

(d)

Load

+

-

DC/DC

Converter

DC

Source

+

-

Input

Output

+

-

CD10

S1

- 5%

Hold-up Time

Output

Voltage

Intput

Voltage

S1 opens

CD-Series

DC/DC Converter 24V/24V, 10A, 240W

OLD-UP TIME

The input side of the DC/DC converter is equipped with a bulk capacitor which keeps the output voltage alive for a

certain period of time when the input voltage dips or is removed. The bulk capacitor can be discharged by loading the

DC/DC converter on the output side or through a load which is parallel to the input. There is no protection in the

DC/DC converter which prevents current from flowing back to the input terminals. If prevention is needed, an external

diode should be used.

At no load, the hold-up time can be up to several seconds. The green DC-ok lamp is also on during this time.

-up Time Typ. 8ms At 24Vdc input voltage, 24V, 5A output, see Fig. 7-1

Min.. 6.5ms At 24Vdc input voltage, 24V, 5A output, see Fig. 7-1

Typ. 4ms At 24Vdc input voltage, 24V, 10A output, see Fig. 7-1

Min.. 3.2ms At 24Vdc input voltage, 24V, 10A output, see Fig. 7-1

Fig. 7-1 Hold-up time vs. input voltage

Fig. 7-2 Shut-down test setup Fig. 7-3 Shut-down behavior, definitions

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

9/27

Page 10

CD10.241

8. E

Efficiency

Average effi

Power losses

Efficiency

2

90

92

94

89

95%

12A4 8 10

Output Current

6

91

93

Power Losses

0 2 4 8 10 12A

0

3

9

15

18W

6

6

12

Output Current

Efficiency

18 20

22

26 28 32Vdc

95%

92.5

93.5

94.5

94.0

93.0

92.0

24

30

Input Voltage

Power Losses

13

14

15

16

17

18

19W

18 20

24

26 28 32Vdc

22 30

Input Voltage

CD-Series

DC/DC Converter 24V/24V, 10A, 240W

FFICIENCY AND POWER LOSSES

Input 24Vdc

Typ. 94.2% At 24V, 10A

Typ. 93.7% At 24V, 12A (Power Boost)

ciency*) Typ. 94.3% At 25% at 2.5A, 25% at 5A,

25% at 7.5A. 25% at 10A

Typ. 1.75W At no output load

Typ. 6.8W At 24V, 5A

Typ. 14.7W At 24V, 10A

Typ. 19.5W At 24V, 12A

*) The average efficiency is an assumption for a typical application where the power supply is loaded with 25% of the nominal load for 25%

of the time, 50% of the nominal load for another 25% of the time, 75% of the nominal load for another 25% of the time and with 100%

of the nominal load for the rest of the time.

Fig. 8-1 Efficiency vs. output current at 24V

output and 24Vdc input voltage, typ.

Fig. 8-2 Losses vs. output current at 24V

output and 24Vdc input voltage, typ.

Fig. 8-3 Efficiency vs. input voltage at 24V,

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

10A, typ.

Fig. 8-4 Losses vs. input voltage at 24V, 10A,

typ.

10/27

Page 11

CD10.241

9. F

+

+

-

-

V

OUT

Input Fuse

&

Input Filter

Output

Voltage

Regulator

Power

Converter

Output

Filter

DC

ok

Output

Over-

Voltage

Protection

Reverse

Polarity

Protection

&

Inrush

Limiter

Chassis

Ground

+

-

10. F

CD-Series

UNCTIONAL DIAGRAM

Fig. 9-1 Functional diagram

RONT SIDE AND USER ELEMENTS

DC/DC Converter 24V/24V, 10A, 240W

Fig. 10-1 Front side

A Input terminals

+ Positive input

- Negative / return input

Chassis ground: to bond the housing to ground, PE or Functional Earth

B Output terminals

Screw terminals, dual terminals per pole, both pins are equal

+ Positive output (two identical + poles)

- Negative / return output (two identical - poles)

C Output voltage potentiometer

Open the flap to set the output voltage. Factory set: 24.1V

D DC-OK LED (green)

On when the voltage on the output terminals is > 21V

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

11/27

Page 12

CD10.241

11. C

Type

Solid wire

Stranded wire

American Wire Gauge

Max. wire diameter (including ferrules)

Recommended tightening torq

Wire stripping length

Screwdriver

DC/DC

Converter

+ +

- -

Input

Output

Load

+

-

max 25A!

DC/DC

Converter

+ +

- -

Input

Output

Load

+

-

Distribution

Terminals

DC/DC

Converter

+ +

- -

Input

Output

DC/DC

Converter

+ +

- -

Input

Output

CD-Series

DC/DC Converter 24V/24V, 10A, 240W

ONNECTION TERMINALS

The terminals are IP20 Finger safe constructed and suitable for field- and factory wiring.

Input Output

Screw terminals Screw terminals

Max. 6mm2 Max. 6mm2

Max. 4mm2 Max. 4mm2

20-10 AWG 20-10 AWG

2.8mm 2.8mm

ue 1Nm, 9lb.in 1Nm, 9lb.in

7mm / 0.28inch 7mm / 0.28inch

3.5mm slotted or Phillips No 1 3.5mm slotted or Phillips No 1

Daisy chaining of outputs:

Daisy chaining (jumping from one DC/DC-converter output to the next) is allowed as long as the average output

current through one terminal pin does not exceed 25A. If the current is higher, use a separate distribution terminal

block.

Fig. 11-1 Daisy chaining of outputs Fig. 11-2 Using distribution terminals

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

12/27

Page 13

CD10.241

12. L

Lifetime expectancy

103 000h

At 24V, 10A and 40°C

13. MTBF

MTBF

MTBF MIL HDBK 217F

CD-Series

DC/DC Converter 24V/24V, 10A, 240W

IFETIME EXPECTANCY

The Lifetime expectancy shown in the table indicates the minimum operating hours (service life) and is determined by

the lifetime expectancy of the built-in electrolytic capacitors. Lifetime expectancy is specified in operational hours and

is calculated according to the capacitor’s manufacturer specification. The manufacturer of the electrolytic capacitors

only guarantees a maximum life of up to 15 years (131 400h). Any number exceeding this value is a calculated

theoretical lifetime which can be used to compare devices.

Input 24Vdc

299 000h At 24V, 5A and 40°C

56 000h At 24V, 12A and 40°C

844 000h At 24V, 5A and 25°C

292 000h At 24V, 10A and 25°C

159 000h At 24V, 12A and 25°C

MTBF stands for Mean Time Between Failure, which is calculated according to statistical device failures, and indicates

reliability of a device. It is the statistical representation of the likelihood of a unit to fail and does not necessarily

represent the life of a product.

The MTBF figure is a statistical representation of the likelihood of a device to fail. A MTBF figure of e.g. 1 000 000h

means that statistically one unit will fail every 100 hours if 10 000 units are installed in the field. However, it can not

be determined if the failed unit has been running for 50 000h or only for 100h.

For these types of units the MTTF (Mean Time To Failure) value is the same value as the MTBF value.

Input 24Vdc

SN 29500, IEC 61709 731 000h At 24V, 10A and 40°C

1 321 000h At 24V, 10A and 25°C

358 000h At 10A and 40°C; Ground Benign GB40

556 000h At 10A and 25°C; Ground Benign GB25

731 000h At 10A and 40°C; Ground Fixed GF40

142 000h At 10A and 25°C; Ground Fixed GF25

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

13/27

Page 14

CD10.241

14. EMC

EMC Immunity

Electrostatic discharge

Electromagnetic

Fast transients (Burst)

Surge voltage on input

Surge

Conducted disturbance

EN 61000-4-6

0.15-80MHz

20V

Criterion A

EMC Emission

Conducted emission on

input

Conducted emission on

output lines

IEC/CISPR 16-1-2, IEC/CISPR 16-2-1

T.B.D.

Radiated emission

This device complies with FCC Part 15 rules.

Operation is subjected to following two conditions: (1) this d

device must accept any interference received, including interference that may cause undesired operation.

Switching Frequency

Main converter

CD-Series

The EMC behavior of the device is designed for applications in industrial environment as well as in residential,

commercial and light industry environments.

The device is investigated according to the generic standards EN 61000-6-1, EN 61000-6-2, EN 61000-6-3 and EN 610006-4.

EN 61000-4-2 Contact discharge

Air discharge

RF field EN 61000-4-3 80MHz-2.7GHz 20V/m Criterion A

EN 61000-4-4 Input lines

Output lines

EN 61000-4-5 + - 1kV Criterion A

+/- chassis ground 2kV Criterion A

voltage on output EN 61000-4-5 + -

+ / - chassis ground

Criterions:

A: The device shows normal operation behavior within the defined limits.

C: Temporary loss of function is possible. The device may shut down and restarts by itself. No damage or hazards for the device will occur.

DC/DC Converter 24V/24V, 10A, 240W

8kV

15kV

4kV

2kV

500V

1kV

Criterion A

Criterion A

Criterion A

Criterion A

Criterion A

Criterion A

lines

IEC/CISPR 16-1-2, IEC/CISPR 16-2-1 Limits for DC power networks

according to EN 61000-6-3

fulfilled

EN 55011, EN 55022 Class B

evice may not cause harmful interference, and (2) this

50kHz to 300kHz Output load and input voltage dependent

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

14/27

Page 15

CD10.241

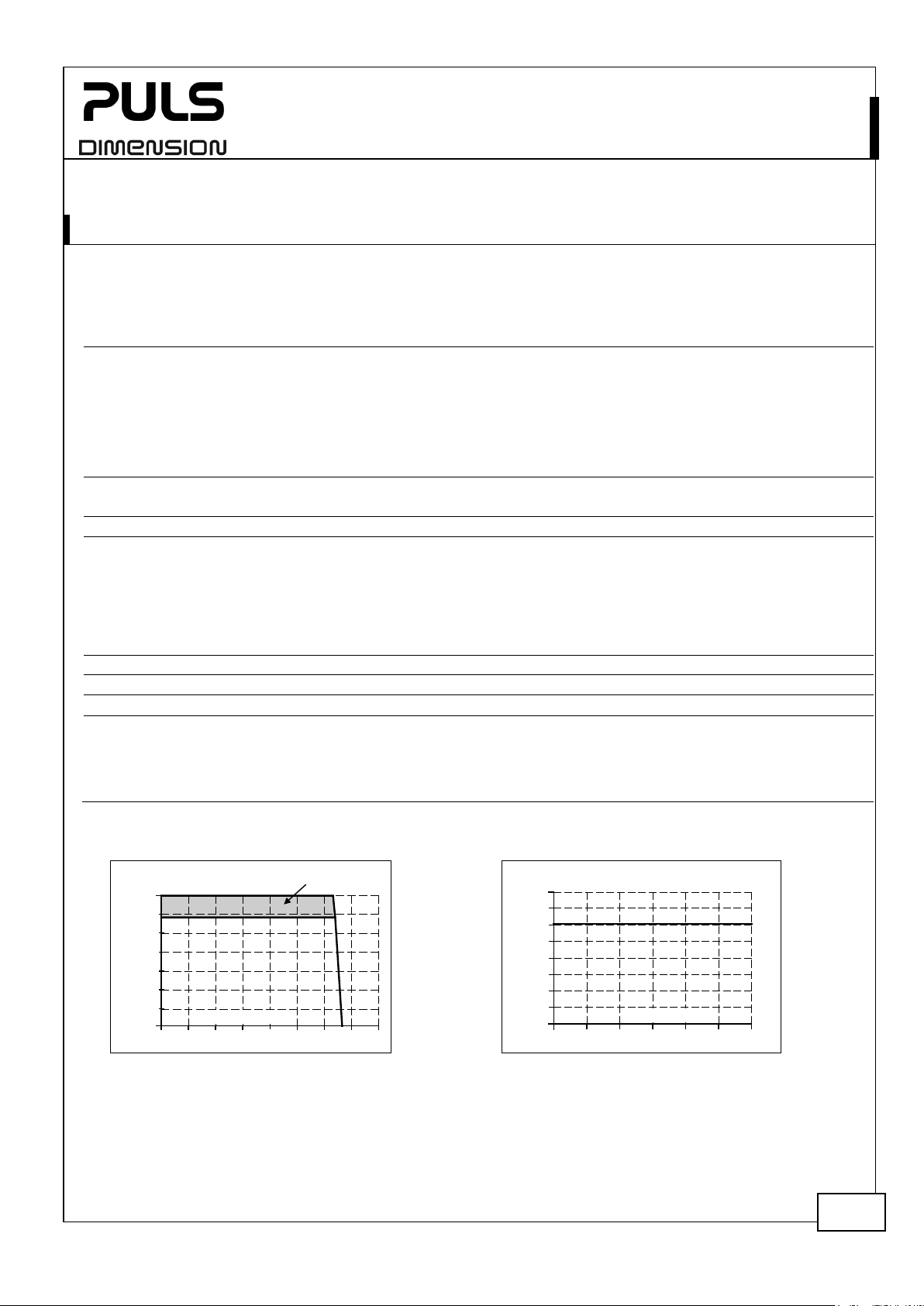

15. E

Operational temperature

Storage temperature

Output de

Humidity

Atmospheric pressure

Altitude

Up to 6000m (20 000ft)

See Fig. 15-2 for details

Degree of pollution

Vibration sinusoidal

Shock

LABS compatibility

Corrosive gases

Audible noi

0

-25 0 20 40

70°C

2A

4A

6A

8A

10A

12A

60

Ambient Temperature

A... Continuous

B... Short term

A

B

Allowed Output Current at 24V

2000m 4000m

6000m

2A

4A

6A

8A

10A

12A

Altitude

Allowed Output Current at 24V

AP

*)

80kPa 62kPa 47kPa110kPa

0m

*) Atmospheric pressure

A... Ambient < 60°C

B... Ambient < 45°C

C... Short term

A

B

C

CD-Series

DC/DC Converter 24V/24V, 10A, 240W

NVIRONMENT

-25°C to +70°C (-13°F to 158°F) The operational temperature is the ambient or

surrounding temperature and is defined as the

air temperature 2cm below the device.

-40°C to +85°C (-40°F to 185°F) For storage and transportation

-rating 3.2W/°C

6W/°C

15W/1000m or 5°C/1000m

9W/-5kPa or 3°C/-5kPa

The de-rating is not hardware controlled. The customer has to take care by himself to

stay below the de-rated current limits in order not to overload the unit.

5 to 95% r.h. According to IEC 60068-2-30

110-47kPa See Fig. 15-2 for details

2 According to IEC 62477-1, not conductive

2-17.8Hz: ±1.6mm; 17.8-500Hz: 2g

2 hours / axis

30g 6ms, 20g 11ms

3 bumps / direction, 18 bumps in total

Shock and vibration is tested in combination with DIN-Rails according to EN 60715 with a

height of 15mm and a thickness of 1.3mm and standard orientation.

As a rule, only non-silicon precipitating materials are used. The unit conforms to the

LABS criteria and is suitable for use in paint shops.

Tested according to ISA-71.04-1985, Severity Level G3 and IEC 60068-2-60 Test Ke

Method 4 for a service life of minimum 10years in these environments.

se Some audible noise may be emitted from the power supply during no load, overload or

short circuit.

Between +45°C and +60°C (113°F to 140°F)

Between +60°C and +70°C (140°F to 158°F)

For altitudes >2000m (6560ft), see Fig. 15-2

For atmospheric pressures <80kPa, see Fig. 15-2

According to IEC 60068-2-6

According to IEC 60068-2-27

Fig. 15-1 Output current vs. ambient temp. Fig. 15-2 Output current vs. altitude at 24V

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

15/27

Page 16

CD10.241

16. S

Isolation resistance

PE resistance

Output over

Class of protection

Degree of protectio

Over

Input transient protection

Internal input fuse

Touch current

17. D

A

C

B

+

Input

Chassis

ground

Output

-

+

-

CD-Series

AFETY AND PROTECTION FEATURES

Min. 500MOhm At delivered condition between input and output,

Min. 500MOhm At delivered condition between input and Chassis

Min. 500MOhm At delivered condition between output and Chassis

Max. 0.1Ohm Resistance between PE terminal and the housing in

-voltage protection Typ. 31Vdc

Max. 32.5Vdc

In case of an internal defect, a redundant circuit limits the maximum

output voltage. The output shuts down and automatically attempts to

restart.

III According to IEC 61140

n IP 20 According to EN/IEC 60529

-temperature protection Not included

MOV (Metal

Oxide Varistor)

Included Not user replaceable slow-blow high-braking

(leakage current) The leakage current, which is produced by the DC/DC converter itself, depends on

the input voltage ripple and need to be investigated in the final application.

For a smooth DC input voltage, the produced leakage current is less than 100µA.

DC/DC Converter 24V/24V, 10A, 240W

measured with 500Vdc

Ground, measured with 500Vdc

Ground, measured with 500Vdc

the area of the DIN-rail mounting bracket.

For protection values see chapter 14 (EMC).

capacity fuse

IELECTRIC STRENGTH

The output voltage is floating and has no ohmic connection to the ground.

The output is insulated to the input by a double or reinforced insulation.

Type and routine tests are conducted by the manufacturer. Field tests may be conducted in the field using the

appropriate test equipment which applies the voltage with a slow ramp (2s up and 2s down). Connect all inputterminals together as well as all output poles before conducting the test. When testing, set the cut-off current settings

to the value in the table below.

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

Fig. 17-1 Dielectric strength

A B C

Type test 60s 1500Vac 1500Vac 500Vac

Routine test 5s 1500Vac 1500Vac 500Vac

Field test 5s 1000Vac 1000Vac 500Vac

Cut-off current setting 40mA 20mA 12mA

It is recommend that either the + pole, the – pole or any other part

of the output circuit shall be connected to the earth/ground system.

This helps to avoid situations in which a load starts unexpectedly or

can not be switched off when unnoticed earth faults occur.

16/27

Page 17

CD10.241

18. A

EC Declaration of Conformity

IEC

2

IEC 61010

2

ANSI/UL

(former UL 508)

EN 60079

ATEX

planned

IEC 60079

planned

IECEx

Marine

planned

EAC TR Registration

19. ROHS, REACH

RoHS Directive

Directive 2011/65/EU of the European Parliament and

REACH Directive

IEC/EN 61558

(Annex BB)

60950-1

nd

Edition

nd

Edition

PPROVALS

-2-201

61010-2-201

-0, EN 60079-7

-0, IEC 60079-7

CD-Series

DC/DC Converter 24V/24V, 10A, 240W

The CE mark indicates conformance with the

- EMC directive and the

- ATEX directive (planned).

CB Scheme,

Information Technology Equipment

CB Scheme for electrical equipment for measurement,

control, and laboratory use - Part 2-201: Particular

requirements for control equipment

Listed as Open Type Device for use in Control Equipment

UL Category NMTR, NMTR7

Ind. Cont. Eq.

3G Ex ec II TX Gc

II

E-File: E198865

Approval for use in hazardous locations Zone 2 Category 3G.

Number of ATEX certificate: T.B.D.

Suitable for use in Class 1 Zone 2 Groups IIa, IIb and IIc

locations. Number of IECEx certificate: T.B.D.

GL (Germanischer Lloyd) classified

Environmental category: C, EMC2

Marine and offshore applications

Registration for the Eurasian Customs Union market

(Russia, Kazakhstan, Belarus)

AND OTHER FULFILLED STANDARDS

Directive 1907/2006/EU of the European Parliament

-2-16

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

Safety Isolating Transformer

the Council of June 8th, 2011 on the restriction of the

use of certain hazardous substances in electrical and

electronic equipment.

and the Council of June 1

Registration, Evaluation, Authorisation and Restriction

of Chemicals (REACH)

Safety Isolating Transformers corresponding to Part 2-6

of the IEC/EN 61558

st

, 2007 regarding the

17/27

Page 18

CD10.241

20. P

Width

Height

Depth

Weight

DIN

Housing material

Installation

Penetration protection

CD-Series

DC/DC Converter 24V/24V, 10A, 240W

HYSICAL DIMENSIONS AND WEIGHT

42mm 1.65’’

124mm 4.88’’

117mm 4.61’’

The DIN-rail height must be added to the unit depth to calculate the total required

installation depth.

500g / 1.10lb

-Rail Use 35mm DIN-rails according to EN 60715 or EN 50022 with a height of 7.5 or 15mm.

Body: Aluminium alloy

Cover: zinc-plated steel

clearances See chapter 2

Small parts like screws, nuts, etc. with a diameter larger than 3.5mm

Fig. 20-1 Front view Fig. 20-2 Side view

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

All dimensions in mm

All dimensions in mm

18/27

Page 19

CD10.241

21. A

CD-Series

DC/DC Converter 24V/24V, 10A, 240W

CCESSORIES

21.1. ZM2.WALL – WALL/PANEL MOUNT BRACKET

These brackets are used to mount the device on a flat surface or panel without utilizing a DIN-rail. The brackets can be

mounted without detaching the DIN-rail brackets.

The order number ZM2.WALL contains two brackets needed for one device.

Fig. 1-1 ZM2.Wall Fig. 1-2 Hole pattern Fig. 1-3 Side view

All dimensions in mm

Fig. 1-4 Isometric view Fig. 1-5 Isometric view Fig. 1-6 Isometric view

All dimensions in mm

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

19/27

Page 20

CD10.241

CD-Series

DC/DC Converter 24V/24V, 10A, 240W

21.2. ZM12.SIDE - SIDE MOUNT BRACKET

This ZM12.SIDE bracket is used to mount the device sideways with or without utilizing a DIN-rail to

save installation depth.

The two aluminum brackets and the black plastic slider of the unit have to be detached, so that the

ZM12.SIDE steel bracket can be mounted.

For sideway DIN-rail mounting, the removed aluminum brackets and the black plastic slider need to be

mounted on the ZM12.SIDE steel bracket.

ig. 2-7

F

Side mounting

without DIN-rail brackets

with DIN-rail brackets

ig. 2-8

F

Side mounting

ig. 2-9

F

Hole pattern

All dimensions in mm

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

20/27

Page 21

CD10.241

CD-Series

DC/DC Converter 24V/24V, 10A, 240W

21.3. YRM2.DIODE - REDUNDANCY MODULE

The YRM2.DIODE is a dual redundancy module, which can be used to build 1+1 or N+1

redundant systems.

The device is equipped with two input channels each 10A nominal, which are individually

decoupled by utilizing diode technology. The output can be loaded with nominal 20A.

The device does not require an additional auxiliary voltage and is self-powered even in case

of a short circuit across the output.

The device has a monitoring circuit included and is the perfect choice when the power supply

has no DC-OK function. Two LEDs and two relay contacts signal when one of the two input

voltages is not in range due to a non-functioning or disconnected power supply.

The unit is very slender and only requires 32mm width on the DIN-rail.

See chapter 22.6 for wiring information.

21.4. UF20.241 - BUFFER MODULE

The UF20.241 buffer module is a supplementary device for 24V DC/DC converters. It delivers

power to bridge typical supply voltage faults or extends the hold-up time after turn-off of

the input power.

In times when the DC/DC converter provides sufficient voltages, the buffer module stores

energy in integrated electrolytic capacitors. In case of a supply voltage fault, this energy is

released again in a regulated process.

The buffer module does not require any control wiring. It can be added in parallel to the load

circuit at any given point.

One buffer module can deliver 20A additional current. Buffer modules can be added in

parallel to increase the output ampacity or the hold-up time.

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

21/27

Page 22

CD10.241

22. A

Peak current voltage dips

typ.

from 24V to 16V

at 20A for 50ms, resistive load

CD-Series

DC/DC Converter 24V/24V, 10A, 240W

PPLICATION NOTES

22.1. PEAK CURRENT CAPABILITY

The unit can deliver peak currents (up to several milliseconds) which are higher than the specified short term currents.

This helps to start current demanding loads. Solenoids, contactors and pneumatic modules often have a steady state

coil and a pick-up coil. The inrush current demand of the pick-up coil is several times higher than the steady-state

current and usually exceeds the nominal output current. The same situation applies when starting a capacitive load.

The peak current capability also ensures the safe operation of subsequent circuit breakers of load circuits. The load

branches are often individually protected with circuit breakers or fuses. In case of a short or an overload in one branch

circuit, the fuse or circuit breaker need a certain amount of over-current to open in a timely manner. This avoids

voltage loss in adjacent circuits.

The extra current (peak current) is supplied by the power converter and the built-in large sized output capacitors of

the power supply. The capacitors get discharged during such an event, which causes a voltage dip on the output. The

following two examples show typical voltage dips:

Fig. 22-1 Peak loading with 2x the nominal current

for 50ms, typ.

Fig. 22-2 Peak loading with 4x the nominal current

for 5ms, typ.

Peak load 20A (resistive load) for 50ms

Output voltage dips from 24V to 16V.

typ. from 24V to 12V at 40A for 2ms, resistive load

typ. from 24V to 6V at 40A for 5ms, resistive load

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

Peak load 40A (resistive load) for 5ms

Output voltage dips from 24V to 6V.

22/27

Page 23

CD10.241

MCB

DC/DC

Converter

DC

DC

+

-

+

-

Load

Wire length

S1... Fault simulation switch

S1

C

C-3A

C

C

B

B

B

CD-Series

DC/DC Converter 24V/24V, 10A, 240W

22.2. OUTPUT CIRCUIT BREAKERS

Standard miniature circuit breakers (MCB’s or UL 1077 circuit breakers) are commonly used for AC-supply systems and

may also be used on 24V branches.

MCB’s are designed to protect wires and circuits. If the ampere value and the characteristics of the MCB are adapted to

the wire size that is used, the wiring is considered as thermally safe regardless of whether the MCB opens or not.

To avoid voltage dips and under-voltage situations in adjacent 24V branches which are supplied by the same source, a

fast (magnetic) tripping of the MCB is desired. A quick shutdown within 10ms is necessary corresponding roughly to

the ride-through time of PLC's. This requires power supplies with high current reserves and large output capacitors.

Furthermore, the impedance of the faulty branch must be sufficiently small in order for the current to actually flow.

The best current reserve in the power supply does not help if Ohm’s law does not permit current flow. The following

table has typical test results showing which B- and C-Characteristic MCBs magnetically trip depending on the wire cross

section and wire length.

The following test results indicate the maximal wire length for a magnetic (fast) tripping. The wire length is always

two times the distance to the load (+ and - wire).

Fig. 22-3 Test circuit for maximum wire length

Test results for maximum wire length:

0.75mm² 1.0mm² 1.5mm² 2.5mm²

-2A 23m 25m 41m 71m

13m 15m 23m 33m

-4A 4m 6m 8m 13m

-6A

-6A

-10A

-13A 1m 2m 3m

1m 2m 2m 5m

8m 10m 14m 23m

1m 2m 2m 3m

22.3. CHARGING OF BATTERIES

The device can be used to charge lead-acid or maintenance free batteries. Two 12V SLA or VLRA batteries are needed

in series connection.

Instructions for charging batteries:

a) Ensure that the ambient temperature of the Device is below 45°C.

b) Set output voltage, measured at no load and at the battery end of the cable, very precisely to the end-of-charge

voltage.

End-of-charge voltage 27.8V 27.5V 27.15V 26.8V

Battery temperature 10°C 20°C 30°C 40°C

c) Use a 16A circuit breaker or blocking diode between the Device and the battery.

d) Ensure that the output current of the Device is below the allowed charging current of the battery.

e) Use only matched batteries when putting 12V types in series.

f) The return current to the Device (battery discharge current) is typ. 10mA when the Device is switched off except

in case a blocking diode is utilized.

g) Do not use the devices for battery charging in mounting orientations other than the standard mounting

orientation or in any other condition where a reduction of the output current is required (e.g. altitude).

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

23/27

Page 24

CD10.241

Unit A

Input

Output

Unit B

-

+

-

+

+

-

Input

Output

Load

Unit A

Input

Output

Unit B

-

+

-

+

+

-

Input

Output

Load

CD-Series

DC/DC Converter 24V/24V, 10A, 240W

22.4. SERIES OPERATION

Devices of the same type can be connected in series for higher output voltages.

It is possible to connect as many units in series as needed, providing the sum of

the output voltage does not exceed 150Vdc. Voltages with a potential above

60Vdc must be installed with a protection against touching.

Avoid return voltage (e.g. from a decelerating motor or battery) which is

applied to the output terminals.

Keep an installation clearance of 15mm (left / right) between two power

supplies and avoid installing the power supplies on top of each other. Do not

use power supplies in series in mounting orientations other than the standard

mounting orientation.

Pay attention that EMI and inrush current will increase when using multiple devices.

22.5. PARALLEL USE TO INCREASE OUTPUT POWER

Devises can be paralleled to increase the output power. The output voltage shall

be adjusted to the same value (±100mV) with the same load conditions on all

devices, or the devices can be left with the factory settings.

The ambient temperature is not allowed to exceed +45°C.

If more than three devices are connected in parallel, a fuse or circuit breaker

with a rating of 15A or 16A is required on each output. Alternatively, a diode or

redundancy module can also be utilized.

Keep an installation clearance of 15mm (left / right) between two devices and

avoid installing devices on top of each other. Do not use devices in parallel in

mounting orientations other than the standard mounting orientation or in any other condition where a reduction of

the output current is required (e.g. altitude).

Pay attention that EMI and inrush current will increase when using multiple devices.

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

24/27

Page 25

CD10.241

Failure

Monitor

I

I

optional

YRM2.DIODE

Redundancy

Module

Output

Input

1

Input

2

+

-

+

-

+

-

o o

o

o

2

1

Input ok

YRM2.DIODE

Redundancy

Module

Output

Input

1

Input

2

+

-

+

-

+

-

o o o

o

2

1

Input ok

Load

Functional Earth

+

-

DC/DC

Converter

+ +

- -

+

-

Output

Input

DC/DC

Converter

+ +

- -

+

-

Output

Input

Failure

Monitor

I

optional

YRM2.DIODE

Redundancy

Module

Output

Input

1

Input

2

+-+

-

+

-

o o o o

2

1

Input ok

YRM2.DIODE

Redundancy

Module

Output

Input

1

Input

2

+-+

-

+

-

o o o

o

2

1

Input ok

Load

I

optional

YRM2.DIODE

Redundancy

Module

Output

Input

1

Input

2

+

-+-

+

-

o o o o

2

1

Input ok

I

optional

YRM2.DIODE

Redundancy

Module

Output

Input

1

Input

2

+-+

-

+

-

o o o o

2

1

Input ok

I

DC/DC

Converter

+ +

- -

+

-

Output

Input

DC/DC

Converter

+ +

- -

+

-

Output

Input

DC/DC

Converter

+ +

- -

+

-

Output

Input

DC/DC

Converter

+ +

- -

+

-

Output

Input

Functional Earth

+

-

optional

CD-Series

DC/DC Converter 24V/24V, 10A, 240W

22.6. PARALLEL USE FOR REDUNDANCY

1+1 Redundancy:

Devices can be paralleled for redundancy to gain higher system availability. Redundant systems require a certain

amount of extra power to support the load in case one device fails. The simplest way is to put two devices in parallel.

This is called a 1+1 redundancy. In case one device fails, the other one is automatically able to support the load current

without any interruption. It is essential to use a redundancy module to decouple devices from each other. This

prevents that the defective unit becomes a load for the other device and the output voltage cannot be maintained any

more.

1+1 redundancy allows ambient temperatures up to +70°C.

Pay attention that EMI and inrush current will increase when using multiple devices.

Recommendations for building redundant power systems:

- Use separate input fuses for each device.

- Use separate supply systems for each device whenever it is possible.

- Monitor the outputs of the individual devices. Use the DC-ok lamp or the Redundancy-ok contact, which is included

in the YR20.246 redundancy module.

- It is desirable to set the output voltages of all devices to the same value (± 100mV) or leave it at the factory setting.

N+1 Redundancy:

Redundant systems for a higher power demand are usually built in a N+1 method. E.g. four devices, each rated for 10A

are paralleled to build a 30A redundant system.

Pay attention that EMI and inrush current will increase when using multiple devices.

Keep an installation clearance of 15mm (left / right) between two devices and avoid installing the devices on top of

each other.

Do not use devices in parallel in mounting orientations other than the standard mounting orientation or in any other

condition, where a reduction of the output current is required.

For N+1 redundancy the ambient temperature is not allowed to exceed +45°C.

Wiring examples for 1+1 and n+1 redundancy:

Fig. 22-4 1+1 Redundant configuration for 10A

load current

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

Fig. 22-5 N+1 Redundant configuration for 30A load current

with multiple DC/DC converters and redundancy modules

25/27

Page 26

CD10.241

Enclosure size

Input voltage

Load

Tem

Temperature outside the box

Temperature rise

CD-Series

DC/DC Converter 24V/24V, 10A, 240W

22.7. USE IN A TIGHTLY SEALED ENCLOSURE

When the device is installed in a tightly sealed enclosure, the temperature inside the enclosure will be higher than

outside. In such situations, the inside temperature defines the ambient temperature for the device.

In the following test setup, the device is placed in the middle of the enclosure; no other heat producing items are

inside the enclosure. The load is placed outside the enclosure.

The temperature sensor inside the enclosure is placed in the middle of the right side of the device with a distance of

1cm.

The following measurement results can be used as a reference to estimate the temperature rise inside the enclosure.

Case A Case B

110x180x165mm

Rittal Typ IP66 Box

PK 9516 100,

plastic

24Vdc 24Vdc

perature inside the box 52.2°C 59.3°C

21.2K 27.9K

24V, 8A; (=80%) 24V, 10A; (=100%)

31.0°C 31.4°C

110x180x165mm

Rittal Typ IP66 Box

PK 9516 100,

plastic

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

26/27

Page 27

CD10.241

Allowed Output Current at 24V

0

+45 +70°C

7.5A

10A

12A

Ambient Temperature

+60

Converter

Allowed Output Current at 24V

0

+30 +70°C

7.5A

12A

Ambient Temperature

+60

Allowed Output Current at 24V

0

+25 +70°C

6.5A

12A

Ambient Temperature

+60

Allowed Output Current at 24V

0

+25 +70°C

6.5A

12A

Ambient Temperature

+60

Converter

Allowed Output Current at 24V

0

+25 +70°C

6.5A

12A

Ambient Temperature

+60

CD-Series

DC/DC Converter 24V/24V, 10A, 240W

22.8. MOUNTING ORIENTATIONS

Mounting orientations other than input terminals on the bottom and output on the top require a reduction in

continuous output power or a limitation in the maximum allowed ambient temperature.

The listed lifetime and MTBF values from this datasheet apply only for the standard mounting orientation.

The following curves give an indication for allowed output currents for altitudes up to 2000m (6560ft).

Fig. 22-6

Mounting

Orientation A

(Standard

orientation)

Fig. 22-7

Mounting

Orientation B

(Upside down)

OUTPUT

DC/DC

Converter

INPUT

INPUT

DC/DC

Fig. 22-8

Mounting

Orientation C

(Table-top

mounting)

Fig. 22-9

Mounting

Orientation D

(Horizontal cw)

Fig. 22-10

Mounting

Orientation E

(Horizontal ccw)

INPUT

OUTPUT

Converter

OUTPUT

DC/DC

DC/DC

OUTPUT

INPUT

Sep. 2019 / Rev. 1.4 DS-CD10.241-EN All values are typical figures specified at 24Vdc input voltage 24V, 10A output load,

25°C ambient and after a 5 minutes run-in time unless otherwise noted.

27/27

Loading...

Loading...