TM-6703

Progressive Scan Double Speed Shutter Camera

Operation Manual

69-0061

Rev. A

Notice

The material contained in this manual consists of information that is proprietary to PULNiX America, Inc., and may only

be used by the purchasers of the product. PULNiX America, Inc. makes no warranty for the use of its product and assumes

no responsibility for any errors which may appear or for damages resulting from the use of the information contained

herein. PULNiX America, Inc. reserves the right to make changes without notice.

Warranty

All of our solid state cameras have a full three-year warranty. If any such product proves defective during this warranty

period, PULNiX America, Inc. will repair the defective product without charge for parts and labor or will provide a

replacement in exchange for the defective product. This warranty shall not apply to any damage, defect or failure caused

by improper use or inadequate maintenance and use.

Certifications

CE Compliance

The TM-6703 has been certified to conform to the requirements of Council Directive 89/336/EC for electromagnetic

compatibility and to comply with the following European Standards:

Immunity: EN500082-2/1995

Emissions: EN55022:1995 Class A / CISPR 22:1993

All PULNiX products bearing the CE mark have been declared to be in conformance with the applicable EEC Council

Directives. However, certain factory installed options or customer requested modifications may compromise

electromagnetic compatibility and prohibit use of the CE mark. Please note that the use of interconnect cables that are not

properly grounded and shielded may affect CE compliance.

Contact the PULNiX Applications Engineering Department for further information regarding CE compliance.

FCC

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

ARNING

W

Changes or modifications to this unit not expressly approved by the party responsible

for FCC compliance could void the user’s authority to operate the equipment.

TM-6703 Operation Manual

Printing:April 26, 1999

PULNiX America, Inc.

1330 Orleans Drive

Sunnyvale, CA 94089

Tel: (408) 747-0300

Tel: (800) 445-5444

Fax: (408) 747-0880

E-mail: imaging@jaipulnix.com

www.pulnix.com

Table of Contents

1 INTRODUCTION .................................................................... 1

1.1 Product Description .......................................................................... 1

1.2 Features ........................................................................................... 1

1.3 Functional Options ........................................................................... 3

2 INSTALLATION ..................................................................... 4

2.1 Getting Started ................................................................................. 4

2.1.1 Unpacking Instructions ........................................................ 4

2.1.2 Components List ................................................................. 4

2.1.3 Accessories ......................................................................... 4

2.2 Camera Setup .................................................................................. 5

2.2.1 Connector Pin Configurations ............................................. 5

2.2.2 Rear Panel .......................................................................... 5

2.2.3 Power Supply and Power Cable Setup ................................ 5

2.2.4 Attaching the Video Output ................................................. 7

2.2.5 Attaching the Camera Lens ................................................. 7

2.2.6 Back Focusing the Lens ...................................................... 7

2.2.7 Auto Iris Lens Setup ............................................................ 8

2.2.8 Non-Interlace Black & White Monitors ................................. 8

3 OPERATION .......................................................................... 9

3.1 Modes of Operation .......................................................................... 9

3.1.1 Asynchronous Reset Mode ................................................. 9

3.1.2 Driving /VINIT ...................................................................... 10

3.1.3 Shutter Control Switch ........................................................ 11

3.1.4 Progressive Scanning ......................................................... 14

3.1.5 Option 7-2 ........................................................................... 15

3.1.6 V-Sync Output Selection for Async Mode (OP51-2) ............ 15

3.1.7 Integration ........................................................................... 16

3.1.8 External Input Signals ......................................................... 16

3.2 Board Layout and Adjustment .......................................................... 17

3.2.1 Top Board (Top Side) .......................................................... 17

3.2.2 Bottom Board (Bottom Side) ............................................... 17

4 TROUBLESHOOTING ........................................................... 18

4.1 Problems and Solutions ................................................................... 18

4.1.1 Symptom: No Video ............................................................. 18

4.1.2 Symptom: Dark Video .......................................................... 18

4.1.3 Symptom: Non-synchronized Video .................................... 18

4.2 Information and Support Resources ................................................ 19

i

Table of Contents

5 APPENDIX .............................................................................20

5.1 Specifications ...................................................................................20

5.1.1 Product Specifications ......................................................... 20

5.1.2 Physical Dimensions ............................................................21

5.1.3 Glass Specifications ............................................................22

5.1.4 C-Mount Specifications ........................................................ 22

5.1.5 Front End Detail ................................................................... 23

5.2 Spectral Response ........................................................................... 24

5.3 Block Diagram .................................................................................. 24

5.4 Timing Chart ..................................................................................... 25

5.4.1 Pixel Mapping (Horizontal) ...................................................25

5.4.2 Vertical Frame Output Timing ..............................................25

ii

List of Figures

FIGURE 1. TM-6703 System Configuration .................................................3

FIGURE 2. 12P-02 Interface Cable (optional) ..............................................6

FIGURE 3. Asynchronous Reset .................................................................. 9

FIGURE 4. VINIT (Vertical Initialization) Trigger Specifications .................... 10

FIGURE 5. Equivalent Circuit .......................................................................10

FIGURE 6. External Pulse Width Control (Async Mode) .............................. 12

FIGURE 7. Internal Fast Reset .....................................................................12

FIGURE 8. Internal Slow Reset .................................................................... 13

FIGURE 9. Scan Output ...............................................................................15

FIGURE 10. I/O Jumpers ................................................................................ 15

FIGURE 11. Integration Timing ....................................................................... 16

FIGURE 12. Internal Input Signals .................................................................16

FIGURE 13. Physical Dimensions .................................................................. 21

FIGURE 14. Camera Front End - Glass Specifications .................................. 22

FIGURE 15. Combination With “CS-Mount” Camera ...................................... 23

FIGURE 16. TM-6703 Imager Location .......................................................... 23

FIGURE 17. Spectral Response .....................................................................24

FIGURE 18. TM-6703 Block Diagram .............................................................24

FIGURE 19. Pixel Mapping (Horizontal) ......................................................... 25

FIGURE 20. Vertical Frame Output Timing ..................................................... 25

iii

April 22, 1999

TM-6703 Progressive Scan

Double Speed Shutter Camera

Operation Manual

1 INTRODUCTION

1.1 Product Description

The TM-6703 is a high resolution monochrome camera with three scanning modes: Non-interlace

double speed scanning VGA format (60Hz); two-row scanning (120Hz); and partial scanning (100 and

200 lines). Features include compact size, rugged construction, double speed scan, asynchronous reset

and electronic shutter, non-interlace 60Hz analog video (VGA), and partial scanning. The double speed

mode is standard, thus the images can be displayed on a standard VGA monitor.

Applications include high speed image capturing, machine vision, computer graphics, gauging,

avionics, microscopy, character and fine pattern recognition, document reading and high end

surveillance.

1.2 Features

1/2" progressive scan interline transfer CCD

•

Advantages include:

-

-

-

-

-

-

-

648H x 484V active pixels for very high resolution and superior image quality

Square pixels (9.0 x 9.0 µ m) for precise dimensional measurements

Double speed scanning

Partial scan capability allows 120Hz two-row scanning (combining two lines), 100 and 200 lines

of partial scan as well as 60Hz frame scanning. All images are centered in the video frame

High speed electronic shutter capability results in high dynamic resolution of moving objects

Progressive scanning eliminates interlace image deterioration

High sensitivity and low noise at fast scanning, excellent S/N ratio (>50db)

Page 1

INTRODUCTION

•

Asynchronous reset

The TM-6703 resets with an external reset pulse (VINIT). This feature is especially important for

capturing moving objects at a precise location in the field of view, for applications such as a

conveyer belt process, fast event observation, and still picture capturing.

Integration

•

The TM-6703 is capable of capturing high resolution integration images. Integration can last from

1/60 sec. to several seconds.

VGA display output

•

The TM-6703’s VGA output scans out at 60Hz non-interlace. Because the double speed mode is

standard, images can be displayed on a standard VGA monitor. PULNiX PVM-1200 series

monitors or equivalent B/W multi-sync monitors can be used to display non-interlace images.

Please contact your PULNiX representative for display monitor information.

•

Sync input (external sync) or output (clock and sync) selection (optional, OP7-2))

Rear board jumpers enable sync input/output selection. When the jumpers are set to internal sync,

the camera accepts HD and VD sync and video output from pin #4 of the 12-pin connector. If the

jumpers are set to OP7-2, then HD, VD and clock output are provided for a frame grabber to take

the data.

•

“One shot sync” (optional, OP51-2)

The composite sync of the video output can be selectable with the rear panel jumper (resistor

location). Continuous V-sync mode outputs the V-sync at all times regardless of async reset or

normal rate V-sync during async mode stand-by. Async V-sync mode outputs the V-sync once only

at async reset (at Vinit trigger) and no V-sync during the stand-by period (H-sync only in video

composite sync) until the next Vinit comes in. These modes can be selected based on a frame

grabber’s sync capability for async reset.

Three-Year Warranty

•

The CCD solid state image sensor allows the camera to maintain a superior performance level

indefinitely while requiring virtually no maintenance. PULNiX backs all of the TM Series cameras

with a three-year warranty.

WARNING: Unscrewing the camera cover or opening the camera in any way

Page 2 TM-6703 Progressive Scan Double Speed Shutter Camera

will void this warranty.

INTRODUCTION

1.3 Functional Options

•

Optical Filter Removal (OP3-2)

Glassless CCD Imager (OP21)

•

•

Internal IR Filter (OP3-1)

Pixel Clock, HD, and VD output (OP7-2)

•

•

One Shot Sync (OP51-2)

Remote Head (OP10-1)

•

FIGURE 1.

TM-6703 System Configuration

Power

External Sync

VIDEO

SHUTTER

0

9

8

7

6

5

N

ASY

P

MANOT

GAIN

1

2

3

4

POWER

Integration

Video Output*

Computer with

Frame Grabber

Board

PULNiX Multi-Sync

Monitor

(PVM-1242 or PVM-942)

* Video Output is the

same as BNC connector

(if required)

Note: Additional cable interface may be required from the frame grabber board manufacturer.

TM-6703 Progressive Scan Double Speed Shutter Camera Page 3

2 INSTALLATION

The following instructions are provided to help you to set up your video camera system quickly and

easily. It is suggested that you read through these instructions prior to unpacking and setting up your

camera system.

2.1 Getting Started

2.1.1 Unpacking Instructions

It is recommended that the original packing cartons for the cameras and lenses be saved in case there is

a need to return or exchange an item.

INSTALLATION

It is also recommended that any equipment being sent to another location for field installation be bench

tested to assure that everything is fully operational as a system.

2.1.2 Components List

Please begin by checking your order against the Components List (below) to assure that you have

received everything as ordered, and that nothing has been overlooked in the packing materials. If any

item is missing, please contact your PULNiX representative immediately.

•

TM-6703 camera

TM-6703 data sheet

•

•

TM-6703 manual (by request)

2.1.3 Accessories

Following is a list of additional accessories or equipment that may be recommended or required for your

particular application. Please check with your PULNiX representative prior to the installation of your

video system to determine what you might need.

•

Cable (power/video) 12P-02

PVM-1242 or PVM-942 multi sync monitor

•

•

Power supply PD-12P

Page 4 TM-6703 Progressive Scan Double Speed Shutter Camera

INSTALLATION

2.2 Camera Setup

2.2.1 Connector Pin Configurations

2.2.1 (a) 12-Pin Connector

The TM-6703 has a 12-pin connector for power input.

Pin# Description Pin# Description

1 GND 7 V

D

in (out OP7-2)

2 +12V DC 8 GND

in (out OP7-2)

3 GND 9 H

D

4 Video Out (clk out OP7-2) 10 N/C

5 GND 11 Integration

6 VINIT In 12 GND

2.2.2 Rear Panel

Functions and controls located on the camera rear panel:

12-pin connector (power, I/Os)

•

•

BNC video cable connector

Shutter speed selection dial

•

•

ASY/MAN switch (asynchronous shutter and manual shutter switch)

N/P and O/T switches (scanning mode selection)

•

•

Manual gain control adjustment

1

2

3

11

4

VIDEO

SHUTTER

0

9

8

7

6

5

N

ASY

P

MANOT

GAIN

1

2

3

4

POWER

Rear Panel

9

8

10

7

12

6

5

2.2.3 Power Supply and Power Cable Setup

2.2.3 (a) Power Supplies

PULNiX recommends the following power supplies:

K25-12 110V AC/12V DC 2.1A power supply

P-15-12 220V AC/12V DC 2.1A power supply

K50-12 110V AC/12V DC 4.2A power supply

PD-12P 110V AC/12V DC 0.5A power supply

For users providing power through the 12-pin connector, the PD-12P power supply is available with the

12-pin mating connector already attached to the leads from the power supply. The PD-12 power supply

can be connected to the PULNiX power cable via a terminal strip or directly.

TM-6703 Progressive Scan Double Speed Shutter Camera Page 5

If wiring the PD-12 power supply directly, please note the following

•

Twist the lead ends together and tin solder for strength and electrical continuity

• Use shrink tubing or a similar insulator to prevent exposed leads from touching

• The +12V lead is marked with a red stripe or white lettering; be sure not to reverse the leads

• Properly insulate all connections to prevent shorting

2.2.3 (b) Using PULNiX Power/Video Cables

If you are using PULNiX power cables, such as the 12P-02, KC-10, etc., please refer to the pin-out

diagram. The color coded leads use Grey for Ground and Yellow for +12V DC.

FIGURE 2. 12P-02 Interface Cable (optional)

INSTALLATION

1

2,000mm± 10mm

(2 Meters)

PC-12P (Hirose Part #10A-10P-12S/PC12P)

1

12P-02 Interface Cable

Pin# Lead Color Function Pin# Lead Color Function

1 Gray GND 7 Black coax VD Input

2 Yellow +12VCD 8 White coax shield GND

3 Red coax shield GND 9 White coax HD Input

4 Red coax Video 10 Brown N/C

5 Orange coax shield GND 11 Blue Integration

6 Orange coax N/C 12 Black coax shield N/C

Flying

Leads

32mm

Note: Make sure that the unused leads are not touching and that there is no possibility that the

leads could short due to exposed wires.

2.2.3 (c) Using the “K” Series Power Supplies

Attach the 110V line cord to the two terminals marked “AC”. Do not plug the cord into a 110V AC

socket until later in the procedure. Next, attach the Grey and Yellow leads of the power cable to the

Ground and 12V DC terminals respectively. Be sure to replace the plastic terminal guard on the power

supply at this time.

Page 6 TM-6703 Progressive Scan Double Speed Shutter Camera

INSTALLATION

Note: The “K” series power supplies are designed primarily for OEM users who will be

mounting the power supply inside a protective enclosure. For use in exposed situations,

the DC-12N and PD-12 are recommended.

2.2.3 (d) Building Your Own Power Cables

If you are building your own power cables, consult the pin-out for the camera purchased and connect the

Ground and +12V power leads of the PC-12P power connector to Pin #1 and Pin #2, respectively

(power must be DC regulated, and of sufficient current to properly power the camera).

2.2.3 (e) Attaching the Power Cable to the Connector

The 12-pin connector is keyed and will only fit in one orientation. Rotate the connector while applying

slight pressure until the keyways line up. Press the connector into place until firmly seated.

The power cord may now be plugged into the 100V AC socket, and the camera powered up.

2.2.4 Attaching the Video Output

Most users utilize the BNC connector for video output from the camera. Connect the output from the

camera to the input of your monitor, VCR or switching device. The input of the monitor should be

balanced for 75Ω termination. Standard RG-59 type coaxial cable should carry a full video signal for up

to 500 feet.

Users wishing to output the video and input the power and sync to a camera over a single cable can use

the PULNiX multi-conductor cables, such as the 12P-02, the KC-10, etc. The mini coaxial leads in

PULNiX multi-conductor cables are designed for short runs of no longer than 100 feet.

Note: Make sure that no extraneous wires are visible which could cause a short.

2.2.5 Attaching the Camera Lens

The TM-6703 camera accepts standard C-mount lenses. To attach the C-mount lens to the camera,

carefully engage the threads and rotate the lens clockwise until it firmly seats on the mounting ring. Do

not force the lens if it does not seat properly. Please note that some lenses with extremely long

flangebacks may exceed the mounting depth of the camera.

2.2.6 Back Focusing the Lens

To backfocus the TM-6703 camera, first attach a C-mount lens in the lens mount. Be sure that the lens is

properly mounted.

Set the lens focus to infinity (if the lens is a manual iris, set the iris to a high f-stop while still retaining a

well-illuminated image). Obtain the best focus possible at this setting, then loosen the two miniature hex

head set screws (hex socket size: 0.89mm) locking the focus ring in place. Now turn the entire lens and

focus ring assembly back and forth until the best image is obtained. Tighten the focus ring set screws.

Your backfocus is now set.

TM-6703 Progressive Scan Double Speed Shutter Camera Page 7

INSTALLATION

2.2.7 Auto Iris Lens Setup

Auto-iris lenses with full video input (1 Vpp) can be used with the PULNiX TM-6703, although this

camera model does not come equipped with auto-iris output.

Note: Make sure that the power is removed from the camera before connecting or disconnecting

the auto-iris lens. There is a small chance that damage could occur to the auto-iris lens by

plugging or unplugging it while the camera is powered up.

To install the auto-iris lens in a PULNiX camera for which the auto-iris output is not supplied, wire the

signal (video) on the lens into the terminal 1 Vp to peak video output on the camera (pin 4 of 12 pin

connector).

Point the camera at a light area and then quickly towards a darker area. If everything is working

properly, the iris should adjust for the light change.

2.2.8 Non-Interlace Black & White Monitors

The PULNiX PVM-942 / 1242 non-interlace black and white monitor, or an equivalent model, can be

used to display the TM-6703’s various display modes. In standard operation, including RS-170

interlace, 60 Hz non-interlace, 30 Hz non-interlace and 120 Hz non-interlace (two-row scanning mode),

the display is normal. In the partial scanning mode, the vertical extends to fill the monitor screen and the

images will be distorted vertically.

Page 8 TM-6703 Progressive Scan Double Speed Shutter Camera

OPERATION

3 OPERATION

3.1 Modes of Operation

The TM-6703 is designed to accommodate a high resolution, on-line inspection reset mechanism with

full frame shutter. It accepts external horizontal sync (HD, TTL Levels) to lock the camera and VINIT

pulse for resetting the camera asynchronously. The shutter speed can be controlled by either an external

double pulse, or by internal speed control by setting the 10-position shutter speed dial switch on the

back panel.

3.1.1 Asynchronous Reset Mode

For the asynchronous reset mode, select ASY on the back panel of the camera.

The TM-6703's asynchronous reset is flexible. External HD can be applied for phase locking if required.

Applying a VINIT pulse resets the camera's scanning and purging of the CCD. Do not supply VD if the

asynchronous reset is used. Instead, use HD to synchronize the camera to the external device.

When external VINIT is high (5V), the TM-6703 expects the async pulse input and the video output will

be black video. It resets at the negative going pulse edge and captures the frame regardless of the shutter

speed (fast or slow mode). The video output is kept disabled as the CCD is discharged continuously

during VINIT high. When the first VINIT pulse comes in, it resets the timing and outputs the image. If

the switch is set to NRM (normal mode), the video output will be real time with manual shutter.

FIGURE 3. Asynchronous Reset

EXTERNAL VINIT

INTERNAL VD

SG (TRANSFER GATE)

DISCHARGE PULSES

VIDEO

ASYNC RESET

NON-INTERLACE OUTPUT

SHUTTER

VIDEO

TM-6703 Progressive Scan Double Speed Shutter Camera Page 9

3.1.2 Driving /VINIT

The TM-6703 VINIT input circuit equivalently has 10K ohm input resistance (Figure 4, “VINIT

(Vertical Initialization) Trigger Specifications,” on page 10). To drive this circuit, at least 0.5mA of

current is required to drive the camera.

Note: The VINIT signal must be a defined, clean pulse for the asynchronous reset function to

work properly. Some triggering systems (e.g., optical isolators, mechanical relays, noisy

electrical devices, etc.) have bounce or rapid transition between high and low states. It is

highly recommended that the input VINIT pulse be analyzed by test equipment to ensure

proper signal characteristics. If an unspecified signal is used, improper camera

performance may result.

FIGURE 4. VINIT (Vertical Initialization) Trigger Specifications

+5V

OPERATION

TTL

Level

0 V

Note: PULNiX does not recommend voltage levels less than standard 0 to 5 V.

FIGURE 5. Equivalent Circuit

VINIT

10K

Min. Max.

t 2H 500H

t

H = 31.8µs

Page 10 TM-6703 Progressive Scan Double Speed Shutter Camera

OPERATION

3.1.3 Shutter Control Switch

The shutter control switch is located on the rear panel of the camera. The dial can be

set from 0 to 9. The settings are detailed below.

Position Manual Shutter Mode Async Reset Mode

0 No Shutter No Shutter

1 1/125 1.0H 1/32,000

2 1/250 2.0H 1/16,000

3 1/500 4.0H 1/8,000

4 1/1,000 8.0H 1/4,000

5 1/2,000 16.0H 1/2,000

6 1/4,000 32.0H 1/1,000

7 1/8,000 64.0H 1/500

8 1/16,000 128.0H 1/250

9 1/32,000 Shutter determined by pulse width

Mode 0: Normal Mode

Mode 1-4: Fast Mode

Mode 5-8: Slow Mode

Mode 9: Pulse Width Mode

0

1

9

8

7

6

5

2

3

4

Note: Manual shutter speeds lower than 1/1,000 (i.e., longer in duration) are not applicable for

partial scan due to the short frame rate.

3.1.3 (a) External Pulse Width Control Mode

To select the External Pulse Width Control mode, set the shutter speed dial switch to “9”. Apply a pulse

width control VINIT signal to the camera via an external event trigger. The internal reset pulse will be

latched to HD. At the 9th HD timing from the external pulse leading edge (negative going edge), the

CCD discharge pulse will be generated to clear the images. The internal VD is generated at the

following edge (positive going edge) of the external pulse, and resets the internal timing, including the

video sync.

The shutter speed will be the same as the external pulse width, but the integration delays 9H from the

leading edge of the external pulse width. For the immediate reset option, please contact PULNiX.

One frame of video output will start from the rising edge of the pulse width control for progressive

format. The camera will output the same video from memory when VINIT is kept high (5V), and update

the image upon receiving the next pulse. At async mode, with external pulse input high, the video output

is disabled as the camera keeps discharging the CCD image and only will provide black video.

TM-6703 Progressive Scan Double Speed Shutter Camera Page 11

FIGURE 6. External Pulse Width Control (Async Mode)

External

Pulse

Width

VINIT

H

D

Internal VD

Transfer Gate

Pulse

Discharge pulse

Composite

Video

X

9H X

9H

Exposure Time

OPERATION

3.1.3 (b) Internal Fast Reset Mode (Async Mode)

For Internal Reset Mode, set the 10-position dial switch from “1” to “4”. When this mode is selected,

the camera resets with internal VD timing, which is latched to Hd, and video output is also synchronized

with internal VD timing without further delay. The shutter speed is controlled by the dial switch.

FIGURE 7. Internal Fast Reset

External pulse

VINIT

HD

Internal VD

Transfer Gate

Pulse

Purge pulse (discharge)

Composite

Video

min. 2H

9H

Exposure Time

Page 12 TM-6703 Progressive Scan Double Speed Shutter Camera

OPERATION

3.1.3 (c) Internal Slow Reset Mode (Async Mode)

For Internal Slow Reset Mode, set the 10-position shutter speed dial switch from “5” to “8”. When the

external VINIT pulse is applied, internal VD is latched to Hd and a second internal VD signal is

generated to set up the shutter speed period. Video output timing starts right after the second internal

VINIT.

FIGURE 8. Internal Slow Reset

External pulse

VINIT

D

H

Internal VD

min. 2H

Transfer Gate

Pulse

Discharge pulse

Composite

Video

9H

9H

EXPOSURE TIME

TM-6703 Progressive Scan Double Speed Shutter Camera Page 13

3.1.4 Progressive Scanning

The TM-6703 uses a state-of-the-art CCD called a “Progressive scanning interline transfer CCD” which

scans all lines sequentially from top to bottom at one frame rate (60 Hz). Like a non-interlace computer

screen, it generates a stable crisp image without alternating lines and provides full vertical TV

resolution of 484 lines. The interline transfer architecture is also important to generate simultaneous

shuttering. This is different from full frame transfer architecture which requires a mechanical shutter or

strobe light in order to freeze the object motion.

The TM-6703 outputs the progressive scanned image with an electronic shutter in three different modes.

These modes are selected via the switches on the rear panel of the camera.

TABLE 1. Scanning Mode Settings

Normal Mode N O (60Hz progressive scan)

Double Scan N T (120Hz progressive scan)

100 Line Scan P O (200Hz progressive scan)

200 Line Scan P T (125Hz progressive scan)

OPERATION

1. Progressive scanning double speed output (Normal mode. Select N, O)

On the rear panel of the camera, select NRM (normal mode), N and O. This produces straight

forward signal output equivalent to non-interlace VGA format (60Hz). Real-time double speed

CCD output is converted through normal analog video processing into 75Ω 1Vp-p output format.

2. Progressive scanning 120Hz output (Rear switches: N, T)

This mode provides 120Hz scanning of the full field of view, but with only 242 lines of vertical

resolution. The CCD signals of each row combine to scan 242 lines; the frame speed therefore is

120Hz of non-interlace video. The async reset, electronic shutter and integration function work as

normal. The analog output is the same as 75Ω, 1Vp-p format at the 120Hz rate.

3. Partial scanning output (Rear switches: P, T for 100 lines; P, O for 200 lines)

By selecting 100 line partial scan (P, T), the TM-6703 outputs the central 100 lines of video. It

repeats the same lines at a rate of 200 frames/sec. with the fast dump blanking of unused lines. The

asynchronous reset and electronic shutter functions are maintained at each partial scan.

By selecting 200 line partial scan (P, O), the TM-6703 outputs the central 200 lines of video at a

rate of 125 frames/sec. The partial scan keeps the same resolution as full progressive scan, but with

a narrower field of view.

Page 14 TM-6703 Progressive Scan Double Speed Shutter Camera

OPERATION

t

FIGURE 9. Scan Output

Normal scan

VD

Partial scan

VD (partial scan)

3.1.5 Option 7-2

In order to connect the TM-6703 camera to various frame grabbers, internal jumper settings allow the

TM-6703 to accept external HD and VD sync at double speed (fH = 31.468 KHz), or to output HD, VD

and pixel clock for variable scan frame grabbers. This option can be requested when ordering the TM-

6703.

Fast dump

Center

of Image

Center

100 lines

FIGURE 10. I/O Jumpers

BOTTOM BOARD, TOP SIDE

3.1.6 V-Sync Output Selection for Async Mode (OP51-2)

At async image capturing, some frame grabbers cannot take the specific frame when continuous video

sync presents. The TM-6703 video output is normally composite sync with frame rate V-sync regardless

of the actual image or blank image.When it is asynchronously reset, the newly reset V-sync may be

random to normal sync rate and can be very close to the regular rate V-sync. This may be problematic to

the frame grabber in capturing the correct image.By selecting the rear plate board jumper, the V-sync

output occurs only at the async reset, and no V-sync occurs until the next Vinit (async trigger) comes in.

The frame grabber can then look for this V-sync and capture the correct timing.

W`1 (VD)

OUT

IN

OUT

W2

W12

IN

(HD)

Last connection

not used; do not

connect to this

position.

CLOCK

W2

W1

VIDEO

REAR BOARD (FACING INWARD)

Standard settings (inputs) Output se

TM-6703 Progressive Scan Double Speed Shutter Camera Page 15

3.1.7 Integration

Integration times can vary depending on the specific application. Pin #11 of the 12-pin connector is

integration control. It accepts standard TTL inputs. High is considered 5 volts, and Low is considered 0

volts. When a low is applied to pin #11, the integration process begins. Integration blocks the transfer

gate of the image data out of the CCD array. Upon returning the signal back to high (which is required

to end the process). the image is output upon the next regular transfer.

FIGURE 11. Integration Timing

Vertical Sync.

(VD)

OPERATION

1

)

sec

(

freq.

CCD Transfer

(SG)

Integration Signal

Example #1

Integration Signal

Example #2

NOTE: Integration may be controlled in increments of frame times only.

H = 1/horizontal frequency.

9H

VD

1

)

(

freq.

VD

sec

1

(

freq.

VD

)

sec

1

)

sec

(

freq.

VD

yields 2 frames of exposure

1

)

sec

(

freq.

VD

1

)

sec

(

freq.

VD

yields 3 frames of exposure

When the integration signal is set back to high (5 volts), the image data will not move out of the CCD

array until the transfer gate occurs. Sg’s occur 9H after the start of the VD. For example, if the camera is

set to expose for 1.5 frame times, the actual exposure is for 2 frame times because the array is still

accumulating light until the sg of that field (or frame if field mode). The remaining image data acquired

before the start of the integration may also be output.

NOTE: The camera should be in normal mode during integration.

3.1.8 External Input Signals

FIGURE 12. Internal Input Signals

+5Volts

HD

TTL Level

0 Volts

+5Volts

VD

TTL Level

0 Volts

Page 16 TM-6703 Progressive Scan Double Speed Shutter Camera

1/HD frequency

1 - 2µsec.

1/VD frequency

1 to 9H

OPERATION

VSUB

RG

PED

GAMMA

AGC

MAX

PLL

ASY

MAN

3.2 Board Layout and Adjustment

3.2.1 Top Board (Top Side)

W5 AGC/MGC Left: AGC

Right: MGC

W6 Gamma Down: On (0.45)

Up: Off (1.0)

W7-W9 CDS pulse delay adjustment

VR1 AGC Set at 2.0V

VR2 MGC Controlled from

back plate

VR3 AGC MAX Set at 2.5V

VR4 PED Set at 50 mV of video

VR5 RG Factory adjustment only

VR7 Vsub Factory adjustment only

3.2.2 Bottom Board (Bottom Side)

VR2 PLL adjustment

W1 (VD), W2 (HD) HD and VD

input/output selection

TM-6703 Progressive Scan Double Speed Shutter Camera Page 17

4 TROUBLESHOOTING

4.1 Problems and Solutions

Following are troubleshooting tips for common problems. Generally, problems can be easily solved by

following these instructions. If the following remedies fail to offer a solution to your problems, please

contact a PULNiX representative.

4.1.1 Symptom: No Video

Remedies: Check that the following are properly connected and operational.

• Power supplies

• Power cables

• Main power source

• Shutter control

• Async mode

• Lens

TROUBLESHOOTING

4.1.2 Symptom: Dark Video

Remedies: Check that the following are properly connected and operational.

• Shutter selection

• Iris opening on the lens

• Async mode (with 5 volt level at Pin #6)

4.1.3 Symptom: Non-synchronized Video

Remedies: Check that the following are properly connected and operational.

• Proper mode output

• Frame grabber software camera selection

Page 18 TM-6703 Progressive Scan Double Speed Shutter Camera

TROUBLESHOOTING

4.2 Information and Support Resources

For further information and support:

Phone: (408) 747-0300

(800) 445-5444

(800) 3-PULNIX (24-hour message access)

Fax: (408) 747-0660

E-mail: imaging@jaipulnix.com

Mail: PULNiX America Inc.

Sales Department

1330 Orleans Drive

Sunnyvale, CA 94089

ATTN: Video Applications

Web Site: www.pulnix.com

TM-6703 Progressive Scan Double Speed Shutter Camera Page 19

5 APPENDIX

5.1 Specifications

5.1.1 Product Specifications

TABLE 2. Product Specifications Table

Imager 1/2" progressive scan interline transfer CCD with on-chip microlens

Pixels 694 H x 496 V

Cell size 9.0 H x 9.0 V µm

Photosensitive Pixels 648 H x 484 V

Output sensitivity 12µV/e-

Micro lens Standard

Scanning 525 lines at 60Hz (double speed mode)

Sync Internal/External auto switch

Pixel clock 25.49MHz

TV resolution 500 H x 484 V

Min. illumination 2.0 lux, f = 1.4 without IR cut filter

Video output Analog 1.0 Vp-p composite video, 75Ω, sync negative non-interlace

Display mode video Analog only fHD=31.468KHz, fVD=60Hz (VGA)

S/N ratio 50dB min AGC = OFF, 56dB typical

AGC On / Off (off = std)

MGC Manual gain adjustable (6dB to 26dB)

Gamma 0.45 or 1.0 (1.0=std)

Lens mount C-mount

Power requirement 12 V DC 500 mA

Operating temp. -10°C to +50°C

Vibration & Shock Vibration: 7Grms (10Hz to 2000Hz), Shock: 70G

Size 46.1mm x 39.4mm x 140.0mm (1.78" x 1.52" x 5.41")

Weight 240 grams (9.0 oz.)

Power cable 12P-02

Power supply K25-12V or PD-12

APPENDIX

HD/VD, 4.0 Vp-p impedance 4.7KΩ

fHD = 31.468KHz / fVD = 60Hz

Page 20 TM-6703 Progressive Scan Double Speed Shutter Camera

APPENDIX

PULNiX

5.1.2 Physical Dimensions

FIGURE 13. Physical Dimensions

39.4 mm

7.0 mm

46.3 mm

2x 11.0 mm

2x M3 x 8

30.4 mm

40 mm

140.8 mm

128.1 mm

1/4-20 UNC-2B

2x M6x1

VIDEO

SHUTTER

0

9

8

7

6

5

N

ASY

P

MANOT

GAIN

1

2

3

4

POWER

TM-6703 Progressive Scan Double Speed Shutter Camera Page 21

5.1.3 Glass Specifications

FIGURE 14. Camera Front End - Glass Specifications

CCD

Glass Cover

APPENDIX

CCD Glass

CCD Glass (BK-7) 0.75mm thickness

Refractive Index = 1.5

Glass Cover (BD-65) 1.0mm thickness

Refractive Index = 1.51

5.1.4 C-Mount Specifications

The Flange Back Length of the “CS-Mount” is 12.5mm versus 17.526 of the “C-Mount”. The shorter

Flange Back Length of the “CS-Mount” allows room for the stripe filter incorporated in the color

camera. Additionally, the shorter Flange Back Length allows for reduction of the effective diameter of

the first lens and reduces the number of lens elements. The common C-Mount lens is completely

compatible with a CS-Mount camera when a 5mm extension ring is inserted between the lens and the

camera.

Page 22 TM-6703 Progressive Scan Double Speed Shutter Camera

APPENDIX

FIGURE 15. Combination With “CS-Mount” Camera

CS-Mount Lens

C-Mount Lens

12.5

5

17.526

Flange Surface of

C-Mount

Focal Point

5mm Extension Ring

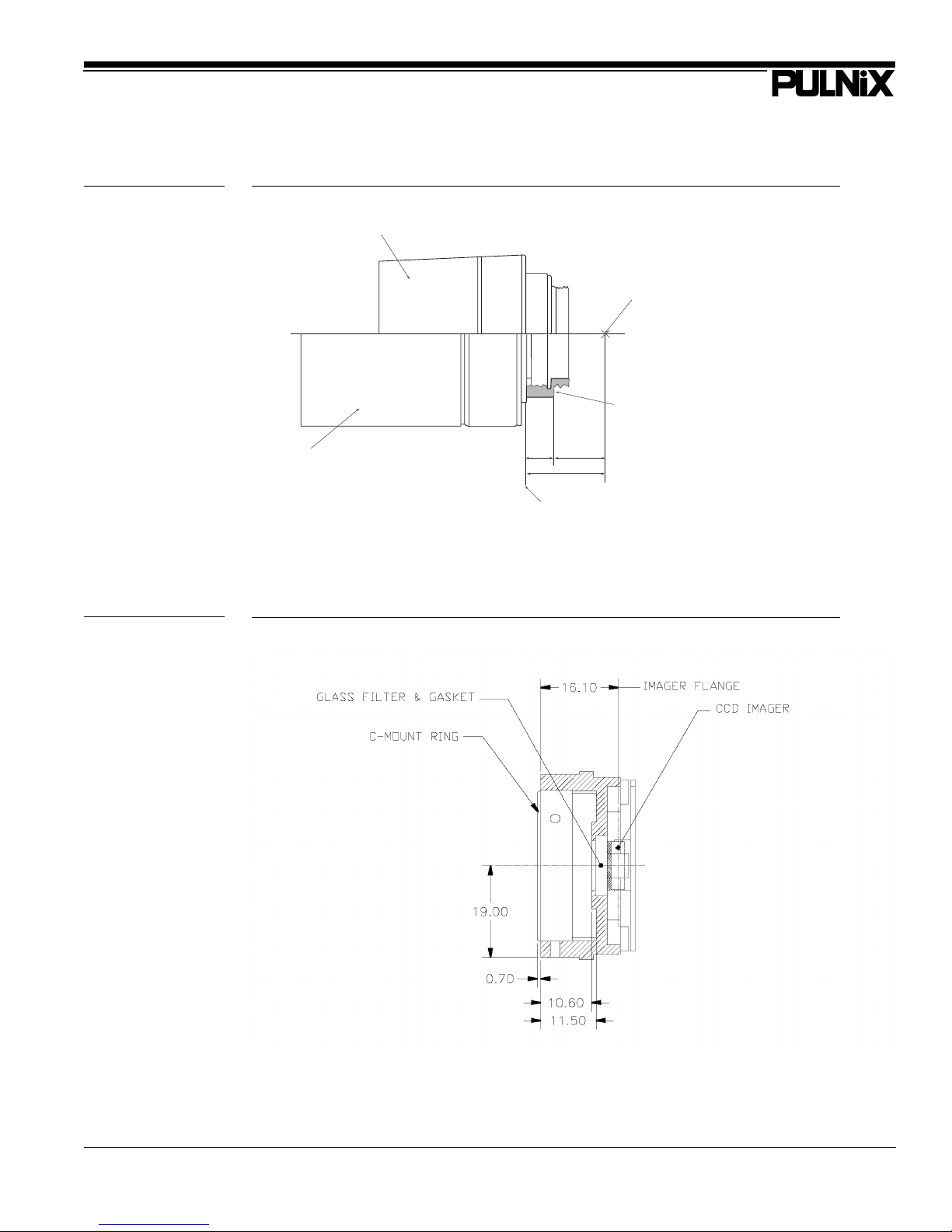

5.1.5 Front End Detail

FIGURE 16. TM-6703 Imager Location

TM-6703 Progressive Scan Double Speed Shutter Camera Page 23

5.2 Spectral Response

FIGURE 17. Spectral Response

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

Relative Sensitivity

0.2

0.1

0

300 400 500 600 700 800 900 1000 1100

APPENDIX

Wave Length (nm)

5.3 Block Diagram

FIGURE 18. TM-6703 Block Diagram

CCD

TIMING

GEN.

CDS & AMP

SYNC

GEN.

SYNC

ADDED

PLL/XTAL

VIDEO

EXT. HD

Page 24 TM-6703 Progressive Scan Double Speed Shutter Camera

APPENDIX

5.4 Timing Chart

5.4.1 Pixel Mapping (Horizontal)

FIGURE 19. Pixel Mapping (Horizontal)

HORIZONTAL RESET

45

TOTAL CLOCK PER 1H = 810 pixels

DUMMY

739

740

738

741

CCD OUTPUT

O.B.

764

BLANK

1

60

202

DUMMY

O.B.

11

10

116

ACTIVE PIXEL

117

740

738

PIXEL CLOCK

CCD LINE CONTENT

1

DUMMY

11

10

OPTICAL BLACK

5.4.2 Vertical Frame Output Timing

FIGURE 20. Vertical Frame Output Timing

VD

HORIZONTAL LINES

484

VIDEO OUTPUT

NORMAL MODE

PARTIAL SCAN (VARIABLE)

EXAMPLE

100 LINE SCAN

200 LINE SCAN

4 O.B.

1

4

9H

99

199 200

11H

BLANK = 41H

481480479

2.5 x (488-100) µsec

100

FAST DUMP

2.5 x (488-200) µsec

483

482

FAST DUMP

TOTAL HORIZONTAL SCANNING = 525H

8 O.B.

1

30

3H 3H

484

3H

3H

34

3H

3H

35

484 ACTIVE PIXELS

ACTIVE PIXEL

35H

35H

35H

682

1

2

123

123

683

3

OPTICAL BLACK

484

691

DUMMY

694

690

TM-6703 Progressive Scan Double Speed Shutter Camera Page 25

,

Industrial Products Division

PULNiX America, Inc.

1330 Orleans Drive

Sunnyvale, CA 94089

Email: imaging@jaipulnix.com

Tel: 408-747-0300

Tel: 800-445-5444

Fax: 408-747-0660

www.pulnix.com

Loading...

Loading...